Blue Max Global Arf Instructions For Assembly And Use

40 - 46 Size Almost Ready to Fly

Instructions for Final Assembly

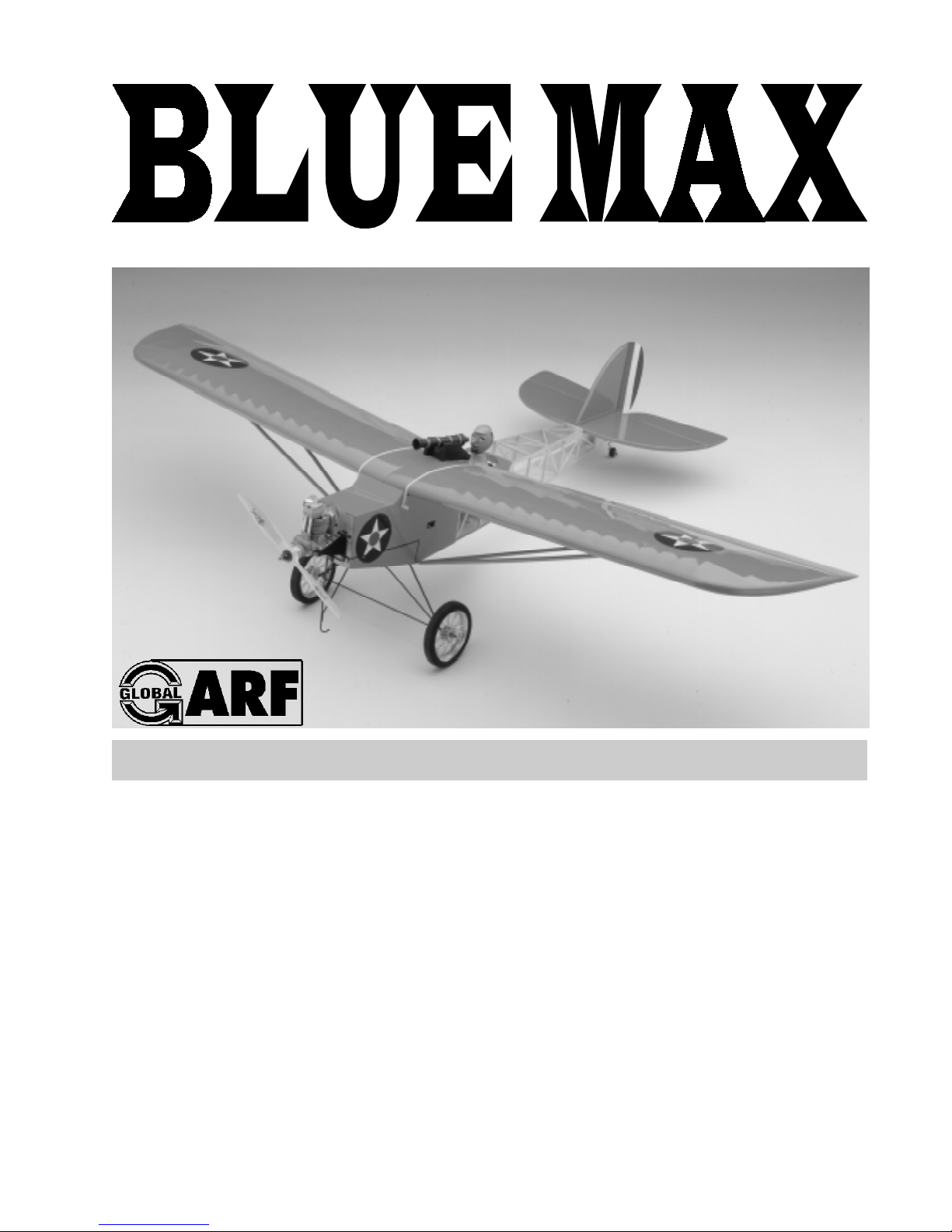

Commemorate the Aviation's beginnings with the new Global Blue Max ARF.

A time when the nose skid was as important as the tail skid to safety minded

pilots landing on unprepared airfields, planes of this style used cutting edge

technology for their day. The Blue Max remembers those years long past. It's

open cockpit, wire spoke wheels and open framework capture a more experimental time in aviation. The high lift wing and generous wing area mean

super slow stall speed and very forgiving flight characteristics. Don't be surprised if you see beginners with this plane. Our test pilots say this plane is

easier to fly than most .40 size trainer planes. And unlike the grossly underpowered airplanes of yesteryear, the Blue Max is favorably powered using a

.40 size two stroke or a .52 size four stroke. So put on your scarf and your

goggles and get ready to go back into time. Oh, and don't forget to load that

cannon!

Version V1.0 4-99 Kit # 232500 All Contents © Copyright 1999

1

TABLE OF CONTENTS

Kit Contents...................................................3

Additional Items Required................................3

Tools and Supplies Needed..............................3

Field Support Equipment Needed......................3

Metric Conversion Chart.................................3

Wing Assembly...............................................4

Install the Dihedral Braces.........................4

Joining the Wing Halves.............................5

Wing Mounting................................................5

Install the Wing Hold Down Dowels...........5

Aligning the Wing to the Fuselage...............6

Install the Wing Struts................................6

Horizontal Stabilizer Mounting..........................6

Align the Horizontal Stabilizer.....................6

Mounting the Horizontal Stabilizer...............7

Vertical Stabilizer Mounting..............................8

Align the Vertical Stabilizer........................8

Mounting the Vertical Stabilizer..................8

Control Surface Installation..............................8

Hinge the Ailerons....................................8

Hinge the Elevator....................................9

Install the Tail Wheel Wire.........................9

Hinge the Rudder......................................9

Mounting the Tail Wheel Bracket.............10

Installing the Tail Wheel...........................10

Main Landing Gear........................................10

Aligning the Main Gear Assembly............10

Installing the Main Gear Assembly...........10

Installing the Main Gear Wheels...............11

Engine Mounting............................................11

Mounting Engine to Motor Mount.............11

Aligning the Motor Mount........................11

Mounting the Engine to Firewall...............12

Nose Skid.....................................................12

Align the Nose Skid.................................12

Installing the Nose Skid............................12

Fuel Tank......................................................13

Fuel Tank Assembly................................13

Fuel Tank Installation...............................13

Throttle Linkage............................................14

Installing the Throttle Linkage..................14

Servo Installation...........................................14

Installing the Fuselage Servo Tray............14

Installing the Aileron Servo Tray...............14

Installing the Aileron Servo......................15

Installing the Fuselage Servos..................15

Throttle Connector........................................15

Installing the Throttle Connector...............15

Rudder Pushrod............................................16

Installing the Rudder Control Horn...........16

Installing the Rudder Pushrod..................16

Elevator Pushrod..........................................17

Installing the Elevator Control Horn..........17

Installing the Elevator Pushrod.................17

Aileron Linkage............................................18

Installing the Aileron Linkage...................18

Pilot and Cannon...........................................19

Barrel Seat Assembly..............................19

Pilot and Cannon Assembly......................19

Barrel Seat Installation.............................20

Pilot Installation.......................................20

Cannon Installation..................................20

Final Assembly..............................................21

Installing the Receiver and Battery...........21

Installing the Switch................................21

Installing the Fuel Lines...........................21

Installing the Propeller.............................21

Balance........................................................21

Lateral Balance......................................22

Control Throws.............................................22

Flight Preparation..........................................22

Preflight Check.......................................23

Basics of Flight.............................................23

Product Evaluation........................................26

Global guarantees this kit to be free from defects in both material and workmanship, at the date of purchase. This does

not cover any components parts damaged by use, misuse or modification. In no case shall Global's liability exceed the

original cost of the purchased kit.

In that Global has no control over the final assembly or material used for final assembly , no liability shall be assumed for

any damage resulting from the use by the user of the final user-assembled product. By the act of using the final userassembled product, the user accepts all resulting liability.

T o make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgable help

with assembly and during your first flights. Your local hobby shop has information about flying clubs in your area

whose membership includes qualified instructors. You can also contact the AMA at the address below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN. 47302-9252

(800) 435-9262

www.modelaircraft.or g

2

This instruction manual is designed to help you build a straight, great flying airplane. Please read this

manual thoroughly before beginning assembly of your new Blue Max. Use the parts listing below to

identify and separate all parts before beginning assembly .

** KIT CONTENTS** W e have organized the parts as they come out of the box for better identification

during assembly . W e recommend you regroup the parts in the same manner. This will ensure you have all

of the parts required before you begin assembly and will also help you familiarize yourself with each part.

KIT CONTENTS

AIRFRAME ASSEMBLIES

o {2} Wing Halves w/Ailerons and Hinges

o {1} Fuselage

o {1 } Horizontal Stabilizer w/Elevator and Hinges

o { 1} Vertical Stabilizer w/Rudder and Hinges

o {2} Wing Struts

MAIN GEAR ASSEMBL Y

o {1 } W ire Main Gear Assembly

o { 1 } Wire Nose Skid

o { 2 } Nylon Mounting Straps w/4mm Slot

o { 5 } Nylon Mounting Straps w/3mm Slot

o { 2} 127mm Diameter W ire Spoke Wheels

o {2 } Nylon Axle Spacers

o { 2} Wheel Collars w/3mm x 6mm Machine Screws

o {14} 3mm x 12mm W ood Screws

TAIL WHEEL ASSEMBL Y

o {1 } T ail Wheel W ire w/ Mounting Bracket

o { 1} 25mm Diameter T ail Wheel

o {2 } Wheel Collars w/3mm x 6mm Machine Screws

o {3 } 3mm x 12mm Wood Screws

ELEV A T OR CONTROL SYSTEM

o {1 } 990mm Nylon Pushrod

o {1 } 1.5mm x 50mm Threaded Wire w/Z-Bend

o {1 } 1.5mm x 45mm Wire Threaded Each End

o {1 } Nylon Clevis w/1.5mm I.D. Hole

o {1 } Nylon Control Horn

o { 1 } Nylon Control Horn Backplate

o {2 } 2mm x 15mm Machine Screws

RUDDER CONTROL SYSTEM

o {1 } 990mm Nylon Pushrod

o {1 } 1.5mm x 50mm Threaded Wire w/Z-Bend

o {1 } 1.5mm x 45mm Wire Threaded Both Ends

o {1 } Nylon Clevise w/1.5mm I.D. Hole

o {1 } Nylon Control Horn

o { 1 } Nylon Control Horn Backplate

o {2 } 2mm x 15mm Machine Screws

THROTTLE CONTROL SYSTEM

o {1} 2mm x 300mm Pushrod W ire

o {1} Adjustable Servo Connector Assembly

AILERON CONTROL SYSTEM

o {2 } Nylon Clevises w/2mm I.D. Hole

o {2 } 2mm x 150mm Threaded Rod

o {2} Nylon Snap Keepers

o {2} Nylon Adjustable Control Horns

MOTOR MOUNT ASSEMBLY

o {2} Nylon Motor Mount Beams

o {4 } 3mm x 25mm Machine Screws

o {4} 3mm x 20mm Machine Screws

o {4 } 3mm Nylon Insert Nuts

o { 4} 3mm Blind Nuts

o {12} 3mm Flat W ashers

MISCELLANEOUS ITEMS

o { 1} Aileron Servo Tray (W-39)

o { 1} Forward Dihedral Brace (W-40)

o {1 } Rear Dihedral Brace (W-41)

o {2 } W ing Hold Down Dowels (W-43)

o { 1} Fuselage Servo Tray (D-47)

o {6 } 3mm x 10mm Machine Screws

o {6 } 3mm Flat W ashers

o {4 } 3mm x 12mm W ood Screws

FUEL T ANK

o {1 } Molded Fuel Tank

o { 1 } 20mm Front Squash Plate

o { 1} 18mm Rear Squash Plate

o { 1} Rubber Stopper

o {1 } 70mm Length of Fuel Tubing

o { 1 } Metal W eighted Pick-Up

o { 3 ) Aluminum Tubes

o {1 } 3mm x 20mm Machine Screw

PILOT AND CANNON ASSEMBL Y

o {1} Prepainted Balsa Cannon Mount

o {2} Plastic Body Halves

o {2} Plastic Cannon Halves

o {2 } Plastic Head Halves

o { 1} Balsa Barrel Seat Platform

o {1 } Plastic Barrel Seat

o { 1} Plastic Barrel Seat Back

3

ADDITIONAL ITEMS REQUIRED

o {1}Hitec 4 or More Channel Radio w/4 Servos

o {1}Dubro Foam Rubber # 513

o {1}Global Fuel Line # 115923

o {1}Arco # 64 Rubber Bands # 24649

FOR 2-STROKE ENGINE

o {1}Magnum XL .40-.46 T wo Stroke

o {1}Magnum 1/4” Spinner Nut # 237310

o {1}Propeller T o Suit Engine

o {1}Thunderbolt Glow Plug # 115493

TOOLS AND SUPPLIES NEEDED

o Kwik Bond Thin C/A # 887500

o Kwik Bond Thick C/A # 887510

o Kwik Bond 5 Minute Epoxy # 887560

o Kwik Bond 30 Minute Epoxy # 887565

o Wilhold Silicon Sealer # 00684

o Electric Drill

o Assorted Drill Bits

o Modeling Knife

o Wire Cutters

o Machine Oil or V aseline

FOR 4-STROKE ENGINE

o {1}Magnum XL .52RFS Four Stroke

o {1}Magnum 1/4” Spinner Nut # 237310

o {1}Propeller T o Suit Engine

o {1}Thunderbolt Glow Plug # 115490

o Straight Edge Ruler

o Dremel Tool w/Assorted Bits

o Phillips Screwdriver

o Z-Bend Pliers

o 3mm Hex Wrench

o Builders Triangle

o 220 Grit Sandpaper

o Masking T ape

o Paper T owels

o Rubbing Alcohol

TO FINISH PILOT AND CANNON

o T estors Contour Putty # 3511X

o 320 Grit Sandpaper

o Find & Medium Paint Brushes

o 3M Fine Line Masking Tape # 218-06300

o Coverite Flat Clear Paint # COVR1280

o Paint Thinner

o Tan, White, Brown and Orange - Mix to

make skin color and lip color

FIELD SUPPORT EQUIPMENT NEEDED

o Magnum 12V Electric Starter (# 361006)

o Magnum 12V Fuel Pump (# 237377)

o Magnum Locking Glow Clip (# 237440)

o Global 12V Battery (# 110171 )

METRIC CONVERSION CHART

T o convert inches into millimeters: Inches x 25.4 = MM

1/64” = .4mm

1/32” = .8mm

1/16” = 1.6mm

3/32” = 2.4mm

1/8” = 3.2mm

5/32” = 4.0mm

3/16” = 4.8mm

1/4” = 6.4mm

3/8” = 9.5mm

1/2” = 12.7mm

5/8” = 15.9mm

3/4” = 19.0mm

o Flat Black - Eyebrows, Mustache, Hair

and Cannon

o White and Blue - Eyes

o Light Blue - Body

o Gold - Simulate Buttons and Straps of Jacket

o Brass - Cannon Trim

o Brown - Cannon Barrel Seat

o Global 12V Charger (# 110270 )

o Magnum Power Panel (# 237390)

o Global Field Buddy Flight Box (# 233072)

o Magnum 4-Way Wrench (# 237420)

1 ” = 25.4mm

2 ” = 50.8mm

3 ” = 76.2mm

6 ” = 152.4mm

12 ” = 304.8mm

18 ” = 457.2mm

21 ” = 533.4mm

24 ” = 609.6mm

30 ” = 762.0mm

36 ” = 914.4mm

4

If you should find a part missing or have questions about assembly , please call or write to the address below:

Customer Service Center

18480 Bandilier Circle

Fountain V alley , CA. 92728

Phone: (714) 963-0329

Fax: (714) 964-6236

E-Mail: globalhobby@earthlink.net

**SUGGESTION** To avoid scratching your new airplane, do not unwrap the pieces until they are

needed for assembly . Cover your workbench with an old towel or brown paper , both to protect the aircraft

and to protect the table. Keep a couple of jars or bowls handy to hold the small parts after you open the

bags.

**NOTE** Please trial fit all the parts. Make sure you have the correct parts and that they fit and are

aligned properly before gluing! This will assure proper assembly . Since the Blue Max is hand made from

natural materials, every plane is unique and minor adjustments may have to be made. However, you

should find the fit superior and assembly simple.

WING ASSEMBLY

PARTS REQUIRED

o {2} Wing Halves w/Ailerons and Hinges

o {1 } Forward Dihedral Brace (W-40)

o {1 } Rear Dihedral Brace (W-41)

INST ALL THE DIHEDRAL BRACES

o 1) Look at the face of each root rib on both

wing halves. Notice how the excess covering material overlaps onto them. Using a modeling knife,

carefully cut away the covering from both of the

root ribs. Leave about 1/16” of covering overlapping so it does not pull away .

It is important that the covering be removed

from the root ribs. This will ensure an adequate wood-to-wood glue joint and prevent

wing failure during flight.

o 2) Using a ruler and a pen, locate and mark

the center section of the forward and rear dihedral braces (W-40 and W-41). Draw a vertical

line at this location on both braces. See photo

# 1 below .

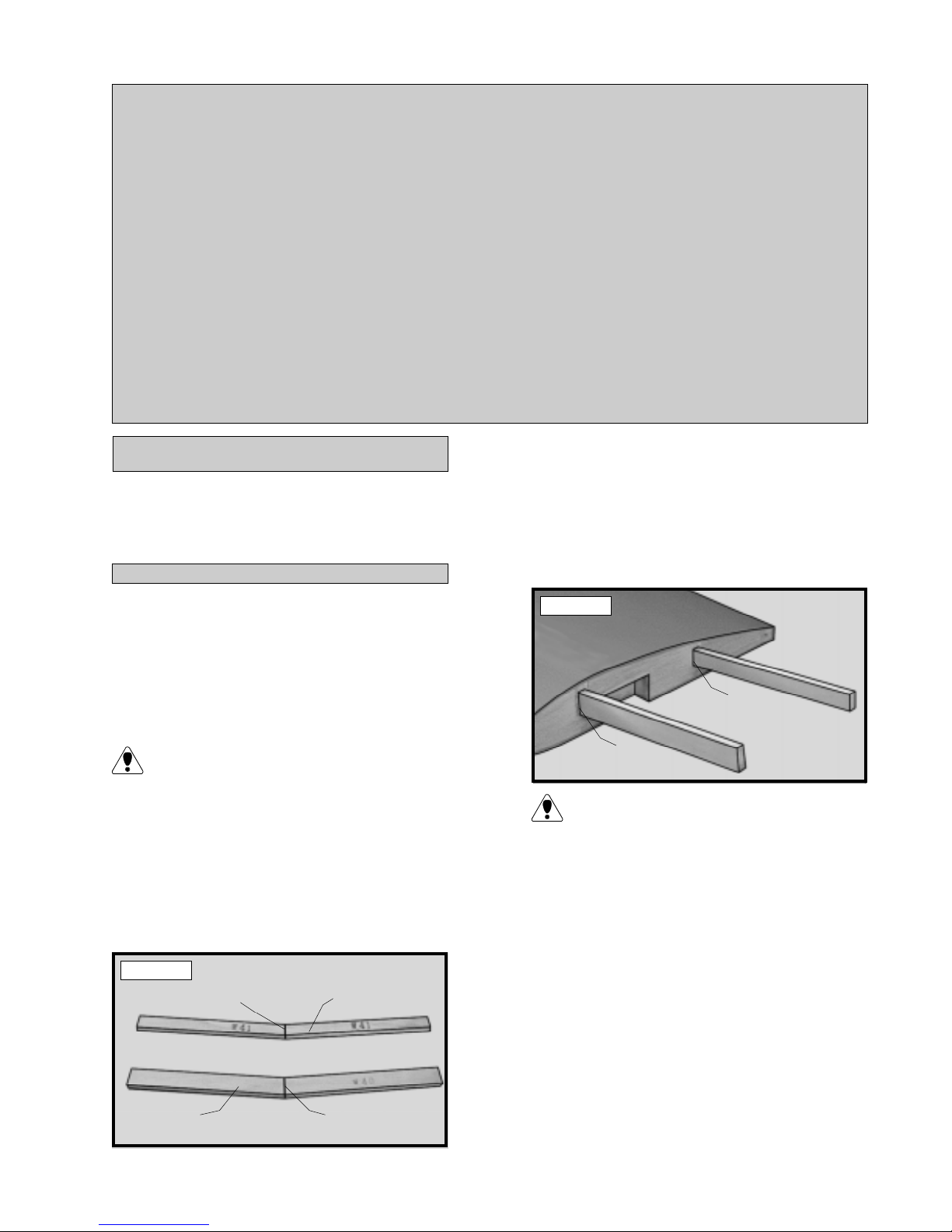

Photo # 1

DRAW CENTERLINE

REAR

DIHEDRAL

BRACE

o 3) T est fit the dihedral braces into their respective boxes in each wing half. W-40 fits into

the forward box and W-41 fits into the rear box.

The braces should slide into each wing half up to

the centerlines. If they do not, remove them and

lightly sand the edges and tip of each one until the

proper fit is obtained. See photo # 2 below .

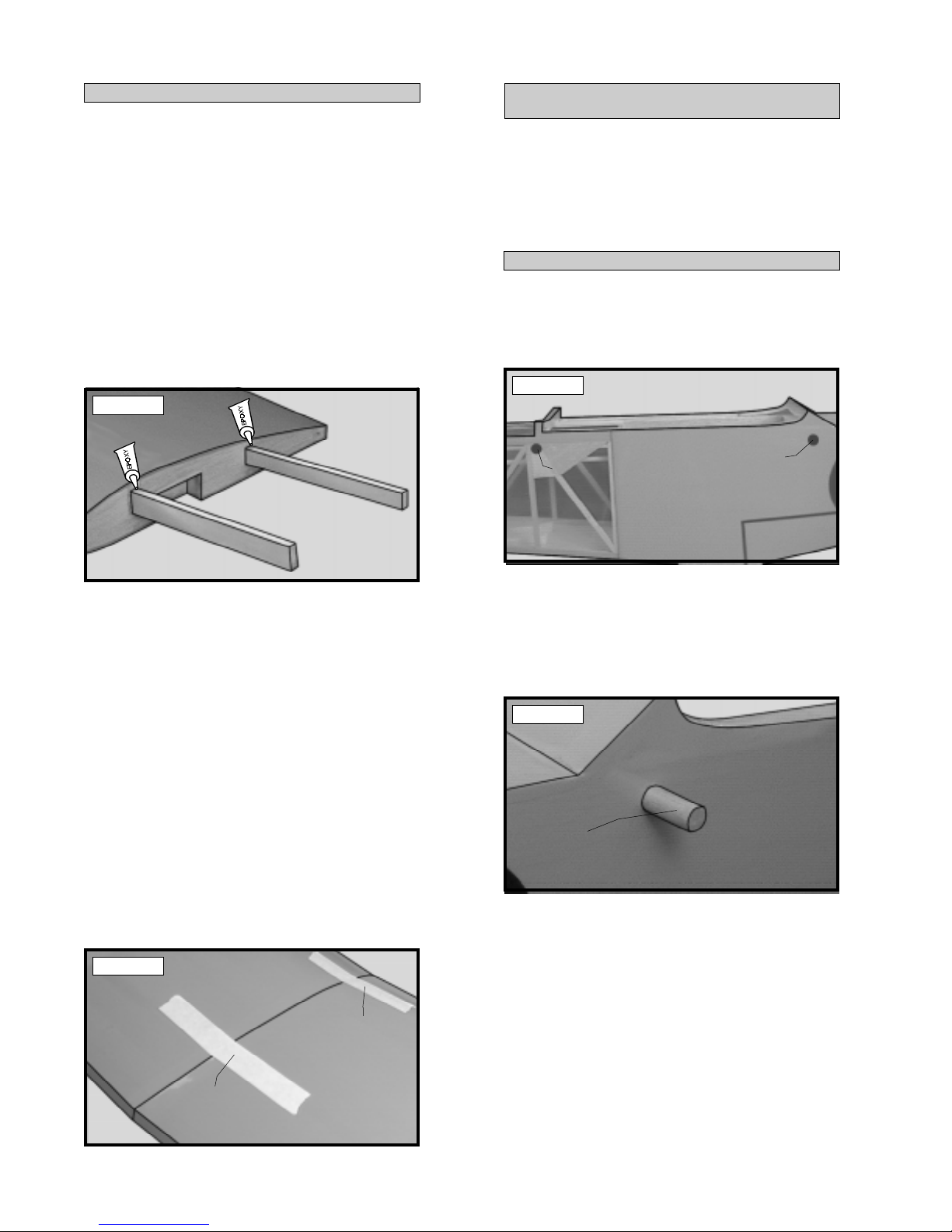

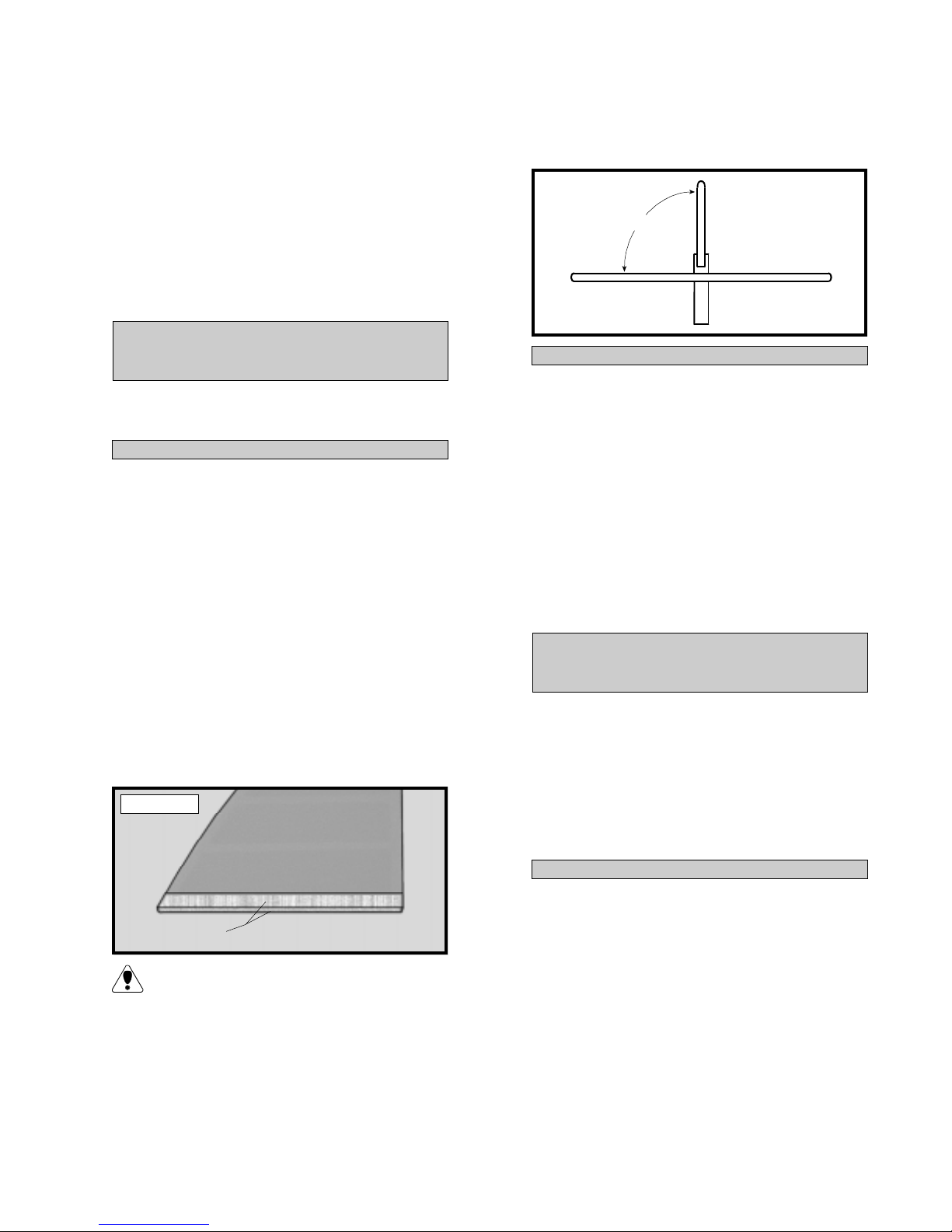

Photo # 2

SLIDE IN UP

TO CENTERLINE

SLIDE IN UP

TO CENTERLINE

The dihedral braces are cut in the shape of

a "V". They should be installed with the "V"

shape facing upright to form the proper dihedral

angle when the wings are joined.

o 4) T est fit both of the wing halves together

with the dihedral braces temporarily installed. Do

not glue them in at this time! The wing halves

should fit together tightly with little or no gaps in the

center section joint. If the center section joint is

not tight, remove the wing halves and lightly sand

the edges and tips of each brace. Reinstall the

wing halves and braces and test the fit until you are

satisfied that the center section joint is tight.

FORW ARD

DIHEDRAL

BRACE

DRAW CENTERLINE

o 5) When satisfied with the fit of the wing

halves, remove the dihedral braces.

5

JOINING THE WING HAL VES

o 6) Mix a generous amount of Kwik Bond

30 Minute Epoxy . W orking with only one wing

half for now , apply a thin layer of epoxy inside

both dihedral brace boxes and on only half of

each dihedral brace. Make sure to cover the top

and bottom as well as the sides and use enough

epoxy to fill any gaps.

WING MOUNTING

PARTS REQUIRED

o {1 } Fuselage

o { 2 } Wing Hold Down Dowels (W-43)

o {2} Wing Struts

o {6 } 3mm x 10mm Machine Screws

o {6 } 3mm Flat Washers

INSTALL THE WING HOLD DOWN DOWELS

o 7) Slide the dihedral braces into the boxes

up to the centerlines. Remove any excess epoxy

before it dries using a paper towel and rubbing

alcohol. Allow the epoxy to cure before proceeding. See photo # 3 below.

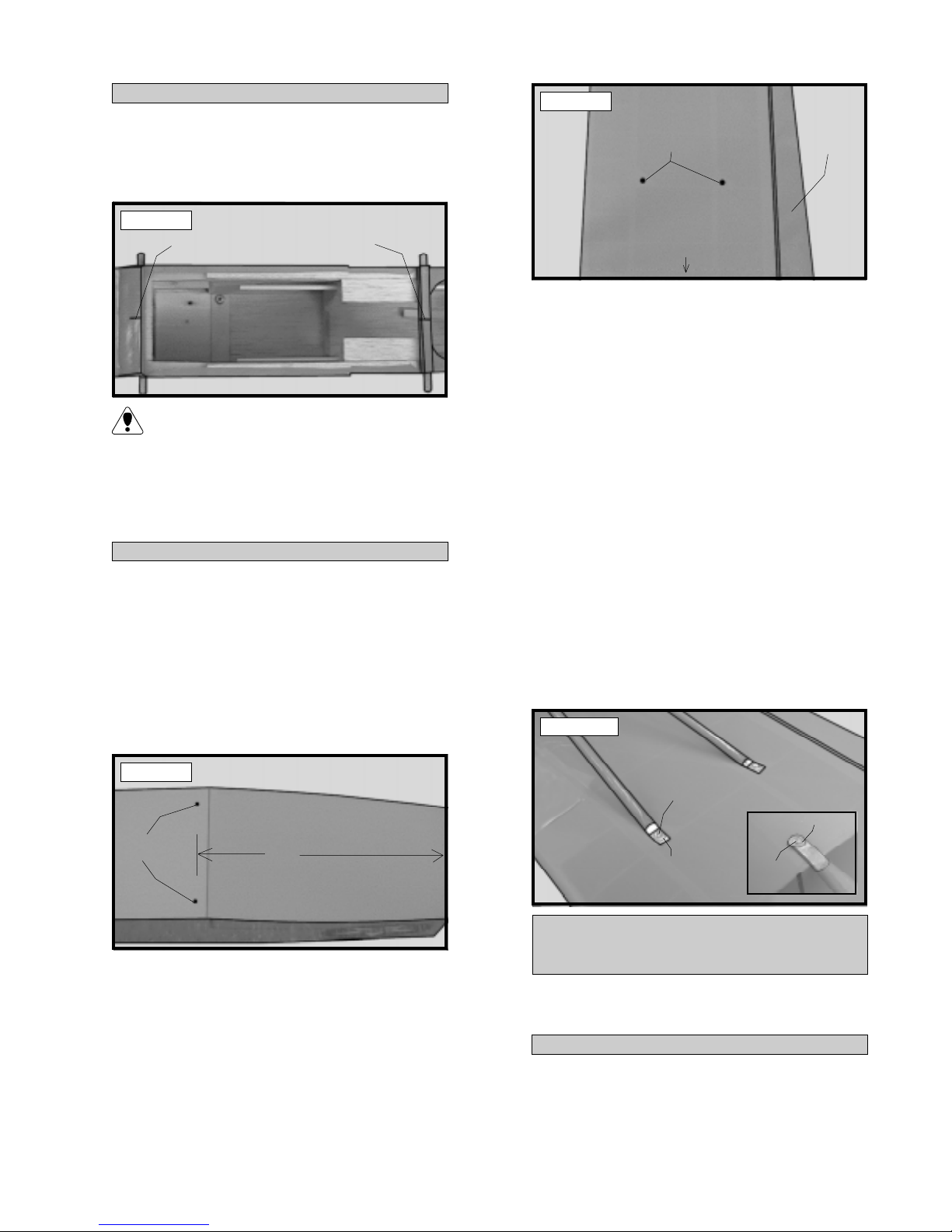

Photo # 3

o 8) Once the epoxy has cured, trial fit both

wing halves together to double check that the wing

halves still fit correctly .

o 9) Mix a generous amount of Kwik Bond 30

Minute Epoxy . Apply a thin layer of epoxy to the

exposed halves of both dihedral braces, the inside

of both dihedral brace boxes i n the second wing

half and the entire surface of both root ribs. Make

sure to use enough epoxy to fill any gaps.

o 1) Using a modeling knife, carefully remove

the covering from over the four predrilled holes in

the fuselage sides. T wo holes are located on each

side of the fuselage. See photo # 5 below .

Photo # 5

REMOVE COVERING

REMOVE COVERING

(both sides)

(both sides)

o 2) Slide one wing hold down dowel through

the two forward holes in the fuselage sides and

the second dowel through the two rear holes in

the fuselage sides. Adjust the dowels so both

ends of each dowel protrude from the fuselage

sides an equal amount. See photo # 6 below.

Photo # 6

o 10) Slide the two wing halves together and

carefully align them at the leading and trailing edges.

Wipe away any excess epoxy using a paper towel

and rubbing alcohol. Use masking tape to hold the

wing halves in place until the epoxy cures. See

photo # 4 below .

Photo # 4

MASKING

TAPE

MASKING

TAPE

WING HOLD

DOWN DOWEL

o 3) When satisfied with the fit, use a pen and

place a mark on each dowel at the point where

they exit the fuselage sides.

o 4) Remove the dowels and mix a small

amount of Kwik Bond 30 Minute Epoxy . Apply

a thin layer of epoxy to the inside edges of all four

holes in the fuselage. Carefully slide the dowels

into place up to the marks made. Double check

that they are centered and use paper towels and

rubbing alcohol to remove any excess epoxy before it cures.

6

ALIGNING THE WING TO THE FUSELAGE

o 5) Using a ruler and a pen, locate and mark

the centerline of the fuselage at both the front and

rear of the wing saddle. Place a mark at both

locations. See photo # 7 below .

Photo # 7

MARK

CENTERLINE

MARK

CENTERLINE

Photo # 9

REMOVE COVERING

WING TIP

AILERON

o 8) Place the wing into the wing saddle. Align

the centerline of the wing at both the leading and

trailing edges with the two marks you made on

the fuselage.

These two marks will help you align the wing

when you install it on the fuselage. Y ou may

wish to make these marks in permanent ink so

you can align the wing correctly each time you

install the wing. This will ensure the wing is aligned

properly each time you fly the airplane.

INST ALL THE WING STRUTS

o 6) There are two preinstalled blind nuts that

are used to mount the wing struts to the bottom

of the fuselage. Using a modeling knife, carefully remove the covering from over the two blind

nut holes on the bottom of the fuselage. The

holes are located 1/2” in from the fuselage sides

and 8-1/4” back from the front of the firewall.

See photo # 8 below .

Photo # 8

REMOVE

COVERING

8-1/4”

o 9) Using a couple of # 64 rubber bands,

temporarily secure the wing in place making sure

it is aligned. T o correctly install the rubber bands,

hook one over one of the front wing hold down

dowels, carefully pull it back over the top of the

wing and hook it over the rear hold down dowel

on the same side. Install two rubber bands on

each side for now .

o 10) Bolt the wing struts to the wing and to

the fuselage using the six 3mm x 6mm machine

screws and six 3mm flat washers. It may be

necessary to move the wing slightly to properly

align the holes in the struts with the blind nuts.

See photo # 10 below .

Photo # 10

3mm x

6mm

SCREW

3mm FLAT

WASHER

3mm FLATWASHER

3mm x 6mm

SCREW

o 7) There are also two blind nuts preinstalled in

each wing half. They are located in plywood gussets, 20” out from the centerline of the wing. The

rear blind nut is 2-3/4” forward of the trailing edge

and the front blind nut is 3” back from the leading

edge. Using a modeling knife, carefully remove the

covering from over the two blind nut holes in each

wing half. See photo # 9 at top right.

HORIZONTAL STABILIZER

MOUNTING

PARTS REQUIRED

o {1} Horizontal Stabilizer w/Elevator and Hinges

ALIGN THE HORIZONT AL STABILIZER

o 1) Remove the elevator from the horizontal

stabilizer and set it aside for now . Turn the stabilizer upside down on your work surface. The bottom side is the flat side and should be facing up.

7

o 2) Using a ruler and a pen, locate and mark

the centerline of the horizontal stabilizer at the

trailing edge and place a mark. Use a triangle

and extend this mark, from back to front, across

the bottom of the stabilizer. Also place centerline marks on the top of the stabilizer at the leading

and trailing edges only. See photo # 11 below .

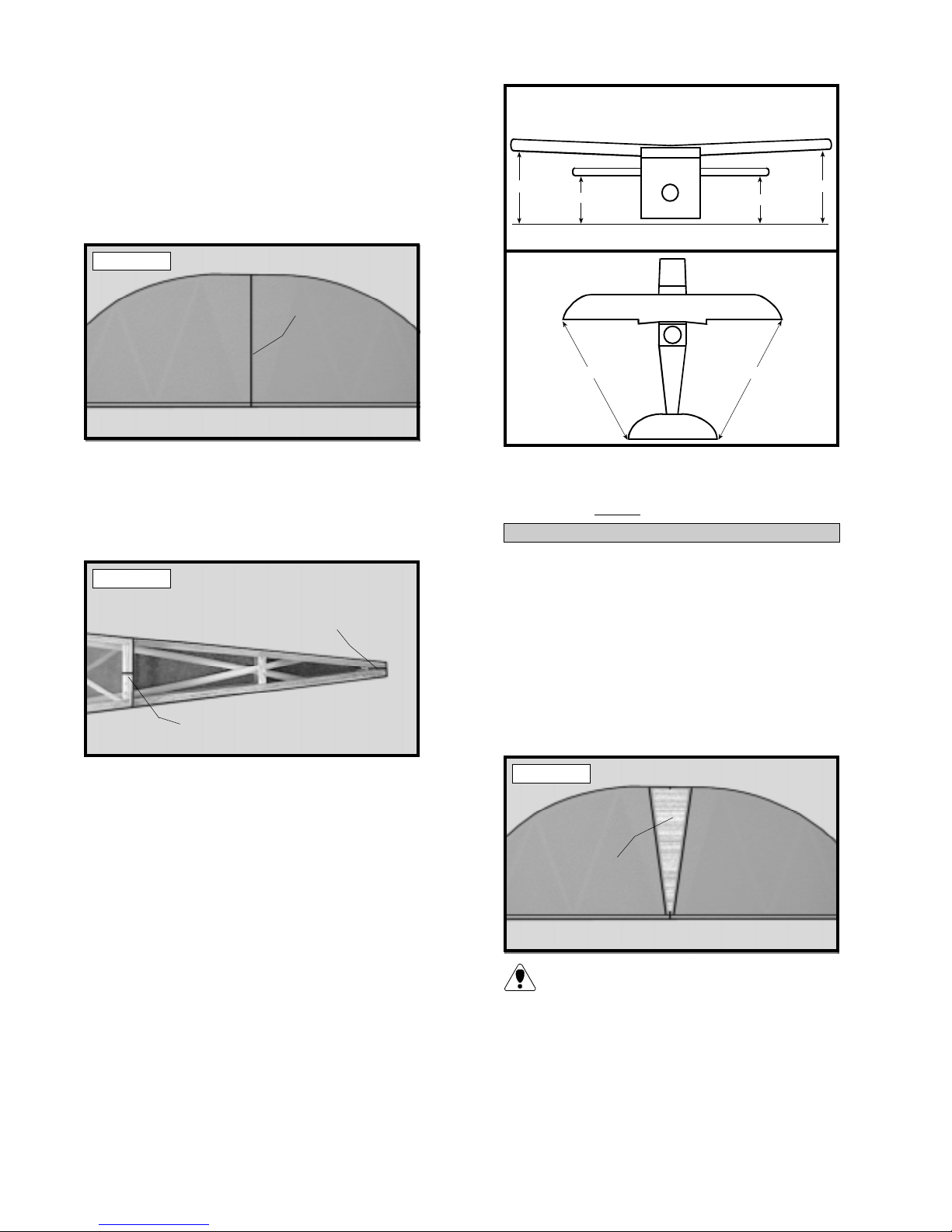

Figure # 1

B

A

A1

B1

Photo # 1 1

DRA W

CENTERLINE

o 3) Using a ruler and a pen, locate and place

a mark at the centerline of the fuselage at the front

and rear of the stabilizer mounting platform. These

marks will be used to line up the stabilizer with

the fuselage. See photo # 12 below .

Photo # 12

DRA W

CENTERLINE

DRAW

CENTERLINE

Figure # 2

C

C1

o 5) When you are satisfied with the alignment,

hold the stabilizer in place with T- pins or masking tape, but do not glue at this time.

MOUNTING THE HORIZONT AL STABILIZER

o 6) With the stabilizer held firmly in place, use

a pen and draw a line on the stabilizer where it

and the fuselage sides meet. Do this on both the

right and le ft sides on the bottom of the stabilizer.

o 7) Remove the stabilizer. Using the lines you

just drew as a guide, carefully remove the covering

from between them, using a modeling knife. See

photo # 13 below.

o 4) Attach the wing to the fuselage and remove both ailerons. Set the horizontal stabilizer

onto the stabilizer mounting platform on the fuselage. Align the centerline marks on top of the

stabilizer with the centerline marks at the front

and rear of the stabilizer mounting platform. When

the marks are aligned hold the stabilizer in position using a couple of T-pins. Align the horizontal

stabilizer with the wing. When viewed from the

rear, the horizontal stabilizer should be level with

the wing. If it is not level, use sandpaper and

sand down the high side of the stabilizer mounting platform until the proper alignment is achieved.

The tips of the stabilizer should also be equal distance from the tips of the wing. See figures # 1

and # 2 at top right.

Photo # 13

REMOVE

COVERING

When cutting through the covering to re-

move it, cut with only enough pressure to

only cut through the covering itself. Cutting into

the balsa structure may weaken it and cause possible failure in flight.

8

o 8) When you are satisfied that everything is

aligned correctly , mix up a generous amount of

Kwik Bond 30 Minute Epoxy . Apply a thin layer

to the bottom of the stabilizer mounting area and

to the top of the stabilizer mounting platform on

the fuselage. Set the stabilizer in place and realign. Double check all of your measurements

once more before the epoxy cures. Hold the stabilizer in place with T-pins or masking tape and

remove any excess epoxy using paper towels and

rubbing alcohol.

o 4) Set the vertical stabilizer back in place.

Using a triangle, check to ensure that the vertical

stabilizer is aligned 90º to the horizontal stabilizer .

See figure # 3 below .

Figure # 3

90º

VERTICAL STABILIZER

MOUNTING

PARTS REQUIRED

o {1} V ertical Stabilizer w/Rudder and Hinges

ALIGN THE VERTICAL ST ABILIZER

o 1) Remove the rudder from the stabilizer .

Slide the stabilizer into the slot in the top of the

horizontal stabilizer . The rear edge of the vertical

stabilizer should be even with the rear edge of the

horizontal stabilizer and fuselage. It should also

be pushed down completely into the slot.

o 2) Using a pen, draw a line on each side of

the vertical stabilizer where it meets the top of the

slot on the horizontal stabilizer.

o 3) Remove the stabilizer. Using a modeling

knife, remove the covering from just below the lines

you drew . Also remove the covering from the bottom edge of the stabilizer. See photo # 14 below .

Photo # 14

MOUNTING THE VERTICAL ST ABILIZER

o 5) When you are satisfied that everything is

aligned correctly , mix up a generous amount of

Kwik Bond 30 Minute Epoxy . Apply a thin layer

to the mounting slot in the top horizontal stabilizer

and to the sides and bottom of the vertical stabilizer mounting area. Set the stabilizer in place

and realign. Double check all of your measurements once more before the epoxy cures. Hold

the stabilizer in place with T-pins or masking tape

and remove any excess epoxy using paper towels and rubbing alcohol. Allow the epoxy to fully

cure before proceeding.

CONTROL SURFACE

INSTALLATION

PARTS REQUIRED

o {2} Ailerons w/Hinges

o { 1 } Elevator w/Hinges

o { 1 } Rudder w/Hinges

o { 1 } Tail Wheel W ire w/Mounting Bracket

o { 1} 25mm Diameter Tail Wheel

o {2 } Wheel Collars w/3mm x 6mm Machine Screws

o {3 } 3mm x 12mm W ood Screws

REMOVE

COVERING

When cutting through the covering to re-

move it, cut with only enough pressure to

only cut through the covering itself. Cutting into

the balsa structure may weaken it. There may

also be covering material overlapped on the inside edges of the vertical stabilizer mounting slot

in the horizontal stabilizer . Using a modeling knife,

carefully remove this covering also. This will help

insure a good glue joint.

HINGE THE AILERONS

o 1) The C/A hinges have already been glued

into the two ailerons. W orking with one aileron

at a time, slide the aileron and it's hinges into their

precut hinge slots in the trailing edge of the wing,

making sure the torque rod is firmly seated in the

precut hole in the leading edge of the aileron. Slide

the aileron in until it is tight against the trailing

edge of the wing. The maximum hinge gap should

be no more than 1/32” and the tip of the aileron

should be flush with the tip of the wing.

9

Loading...

Loading...