Page 1

SOLAR BOOST™ 3024iL

30AMP 24VDC / 40AMP 12VDC MAXIMUM POWER POINT TRACKING

PHOTOVOLTAIC CHARGE CONTROLLER

INSTALLATION AND OPERATION MANUAL

© Blue Sky Energy, Inc. 2011 430-0024 D

2003167

This device complies with part 15 of the

FCC rules. Operation is subject to the

following two conditions: 1) This device may

not cause harmful interference, and 2) This

device must accept any interference

received, including interference that may

cause undesired operations.

THIS MANUAL INCLUDES IMPORTANT SAFETY INSTRUCTIONS FOR MODELS SB3024iL, SB3024DiL

CE MANUEL CONTIENT D’INSTRUCTIONS IMPORTANTES POUR LES MODELES SB3024iL, SB3024DiL

ESTE MANUAL INCLUYE INSTRUCCIONES DE SEGURIDAD IMPORTANTES PARA LOS MODELOS SB3024iL, SB3024DiL

CONFORMS TO

UL STD. 1741

CERTIFIED TO

CAN/CSA STD. E335-1/2E

CONFORMS TO

EN 61326-1:2006

EN 60335-1:2002 + A11:2004 + A1:2004

EN 60335-2-29:2004

SAVE THESE INSTRUCTIONS

PRIERE DE SAUVEGARDER CES INSTRUCTIONS

DIESES HANDBUCH ENTHÄLT WICHTIGE HINWEISE FÜR DIE MODELLE SB3024iL, SB3024DiL

BITTE BEHALTEN SIE DIESE HINWEISE

CONSERVE ESTAS INSTRUCCIONES

COVERED UNDER ONE OR MORE OF THE FOLLOWING US PATENTS

6,111,391 • 6,204,645

Page 2

Blue Sky Energy - Solar Boost 3024iL

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS................................................................................................................................ 2

PRODUCT DESCRIPTION...................................................................................................................................................... 3

Part Numbers and Options..................................................................................................................................... 3

OPERATION ........................................................................................................................................................................... 3

Charge Status Indicator.......................................................................................................................................... 4

Optional Digital Display .......................................................................................................................................... 3

Optional Remote Displays...................................................................................................................................... 3

Multi-Stage Charge Control.................................................................................................................................... 3

Bulk Charge ................................................................................................................................... 3

Acceptance Charge........................................................................................................................ 3

Float Charge .................................................................................................................................. ..4

Equalization............................................................................................................................................................ 4

Automatic Equalization................................................................................................................... 4

Manual Equalization....................................................................................................................... 4

Current Limit........................................................................................................................................................... 4

Temperature and Output Power............................................................................................................................. 4

Optional Temperature Compensation .................................................................................................................... 5

Maximum Setpoint Voltage Limit............................................................................................................................ 5

Maximum Power Point Tracking (MPPT) ............................................................................................................... 5

Multiple Charge Controllers On The IPN Network.................................................................................................. 5

INSTALLATION....................................................................................................................................................................... 5

Electrostatic Handling Precautions......................................................................................................................... 5

Selecting PV Modules ............................................................................................................................................ 6

Solar Boost 3024i Setup......................................................................................................................................... 6

As Shipped Factory Default Settings ............................................................................................. 6

Restoring As Shipped Default Settings.......................................................................................... 6

Battery And PV Voltage ................................................................................................................. 7

Charge Voltage, Float Voltage & Charge Time.............................................................................. 7

Output Current Display................................................................................................................... 8

Battery and PV Wiring............................................................................................................................................ 8

Electromagnetic Compatibility................................................................................................................................ 8

Battery Temperature Sensor.................................................................................................................................. 8

Auxiliary Output...................................................................................................................................................... 8

Auxiliary Battery Charge ................................................................................................................ 9

Load Controller............................................................................................................................... 9

Dusk-to-Dawn Lighting Control ...................................................................................................... 9

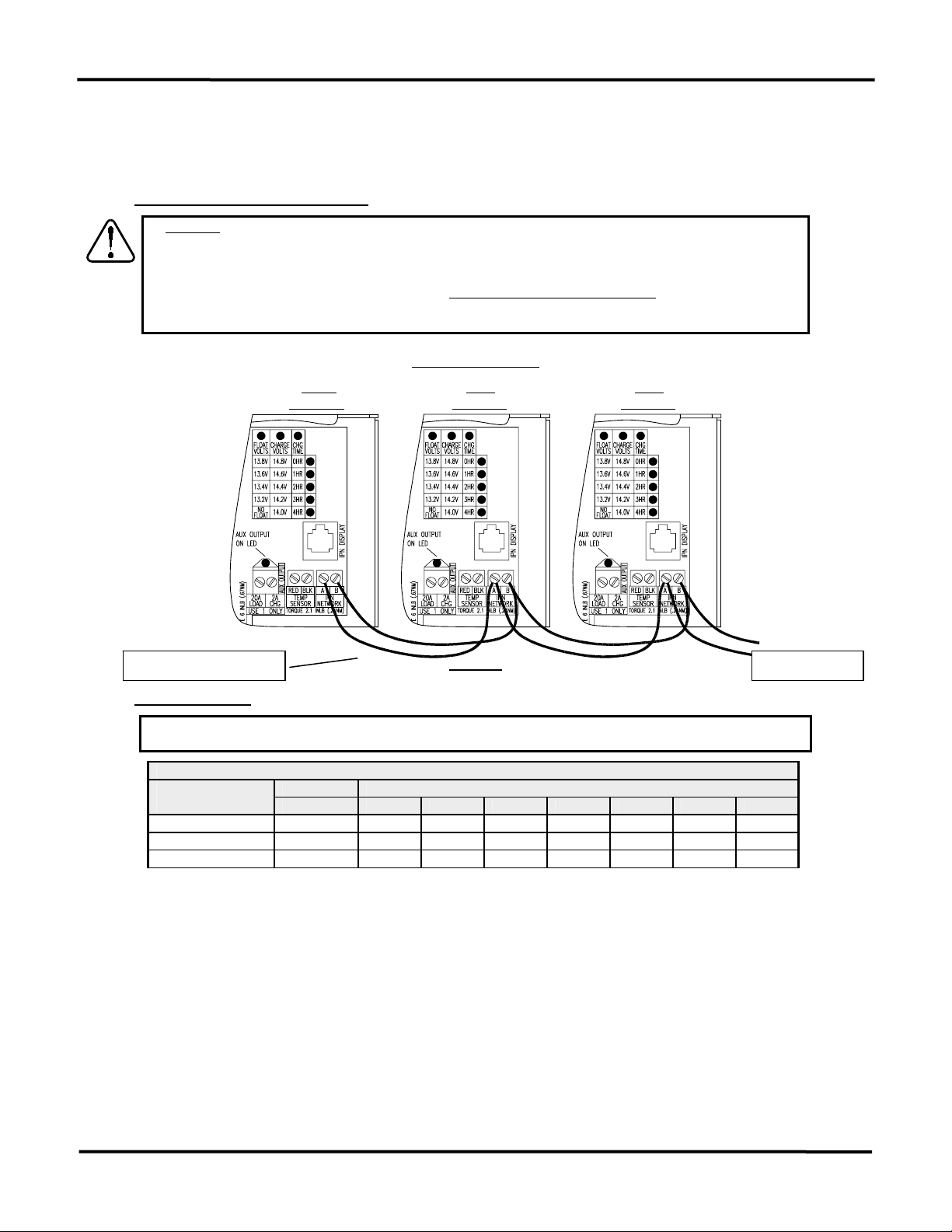

Installing a Multi-Controller System........................................................................................................................10

Multi-Controller Wiring And Setup..................................................................................................10

IPN Network................................................................................................................................... 10

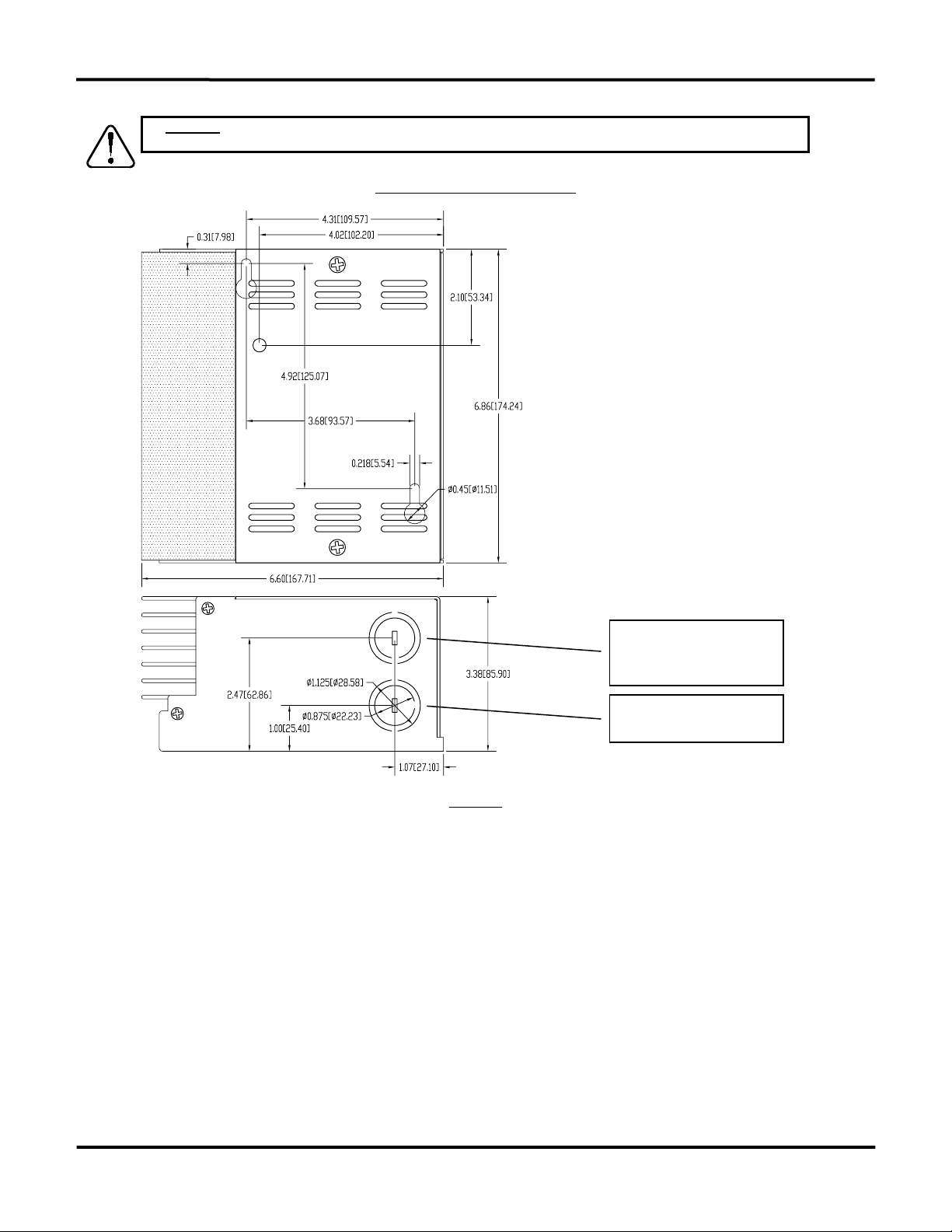

Mounting................................................................................................................................................................. 11

TROUBLESHOOTING GUIDE................................................................................................................................................12

SPECIFICATIONS................................................................................................................................................................... 14

TWO YEAR LIMITED WARRANTY........................................................................................................................................ 15

TABLES AND FIGURES

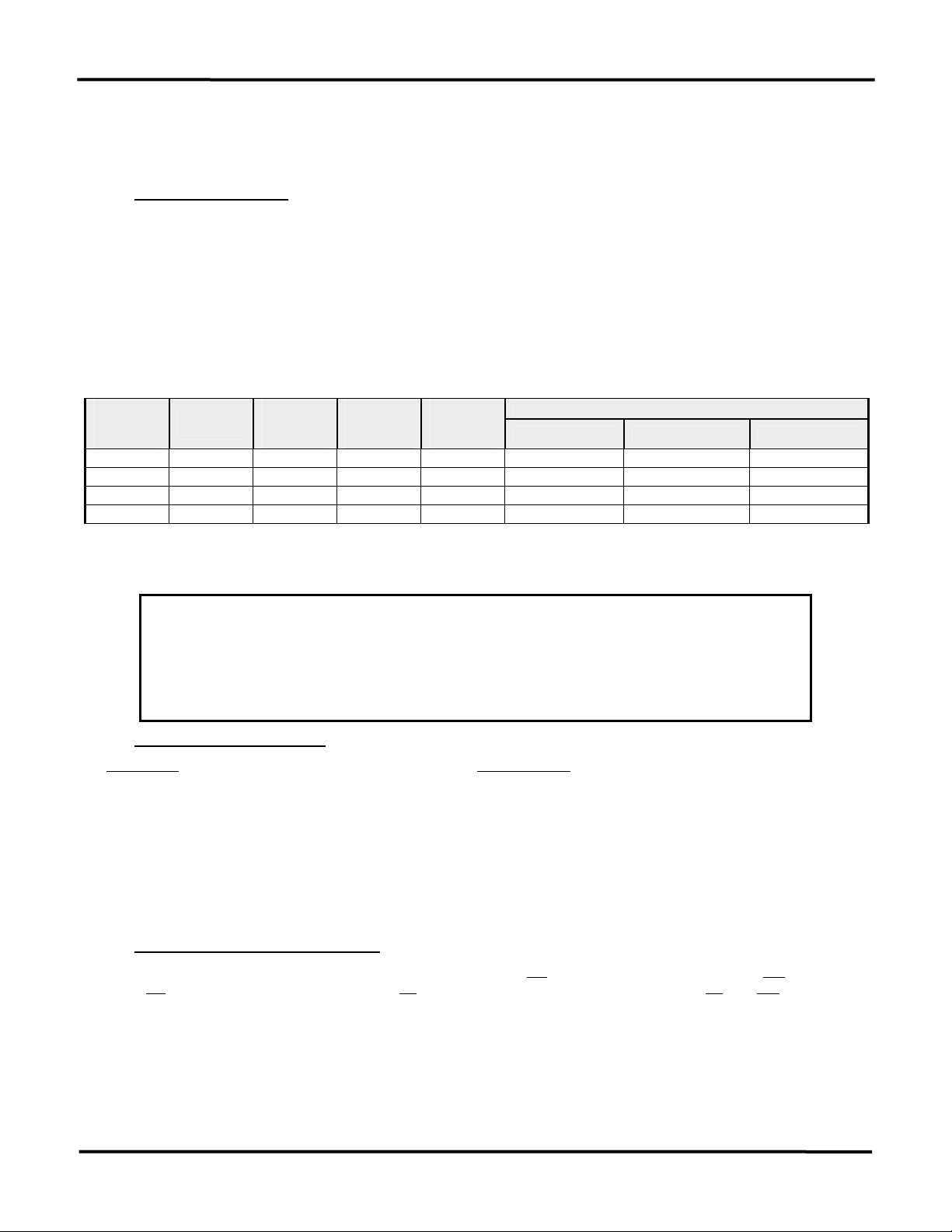

Table 1 Charge Status Indicator ................................................................................................................. 3

Table 2 Maximum Conductor Length - 3% Voltage Drop............................................................................ 8

Figure 1 Front Panel and Remote Display Indicators................................................................................... 4

Figure 2 Factory Charge Voltage Setpoint -vs.- Battery Temperature......................................................... 5

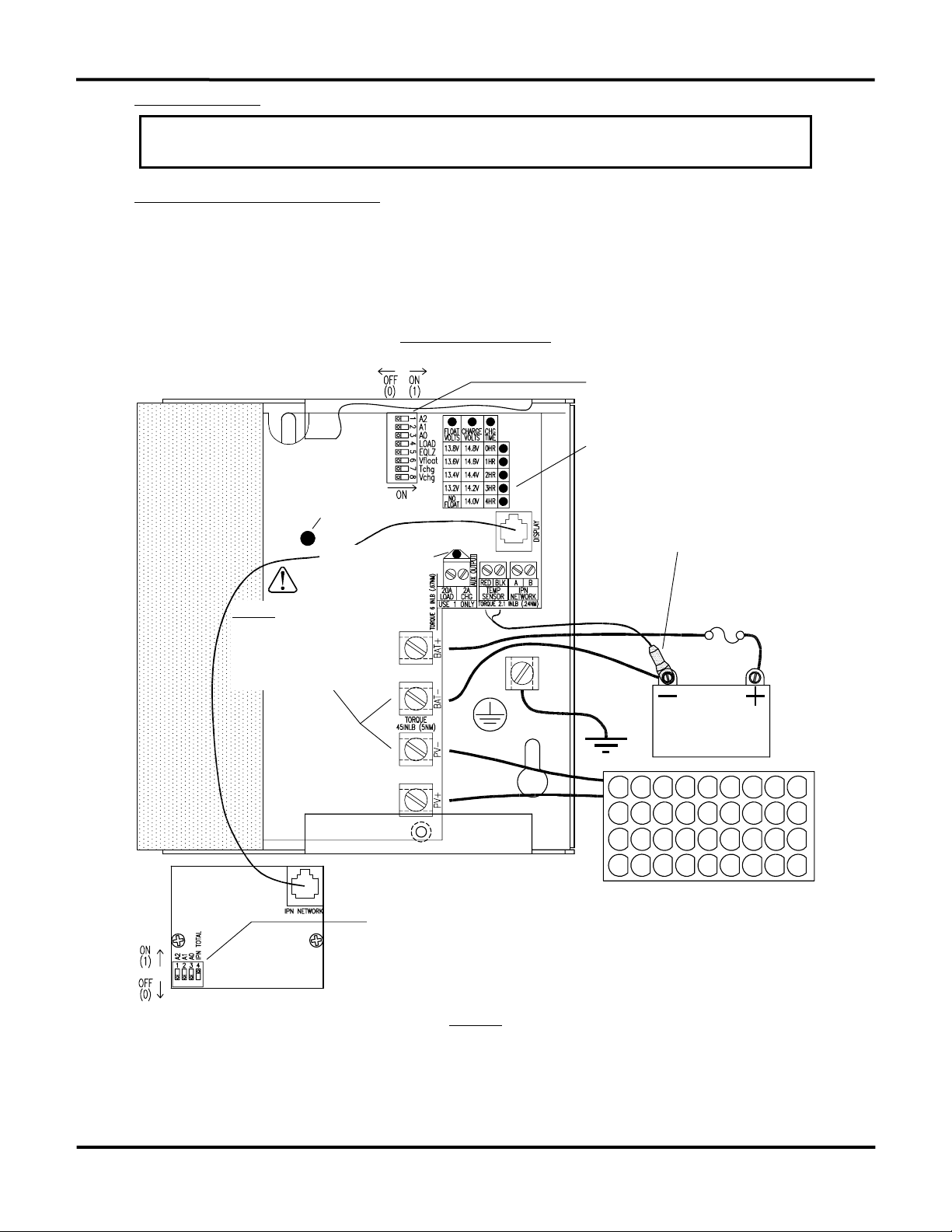

Figure 3 Setup and Wiring Diagram.............................................................................................

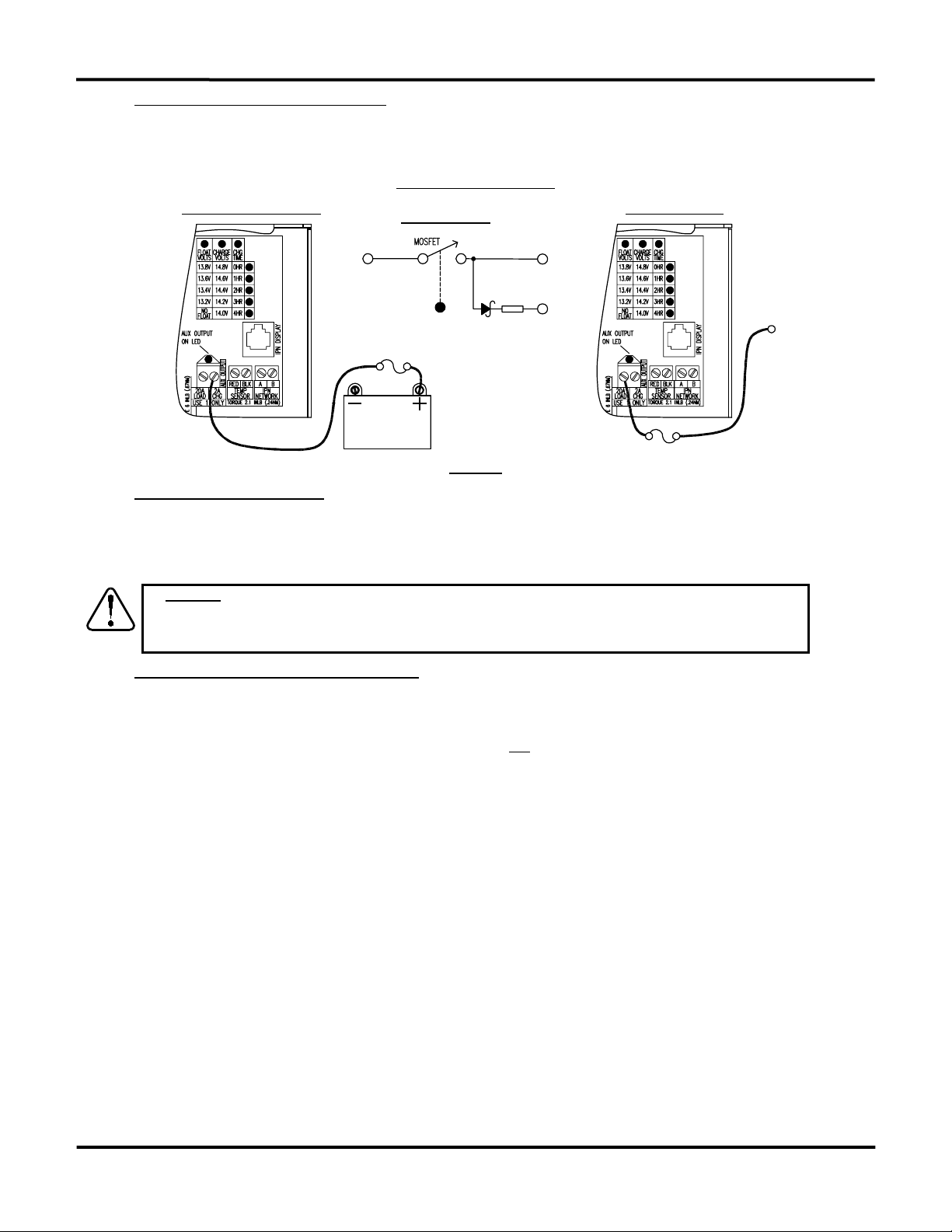

Figure 4 Auxiliary Output Wiring................................................................................................................... 9

Figure 5 IPN Network Wiring........................................................................................................................ 10

Figure 6 Detailed Dimensional Drawing....................................................................................................... 11

Versión en Español................................................................................................................................................................ 16

Version en Française.............................................................................................................................................................32

Deutsch Sprachversion.........................................................................................................................................................48

................ 7

1

Page 3

Installation and Operation Manual

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions for Models SB3024iL and SB3024DiL

SAVE THESE INSTRUCTIONS

1. Refer installation and servicing to qualified service personnel. No user serviceable parts in this unit.

2. To reduce the risk of electric shock, fire or personal injury, the following symbols are placed throughout this manual to indicate dangerous conditions, or

important safety or operational instructions.

WARNING CAUTION IMPORTANT

)

Indicates dangerous conditions or electric

shock potential. Use extreme caution.

Indicates items critical to safe installation or

operation of the unit.

3. PERSONAL PRECAUTIONS

a) Working in the vicinity of lead-acid batteries is dangerous. Batteries produce explosive gasses during normal operation.

b) To reduce risk of battery explosion, follow these instructions and those published by battery manufacturer and manufacturer of any equipment you intend

to use in vicinity of battery.

c) Someone should be within range of your voice or close enough to come to your aid when you work near a lead-acid battery.

d) Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

e) Wear complete eye protection and clothing protection. Avoid touching eyes while working near battery.

f) If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye, immediately flood eye with running cold water for at

least 10 minutes and get medical attention immediately.

g) NEVER SMOKE or allow a spark or flame in vicinity of battery.

h) Be extra cautious to reduce risk of dropping metal tool onto battery. It might spark or short circuit battery or other electrical part that may cause explosion.

i) Remove personal metal items such as rings, bracelets and watches when working with a lead-acid battery. A lead-acid battery can produce a short circuit

current high enough to weld a ring or the like to metal, causing a severe burn.

j) Remove all sources of power, photovoltaic and battery before servicing or installing.

4. CHARGER LOCATION & INSTALLATION

a) This unit is designed to charge 12V (6-cell) or 24V (12-cell) flooded or sealed type lead-acid chemistry batteries within the range of 20 to 10,000 amp-

hours. Follow battery manufacturers charging recommendations when considering this unit for use with other battery chemistry.

b) This unit employs components that tend to produce arcs or sparks. NEVER install in battery compartment or in the presence of explosive gases.

c) This unit must be installed and wired in accordance with National Electrical Code, ANSI/NFPA 70.

d) Over current protection for the battery must be provided externally. To reduce the risk of fire, connect to a circuit provided with 50A maximum branch-

circuit over current protection in accordance with National Electrical Code, ANSI/NFPA 70.

e) Over current protection for the auxiliary load control output or auxiliary battery charge output must be provided externally. To reduce the risk of fire,

connect to load or auxiliary battery with 25A maximum over current protection in accordance with National Electrical Code, ANSI/NFPA 70.

f) Insure that unit is properly configured for the battery being charged.

g) Unit is not water tight. Do not expose to rain or snow.

h) Insure all terminating connections are clean and tight. Battery and PV compression terminals are to be tightened to 45 in-lb (5 nm). IPN Network and

battery temperature sensor compression terminals are to be tightened to 2.1 in-lb (0.24 nm). Auxiliary output compression terminals are to be tightened

to 6 in-lb (0.67 nm).

i) Do not connect to a PV array capable of producing greater than 32A short circuit current for 12V nominal PV modules, or 24A short circuit for PV

modules greater than 12V nominal. Limit input short circuit current to 12A if the 24V input 12V output mode is used.

j) This unit is not provided with a GFDI (ground-fault detector/interrupter) device and must be used with an external GFDI device as required by Article 690

of National Electrical Code for the installation location.

5. PREPARING TO CHARGE

a) Never charge a frozen battery.

b) Be sure battery is mounted in a well ventilated compartment.

c) Add distilled water in each cell of a lead-acid battery until battery acid reaches level specified by battery manufacturer.

Follow these instructions closely for proper

operation of the unit

2

Page 4

Blue Sky Energy - Solar Boost 3024iL

PRODUCT DESCRIPTION

Solar Boost™ 3024iL is multi-stage Maximum Power Point Tracking (MPPT) photovoltaic battery charge controller capable delivering up to 30A or 40A

depending on PV modules and battery voltage. The auxiliary output can serve as either a 2A auxiliary battery charger, or as a 20A load controller with or

without variable Dusk-to-Dawn lighting control. The 3024 includes an IPN Network interface which allows multiple charge controllers to communicate with

each other and operate as a single charging machine.

PART NUMBERS AND OPTIONS

• SB3024iL.............Solar Boost 3024iL charge controller • SB3024DiL.......... Solar Boost 3024iL controller with volt/amp display

• IPNPRO ..............IPN-ProRemote display & battery monitor • IPNPRO-S...........IPN-ProRemote with required 500A/50mV current shunt

• CS-500................ 500A/50mV current shunt • IPNREM.............. IPN-Remote display

• 930-0022-20........ Battery temperature sensor

OPERATION

Charge control and MPPT operation are fully automatic. At night when PV power production stops, the PV array is disconnected from the battery to

prevent unwanted current drain. There is a 5 second turn-on delay, and a 45 second turn-off delay.

¾ The 3024 operates on battery power, not PV power. A battery must be connected with a minimum voltage of 9V for the unit to

)

CHARGE STATUS INDICATOR

A charge status indicator is provided on the face of the 3024, and on the optional remote displays. If net battery charge current is greater than ≈3 to 5A per

100 amp-hours of battery capacity the charge status indicator can provide a rough indication of battery state of charge.

OPTIONAL DIGITAL DISPLAY

The SB3024DiL includes a digital display of battery voltage and output charge current. The display alternates between voltage and current when

charging. Current is displayed when the “AMPS” indicator is on and can be the total of all controllers on the IPN network (factory default), or the current of a

single controller on the IPN network. An automatic night time dimming feature reduces display brightness when PV charge is OFF.

OPTIONAL REMOTE DISPLAYS

Two remote displays are available. The IPN-Remote has the same display functionality as the SB3024DiL. The full featured IPN-ProRemote provides

setup capability and enhanced monitoring of charge controllers on the IPN network. It also provides a complete battery system monitor with various amp-hour

counters and a highly accurate “fuel gage” type battery level indicator.

MULTI-STAGE CHARGE CONTROL

current as possible to rapidly recharge the battery. Automatic current limit prevents output current from exceeding the 3024’s maximum current rating.

necessary to control at the Acceptance Voltage. The 3024 remains in Acceptance until the battery is fully charged as determined by either;

operate.

CHARGE STATUS INDICATOR

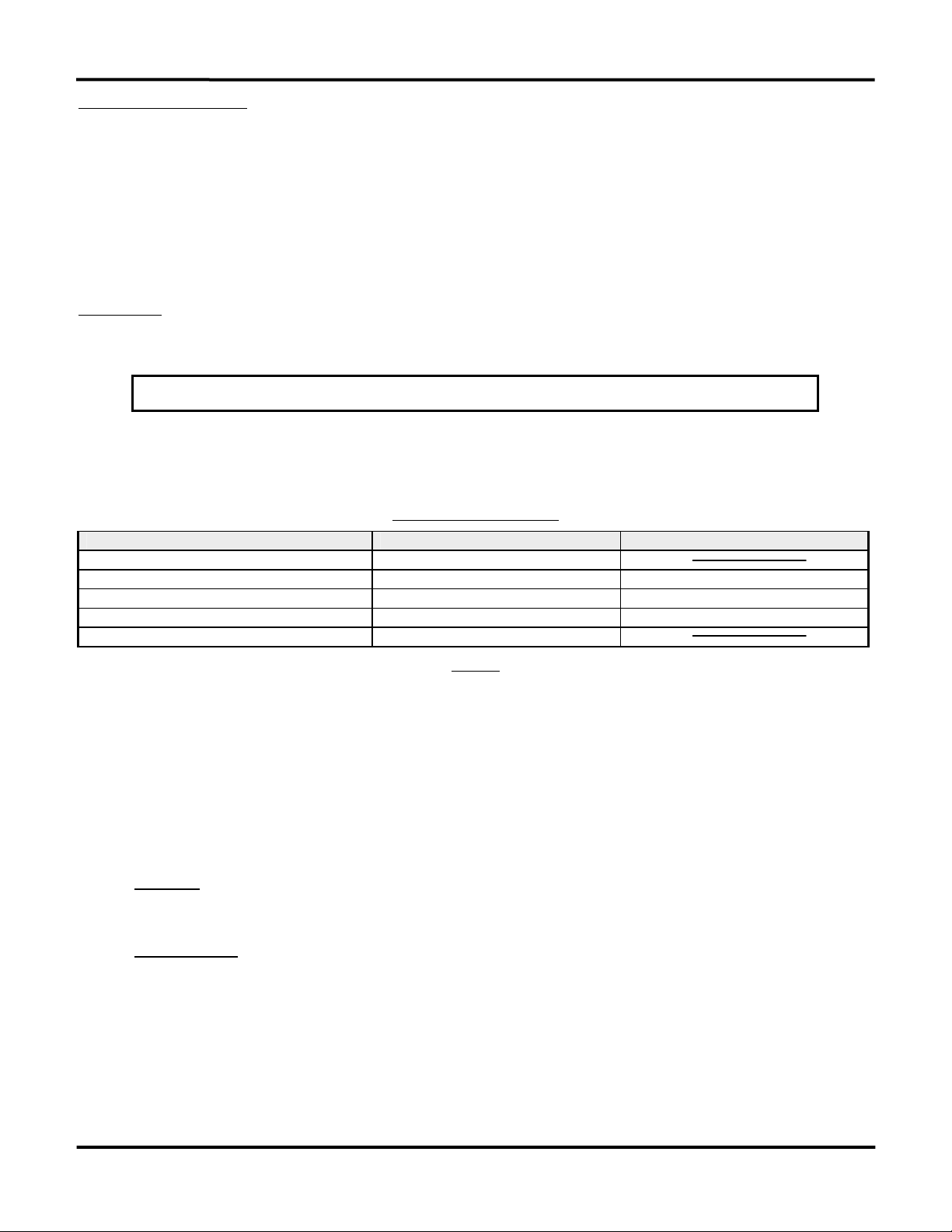

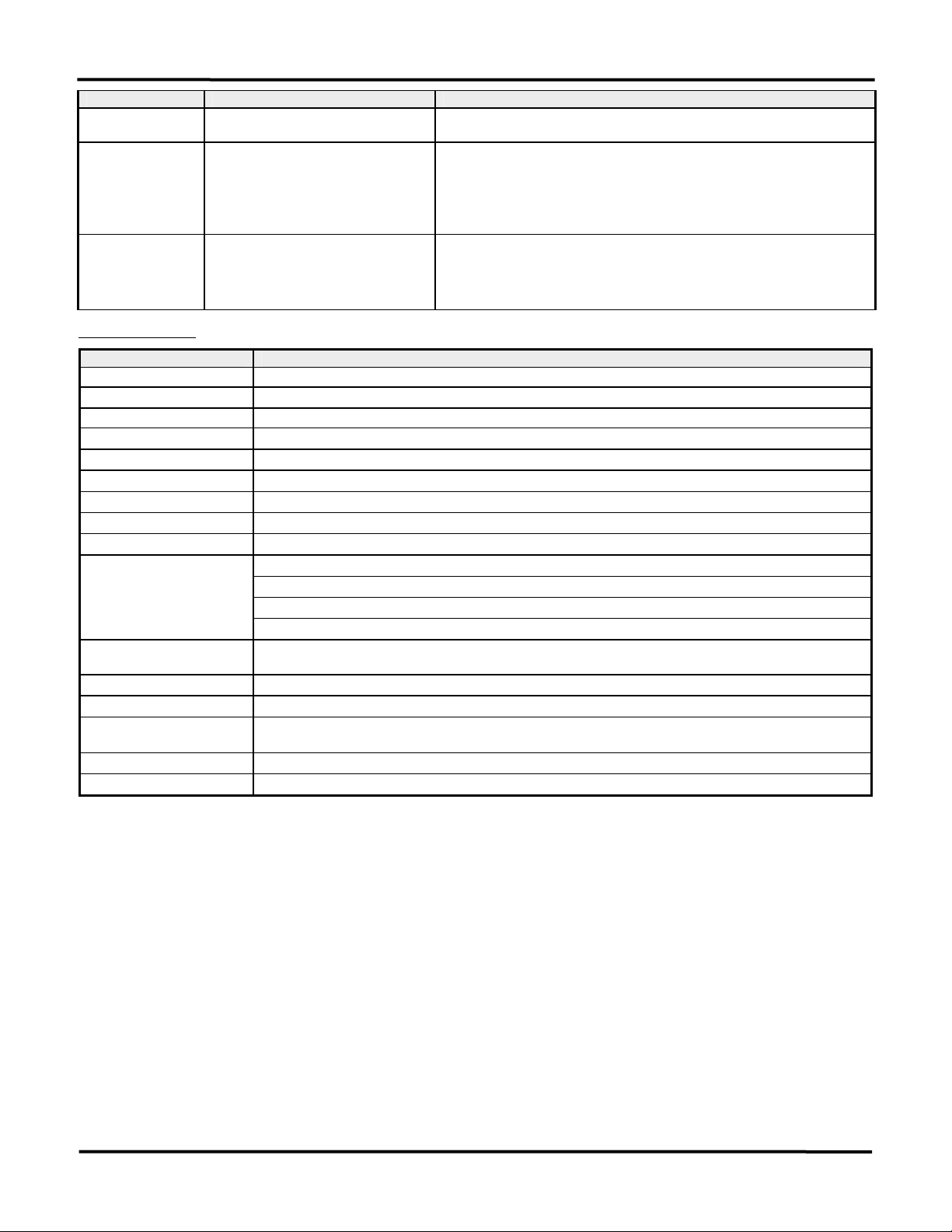

CHARGE STATUS INDICATOR CHARGE MODE APPROXIMATE CHARGE LEVEL

OFF CHARGE OFF

CONTINUOUSLY ON BULK <70% FULL

BLINKING • 1 SEC ON / 1 SEC OFF

BLINKING • 0.2 SEC ON / 1 SEC OFF

RAPID BLINKING • 0.2 SEC ON / 0.2 SEC OFF

ACCEPTANCE 70% - 95% FULL

FLOAT FULLY CHARGED

EQUALIZE

TABLE 1

Bulk Charge

The 3024 will be in Bulk charge when battery voltage is below the Acceptance Charge Voltage setpoint. During Bulk the 3024 delivers as much charge

Acceptance Charge

When the battery recovers sufficient charge for voltage to rise to the Acceptance Charge Voltage setpoint (factory set to 14.4/28.8V) current is reduced as

1. The 3024 has remained in Acceptance for the Charge Time period (factory set to 2 hours).

– OR –

2. With the IPN-ProRemote display, net battery charge current while in Acceptance decreases to the Float Transition Current setting (factory

set to 1.5A per 100 amp-hours of battery capacity).

3

Page 5

Installation and Operation Manual

without excessive water loss.

Float Charge

Once the battery is fully charged a somewhat lower Float Voltage (factory set to 13.2/26.4V) is applied to maintain the battery in a fully charged state

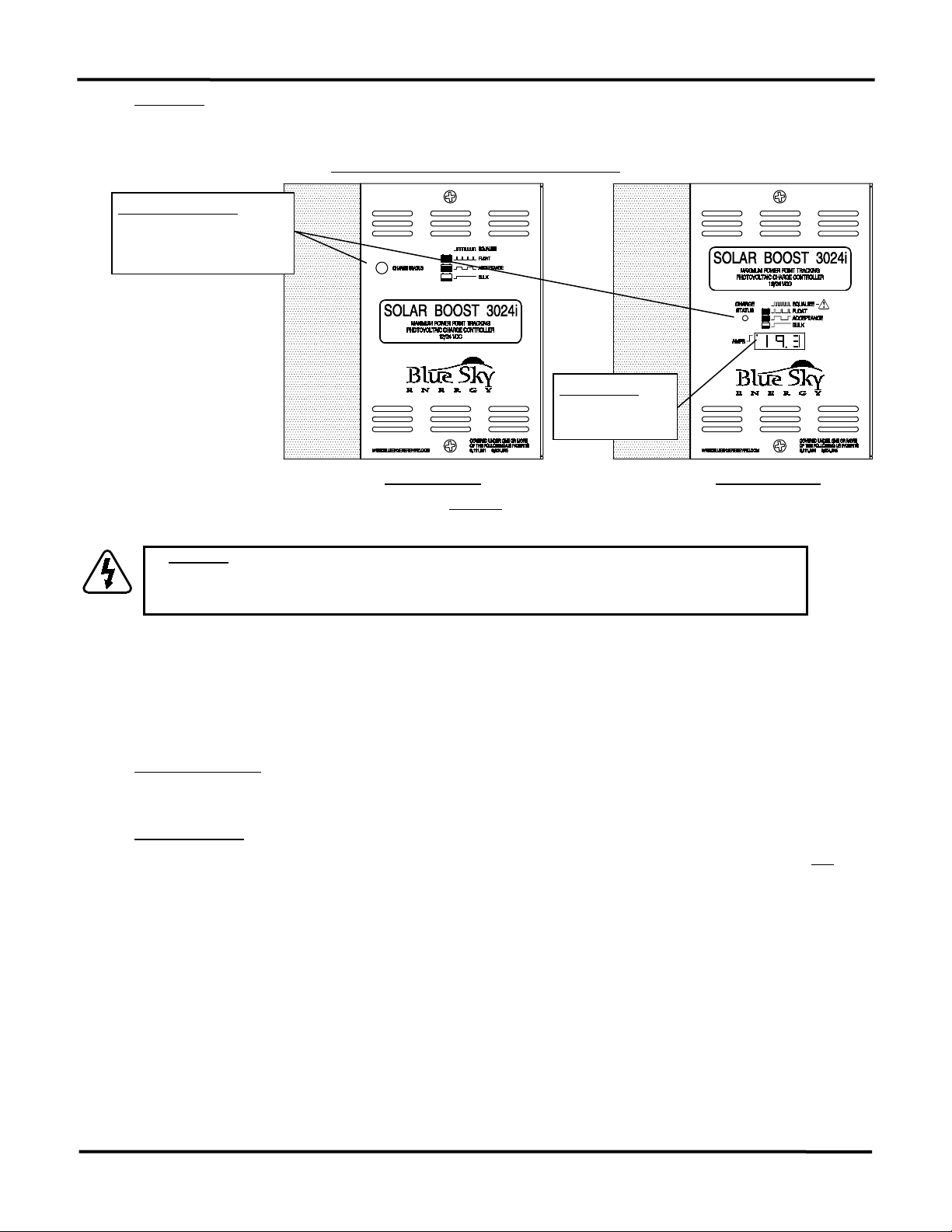

FRONT PANEL AND REMOTE DISPLAY INDICATORS

Charge Status Indicator

Indicator shows present charge

mode and approximate battery

state of charge

AMPS Indicator

Display shows output

current when ON

FIGURE 1

EQUALIZATION

¾ WARNING: Not all batteries can be safely equalized. Equalization should only be performed on vented liquid electrolyte

Solar Boost 3024iL Solar Boost 3024DiL

lead-acid batteries. Always follow battery manufacturers recommendations pertaining to equalization. Equalization applies a

high voltage producing significant battery gassing. Disconnect equipment that cannot tolerate the high equalization voltage

which is temperature compensated.

Periodic equalization improves battery performance and life by bringing all battery cells up to the same specific gravity and eliminating electrolyte

stratification. Equalization parameters are factory set to 15.2/30.4V for 2 hours every 30 days. A minimum net charge current of approximately 3A per 100 amphours of battery capacity is required for proper equalization. If insufficient current is available equalization may have to be canceled manually since the equalization

time accumulator may not complete count down.

The equalization timer is a “time at voltage” time accumulator which counts in 3 minute increments. The equalization timer will not count down unless the

battery is at the equalization voltage setpoint. Unless manually disabled the 3024 will stay in equalize for as long as necessary to accumulate the required time at

voltage. If equalize does not complete by end of the charging day it will resume where it left off the next charging day.

Automatic Equalization

If DIP switch #5 is turned ON prior to the application of battery power, automatic equalization is enabled. The 3024 will perform automatic equalization

after the set number of days has elapsed. (factory set to 30 days).

Manual Equalization

If DIP switch #5 is turned OFF, equalization is completely disabled. A manual equalize can be performed by turning DIP switch #5 ON, after battery

power is applied. Following completion of a manually initiated equalization cycle, turn DIP switch #5 OFF. If DIP switch #5 remains ON automatic equalize is

enabled. Equalization can also be controlled from the IPN-ProRemote if DIP switch #5 is ON.

CURRENT LIMIT

Automatic current limit prevents output current from exceeding 40A with 12V batteries and 12V PV’s. If PV open circuit voltage (VOC) ever exceeds

30V which would occur with PV voltage greater than 12V nominal, current limit will become 30A until the 3024 reboots. Note that when the 3024 exits current

limit, it will briefly enter acceptance on it’s way back to MPPT even though battery voltage may be low.

TEMPERATURE AND OUTPUT POWER

When mounted vertically as described in the installation section, the 3024 can deliver full output in an ambient temperature of up to 40°C (104°F). If an

over temperature condition exists, the 3024 will cycle on/off, reducing average power delivery to within safe limits. During thermal shutdown the Charge Status

Indicator will display an OFF condition.

4

Page 6

Blue Sky Energy - Solar Boost 3024iL

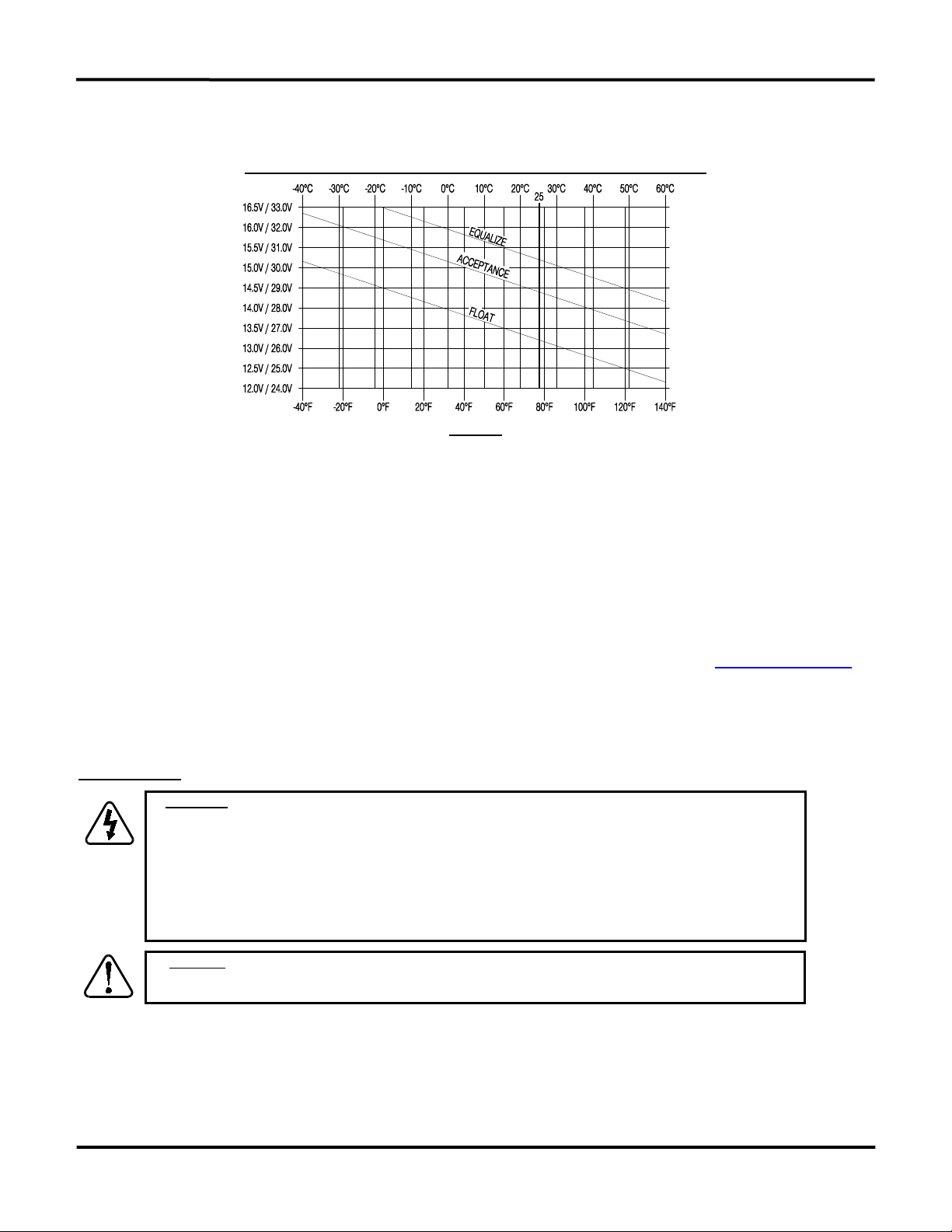

OPTIONAL TEMPERATURE COMPENSATION

The optional battery temperature sensor automatically adjusts charge voltage setpoints based on battery temperature which enhances battery

performance and life, and decreases maintenance. The default compensation factor of −5.00mV/°C/cell is suitable for most lead-acid chemistry batteries.

FACTORY DEFAULT CHARGE VOLTAGE SETPOINT -VS.- BATTERY TEMPERATURE

MAXIMUM SETPOINT VOLTAGE LIMIT

FIGURE 2

Regardless of setpoint values entered by the user or result from temperature compensation the 3024 will not apply a charge voltage setpoint greater

than the maximum voltage setpoint limit factory configured to 15.5/31.0V. Note that actual battery voltage may briefly exceed this value by 0.1 – 0.2V as the

voltage control servo responds to changes in load.

MAXIMUM POWER POINT TRACKING (MPPT)

Patented MPPT technology can extract more power and increase charge current up to 30% or more compared to conventional controllers. The

principal operating conditions which affect current boost performance are PV array temperature and battery voltage. At constant solar intensity, available PV

voltage and power increase as PV temperature decreases but it takes an MPPT controller to access this extra power. When PV voltage is sufficiently high in Bulk

for MPPT to operate, a constant power output is delivered to the battery. Since output power is constant a decrease in battery voltage produces a further increase

in charge current. This means that the 3024 provides the greatest charge current increase when you need it most, in cold weather with a discharged battery. In

cool comfortable temperatures most systems see about 10 – 20% increase. Charge current increase can go to zero in hot temperatures, whereas charge current

increase can easily exceed 30% with a discharged battery and freezing temperatures. For a more complete MPPT description see www.blueskyenergyinc.com

MULTIPLE CHARGE CONTROLLERS ON THE IPN NETWORK

.

The IPN network architecture allows multiple charge controllers operate as a single charging machine. Up to 8 IPN compatible charge controllers can

reside on a single network and can share a single display or battery temperature sensor. Charge controllers can be added to grow a small system into a

large system and have this large system operate from the users standpoint as a single charge controller.

INSTALLATION

¾ WARNING: Read, understand and follow the Important Safety Instructions in the beginning of this manual before proceeding.

This unit must be installed and wired in accordance with National Electrical Code, ANSI/NFPA 70. Over current protection must be

provided externally. To reduce the risk of fire, connect to a circuit provided with 40A maximum branch-circuit over current protection

(50A with 12V battery and 12V PV modules) in accordance with National Electrical Code, ANSI/NFPA 70. Do not connect a PV

array capable of delivering greater than 24A of short circuit current I

at STC (32A with 12V battery and 12V PV modules). Do not

SC

connect BAT– and PV– together external to the unit. The unit is not provided with a GFDI (ground-fault detector/interrupter) device

and must be used with an external GFDI device as required by Article 690 of NEC for the installation location. To reduce risk of

electric shock, remove all sources of power before installing or servicing. Figures 3, 4 and 5 show generalized connections only and

are not intended to show all wiring, circuit protection and safety requirements for a photovoltaic electrical system.

¾ CAUTION: The 3024 is protected against reverse battery and PV polarity, and swapped PV and battery connections, but will be

damaged by reverse battery to the PV terminals. Transient voltage lightning protection is provided, but steady state voltage in

ELECTROSTATIC HANDLING PRECAUTIONS

excess of 57VDC on the battery or PV terminals will damage the unit. Damage of either type voids the limited warranty.

To minimize the likelihood of damage, discharge yourself by touching a water faucet or other electrical ground prior to handling the 3024 and avoid touching

circuit board components. The risk of electrostatic damage is highest when relative humidity is below 40%.

5

Page 7

Installation and Operation Manual

SELECTING PV MODULES

Voltage, current and power produced by Photovoltaic (PV) modules fluctuate widely with operating conditions. As a result a set of test conditions

referred to as Standard Test Conditions (STC) are used to rate modules in a meaningful manner and accurately predict real world performance. STC

ratings are not maximum or optimal ratings. Conditions can be present where V

Code and our recommendations call for 1.25 derating of both V

Key PV module specifications;

P

V

I

I

Maximum power in watts (P

MAX

Voltage with module open circuit (typically ≈20 – 22V for 12V modules)

OC

V

Voltage where module produces Maximum Power (typically ≈17 – 18V for 12V modules)

MP

Current where module produces Maximum Power

MP

Current with module Short Circuit

SC

= VMP x IMP)

MAX

and ISC. Yet in real world conditions IMP is commonly only about 75 – 80% of IMP at STC.

OC

and ISC approach 1.25 times STC ratings which is why National Electrical

OC

The 3024 will provide the best MPPT current boost performance if all PV modules are identical. If module types are mixed, do not put dissimilar

modules in series. Dissimilar modules in parallel should have V

will tend to track as operating conditions change. If module types are very different consider using a separate charge controller for each module

their V

MP

type to obtain the best MPPT current boost performance.

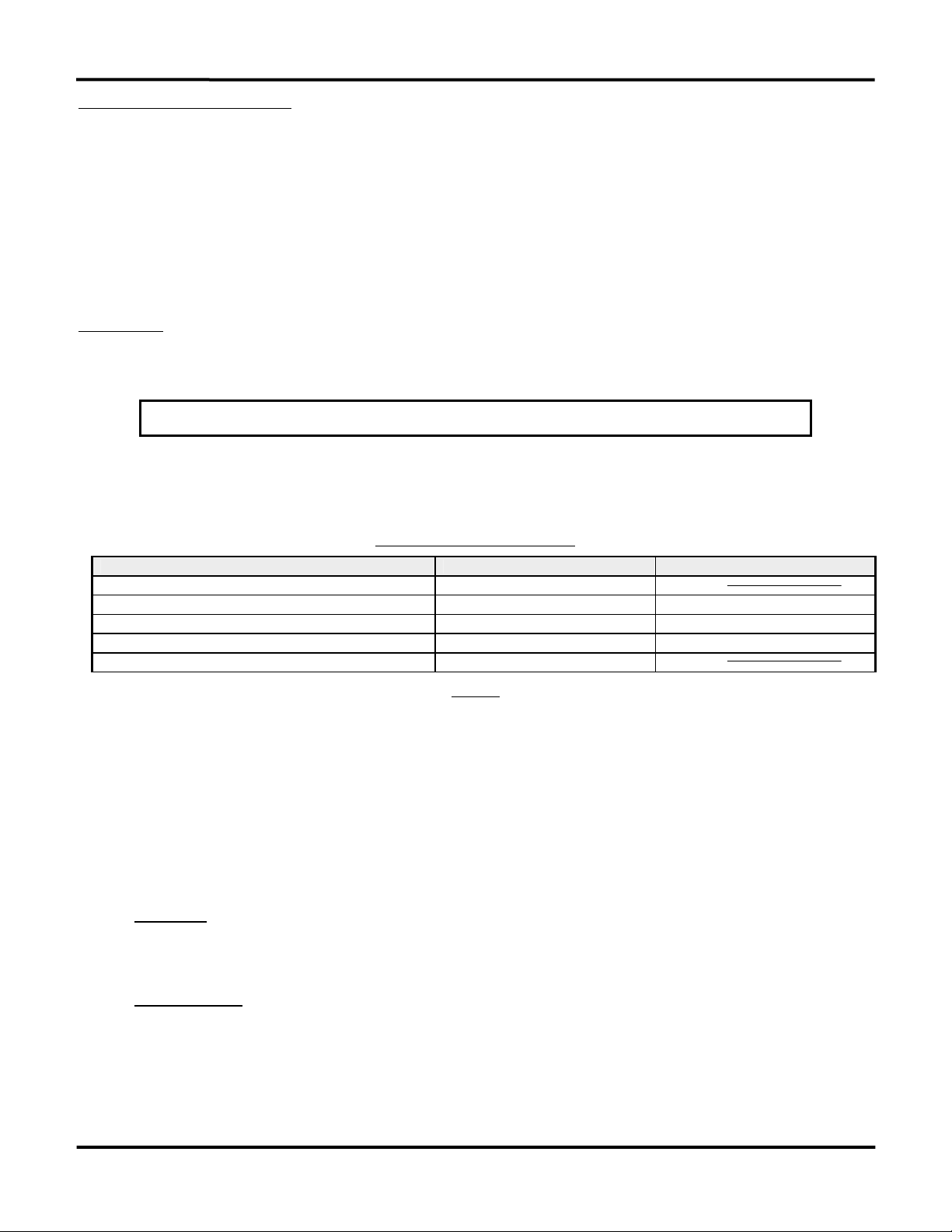

Select PV modules that do not exceed the maximum ratings shown below, and preferably produce at least 3A of IMP per 100 amp-hours of battery capacity.

Nominal

Battery

Voltage

Automatic

Current Limit

Maximum

PV Power @

STC

Maximum

Isc @ STC

12V 40A* 540W 32A* 24.0V* 16.5 – 18.5V

12V 30A 400W 16A 45.6V

12V 30A 400W 12A 45.6V

24V 30A 800W 24A 45.6V

values within ≈0.5V or better for 12V modules, and be of the same basic cell technology so

MP

PV

Maximum

PV

V

@ STC

OC

Nominal 12V PV Nominal 18V PV Nominal 24V PV

Recommended range of VMP at STC

5 5

5

5 5

5 5

24.8 – 27.8V

33.0 – 37.0V

33.0 – 37.0V

5

*Current rating and current limit are 40A when charging a 12V battery from nominal 12V PV modules. If

PV V

ever exceeds 30V (>12V nominal PV modules) current rating and current limit become 30A.

SOLAR BOOST 3024 SETUP

¾ The 3024 has various setup parameters all of which are preconfigured at the factory. Confirm that the 3024’s charge

)

parameter settings are within the ranges specified by the battery manufacturer. Default settings are typically suitable for most

flooded or sealed lead-acid batteries and likely require no changes.

¾ Setup parameters are divided into two categories, Basic and Advanced. Basic parameters can be configured with the 3024

alone within limited steps and ranges as shown in Figure 3. Advanced parameters require the IPN-ProRemote to access. The

IPN-ProRemote also allows basic settings to be configured in smaller steps and over wider ranges. All setup parameters are

retained if power is lost, or the IPN-ProRemote is used as a setup tool only and removed.

As Shipped Factory Default Settings

Basic Settings Advanced Settings

• Charge mode .............................................. 3-stage • Equalize voltage ....................................................... 15.2/30.4V

• Acceptance voltage .................................... 14.4/28.8V • Equalize time ............................................................ 2.0 hours

• Float voltage ................................................ 13.2/26.4V • Auto equalize days ................................................... 30 days

• Charge time ................................................ 2.0 hours • Maximum voltage setpoint limit ................................ 15.5/31.0V

• Equalize ....................................................... Disabled • Float Transition Current ............................................ 1.5A/100 amp-hours

• IPN Network address .................................. 0 (zero) • Temperature compensation factor ........................... −5.00mV/°C/cell

• Auxiliary Output mode ................................. Aux. bat. charger • Load control ON voltage ......................................... 12.6/25.2V

• All DIP switches ........................................... OFF • Load control OFF voltage ....................................... 11.5/23.0V

• Current display (SB3024Di)......................... IPN network total • Dusk-to-Dawn lighting control................................. Disabled

Restoring As Shipped Factory Default Settings

1. Remove PV and battery power. 4. Return ALL 8 power board DIP switches to their default OFF position.

2. Turn ALL

3. Restore battery power for 10 seconds, then remove battery power. 6. The unit is now set to as shipped factory default settings.

8 power board DIP switches shown in Figure 3 ON. 5. If display is present, set display DIP’s to #4 ON, #1-3 OFF

OC

6

Page 8

Blue Sky Energy - Solar Boost 3024iL

)

Acceptance Charge Voltage, Float Charge Voltage and Charge Time setpoints can be viewed or changed using the parameter setup LED’s and DIP switch

shown in Figure 3. Operate only one switch at a time. To view the present setting turn the appropriate DIP switch ON momentarily ( V

For a 24V battery the actual voltage setpoints are doubled.

through available settings. Turn the DIP switch off at the desired setting to store the new value. If Float Charge Voltage is set to “No Float” the 3024 operates as a

two stage charger, will not switch to Float, and will not display Charge Time on the setup LED’s.

Battery and PV Voltage

¾ Nominal battery and PV voltage are determined automatically. The battery is considered to be 12V if battery voltage when first

connected is less than 16V, or 24V if battery voltage is greater. PV voltage is also determined automatically. If nominal PV

voltage is changed following installation power must be momentarily removed to reboot the 3024.

Charge Voltage, Float Voltage & Charge Time

CHG

#8, V

FLOT

#6 or T

CHG

#7).

To change a setting, turn the appropriate DIP switch ON, OFF, and then back ON before the LED’s turn OFF. The 3024 will enter setup mode and scan

SETUP AND WIRING DIAGRAM

Power Board

DIP Switch

Parameter Setup LED’s

Charge Status LED

Optional Battery

Temperature Sensor

Auxiliary Output LED

Caution: Do not connect PV- &

40A / 50A Maximum

Bat- together external to the

3024, improper operation will

result. PV- & Bat- are

connected together internally.

Battery

Display Board

DIP Switch

FIGURE 3

7

Page 9

Installation and Operation Manual

)

BATTERY AND PV WIRING

A desirable installation would produce a total system wiring voltage drop of 3% or less. The lengths shown in Table 2 are one way from the PV to the battery

with the 3024 located along the path. Wire length can be increased inversely proportional to actual current. If current was reduced by ½, wire lengths could doubled

and still provide 3% voltage drop.

ELECTROMAGNETIC COMPATIBILITY

To comply with electromagnetic compatibility requirements the 3024’s battery and PV wiring must be installed in grounded metallic conduit, and the two

clamp on type ferrite suppressors supplied must be installed. Clamp one suppressor around both Bat+ and Bat– cables. Clamp the second suppressor around

both the battery temperature sensor and remote display cables with the cables looped to pass through the core 3 times. If both sensor and display cables are

used, the sensor cable outer cover must be stripped back ≈12” (30cm) so both cables will fit through the core 3 times. Ensure that the two suppressors are

restrained so they will not damage circuit board components. Additional suppressors can be ordered as BSE p/n 523-0005-01.

BATTERY TEMPERATURE SENSOR

Installation of the optional battery temperature sensor enables temperature compensation of all charge voltage setpoints. In a multi-controller system a

single temperature sensor must connect to the IPN master. Do not attach a sensor or connections other than Blue Sky Energy battery temperature sensor p/n

930-0022-20. Be certain to observe proper RED/BLK polarity.

AUXILIARY OUTPUT

The auxiliary output can serve one of three functions; a 2A auxiliary battery charger, a 20A load controller with Low Voltage Disconnect (LVD), or a 20A

variable Dusk-to-Dawn lighting load controller. The Charge/Load function is selected by DIP switch #4 shown in Figure 3. The IPN-ProRemote is required to adjust

LVD thresholds or enable Dusk-to-Dawn lighting control. Auxiliary outputs in a multi-controller system will function normally, but only the auxiliary output in the

master can be configured or monitored using the IPN-ProRemote. The auxiliary output “Load” LED will illuminate whenever the auxiliary output is ON.

Output Current Display (SB3024DiL only)

¾ The display can show total output current from all networked controllers, or the output current of a single controller. To show

output current from a single controller IPN network address of the display and charge controller must match.

DIP SWITCH

IPN ADDRESS – OUTPUT CURRENT OF SINGLE CHARGER UNIT DISPLAY BOARD

0 1 2 3 4 5 6 7

TOTAL OUTPUT CURRENT OF ALL

CHARGERS ON IPN NETWORK

# 1 (A2) OFF OFF OFF OFF ON ON ON ON Don’t care

# 2 (A1) OFF OFF ON ON OFF OFF ON ON Don’t care

# 3 (A0) OFF ON OFF ON OFF ON OFF ON Don’t care

# 4 (IPN Total) OFF OFF OFF OFF OFF OFF OFF OFF ON

¾ CAUTION: Battery and PV compression terminals accept #14−4 AWG wire and are tightened to 45 in-lb (5 nm). IPN network

compression terminals accept #24−14 AWG wire and are tightened to 2.1 in-lb (0.24 nm). Auxiliary Output compression

terminals accept #24−12 AWG wire and are tightened to 6 in-lb (0.67 nm).

¾ CAUTION: DO NOT connect Bat– and PV– together external to the 3024 or improper operation will result. Bat– and PV–

connect together internally.

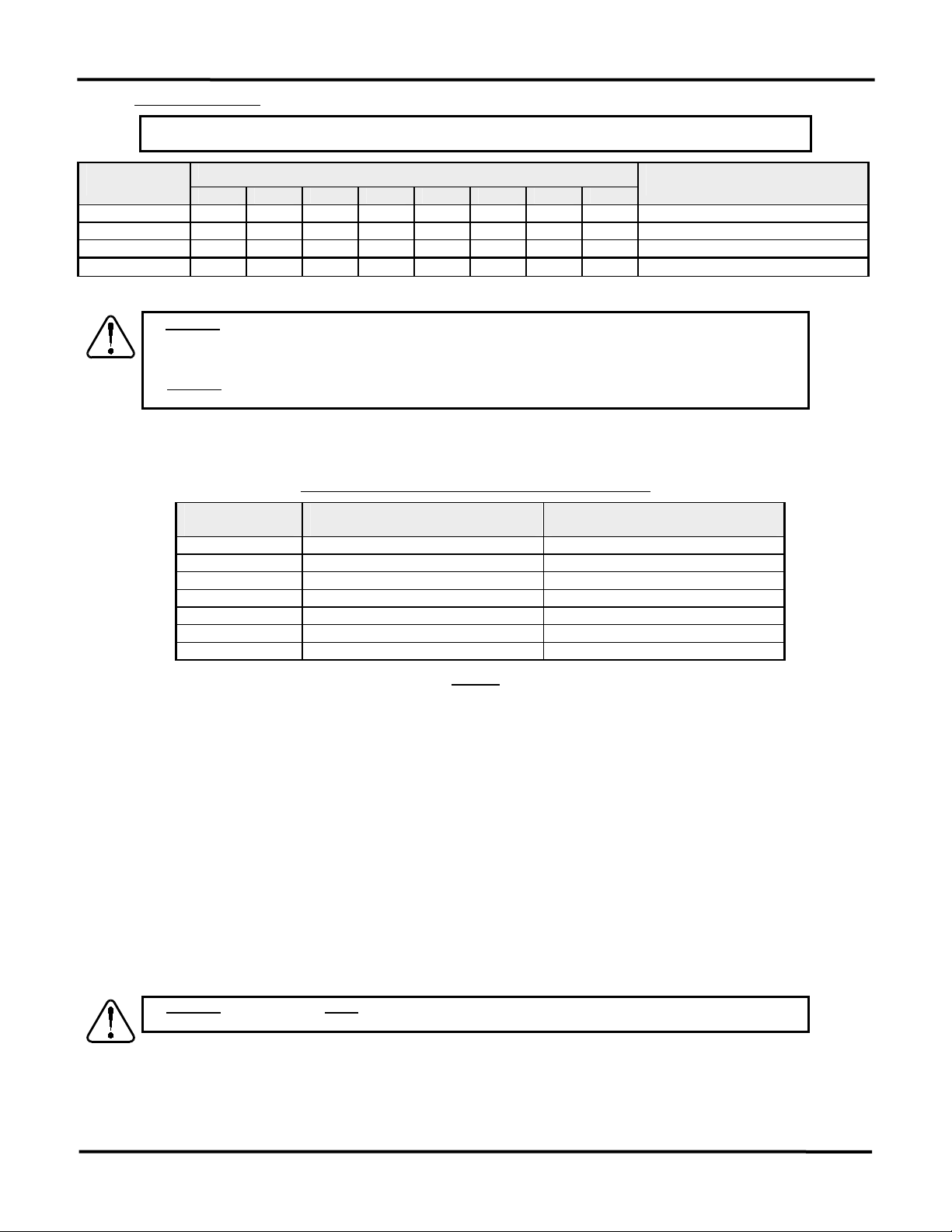

MAXIMUM CONDUCTOR PAIR LENGTH - 3% VOLTAGE DROP

WIRE GAUGE

AWG

12 VOLT SYSTEM @32A

FEET / METERS

24 VOLT SYSTEM @24A

FEET / METERS

12 AWG 4.0 / 1.2 10.7 / 3.3

10 AWG 6.4 / 2.0 16.9 / 5.2

8 AWG 10.1 / 3.1 26.9 / 8.2

6 AWG 16.1 / 4.9 42.8 / 13.0

4 AWG 25.5 / 7.8 68.1 / 20.7

2 AWG 40.6 / 12.4 108.2 / 33.0

1/0 AWG 64.6 / 19.7 172.2 / 52.5

TABLE 2

¾ CAUTION: The auxiliary output cannot perform both auxiliary battery charge and load control functions at the same time. Do not

connect to the 20A Load terminal for auxiliary battery charge.

8

Page 10

Blue Sky Energy - Solar Boost 3024iL

A

The auxiliary charge function is used to charge an auxiliary battery of the same voltage as the primary battery. If the primary battery is charging in

Acceptance or Float, up to 2A is diverted to the auxiliary battery at roughly the same charge voltage. Auxiliary battery charge is disabled during bulk or equalization.

Use 14awg wire to minimize voltage drop and 25A over current protection. Auxiliary battery negative must connect to primary battery negative.

AUXILIARY BATTERY CHARGE – DIP #4 OFF

2A Auxiliary Battery Charger 20A Load Controller

AUXILIARY OUTPUT WIRING

Equivalent Circuit

Bat+

Auxiliary Output LED

25

2A Current

Limiter

20A

Load

2A

Charge

Load +

20A Maximum

Battery

LOAD CONTROLLER – DIP #4 ON

FIGURE 4

25A Maximum

The load controller can deliver up to 20A of continuous output from the battery. Default settings are for LVD operation with ON at V

OFF at V

≤11.5/23.0V, which can be changed using the IPN-ProRemote. Operation can also be based on net battery amp-hours if an IPN-ProRemote is

BAT

≥12.6/25.2V, and

BAT

present. The ON/OFF condition must be valid for 20 seconds before switching will occur. If the higher/lower values are reversed the output control logic is inverted.

Load negative must connect to battery negative.

¾ CAUTION: 25A maximum over current protection for load control output must be provided externally. If the load control output is

configured to operate based on net battery amp-hours, configure ON/OFF voltage thresholds as well. If amp-hour from full data

is not available, voltage based operation will resume. Voltage or amp-hour ON/OFF thresholds must not be the same value or

improper operation will result.

DUSK-TO-DAWN LIGHTING CONTROL – DIP #4 ON

An IPN-ProRemote with software version V2.00 or later is required to enable lighting control. Refer to IPN-ProRemote operators manual for lighting control

setup instructions. Variable time settings are available to turn lighting ON after Dusk (Post-Dusk timer) and/or ON before Dawn (Pre-Dawn timer). If both timers are

set to DISABLED (factory default), the lighting control feature is disabled. If either the Post-Dusk or Pre-Dawn timers are set to a time value the lighting control

feature is enabled. When lighting control is enabled the auxiliary output is controlled by both

that whichever function wants the auxiliary output OFF prevails.

the normal load control function and the lighting control function such

Dusk or night time begins when the charge control system turns OFF which occurs when PV module current drops below ≈50mA at battery voltage. Dawn

or day time begins when the charge control system turns ON which occurs when PV module current rises to ≈100mA at battery voltage. If the Post-Dusk timer

was set to 1.0 hour and the Pre-Dawn timer was set to 2.0 hours, lights would turn ON at Dusk, remain ON for one hour, and then turn OFF. Two hours before

Dawn the lights would again turn ON and remain ON until Dawn. For full Dusk to Dawn lighting set the Post-Dusk timer to 20 hours. Lights will always be OFF

when the charge control system is ON.

When the 3024 first receives battery power it does not know when Dawn is expected to occur. As a result Pre-Dawn control does not operate for the first

night. Once a night time period of 4 hours or more is detected this night time period is stored and Pre-Dawn control will operate. Each subsequent night time period

greater 4 hours is added to a filtered average of night time.

9

Page 11

Installation and Operation Manual

INSTALLING A MULTI-CONTROLLER SYSTEM

A communication link is established between controllers by daisy chaining a twisted pair cable from the IPN Network terminal block, controller to controller

(A-to-A, B-to-B) as shown in Figure 5. Up to 8 IPN based charge controllers can be connected together in a multi-controller system. Device address 0 (zero) is the

master and 1 – 7 are slaves. The master controls the charging process and directs the activities of the slaves. The charge control system will start whenever

one or more controllers receives PV input power.

MULTI-CONTROLLER WIRING AND SETUP

¾ CAUTION: A multi-controller system requires the following specialized installation and setup:

1) Each controller must connect to and charge the same battery.

2) One controller must be set to IPN address 0 (zero) and the others be set to addresses 1 – 7 with no controllers set the same.

3) Charge parameters are set in the master only.

4) While outputs connect in parallel to a common battery, PV inputs must be completely separate

. A large PV array must be

divided into sub-arrays, each with separate PV+ and PV– wiring.

5) All controllers must be connected to the IPN network as shown in Figure 5.

IPN NETWORK WIRING

Master Slave Slave

Address 0

Address 1 Address 2

)

Twisted Pair, 18 – 22 awg To Other Slaves

FIGURE 5

IPN Network Address

¾ A single controller must be set to IPN network address 0 (zero). In a multi-controller system one controller must be set to

address 0 (zero) to serve as the master. The other controllers must be set to address 1-7 with no two controllers set the same.

IPN NETWORK ADDRESS

MASTER SLAVES POWER BOARD

DIP SWITCH

0 1 2 3 4 5 6 7

# 1 (A2) OFF OFF OFF OFF ON ON ON ON

# 2 (A1) OFF OFF ON ON OFF OFF ON ON

# 3 (A0) OFF ON OFF ON OFF ON OFF ON

10

Page 12

Blue Sky Energy - Solar Boost 3024iL

MOUNTING

¾ CAUTION: Mount the unit with heatsink fins oriented vertically to promote cooling and do not enclose in a confined space. The

3024 is not watertight and must be protected from rain, snow and excessive moisture.

DETAILED DIMENSIONAL DRAWING

This knockout symmetrically

duplicated in opposite wall

(cabinet top)

Combination ½ - ¾ inch

conduit knockouts, 3 places

FIGURE 6

11

Page 13

Installation and Operation Manual

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

Completely dead, no

display

Unit will not turn on

(charge status LED

off), Display if

present may be OK

Unit cycles on/off PV- connected to BAT- external to unit PV- & BAT- must be separate external to the unit for proper operation and cannot

Charge status LED

on., but no output

charge current

Charge status LED

blinks rapidly

Charge current is

lower than expected,

PV current may be

low as well

MPPT Current boost

is less than expected

Auxiliary battery not

charging

No battery power Battery disconnected, overly discharged (<9V), or connected reverse polarity.

Battery powers unit, not PV.

PV disconnected

PV reverse polarity

IPN network address set wrong

Low battery power

Extreme voltage fluctuations or

PV must supply at least 0.15A at just above battery voltage to begin charge.

Reverse polarity PV will cause heat sink to heat.

A single unit must be set to IPN network address 0 (zero). One unit of a multi-unit

network must be set to IPN network address 0 (zero), AND all other units must be

set to different addresses.

Battery overly discharged (<9V). Battery powers unit, not PV.

Reboot microprocessor by momentarily removing all power. Reattach power crisply.

interference has caused microprocessor

lock-up

connect to a common location. External connection prevents proper operation of

internal shunts and current measurement system.

Battery voltage greater than charge

voltage setpoint

Battery voltage too low

Unit recognized battery voltage to be 12V

when it is actually 24V

This is normal operation. Output is off due to high battery voltage which may be

caused by other charging systems.

Battery voltage must be at least 9V for the unit to operate.

Battery voltage is determined automatically when the unit first receives power.

Voltage must be greater than 16V to recognize battery as 24V. Remove all power,

and reapply battery quickly and crisply.

System in equalize mode Disable equalize via IPN-ProRemote, or by turning DIP switch #5 off.

Battery is highly charged

Worn out PV modules

Low insolation

PV- connected to BAT-

Nominal PV voltage has changed from

18V or 24V to 12V

Current limit has switched to 30A

Normal operation, current is reduced if battery voltage is at setpoint.

Replace, or use as is.

Atmospheric haze, PV’s dirty, sun low on horizon, etc.

PV- & BAT- must be separate external to the unit for proper operation and cannot

connect to a common location. External connection prevents proper operation of

internal shunts and current measurement system.

If PV voltage is changed to 12V, all power must be removed momentarily to reboot

unit and load initial PV control values.

Normal operation. Current limit will change to 30A if PV VOC has exceeded 30V

which will occur with greater than 12V nominal PV’s. Reconfigure PV’s for 12V and

reboot 3024 to resume 40A current limit.

PV maximum power voltage (V

) is not

MP

much higher than battery voltage, leaving

little extra power to be extracted

PV’s hot

Nominal PV voltage has changed from

18V or 24V to 12V

Auxiliary output not configured for

auxiliary battery charge

Primary battery not highly charged

Load on Auxiliary battery too high

PV’s with low V

potential. PV’s with V

Excessive PV wiring voltage drop due to undersize wiring, poor connections etc.

Battery is nearly charged and battery voltage is high. Output during MPPT

operation is “constant power”, higher battery voltage reduces charge current

increase.

VMP and available power decrease with increasing PV cell temperature. Cooler PV’s

will produce greater boost. It is normal for boost to decrease as temperature rises.

If PV voltage is changed from to 12V, all power must be removed momentarily to

reboot unit and load initial PV control values.

Confirm dip switch #4 is OFF.

Auxiliary battery will not receive charge unless primary battery is highly charged in

Acceptance or Float.

Maximum auxiliary charge current is roughly 2A. Load may need to be reduced.

PV’s with higher VMP produce greater power and current boost

MP.

≥ 17V work best.

MP

12

Page 14

Blue Sky Energy - Solar Boost 3024iL

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

System appears OK,

but will not correctly

switch between Bulk,

Acceptance & Float

Not set for 3 stage charge

System will not switch out of Bulk and into

Acceptance or Float

System will not switch from Float to Bulk

or Acceptance

System will not switch from Acceptance to

Float

System shows Acceptance at times but

battery voltage is low and current is very

Check Float voltage setpoint.

Battery is highly discharged or very large relative to relative to available net charge

current. PV power may be too low or loads too high.

Normal operation. Unit will stay in Float and not switch to Bulk or Acceptance until it

is unable to hold the battery at the Float voltage setpoint.

Battery not fully charged. Unit will not switch to Float until battery voltage remains at

the Acceptance voltage setpoint continuously for the Charge Time period (or net

battery current drops to the Float Transition Current setpoint if using IPN-

ProRemote).

Normal operation. If the unit enters current limit, it will pass through Acceptance for

about 10 seconds upon exiting current limit and returning to Bulk/MPPT.

high near max. rating.

Load control not

working properly

Dusk-to-Dawn

feature, lights will not

turn ON or remain

ON

Auxiliary output not set for load control

Output may have shut off due to low

battery charge

ON/OFF thresholds set to inappropriate

values

Dusk-to-Dawn feature enabled

Auxiliary output not set for load control

Output may have shut off due to low

battery charge

Charge control system ON

Timers set incorrectly

First valid night time not seen yet

Confirm dip switch #4 is ON.

Load will shut off if battery voltage drops below OFF threshold (default 11.5/23.0V).

Once shut off, the load will turn on until battery voltage is above ON threshold

(default 12.6/25.2V).

Correct settings.

Disable Dusk-to-Dawn control.

Confirm dip switch #4 is ON and Dusk-to-Dawn enabled.

Load will shut off if battery voltage drops below OFF threshold (default 11.5/23.0V).

Once shut off, the load will not come back on until battery voltage is above ON

threshold (default 12.6/25.2V).

Lights will not turn on if charge control system is ON and charging.

Check Post-Dusk and Pre-dawn timer settings

Pre-Dawn lighting will not operate until a valid night time of greater than 2 hours is

detected to initialize the night time period.

Dusk-to-Dawn

feature, lights will not

turn OFF or remain

OFF

Networked units do

not seem to

coordinate action or

slaves do not turn on

Auxiliary output not set for load control

Dusk-to-Dawn feature not enabled.

Timers set incorrectly

Charge control does not turn ON

IPN network address set wrong

Network wiring problem

Confirm dip switch #4 is ON and Dusk-to-Dawn enabled.

Post-Dusk and Pre-dawn timers both set to DISABLED. One or both timers must be

set to enable Dusk-to-Dawn feature.

Correct Post-Dusk and Pre-dawn timer settings.

Check charge control operation

A single unit must be set to IPN network address 0 (zero).

One unit of a multi-unit network must be set to IPN network address 0 (zero), AND

all other units must be set to different addresses.

Confirm wiring. Use IPN-ProRemote to View Charge Unit Status and confirm

communication.

Temperature related

functions do not

work.

Temperature sensor missing, failed or

installed reverse polarity

Temperature sensor not installed on

If sensor is open, short, reverse polarity or missing unit will operate as if sensor was

at 25°C. Sensor voltage when connected should be 2.98V at 25°C, changing at

+10mV/°C.

Temperature sensor must be installed on the master in a multi-controller system.

master

Display turns on, but

battery voltage

displays “– – –“

rather than a number

Display not communicating with charge

controller

Cable faulty

One charge controller only must be Master.

Poor or missing Bat – connections preventing communication

When charger turns

on, output current

Output current display selection set for an

address not present on the IPN network

Configure display IPN network address to a charger present on the IPN network.

displays “– – –“

rather than a number

13

Page 15

Installation and Operation Manual

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

Charge OFF at high

ambient temperature

When charger turns

on, output current

displays but the

value seems

incorrect

Voltage or current

value displayed

seems to be stuck

and does not change

SPECIFICATIONS

SPECIFICATIONS Solar Boost 3024iL & 3024DiL

Output Current Rating

Nominal Battery Voltage 12 / 24VDC

PV Input Voltage 57VDC maximum

Power Consumption

Charge Algorithm

Acceptance Voltage

Float Voltage

Equalization Voltage

Voltage Setpoint Limit

Auxiliary Output

• Aux. Battery Charge

• Load Control

• Dusk-to-Dawn Controlℑ

Temperature Compensation Optional sensor adjusts charge voltage based on battery temperature

Power Conversion Efficiency 97% typical @ 28V / 24A Output

Cabinet Dimensions 6⅞”H x 6⅝”W x 3⅜”D (17.4cm x 16.8cm x 8.59cm)

Volt/Amp Accuracy/Range

Communication Blue Sky Energy’s proprietary IPN Network interface

Environmental

As a part of our continuous improvement process

specifications are subject to change without prior notice

System temporarily shuts down due to

high heat sink temperature

Output current display selection set for

wrong IPN network address

Bat– connected to PV– outside charge

controller

Display or charge controller IPN network

addressed has changed

Display not communicating with charge

controller

Single output configurable as either: 20A load controller –or– 2A auxiliary battery charger

20A maximum, ON ≥12.6VDCℵ / OFF ≤11.5VDCℵ (Range 10.0 – 40.0VDCℑ, or net battery AHℑ)

Variable Post–Dusk and Pre–Dawn timers

–5.00 mV/°C/cell correction factor (Range 0.00 to –8.00 mV/°C/cell

Battery voltmeters 40.0VDC±0.50% FS • PV voltmeter 60.0VDC±0.50% FS

Improve ventilation or reduce PV power. Sufficient ventilation to prevent over

temperature shut down will improve reliability. See Technical Bulletin #100206.

Configure display IPN network address DIP switch to read desired output current.

PV- & BAT- must be separate external to the unit for proper operation and cannot

connect to a common location. External connection prevents proper operation of

internal shunts and current measurement system.

Configure display IPN network address DIP switch to properly read output current

of a charger present on the IPN network

Intermittent display cable.

ℜ

30A / 40A

Typical 0.35W standby • 1.0W Charge ON

3-stage Bulk/Acceptance/Float • plus Equalize

ℵ

14.4VDC

13.2VDC

15.2VDC

(range 14.0 – 14.8VDCℵ, 10.0 – 40.0VDCℑ)

ℵ

(range 13.2 – 13.8VDCℵ, 10.0 – 40.0VDCℑ)

ℵ

(range 10.0 – 40.0VDCℑ) • automatic or manual

15.5VDC

ℵ

(range 10.0 – 40.0VDCℑ)

2A typical, same charge voltage as primary battery

ℑ

, Range 0.5 – 20.0 hours

ℑ

) • sensor range –60 to +80°C

Ammeters 41.0A±0.50% FS

–40 to +40°C, 10 – 90% RH non-condensing

ℵ

SB3024i alone, voltages double for 24V battery

ℑ

With IPN-ProRemote

ℜ

40A with 12V battery and 12V PV modules

14

Page 16

Blue Sky Energy - Solar Boost 3024iL

FIVE YEAR LIMITED WARRANTY

Blue Sky Energy, Inc. (hereinafter BSE), hereby warrants to the original consumer purchaser, that the product or any part thereof shall be free from defects

due to defective workmanship or materials for a period of five (5) years subject to the conditions set forth below.

1. This limited warranty is extended to the original consumer purchaser of the product, and is not extended to any other party.

2. The limited warranty period commences on the date the product is sold to the original consumer purchaser. A copy of the original purchase receipt

identifying purchaser and date of purchase, must accompany the product to obtain warranty repairs.

3. This limited warranty does not apply to, and future warranty shall become void, for any product or part thereof damaged by; a) alteration, disassembly

or application of a foreign substance, b) repair or service not rendered by a BSE authorized repair facility, c) accident or abuse, d) corrosion, e) lightning

or other act of God, f) operation or installation contrary to instructions pertaining to the product, or g) cosmetic aging.

4. If BSE’s examination of the product determines that the product is not defective the consumer shall be charged a test and evaluation fee of $40 and be

responsible for all transportation costs and insurance related to returning the product to the consumer. The consumer is ultimately responsible for

proper installation and operation of the product and BSE’s prior troubleshooting assistance shall not serve as a waiver of the test and evaluation fee.

The test and evaluation fee is subject to change without prior notice.

5. If within the coverage of this limited warranty, BSE shall repair or replace the product at BSE’s sole discretion and return the product via standard

ground transportation of BSE’s choosing within the continental US. The consumer shall be responsible for all transportation costs and insurance to

return the product outside the continental US, and for all transportation costs and insurance related to expedited return of the product. BSE’s liability for

any defective product or any part thereof shall be limited to the repair or replacement of the product. BSE shall not be liable for any loss or damage to

person or property, or any other damages, whether incidental, consequential or otherwise, caused by any defect in the product or any part thereof.

6. Any implied warranty for merchantability or fitness for a particular purpose is limited in duration to the length of this warranty.

7. To obtain warranty repairs, contact BSE at 760-597-1642 to obtain a Returned Goods Authorization (RGA) number. Mark the outside of the package

with the RGA number and return the product, postage prepaid and insured to the address below. The consumer is responsible for all transportation

costs and insurance related to returning the product to BSE, and for any shipping damage which may void the warranty or increase the cost of repairs.

Blue Sky Energy, Inc.

2598 Fortune Way, Suite K

Vista, CA, 92081, USA

800-493-7877 • 760-597-1642 • Fax 760-597-1731 • www.blueskyenergyinc.com

15

Page 17

Installation and Operation Manual

SOLAR BOOST™ 3024iL

CONTROLADOR DE CARGA FOTOVOLTAICA DE 30A 24VCC / 40A 12VCC

CON SEGUIMIENTO DEL PUNTO DE MÁXIMA POTENCIA

MANUAL DE INSTALACIÓN Y OPERACIÓN

2003167

Este dispositivo cumple con la parte 15 de las

reglas de FCC. La operación está sujeta a las

siguientes dos condiciones: 1) Este dispositivo

no puede causar interferencia dañina y 2) Este

dispositivo debe aceptar toda interferencia

recibida, incluyendo interferencia que pueda

causar operaciones indeseadas.

ESTE MANUAL INCLUYE INSTRUCCIONES DE SEGURIDAD IMPORTANTES PARA LOS MODELOS SB3024iL, SB3024DiL

CONFORME A

UL STD. 1741

CERTIFICADO PARA

CAN/CSA STD. E335-1/2E

CONFORME A

EN 61326-1:2006

EN 60335-1:2002 + A11:2004 + A1:2004

EN 60335-2-29:2004

CONSERVE ESTAS INSTRUCCIONES

CUBIERTO POR UNA O MÁS DE LAS SIGUIENTES PATENTES DE E.U.A.

6,111,391 • 6,204,645

16

Page 18

Blue Sky Energy - Solar Boost 3024iL

TABLA DE CONTENIDOS

INSTRUCCIONES IMPORTANTES DE SEGURIDAD........................................................................................................... 18

DESCRIPCIÓN DEL PRODUCTO.......................................................................................................................................... 19

Números de partes y opciones............................................................................................................................... 19

OPERACIÓN ..........................................................................................................................................................................19

Indicador de estado de carga.................................................................................................................................19

Visor digital opcional ..............................................................................................................................................19

Visores remotos opcionales ...................................................................................................................................19

Control de carga multietapa ...................................................................................................................................19

Carga masiva.................................................................................................................................19

Carga de aceptación...................................................................................................................... 19

Carga flotante.................................................................................................................................20

Ecualización ...........................................................................................................................................................20

Ecualización automática ................................................................................................................ 20

Ecualización manual ......................................................................................................................20

Límite de corriente.................................................................................................................................................. 20

Temperatura y potencia de salida.......................................................................................................................... 20

Compensación opconal de temperatura ................................................................................................................21

Valor configurado del límite máximo de voltaje......................................................................................................21

Seguimiento del punto máximo de potencia (MPPT)............................................................................................. 21

Múltiples controladores de carga en la red IPN .....................................................................................................21

INSTALACIÓN ........................................................................................................................................................................ 21

Precauciones para la manipulación electrostática .................................................................................................21

Selección de los módulos PV.................................................................................................................................22

Configuración del Solar Boost 3024i...................................................................................................................... 22

Ajustes predeterminados según se envía de fábrica .....................................................................22

Restablecimiento de los ajustes predeterminados según se envía de fábrica ..............................22

Voltaje de batería y del PV.............................................................................................................23

Voltaje de carga, voltaje flotante y tiempo de carga ......................................................................23

Visor de corriente de salida............................................................................................................24

Cableado de la batería y del PV............................................................................................................................. 24

Compatibilidad electromagnética ...........................................................................................................................24

Sensor de temperatura de la batería...................................................................................................................... 24

Salida auxiliar.........................................................................................................................................................24

Carga auxiliar de batería................................................................................................................ 25

Controlador de carga .....................................................................................................................25

Control de iluminación de anochecer a amanecer.........................................................................25

Instalación de un sistema de múltiples controladores............................................................................................ 26

Cableado y configuración de un sistema de controladores múltiples ............................................26

Red IPN..........................................................................................................................................26

Montaje .................................................................................................................................................................. 27

GUÍA DE RASTREO DE FALLAS.......................................................................................................................................... 28

ESPECIFICACIONES..............................................................................................................................................................31

GARANTÍA LIMITADA DE DOS AÑOS ................................................................................................................................. 31

TABLAS Y FIGURAS

Tabla 1 Indicador del estado de carga........................................................................................................19

Tabla 2 Longitud máxima del conductor – Caída de voltaje de 3%............................................................ 24

Figura 1 Panel frontal y visores indicadores remotos ..................................................................................20

Figura 2 Configuración de voltaje de carga de fábrica vs. temperatura de batería .....................................21

Figura 3 Configuración y diagrama de cableado.......................................................................................... 23

Figura 4 Cableado de salida auxiliar............................................................................................................ 25

Figura 5 Cableado de la red IPN..................................................................................................................26

Figura 6 Esquema dimensional detallado ....................................................................................................27

17

Page 19

Installation and Operation Manual

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este manual contiene instrucciones importantes para los modelos SB3024iL y SB3024DiL

CONSERVE ESTAS INSTRUCCIONES

1. Deje la instalación y las reparaciones en manos de personal de servicio calificado. No hay partes reparables por el usuario en esta unidad.

2. Para reducir el riesgo de recibir descargas eléctricas, fuego o daños personales, se han colocado los siguientes símbolos a lo largo de este manual para

indicar condiciones peligrosas o instrucciones importantes de seguridad u operación.

ADVERTENCIA PRECAUCIÓN IMPORTANTE

)

Indica condiciones peligrosas o potenciales

descargas eléctricas. Use extrema precaución.

Indica artículos críticos para instalar u operar

la unidad en forma segura.

3. PRECAUCIONES PERSONALES

a) El trabajo en las proximidades de baterías de plomo-ácido es peligroso. Las baterías producen gases explosivos durante la operación normal.

b) Para reducir el riesgo de explosión de la batería, siga estas instrucciones y aquellas publicadas por el fabricante de la batería y del fabricante de

cualquier equipo que quiera usar en las proximidades de una batería.

c) Debe haber una persona en el rango de alcance de su voz o suficientemente cerca para darle ayuda cuando trabaje cerca de una batería de plomo-

ácido.

d) Tenga buena cantidad de agua potable y jabón en las cercanías en caso de que el ácido de la batería entre en contacto con la piel, ropa u ojos.

e) Utilice protección completa para sus ojos y su ropa. Evite tocar sus ojos mientras trabaje cerca de una batería.

f) Si el ácido de la batería entra en contacto con la piel o la ropa, lave inmediatamente con agua y jabón. Si entra ácido en el ojo, inmediatamente enjuague

el ojo con agua corriente fría por lo menos durante 10 minutos y consiga atención médica inmediatamente.

g) NUNCA FUME o permita la presencia de una chispa o una llama en las proximidades de la batería.

h) Sea extremadamente precavido para así reducir el riesgo de dejar caer una herramienta metálica en la batería. Esto puede generar una chispa o

cortocircuitar la batería u otras partes eléctricas que pueden causar una explosión.

i) Quítese todos los artículos metálicos personales tales como anillos, brazaletes y relojes cuando trabaje con una batería de plomo-ácido. Una batería de

plomo ácido puede producir una corriente de cortocircuito suficientemente alta como para soldar un anillo o similar a algún metal, causando una

quemadura severa.

j) Quite todas las fuentes de energía, el fotovoltaico y la batería antes de realizar servicios o instalarlo.

4. UBICACIÓN E INSTALACIÓN DEL CARGADOR

a) Esta unidad está diseñada para cargar baterías de química de plomo ácido de 12V (6 celdas) o 24V (12 celdas) del tipo inundado o sellado, dentro del

rango de 20 a 10000 A/H. Siga las recomendaciones de carga del fabricante cuando considere esta unidad para su uso con otra química de batería.

b) Esta unidad emplea componentes que tienden a producir arcos o chispas. NUNCA la instale en un compartimiento para batería ni en la presencia de

gases explosivos.

c) Esta unidad debe ser instalada y cableada de acuerdo con el Código Eléctrico Nacional, ANSI/NFPA 70.

d) La protección ante exceso de corriente para la batería debe ser provista externamente. Para reducir el riesgo de fuego, conéctela a un circuito provisto

con una protección máxima por rama de 50A contra exceso de corriente, de acuerdo con el Código Eléctrico Nacional, ANSI/NFPA 70.

e) La protección contra exceso de corriente para la salida de control de carga auxiliar o la salida auxiliar de carga de batería debe ser provista externamente.

Para reducir el riesgo de fuego, conecte a la carga o a la batería auxiliar con una protección contra exceso de corriente de un máximo de 25 A de acuerdo

con el Código Eléctrico Nacional, ANSI/NFPA 70.

f) Asegúrese de que la unidad esté configurada adecuadamente para el tipo de batería a ser cargada.

g) La unidad no es a prueba de agua. No la exponga a lluvia ni a nieve.

h) Asegúrese de que todas las conexiones terminales estén limpias y ajustadas. Los terminales de compresión de la batería y el PV deben ser ajustados a 5

Nm (45 libras por pulgada) Los terminales de compresión de la red IPN y del sensor de temperatura de la batería deben ser ajustados a 0.24 Nm (2.1

libras por pulgada). Los terminales de compresión de la salida auxiliar deben ser ajustados a 0.67 Nm (6 pulgadas por libra).

i) No conecte un conjunto de PV que sea capaz de producir una corriente de cortocircuito mayor a 32A para módulos PV de 12V nominales o 24A de

cortocircuito para módulos PV mayores a 12V nominales. Limite la corriente de entrada de cortocircuito a 12A si se usa el modo de entrada de 24V y

salida de 12V.

j) Esta unidad no viene provista con un dispositivo detector/interruptor de deriva a tierra (disyuntor diferencial) y debe ser usado con un disyuntor diferencial

externo según lo requiere el Artículo 690 del Código Eléctrico Nacional para el lugar de instalación.

5. PREPARACIÓN PARA LA CARGA

a) Nunca cargue una batería congelada.

b) Asegúrese de que la batería esté montada en un compartimiento bien ventilado.

c) Agregue agua destilada en cada celda de una batería de plomo-ácido hasta que el ácido de la batería alcance el nivel especificado por el fabricante de la

batería.

Siga estas instrucciones al pie de la letra para

una un funcionamiento correcto de la unidad.

18

Page 20

Blue Sky Energy - Solar Boost 3024iL

DESCRIPCIÓN DEL PRODUCTO

El Solar Boost™ 3024iL es un controlador de carga de batería fotovoltaico con seguimiento del punto de máxima potencia de múltiples etapas

“Maximum Power Point Tracking (MPPT)” capaz de proveer hasta 30A o 40A, dependiendo de los módulos PV y del voltaje de la batería. La salida auxiliar

puede servir tanto como cargador de auxiliar de batería o como un controlador de carga de 20A con o sin control variable de iluminación desde el anochecer

al amanecer. El 3024 incluye una interfaz de red IPN que permite que múltiples controladores de carga se comuniquen los unos con los otros y operen

como una máquina única de carga.

NÚMEROS DE PARTE Y OPCIONES

• SB3024iL........... Controlador de carga Solar Boost 3024iL • SB3024DiL.......... Controlador Solar Boost 3024iL con visor de voltios /amperios

• IPNPRO ............ Visor remoto y monitor de batería IPN-Pro • 930-0022-20 ........Sensor de temperatura de batería

• CS-500.............. Derivación de corriente de 500A/50mV • IPNREM ..............Visor remoto IPN

• IPNPRO-S......... Remoto IPN-Pro con derivación de corriente requerida de 500A/50mV

OPERACIÓN

El control de carga y la operación MPPT son completamente automáticos. Por la noche, cuando se detiene la producción de potencia PV, el conjunto

PV es desconectado de la batería para prevenir un indeseado drenaje de corriente. Hay un retardo de 5 segundos para el encendido y un retardo de 45

segundos para el apagado.

¾ El 3024 opera sobre la potencia de la batería, no sobre la potencia del PV. Debe conectarse una batería con un voltaje

)

INDICADOR DE ESTADO DE CARGA

mínimo de 9V para que la unidad pueda operar.

En el frente del 3024 viene provisto un indicador de estado de carga y también en los visores remotos opcionales. Si la corriente de carga de batería neta

es mayor a ≈3 y hasta 5A por cada 100 AH de capacidad de la batería, el indicador de estado de carga puede proveer una indicación aproximada del estado de

carga de la batería.

INDICADOR DE ESTADO DE CARGA

INDICADOR DE ESTADO DE CARGA MODO DE CARGA NIVEL DE CARGA APROXIMADO

APAGADO (OFF) CARGA APAGADA (OFF)

CONTINUAMENTE ENCENDIDO MASIVA <70% DE LA CARGA COMPLETA

DESTELLANDO • 1 SEG. ENC. / 1 SEG. APAG.

DESTELLANDO • 0.2 SEG. ENC. / 1 SEG. APAG.

DESTELLANDO RÁPIDAMENTE • 0.2 SEG. ENC./ 0.2 SEG. APAG.

DE ACEPTACIÓN 70% - 95% DE LA CARGA COMPLETA

FLOTANTE CARGADO COMPLETAMENTE

ECUALIZACIÓN

TABLA 1

VISOR DIGITAL OPCIONAL

El SB3024DiL incluye un visor digital de voltaje de batería y de corriente de salida de carga. Durante la carga, el visor alterna entre voltaje y corriente.

La corriente es mostrada cuando el indicador “AMPS” está encendido y puede ser la total de todos los controladores de la red IPN (predeterminado de fábrica), o

la corriente de un único controlador de la red IPN. Mediante una prestación de disminución de luz por la noche, se reduce el brillo del visor cuando la carga PV

está apagada.

VISORES REMOTOS OPCIONALES

Se encuentran disponibles dos visores remotos. El remoto IPN tiene la misma funcionalidad de visor que el SB3024DiL. El remoto IPN-Pro, muy

completo, incluye la capacidad de ajustar y mejorar el monitoreo de los controladores de carga de la red IPN. También provee un monitoreo completo de la

batería del sistema con varios contadores de A/h y un indicador de nivel de batería altamente preciso del tipo “medidor de combustible”.

CONTROL DE CARGA MULTIETAPA

Carga masiva