Page 1

TO BE VALID, WARRANTY CARD MUST BE COMPLETED IN ITS

ENTIRETY BY AN AUTHORIZED DISTRIBUTOR OR DEALER AND SENT

TO AUTOMATIC EQUIPMENT MFG. CO., PENDER, NEBRASKA. FAILURE

TO DO SO WILL VOID THE WARRANTY.

Product Safety Policy Statement

It is, and shall continue to be, a primary objective of Automatic Equipment Manufacturing Company

to provide customers with safe and reliable products. Automatic will, and has, established safety

procedures in product design, manufacture, promotion and sales; and will coordinate efforts to promote

customer safety to the greatest extent possible. Each department has primary responsibility for the

promotion of safety under the guidelines of the Product Safety Committee.

292-2215 7/02

BX8894, BX88100

TM

AutoStop

Automatic Equipment Mfg. Co.

One Mill Road, Industrial Park l Pender, Nebraska 68047

Page 2

BX8894

TM

AutoStop

BX88100

OPERATOR, PARTS

& INSTALLATION

MANUAL

BX8894, BX88100 AutoStop

TM

TOWING PRODUCTS DIVISION

Page 3

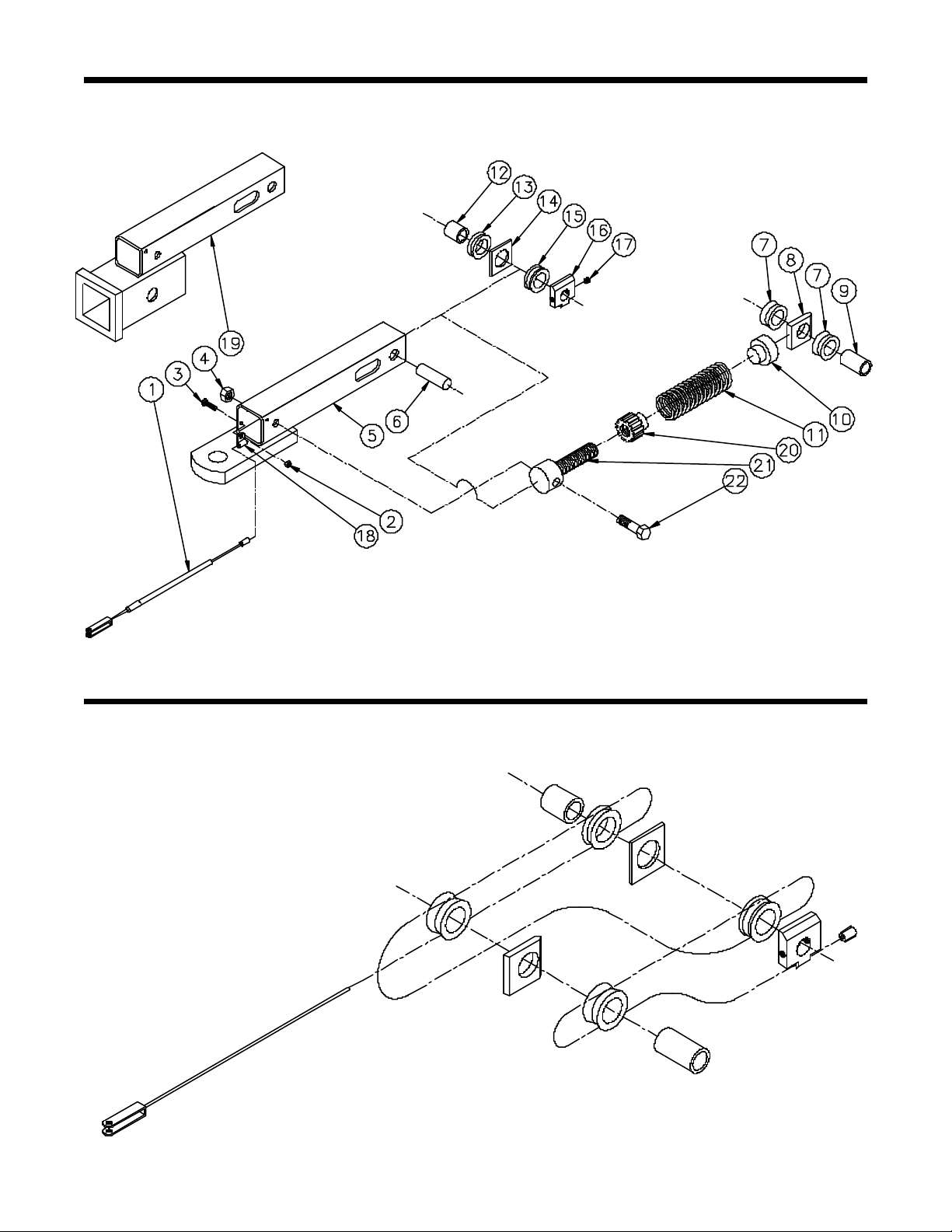

REPLACEMENT PARTS

Parts List

Ref. No. Qty. Part No. Description

1 1 62-3161 ............................................................................... Receiver Cable Assembly

2 1 202-0047 ................................................................................................ 10-32 Hex Nut

3 1 201-0192 .....................................................................10-32 x 1/2 Round Head Screw

4 1 202-0110 ..................................................................................... 7/16-20 Hex Jam Nut

5 1 299-0259 .............................................Ball Mount, Spring Autostop, Chrome, BX8894

6 1 229-0369 ....................................................................................Rod, 5/8 x 2, Autostop

7 2 229-0356 ................................................................. Pulley, Shock Absorber, Autostop

8 1 299-0382 ......................................................................Flat, Spacer, Narrow, Autostop

9 1 299-0384 ............................................................................... Bushing, Front, Autostop

10 1 207-0842 ....................................................................................Cap, Spring, Autostop

11 1 222-0076 ................................................................................Spring, Comp., Autostop

12 1 299-0385 ................................................................................Bushing, Rear, Autostop

13 1 229-0354 .......................................................................Pulley, Narrow Rear, Autostop

14 1 299-0289 .........................................................................Flat, Pulley Divider, Autostop

15 1 299-0383 .........................................................................Pulley, Front, Med., Autostop

16 1 299-0286 .................................................................................Cable Anchor, Autostop

17 1 201-0150 .....................................................................1/4-20 x 3/8 Knurled Set Screw

18 1 294-0811 .................................................................................5/16 Metal Cable Clamp

19 1 299-0277 ......................................................................M H Universal A-Stop, Chrome

20 1 299-0255 .......................................................................... Nut, Adjusting, Autostop, ZP

21 1 299-0256 ..........................................................................Bolt, Adjusting, Autostop, ZP

22 1 201-0366 ........................................................... 7/16-20 x 2 1/4 Hex Head Bolt, Grd. 5

Parts not shown:

Ref. No. Qty. Part No. Description

23 2 225-0052 ......................................................................................Clip, 3/32 Wire Rope

24 1 229-0362 ..................................................................................3/32 SS Cable Thimble

25 1 229-0363 ...............................................................................Ring Detent Pin, 3/16 x 1

26 3 294-0811 .................................................................................5/16 Metal Cable Clamp

27 3 201-0192 .....................................................................10-32 x 1/2 Round Head Screw

28 3 202-0047 ................................................................................................ 10-32 Hex Nut

29 1 290-0324 ...................................................................................Red Cap, .207 ID x 3/4

30 2 294-0250 .............................................................................Butt Connector, 16-14 Ga.

31 3 294-0187 .............................................................Ring Terminal. 5/16 Stud, 16-14 Ga.

32 8 294-0518 ................................................................Term. Coupler, Female, 16-14 Ga.

33 1 294-0813 .................................................................................................Indicator Light

34 1 294-0729 ...........................................................................................Automotive Relay

35 1 62-3366 .......................................................................Brake Cable Assembly, Coated

36 1 194-0140 ........................................................................65 Ft Coil 16 Ga. Yellow Wire

37 1 194-0139 ...................................................................................4 Ft 14 Ga. Black Wire

38 4 290-0159 ........................................................................................13" Nylon Cable Tie

39 2 290-0131 ....................................................................................5 7/8" Nylon Cable Tie

40 1 101-6377 ...................................................................... Bracket, Cable Housing Mount

41 1 201-0050 .................................................................... 1/4-20 x 3/4 Hex Bolt, Grd.5, ZP

42 1 202-0001 ............................................................................................... 1/4-20 Hex Nut

43 1 203-0008 .....................................................................................1/4 Lock Washer, ZP

44 1 203-0001 ........................................................................................1/4 Flat washer, ZP

45 1 294-0807 ........................................................................................... Mini Fuse Tapper

292-2215 7/02 10 of 10

Page 4

REPLACEMENT PARTS

CABLE ROUTING

292-2215 7/02 9 of 10

Page 5

initial setting, adjust to your driving preference if

needed. The location of the adjusting nut is shown

in Figure 23. The initial preload ranges are listed in

Figure 24.

10. Once you have the cable wrapped properly, pull

slowly on the other end of the cable while holding

the pulleys and swage in place with the other hand

to prevent the cable from unwrapping. Keep tension

on the cable and slide the pulleys into the AutoStop

tube. (Figure 20) When the second set of pulleys

start into the tube, stop and remove the 5/8 rod.

ASSEMBLY INSTRUCTIONS

11. Pull slowly on the cable until the holes in the

second set of pulleys line up with the holes in the

end of the AutoStop tube and insert the 5/8 rod.

12. With the AutoStop still on its side, be sure that the

pulleys, cable anchor, and pulley divider are all

together and pressed down to the side of the tube.

Place a 20 thousanths inch (.020") feeler gauge

between the cable anchor and wide pulley and

tighten the set screw in the end of the cable anchor.

(Figure 21) NOTE: Be sure to keep the

5/8 rod centered in the AutoStop tube while

tightening the set screw.

Figure 20

Figure 21

292-2215 7/02 8 of 10

Page 6

ASSEMBLY / ADJUSTING INSTRUCTIONS

Figure 18

6. Set the wide pulley on top of the pulley divider. It is

symetrical so it can be put on either way. (Figure

16) Set the cable anchor on top of the wide pulley

with the groove facing you and the notch out of the

corner to your right. (Figure 17)

7. Set the movable pulley assembly next to the

AutoStop tube, and next to it place the stationary

pulley assembly.(Figure18) You are now ready to

route the cable around the pulleys.

8. Pull the cable through so you have all the slack at

the back where you will be wrapping the cable. The

AutoStop tube should still be positioned with the

tongue flat side towards you. (Figure 18)

9. Refer to (Figure 19) while wrapping cable around the

pulleys. The cable should protrude from the

AutoStop tube at the lower corner of the tongue flat

side facing you. From here, route the cable in front

of pulley "A" and counterclockwise around pulley

"B". Continue on the back side back to pulley "A"

and go around it counterclockwise also. From here,

route the cable around pulley "C" counterclockwise

then pulley "D" counterclockwise. Lay the cable in

the groove in the cable anchor and set the cable

swage into the notch in the cable anchor.

Suggested initial preload ranges are:

1/4" - Towed vehicle under 2,000 lbs.

1/2" - 2,000 to 3,500 lbs.

3/4" - 3,500 to 5,000 lbs.

1" - Maximum preload

Figure 24

ADJUSTMENT INSTRUCTIONS

The Autostop "Load Ranger" is equipped with a return

spring and an adjusting nut to set the spring pre-load in

proportion to the weight of the towed vehicle. This preload will not allow the activation of the towed vehicle's

brakes during light braking of the towing vehicle. This

also prevents application of the towed vehicle's brakes

when descending a moderate grade against engine

compression, jake brake or exhaust brake, but still

allows proportional braking when the towing vehicle's

service brakes are applied. Before making any adjustment, drive the rig a few blocks and re-check the

installation for proper cable slack. With a flat blade

screwdriver, rotate the adjusting nut upward with a down

motion of the screwdriver handle to increase the

preload. This will move the nut in the direction of the

towing vehicle, compressing the return spring. Continue

to rotate the adjusting nut to the desired preload. If you

desire the Autostop to activate only during very heavy

braking, adjust to the max. setting. After your

292-2215 7/02 7 of 10

Figure 19

Figure 23

Page 7

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

1. Slide the cable assembly back into the AutoStop

tube and secure the cable clamp with the round

head screw and hex nut. (Figure 11) Leave

approximately one inch of cable sheathing

extending outside of the AutoStop tube. NOTE: As

described earlier on page 1, your AutoStop can be

configured to give a 2 inch rise. If this is

necessary, the AutoStop tube must be rotated 180

degrees and the cable assembly attached to the

opposite hole. Remember, the cable assembly

MUST protrude out of the lower, driver side of the

AutoStop tube when in use.

2. Lay the AutoStop tube on a table or bench with the

tongue flat side towards you.(Figure 13) Thread the

adjusting nut onto the adjusting bolt half way on the

threads. Slide the compression spring onto the

adjusting bolt all the way onto the adjusting nut.

Then place the end fitting on the other end of spring.

Slide this assembly into the AutoStop tube until

adjusting bolt hole is lined up with the two front

holes of AutoStop tube, then insert the 7/16" hex

bolt through the AutoStop tube and secure bolt with

hex nut. NOTE: If you are configuring the AutoStop

for a 2 inch rise as described on page 1, flip the

AutoStop tube over so the tongue flat side is away

from you before sliding in the shock absorber.

5. Place the pulley divider on the pulley. (Figure 15)

NOTE: The pulley divider is NOT square. It is

slightly wider one direction than the other. During

use, the pulley divider must be oriented long side

vertical, to keep the cable from jumping between

pulleys.

Figure 14

Figure 15

3. Place one of the two identical pulleys with the

beveled edge on the table. Place the long bushing

through this pulley, next place the center spacer

with the chamfer on the bottom right side. Place on

top of the spacer the other pulley with the beveled

edge on top.

4. Set the AutoStop tube aside and find the narrow

pulley. Please note that the narrow pulley's groove

is off center. Set the pulley on the bench with the

groove oriented closest to the bench. (Figure 14)

Insert the short bushing into the pulley and the 5/8

rod into the bushing. (Figure 14)

Figure 16

Figure 17

Figure 13

292-2215 7/02 6 of 10

Page 8

DISASSEMBLY / ASSEMBLY INSTRUCTIONS

MAINTENANCE

The AutoStop and the inside of the receiver tube

should be cleaned and lubricated with silicon spray at

1,000 mile intervals to prevent the buildup of road dust

preventing the action to slide with ease. The AutoStop

should be disassembled, thoroughly cleaned and

lubricated every 10,000 miles. At this time the

actuating cable should be replaced if there are any

signs of cable wear. Pages 5 - 9 show actuator cable

routing and parts assembly of the AutoStop.

DISASSEMBLY INSTRUCTIONS

If your AutoStop becomes sluggish or you are in

need of replacing a broken part, the following

disassembly instructions will step you through how to

dismantle, clean and reassemble your AutoStop.

1. Remove the AutoStop from the receiver hitch.

Remove the hex bolt. (Figure 10)

2. Loosen the set screw in the cable anchor and

remove the 5/8 rod going through the AutoStop

tube. NOTE: You may need to tap out the 5/8 rod

with a punch.

3. At this point, slide the pulleys and adjusting bolt

assembly out of the AutoStop tube. NOTE: Use

caution when removing the pulleys. The cable is

coiled around the pulleys several times and may

Figure 10

unwind when removed from of tube. This is normal,

reassembly will be explained in a later section.

4. Remove the round head screw holding the cable

clamp, then pull the cable assembly out of the

AutoStop tube.

5. Clean all parts with a mild solvent such as WD-40

and be sure to dry all parts thoroughly. Use a

brush to insure the inside of the AutoStop tube is

clean as well.

Figure 11

292-2215 7/02 5 of 10

Page 9

INSTALLATION / MAINTENANCE

We also include in the kit a lighted switch that should

be installed in the dash of the towing vehicle and will

light up when the brake pedal in the towed vehicle is

pulled on by the AutoStop. If the operator is distracted

by the light, the switch can be turned off. (Figure 9)

1. Locate the brake light switch which is activated

when the brake pedal is pressed down. Locate the

hot wire into the switch and the wire from the switch

to the brake lights. You will need to splice into the

wire coming from the switch to the brake lights.

Cut the wire at convenient place and strip the two

ends.

2. If there is room, you can locate the relay where you

cut the wires. If there isn’t room, you may want to

splice wire onto the wires you cut to give yourself

working room. The black wire and butt connectors

supplied can be used for this.

3. Strip one end of the yellow wire and twist it together

with the wire coming from the brake pedal switch.

Crimp a female spade terminal on the twisted pair.

Slide the terminal over the male terminal on the

relay labeled “87”.

4. Crimp a female spade terminal on the end of the

wire going the brake lights. Slide this terminal over

the male terminal on the relay labeled “30”.

5. Locate a bolt to use as a ground. Cut a piece of

the black wire long enough to reach from the relay

to the bolt. Strip both ends of the black wire and

crimp a ring terminal on one end and a female

spade terminal on the other. Put the ring terminal

under the head of the bolt and the spade terminal

on the male terminal on the relay labeled “85”.

6. In the car's fuse panel or another convenient place,

locate a power wire that is "hot" only when the

ignition switch is on. Cut a piece of black wire to

reach from the "hot" wire to the relay. Use a butt

connector to splice into the "hot" wire and crimp a

spade terminal on the other end and slide it over the

remaining terminal on the relay labeled "86".

7. Route the yellow wire from the relay through the

engine compartment of the car, along the bottom of

the coach and into the dash of the coach. You will

need to provide a disconnect between the car and

the coach if you don’t have any extra terminals in

the plug you are currently using between the coach

and the car. Tie the wire to the frame of the coach

with cable ties or other suitable means.

8. Locate a suitable place in the dash for the switch.

With the switch mounted, cut the yellow wire to

length, strip and crimp on a female spade terminal,

and plug the spade into the switch on the terminal

marked “3”.

9. Locate a bolt to use as a ground. Cut a piece of

the black wire long enough to reach from the switch

to the bolt. Strip both ends of the black wire and

crimp a ring terminal on one end and a female

spade terminal on the other. Put the ring terminal

under the head of the bolt and the spade terminal

on the male terminal on the switch labeled “2”.

NOTE: The terminal marked “1” will not be used.

10. Gather up the wires and the relay. Anchor them up

out of the way so they will not interfere with driving

the vehicle.

Figure 9

292-2215 7/02 4 of 10

Page 10

INSTALLATION

When installed properly, the nylon thumb nut

should be showing on top of the carpet. Avoid

abrupt bends in the cable housing as this will cause

friction and premature wear of the cable. If the

cable housing runs through the bumper or the

bumper skirt, drill a 5/16 inch hole there to align the

cable as previously mentioned with the actuating

cable. The cable housing should protrude a 1/2

inch beyond the bumper, or bumper skirt or where

ever the flag terminal is mounted, pointing directly

at the hitch ball. Retract the cable and cut off any

excess cable housing with side cutters. Fig.25

Figure 25

8. Lubricate the cable with silicon spray and feed the

cable back through the cable housing, and secure

the loop around the brake pedal arm allowing the

cable to feed directly and straight into the cable

housing. Use wire ties or wrap with electrical tape

Figure 8

to insure that the loop around the pedal arm does

not loosen when the brake pedal is being used. If

alignment is proper, the cable will feed into the

cable housing when the brake pedal is depressed.

Figure 22

9. Attach the cable thimble into the clevis on the

AutoStop actuating cable with the quick release

pin. (Figure 3 or 4) Run the loose end of the pedal

cable through the clevis and thimble and secure this

loop with the two cable clamps. Place the first

clamp as close as possible to the thimble and the

second cable clamp about four (4) inches from the

first. Before tightening the clamps adjust the cable

length so there is about four to five (4-5) inches of

vertical play in the cable before the towed vehicle’s

braking lights come on. (Fig. 22) Cut off and

discard any excess cable. Recheck this

adjustment after a short trial run. If the towed

vehicle’s brake lights come on at the slightest touch

of the cable, with the cable properly adjusted, the

brake lights are coming on during pedal free travel.

Most brake light switches are not adjustable, so

install a bungee cord from the pedal to the driver’s

seat base to reduce the free travel movement of the

pedal while towing.

10. Install all other safety and towing equipment as

required. The AutoStop only actuates the towed

vehicles brakes. It does not eliminate the necessity

of safety chains, towing lights, transmission pumps

or driveshaft disconnects.

MECHANICAL INSTALLATION NOTES

In Steps 4 and 7 when routing the housing, do not make

a turn tighter than a four (4) inch radius. If you need to

make a bend in the housing you will need to anchor the

housing in the middle of the bend. There are plastic

cable ties and two clamps and stove bolts included with

the kit. You will also need to anchor the housing as

close as possible to the end that sticks out of the grill of

the car. After you have the housing installed and the

cable inserted, lay under the vehicle and have someone

pull on the cable. When pressure is applied to the

cable the housing will tend to try to “straighten out”

through the bends. If there are several places where

this happens, most of the cable pull will be used up

straightening the housing rather than pulling on the

brake pedal. Note where the housing is trying to

straighten and anchor these areas.

ELECTRICAL INSTALLATION

If the towed vehicle’s brake lights will work with the key

off, there is a possibility that the towed vehicle’s battery

may be drained after towing as the brake lights will be

activated each time the brake pedal is depressed by the

AutoStop. To keep this from happening we have

included electrical parts with the kit to automatically

disconnect the brake lights when the key is off. The

only change you will notice to the towed vehicle is that

the brake lights on the car will only be activated by the

brake pedal when the ignition is in the "on" position.

292-2215 7/02 3 of 10

Page 11

INSTALLATION

a. If readjustment of cable is needed, this is

usually an indication that the cable is too

tight or is hanging up on one of the towing

components.

MECHANICAL INSTALLATION

Figure 6

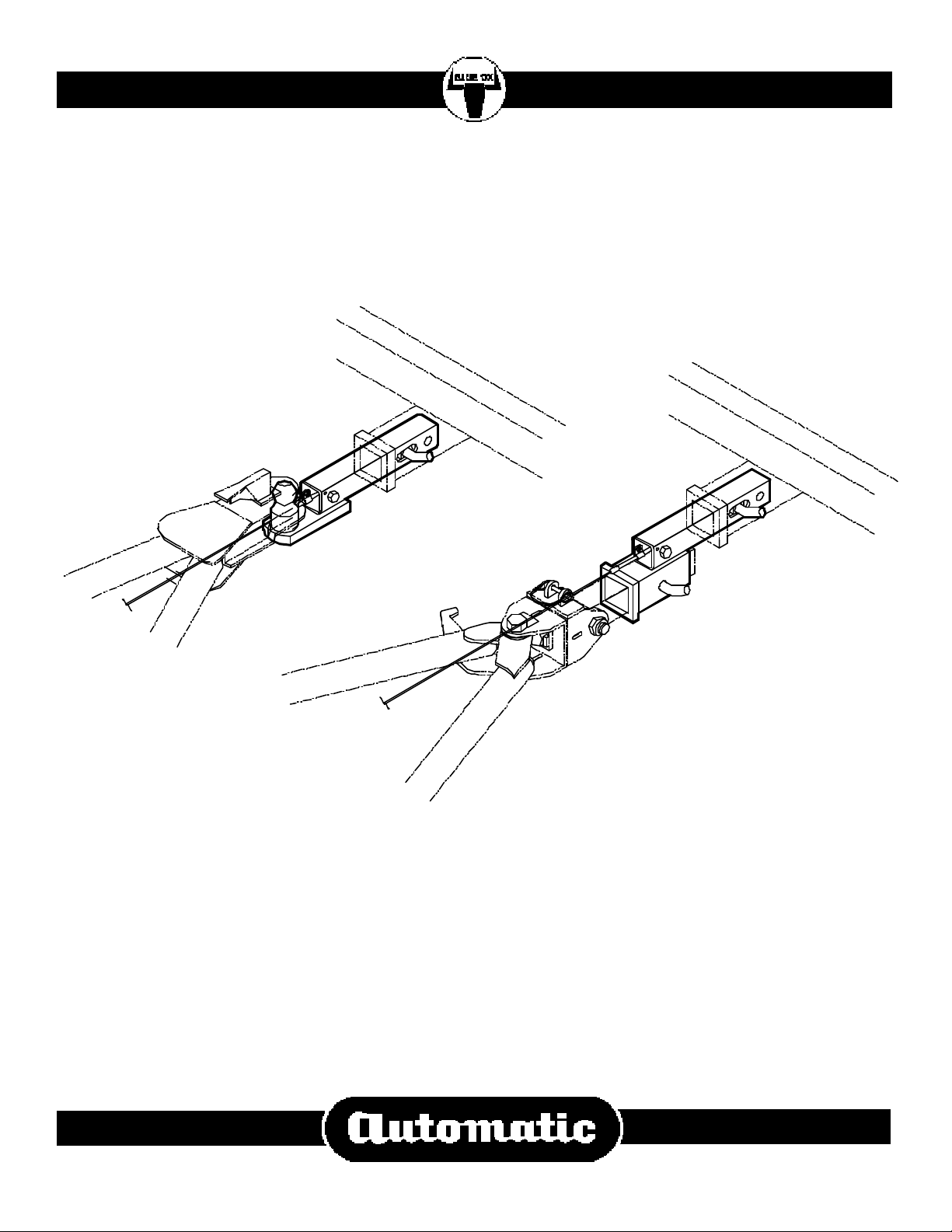

1. Insert the AutoStop into the receiver tube with the

actuating cable on the drivers side of the

opening. (Figure 6) Align the holes and insert the

cross pin and safety clip (or locking pin). If the

receiver tube is open at the front, it must be closed

to keep road dust out of the mechanism. Clean the

area and cover with tape.

arms are locked in the towing position.

4. Now you are ready to install the brake pedal cable

on the towed vehicle. This cable should run from

the end of the AutoStop actuating cable in a line

about parallel to the bottom plane of the tow bar

coupler, but staying inboard of the driver’s side arm,

probably through the bumper or bumper skirt and up

to the brake pedal through the floor board. Visually

select a route that will not interfere with any moving

components or possibly contact electrical

terminals. Also, make sure cable doesn't come

into contact with any aluminum components, such

as a transmission housing, which could cause

significant wear. Make sure cable route will lead to

the general area where the steering column goes

through the floor.

5. From the drivers seat note the distance and

direction from the steering column to the brake

pedal when the brake pedal is fully depressed. This

will normally be a little below and a little inboard of

the steering column. Mark the spot on the carpet

with chalk where the cable should pass through the

floor after making a loop around the brake pedal

arm. (Figure 7) Measure the distance and direction

and confirm that a drilled hole will not interfere with

2. For coupler style tow bars install a hitch ball of

the matching size for the tow bar coupler, preferably

using a one inch diameter shank and a one inch nut

and lock washer. Do not use a hitch ball that has a

bolt which threads into the ball. For added safety,

it is recommended that after tightening the hitch ball

nut to the required torque, drill the hitch ball nut and

install a cotter key. Note: Be sure tow bar and

Autostop are both parrallel with the ground.

3. Hook up the towed vehicle to the towing vehicle and

gently back the towed vehicle until all the slack is

out of the AutoStop, moving it to its fully extended

towing position. If a self aligning tow bar is

being used, be sure both arms, are fully

extended to the locked towing position. Drive

the towing vehicle forward a few feet if

necessary and pull on the AutoStop actuating

cable to remove all slack. It is very important

that the connecting cables have 4 inches of vertical

slack when in the towing position. This assures the

Autostop will not be active when towing and allows

for turns in either direction. This does not reduce

the effectiveness of the Autostop.

Before the adjustment is made:

(1) Be sure the Autostop is fully retracted to the

towing position. (2) Be sure the cross pin is

inserted through the pulley hole. (3) Be sure both

tow bar arms are fully extended. (4) Be sure both

Figure 7

anything as stated in Step 4. When selecting the

location for the hole, it should be positioned so the

cable is pulling straight away on the brake pedal

arm, not to either side and not up or down. (Figure

7)

6. After you have confirmed that the location for the

hole will not cause any problems, pull the carpet

back and drill a 1/8 inch pilot hole. Allow the drill

bit to just barely break through the metal floor.

Next, inspect where the hole actually is from the

engine compartment side to verify that this location

will not cause problems and to see how the cable

aligns with the brake arm. If the hole needs to be

relocated slightly, redrill and seal the previous hole

with a rivet or sealant.

7. When alignment is correct, enlarge the pilot hole

with a 5/16 inch bit. Cut a slit in the carpet to

correspond to the hole in the floor. Feed the cable

housing through the carpet and hole in the floor

following your selected route as mentioned above.

292-2215 7/02 2 of 10

Page 12

REQUIREMENTS

REQUIREMENTS FOR PROPER OPERATION

A. You must have a two (2) inch square receiver type

hitch on your towing vehicle that aligns within two

(2) inches of the height of the tow bar.

NOTE: The tow bar may slope upward toward the

towing vehicle, but should not slope downward

toward the towing vehicle.

The AutoStop needs a level push on the ball

mount tube to operate properly. This requires that

the height of the

receiver tube be

adjusted rather than the

height of the ball as

happens normally.

There are several

options available if you

need to adjust the

receiver tube height.

A two (2) inch drop can

be achieved by welding

another receiver tube

under the existing

receiver tube. (Figure 1)

A six (6) inch drop

receiver is available that

pins into the existing

receiver. (Figure 2)

Figure 1

Figure 2

Combining the drop receiver and a rise in the

AutoStop will give a four (4) inch drop. (Figure 5)

Figure 5

B. You may use any conventional style tow bar with

the hitch ball at the towing vehicle. (No reversed

tow bars).

C. You must tow the vehicle with all four (4) wheels on

the ground.

D. The loaded weight of the towed vehicle must not

exceed the weight rating of any of the towing

accessory components such as; the tow bar, the

hitch ball, the receiver hitch, the receiver cross pin,

the safety chains, or the AutoStop.

NOTE: The AutoStop does not allow you to tow

more than the ratings of your towing hardware, it

just reduces the stopping distance of the

combination.

Figure 3

Figure 4

The AutoStop shown in Figure 3 is set up as it

comes from the factory.

The AutoStop can be reconfigured to give a three (3)

inch rise as shown in Figure 4.

NOTE: If this configuration is used, the internal parts

will need to be rotated so that the actuator cable

still protrudes from the lower driver’s corner of the

AutoStop. See Disassembly / Assembly

instructions Page 5-8.

ILLUMINATED DASH INDICATOR LIGHT IN RV

WARNING: Motorhome dash light must be installed

according to installation instructions or warranty

will be void.

A. RV DASH LIGHT

1. Dash light will allow a visual indication that the

towed vehicles' brakes are activated.

2. Should light remain "ON" after braking,

corrective action must be taken. "STOP" the RV to

investigate. You may be experiencing a

malfunction of the system, which would require you

to check, the braking system for proper operation.

a. Cable tension should comply with the

installation instructions.

b. Check wiring of relay in towed vehicle to

insure proper installation.

c. If breakaway device is installed, refer to its

installation instructions.

3. Should dash light activate while turning,

corrective action must be taken. "STOP" the RV to

investigate.

292-2215 7/02 1 of 10

Loading...

Loading...