Page 1

Installation Instructions

GM Powerglide Bracket and

Lever Kit

Part Number 70497

©2008, 2001, 1994 by B&M Racing and Performance Products

STEP 1. Disconnect the throttle to transmission linkage,

if any and discard. The Powerglide shift lever supplied with

this kit has no provision for a throttle linkage.*

STEP 2. Drain the transmission oil pan. Caution: Be sure

the transmission is cool before attempting to drain the oil.

Place a drain pan under the transmission. Remove the

drain plug, if so equipped. If your pan does not have a drain

plug, remove the oil pan bolts one at a time, working toward

the front. As you loosen the last two bolts, the oil pan will

tilt down and allow the oil to drain. Note: If your oil pan

sticks to the gasket, pry it down with a screwdriver before

loosening the last two bolts to break it free. Remove the oil

pan and set it aside.

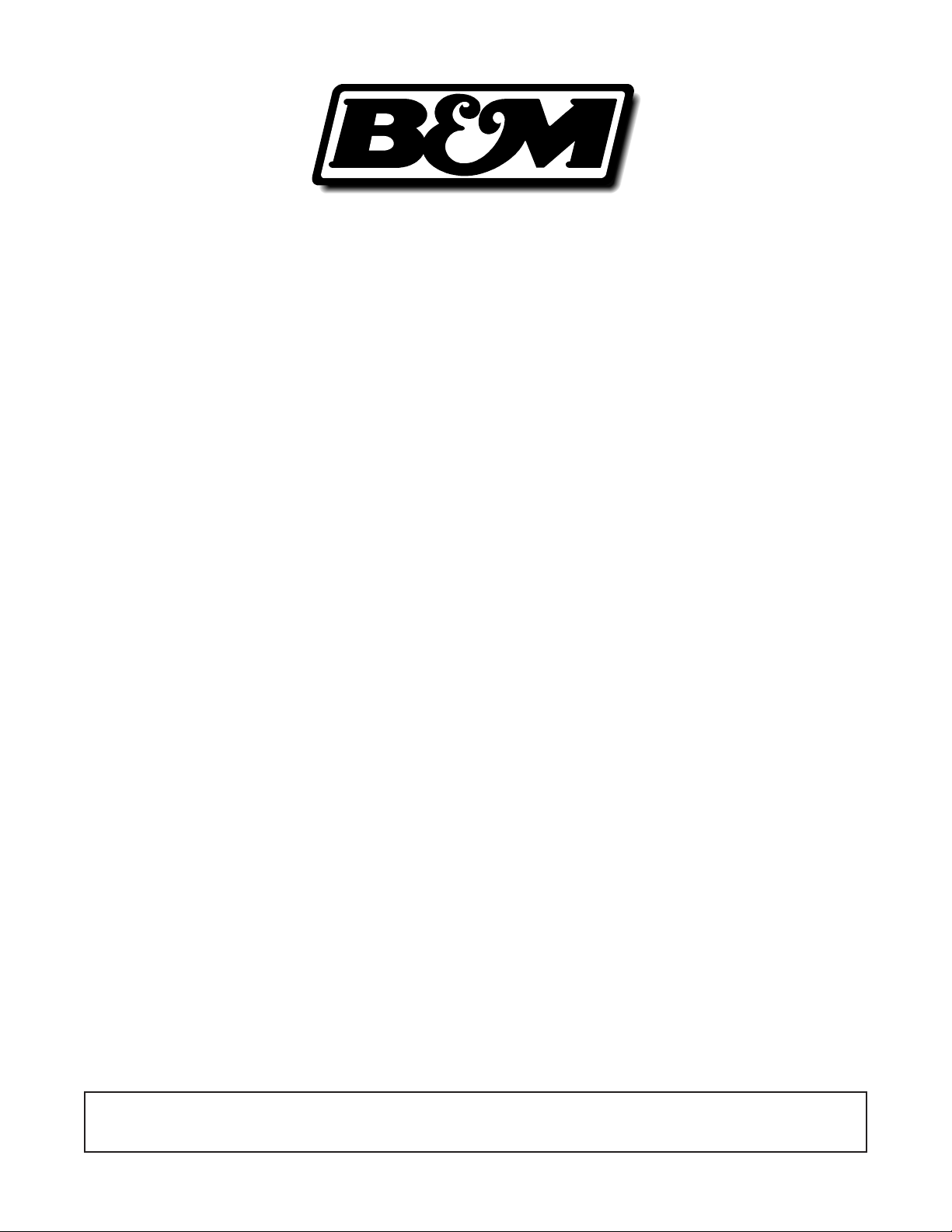

STEP 3. Remove the manual valve guide plate by removing

two bolts (See Figure 1). Unhook and remove the detent

roller spring. Allow the detent roller to pivot out of the way.

Note how the pin on the manual valve selector engages the

groove in the manual valve.

STEP 4. If your transmission has a throttle valve lever on

the outside of the shift lever, loosen the inner pinch bolt on

the throttle lever. Slide the throttle lever and the shaft out

of the transmission. Remove the inner throttle valve lever.

Discard these parts.

STEP 5. Loosen the pinch bolt on the selector lever. This

can be either an Allen head bolt or a 12 point bolt head. Do

not remove the pinch bolt. Slightly pry the manual valve

lever and slide the selector shaft from the transmission.

Discard the selector shaft.

STEP 6. This kit includes the B&M Powerglide ProLever shift lever, which is a two piece lever with separate

lever and shaft. Install the B&M selector shaft into the

transmission with the lever pointing down. Hold the stock

selector lever in position in the case, engage the pin on the

selector lever with the manual valve and rotate the B&M

shaft until the flat on the shaft engages the serrations on

the lever. Push the B&M lever firmly into the transmission

until the lever stops on the shoulder of the shaft. Tighten the

pinch bolt securely.

STEP 7. Install the manual valve guide plate in place.

(Make sure that pin on selector lever is engaged in the

groove in the manual valve.) Install the two bolts and tighten

to 15 lbs.ft. Install the detent roller spring. Hook the spring

to detent roller and the tab. The selector lever must travel

freely and smoothly from front to back with a positive click

in each gear position.

STEP 8. Clean the oil pan and scrape the old gasket off of

the pan and the case. (Note: If your pan does not have a

drain plug, you may wish to install a B&M Drain Plug Kit,

#80250, at this time.) The old gasket can cause leaks.

Install the oil pan with a new gasket. Install the pan bolts

except for the two center bolts on left side of the pan.

Thighten the pan bolts to 8 lbs.ft. Do not overtighten as this

can damage the pan gasket.

STEP 9. Install the cable bracket in position with the two

remaining pan bolts (See Figure 1). Install the B&M lever

onto the shaft with the lever pointing down. If your cable

comes from the front (usually a rear engined car) the lever

is installed pointing upwards. You will have to make your

own cable bracket for this installation.

STEP 10. Remove the two rubber boots, one large nut, and

a large lockwasher from the threaded end of the shifter

cable. Avoid sharp bends and route the cable away from

*WARNING

This kit is intended for transbrakes or full manual valve bodies only. If your transmission requires throttle

linkage, you cannot use this kit.

Printed in the U.S.A.

9500230-05

Page 2

Cable bracket

mounts on

outside of oil pan

Detent roller spring

B&M shift lever

Manual valve guide plate

Manual valve.

Note that pin on

selector lever fits

in groove on valve

Selector lever

pinch bolt

Figure 1

hot engine and exhaust parts. The cable may be secured

up out of the way with nylon cable ties. Slide the end of the

cable into the cable bracket, install the lockwasher and the

large nut over the end of the cable. Position the cable so

the threaded portion of the cable housing is centered in the

cable bracket. Tighten both the large nuts to hold the cable

in this position. Install the two rubber boots onto the end of

the cable.

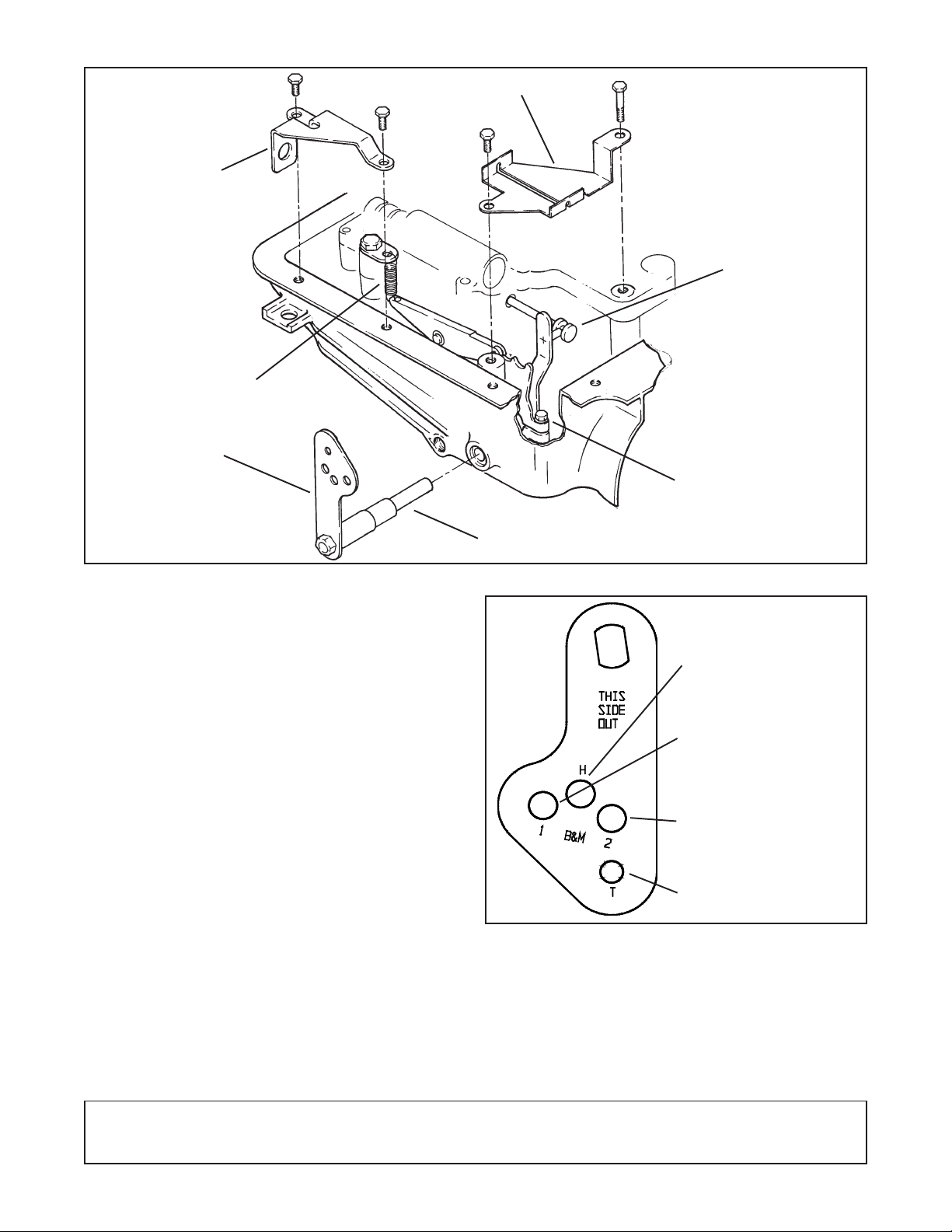

STEP 11. Move the transmission selector lever by hand to

full rear position (Low). Place the shifter lever to the full rear

position (Low gear with a forward pattern valve body).

Adjust the large nuts on the cable so that the swivel will

slide into the hole on the selector lever that is correct for

your shifter (See Figure 2). Tighten the large nuts completely. Be sure that the swivel will slide freely in an out of

the hole in the selector lever. Note: The shifter will not

operate correctly unless the correct hole for your shifter in

the shift lever is used. Leave the swivel out of the hole and

move the selector lever to Park, all the way forward. Also

move the shifter to the Park position (all the way forward).

Reinsert the swivel into the hole in the selector lever.

Check to see that the swivel will slide freely in and out of

the rear hole in the selector lever in this position. If it does

slip in freely, adjust the swivel slightly until it will slip into

the hole in the lever. Move the shifter back to the Low gear

position and check that the swivel will still slide easily in

B&M selector shaft

Use this hole for Hurst shifter

and B&M Bandit shifter &

Pro Stick

Use this hole for B&M

Megashifter or Street

Stick

Use this hole for B&M

Pro Ratchet, Quick Silver, or Quick Click

Use this hole for

Turbo Action Shifter

Figure 2

and out of the rear hole in the selector lever. (If you do not

use the correct hole in the lever, it will be impossible to

correctly adjust the cable.) Operate the shifter through all

the gear positions. Check to make sure the swivel will slide

in and out of the rear selector lever hole in each gear

position. The shift cable is now correctly adjusted. Install

the cotter key into the swivel and spread the key ends.

WARNING

Periodic inspection and maintenance of your shifter is recommended to ensure that the mechanism is well lubricated, free from dirt or rust

and that the cable is properly adjusted. Lack of maintenance could result in a failure, including a failure of the reverse lockout safety feature.

Loading...

Loading...