Page 1

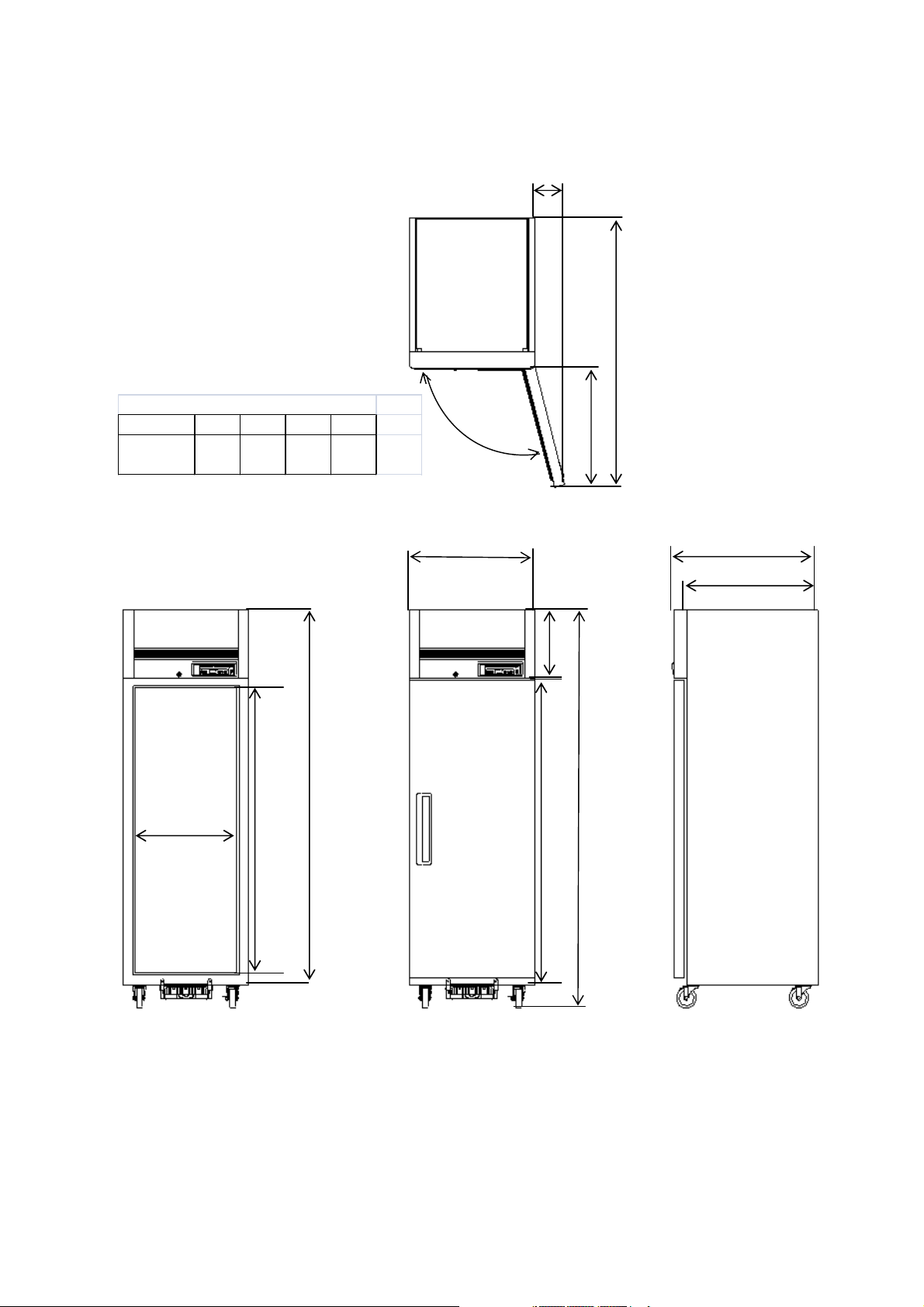

B. Dimensions

1. BSR23T(LRT-23S), BSF23T(LFT-23S)

MODEL

LRT-23S

LFT-23S

1403

(55.2i n)

mm (in)

ABCD

163

617

(6.4in)

(24.7in)

105˚

B

A

D

C

551 (21.7in)

(INSIDE)

1483

(58.4in)

1954

(76.9in)

681 (26.8in)

1549

(61in)

786 (30.9in)

717 (28.2in)

358

(14in)

2077.6

(81.8in)

Page 1

Page 2

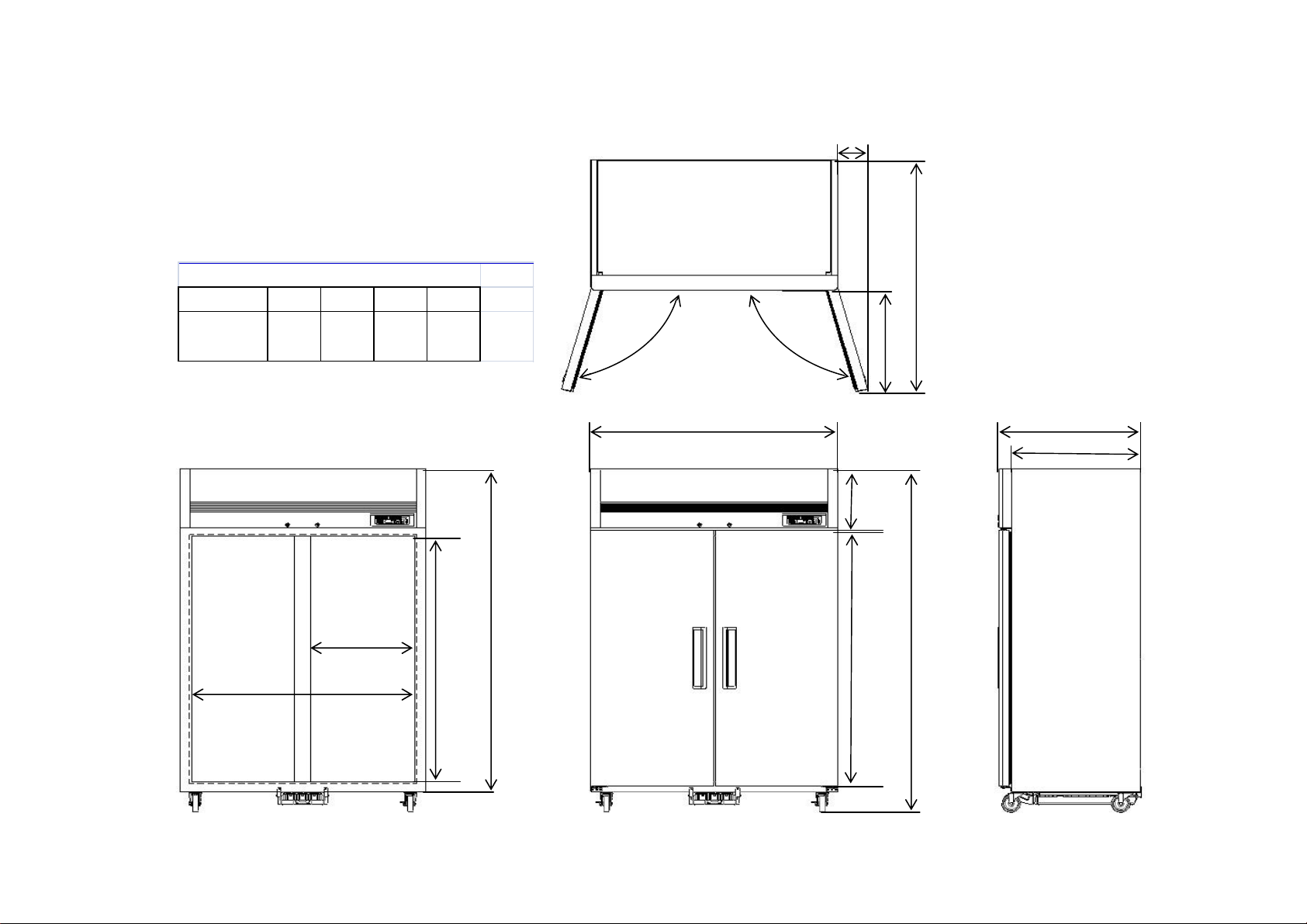

B. Dimensions

1. BSR49T(LRT-49D), BSF49T(LFT-49D)

B

MODEL

LRT-49D

LFT-49D

mm (in)

ABCD

1403

(55.2i n)

163

(6.4in )

573 (22.5in)

(INSIDE)

1240 (48.8in)

(INSIDE)

617

(24.7i n)

105˚

1483

(58.4in)`

1954

(76.9in)

A

D

1370 (53.9in)

D

C

786 (30.9in)

717 (28.2in)

358

(14in)

2077.6

(81.8in)

1549

(61in)

Page 2

Page 3

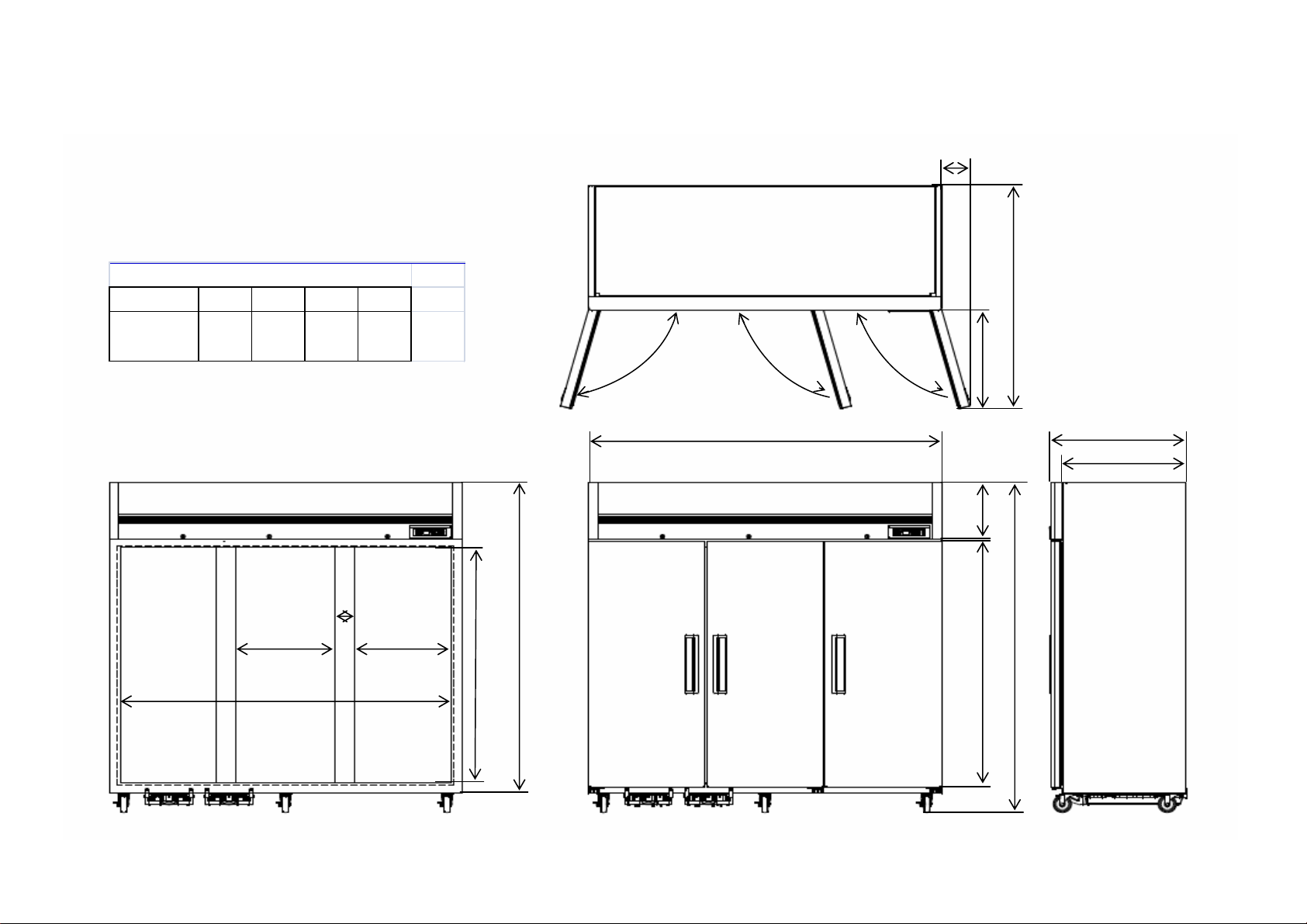

B. Dimensions

1. BSR72T(LRT-72T), BSF72T(LFT-72T)

mm (in)

MODEL

LRT-72T

LFT-72T

ABCD

1403

(55.2i n)

163

(6.4in)

617

(24.7in)

105˚

B

A

D

D D

C

114 (4.5in)

566 (22.3in)

(INSIDE)

1926 (75.8in)

(INSIDE)

566 (22.3in)

(INSIDE)

1483

(58.4in)`

195

4

(76.

9in)

Page 3

2060 (81.1in)

358

(14i

n)

154

9

(61i

n)

786 (30.9in)

717 (28.2in)

207

7.6

(81.

8in)

Page 4

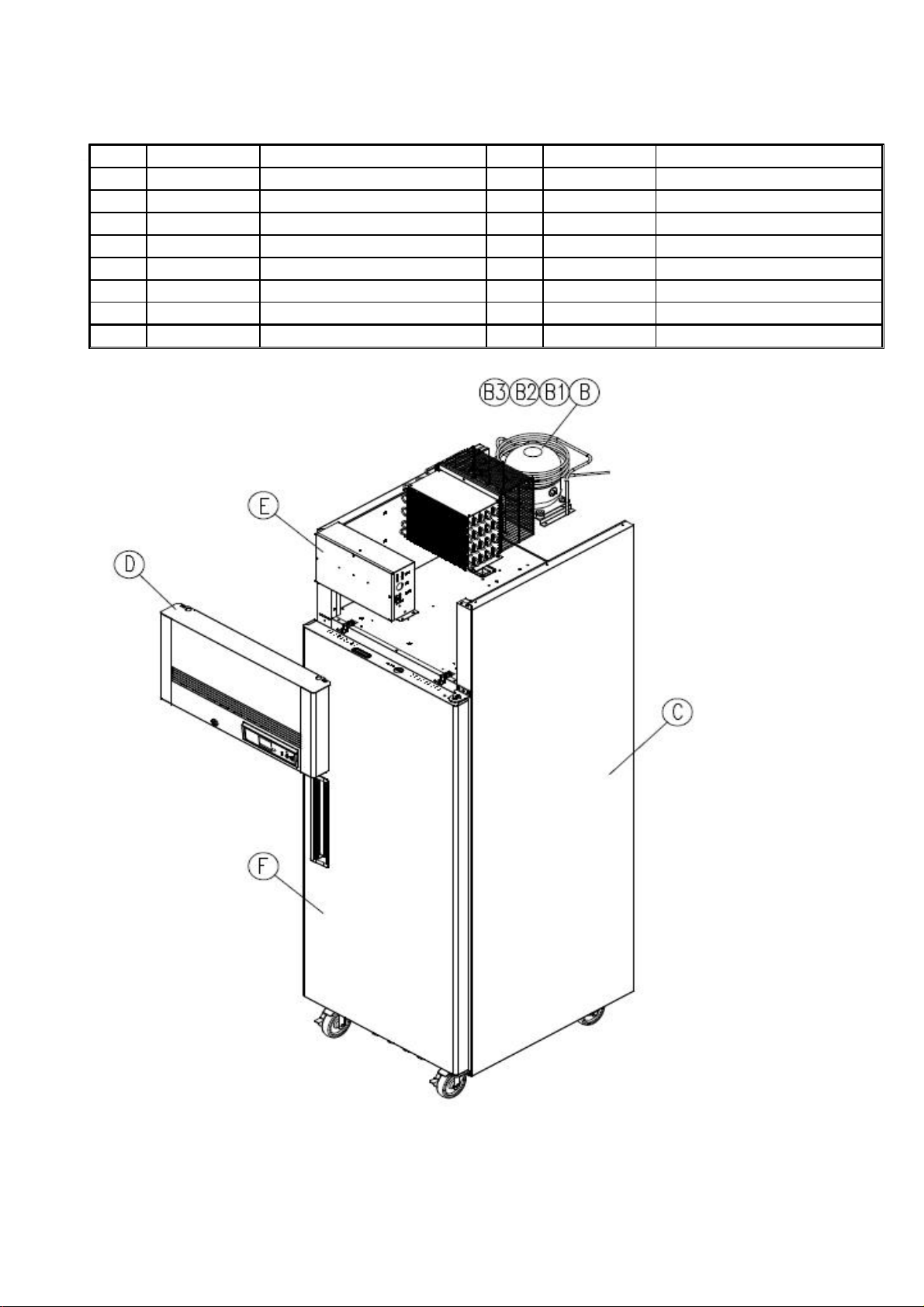

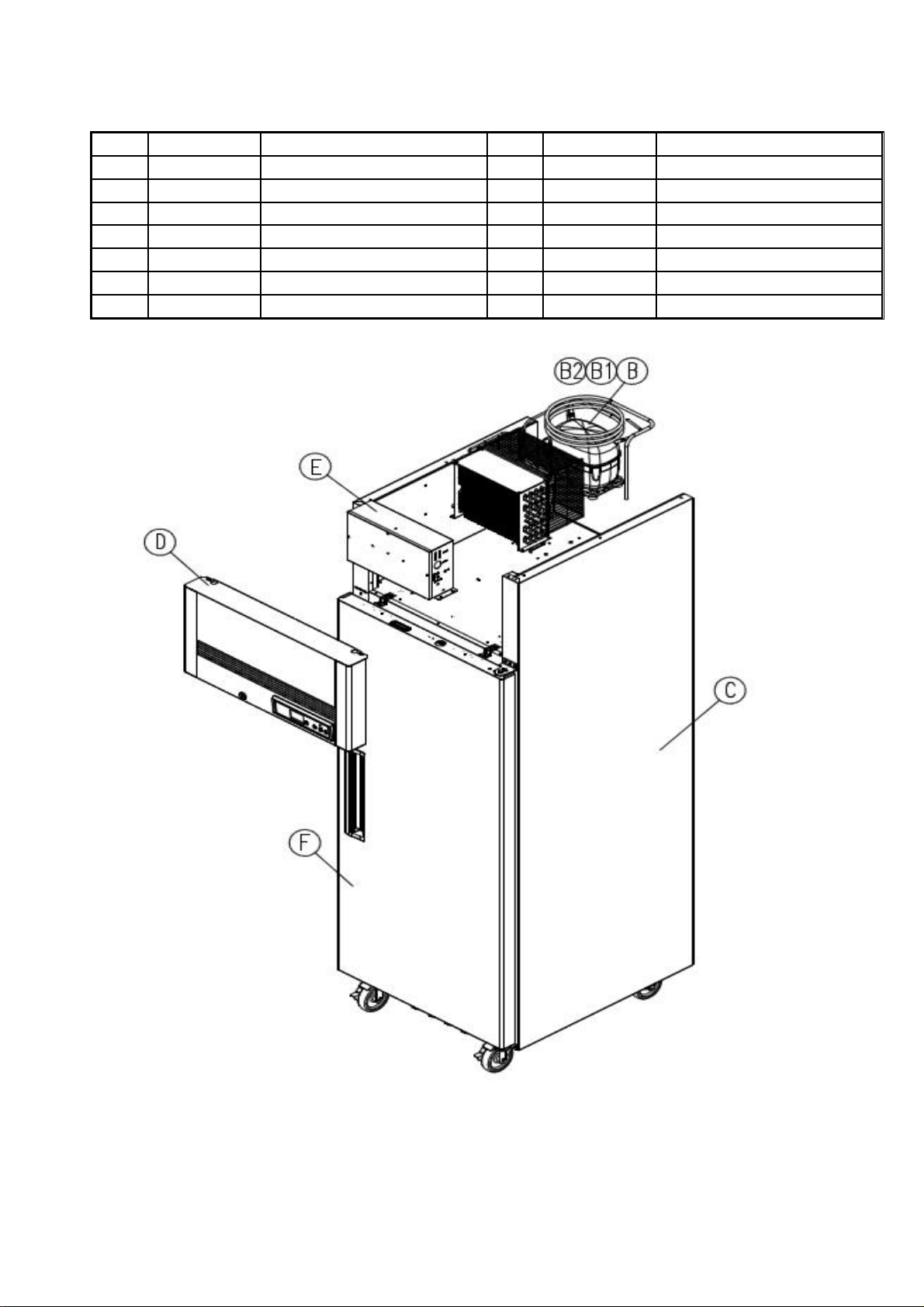

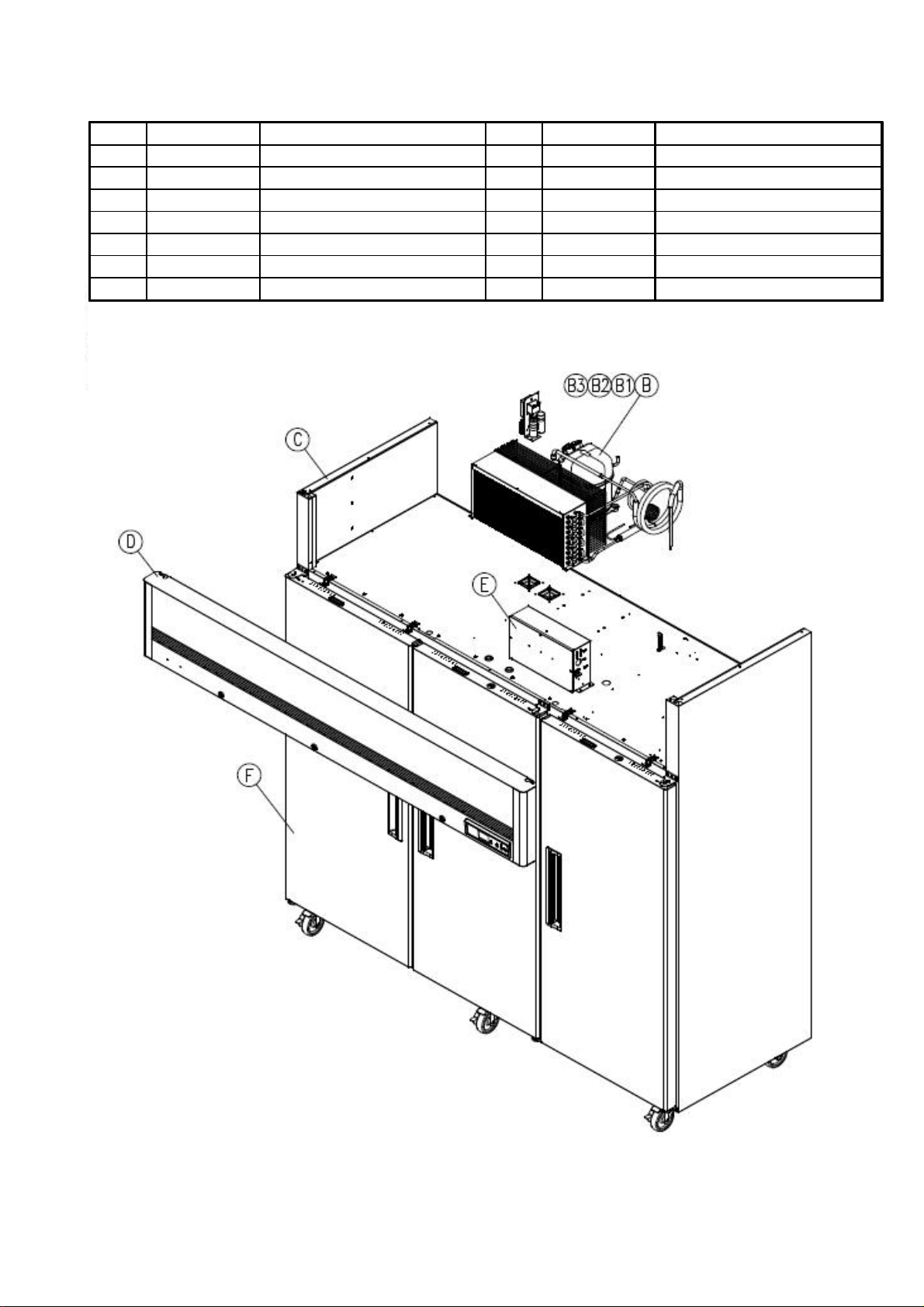

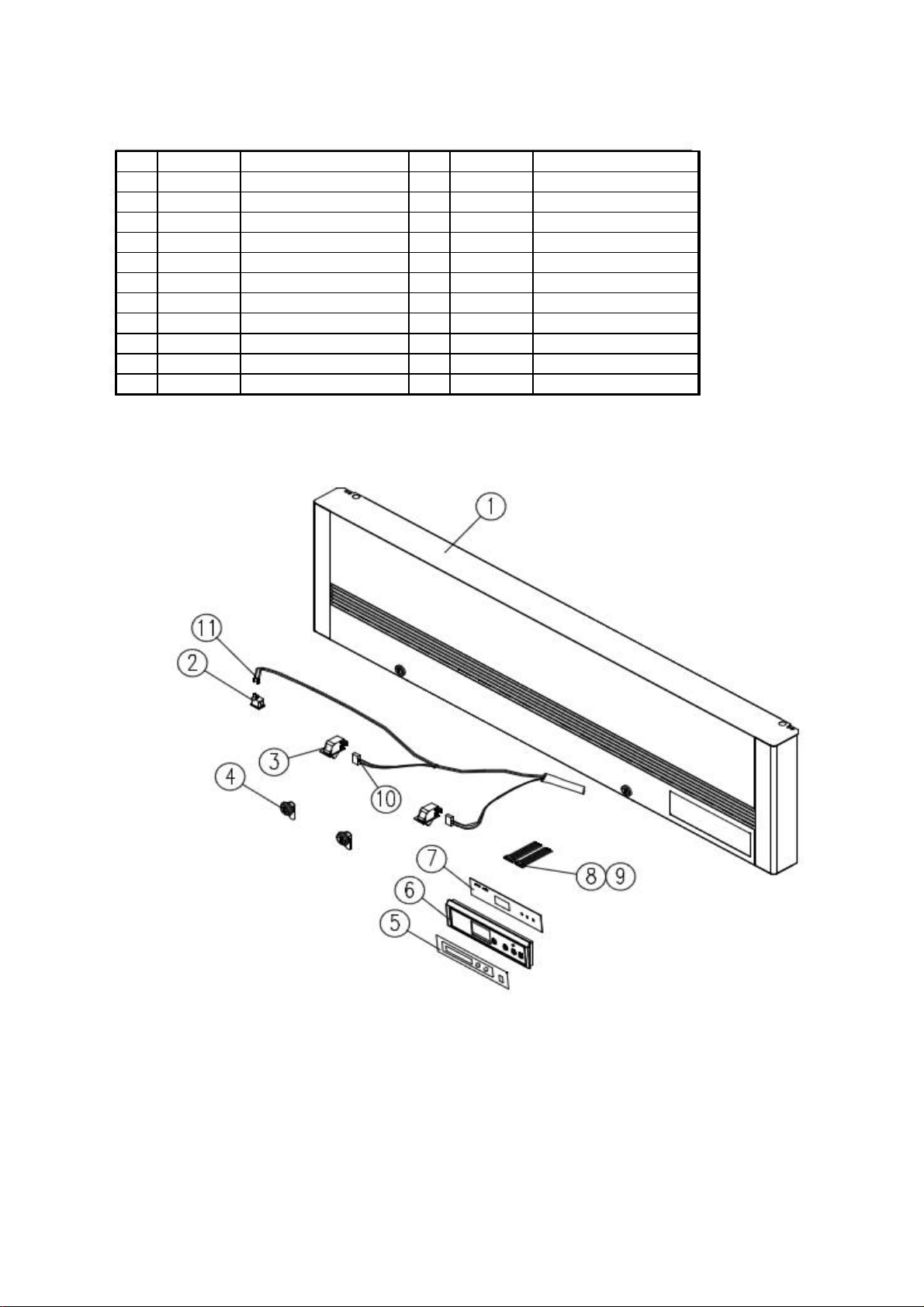

A. Main Assembly

4B24

Ass'

M

0

103-950

Mai

8249-630

ill A

8582-510

3243-040

GIT1.6x135x236

3884-030

G

NRN

k

439-110

C

SK1A1C-L2W,115V/60H

3004-270

C

1. BSR23T

NO. Qty

M odel Code Description M aterial Spec

B1

B1

B3 1

C1

D1

E1

F1

R7

R

R

R

R

R

R7

ompressor ompressor Bolt-

rommet Comp

Reinf Comp

Body Assembly-Top Gr

n PCB Box - -

y Door RH T

ssembly--

--R817A-05

M6x30Y ∮10

R-Rubber, Blac

z

Page 4

Page 5

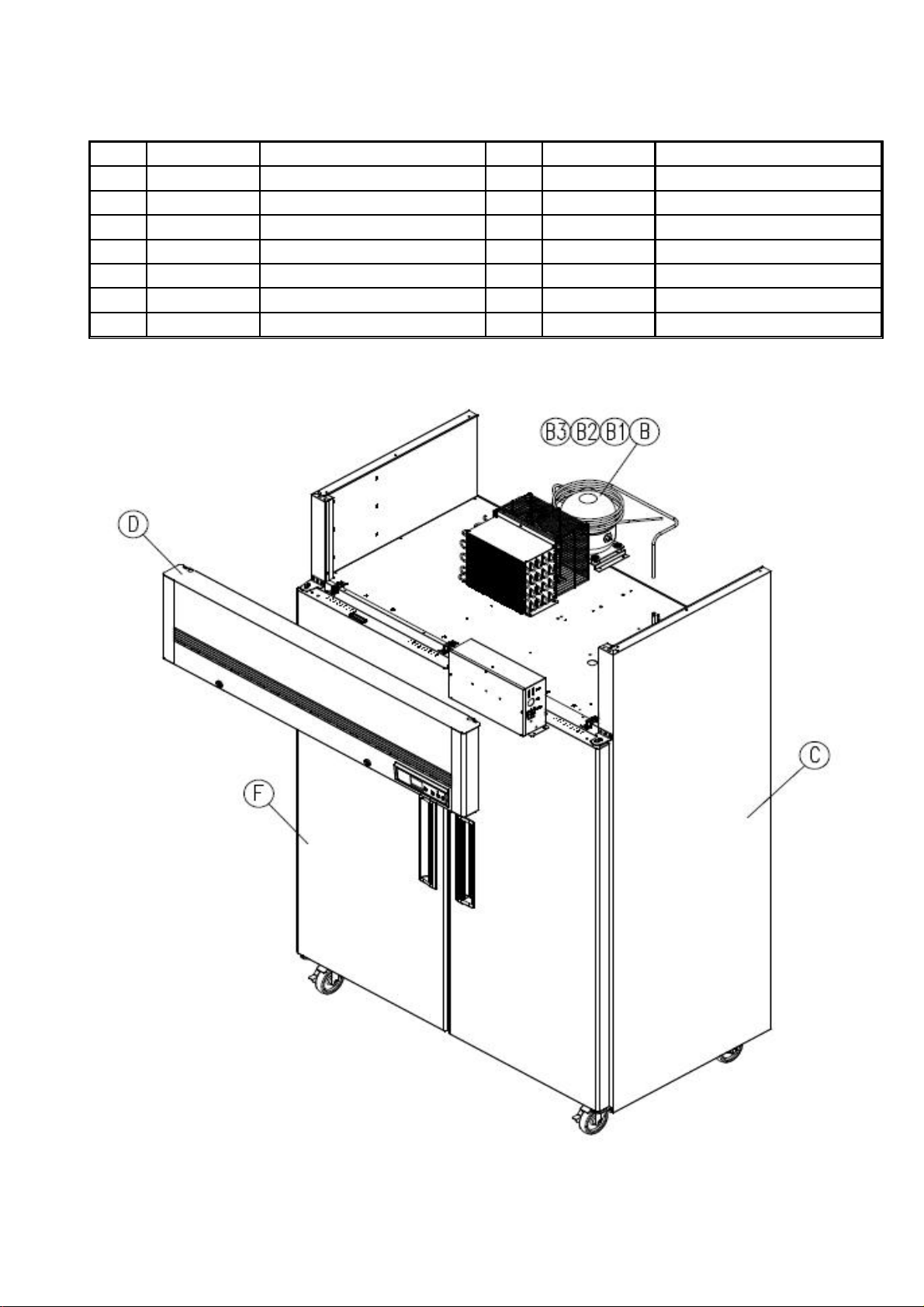

A. Main Assembly

y

4B24

E

3004-270

0

Ass'y

M

Mai

dy A

bly

p Grill A

bly

3884-030

G

p

NRN

k

Comp

p

439-640

Comp

SC1 2CLX2,115V/60H

8582-510

8249-630

103-960

2. BSF23T

NO. Qt

Model Code

B1

B1

C1

D1

F1

R7

R

R

R

R

R7

R817A-05

rommet Com

Bo

To

Descri

ressor ressor Bolt-

ssem

n PCB Box

Door RH T

tion Material Spec

M6x30Y ∮10

R-Rubber, Blac

--

ssem

1

--

--

--

z

Page 5

Page 6

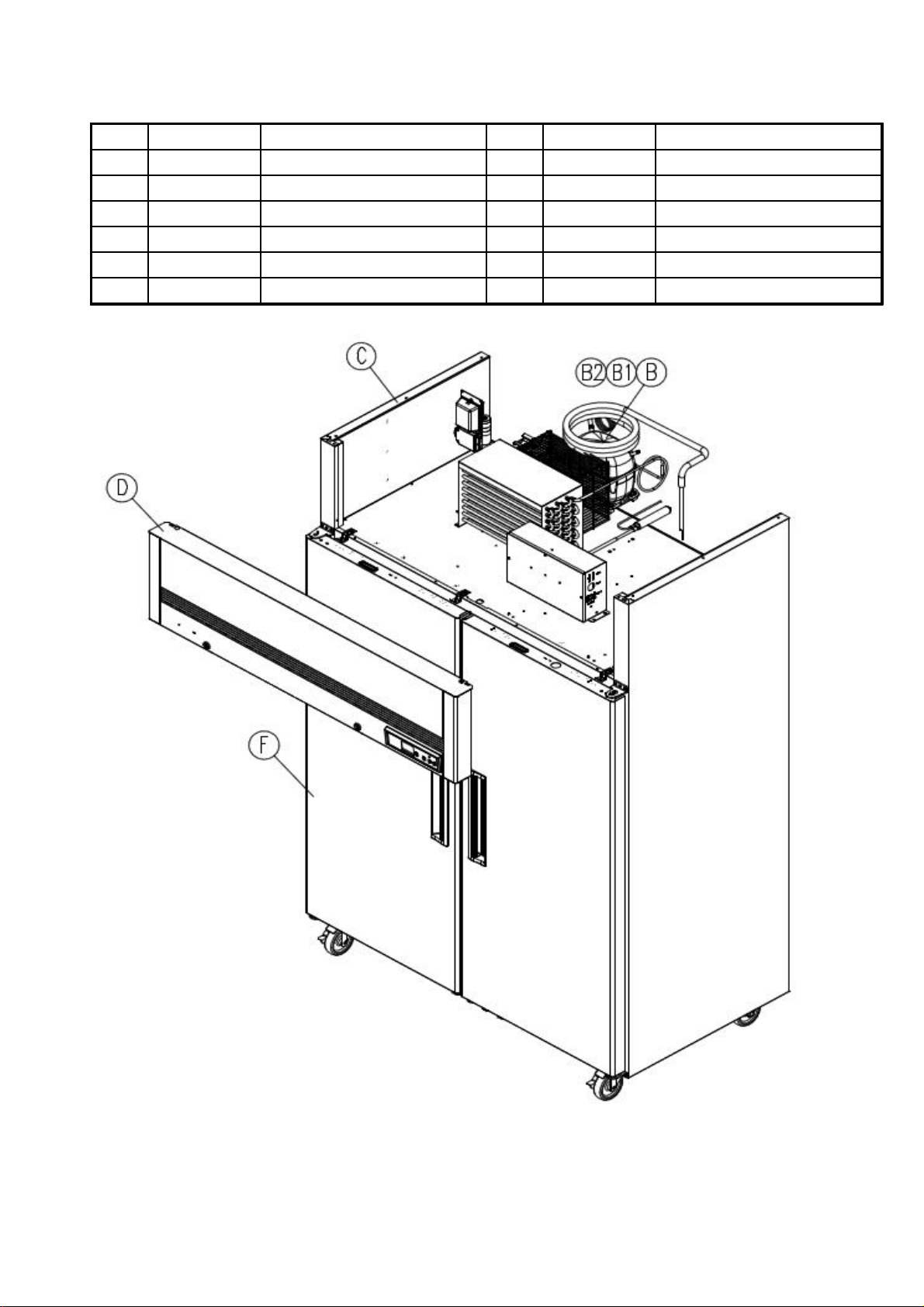

A. Main Assembly

4B24

E

103-970

Mai

8249-640

ill A

bly

8582-450

3243-040

p

GIT1.6x135x236

G

p

NRN

k

439-110

Comp

SK1A 1C-L2W,115V/60H

p

3004-270

Comp

3884-030

3. BSR49T

NO. Qty

M odel Code Descri

B1

B1

R7

R

R

B3 1

C1

D1

R

R

R

Reinf Com

Body Assembly-Top Gr

R7

ressor ressor Bolt

rommet Com

n PCB Box - -

tion Material Spec

-

M6x30Y ∮10

R-Rubber, Blac

ssem

--

1

z

Page 6

Page 7

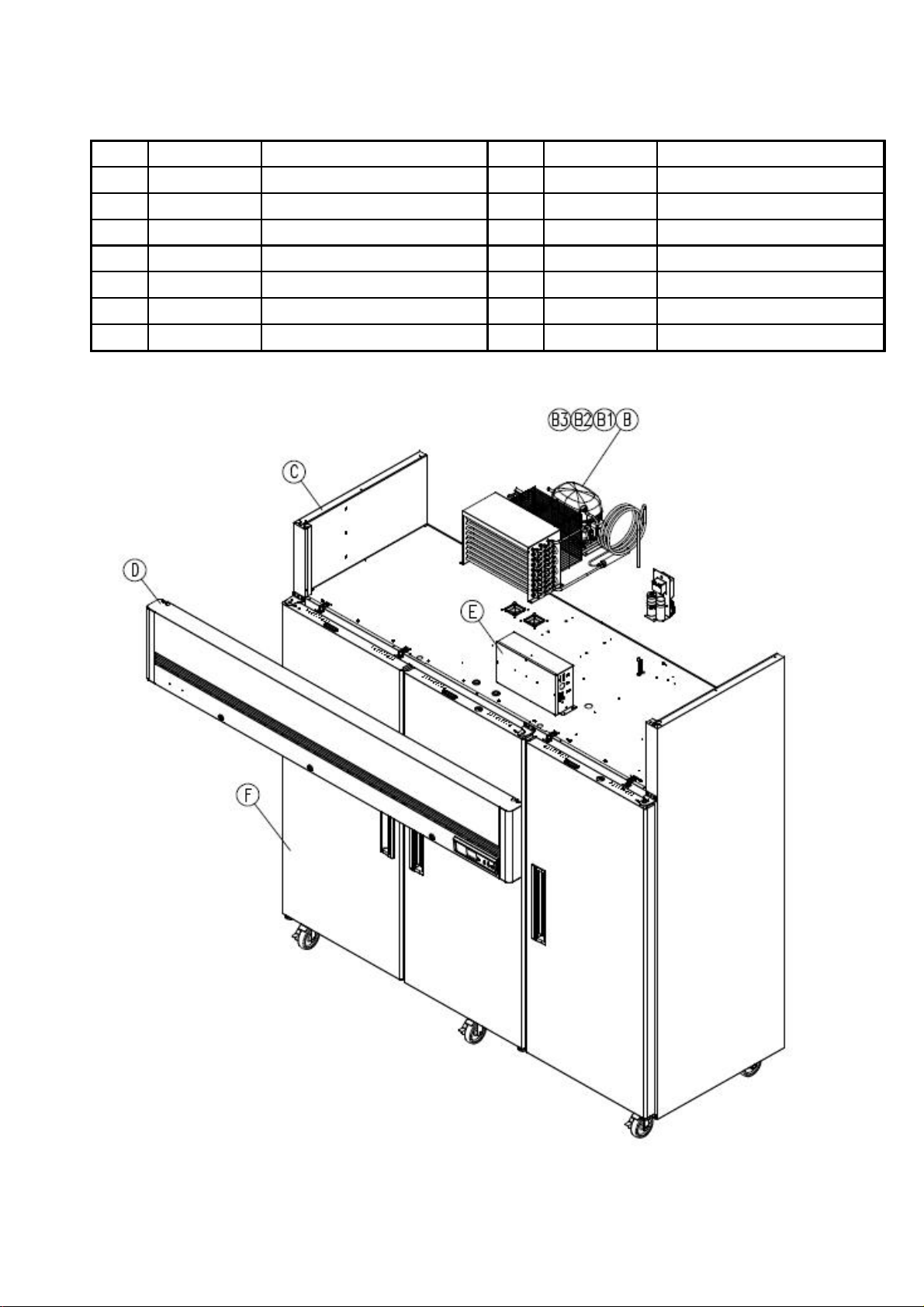

A. Main Assembly

4B24

E

N

k

8249-640

ill A

3884-030

G

N

3004-270

C

V

4. BSF49T

NO. Qty

M odel Code Description M aterial Spec

B1

B1

C1

D1

R7439-600 Compressor - SC18CLX2, 115

R

R

R8582-450

R

R7103-980 M ain PCB Box - -

ompressor Bolt-

rommet Comp

R

M6x30Y ∮10

R-Rubber, Blac

Body A ssembly - Top Gr

ssembly-

1

60Hz

Page 7

Page 8

A. Main Assembly

4B24

818A-030

ill A

829A-020

Ass'y C

3243-040

p

GIT1.6x135x236

844A-080

3004-270

Comp

3884-030

G

p

NRN

k

439-600

Comp

SC18CLX2, 115V60H

5. BSR72T

NO. Qty

M odel Code Description Material Spec

B1

B1

R7

R

R

B3 1

C1

D1

E1

R

R

R

R

Reinf Com

Body Assembly-Top Gr

ressor ressor Bolt-

rommet Com

M6x30Y ∮10

R-Rubber, Blac

ssembly--

ontrol Box T72R--

z

Page 8

Page 9

A. Main Assembly

4B24

E

818A-030

ill A

bly

829A-010

Ass'y C

dy A

14A-020

C

GS26CLX

3884-030

G

3004-270

C

NRN

k

3243-040

GIT1.6x135x236

844A-070

6. BSF72T

NO. Qty

M odel Code Description M aterial Spec

B1

B1

B3 1

C1

D1

R7

R

R

R

R

R

R

ompressor ompressor Bolt-

rommet Comp

Reinf Comp

Bo

Top Gr

ssembly--

ssem

ontrol Box T72R--

1

--

M6x30Y ∮10

R-Rubber, Blac

Page 9

Page 10

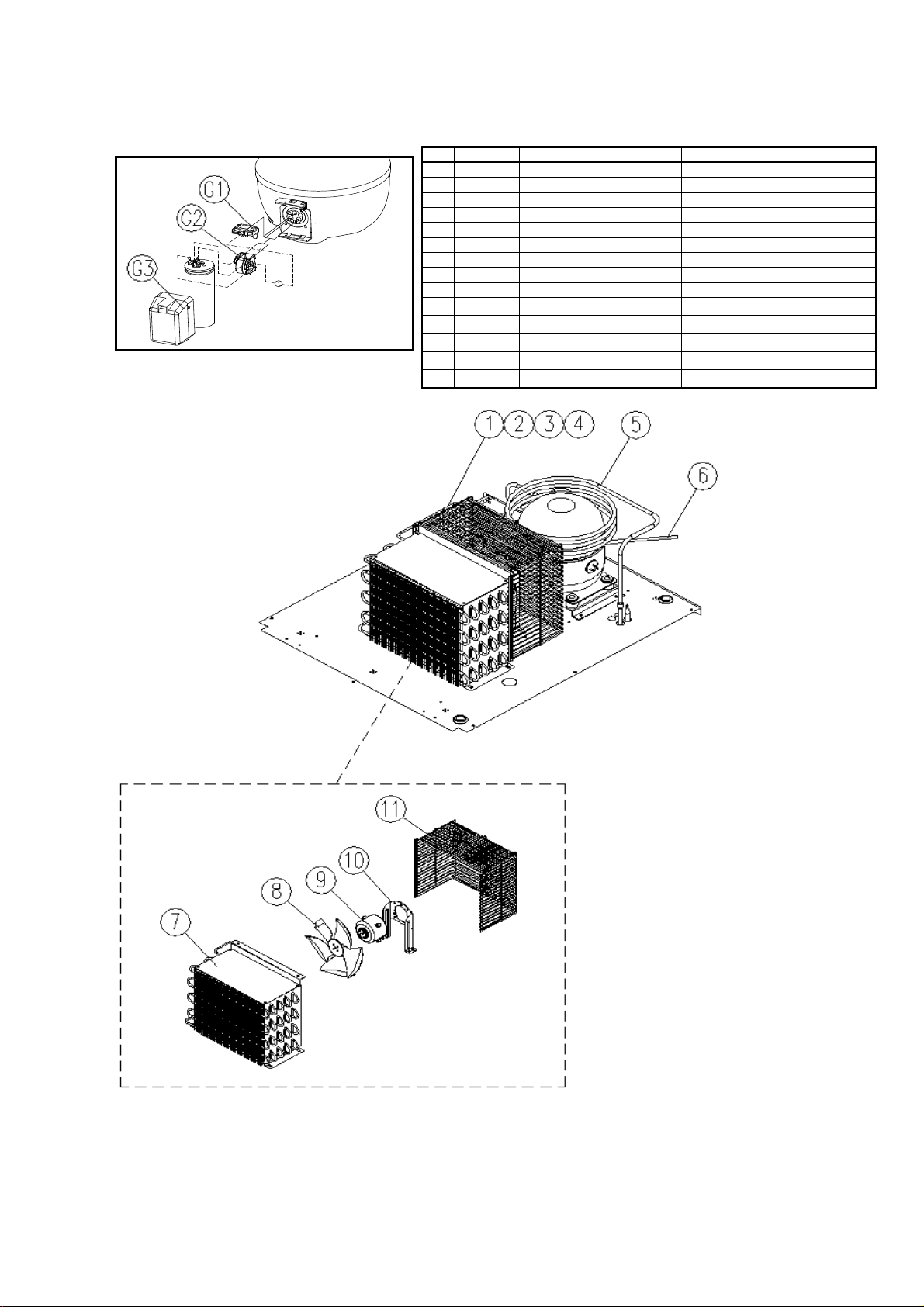

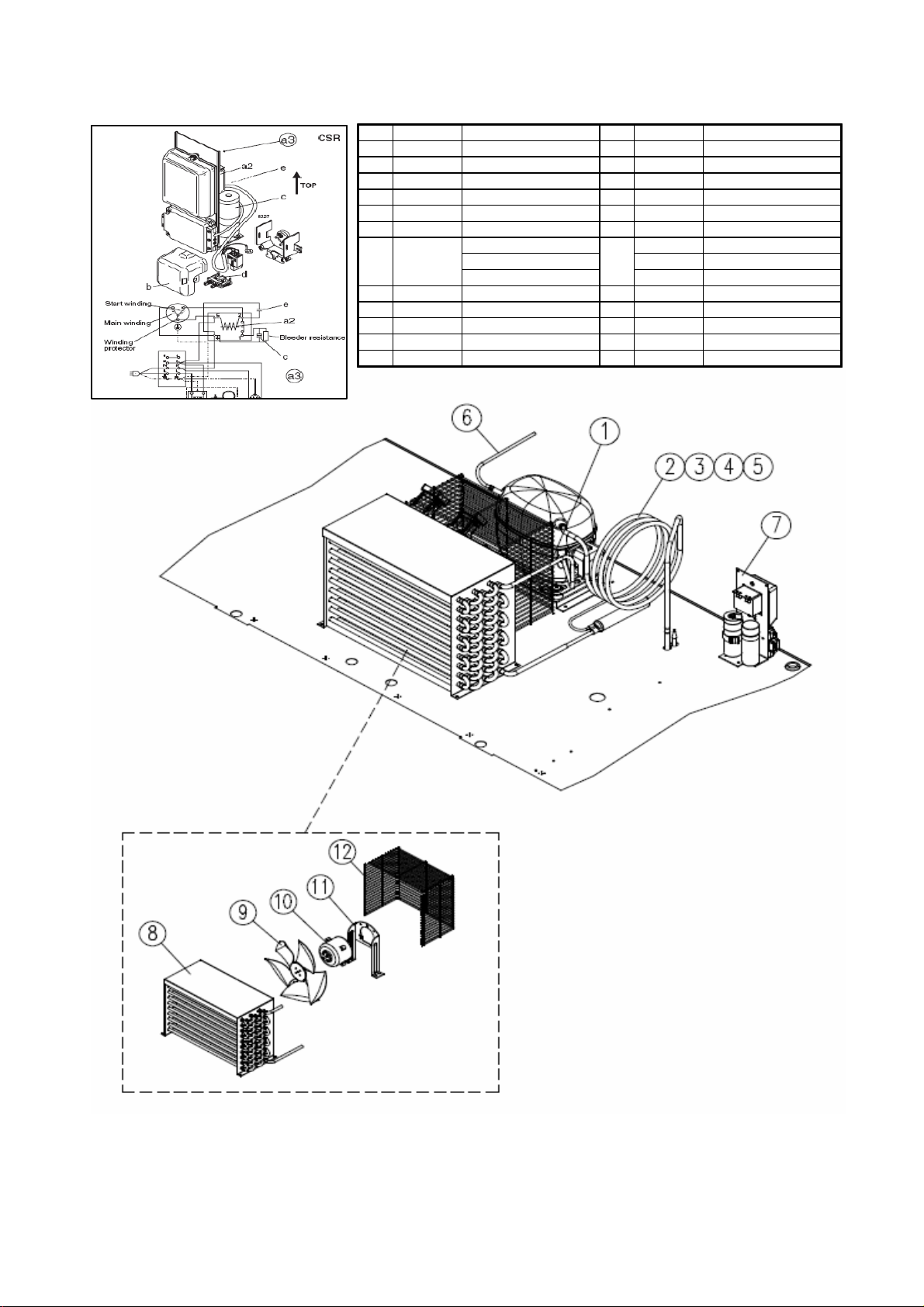

B. Assembly Unit

4

423-311

Cond

115V60H

8204DYCA

8633-010

Cond

AS

2183-610

2104-610

3723-070

Cond

AL

9" CCWR8603-830

Ass'y S

R210 4-981

Pi

134

2113-980

2113-970

1. BSR23T, BSR49T

Model Code Description Material Spec

NO. Qty

R

11

R

21

R

31

51

R

61

R

71

R

81

R7

91

R3313-260 Condenser Fan Motor B/K - -

10 1

R3813-150 Conden ser Fan wi re M SWR10 ∮2.5 275x237

11 1

R7519-100 Overl oad Protector - 4TM 412PFBYY-53

G1 1

R7543-180 PTC Rel ay - J531Q 35E330M 385-3

G2 1

R3813-900 Cover Rel ay

G3 1

Pipe Discharge - Pipe Connect Dryer - Dryer -

pe Dryer - -

uction Pipe - -

Tube Vaccu m - -

enrser

enser Fan Blade

enser Fan Motor -

1

-

--

R-

-

a, 36g

z DAI-

Page 10

Page 11

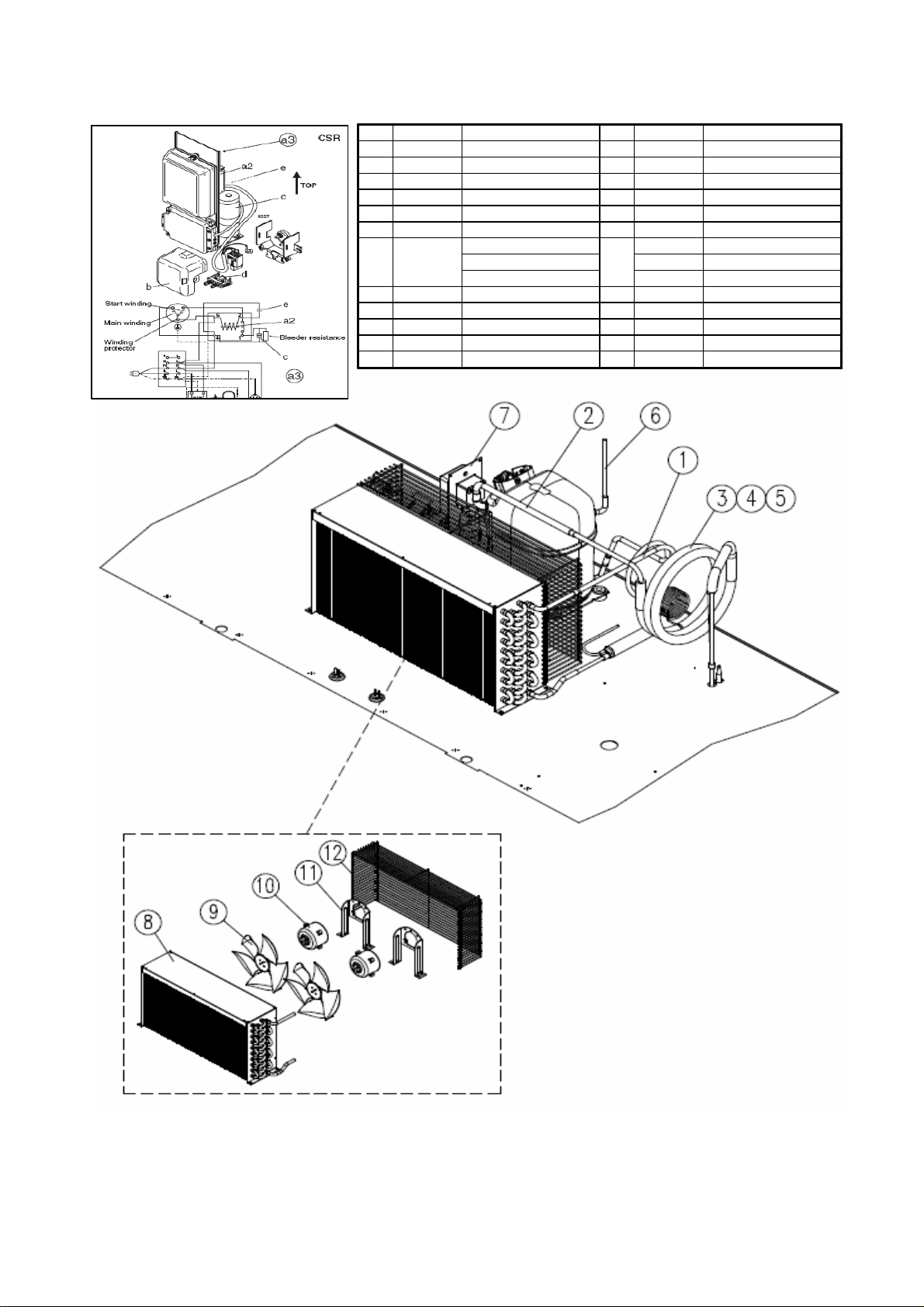

B. Assembly Unit

2. BSF23T

Model Code Description M aterial Spec

NO. Qty

R2113-970

11

R2113-980 Pi pe Con nect Dryer - -

21

R2183-610 Dryer - R-134a, 36g

31

R2104-981 Pi pe Dr yer - -

41

R8603-830

51

R2104-610 Tu be V accum - -

61

R8633-010 Condenrser AS - -

71

R3723-070 Condenser Fan Blade AL 9" CCW

81

R7423-311 Condenser Fan M otor

91

R3313-260 Condenser Fan M otor B/K -

10 1

R3813-791 Condenser Fan wire

11 1

Pipe Discharge - -

Ass'y Suction Pipe -

-

MSWR10 ∮2.5 275x237

-

115V 60Hz DA I-8204DYCA

-

Page 11

Page 12

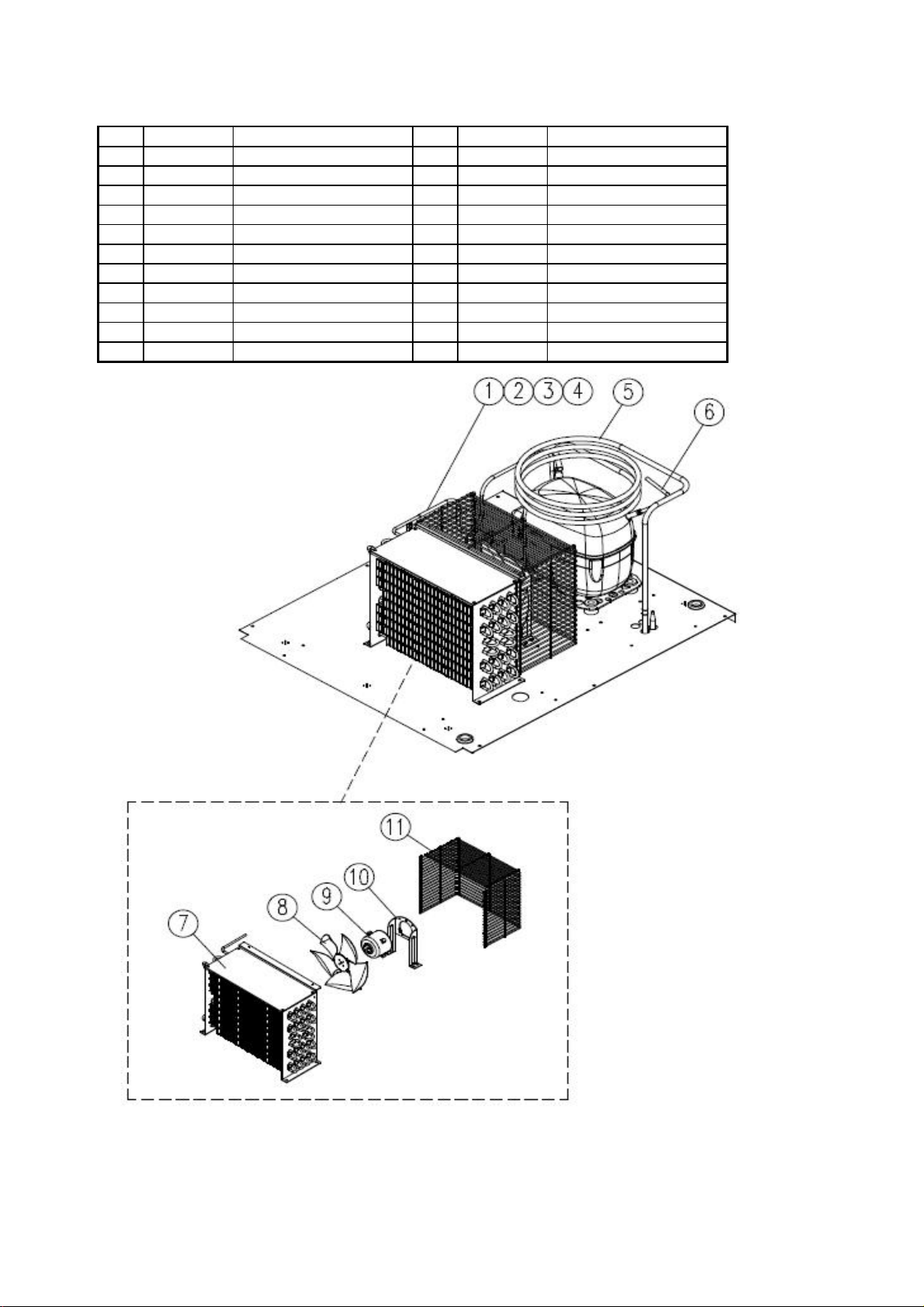

B. Assembly Unit

3. BSF49T

M odel Code

NO. Qty

R2113-570 Di scharge Con nector CU -

11

R8603-813 Ass'y Sucti on Pip e T49F - -

21

R2213-210 Pip e Con nect Dryer T49 - R-134a, 36g

31

R2183-610 Dryer - -

41

R2104-982 Pip e Dryer -

51

R2103-230 Pip e Com p Ch arging -

61

7 R7539-200

R2272-023 Condenr ser A S

81

R3723-070

91

R7423-311 Condenser Fan M otor - 115V60Hz D AI-8204DYCA

10 1

R3313-260 Condenser Fan M otor B/K - -

11 1

R3813-781 Condenser Fan wire M SWR10 ∮2.5

12 1

St ar ti ng D evi ce

Starti ng Capicitor - 410uF

Running Capicitor - 23.5uF

Condenser Fan Blade AL

Material SpecDescription

-

-

-

Code No : 117-7045

1

-9" CCW

Page 12

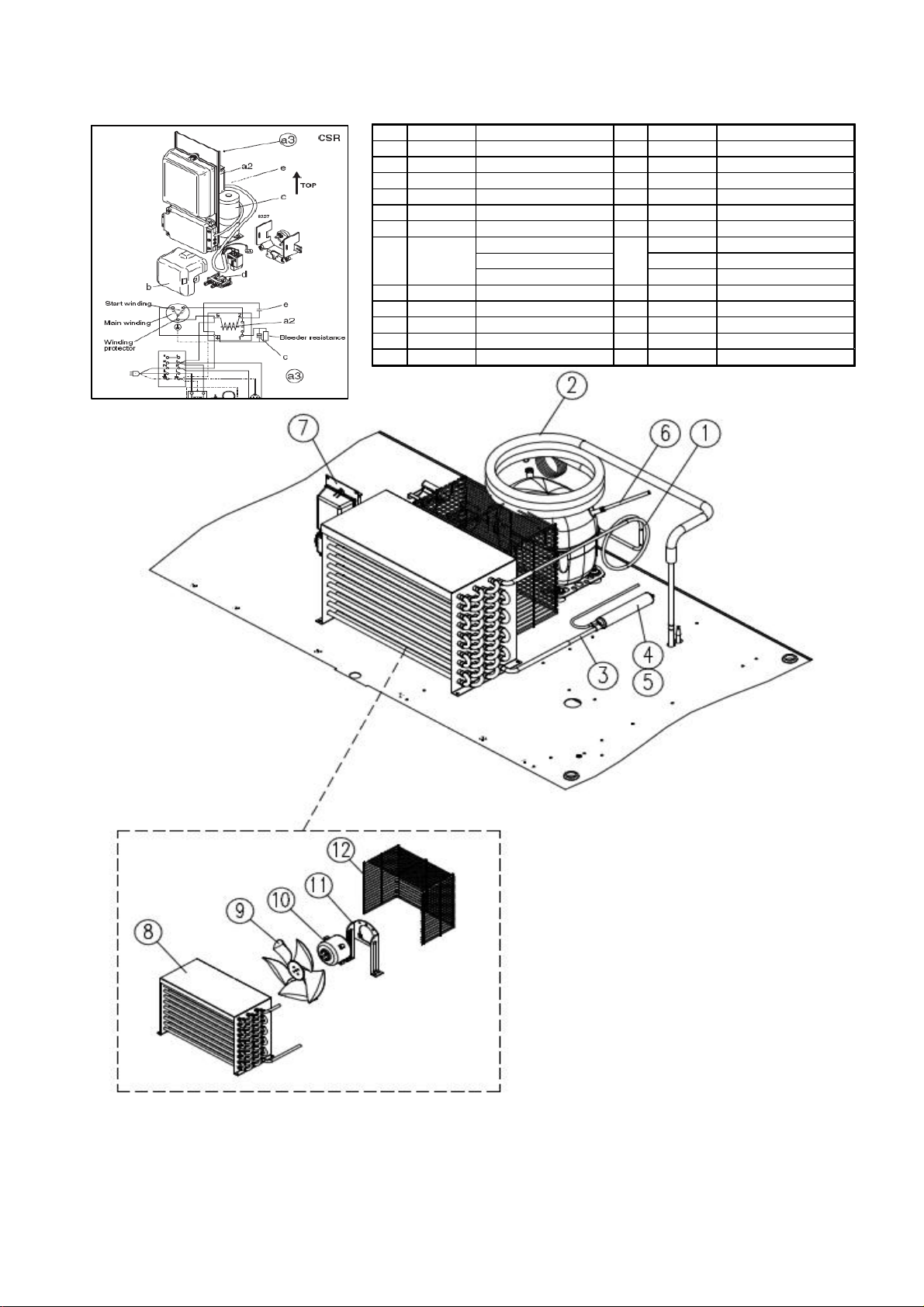

Page 13

B. Assembly Unit

4. BSR72T

M odel Code Description M aterial

NO. Qty

R2113-960 Pip e D ischar ge T49F - -

11

R845A-010 Ass'y Suction Pi pe T72R - -

21

R2213-200 Pipe Connect Dryer T49

31

R2183-200 Dr yer - -

41

R2104-421 Pip e D ryer - -

51

R2114-321

61

R7539-200

7

R2272-023 Con denrser AS

81

R3723-070 Con denser Fan Blade

91

R7423-311 Con denser Fan M ot or -

10 1

R3313-260 Con denser Fan M ot or B/K - -

11 1

R3813-150 Con denser Fan wir e MSWR10 ∮2.5 275x237

12 1

Compressor Charging Pipe - St ar ti ng D evi ce

Starti ng Capicitor

Running Capicitor - 23.5uF

1

--

- Co de N o : 117-7053

410uF

-

-9" CCW

AL

115V60Hz DAI -8204DYCA

Spe c

Page 13

Page 14

B. Assembly Unit

5. BSF72T

M odel Code

NO. Qty

R2113-311 Con den ser Connector -

11

R2114-330 Compressor Pull Out, B -

21

R845A-020 Ass'y Suction Pi pe T72F -

31

R2104-421 Con denser D ryer Pip e - -

41

R2183-200 Dr yer Ass'y - -

51

R2114-321 Compressor Charging Pipe -

61

R7539-200

7

R2272-030 Con denrser AS -

81

R3723-070 Con denser Fan Blade AL 9" CCW

92

R7423-311

10 2

R3313-260 Con denser Fan M ot or B/K - -

11 2

R3813-770 Con denser Fan wir e-B

12 1

Description M aterial

St ar ti ng D evi ce

Starti ng Capicitor Running Capicitor -

Condenser Fan M otor -

1

MSWR10

-

-

-

-

-

Code No : 117-7073

100uF

20uF

-

115V60Hz DAI -8204DYCA

-

Spe c

Page 14

Page 15

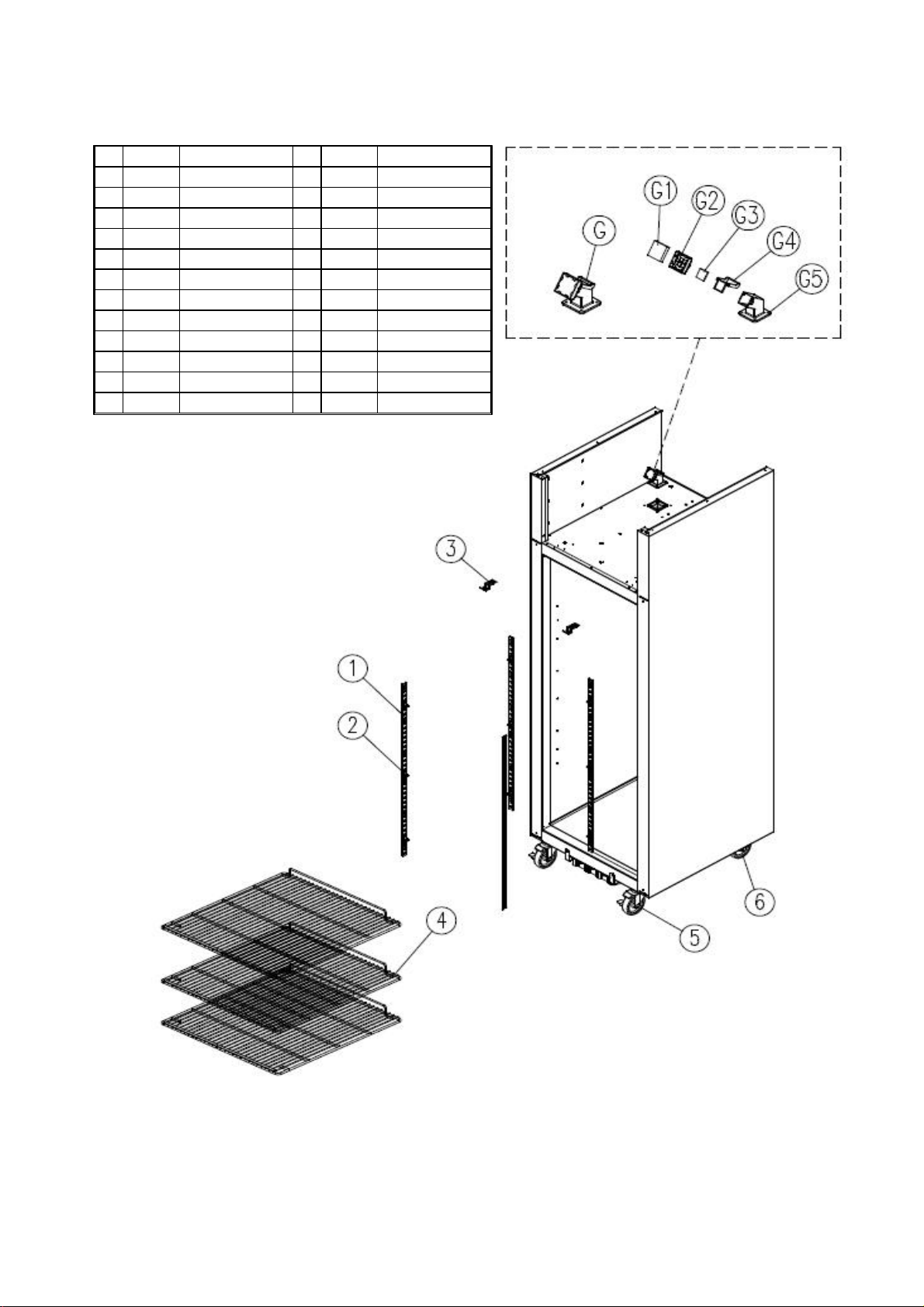

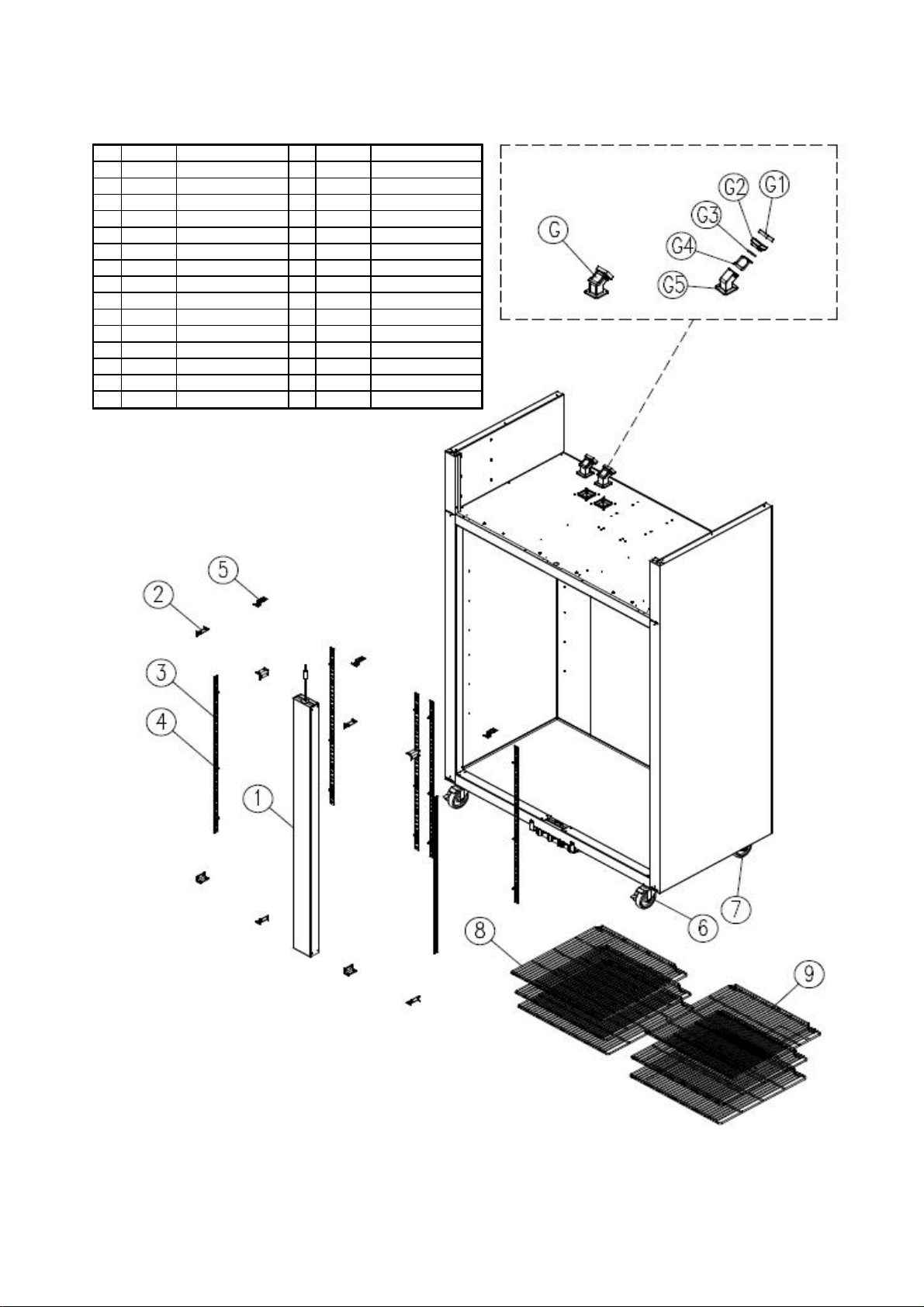

C. Body Assembly

1. BSR23T, BSF23T

Model Code Description Material Spec

NO. Qty

R3373-630 Shelf Standard L - T=1.2, L=930

14

R3313-151 Shelf Clip POM W hite

212

R3114-601

32

R3232-450 Assy Packi ng Shel f 558x587

41SET

R3323-200 Caster - 4" M oving / Stoppi ng

52

R3323-190

62

R8173-130 Check Valve As - -

G1

R3253-050 Filter Check V al ve Filt er Fome #10, T10, Black

G1 1

R3253-040 Cap Ch eck V al ve ABS

G2 1

R3253-060 Packing Fl ap PE T= 4, Wh ite

G3 1

R3253-030 Flap Check V al ve

G4 1

R3253-020 Body Ch eck V alve ABS 60x60x75.05

G5 1

U-Cover Bracket A POM White

Caster 4" M oving

MSWR10

-

45.5x45.5x23.5

ABS 40.5x45x36

Page 15

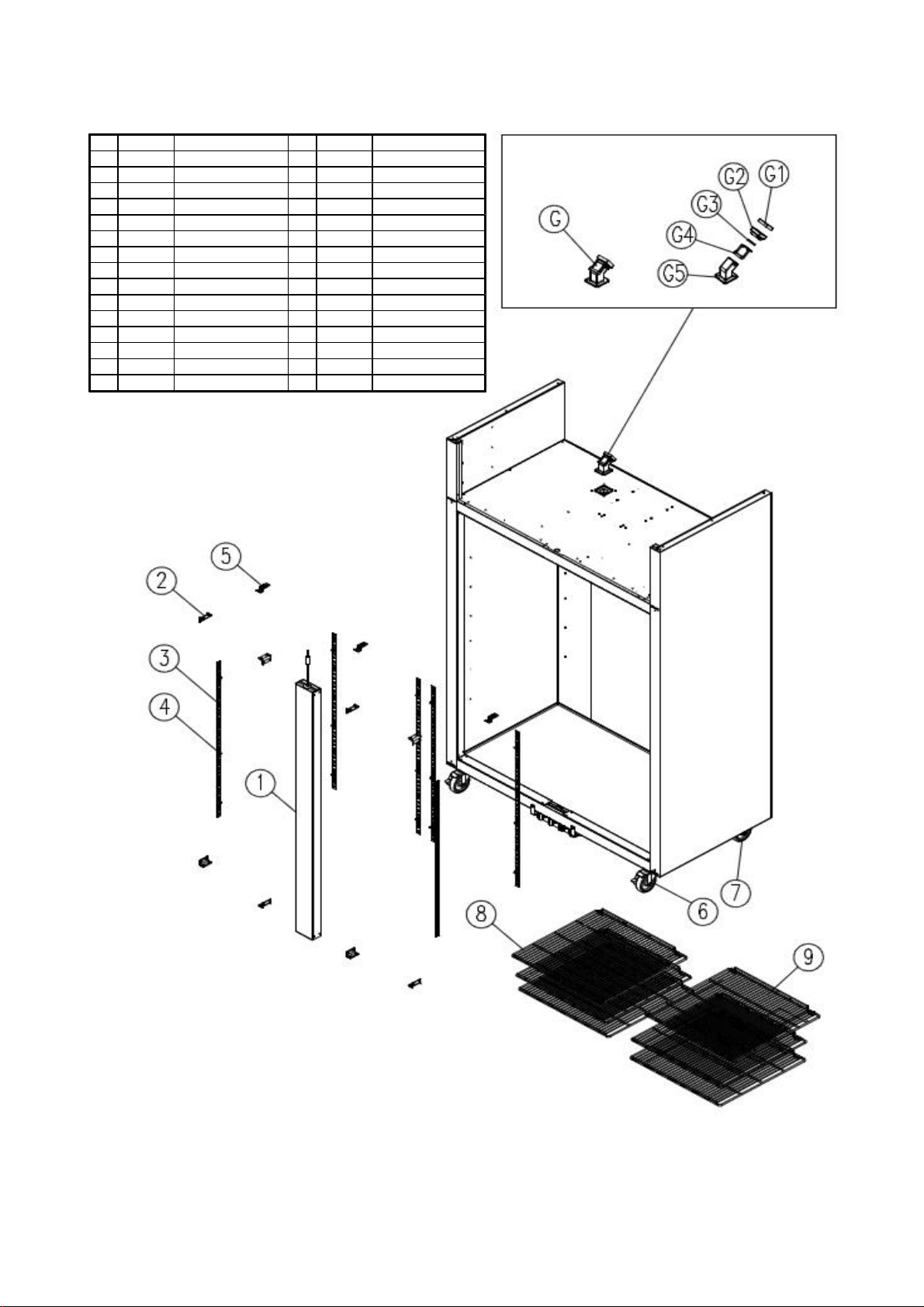

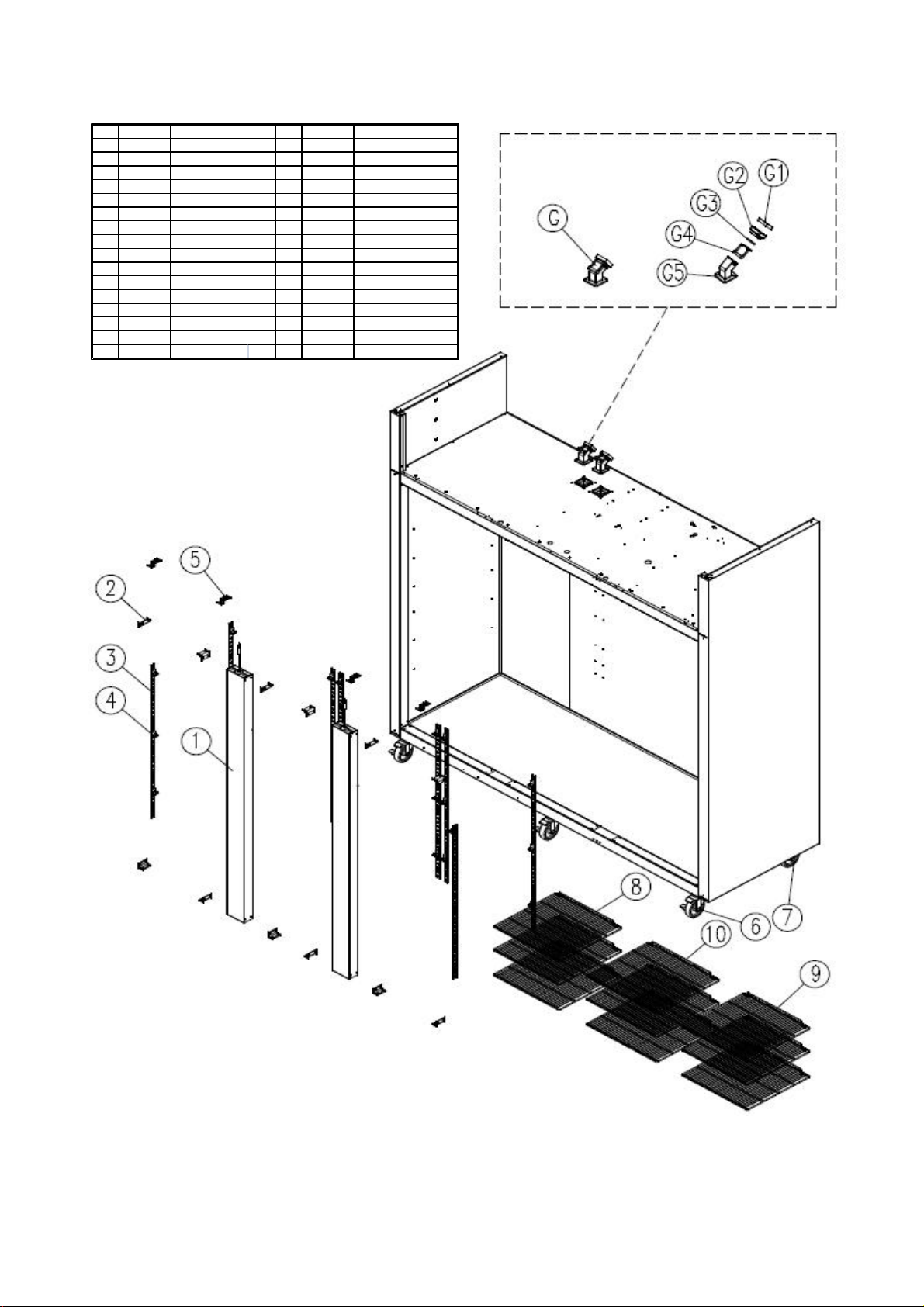

Page 16

C. Body Assembly

.Qty

424

4

ABSR3253-030

40

36

020

ABS

60x60

lap Check Val

ABS

45.5x45.5x23.5

060

p

Whi

R3253-040

Cap Check Val

R8173-130

R3253-050

Fi l

Fi l

#10, T10, Black

Check Val

3233-162

Shelf-L

MSWR10

R3233-172

Shelf-RH

MSWR10+PE

4" Moving / Stopping

3323-190

C

4" Moving

3323-200

C

WhiteR3314-601

U-C

GI

T=1.2, 61x20

Shelf S

L

930

R3313-151

Shelf Cli p

POM

R325A-030

C

ABS

28.5x28.5x53

R3373-630

cR816A-040

C

p

2. BSR49T

Model Code Descri

NO

11

28

36

ross Bar AS T72R-over Corner

tion

tandard

Material Spe

-T=1.2, L=

53

R

62

R

72

R

83

93

G1

G1 1

G2 1

R3253-

G3 1

G

R3253-

G5 1

over Bracket

1

-

-

-

ter Fome

PET=4,

+PE

-

te

.5x45x

x75.05

aster

aster -

F-

ve As

ter Check Valve

ve

Packing Fla

F

Body Check Valve

ve

Page 16

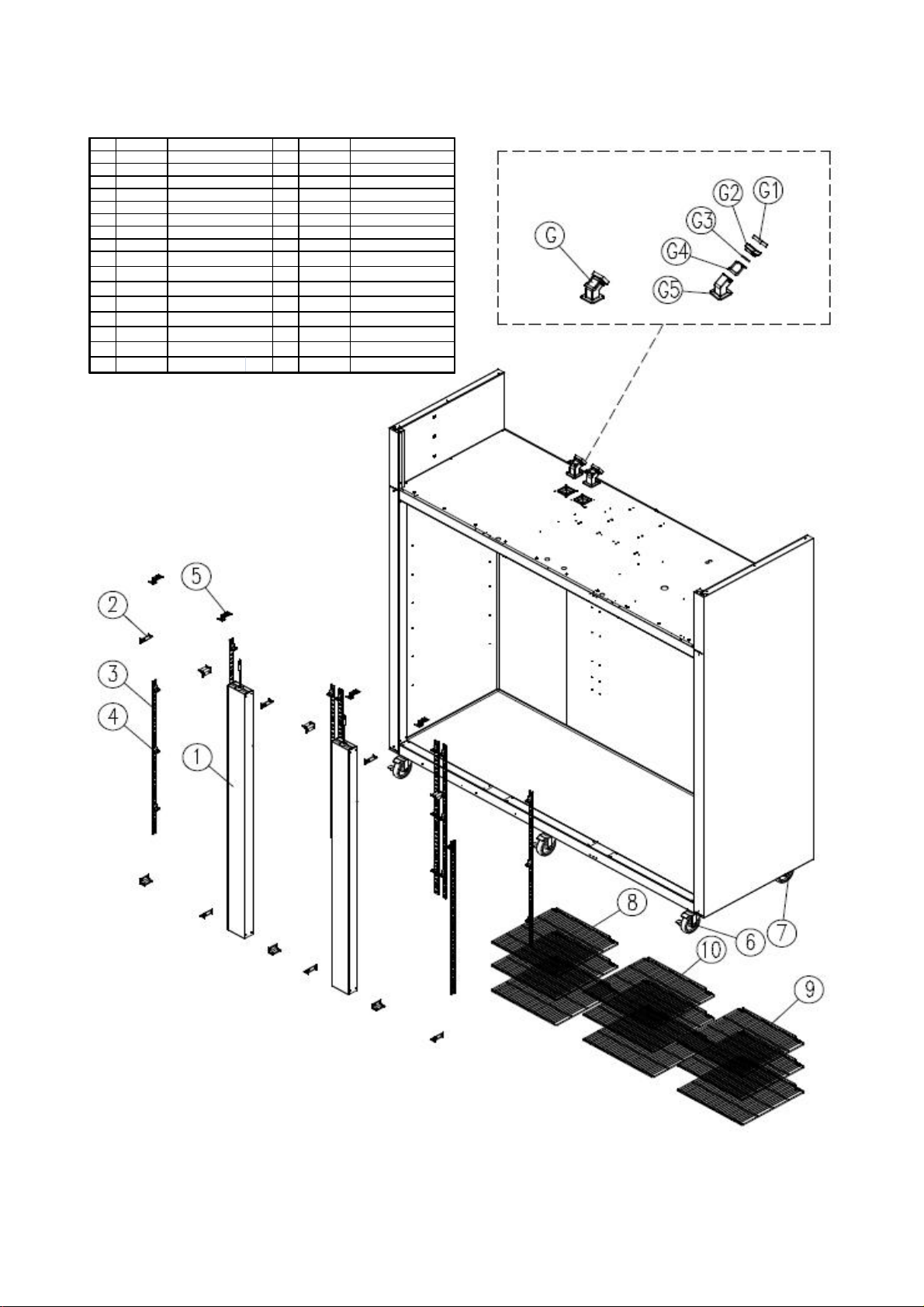

Page 17

C. Body Assembly

y

40

36

ABSR3253-030

020

Cap Check Val

ABS

60x60

lap Check Val

ABS

4

10

k

060

p

Whi

3253-040

-

-R3253-050

-

-

4" Moving

3233-162

Shelf-LF

-

MSWR10

3323-190

C

GIT=1.2, 61x20

3323-200

C

-

4" Moving / Stopping

3314-601

U-C

1.2, L=930

3313-151

Shelf Clip

OM

Whi

3373-630

Shelf S

L

-R325A-030

C

ABS

28

3

816A-030

C

2F

-

-

3. BSF49T

NO. Qt

M odel Code Description

R

11

28

R

36

R

424

R

53

R

62

R

72

R

83

R3233-172 Shelf-RH

93

R8173-130

G2

G1 2

R

G2 2

R3253-

G3 2

G4 2

R3253-

G5 2

ro ss Bar AS T7

over Corner

tandard

over Bracket

aster

aster

Check Valve As

Filter Check Valve Filter Fome

ve

Packing Fla

F

Body Check Valve

ve

Material Spec

.5x28.5x5

T=

P

PE T=4,

te

+PE

M SWR10+PE

#

, T10, Blac

5.5x45.5x23.5

te

.5x45x

x75.05

Page 17

Page 18

C. Body Assembly

3253-060

Whi

371A-010

Shelf

2

MSWR10

1.2 61x20

3233-172

Shelf-RH

MSWR10

"

"

3313-151

Shelf Cli

OM

Whi

3114-601

U-C

A

GI

'

R

4. BSR72T

NO. Qty

M odel Code Description M aterial

R816A-040 A ss

12

R325A-030 Cover Corn er ABS 28.5*28.5*53

212

R3373-630 Shelf Standard L -

38

R

436

R

54

R3323-200 Caster - 4

63

R3323-190

73

R3233-162 Shelf-LF - M SW R10+ PE

83

R

93

R

10 3

R8173-130 Check V alve As - -

G2

R3253-050 Fi lt er Ch eck V alve Filter Fome #10, T10, Black

G1 2

R3253-040 Cap Check Val ve ABS 45.5x45.5x23.5

G2 2

R

G3 2

R3253-030 Flap Check V al ve ABS 40.5x45x36

G4 2

R3253-020 ABS 60x60x75.05

G5 Body Check V alve 2

y Cr oss Bar T72

pP

over Bracket

Caster

-T 7

Packing Flap PET=4,

--

T= 1.2, L= 930

te

T=

M oving / Stopping

-4

M oving

-

-

+PE

+PE

te

Sp ec

Page 18

Page 19

C. Body Assembly

y

4

4

MSWR10+PE

R3233-162

Shelf-LF

R3323-200

C

pping

R3323-190

C

R3313-151

Shelf Clip

POM

WhiteR3114-601

U-C

A

GI

T=1.2 61x20

030

C

ABS

28

3

R3373-630

Shelf S

L

930

R816A-030

Ass'y C

T72F

5. BSF72T

NO. Qt

Model Code Description M aterial Spec

12

R325A-

212

38

5

63

73

83

R3233-172 Shelf-RH - M SWR10+ PE

93

R371A-010 Shelf-T72

10 3

R8173-130 Check V alve As - -

G2

R3253-050 Filter Check V alve Filter Fome #10, T10, Black

G1 2

R3253-040 Cap Check Val ve A BS 45.5x45.5x23.5

G2 2

R3253-060 Packing Flap PE T= 4, W hi te

G3 2

R3253-030 Flap Check Val ve ABS 40.5x45x36

G4 2

R3253-020

G5 Body Check Valve 2

ross Bar

over Corner

tandard

over Bracket

aster -4" Moving / Sto

aster -4" Moving

-.5 *28.5 *5

-T=1.2, L=

36

-

- M SWR10+ PE

ABS 60x60x75.05

Page 19

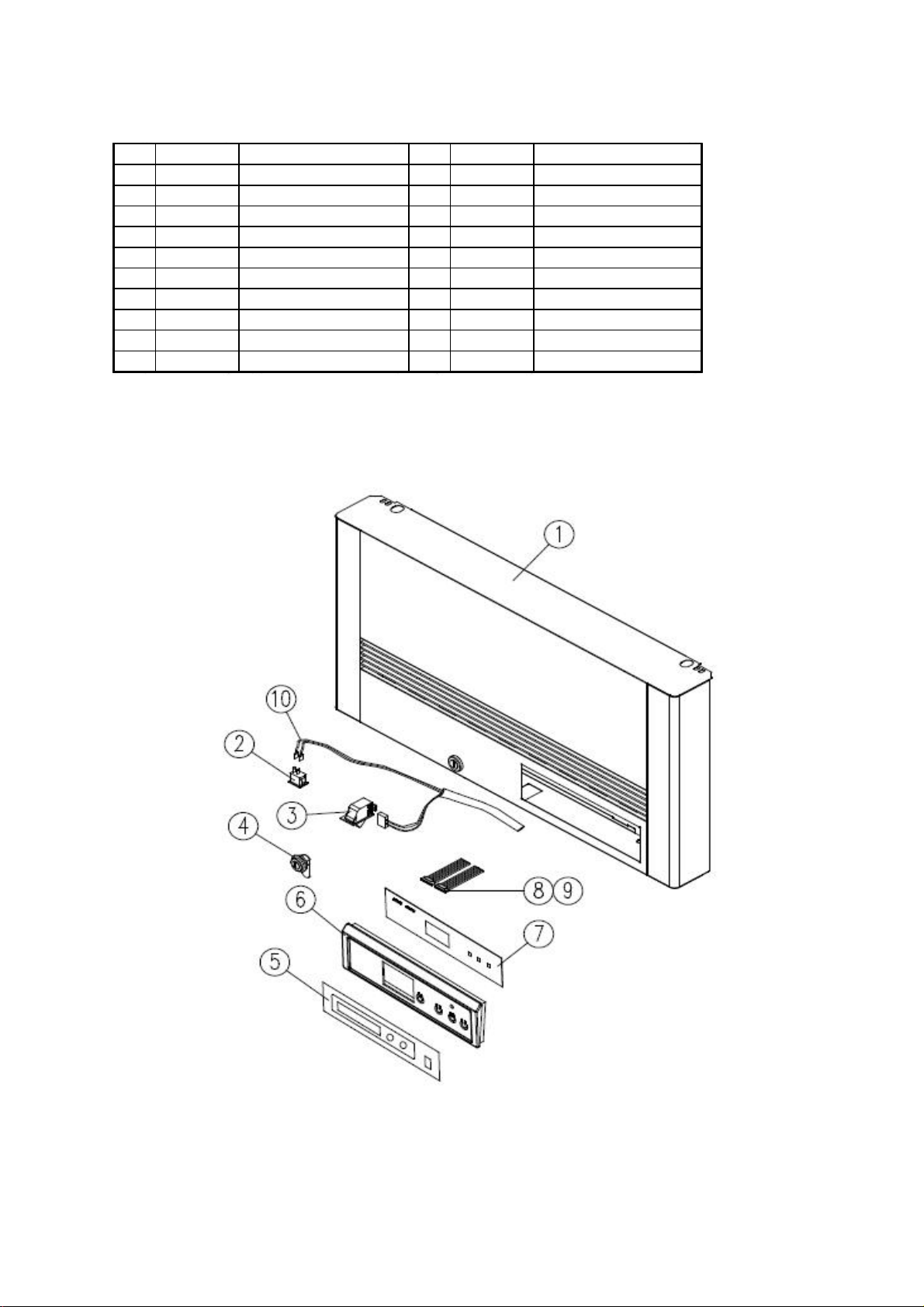

Page 20

D. Top Grill Assembly

1. BSR23T, BSF23T

Model Code Description

NO. Qty

R8249-630 Top Gril l As T23

11

21

R7203-020 Door Switch - WHT, SP201R-9D

31

R3734-030 Door Lock ing Ass'y

41

51

R4142-122

61

R7129-550 Front PCB-88 DP1

71

81

R7613-320 Harness F-PCB 10P B

91

R7403-080 Ass'y Harness

10 1

Inlay ControlR4103-680

Harness F-PCB 8P BR7613-300

Material Spec

--

- SL112A, 115V 15AR7204-070 Power Switch

--

- T = 0.2, 54 x2 18

ABS Dark Gray, T2x242x72Control Board

- 88 Display

- AGW 24, 8P, 연접 L450

- AGW 24, 10P, 연접 L450

-

Page 20

Page 21

D. Top Grill Assembly

2. BSR49T, BSF49T

M odel Code

NO. Qty

R8249-640

11

R7204-070

21

R7203-020 Door Switch - WH T, SP201R-9D

32

R3734-030 Door Locki ng Ass'y

42

51

R4142-122 Control Board

61

71

R7613-300 Harness F-PCB 8P B

81

R7613-320

91

R7403-080 Harness Swit ch A

10 2

R7373-990 Ass'y Harness Power S/W D

11 1

Top Grill As T49

Power Switch

Harness F-PCB 10P B

Description

Material Spec

-

-

- SL112A, 115V 15A

--

-R4103-680 Inlay Control

T= 0.2, 54x218

ABS

Dark Gray, T2x242x72

88 Display

-R7129-550 Front PCB-88 D P1

AGW 24, 8P, 연접 L450

-

-

AGW 24, 10P, 연접 L450

-

UL AWG18

115V

Page 21

Page 22

D. Top Grill Assembly

3. BSR72T, BSF72T

NO. Qty

R818A-030

11

R7204-070 Power Switch

21

R7203-020

33

R3734-030 Door Locki ng Ass'y

43

R4103-680

51

R4142-122 Cont rol Board ABS D ark Gray, T2x242x72

61

R7129-550 Fron t PCB-88 DP1

71

R7613-300 Harness F-PCB 8P B -

81

R7613-320 Harness F-PCB 10P B

91

R7403-080 Harn ess Switch A - U L AWG18

10 3

R7373-990

11 1

Ass'y Gril l Top T72

Ass'y Harness Po wer S/W D

Description

MaterialM odel Code

-

- SL112A, 115V 15A

- WHT, SP201R-9DDoor Switch

-

-T=0.2, 54x218Inlay Control

-88 Display

- AGW24, 10P, 연접 L450

-

-

AGW 24, 8P, 연접 L450

115V

Spec

Page 22

Page 23

E. Main PCB Box

1. BSR23T, BSR49T

M odel Code Description Spec

NO. Qty

11

R7119-880

21

R7129-700 PCB M ain - FR1, 165x115

31

41

R7613-740 Harness M ain AC-A 23R

51

R7613-890

61

71

R7549-170

81

91

Box M ain PCB

M -PCB Box Cover

Harn ess M ain DC TM -R Ass'y U L

Capacitor StartingR7549-160

Running Capacitor 230vac 50/60Hz-

Material

GIR7119-870

GI

-

-

-

-

Nylon-66R3834-130 Cabl e Cl amp

T= 0.5, 558.34x330.71

T= 0.5, 357.07x218.97

120V60Hz, DT-1213R7504-060 Power Trans

Ass'y UL

200vac 50/60Hz

DA-18N

Page 23

Page 24

E. Main PCB Box

2. BSF23T, BSF49T

M odel Code Description

NO. Qty

R7119-870 Box M ain PCB

11

R7119-880 M -PCB Box Cover

21

R7129-710

31

R7504-060 Power Trans

41

R7253-080 Power Relay

51

R7613-750 Harness M ain AC-A 23F

61

71

PCB M ain

Harness Main DC TM -FR7613-900

Material Spec

T= 0.5, 558.34x330.71GI

GI T= 0.5, 357.07x218.97

- FR1, 165x115

-

120V60Hz, DT-1213

- UZ-2A-BT110, 25A /277V AC

- Ass'y U L

- Ass'y U L

Page 24

Page 25

F. Door Assembly

1. BSR23T, BSF23T

Model Code Description M aterial Spec

NO. Qty

R817A-050 Ass'y Door RH TM -

F1

R4122-281 Han dl e Cover

F1 1

R338A-010 Gasket Door TM

F2 1

R1254-051 Door Rubber Leg

F3 2

R858A-410 Shaft Top Hinge AS SUM 24L

F4 1

R374A -020

F5 1

R828A -020

F6 1

F7 1

R412A-020 Pin Tension SUM 24L -

F8 1

Spring Door RH

Hinge Bottom RH As

-

A BS+ C R도 금 340 .6x 6.8

난연 PVC

Sil i co n ∮16x12

SW -C STS3 04

STS3 04R828A-061 Hinge Top RH As

1508x585

-

T= 4.0

T= 4.0

Page 25

Page 26

F. Door Assembly

2. BSR49T, BSF49T

R412A-020 Pin Tension SUM 24L

F7 2

R828A-050 Assy Hinge Top LF

F8 1

R374A-010 Spring Door LF

F9 1

R375A-010 Stopper Hinge RH

F10 1

R828A-020 Assy Hinge Bottom RH - -

F11 1

R375A-020 Stopper Hinge LF

F12 1

R828A-030 Assy Hinge Bottom LF - -

F13 1

--

SW -C ∮2.3 백색 도금

POM (FW700S)

POM (FW700S)

45.5*31*8

45.5*31*8

Page 26

Page 27

F. Door Assembly

3. BSR72T, BSF72T

Model Code

NO. Qty

R817A-040 Ass'y Door LF TM - -

F

R817A-050 Ass'y Door RH TM - R4122-281 Hand le Cover ABS+CR도금 340.6x6.8

F1 3

R338A-010 Gasket Do or TM 난 연 PV C 1508x585

F2 3

R1254-051

F3 6

R828A-060

F4 2

R858A-410

F5 3

R374A-020

F6 2

R412A-020 Pin Tensi on SU M 24L

F7 3

R828A-050 Assy Hing e Top LF - -

F8 1

R374A-010 Sprin g D oor LF SW-C ∮2.3 백색 도금

F9 1

R375A-010 Stopper Hi ng e RH

F10 2

R828A-020 Assy Hing e Bot tom RH - -

F11 2

R375A-020 Stopper Hi ng e LF

F12 1

R828A-030 Assy Hing e Bot tom LF - -

F13 1

Door Rubber Leg Silicon ∮16x12

Assy Hinge Top RH - Sh aft Top H in ge AS - Spring Door RH SW-C ∮2.3 천연색 도금

1

2

Material SpecDescription

POM(FW700S)

POM(FW700S)

45.5*31*8

45.5*31*8

Page 27

Page 28

G. Evaporator Assembly

1. BSR23T

M odel Code Descript ion

NO. Qty

R2263-072 Evapor ator Assy

11

21

R1143-202 Evap D rai n In sul -S

31

R3853-580 Evap A ir Gui de Left

41

R3853-570

51

R3813-810 Evap Co ver Bracket LF

61

R3813-802

71

R3813-600

81

R3744-090 Evap D rai n Elb ow-U pp

91

R3744-100 Evap D rai n Elb ow-Low

10 1

R2124-021 Evapor ator Dr ain Hose-A

11 1

R7393-020 Lamp Soket

12 1

R7394-010 -

13 1

R3813-990 Lamp Cover - M ips W hi te

14 1

R3203-482 M otor Fix Bracket

15 1

R7423-300 Evapor ator Fan M otor

16 1

R3729-010

17 1

R3812-141 Evapor ator Fan M otor Guard

18 1

19 1

R3314-191 Sensor Bracket

20 1

R7213-112 Temp Di splay Sensor - Wh it e, L=200

21 1

Evap Air Guide Right

Evap Cover Bracket RH

Eva Cover T23

Lam p Bu lb

Evap Fan Blade

Material

-

ALR3743-220 Evap D rai n Pan Smal l

Fo am -P S-T= 17, 256x530

STS443CT-2B T= 0.5, 255.3x155.6

STS443CT-2B T= 0.5, 255.3x155.6

STS430-2B T=1.0, 565x34.8

STS430-2B T=1.0, 565x34.8

AL3003 T= 0.5, 654.6x573

PP White

PP White

Si li con ∮16x12, L= 213

- L-125B 660W 250V

STS430-2B

CCW

CCW 8"

HIPS V H-1800EX

-R7403-110 Harness Lamp L

PP White

Spe c

-

25T10/120V 25W

T= 1.0, 90x146

AC115V 60Hz DAI-8204DYCA-1

UL AWG 18

Page 28

Page 29

G. Evaporator Assembly

d

2. BSF23T

M odel Code Description M aterial Spec

NO. Qty

R2263-051 Evapor ator Assy

11

R7313-331 Def rost Heat er - 115V /445W

21

R3743-220 Evap D rain Pan Smal l AL -

31

R1143-202 Evap D rain Insul -S Foam-PS T= 17, 256x530

41

51

R3853-570 Evap A ir Gui de Ri ght STS443CT-2B T= 0.5, 255.3x155.6

61

R3813-810 Evap Cov er Bracke t LF STS430-2B T= 1.0, 565x34.8

71

R3813-802 Evap Cov er Bracke t RH STS430-2B T=1.0, 565x34.8

81

R3813-604 Eva Cover T23 AL3003

91

R3744-090 Evap D rain Elbow-U pp PP Whit e

10 1

R3744-100 Evap D rain Elbow-Lo w

11 1

R2124-021 Evapor ator Dr ain Hose-A Sil icon ∮16x12, L=213

12 1

R8393-030 Heat er Cord Drai n H ose - 115V 10W

13 1

R7393-020 Lamp Soket -

14 1

R7394-010 Lamp Bulb -

15 1

R3813-990 Lamp Cover - M ips W hite

16 1

R3203-482 M otor Fix Bracket STS430-2B T=1.0, 90x146

17 1

R7423-300 Evaporator Fan M otor

18 1

R3729-010 Evap Fan Blade CCW 8"

19 1

R3812-141 Evapor ator Fan M otor Guar

20 1

R7403-110

21 1

R3314-191

22 1

R7213-082

23 1

R7303-174 Heat er Drai n P an - 115V ,90W

24 1

Evap A ir Guide LeftR3853-580

Harness Lamp L UL AWG 18

Sensor Bracket

Temp Ther misor, FRE

-

-

STS443CT-2B T= 0.5, 255.3x155.6

T= 0.5, 654.6x573

PP

White

L-125B 660W 250V

25T10/120V 25W

CCW

AC115V 60Hz DAI-8204D YCA-1

HIPS V H-1800EX

White

PP

Yellow

-

Page 29

Page 30

G. Evaporator Assembly

3. BSR49T

M odel Code Description Materi al Spec

NO. Qty

R3853-800 Evap Cover Support LF STS443CT-2B T= 0.5, 519.4x176.7

11

R3813-554 Eva Cover T49R

21

R3853-790 Evap Cover Support RH STS443CT-2B T= 0.5, 519.4x176.7

31

R3812-141

41

R2263-082 Evaporato r A ssy - -

51

R3743-041 Evaporato r D rain Fan-M id AL -

61

R3853-050 Evap Ai r Gu ide Left

71

R1143-222 Evaporato r D rain In sul -M Foam-PS

81

R3853-040 Evap Ai r Gu ide Righ t

91

R3203-482 M otor Fix Bracket STS430-2B T= 1.0, 90x146

10 1

R7423-300 Evaporato r Fan M otor CCW

11 1

R3729-010 Evap Fan Blade CCW 8"

12 1

R3744-090 Evap Drai n Elbow-Upp PP Wh ite

13 1

R3744-100 Evap Drai n Elbow-Low PP Wh it e

14 1

R2124-021 Evaporato r D rain Hose-A Sil icon ∮16x12, L= 213

15 1

R7393-020 Lamp Soket - L-125B 660W 250V

16 1

R7394-010 Lamp Bul b - 25T10/120V 25W

17 1

R3813-990 Lamp Cover - M ips Wh ite

18 1

R7403-110 H arness Lamp L - UL AW G 18

19 1

R3314-191 Sensor Bracket PP Wh ite

20 1

R7213-082 Tem p Displ ay Sensor - Wh ite, L=200

21 1

Evaporator Fan Motor Guard

STS443CT-2B T= 0.5, 727x522

HIPS VH -1800EX

AL T= 0.5, 255.3x155.6

T= 17, 256x622

AL T= 0.5, 255.3x155.6

AC115V 60Hz DAI-8204DYCA-1

Page 30

Page 31

G. Evaporator Assembly

4. BSF49T

M odel Code Descri ption M aterial Spec

NO. Qty

R3853-800 Evap Cover Support LF STS443CT-2B T= 0.5 , 519.4x176.7

11

R3813-564 Eva Cover T49F STS443CT-2B T=0.5, 727x522

21

R3853-790 Evap Cover Support RH STS443CT-2B T= 0.5 , 519.4x176.7

31

R3812-141

42

R2263-062 Evapora tor Assy - -

51

R7313-440 Def rost Heat er 60 -

61

R3743-041 Evapora tor Dra in Fan-Large AL -

71

R7313-431 Heat er D rai n Pan _ 115V 90W

81

R3853-050 Evap A ir Gui de Left AL T=0.5, 255.3x155.6

91

R1143-212 Evapora tor Dra in Insu l-L Foam-PS T=17, 256x800

10 1

R3853-060 Evap A ir Gui de M id A L T= 0.5 , 245x127

11 1

R3853-040 Evap A ir Gui de Rig ht A L T= 0.5, 255.3x155.6

12 1

R3203-482 M otor Fix Br acket STS430-2B T=1.0, 90x146

13 2

R7423-300 Evaporator Fan Mot or CCW

14 2

R3729-010 Evap Fan Bl ade CCW 8"

15 2

R3744-090 Evap D rain Elbo w-U pp PP Whi te

16 1

R3744-100 Evap D rain Elbo w-Low PP W hit e

17 1

R2124-021 Evapora tor Dra in Hose-A Silicon ∮16x1 2, L=213

18 1

R7313-490 Heat er Co rd D rai n H ose - 115V1 0W

19 1

R7393-020 Lamp Soket - L-125B 660W 250V

20 1

R7394-010 Lamp Bulb - 25T10/120V 25W

21 1

R3813-990 Lamp Cover - M ips Wh ite

22 1

R7403-110 Har ness Lamp L - U L AW G 18

23 1

R3314-191 Sensor Bracket PP Wh ite

24 1

R7213-082 Temp Disp lay Sensor - Wh ite , L=200

25 1

Evapor ator Fan Motor Guard

HIPS V H-1800EX

AC115V 60Hz DAI-8204D YCA-1

Page 31

Page 32

G. Evaporator Assembly

5. BSR72T

M odel Code Descri ption M aterial Spec

NO. Qty

R3853-800 Evap Cover Support LF STS443CT-2B T=0.5, 519.4x176.7

11

R325A-010 Co ver Eva T72R STS443CT-2B T= 0.5, 845x653.5

21

R3853-790 Evap Cover Support RH STS443CT-2B T= 0.5, 519.4x176.7

31

R3812-141

42

R840A-010 A ss'y Evaporat or T72R AL -

51

R3743-031 Evap orat or Drai n Fan-Larg e

61

R3853-050 Evap Ai r Gu id e Left A L T= 0.5, 255.3x155.6

71

R1143-212 Evap orat or Drai n Insu l-L Fo am-PS T=17, 256x800

81

R3853-060 Evap Ai r Gu id e M id A L T= 0.5, 245x127

91

R3853-040 Evap Ai r Gu id e Rig ht AL T= 0.5, 255.3x155.6

10 1

R3203-482 M otor Fix Bracket STS430-2B T= 1.0, 90x146

11 1

R7423-300 Evap orat or Fan M otor CCW

12 1

R3729-010 Evap Fan Blad e CCW 8"

13 1

R3744-090 Evap Drain Elbow -Up p PP White

14 1

R3744-100 Evap Drain Elbo w-Low

15 1

R2124-021 Evap orat or Drai n Hose-A

16 1

17 2

R7393-021 Lam p Sok et - L-125B 660W 20V

18 2

R3813-991 Lam p Cover

19 2

R7403-111 H arn ess Lamp L - U L AWG 18

20 2

R3314-191 Sen sor Bracket PP W hite

21 1

R7213-082 Temp D ispl ay Sensor - Wh it e, L=200

22 1

Evaporator Fan Motor Guard

Lam p Bu l bR7394-010 - 25T10/120V 25W

HIPS V H-1800EX

AL(Coating) -

AC115V 60Hz DAI-8204DYCA-1

PP W hi te

Si l icon ∮16x12, L= 213

- M ips White

Page 32

Page 33

G. Evaporator Assembly

5. BSF72T

Model Code D escripti on M at erial Spec

NO. Qty

R3853-800 Evap Cover Su pport LF STS443CT-2B T= 0.5, 519.4x176.7

11

R325A-0 20 Cover Eva T72F STS443CT-2B T= 0.5, 1082x654

21

R3853-790 Evap Cover Su pport RH STS443CT-2B T= 0.5, 519.4x176.7

31

R3812-141

42

R2263-100 Ass'y Evaporat or T72F CU + AL -

51

R7313-440 Defrost Heater 60 - 115V 900W 14.7Ω

61

R3743-240 Evaporato r Dr ain Fan-Lar ge AL(Coat ing) -

71

R7313-431 Heater Drai n Pan _ 115V 90W

81

R3853-050 Evap Ai r Gui de Left AL T= 0.5, 255.3x155.6

91

R1143-212 Evaporato r Dr ain Insu l-L Foam-PS T= 17, 256x8 00

10 1

R3853-060 Evap Ai r Gui de M id A L T= 0.5, 245x127

11 1

R3853-040 Evap Ai r Gui de Right AL T= 0.5, 255.3x155.6

12 1

R3203-482 Mo tor Fix Bracket STS430-2B T= 1.0, 90x146

13 2

R7423-300 Evaporato r Fan M otor CCW

14 2

R3729-010 Evap Fan Blade CCW 8"

15 2

R3744-090 Evap Drai n Elb ow-U pp PP W hit e

16 1

R3744-100 Evap Drai n Elb ow-Low PP Wh ite

17 1

R2124-021 Evaporato r Dr ain Hose-A Sili con ∮16x12, L= 213

18 1

R7313-490 Heater Cord Drai n H ose - 115V 10W

19 1

R7394-010 Lamp Bul b - 25T10/120V 25W

20 2

R7393-021 Lamp Soket - L-125B 660W 20V

21 2

R3813-991 Lamp Cover - Mi ps Whi te

22 2

R7403-111 Harness Lam p L - UL AW G 18

23 2

R3314-191 Sensor Bracket PP Wh ite

24 1

R7213-082 Temp D ispl ay Sensor - Yel low

25 1

Evaporator Fan Motor Guard

HIPS V H-1800EX

AC115V 60Hz DAI-8204DYCA-1

Page 33

Page 34

H. Vapori Assembly

1. BSR23T, BSF23T, BSF49T

M odel Code Description M aterial Spec

NO. Qty

R3132-600 Case Vapori T49 ABS 602.5x275x106.5

11

R3422-050 Cover DC M otor T49 ABS 280.5x131x11.5

21

R3422-030 Case DC M otor T49 ABS 283x143.5x69.5

31

R7423-442 M otor DC V apori - DC12V, 250mA, 3000RPM

41

R1154-090 Wicking Drain Water 부직포 2.5Tx480x63.5

58

R3853-780 Gui de Wi cking (49D) PP T=1.5, 269x40

62

R3313-730 Bracket Case V apori Front STS304 T= 1.2, 85.5x20.5

72

Page 34

Page 35

H. Vapori Assembly

2. BSR49T

M odel Code Description M aterial Spec

NO. Qty

R3132-600 Case Vapori T49 ABS 602.5x275x106.5

11

R3422-050 Cover DC M otor T49

21

R3422-030

31

R7423-442

41

R3743-400 Holder V apori Heater

55

R7703-290

61

R3313-730 Brack et Case V apori Front STS304 T= 1.2, 85.5x20.5

72

Case DC M otor T49 ABS 283x143.5x69.5

Motor DC Vapori -

Heater Vaporizer 115V 50W Sheath Heater

ABS 280.5x131x11.5

DC12V , 250mA, 3000RPM

Sil icon 33x20x13.5

Page 35

Page 36

H. Vapori Assembly

3. BSR72T

M odel Code Description M aterial Spec

NO. Qty

R3132-600 Case Vapori T49 ABS 602.5x275x106.5

12

R3422-050 Cover DC M otor T49 ABS 280.5x131x11.5

22

R3422-030 Case DC M otor T49 ABS 283x143.5x69.5

32

R7423-442 M otor DC V apori - DC12V, 250mA , 3000RPM

42

R3743-400 Hol der V apori Heater Sili con 33x20x13.5

510

R7703-290 Heater Vaporizer 115V 50W Sheath Heat er

62

R3313-730 Brack et Case V apo ri Fron t STS304 T= 1.2, 85.5x20.5

74

R223A-020

82

R223A-010 FITTING DIVIDER VAPO RI - BSPP AM CB 1207M

92

R225A-010 FITTING TUBE - PE TUBE ¢12 L= 100mm

10 1

FITTING DIVIDER VAPORI NUT

- PP NU T 20M

Page 36

Page 37

H. Vapori Assembly

3. BSF72T

M odel Code Description Material Spec

NO. Qty

R3132-600 Case V apori T49 ABS 602.5x275x106.5

12

R3422-050 Cover DC M otor T49 ABS 280.5x131x11.5

22

R3422-030 Case DC M o tor T49 ABS 283x143.5x69.5

32

R7423-442 M ot or DC V apori - DC12V, 250mA , 3000RPM

42

R1154-090

516

R3853-780 Guide Wicki ng (49D) PP T= 1.5, 269x40

64

R3313-730 Bracket Case V apori Front STS304 T= 1.2, 85.5x20.5

74

R223A-020

82

R223A-010 FITTING DIV IDER V APORI - BSPP AM CB 1207M

92

R225A-010 FITTING TUBE - PE TU BE ¢12 L=100mm

10 1

Wicking Drain Water

FITTING DIVIDER VAPORI NUT

부직포

- PP NUT 20M

2.5Tx480x63.5

Page 37

Page 38

Ⅲ. WIRING DIAGRAM

A. BSR23T(LRT-23S)

B. BSF23T(LFT-23S)

Page 38

Page 39

Ⅲ. WIRING DIAGRAM

C. BSR49T(LRT-49D)

D. BSF49T(LFT-49D)

Page 39

Page 40

Ⅲ. WIRING DIAGRAM

E. BSR72T(LRT-72T)

F. BSF72T(LFT-72T)

Page 40

Page 41

Ⅳ. General Information

A. Control Buttons and Functions

1. Display Board

a) Setting

- Down : level-down of temperature.

- Up: level-up of temperature

Preset Setting Level Level Note

Refrigerator

℃

Freezer -18 -23~-15 9 Step

Refrigerator

℉

Freezer 0 -9~5 15 Step

b) Display

① 888 SEGMENT Display

- The temperature setting button pressed, the 888 Segment blinks

at 0.5-second intervals showing the set temperature.

- Temperature setting is available with the △▽ buttons.

- The setting is auto-saved in 5 seconds and the current inside temperature is displayed.

② Temperature Display

- Regular mode: The inside temperature is displayed.

- Pre-cool mode: The off-point temperature set is displayed.

ex) -0.4℉(-18℃) set, the temperature of “-4℉(-20℃),” identical to the compressor-off

temperature, is shown for -4℉(-20℃) or below.

2 -2~4 6 Step

35 28~39

12 Step

℃

℉

- In defrosting: “dF” display: Defrosting heater on -> 5-min respite -> fan (respite)

Display until 1 minute after the inside fan is on (regular mode)

*In refrigerator, the actual inside temperature is shown.

③ Door LED Display

- LED blinking while the door is opened.

Page 41

Page 42

c) Location

The display board is located on the right hand side of "Top Grill Assembly"

From the display board, various electronic controls and function can be adjusted.

See " C - 3."

Top Grill

assembly

Door

d) Lay out

Ribbon Cable Connector

Door Open LED

RT Sensor

888 SEGMENT

* RT Sensor : Ambient temperature Sensor

DOWN Button

UP Button

Page 42

Page 43

2. Control Board

1. Fragile, handle very carefully.

2. The control board contains integrated circuits, which are susceptible to failure

due to static discharge. It is especially important to touch the metal part of the

unit before handling or replacing the board.

3. Do not fix the electronic devices or parts on the board in the field. Always

replace the whole board assembly if it goes bad.

4. To prevent damage to the borad, do not touch the electronic devices on the

board or the back of the board.

5. Do not short out power supply to test for voltage.

a) Location

The control box is located behind the "Top Grill Assembly".

If you remove 7 fixing screws, the control box can be found.

CAUTION

Top Grill

assembly

Screw

Control

box

Page 43

Page 44

b) Control Board Layout

r

r

r

r

y

y

r

y

r

r

CON7

Cabinet

Heater

CON14 Transformer DC

CON5 Defrost SENSOR

RY3

C-Heate

Rela

E-Fan

Rela

RY4

CON9 Room Sensor

RY2

D-Heate

Rela

CON2

Power Cord

CON10 Display cable 10P

RY1

Compresso

Relay

Door Signal

CON6

Compresso

Test Switch

CON11 Display cable 8P

CON12

CON13

Vaporizer Fan

CON4

Evaporato

Fan

CON1

Transforme

AC

CON4

Defrost Heate

* Regerator models (BSR23T, BSF23T) do not have CON4 and RY2.

Page 44

Page 45

B. Sequence of Operation and Timing Charts

A

k

1. Refrigerator ( BSR23T, BSR49T)

a) Sequence of Operation

POWER ON

BOARD CHECK

(Type & Beep will blink

-->℉/℃ will blink

--> Model Name will blink

--> All LED will blink)

1. Frame Heater on*

Cycle On(Cut-on

temperature reached)

1. Compressor on

2. Condenser fan on

5 minutes delay

1. Compressor start-up

2. Condenser fan start-up

3. Evaporator fan start-up

Defrost Start

Preprogrammed time interval*

1. Comperssor off

2. Condenser fan off

* default : 5hr

Cycle Off(Cut-out

temperature reached)

1. Compressor off

2. Condenser fan off

Defrost End

fter 30 minutes, Chec

set return temperature*

1. Comperssor on

2. Condenser fan on

Normal cycling continues

Note : The start circuit of the compressor is timed such that at power-up and during

any compressor off time, there will be at least 5minutes delay before the com pressor will start. The only exception is when the overload activates and deact ivates. The compressor has a 5 minute minimum run time during every run cycle.

Page 45

Page 46

b) Timing Chart (BSF23T, BSF49T)

P

ON

5min

Max.

45min

* Defa ult s etting 8hour s , a djustab le

▲ S etva lue minus 8℃

● Defros t senser Temp' - 10℃

Max.

5min

Max . 5 0min

*8 hours

Defrost S tart

Ti me

5 min.

ON

No meani ng

Pr e-se t val ue

Pre-set val ue

Defrost Sensor

Pr e-se t val ue

Roo m Sensor

Com pressor

ON

OFF

Co nd enser Fan

ON

OFF

Evap orator Fan

ON

OFF

Defrost Heater

ON

OFF

Defrost indicator

ON

OFF

*Cabinet Heater

ON

OFF

OFF

Vaporizer Fan

ower

Page 46

Page 47

2. Freezer (BSF23T, BSF49T)

a) Sequence of Operation

POWER ON

BOARD CHECK

(Type & Beep will blink

--> ℉/℃ will blink

--> Model Name will blink

--> All LED will blink)

1. Frame Heater on*

Cycle On(Cut-on

temperature reached)

1. Compressor on

2. Condenser fan on

Defrost End

Defrost sensor reaches 51℉

(11℃)

Defrost Heater off

5 minute delay

1. Compressor start-up

2. Condenser fan start-up

3. Evaporator fan start-up

Pre-Cool

Cabinet Temp' falls to

set temp' 17℉(-8℃) within

45minutes.

Five minutes after defrost

heater off

1. Compressor on

2. Condenser fan on

Cycle Off(Cut-out

temperature reached)

1. Compressor off

2. Condenser fan off

Defrost Start

Preprogrammed time interval*

1. Comperssor off

2. Condenser fan off

3. Evaporator fan off

4. Defrost Heater on

5."dF" displayed

*Default : 8hours

Defrost sensor reaches below 14℉(

-10℃)

1. Evaporator fan on

2. Cabinet Temp displayed

Normal cycling continues

Note : The start circuit of the compressor is timed such that at power-up and during

any compressor off time, there will be at least 5minute delay before the com pressor will start. The only exception is when the overload activates and deact ivates. The compressor has a 5 minute minimum run time during every run cycle.

Page 47

Page 48

b) Timing Chart

P

ON

* Defa ult s ettin g 8hours, a djustab le

▲ Set va lue minus 8℃

● Defros t senser T emp' -10℃

Max.

5min

5min

Max. 50min

Max.

45min

*8 hours

Defrost S tart

Time

5 min.

ON

No meani ng

Pre-set val ue

Pr e-set value

Defrost Sensor

Pre-set value

Room Sensor

Co m p ressor

ON

OFF

Co nd ense r Fan

ON

OFF

Evaporator Fan

ON

OFF

Defrost Heater

ON

OFF

Defrost indicator

ON

OFF

*Cabinet Heater

ON

OFF

OFF

Vaporizer Fan

ower

Page 48

Page 49

C. Board Details & Setting

1. Board Details

MODE Description

No.

Initial power

1 1. Stand by

supply

- In operation, all output is off for 2 seconds.

- In 2 seconds, the buzzer sounds with 2 blinks at a 0.5-second interval.

- Then, additional 2 blinks of “℉/℃” follow at a 0.5-second interval.

- Model name blinks 5times.

- Every LED blinks 3 times at 0.5-second intervals.

- The cabinet temperature is displayed.

2. Initial Defrost Check

< Type F > : BSF23T, BSF49T

- The temperature of defrost sensor controls operation

1) The compressor is on at 38℉(3.5℃) or above.

2) The defrost mode is on when every sensor is at 38℉(3.5℃)

or below

※ The pre-cool mode is on 5 minutes after the defrosting mode is on.

Board Details

<Type R > : BSR23T, BSR49T

- The temperature of room sensor controls operation.

1) The compressor is on at 41℉(5.0℃) or above

2) The defrost mode is on below 41℉(5.0℃).

Regular

2 - 5-min compressor delay

Operation

3 Freezer - Defrost is available at 5, 6, 7, 8, 9 or 10-hour intervals.

(The compressor stops operation for 5 minutes after it is off.)

- The compressor is turned on or off

depending on the room sensor temperature.

The default setting is 8 hours.

Page 49

Page 50

Board Details

MODE Description

No.

4 Refrigerator - defrosting every 5 hours

5 Defrost system - This process is to lower the inside temperature

- Freezer before the defrost heater is on.

1. PRE-COOL - When defrost begins, the pre-cool mode is on

before the defrosting heater is on.

- The defrost heater is on if the cabinet temperature

goes down to or below 17℉(-8℃) within 45 minutes.

- The maximum duration of the pre-cool mode is 45 minutes.

2. HEATER ON - When the D-sensor on evaporator reaches 51℉(11℃),

the defrost heater is off.

- The defrost heater can remain on for up to 50 minutes.

- In case of a D-sensor error,

the heater is in operation for 20 minutes.

Then, it is off if the room sensor temperature is 28℉(-2℃) or above.

- In case of a defrosting or room sensor error,

the heater is operates for up to 20 minutes.

- When the D-sensor does not resume

the defrosting temperature even 50 minutes

after the defrosting heater is on, the error code is automatically saved.

※ The pre-cool mode is off in case of a defrosting limit error.

3. Respite - When the defrost heater turns off,

a 5-minute respite is given to stabilize the freezing cycle.

-Defrost heater, fan and compressor is all off.

4. FAN stop - When the respite is over, the fan stops operation for up to 5 minutes

to prevent the heated evaporator air from entering inside.

- Only the compressor is in operation in this mode,

cooling the evaporator and cabinet air.

- If the D-sensor temperature goes down to or

below 14℉(-10℃) within 5 minutes,

the fan-stop mode is over and regular operation is available.

6 Defrost system - Defrost is available with the operation of the cooling fan.

- Refrigerator - In case of a refrigerator room sensor error,

a 30-minute defrosting begins.

- In 30 minutes, the system checks the refrigerator room sensor temp'.

- Auto-return is on at a certain temperature.

※ If the set temperature is 30℉(-1℃) or below, the return temperature is

37℉(+3℃). If the former is 32℉(0℃), the latter is 41℉(5℃).

Page 50

Page 51

Board Details

MODE Description

No.

7 Cabinet heater - If the compressor-on temperature is lower than the ambient

control temperature, the heater is off.

- If the ambient temperature is 78℉(26℃) or above, the heater is on.

- If the ambient temp' is between 78℉(26℃) and the compressor-on

temp', the heater is turned on and off every 10 minutes.

- If the RT temperature is lower than the compressor-on temperature,

the code heater is off.

8 Refrigerator - When the compressor is off, the evaporator fan is off.

Prevention of - To prevent the refrigerator evaporator from over-frosting,

over-frosting the fan starts operation irrespective of the compressor-on

system or –off temperature if the inside temperature is 32℉(0℃) or below.

9 Door - Door opening: the door-open lamp blinks

- 5 minutes after door opening, the buzzer sounds

and the lamp blinks until it is closed.

10 Evaporator - The fan starts operation when the compressor is on.

fan control - The fan stops operation when the door is opened.

- The fan is off when the compressor is off.

(The fan starts operation irrespective of the compressor-on

or –off temperature if the inside temperature is 32℉(0℃) or below.)

- The fan start operation 3 seconds after the door is closed.

2. Compressor Operation and Re-run Prohibition

a) Compressor Operation

1) The compressor is not to be operated for 5 minutes after it is off.

2) Operation is to depend on the refrigerator and freezer sensor temperatures.

3) Operation is to depend on the preset difference. ( Ex) preset difference >±35℉(2℃): )

- The compressor is on at 35℉(2℃) or more above the set temperature and

off 35℉(2℃) or more below the set temperature.

b) AC Load Sequential Control

1) Simultaneous operation is not available.

An operation starts 1.5 seconds later than another.

COMP 1.5sec

FAN 1.5sec 1.5sec

HTR

Page 51

Page 52

3. SETTING

The Up and Down keys pressed at the same time, the setting mode is on.

S E L SEL is displayed on the 888 Segment

NO

1

2

3

4

5

6

7

8

MODE SW 4(△) DISPLAY Note

Forced Defrost once ds

Mode setting twice OF

TEST 3 times St

Errer check 4 times no

Function change 5 times 23F

℉ / ℃ change 6 times F

Cabinet Heater

setting change

LED check and

EEPROM clear

7 times Ht

8 times All LEDs blinking

a) Forced Defrost mode

1) Display : : “ds” is displayed on the 888 Segment.

2) Activation: The Down switch (▽) pressed in 1),

the setting mode is off and forced defrosting mode is on.

② 888 SEGMENT displays "dF".

b) Mode setting

1) Display: The 888 Segment is displayed like the following.

0 F In 1 second 0 0

Display in 2seconds

(LEDs are off except 888

segment.)

2) Control: The Up button (△) pressed,

the setting mode is altered in order of off-point change, DIF change,

temperature revision and defrosting duration adjustment.

00 a second after 0F: level-up and –down by 32℉(0.5℃)

between 23℉(-5.0℃) and 41℉(+5.0℃)

① 0F, display 00 after a second : level-up and –down by 32℉(0.5℃) between.

(Decimal point and the zero in front of it omitted: 32℉(5) displayed for 32℉(0.5℃)

② 0d, display 20 after a second : 32(0.25) -> 32(0.5) -> 33(0.75) -> 33(1.0) -> 34(1.5)

-> 35(2.0) -> 37(3.0) -> 39(4.0) -> 41(5.0) (decimal point omitted)

③ CA, display 00 after a second : level-up and –down by 33℉(1℃) between 23℉(-5.0)

and 41℉(+0.5) (Inside temperature display adjusted: decimal point omitted)

④ dt, display 6 after a second : In freezing, the minimum defrosting duration levels

up and down by an hour between 0.5 and 10 hours. (no defrosting for 0)

In refrigeration: the defrosting duration levels up and down

by an hour between 0.5 and 10 hours.

- Down(▽): level-up and –down available with the switch

- Adjustments are auto-saved.

- Auto cancellation if no buttons are pressed for 5 seconds.

Page 52

Page 53

c) Equipment Test Mode

1) "St" is displayed on the 888segment.

2) The Up switch(△) pressed, the operations allotted to Level 0 to 3 start.

3) Test Mode Stop : Auto cancellation if no buttons are pressed for 10 seconds at Level 0.

Level Load operation

0 All off

Compressor on

1

Fan on

2

3

Defrost

heater on

Cabinet

heater on

d) Error mode check

1) Display

: The 888 Segment display is like the following.

① No error

Operation

duration

Auto return

in 10 seconds

Contunue

Contunue

Contunue

DISPLAY Note

St

CP

DH t

C

Ht

Not available

for Type R

nO

② Error

S 1 _ : Short error of the S1 sensor

- All of the errors saved in the Micom can be checked with the Up switch(△).

- Please refer to the trouble-shooting guide.

e) Type Change Mode

1) The Down switch(▽) pressed, the mode changes to "FrE".

2) Auto-cancellation and type saving is carried out,

if no buttons are pressed for 5 seconds.

※ If change type, must re-input power.

(The preset values are initialized in type change.)

f) ℉ / ℃ Change Mode

1) The Down switch(▽) pressed, ℉ change to ℃.

2) Auto-cancellation and type saving is carried out,

if no buttons are pressed for 5 seconds.

Page 53

Page 54

g) Cabinet Heater Setting Adjustment

① The Down switch(▽) pressed, change to setting value.

- "00"->"02"->"04" -> ~ "30" -> "40" -> "100" -> "00"

② Mode

Value On Time Off Time Value On Time Off Time

00 15 15 min

02 2 min 10 min 20

04

06 6 min 10 min 30 30 min 10 min

08 8 min 10 min

10 10 min 10 min 100 Cord H/T on

Cord H/T off

4 min 10 min 25

③ Auto-cancellation and type saving is carried out,

if no buttons are pressed for 5 seconds.

f) LED Check and EEPROM Clear

1) All LED automatically turns off after blinking 5 times at 0.5 second intervals.

2) The EEPROM is cleared to save new defaults.

The type set and temperature mark(℉ / ℃) are not cleared.

40

10 min

20 min 10 min

25 min 10 min

40 min 10 min

Page 54

Page 55

D. Error Mode Display

1. ERROR Mode

a) S1 - Sensor Error

1) If the S1-Sensor is short or its temperature is 143℉(62℃) or above,

the segment blinks ESH.

2) If the S1-Sensor is opened or its temperature is -58℉(-50℃) or below,

the segment blinks ESL.

3) Please follow the following operation in case of an S1-Sensor error.

Freezer : On for 10 and off for 20 minutes

Refrigerator : On for 10 and off for 6 minutes

4) Regular operation is available when the error is fixed.

※

Types of Sensors

No.

1

2

3

Sensor Description

S1 - Sensor Detected cabinet temperature.

D1 - Sensor Detected Evaporator Coil temperature to defrost system.

Rt - Sensor Detected ambient temperature.

Page 55

Page 56

2. Trouble Shooting : by blinking location

* Please refer to the Error Check Mode.

NO Category Display Error detail Note

1 S1-SENSOR

2 Rt-SENSOR

D1-SENSOR

3

4

(Defrost -

Sensor)

Defrost

Error

S1

S1_

rt

rt_

D1

D1 _

dF1

Sensor is opened or

at -58℉(-50℃) or below

Sensor is short or

at 149℉(65℃) or above

Sensor is opened

Sensor is short

Sensor is opened or

at -58℉(-50℃) or below

Sensor is short or

at 149℉(65℃) or above

In case of no D1 Sensor

return or auto cancellation

within 50 minutes

Error Mode

operation

Regular

operation

Regular

operation

Regular

operation

5

6

7

8

9

Cycel

Error

Freezer

Temperature

Error

Refrigerator

Temperature

Error

EEPROM

Error

Door

Error

CF1

EHF

EH r

EEP

ED r

If the D1 Sensor temperature is

32℉(0℃) or above 30 minutes

after compressor begins to

operate

If operation at over 59℉

(15℃) continues for 2 hours

If operation at over 44℉

(7℃) continues for 8 hours

in a row

If EEPROM reading and

writing is unavailable

If the door s/w is sensed

open for over an hour

Regular

operation

Regular

operation

Regular

operation

Regular

operation

Error Mode

operation

Page 56

Page 57

E. Compressor Protector

When a combined temperature/amperage value is above the limit specified by the

compressor manufacturer, a protector will operate independently, turning off the

compressor. The compressor will restart when this protector has reset.

Note :

1. Compressor protector resets automatically.

2. If condenser fan is operating and the compressor is off, it is most likely that the

protector has operated.

Page 57

Page 58

Ⅴ. Service Diagnosis

A. Diagnosis Chart

Problem Possible Cause

1. Compress will not

start - no current

draw.

1. Power Switch

2. Cord and Plug 1. Defective. 1. Replace.

3. Ground Fault Circuit

interrupter

4. Voltage 1. Too low. 1. Call electrician.

5. Wiring to Control Board 1. Loose connection. 1. Tighten.

6. Transformer

7. Control Board

8. Compressor Overload

9. Compressor

10. Relay(Compressor) 1. Bad contacts. 1. Replace.

2. Compressor will

not run - draws

1. Voltage 1. Too low. 1. Call electrician.

2. Start Relay 1. Bad contacts. 1. Replace.

current and trips

on overload.

3. Compressor

3. Compressor 1. Locked rotor. 1. Replace.

4. Start Capacitor 1. Defective. 1. Check and replace.

1. Voltage

runs

intermittently

and trips on

overload.

4. Cabinet inside

2. Refrigerant Line or

Component

3. Condenser Fan Motor 1. Failed. 1. Replace.

4. Refrigerant 1. Overcharged. 1. Evacuate and recharge

5. Location of Unit

1. Compressor Relay 1. Defective. ( 115V to

temperature too

high;

2. Circuit Board 1. Defective. ( Compressor

compressor will

not start

Remedy

1. "OFF" position. 1. Move to "ON' position.

2. Loose connection.

3. Failure. 3. Call electrician.

1. Tripped. 1. Check and reset.

2. Defective. 2. Replace.

2. Too hige. 2. Call electrician.

2. Faulty.

1. Open coil winding.

1. Defective. 1. Replace control board.

1. Defective. 1. Replace.

1. Open windings.

2. Open coil winding. 2. Check and replace.

2. Open coil winding. 2. Replace.

1. Too low. 1. Call electrician.

2. Too hige. 2. Call electrician.

1. Plugged or restricted. 1. Clean and replace filter

2. Non-condensible

in system

1. Restricted air flow to

condenser.

relay coil.)

relay coil not energized

at 115V.)

2. Tighten.

2. Check continuity

and replace.

1. Check continuity

and replace.

1. Check continuity

and replace.

2. Evacuate and recharge

1. Move unit or increase

ventilation.

1. Check and replace.

1. Replace.

Page 58

Page 59

Problem Possible Cause Remedy

5. Cabinet

temperature too

high.

1. Setpoint 1. Incorrect. 1. Correct setpoint.

Factory defaults :

Freezer -0.4℉(-18℃)

Refrigerator 35℉(2℃)

6. Cabinet

temperature dis

- play indicator

does not illumi

- nate properly.

7. Cabinet inside

temperature too

low.

8. Evaporator does

not defrost

completely

2. Door 1. Not sealing, or open

for long intervals.

3. Defrost 1. Not enough defrosts

occurring per day.

Operation in humid

conditions.

4. Refrigerant 1. Leak.

5. Fan Motor 1. Defective. 1. Check and replace.

6. Condenser 1. Dirty. 1. Clean.

7. S1-Sensor 1. Defective. 1. Check and replace.

8. Control Board 1. Defective. 1. Replace.

1. Board Connection 1. Bad connection

between control board

and display board.

2. Display Board 1. Defective. 1. Replace.

3. Control Board 1. Defective. 1. Replace.

1. Sensor 1. Defective. 1. Check and Replace.

2. Compressor Relay 1. Defective;

contacts welded.

3. Circuit Board 1. Defective. 1. Replace.

1. D-Sensor 1. Defective. 1. Check and replace.

2. Defrost 1. Not enough defrosts

occurring per day.

Operation in humid

conditions.

1. Check for sealing,

check for door open

at time of warm

cabinet temperature.

1. Freezer ; See "C. 1. 5

Defrost System."

2. Refrigerator : "C. 1. 6

Defrost System."

3. Check D-Sensor

position.

1. Repair leak and

recharge

1. Check connection.

1. Replace.

1. Freezer ; See "C. 1. 5

Defrost System."

2. Refrigerator : "C. 1. 6

Defrost System."

3. Check D-Sensor

position.

3. Defrost Heaters 1. Defective. 1. Freezer : Replace

heaters.

4. Safety Defrost Thermostat 1. Defective, turning off

heaaters prematurely,

or fused open.

1. Freezer : Replace

safety deforst

thermostat.

Page 59

Page 60

Problem Possible Cause Remedy

9. Defrost cycle

lasts too long.

1. Defrost Sensor 1. Defective. 1. Replace.

2. Control Board 1. Defective. 1. Replace.

3. Defrost 1. Not enough defrosts

occurring per day.

Operation in humid

conditions.

3. Defrost Heaters 1. Defective. 1. Freezer : Replace

1. Freezer ; See "C. 1. 5

Defrost System."

2. Refrigerator : "C. 1. 6

Defrost System."

3. Check D-Sensor

position.

heaters.

4. Safety Defrost Thermostat 1. Defective, turning off

heaaters prematurely,

or fused open.

11. Abnormal noise 1. Fasteners 1. Loose fasteners

allow vibration

of part.

2. Compressor 1. Problem with mount. 1. Properly mount comp-

2. Floodback to

compressor.

3. Defective. 3. Replace.

3. Fan 1. Fan blade loose. 1. Adjust and tighten.

2. Defective motor. 2. Replace.

4. Relay 1. Chattering. 1. Replace.

1. Freezer : Replace

safety deforst

thermostat.

1. Tighten fasteners.

ressor. Replace any

missing grommets.

2. Check for signs of

floodback to compre ssor. Evacuate and

recharge if necessary.

B. Thermistor Check

Thermistors (semiconductors) are used for the cabinet control sensor and defrost termination

sensor. The resistance varies depending on temperature. No adjustment is required.

If necessary, check for resistance between thermistor leads and visually check the thermistor

mounting.

Page 60

Page 61

Pre-set value

5

Room Sensor

Pre-set value

Compressor

OFF

Condenser Fan

OFF

ON

Evaporator Fan

OFF

ON

*Cabinet Heater

OFF

■

ON

min.

ON

ON

Vaporazer Fan

OFF

Time

Power ON

5hours

Defrost start

■ Set value -1℃↓ : Return Temp' +3℃

Set value 0℃ ↑ : Return Temp' +5℃

* AT <Comp ON Temp : Heater OFF

Comp ON Temp <AT < 26℃ : 10 min. ON / OFF

26 ℃ < AT : Heater ON

AT : Ambient Temperature

Page 61

Page 62

Pre-set value

Defrost Sensor

No meaning

Pre-set value

Room Sensor

Pre-set value

ON

Compressor

OFF

ON

Condenser Fan

OFF

5 min.

5min

Max.

45min

ON

Evaporator Fan

OFF

ON

Defrost Heater

OFF

ON

Defrost indicator

OFF

ON

*Cabinet Heater

OFF

ON

Vaporizer Fan

OFF

Time

Power ON

*8 hours

Defrost Start

Max.5

min

Max. 50min

▲ Set value minus 8℃

● Defrost senser Temp' -10℃

* Default setting 8hours, adjustable

Page 62

Page 63

Ⅵ. Removal and Replacement of Components

A

A. Removal and Replacement of Compressor

IMPORTANT

lways install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

flow.

Note : When replacing a compressor with a defective winding, be sure to install the

new start capacitor and start relay supplied with the replacement compressor.

Due to the ability of the POE oil in the compressor to absorb moisture quickly,

the compressor must not be opened more than 15 minutes for replacement or

service.

1) Unplug the unit from the electrical outlet.

2) Recover the refrigerant and store it in approved container.

3) Remove the terminal cover on the compressor, and disconnect

the compressor wiring.

4) Remove the discharge and suction pipes.

5) Remove the hold-down bolts.

6) Remove the compressor. Unpack the new comoressor package.

7) Attach the rubber grommets of the prior compressor.

8) Place the compressor in position and secure it using the bolts.

9) Remove the drier, then place the new drier in position.

10) Remove plugs from the suction, discharge and process pipes.

11) Braze all fittings while purging with nitrogen gas flowing at a pressure

of 3 to 4 PSIG.

12) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

13) Evacuate the system, and charge it with refrigerant. See the nameplate for

the required refrigerant charge.

14) Connect the terminals and replace the terminal cover in its correct position.

15) Plug the unit back in.

Page 63

Page 64

B. Removal and Replacement of Evaporator

A

IMPORTANT

lways install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

flow.

1) Unplug the unit from the electrical outlet.

2) Recover the refrigerant and store it in am approved container.

3) Remove the insulation tubing.

4) Disconnect evaporator inlet & outlet pipes.

5) Remove fixed screws and remove " cover evaporator."

6) Unhook all wiring connections to cover evaporator.

7) Remove the screws that secure evaporator.

8) Place the new evaporator in position and secure it using screws.

9) Remove the drier, then place the new drier in position.

10) Check for leaks using nitrogen gas ( 140 PSIG ) and soap bubbles.

11) Evacuate the system, and charge it with refrigerant. See the nameplate for

the required refrigerant charge.

12) Replace the removed parts in the reverse order of which they wer removed.

13) Plug the unit back in.

Page 64

Page 65

C. Removal and Replacement of Door Closer

1) Remove the top Grill assembly.

2) Remove the bolts at top hinge.

3) Open the door approximately 90°

4) Remove stopper door.

5) Insert the new door closer.

Note : When install door closer, Check door closer right and left

*Check right and left

and lift door up.

Door Closer

6) Replace the stopper door and secure it using the screws.

7) Reverse procedure to reassemble door to cabinet.

Stopper Door

Page 65

Page 66

D. Removal and Replacement of Control Board

1) Unplug the unit from the electrical outlet.

2) Remove the control box cover.

3) Unhook all wiring connections to the control board.

4) Remove the control board by carefully squeezing the tips of the board mounts.

5) Identify the board revision and function(refrigerator/freezer).

6) Replace the board in the control box taking care not to damage it.

7) Hook all wiring connections back to the control board.

8) Replace the control box cover.

9) Plug the unit back in.

Page 66

Page 67

E. Door Re-Hinging ( only 23 models )

A

23 models of the door is reversible as shown below.

: The door hinges

on the right cabinet wall

* manufacture specification.

Page 67

B : The door hinges

on the left cabinet wall

Page 68

1) Remove the top grill assembly.

2) Remove the bolts at top hinge.

3) Open the door approximately 90°

4) Remove stopper door and door closer(R).

5) Remove the bushing door and insert door closer (L) and stopper door.

Bushing Door

and lift door up.

Door Closer(L)

6) Insert bushing door on the opposite side of door.

7) Replace the bottom hinge (L).

8) Replace the door that changed door closer.

9) Replace the top hinge (R).

10) Reassemble the top grill assembly.

Note : Door closer (L) , bottom hinge (L) and top hinge (L) are optional parts.

Page 68

Page 69

Ⅶ. Cleaning Instructions

1. CLEANING THE INTERIOR AND EXTERIOR

- The interior and exterior of the unit can be cleaned using warm water with soap.

- Do not use an abrasive cleaner because it will scratch the surface.

2. CLEANING THE CONDENSER FINS

- To maintain proper refrigeration performance, the Condenser coil must be free of dust,

dirt, and grease.

It will require to clean it periodically. Condenser fins should be cleaned, at least every

three months (90 days) or as needed.

3. CLEAN THE GASKET

- The door gasket should be cleaned frequently to maintain proper sealing.

Use warm water and a mild soap.

4. CHECK AFTER CLEANING

- Check the unit again for safety.

- Check that the unit is operating properly.

Page 69

Loading...

Loading...