Page 1

Installation Instructions

CommandFlo

Fuel Flow Modifier

1988-00 Honda Civic/CRX

1990-00 Acura Integra/NSX

©2000 by B&M Racing and Performance Products

The B&M CommandFlo Fuel Flow

Modifier has been designed to work

on all 1988 thru 2000 Honda Civics/

CRX's and 1990 thru 2000 Acura

Integras/NSX's, except those models

with TBI (Throttle Body Injection).

The B&M CommandFlo Fuel Flow

Modifier allows the user to accurately

adjust fuel flow (and hence fuel

pressure) in response to engine

modifications.

Most factory computers will

compensate for minor airflow

modifications (low restriction intake

and exhaust) at part throttle operations

but have no way to adjust at WOT

(Wide Open Throttle). The results are

a lean mixture right where you need

more fuel! One way to correct this is

to adjust fuel flow via fuel pressure.

Most people don't understand that by

increasing fuel pressure (on a fuel

injection system), fuel flow increases.

The formula for calculating flow

increase based on fuel pressure is:

F1 = Injector Flow (cc/min)

P1 = Current Fuel Pressure (psi)

F2 = New Injector Flow (cc/min)

P2 = New Fuel Pressure (psi)

2

P2 = P1 x

Example:

F2

( )

F1

We added a high flow exhaust that

increases airflow 5%. What pressure

should the system be set to?

F1 = 270 cc/min

F2 = 284 cc/min (270 + 5%)

P1 = 43 psi

2

P2 = 43 psi x

or

P2 = 48 psi

We recommend that you read

through the instructions completely

before beginning the installation, so

you can familiarize yourself with the

installation procedure and tools

required. Check the tool list at the

end of these instructions for the tools

required to install your B&M

CommandFlo Fuel Flow Modifier.

Installation of the CommandFlo Fuel

Flow Modifier can be accomplished

by anyone with minimum mechanical

experience. It is however, important

to closely follow the instructions.

When installing your CommandFlo

Fuel Flow Modifier there are several

other B&M products you may wish

to consider: B&M Fuel Pressure

Gauge Set: #46053 or #46054. In

order to take full advantage of the

adjustability of the CommandFlo

284

( )

270

Fuel Flow Modifier, it is important to

know the exact fuel pressure of your

system. #46053 also includes adapt-

ers for various import and domestic

applications.

INTRODUCTION

The B&M CommandFlo Fuel Flow

Modifier can be installed in less

than an hour by carefully following

the instructions. Read all instruc-

tions first to familiarize yourself with the parts and procedures. This kit contains all parts

necessary to install the fuel flow

modifier on all Honda Civics/CRX's

and Acura Integras/NSX's.

DISASSEMBLY

We suggest the vehicle be allowed

to cool for an hour or two before

you begin since you will be working around the fuel system.

CAUTION: THE FUEL SYSTEM

CONTAINS FUEL UNDER HIGH

PRESSURE EVEN WHEN THE

ENGINE IS NOT RUNNING. BEFORE DISCONNECTING A FUEL

LINE, WRAP THE FITTING WITH

A RAG TO PREVENT FUEL

SPRAY.

Printed in the U.S.A.

9500645-04

Page 2

STEP 1. Remove the fuel pump fuse

from the fuse box. Try starting the

vehicle several times until it will not

remain running. This will help relieve pressure in the fuel system.

Remove the plug and washer on the

top of the fuel filter and attach an

accurate pressure gauge. Remove

and plug the vacuum line running to

the fuel pressure regulator. Replace

the fuse and start the vehicle. Note

fuel pressure.

STEP 2. Again, remove the fuel

pump fuse from the fuse box. Try

starting the vehicle several times

until it will not remain running.

This will help relieve pressure in

the fuel system. Remove the negative battery cable.

STEP 3. Using a pair of pliers,

loosen the clamp holding the return fuel line to the fuel pressure

regulator. Place a rag over the

connection and carefully slide the

fuel line off of the regulator.

STEP 4. Using a 10mm socket

and short extension, remove the

two bolts holding the stock regulator to the fuel rail. Remove the

regulator. Be careful of spraying

fuel!

STEP 5. Remove and inspect the

regulator o-ring for tears. Replace

if damaged.

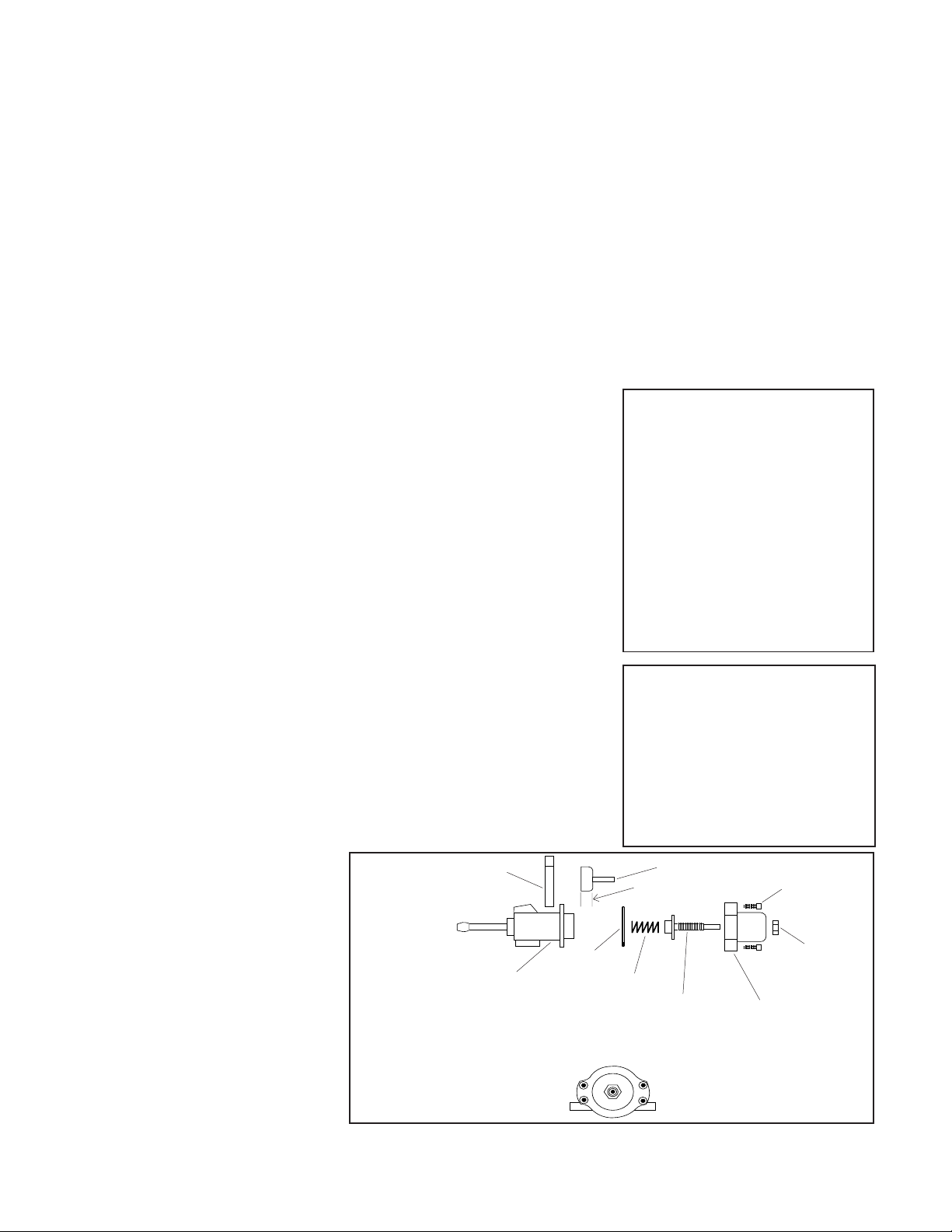

STEP 6. Carefully mount the regulator body in a vise and mark 1/4"

down on the regulator "hat." Using

a hacksaw, cut off the top of the

regulator hat at the mark. Be care-

ful: the top is under pressure from

the spring inside! Remove and discard the top and spring (see fig.

1).

STEP 7. Using a file, remove the

sharp edges from the regulator.

ASSEMBLY

STEP 8. On the underside of the

new CommandFlo body, carefully

insert the supplied silicone o-ring

into the machined groove.

STEP 9. Again, from the underside thread the brass piston into

the CommandFlo body until it bot-

toms out. Thread the supplied

stainless steel nut onto the brass

piston but

do not tighten.

STEP 10. Position the supplied

spring into the CommandFlo

body, making sure to seat it on the

brass piston. Without dropping the

spring, install the CommandFlo

body onto the stock pressure regulator. Place a drop of Locktite® on

each of the four supplied 6-32 bolts

and carefully attached the

CommandFlo base (use caution

when installing the screws to avoid

stripping out the base). Once the

base is attached, align the

CommandFlo assembly as shown

(see fig. 1).

STEP 11. Hand tighten each of

the four bolts until the base and

body come together. DO NOT

OVER TIGHTEN!

STEP 12. Reinstall the stock regulator o-ring and attach the assembly the fuel rail. Using the 10mm

socket, tighten the two bolts to 6

lb-ft.

STEP 13. Slip the return fuel line

back onto the regulator and retighten the clamp.

STEP 14. Reinstall the fuel pump

fuse and negative battery cable.

STEP 15. Turn the key to on but

do not start vehicle. Repeat this

three times. Check the regulator

for leaking fuel. If there is evidence of a leak, repair before proceeding. NOTE: The

CommandFlo does not directly

connect to the fuel side and thus

will not cause the regulator to leak.

STEP 16. Start the vehicle and

using a 3/16" wrench, adjust the

fuel pressure to the desired value

based on the pressure measured

before disassembly. Turning the

piston clockwise will raise pressure while counterclockwise will

lower pressure. Once the pressure

CommandFlo base

Stock regulator

O-ring

body

Align CommandFlo body as shown

Figure 1

is set, tighten the jam nut.

STEP 17. Remove the factory

vacuum line and replace it with

the longer supplied line. Cut to fit

if necessary.

STEP 18. For nonpermanent type

gauge sets, remove the fuel pump

fuse from the fuse box. Try starting the vehicle several times until

it will not remain running. This will

help relieve pressure in the fuel

system. Remove the fuel pressure

gauge and reinstall the plug and

washer on the top of the fuel filter.

Replace fuel pump fuse.

STEP 19. Verify that there are no

signs of fuel leakage.

Parts List

1 CommandFlo Body

1 CommandFlo Base

1 Brass Piston

1 Spring

1 Silicone o-ring

4 6-32 Bolts

1 Jam Nut

1 Vacuum Line

1 Tube of Locktite®

1 Instruction Sheet

Tool List

Fuel Pressure Guage

10mm Socket and Drive

3/16", 1/2" Wrench

Pliers

Hacksaw

7/64" Hex Wrench

Rags

Discard this

1/4"

section

6-32 bolts

Jam nut

Spring

Piston

CommandFlo body

Loading...

Loading...