Page 1

Instructions

NAG-1 Cast Aluminum

Deep Oil Pan

(see www.bmracing.com for the latest vehicle fitment applications and model years)

Part Number 10300

© 2012 by B&M Racing and Performance Products

Congratulations! You have just purchased one of the finest cast aluminum pans available for the Chrysler

NAG-1 transmissions. This B&M

Cast Aluminum Deep Oil Pan has

been designed to work on most

Chrysler/Dodge/Jeep vehicles

equipped with NAG-1 (W5A380 &

W5A580) transmissions. The B&M

Cast Aluminum Deep Oil Pan provides several advantages over stock

factory oil pans. The extra capacity

provides increased oil volume and

added cooling, while the aluminum

construction increases case rigidity.

The magnetic drain plug feature allows regular transmission maintenance and oil changes without the

usual mess associated with “dropping the pan,” and limits ferrous debris from circulating in the transmission.

NOTE: The NAG-1 transmissions

do not come with a dip stick. You

will need a B&M NAG-1 Locking

Dipstick P/N 22300, P/N 22301 or

P/N 22302 (check for vehicle applications) to measure fluid level

or have a shop with a scanner

tool do the installation for you.

When installing your B&M Cast

Aluminum Deep Oil Pan you may

wish to consider a B&M Transmis-

sion Temperature Gauge. Most

transmission and converter failures

can be traced directly to excessive

heat. This accurate temperature

gauge comes with a light kit, colorcoded dial face, antiglare enclosure, wires, terminals, special

sending unit, and T-fitting for easy

installation. Available at your B&M

dealer.

INTRODUCTION

This deep oil pan can be installed

in about an hour by carefully following the instructions. Check the

tool list at the end of these instructions for the tools required to install

your B&M Cast Aluminum Deep

Oil Pan. Transmission components

are precision fit and dirt is the

number one enemy of an automatic transmission. Automatic transmissions operate at temperatures

between 150°F and 250°F. It is

suggested that the vehicle be allowed to cool off for a few hours to

avoid burns from hot oil and parts.

The vehicle should be off the

ground for ease of installation –

jack stands, wheel ramps or a hoist

will work fine. MAKE SURE VEHICLE IS FIRMLY SUPPORTED DO NOT WORK UNDER A VEHICLE IF IT IS SUPPORTED BY

ONLY A JACK! Try to raise the vehicle 1-2 feet so you will have plenty

of room to work. Also, have a small

box to put bolts in and a drain pan to

catch oil.

NOTE: This kit does not come

with a transmission filter or gasket.

INSTALLATION

STEP 1. Place a drain pan under-

neath transmission. To drain the oil

pan, remove the two bolts and hold

downs at the front of the transmission using a T30 torx socket, extension and ratchet.

STEP 2. Loosen the two middle

bolts until fluid starts to drip from the

front of the pan. If the pan and gasket sticks, pry it down slightly with a

screwdriver to break the seal.

NOTE: Don’t damage the transmission surface as leaks could

develop.

STEP 3. Loosen the two rear bolts

by 2 turns and let the pan hang

down so the fluid can drain.

NOTE: On some applications it

might be easier to reach the rear

bolts by using a torx bit and a

wrench.

STEP 4. After the fluid has drained

from the pan, remove the two middle

Printed in the USA 9500869-00

Page 2

Figure 1

bolts and hold downs while supporting the oil pan. Remove the last two

bolts and hold downs slowly while

tilting down the pan to allow the last

of the fluid to drain. After the last

bolts are removed, the pan and gasket can be lowered and set aside.

STEP 5. Remove the magnet from

the pan, fully clean it and set it

aside.

STEP 6. The oil filter will now be

exposed. Pull the filter out of the

valve body, being careful not to

bend the filter pickup tube as it is

plastic and may crack or break. If

the seal remains in the valve body

and does not come out with the filter, remove it by using a flat head

screwdriver. Be careful not to damage the surface.

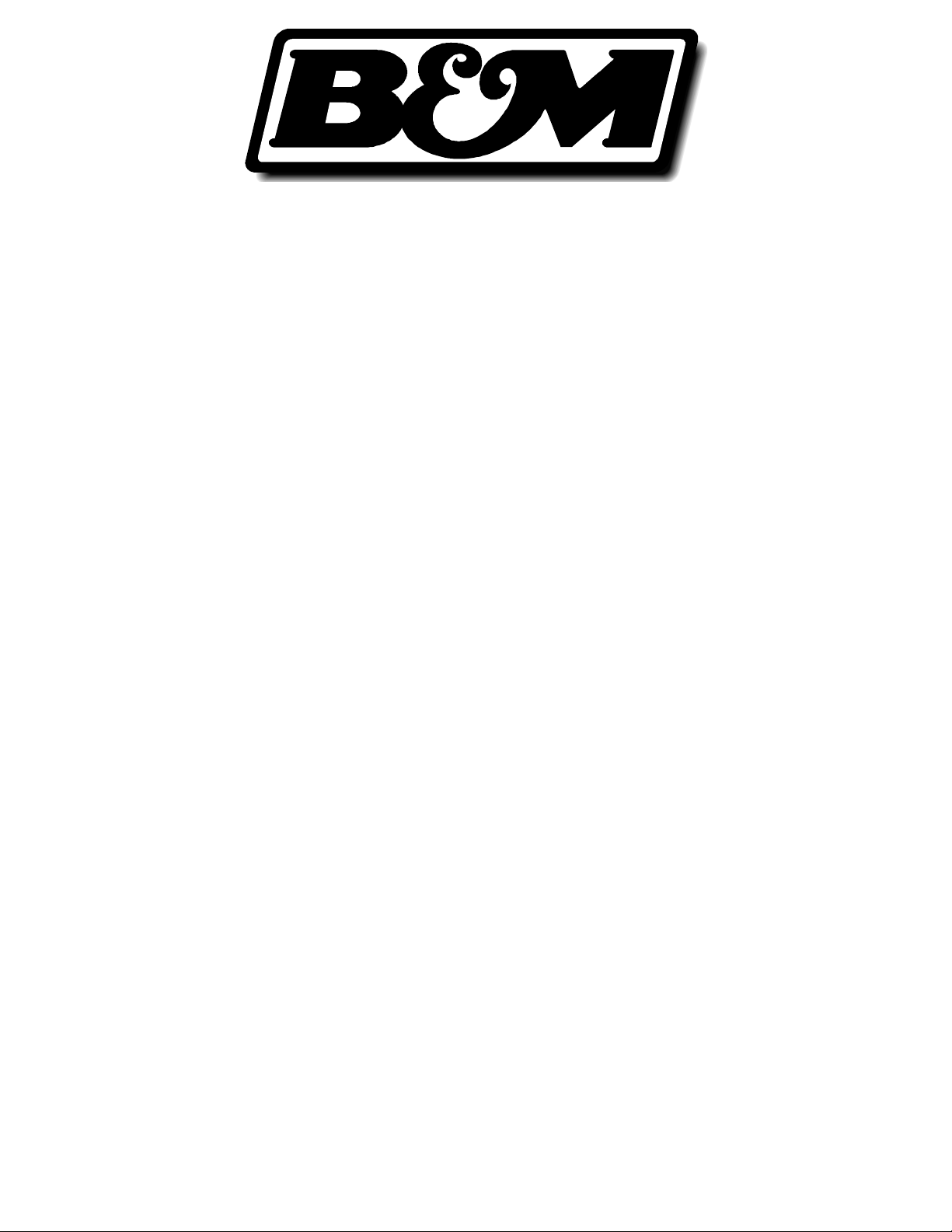

STEP 7. Install the supplied o-ring

on the extension tube provided in

the kit (See Figure 1). B&M recommends that the transmission filter

be changed at this time. Lubricate

the seal on the transmission filter

(MOPAR p/n: 52108325AA) and the

o-ring with new transmission fluid.

Place the extension tube on the

transmission filter (See Figure 2).

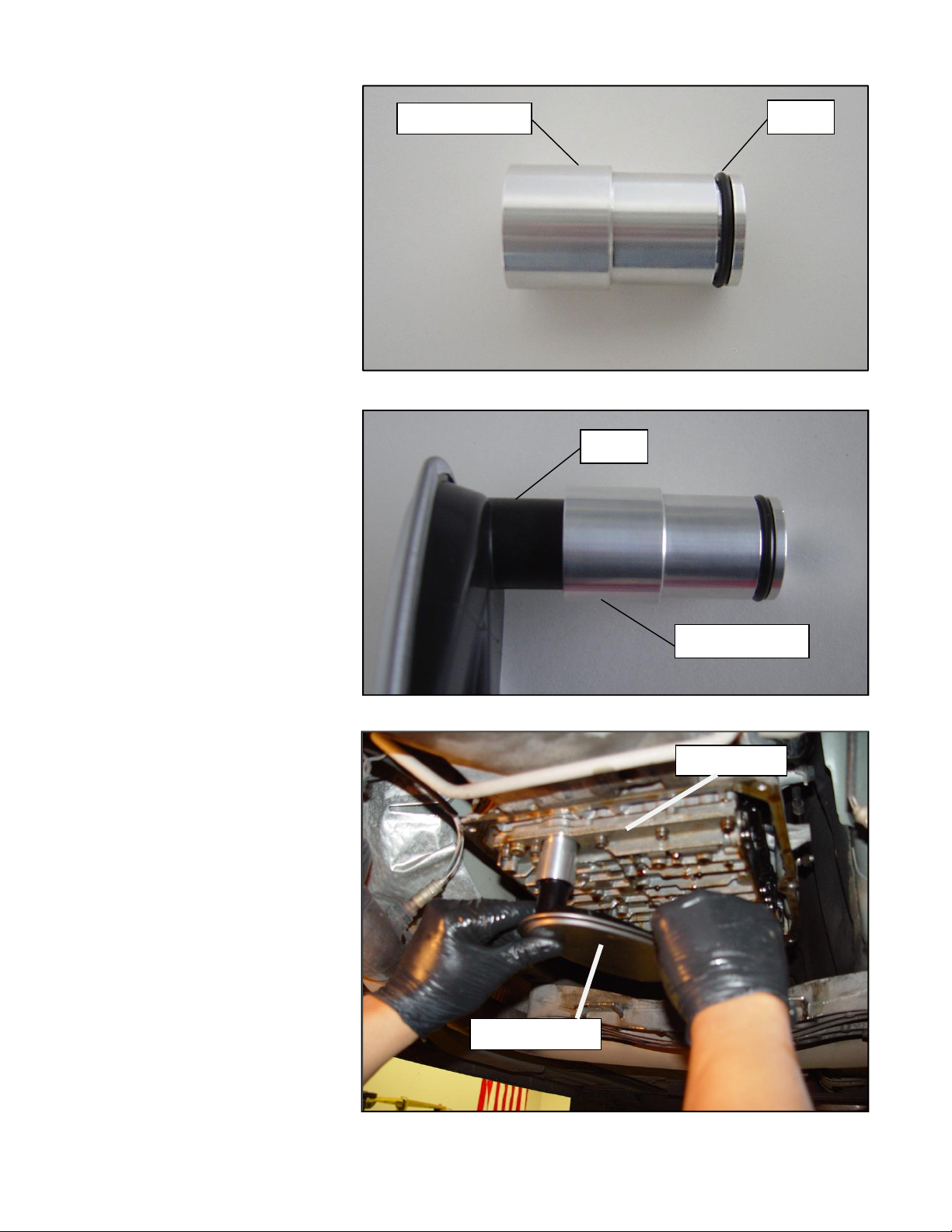

STEP 8. Install the filter assembly

into the valve body (See Figure 3).

STEP 9. Make sure the flat end of

the filter is parallel to the back of the

transmission (See Figure 4).

STEP 10. Stick the magnet removed

earlier on the bottom of the transmission filter as shown (See Figure

5).

STEP 11. Install the reusable gasket

(MOPAR p/n: 52108332AA) onto the

B&M Cast Aluminum Deep Oil

Pan.

STEP 12. Clean the transmission

mating surface with a clean rag.

STEP 13. Install the B&M Cast

Aluminum Deep Oil Pan by using

the supplied hold downs with the

original six bolts removed earlier

and torque the bolts to 8 N-m (70

in.lbs.). Do not over tighten as this

can cause leaks or damage to the

transmission case or gasket.

STEP 14. Using a 3/4” socket &

ratchet, install and tighten the supplied drain plug and gasket.

STEP 15. If using a temperature

sensor, install in provided 1/8” NPT

port on side of pan. Otherwise install

Extension Tube

Filter Assembly

O-ring

Filter

Extension Tube

Figure 2

Valve Body

Figure 3

Page 3

supplied 1/8” NPTF plug and tighten

Figure 5

NOTE: No Teflon is needed as

this plug has a Dryseal thread.

STEP 16. Lower vehicle and add 6

quarts of ATF +4.

STEP 17. Check the oil level and

add oil as necessary and recheck

the oil level.

STEP 18. Once the oil level is correct, install the dip stick or cap.

Parts List

(1) Aluminum Cast Oil Pan

(6) Hold Downs

(1) Filter Extension Tube

(1) O-ring

(1) Magnetic Drain Plug

(1) Drain Plug Gasket

(1) 1/8” NPTF Plug

Tools List

B&M Dipstick or scanner tool

Jack & Jack Stands

Drain Pan

Rags or Paper Towels

T30 Torx Socket & Ratchet

3” Socket Extension

3/4” Socket

3/16” Allen Wrench

Flat Blade Screwdriver

ATF +4 Fluid

This should

be parallel

Filter

Figure 4

Magnet

Loading...

Loading...