TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS

SAFETY PROCEDURES

PRECAUTIONS FOR RECEIVING AND STORING HOOD

WALL HOODS

INSTALLATION - REMOVABLE BACK PANEL

CFM300 - 6" ROUND COLLAR

CFM600 - 8" ROUND COLLAR

CFM600 - 8" TRANSITION

CFM1200 - 10" TRANSITION

ISLAND HOODS

INSTALLATION

DUCT COVER INSTALLATION

2

3

3

4,5

6

7

8

9

10

11

DUCT WORK INSTALLATION

CFM600 - 8" TRANSITION

CFM1200 - 10" TRANSITION

REMOTE FAN - ROOF OR WALL MOUNTED

VOLUMETRIC FLOW RATE GRAPHS

WIRING DIAGRAM - WALL AND ISLAND HOODS

HOOD FEATURES

BAFFLE FILTERS - GREASE TROUGHS - HALOGEN LIGHTS

CLEANING RECOMMENDATIONS

12

13

14

15

16

17

18

19

20

1

PLEASE READ COMPLETE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LCOAL CODES.

IMPORTANT: Save these instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

SAFETY Turn power circuit OFF at the service panel and lock panel door

WARNING: before wiring this unit.

IMPORTANT SAFETY INSTRUCTIONS

CAUTION - TO REDUCE THE

RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PEOPLE,

OBSERVE THE FOLLOWING:

1.

Use this rangehood only in the

manner intended by the

manufacturer. If you have any

questions, contact the

manufacturer - Prizer Hoods.

2.

Before servicing or cleaning the

unit, switch power o at service

panel and lock the service

disconnecting means to prevent

power from being switched on

accidentally. When the service

disconnecting means cannot be

locked, attach a tag to the service

panel to indicate power has been

switched o for maintenance.

3.

Install this rangehood only with

remote fan models rated

maximum 12.8A or in-hood fans

manufactured by Prizer Hoods,

models CFM300, CFM600,

CFM1200.

CAUTION - TO REDUCE THE

RISK OF A R ANGETOP GREASE

FIRE:

1.

Never leave cooktop surface

unattended while on high

setting.

Boilovers cause smoke and greasy

spillovers may ignite. Heat oils

slowly on low or medium

settings.

2.

Hood fan should always be ON

when cooking on high heat or

when ambeing foods (i.e.

Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambe.)

3.

Clean in-hood fans frequently.

Do not allow grease to

accumulate on fan or bae

lters.

4.

Always use cookware appropriate

for the size of the surface element.

CAUTION - TO REDUCE THE

RISK OF INJURY TO PEOPLE, IN

THE EVENT OF A RANGETOP

GREASE FIRE, OBSERVE THE

FOLLOWING:

1.

SMOTHER FLAMES with a

tight-tting lid, cookie sheet, or

other metal tray. Immediately

turn the gas burner OFF.

2.

PREVENT BURNS. If gas

ames do not extinguish

immediately; EVACUATE

AND CALL THE FIRE

DEPARTMENT.

3.

NEVER PICK UP A FLAMING

PAN as you may sustain burns.

4.

NEVER USE WATER, wet

dish-cloths or towels as a violent

steam explosion will occur.

5.

Use re extinguisher ONLY if:

You know you have a class

•

ABC extinguisher, and you

already know how to operate it.

CAUT ION: FOR GE N E R AL

VENTILATION USE ONLY. DO NOT

USE TO EXHAUST HAZARDOUS OR

EXPLOSIVE MATERIALS OR VAPOR.

e re is small and contained

•

in the area where it started.

e re department is being

•

called.

You can ght the re with your

•

back to an exit.

2

SAFETY PROCEDURES FOR INSTALLING

YOUR NEW PRIZER HOOD (continued)

CAUTION - TO REDUCE THE

RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PEOPLE,

OBSERVE THE FOLLOWING:

CAUTION - FOR GENERAL

VENTILATION USE ONLY. DO

NOT USE TO EXHAUST

HAZARDOUS OR EXPLOSIVE

MATERIALS OR VAPORS.

A.

Installation work and electrical

wiring must be done by a

qualied installer in accordance

with all applicable codes and

standards, including re rated

construction.

B.

Sucient air is needed for proper

combustion and gas exhaustion

through the ue (duct cover) of

fuel burning cooktop to prevent

backdrafting. Follow the

equipment manufacturer’s

guidelines and safety standards

such as those published by the

National Fire Protection

Association (NFPA), and the

American Society for Heating,

Refrigeration and Air

Conditioning Engineers

(ASHRAE), and the local code

authorities.

C.

When cutting/drilling into a wall

or ceiling, avoid damage to

electrical wiring and other

hidden utilities.

D.

In-hood or in-line fans must be

vented to the outdoors.

E.

If a ventilation unit is to be

installed over a tub or shower, it

must be marked as appropriate

for the application and be

connected to a GFCI (Ground

Fault Circuit Interrupter) protected branch circuit.

F.

NEVER place a control switch

where it can be reached from a

tub or shower.

CAUTION - TO REDUCE THE

G.

RISK OF FIRE WITHIN WALLS

OR ROOFS, USE ONLY METAL

DUCTWORK.

Install this hood in accordance

H.

with all requirements specied by

the manufacturer of your

cooktop/range.

Install this hood using required

I.

clearance from cooking surface to

combustible material specied in

cooktop installation instructions.

READ AND SAVE

UPON RECEIVING YOUR HOOD...

e high degree of craftsmanship in the construction

•

and nish of your hood requires careful handling to

ensure proper installation.

Do not remove your hood from its carton until you are

•

ready to hang it.

Do not store your hood anywhere other than within the

•

carton. If it is necessary to remove your hood from the

carton, place it on a blanket or padded area that will

protect your hood from scratches or indentations.

Do not lift the hood by its utensil rail. Place your ngers

•

under the lower reveal of the hood. Grasp rmly and

lift.

Wearing cotton gloves are preferred. ey will protect

•

the surface from ne scratches and eliminate

ngerprints.

Remove all rings, watches, belt buckles, and jackets

•

(snaps-zippers) to prevent scratches on the hood.

If applicable, do not remove the cotton annel from your

•

hood until the installation process is complete. It will be

necessary to remove only a small portion on the

back-side for a wall mounted hood in order to position in

place.

Located within the hood cavity (behind the bae lters)

•

are component parts and halogen bulbs.

3

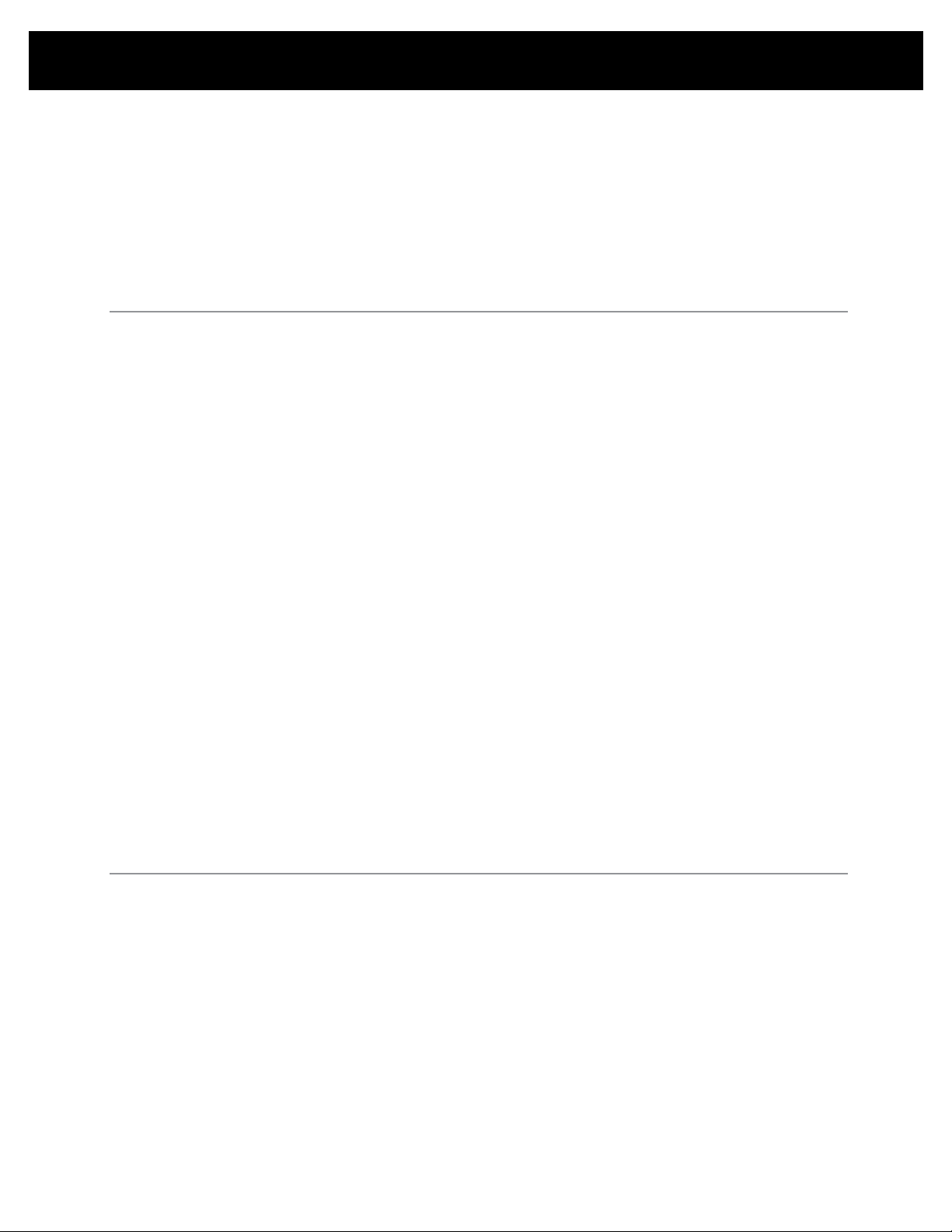

WALL HOOD INSTALLATION - REMOVABLE BACK PANEL

e hood is shipped with the removable back panel and

1.

the transition.

Note: e transition is shipped upside down within the

hood. It must be removed then reinstalled.

(See Figures 1 through 3)

To detach the removable back panel and transition from

2.

the hood, remove four (4) screws from the top and four

(4) screws from the back of the unit. (See Figure 1)

Detach the transition from the removable back panel

3.

removing four (4) screws. ese shipping screws are

needed for re-attaching the transition to the removable

back panel.

Secure the transition to the top of the removable back

4.

panel, using the four (4) screw provided. Use duct tape

to seal the joints of the transition and the top of the

removable back panel. (See Figure 2)

Figure 1.

Shipping Screws

Removable Back Panel

Transition

Hood

Assembly

To detach the removable back panel/transition from the

5.

hood unit, remove four (4) screws from the top and four

(4) screws from the back of the unit. (See Figure 1)

Secure the back side of the removable back panel to the

6.

wall stud. (See Figure 3)

Using the wire harness from the remote fan, connect it

7.

to the molex plug within the hood cavity.

Power in

Remote

Blower

5-wire in

In-Hood

J-Box

Hood wiring harness

Remote pigtail

connected to 6-pin plug

Molex plug

10" Transition

Figure 2.

Removable Back Panel

10" Duct

Shipping Screws

Duct Tape

Centerline

of Sot

Sot

Figure 4.

* Remote pigtail are supplied with remote fans

(View from back of hood)

Removable Back Panel

Figure 3.

Centerline of

Removable Back Panel

4

WALL HOOD INSTALLATION - (continued)

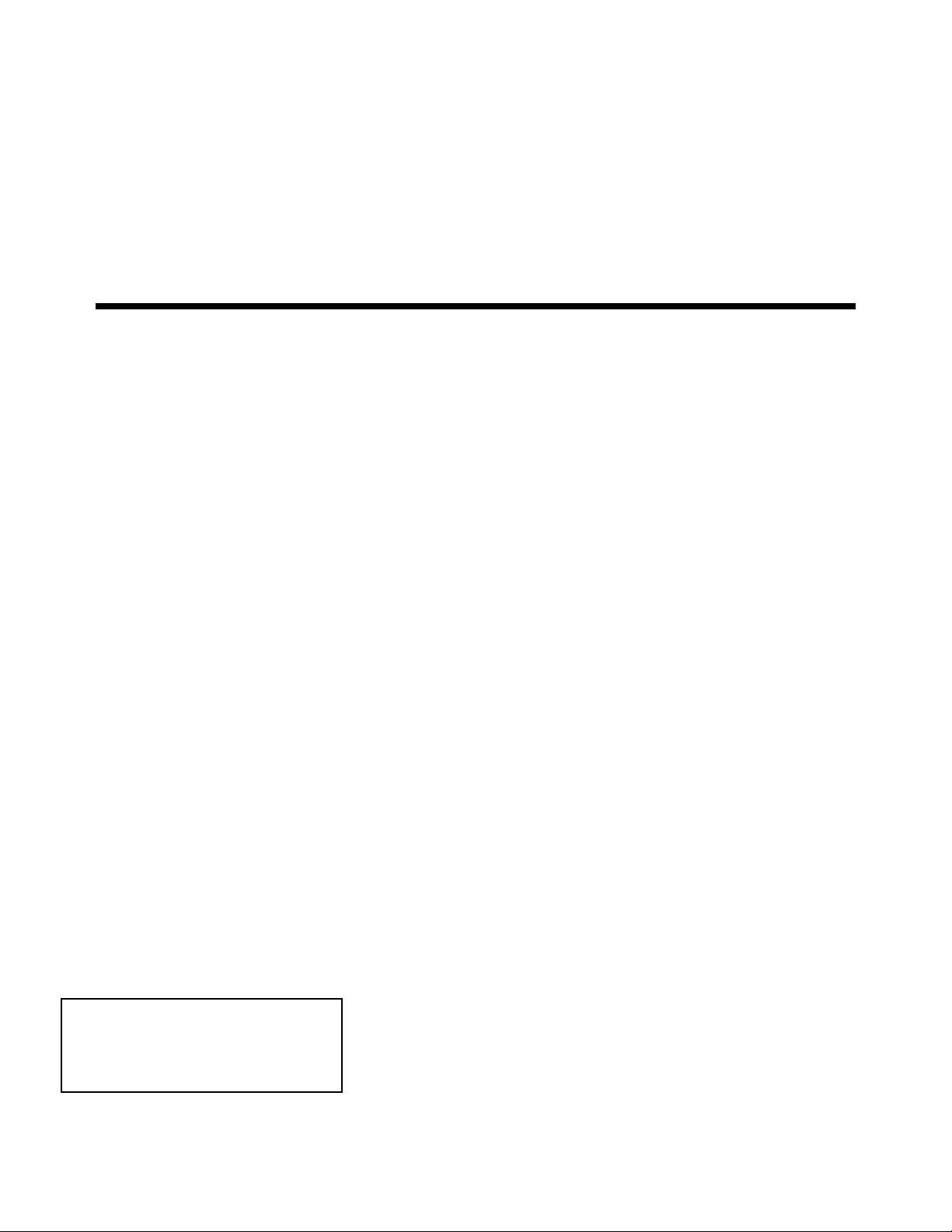

Attach the hood to the removable back panel by aligning

1.

the welded studs on the removable back panel with the

slotted holes on the back of the hood. (See Figure 5)

Using the screws provided, secure the hood assembly to

2.

the removable back panel. (See Figure 5)

Add 2”x4” wood framing block to aid in securing the top

3.

and rear of the hood to the wall. (See Figure 6)

To mount CFM300, CFM600 and CFM1200 fans

4.

within wall hoods. (See Figures 8, 9, 10, 11) (Page 6-9)

Install the fan by aligning the fan holes with the welded

5.

studs on the removable back panel. Tighten the fan to

the panel using the hex nuts provided. (See Figures 8, 9,

10, 11) (Page 6-9)

Connect the “Molex” from the fan to the “Molex” plug

6.

on the hood. (See Figure 4.) (Page 4)

Figure 5.

Mounting

Holes

Sot

Connector

Attach three wires: black, white and green (#16 AWG) in

7.

1/2” conduit from the service panel to the hood junction

box. Power supply must be rated for 120v, 60Hz, 15

amps (minimum). (See Page 17)

Remove junction box and selected “knockout”. en

8.

install the strain relief (conduit) connector in the

removable back panel hole. (See Pages 6, 7, 8, 9)

Remove the junction box from the rough-in plate.

9.

Connect black wire to power supply black wire, white

wire to power supply white wire, and green wire to

power supply green wire. (See Pages 6, 7, 8, 9)

Place all wiring connectors inside junction box and

10.

reinstall removable back panel.

OPTIONAL DUCT COVER

1. Install the hood as described in “Hood Rough-In Plate Mount”

Note: Be sure to allow enough room for duct cover width

on the top section of the rough-in plate.

2. Slide Duct Cover into opening.

Figure 6.

Framing

Finished Lag Screws (4 total)

Mounting

Screws

2"x 4"

1/2" ick

Drywall

Screw

Hood

Front

Optional

Duct Cover

3. Attach Duct Cover from the inside of the hood through lter

opening using the screws provided. (See gure 7)

Note: Do not completely tighten screws until all components

have been installed. At this point, check the alignment of the

duct to the hood. First tighten the four corners to secure the

duct, then tighten the remaining screws.

Figure 7.

5

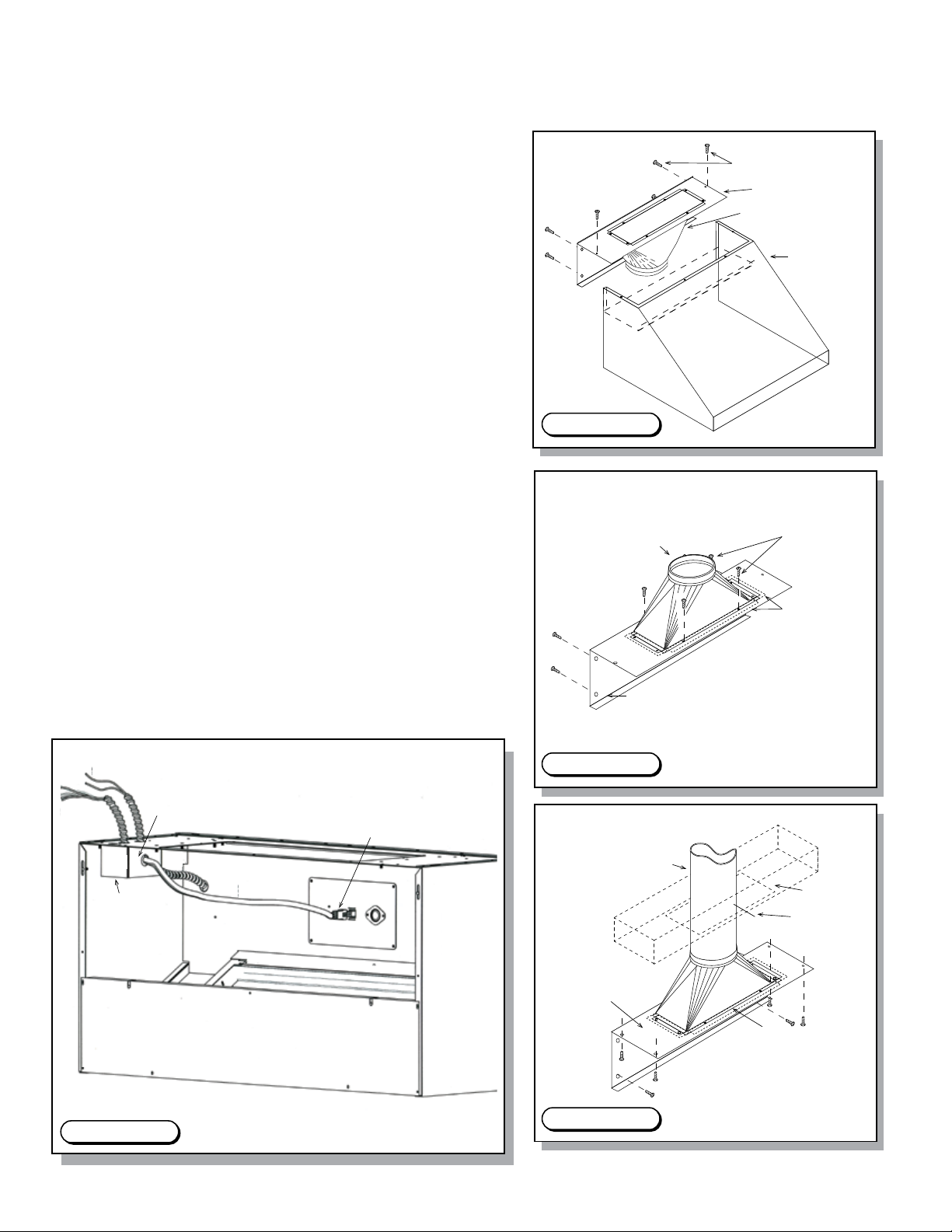

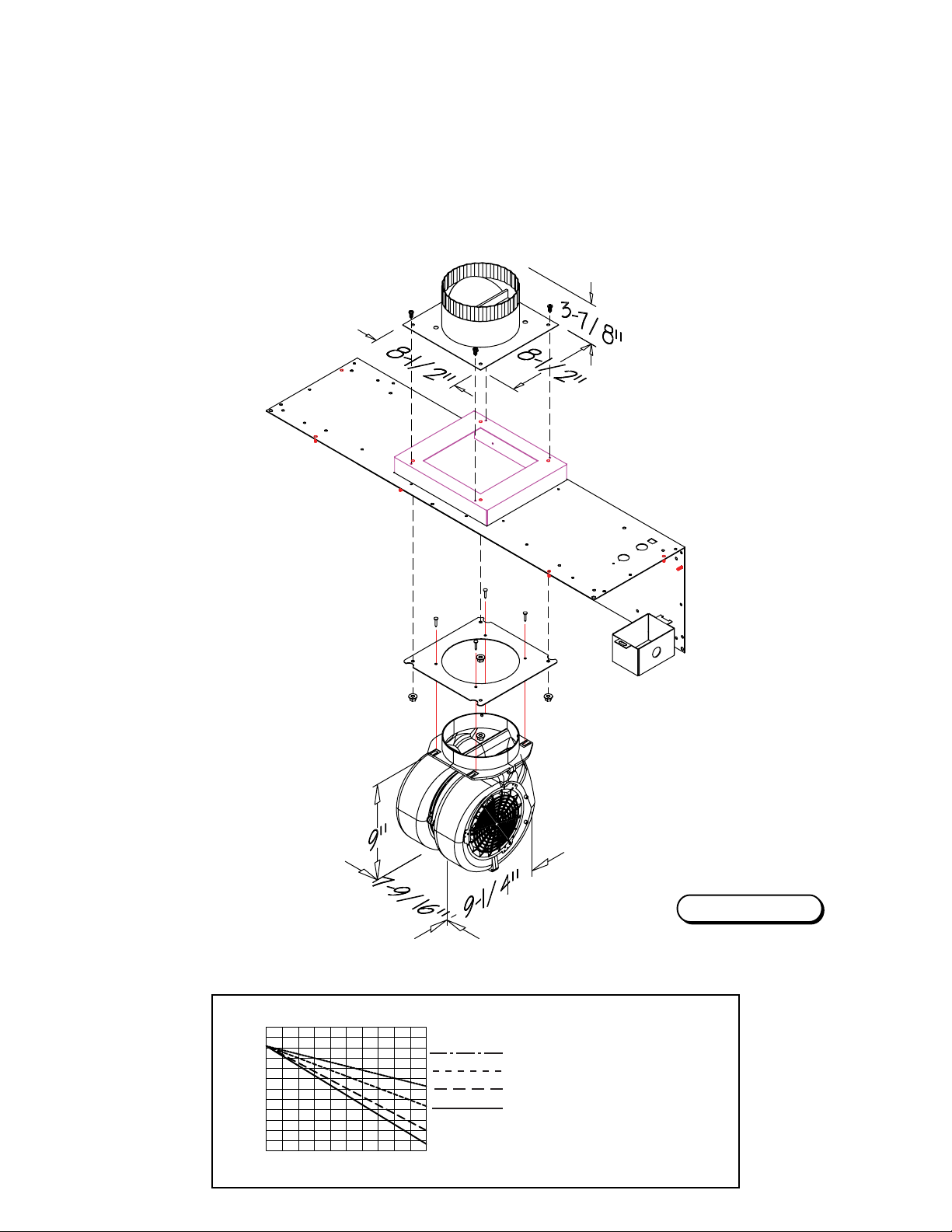

CFM 300 IN-HOOD FAN

WALL APPLICATION - 6” ROUND COLLAR

COMPATIBLE WITH:

- LOW PROFILE

- SANTA FE 10” TALL

- PRO METAL LINER 28” WIDE

- METAL LINER 28” WIDE

- COMPACT METAL LINER

CFM300 Fan

300

250

200

150

100

50

Volumetric Flow Rate, CFM

0

0 20 40 60 80 100

Total Equivalent Duct Length, ft.

Duct Dimensions

8" dia.

7" dia.

3 1/4" x 10"

6" dia.

Figure 8.

Maximum CFM: 300

Electrical Motor Rating:

1.79 Amps @ 115V AC, 60 Hz

6

Loading...

Loading...