Page 1

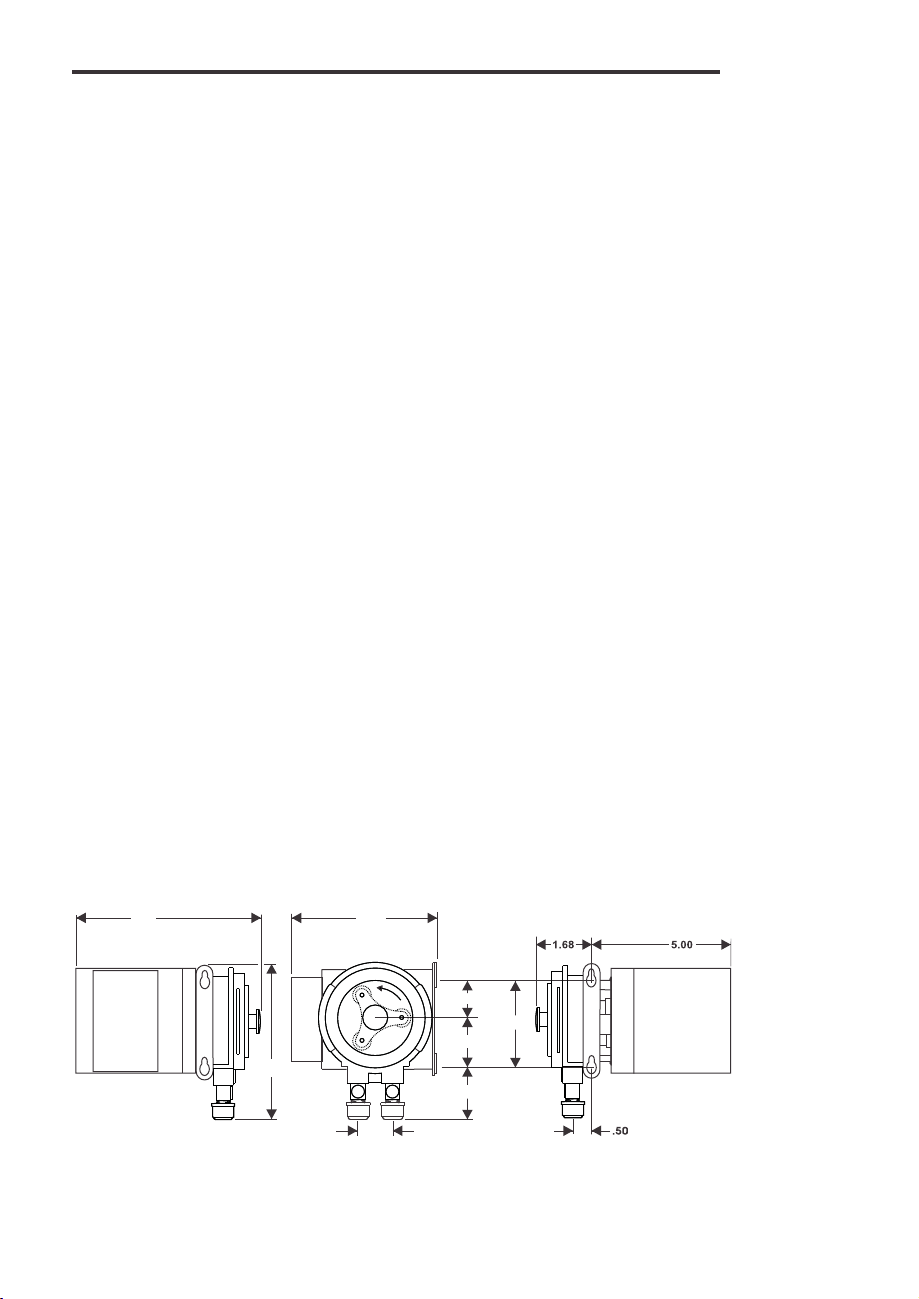

MODEL A-1600

R

Peristaltic Injection Pump

Operating Manual

5300 Business Drive

Huntington Beach, CA 92649, USA

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.Blue-White.com

Page 2

Page 2

L

R

Thank You for purchasing the A-1600 Peristaltic Metering Pump. It is our policy

to produce, market and provide service on our products to ensure your safety

and

complete satisfaction. When installed and used in accordance with the following

instructions, the A-1600 will provide years of safe, reliable service.

For your safety the A-1600 was designed to be safe and easy to use. However,

there are limits to its operation. This instruction manual contains safety precautions, which if ignored could result in personal injury and/or property damage.

Read these instructions carefully before installing the pump. If you are not

satisfied that the unit can be safely operated, call the place of purchase for

Thank You

Blue White Industries

(714)893-8529.

LEAVE THIS INSTRUCTION MANUAL WITH INSTALLED METER!

******** SPECIFICATIONS ********

MODEL NO: MAXIMUM MAXIMUM FEED RATE

P.S.I ML/MIN OZ/MIN G.P.H G.P.D

A-1614-3N

A-1614-4

A-1614-6

A-1614-7

A-1630-3N

A-1630-4

A-1630-6

A-1630-7

A-1645-3N

A-1645-4

A-1645-6

A-1645-7

25

25

25

25

25

25

25

25

25

25

25

25

17

60

75

11

40

130

195

14

54

195

295

3

.1

.5

2.0

2.5

.3

1.3

4.4

6.5

.4

1.8

6.5

9.9

NOTE: Norprene tubing same feed rate as Tygon

6.75

5.12

.04

.26

.95

1.18

.17

.63

2.05

3.08

.22

.85

3.08

4.67

1

6

22

28

4

15

49

74

5

20

74

112

5.75

1.43

3.18

1.75

1.87

1.18

Page 3

Page 3

INSTALLATION INSTRUCTIONS

UNPACKING INFORMATION

Verify that you have received all of the following equipment:

- One A-1600 series pump

- 10 ft. 3/8” O.D. Clear vinyl tubing with flow indicator

- One threadless injector (T.I.) Fitting

- One suction tube strainer

- One ceramic weight

- Two pump head tube assemblies (with fittings)

- Two mounting screws

LOCATION AND MOUNTING

CAUTION

ALWAYS WEAR EYE PROTECTION AND PROTECTIVE CLOTHING WHEN

WORKING AROUND CORROSIVE MATERIAL.

A. Choosing a well ventilated area located near the supply tank, Electrical

supply and injection points.

B. The injector may be shelf or wall mounted. Use the inclosed hardware for

wall mounting.

C. When using wall corrosive chemicals, avoid mounting the injector directly

above the supply tank. Although the pump housing is designed to withstand

corrosion, some chemical fumes may damage the unit.

D. Your solution tank should be sturdy plastic and chemically resistant to the

chemicals you are using to protect from fume, a tight fitting cover should be in

place at all times. A variety of tanks are available from the factory.

ELECTRICAL CONNECTIONS

WARNING - RISK OF ELECTRIC SHOCK

Be certain you connect the unit to the proper supply voltage. Using the incorrect

voltage will damage the injector and may result in injury. The units voltage

requirements is printed on the name plate

A-1600 MODELS

A-1600 Model Injector are supplied with a junction box and cover. To reduce

the risk of electric shock when field wiring, be certain that the grounding

conductor is attached to the green ground screw, located inside the junction box.

A-1600T MODELS

(Timer Equipped Model)

115V Model Injector are supplied with a ground wire conductor and a grounding

type attachment plug. To reduce the risk of electric shock, be certain that it is

connected only to the properly grounded, grounding type receptacle. A ground

fault interrupter (GFI) receptacle is recommended for use in wet locations.

24V/230V Models Injectors are supplied with a ground wire conductor. To

reduce the risk of electric shock, be certain that the green grounding conductor

is connected only to a properly grounded field wiring box.

Page 4

L

R

Page 4

L

R

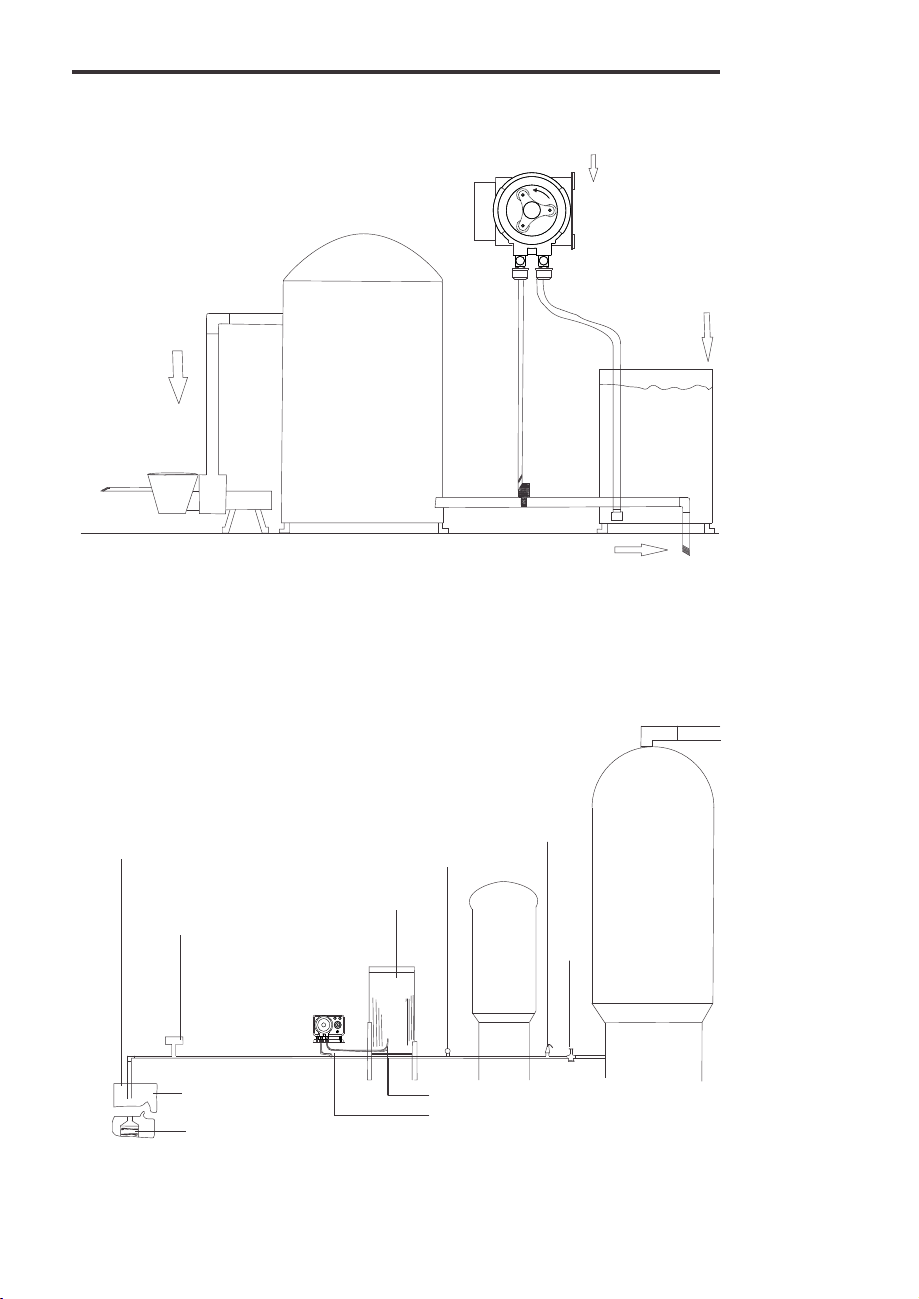

SWIMMING POOLS

Figure 1

CIRCULATION

PUMP

FILTER

INJECTOR

RETURN

LINE

SOLUTION

TANK

WATER WELLS

Figure 2

Well cover

Pressure

switch

WELL

Submersible well pump

Solution

tank

L

Pressure

guage

Suction Tube

Injector Point

Pressure

relief

valve

Drain

To system

Contact

tank

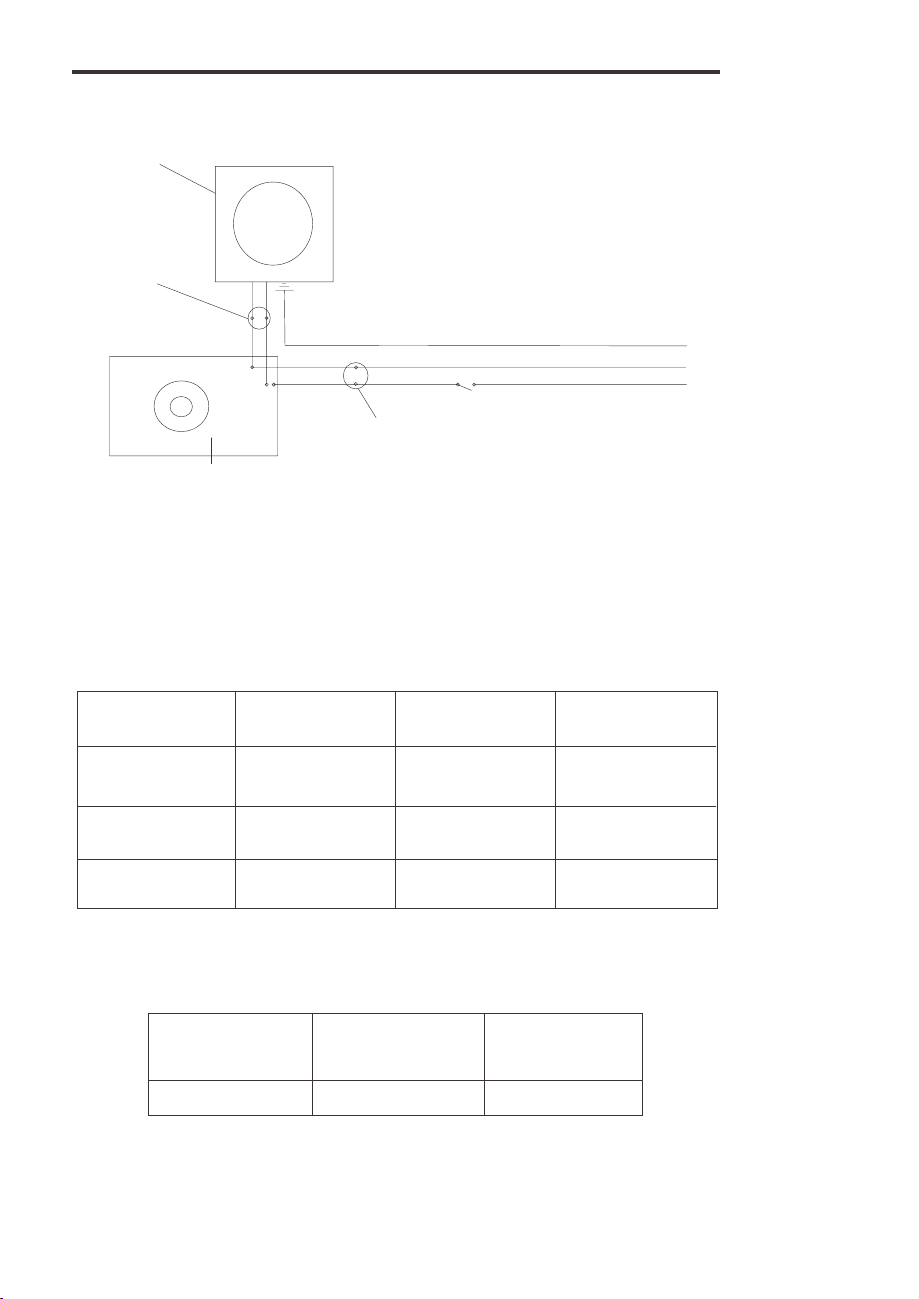

Page 5

Motor

Injecting

Indicator

Light

Cycle Timer

WIRING DIAGRAM

Figure 3

WIRING DIAGRAM

A-1600T SERIES

(Timer Models Only)

Black

Red

White

Power

Indicator

Light

Power

Switch

A- 1600 SERIES

WIRING COLOR CODES

Figure 4

Page 5

Ground

Hot

Common

**************MOTOR************

VOLTAGE HOT COMMON GROUND

115v Black or Yellow Blue Green

230v Black or Yellow Red Green

24v Blue White Green

******** CIRCUIT BOARD*******

(TIMER MODELS ONLY)

HOT

(Load and Input)

Black White Red

COMMON

(Input)

LOAD

(Load)

Page 6

Page 6

OPERATING INSTRUCTIONS

SUPPLY TANK FOR CHEMICALS

Plastic containers must be designed and manufactured for this purpose. Your

container must be designed for whatever chemical you are using. Do not

place the container in direct sunlight. Ultraviolet (UV) rays attack many

materials which can cause them to become brittle.

OPERATION - MAINTENANCE

Once every week inspect tubing, and accessory valves and fittings. Inspect

all parts for signs of leaks, swelling, cracking, corrosion or discoloration. Also,

inspect the tubing for elasticity.

Cracking, crazing, discoloration, etc., during the first week of operation are

signs of severe chemical attack. If this occurs, immediately remove the fluid

from the injector. Determine which parts are being attacked and replace with

parts that have been manufactured using more suitable material.

The pump is designed to perform in a wide variety of installations. However,

the service life of the pump will vary, depending on many factors such as;

fluid , temperature, pressure, etc. Because of the wide variety of installations,

the pump has been factory tested for pressure and performance using water

only. Do not use chemicals if you are not satisfied they are compatible with

the pumps construction.

The pump tube assemblies are designed for maximum service life. However,

the service life can be adversely affected by the chemicals used, the amount

of back pressure, the motor RPM, and temperature.

The pump tube assemble should be inspected frequently. Replace the tube if

any cracking, leaking or loss of feed rate occurs.

THREADLESS AND THREADED INJECTORS

The most common problem is calcium and/or lime build up inside the injector,

foot valve and tubing. This is basic material and can easily be removed by

running a weak solution of muriatic acid through it. After flushing the pump

with clear water, place the injection fitting and foot valve with the tubing

attached in a container of weak (1-5) solution of commercial grade muriatic,

then run the pump for a few minutes. After flushing out the wetted parts with

clear water again, return pump to service. CAUTION do not allow acid and

chlorine products to come together. This is VERY DANGEROUS to your

health!

Page 7

L

R

OPERATING INSTRUCTIONS

MEASURING THE OUTPUT

Page 7

FIGURE 5

This volumetric test will take into

account installation factors such as

line pressure, fluid viscocity, specific

gravity, etc. This test is the most

accurate for measuring the injector’s

output in an individual installation.

1. With the injector installed under

normal operating conditions, place

the foot valve/strainer in a large

graduated container.

2. Fill the container with the

chemical to be injected and run the

unit until all air is removed from the

suction line.

3. Refill the container, if necessary,

and with the foot valve in the

solution, note the amount of

chemical in the container.

4. Run the injector for a measured

amount of time and note the amount

of chemical injected.

Blue-White

Injection Fitting

Discharge

Tubing

Blue-White

Suction

Tubing

Graduated

Container

(not provided)

Pump

R

ADJUSTING THE OUTPUT

A. The pause control knob adjusts the cycle timer’s time on. The model A-1600T

standard cycle timer set at one minute. (+-10%) Other cycle lengths are available.

B. To adjust the amount of time on, turn the pause control knob to the correct

setting. ½ equals approximately 30 seconds on. 3/4 equals approximately 45

seconds on, etc.

Page 8

Page 8

OPERATING INSTRUCTIONS (Con’t)

FIGURE 6

1. 2.

L

R

Hold the tube in your right hand with

“R” facing you. Note that the fitting marked “L” is

facing downward and away from you to the left. The

tube is purposely twisted to allow for the difference

between the inside length and the outside length of

the tube when installed in the pump head. Hold the

tube with your thumbs over the “R” and the “L.”

R

the fitting marked

RL

The tube will naturally curve toward the rear of the

pump head. The curve in the tubing is a patented

feature which prevents the pump tube from running

outward and against the cover.

3. 4.

L

R

Attach the plastic tube fitting (marked “R”) into the right

side of the pump head.. Push the groove of the fitting

straight into the slot. With the pump running, hold the

fitting marked “L’ with your left hand (your thumb should

be covering the “L”). At the same time, use your right

thumb to guide the tube into the pump head.

With the tubing riding well between the rollers, push the

fitting marked “L” into the chamber lock. Be sure both

fittings are pushed all the way in place.

TUBE CONNECTIONS INSTRUCTIONS

1. Connect the flow indicator end of the suction tube to pump fitting marked

“R.” Indicator to be vertical.

2. Trim the other end so strainer assembly will hang about one or two inches

above bottom of solution tank (sediment space).

3. Slide the ceramic weight over the end and attach the foot strainer

assembly.

4. Connect the discharge tube to the “L” fitting then to the injector fitting.

NOTE: A threaded injection fitting is available. Fitting is equipped with 1/4”

and 1/2” NPT threads.

RL

Pump Tube Lubricant: Place 1 or 2 drops of silicone oil on each roller to

lubricate new pump tubes or when required.

Page 9

Page 9

OPERATING INSTRUCTIONS (Con’t)

THE PUMP TUBE ASSEMBLY

A. The A-1600 Pump Tube Assemblies are designed for a service life of at least

800 hours. However, the service life can be adversely affected by the chemicals

used, the amount of back pressure, the motor RPM, and temperature. The

service life of 800 hours is based on the A-002-6 tube tested with water at 70F.

(21C), 0PSI, 45 RPM gearbox.

B. The pump tube assembly should be inspected frequently. Replace the tube if

any cracking, leaking or loss of feed rate occurs.

NOTE: Place 1 or 2 drops of silicone oil on each roller to lubricate new pump

tubes or when required.

CLEANING

A. The most common problems occur from deposits that can build up in the foot

valve, injection fitting and pump tube assembly, (wetted parts. Keeping these

parts clean will dramatically increase the life of the injector.

B. For simple maintenance cleaning, remove the injection fitting and footvalve /

strainer. Disassemble and clean the individual parts with clean water.

With these fittings removed, set the pause control to ON and run the injector

using clean water.

C. For removing harsh deposits that can build up in the wetted parts.....

1. Flush the system by pumping clean water to remove any chemicals that may

be present.

2. Run a weak solutions of muriatic acid (5%) through the wetted parts.

3. Again flush the system with clean water.

CAUTION

MURIATIC ACID WHEN MIXED WITH OTHER CHEMICALS CAN BE

EXTREMELY DANGEROUS. ALWAYS FLUSH THE SYSTEM WITH CLEAN

WATER BEFORE AND AFTER YOU ACID WASH.

D. When changing the pump tube assemble, always wipe the pumphead to

remove any debris. Clean with soap and water if necessary.

Page 10

Page 10

EXPLODED VIEW

19

17

15

Front View

12

8

4

2

1

Page 11

alve Weight

Assy. 1 Min. 115v

Page 11

CONTACT LOCAL AUTHORIZED REPAIR CENTER

FOR PARTS AND SERVICE

A- 1600 PARTS LIST

A-008-2 Gear Box Assembly 30 RPM

A-008-3 Gear Box Assembly 45 RPM

A-309-1 Motor Assy. 24v/60HZ For 30 & 45 RPM

A-149-2 Motor Assy. 115v/60HZ for 14 RPM

A-309-2 Motor Assy. 115v/60HZ for 30 & 45 RPM

A-149-4 Motor Assy. 220v/50HZ for 14 RPM

A-309-4 Motor Assy. 220v/50HZ for 30 & 45 RPM

A-149-3 Motor Assy. 230v/60HZ for 14 RPM

A-002-4 Pump Tube Assy. 1/4” OD Tygon 25.C-330-4 Tube Nut1/4 OD Tubing

A-002-4n Pump Tube Assy. 1/4”OD Norprene C-330-6 Tube Nut 3/8” OD Tubing

A-002-6 Pump Tube Assy. 3/8” OD Tygon 26.C-334-4-10 Tubing 1/4” OD x 10’

A-002-6n Pump Tube Assy. 3/8” OD Norprene C-334-6-10 Tubing 3/8” OD x10’

A-002-7 Pump Tube Assy. 7/16” OD Tygon 27.T140-4V T.I. Fitting 1/4” OD Tube Viton W/ Clamp

A-002-7N Pump Tube Assy. 7/16” OD Norprene T140-6V T.I. Fitting 3/8” OD Tube Viton W/ Clamp

1. A-011 Pumphead Cover Retaining Knob 19.C-608P Motor Housing

2. A-001 Pumphead Cover 20.C-628 Screw 6-32x2-3/4 Phil RD

3. A-002-3N Pump Tube Assy. 3/16” OD Norprene 24.C-308J Junction box assembly

A-003-1 Roller Assy. 2 Lube 29.C-346 Ceramic Foot V

4. A-003 Roller Assy. 3 Lobe 28.CF-3040 Clamp Fits 1” Thru 2-1/2”Pipe

5. A-004 Pumphead Mounting screw 10-32 x 3/4” 30.C-340-4V Foot Valve/Strainer 1/4”OD Viton

6. A-031 Pumphead Spacer C-340-6V Foot valve/Strainer 3/8” OD Viton

7. 2-010E Motor Shaft Seal 31.A-023-B Electronic Timer

8. A-005 Pumphead A-023-C Electronic Timer Assy. 1 Min. 230v

9. A-006 Motor Mount Screw 10-32 x ½ A-023-D Electronic Timer Assy. 1 Min. 24v

12. C-302 Motor Mount A-023-E Electronic Timer Assy. 2 Min. 220v

14. C-649 Bushing .50-20x.31Alum. Hex A-023F Electronic Timer Assy. 6 Sec. 115v

15. A-008-1 Gear Box Assembly 14 RPM A-023-G Electronic Timer Assy. 6 Sec. 230v

17. A-149-1 Motor Assy. 24v/60HZ For 14 RPM

A-309-3 Motor Assy. 230v/60HZ for 30 & 45 RPM

Page 12

TROUBLE SHOOTING GUIDE

SYMPTOM

POSSIBLE CORRECTIVE

Tube wears out to fast 1. High back pressure

2. Temp. above 105° F

3. Clogged injection

fitting

Injector runs noisy

1. Normal with 14 RPM

2. Worn motor bearing

Injector runs hot

1. Normal heat rise is

approx. 70° F

Solution tank is filling

instead of emptying

1. Suction & Discharge

tubing is reversed

2. Rollers worn far

beyond standard

tolerance

Swollen O-Rings 1. O-Ring material is

not compatible with

chemical being used.

1. MAX PSI = 25

2. Do not install near

a heat source

3. Clean fittings

1. None

2. Replace bearing

1. Do not install bear

a heat source

1. Connect suction

tube to fitting marked

“R” and Discharge to

“L”

2. Replace Roller

Assembly

1. Replace with

compatible O-Rings.

Cycle Timer is erratic or

run constantly

Pressure is below 25

PSI but chemical is not

injecting

2. System was not

flushed

1. Spikes or surges in

electricity caused by

“ORP” or “PH”

controllers

2. Surge protector has

been overlooked

1. Tube assembly is worn

2. Roller Assembly is worn

3. Injection fitting or foot /

valve assembly is clogged

4. Discharge tubing is to

long creating added back

pressure (especially with

high viscosity chemicals)

1. Consult controller

manufacturer

2. Replace timer

board

1. Replace tube assy

2. Replace roller

3. Clean fittings

4. Install injector as

close to injection

point as possible Trim

Discharge tubing

Page 13

REPAIR CENTERS

ARKANSAS American Pump TENNESSEE

BT Environmental, Inc 7580-A W. Tennessee St. Rock City Machine

Bill Thomason Tallahassee, FL 32304 307 3rd Avenue South

225 Castleberry Street 850-575-9618 Nashville, TN 37201

Hot Springs, AR 71901 615-244-1371

501-624-3837

CALIFORNIA (NORTHERN) Pensacola, FL 32505

Howard E. Hutching 904-432-9929

company

(Repair Center) Picard Chemical

7190 Penryn Plaza 1670 S. Congress Avenue

Penryn, CA 95663 W. Palm Beach, FL 33406

800-568-3958 561-965-3434

Swimco Electric Co. 2708 E. Randol Mill Rd.

753 Camden Avenue Arlington, TX 76011

Campbell, CA 95008 817-640-6188

408-378-2607

CALIFORNIA (SOUTHERN) Alsip, IL 60658

Blue-White Industries 708-597-5558

(Repair Center)

5300 Business Drive MARYLAND

Huntington Bch. CA 92649 Century Pool Service, Inc

714-893-8529 5020 Nicholson Court, #201

COLORADO

Denver Winpump

5754 Lamer ave

.Arvada, CO 80002

303-424-3551

CONNECTICUT Wilson, NC 27893

Cronin-Cook & Associates 800-872-7665

24 West Road

Vernon, CT 06029

860-875-0544

FLORIDA

Rice Pump & Motor Repair

5740 Powerline Road

Ft. Lauderdale FL 33309

954-776-6049

Jerry Lee Chemical Co.

3407 W. Old Fairfield Drive

ILLINOIS

Mullarkey Associates

(Repair Center)

12346 S. Keeler Ave.

Kensington, MD 20895

301-231-8999

NORTH CAROLINA

Southern Industrial Sales

1903 Herring Avenue

SOUTH DAKOTA

Son-Aqua Distributing

Jim Robinson

2447 W. Main Street

Rapid City, SD 57702

605-343-7716

TEXAS

Alamo Water Refiners

13700 Hwy. 90 West

San Antonio, TX 78245

210-677-8400

Shelter’s Water Refining

Robert Shelton

Page 14

LIMITED WARRANTY

Your new pump is a quality product and is warranted to be free of

defects as set down it this policy. All parts, including rubberized goods

and labor are covered under warranty for 90 days from date of purchase. Used peristaltic tubes are not warranted. Parts (excluding

rubberized goods and labor) are covered for a period of 12 months

from date of purchase. Warranty coverage does not include damage to

the pump that results from misuse, carelessness, abuse, or alteration.

Only the repair or replacement of the pump is covered. The manufacturer does not assume responsibility for any other loss of damage.

Warranty status is determined by the pumps serial number. The serial

number label must be on the pump to obtain warranty coverage.

Enclose your invoice or sales receipt, with date of purchase, when you

return the pump for warranty repair. Warranty status will be verified by

the factory or authorized service center.

Also: Please be advised, injections and metering devices are not

intended as a means of treating water to render it suitable for human

consumption. When used as hypochlorinators, they are meant to

destroy bacteria and algae contamination, before it’s removal by

filtration. Acid and soda injectors are used for pH control (balance).

The injectors are factory tested with water only for pressure and

performance. Installers and operators of these devises must be well

informed and aware of the precautions to be taken when injecting

various chemicals, especially those considered hazardous or dangerous. Should it be necessary to return an injector for repair or service,

you must attach information regarding the chemical used as some

residue may be present within the unit and could be hazard to service

personnel.

The manufacturer will not be liable for any damage that may result by

the use of chemicals and injectors and its components. Thank you.

PROCEDURE FOR IN-WARRANTY REPAIR

Carefully, pack the pump to be repaired, included the foot valve and

injection fitting. Enclose a brief description or the problem, as well as

original invoice or sales receipt showing date fo purchase. The receipt

will be returned with the unit. Prepay all shipping costs. COD shipments will not be accepted. Warranty repair service must be preformed

by the factory, or an authorized service center. Damage caused by

improper packaging is the responsibility of the sender.

80000-038 09-03-2010

Loading...

Loading...