Bloomfield E-Max LX 2212, E-Max LX 2216, E-Max LX 2216EX, E-Max LX 2272, E-Max LX 2274EX Owner's Manual

Page 1

BLOOMFIELD INDUSTRIES

2 ERIK CIRCLE, P.O.Box 280

Verdi, NV 89439 U.S.A.

Customer Service (775) 345-0444 Ext.502

fax (775) 345-0569

www.wellsbloomfield.com

OWNERS MANUAL

DECANTER

BREWER

656

LX

Model 2216

shown with

optional

decanters

MODELS

2212

2216

2216EX

2272

2274EX

Includes

INSTALLATION

OPERATION

USE & CARE

SERVICE

p/n 74733 Rev. D M656 050208 cps

Page 2

WARRANTY STATEMENT

All electrical equipment manufactured by BLOOMFIELD

INDUSTRIES is warranted against defects in materials and

workmanship for a period of one year from the date of original

installation or eighteen (18) months from the date of shipment

from our factory, whichever comes first, and is for the benefit

of the original purchaser, except that:

a. airpots carry a 30 day parts warranty only.

b. dispensers; i.e., tea and coffee carry a 90 days parts

warranty only, excludes decanters.

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN IN

LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE HEREBY EXCLUDED.

BLOOMFIELD INDUSTRIES DIVISION / SPECIALTY

EQUIPMENT MANUFACTURING CORPORATION SHALL

NOT BE LIABLE FOR INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES FROM ANY

CAUSE WHATSOEVER.

This warranty is void if it is determined that upon inspection by

an Authorized Service Agency that the equipment has bee n

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God.

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers,

overload protectors, or fuse replacements unless

warranted conditions are the cause.

2. All problems due to operation at voltages other than

specified on equipment nameplates; conversion to

correct voltage must be the customer’s responsibility.

3. All problems due to electrical connections not made in

accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Replacement of items subject to normal wear, to include

such items as knobs and light bulbs. Normal maintenance

functions including adjustment of thermostats, microswitches,

and replacement of fuses and indicating lights are not

covered under warranty.

5. All problems due to inadequate water supply, such as

fluctuating, or high or low water pressure.

6. All problems due to mineral/calcium deposits, or

contamination from chlorides/chlorines. De-liming is

considered a preventative maintenance function and is

not covered by warranty.

It also does not apply if the serial nameplate has been

removed or unauthorized service personnel perform serv ice.

The prices charged by Bloomfield Industries for its products

are based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of defects

without charge by a Bloomfield Industries Authorized Service

Agency or one of its sub-agencies. This service will be

provided on customer’s premises for non-portable models.

Portable models (a device with a cord and plug) must be

taken or shipped to the closest Authorized Service Agency,

transportation charges prepaid, for services.

In addition to restrictions contained in this warranty, specific

limitations are shown below (Additional W arranty Exclusions).

Bloomfield Industries Authorized Service Agencies are located

in principal cities.

This warranty is valid in the United States and void elsewhere.

Please consult your classified telephone directory or your food

service equipment dealer; or, for information and other details

concerning warranty, write to:

Phone: (775) 345-0444 Fax: (775) 345-0569

7. Full use, care and maintenance instructions are supplied

with each machine. Those miscellaneous adjustments

noted are customer responsibility. Proper attention will

prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an

authorized Service Agency or one of its sub-agencies.

9. All labor shall be performed during normal working hours.

Overtime premium shall be charged to the customer.

10. All genuine Bloomfield replacement parts are warranted

for ninety (90) days from date of purchase on non warranted equipment. Any use of non-genuine

Bloomfield parts completely voids any warranty.

11. Installation, labor and job check-out are not considered

warranty.

12. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technicians ability

to perform services are not covered by warranty.

This includes institutional and correctional facilities.

Service Parts Department

Bloomfield Industries

P.O. Box 280

Verdi, NV 89439

SHIPPING DAMAGE CLAIMS PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory.

Upon acceptance of this shipment, the transportation

company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill

or express receipt, and that the note of loss or damage

is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

must be done within fifteen (15) days from the date the

delivery was made to you. Be sure to retain the

container for inspection.

Bloomfield Industries cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY STATEMENT xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

INSTALLATION INSTRUCTIONS 5

AGENCY APPROVAL INFORMATION 5

OPERATION 6

USERS GUIDE 7

CLEANING INSTRUCTIONS 8

SERVICING INSTRUCTIONS

Operational Adjustments 9

Electrical 10

Plumbing 12

De-liming Heater Tank 14

Diagnostics & Troubleshooting 15

EXPLODED VIEW & PARTS LIST

In-Line Models 16

Step-Up Models 18

WIRING DIAGRAMS

In-Line Models 20

Step-Up Models 21

Inline Export models 22

Step-up Export models 23

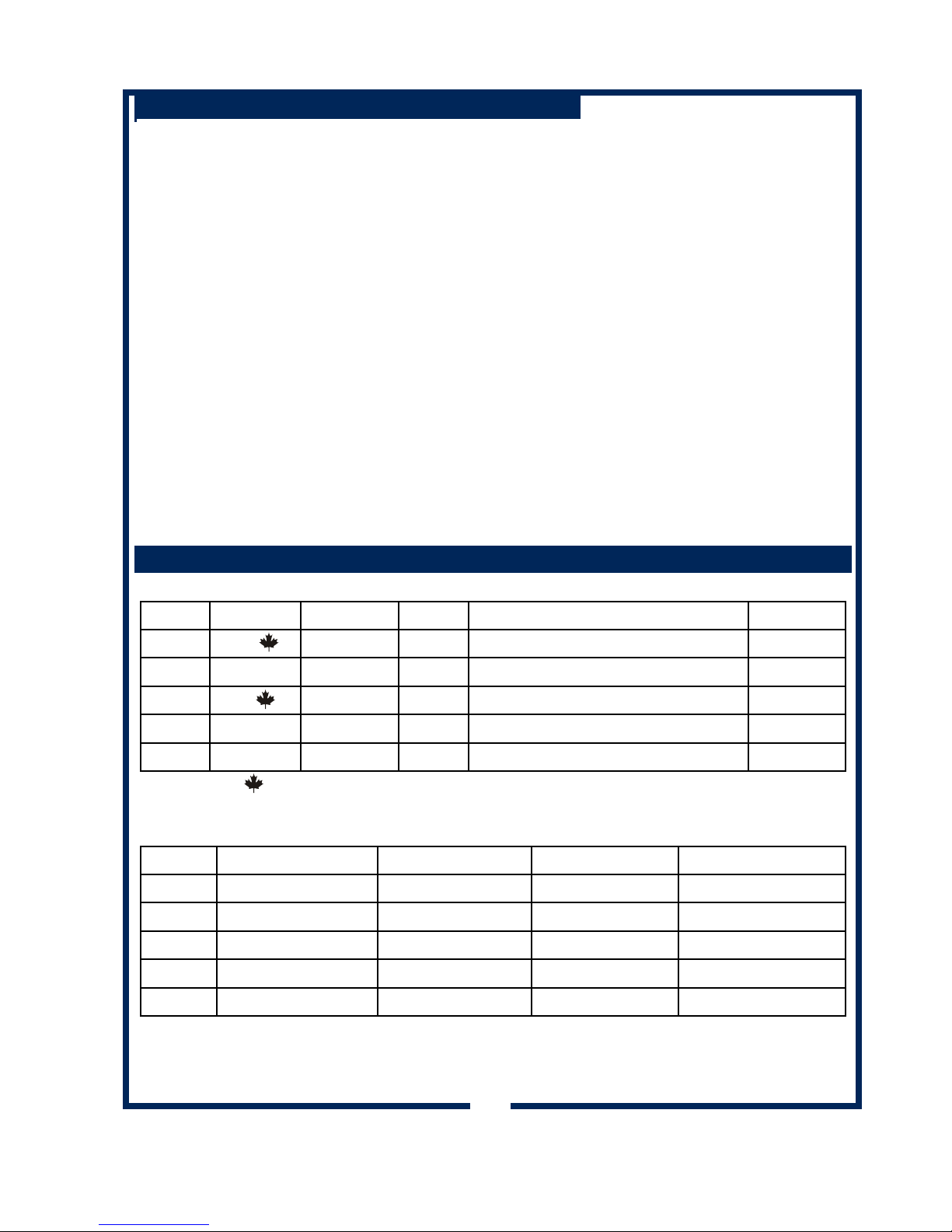

SPECIFICATIONS

Thank You for purchasing this

Bloomfield Industries appliance.

Proper installation, professional

operation and consistent

maintenance of this appliance will

ensure that it gives you the very

best performance and a long,

economical service life.

This manual contains the

information needed to properly

install this appliance, and to use,

care for and maintain or repair the

appliance in a manner which will

ensure its optimum perf ormance.

ELECTRICAL SPECIFICATIONS*

MODEL WATTS VOLTS 1ø Hz CIRCUIT REQUIRED WIRE

2212 1800 120 50/60

2216 3500 120/240 50/60 HAR D WIRE TO CIRCUIT BREAKER 3 + ground

2272 1800 120 50/60

2216EX 3500 240 50/60 HAR D WIRE TO CIRCUIT BREAKER 2 + ground

2274EX 3500 240 50/60 HAR D WIRE TO CIRCUIT BREAKER 2 + ground

Canada 1500 watts

15 AMP (NEMA 5-15R)

15 AMP (NEMA 5-15R)

2 + ground

2 + ground

DIMENSIONS*

MODEL CONFIGURATION HEIGHT WIDTH OVER ALL DEPTH

2212 3 Warmer In-Line 19 D” (498 mm) 9 h” (235 mm) 22 D” (575 mm)

2216 3 Warmer In-Line 17 D” (498 mm) 9 h” (235 mm) 22 D” (575 mm)

2272 3 Warmer Step-Up 19 D” (498 mm) 16 h” (235 mm) 22 D” (575 mm)

2216EX 3 Warmer In-Line 17 D” (498 mm) 9 h” (235 mm) 22 D” (575 mm)

2274EX 3 Warmer Step-Up 19 D” (498 mm) 16 h” (235 mm) 22 D” (575 mm)

* for complete information regarding specifications and dimensions, please consult the GLD

(General Layout Data) for the appliance ( 2212 & 2216 GLD p/n 75038, 2272 GLD p/n 75046 ).

1

Page 4

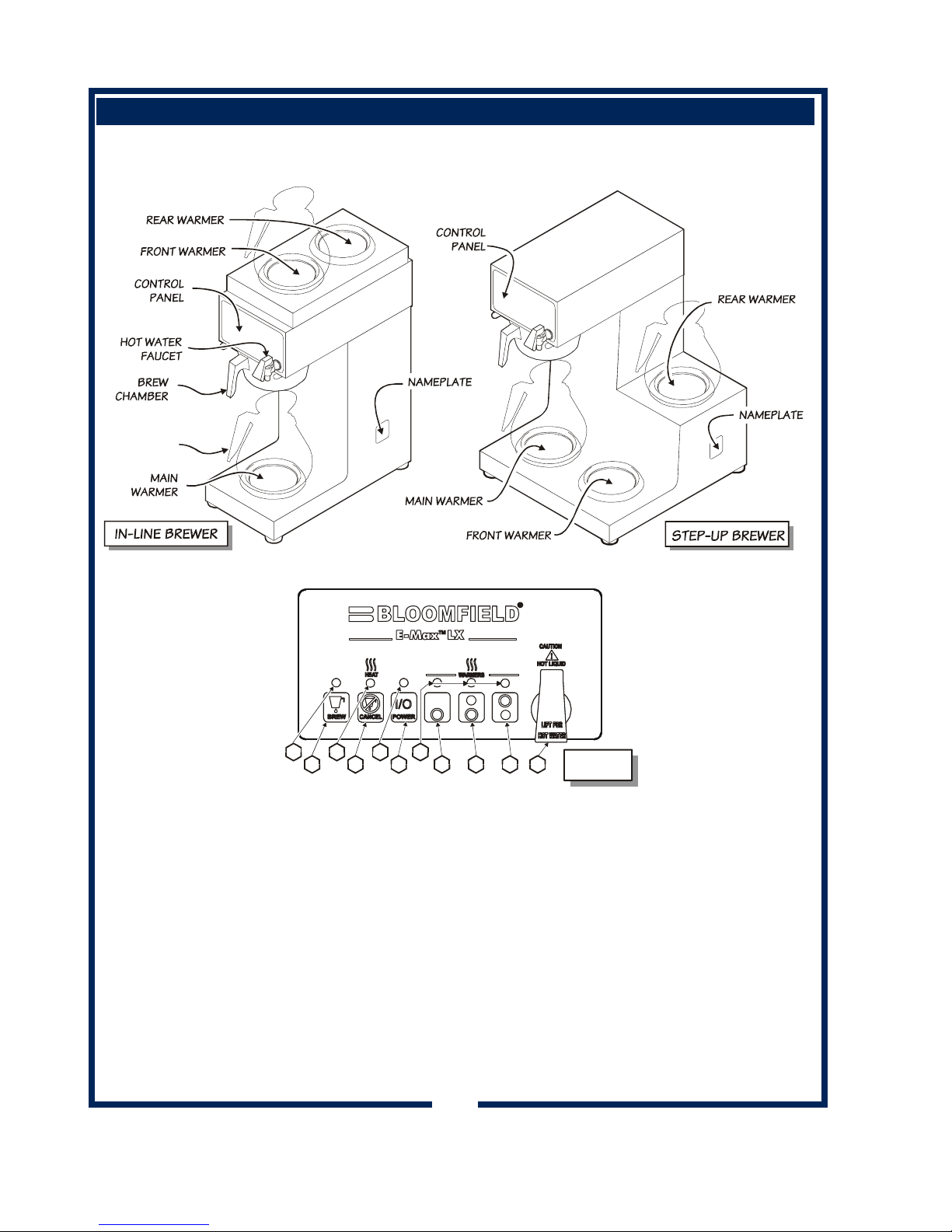

FEATURES & OPERATING CONTROLS

DECANTER

(IN BREWING

POSITION)

12

5

3

6

4

7

8

910

CONTROL

11

PANEL

1. Brew Indicator Glows during brew cycle, flashes in “Brew Wait”

2. Heat Indicator Glows when heating elements are energized

3. Power Indicator Glows when power is on

4. Warmer Indicators Glow when individual warmers are turned on

5. Brew Key Press to initiate brew cycle

6. Cancel Key Press to terminate brew cycle

7. Power Key Press to turn brewer on or off

8. Main Warmer Key Press to turn main warmer on or off

Note: Turns on automatically when brew is started

9. Front Warmer Key Press to turn front warmer on or off

10. Rear Warmer Key Press to turn rear warmer on or off

11. Hot Water Faucet Dispen se up to 2 cu ps of hot water at a time for tea, etc.

2

Page 5

PRECAUTIONS AND GENERAL INFORMATION

WARNING: Electric Shock Hazard

All servicing requiring access to non-insulated components must be performed by qualified

service personnel. Do not open any access panels which require the use of tools. Failure to

heed this warning can result in electrical shock.

WARNING: Injury Hazard

All installation procedures must be performed by qualified personnel with full knowledge of all

applicable electrical and plumbi n g code s. Failure could result in property damage and

personal injury.

WARNING Electric Shock Hazard

Brewer must be properly grounded to prevent possible shock hazard. DO NOT assume a

plumbing line will provide such a ground. Electrical shock will cause death or serious Injury.

WARNING: Burn Hazard

This appliance dispenses very hot liquid. Serious bodily injury from scalding can occur from

contact with dispensed liquids.

This appliance is intended for commercial use only.

This appliance is intended for use to brew beverage products for

human consumption. No other use is recommended or

authorized by the manufacturer or its agents.

This appliance is intended for use in commercial establishments,

where all operators are familiar with the appliance use,

limitations and associated hazards. Operating instructions and

warnings must be read and understood by all operators and

users.

Except as noted, this piece of equipment is made in the USA

and has American sizes on hardware. Please note: Metric

hardware is used to mount the inlet (Fill) solenoid. All metric

conversions are approximate and can vary in size.

The following trouble shooting, component views and parts lists

are included for general reference, and are intended for use by

qualified service personnel.

This manual should be considered a permanent part of this

appliance. The manual must remain with the appliance if it is

sold or moved to another location.

CAUTION: Equipment

Electrical Damage

DO NOT plug in or

energize this appliance until all

Installation Instructions are read

and followed. Damage to the

Brewer will occur if these

instructions are not followed.

CAUTION: Burn Hazard

To avoid splashing or

overflowing hot liquids,

ALWAYS use an empty decanter

before starting the brew cycle.

Failure to comply can cause

serious burns.

CAUTION: Burn Hazard

After a brew cycle, brew

basket contents are HOT.

Remove the brew basket and

dispose of used grounds with

care. Failure to comply can cause

serious burns.

CAUTION: Burn Hazard

Exposed surfaces of the

appliance, brew basket

and decanter may be HOT to the

touch, and can cause serious

burns.

3

Page 6

INSTALLATION INSTRUCTIONS

READ THIS CAREFULLY BEFORE STARTING THE INSTALLATION

IMPORTANT:

To enable the installer to make

a quality installation and to

minimize installation time, the

following suggestions and tests

should be done before the

actual unit installation is started:

CAUTION: Equipment

Electrical Damage

DO NOT plug in or energize this

appliance until all Installation

Instructions are read and

followed. Damage to the

Brewer will occur if these

instructions are not followed.

CAUTION: Unstable

Equipment Hazard

It is very important for safety

and for proper operation that the

brewer is level and stable when

standing in its final operating

position. Provided adjustable,

non-skid legs must be installed

at each corner of the unit.

Failure to do so will result in

movement of the brewer which

can cause personal Injury and/

or damage to brewer.

NOTE: Water supply inlet line

must mee t cer tain minimum

criteria to insure successful

operation of the brewer.

Bloomfield recommends 1/4"

copper tubing for installation of

less than 12 feet and 3/8" for

more than 12 feet from a 1/2"

water supply line.

REFER TO EXPLODED VIEWS PAGES 16 thru 19 FOR

COMPONENT NAMES/NUMBERS

1. Unpack the unit. Inspect all components for completeness

and condition. Ensure that all packing materials have been

removed from the unit.

2. (See page 13.) Remove the Top Warmer Unit (#106) or Top

Cover (#102) and inspect the internal components. Verify

that all wiring and hoses are connected and are properly

seated. Verify that the Tank Cover Assembly (#9) and Tank

Cover Gasket (#6) are securely installed. Reinstall top.

3. (See page 13.) Verify that the Spray Head (#24) and Spray

Head Gasket (#23) are properly installed.

LEVELING THE UNIT

1. Verify that an adjustable leg is installed at each corner of the

brewer.

2. Set Brewer in its operating location.

3. Level the Brewer. A spirit level should be placed on the top

of the unit, at the edge, as a guide when making level

adjustments.

4. Level the unit from left to right and front to back by turning the

adjustable feet. Be sure all four feet touch the counter to

prevent tipping.

PLUMBER’S INSTALLATION INSTRUCTIONS

1. Brewer should be connected to a POTABLE WATER, COLD

WATER line. Flush water line before connecting to Brewer.

2. DO NOT use a saddle valve with a self-piercing tap for the

water line connection. Such a tap can become restricted by

waterline debris. For systems that must use a saddle tap,

shut off the main water supply and drill a 3/16” (minimum) tap

for the saddle connection, in order to insure an ample water

supply. Remember to flush the line prior to installing the

saddle.

3. The brewer must be installed on a water line with average

pressure between 20 PSI and 90 PSI. If your water pressure

exceeds 90 PSI at anytime, a pressure regulator must be

installed in the water supply line to limit the pressure to not

more than 90 PSI in order to avoid damage to filters, lines

and solenoid.

4

Page 7

INSTALLATION INSTRUCTIONS (continued)

Y

4. A water shut-off valve should be installed on the incoming

water line in a convenient location (Use a low restriction type

valve, such as a 1/4-turn ball valve, to avoid loss of water

flow thru the valve.

5. NSF requires that the brewer be able to be moved for

cleaning underneath. A flex line or loops of copper tubing

will satisfy this requirement.

COPPER LOOPS OR FLEX LINES

(PROVI DED BY PLU MBER)

SHUT-OFF VALVE

(PROVIDED BY

PLUMBER)

SOLENOID

STRAINER

WASHER

WATER

SUPPL

FLOW

6. In some areas, local codes require a backflow preventer

(check valve) to be installed on the inlet water line. If a back

flow preventer is used, you must install a water hammer

arrester in the incoming line, between the backflow

preventer and the brewer inlet, as far away from the brewer

as space will allow. This will relieve the excessive back

pressures that can cause faucet leaks and solenoid

malfunctions.

ELECTRICIAN’S INSTALLATION INSTRUCTIONS

REFER TO ELECTRICAL SPECIFICATIONS - Page 1

Check the nameplate to determine correct electrical service

required for the Brewer to be installed.

NOTE: Models 2212 & 2272 require a 115 - 125 V 15A circuit

(50/60 Hz, 2 wire plus earth ground, with

NEMA 5-15R or 5-20R Receptacle)

Model 2216 requires a 120/240V 20A circuit

(50/60 Hz, 2 hot legs / 1 neutral leg, plus earth ground).

Circuit must be capable of 3500 Watts.

AGENC Y APPROVAL INF O RMATIO N

This brewer is and

This brewer meets

operated and maintained in accordance with the enclosed

instructions.

listed under UL file E9253.

Standard 4 only when installed,

NOTE: This equipment must be

installed to comply with applicable federal, state and local

codes and ordinances.

WARNING ELECTRIC

SHOCK HAZARD:

Brewer must be properly

grounded to prevent possible

shock hazard. DO NOT

assume a plumbing line will

provide such a ground.

Electrical shock will cause death

or serious injury.

IMPORTANT: Do not attempt to

override the automatic tank fill

feature which requires that the

tank must be full of water to

start operations. Any attempt to

override this feature will void

the warranty.

IMPORTANT:

Before connecting to electricity,

make sure the E-Max™ LX has

been properly connected t o the

water supply.

IMPORTANT:

Supply power must match

nameplate for voltage and

phase. Connecting to the

wrong voltage will damage the

brewer or result in decreased

performance. Such damage is

not covered by warranty.

E9253

STD 4

E9253

5

Page 8

OPERATION

OPERATING INSTRUCTIONS

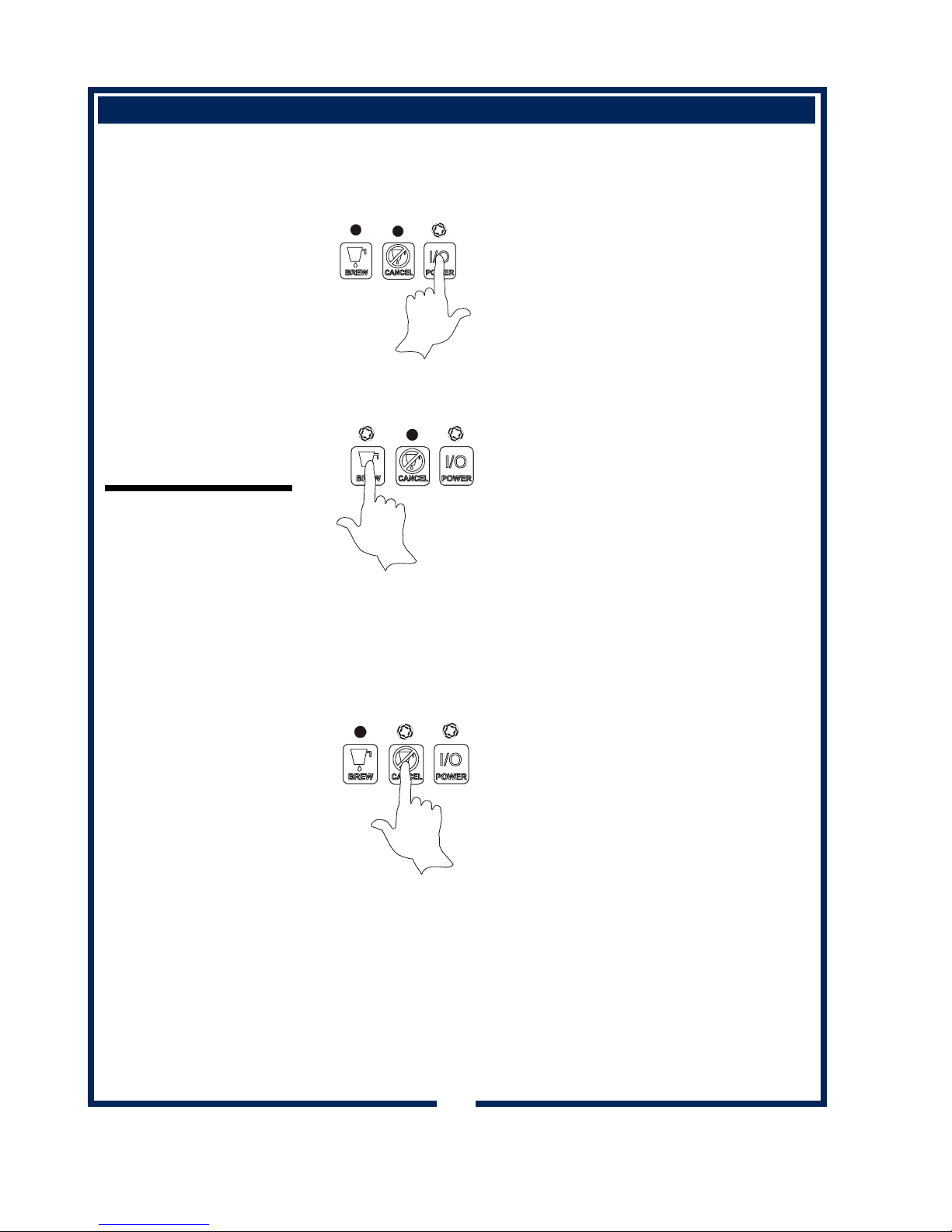

To over-ride the Brew

Wait mode, press and

hold the BREW key for

3 seconds when the

brewer is in Brew Wait

mode (i.e. when brew light

is flashing). The brew will

proceed immediately

regardless of water

temperature. This feature

should only be used when

testing water volume,

otherwise the brew will

proceed with the water

below the precise brew

temperature.

Note: the following

safety features have been

incorporated to prevent

multiple unattended

brews:

The brew key is inoperative during a brew

cycle. This minimizes the

possibility of double

brewing.

When the “Brew” light is

on or flashing, repeated

pressing of the BREW

switch will be ignored,

(there will be a beep each

time it is pressed). A

Brew will only be activated

when the “Brew” light is

off.

1. Energizing the Brewer: When electricity has been connected to

the unit, there will be a momentary flash of the power light. Turn

the brewer on by pressing the POWER key.

The brewer will start to fill the tank. With the

proper water supply the tank should be filled in

about 2½ minutes. Once filled, the heating

element will come on until the proper tank

temperature has been reached, (which will take

about 20 minutes on 120-Volt models or about

2. Brewing (Precise Temperature for Brewing™ — PTB™): In the

regular operating mode, the E-Max™ LX maintains the tank

is pressed. However, there may be a slight

after a brew has been completed (notably on

temperature is reached the bre w will commence with the brew light on

continuously during the brew. When the brew begins the main warming

station will be turned on automatically (if it is not already on). During the

brew cycle, if the BREW key is pressed, it will be ignored. Only when

the brew is complete can another brew be started.

3. Brew Cancel: To cancel a brew in progress, press the CANCEL

will go out. Water flowing to the brew chamber

will be stopped immediately, but if there is

already water in the brew chamber, it will take a

few moments before this drips through as

coffee.

4. Normal Operation (Non Brewing): When the unit is not brewing,

the E-Max™ LX maintains the water temperature at the Precise

Temperature for Brewing™ (PTB™). The heating element will

cycle on and off automatically to maintain this temperature.

5. After Hours Mode: If no brew is detected for a pre-selected length

of time, the brewer will enter the After Hours mode. Temperature

will be allowed to drop to save energy. Pressing the BREW KEY

returns the brewer to normal operation.

12 minutes on 120/240 Volt models).

temperature within +/- 1ºF of the brew

temperature. Normally this will mean that a

brew will be started as soon as the BREW key

delay if the BREW key is pressed immediately

120-volt models). If the tank temperature is

below the brew temperature, the brew will be

delayed, going into the “Brew Wait” mode, with

the brew light flashing. As soon as the correct

KEY: two beeps will sound and the “Brew” light

6

Page 9

USER’S GUIDE

OPERATION (continued)

1. Remove the brew chamber from under the spray head.

Place one (1) genuine Bloomfield paper filter into the brew

chamber. Add your choice of pre-measured ground coffee.

Shake the brew chamber gently to level the coffee.

Slide the brew chamber back into place.

PAPER

FILTER

BREW

CHAMBER

2. Place an empty decanter under the brew chamber.

3. To begin the brew cycle, press BREW key. Hot water will start

spraying over the coffee, and brewed coffee will start filling the

decanter. When the coffee stops flowing from the brew chamber,

the fresh coffee is ready to serve.

NOTE: Brewing will not begin until the Precise Temperature for

Brewing™ has been reached. (See page 6)

4. After all dripping has stopped, remove the brew chamber from the

brewer. Discard the used paper filter and product.

5. The brewer is now be ready to begin another brewing cycle.

WARNING:

Burn Hazard.

This appliance

dispenses very hot liquid.

Serious bodily injury from

scalding can occur from

contact with dispensed

liquids.

CAUTION:

Burn Hazard

To avoid splashing or

overflowing hot liquids,

ALWAYS use an empty

decanter before starting

the brew cycle. Failure to

comply can cause serious

burns.

CAUTION:

Burn Hazard

After a brew cycle, brew

chamber contents are

HOT. Remove the brew

chamber and dispose of

used filter and grounds

with care. Failure to

comply can cause serious

burns.

CAUTION:

Burn Hazard

Exposed surfaces of the

appliance, as well as brew

chamber and decanter

may be HOT to the touch,

and can cause serious

burns.

7

Page 10

CLEANING INSTRUCTIONS

CAUTION:

Burn Hazard

Brewing and serving

temperatures of coffee are

extremely hot.

Hot coffee will cause

serious skin burns.

CAUTION:

Electric Shock

Hazard

Do not submerge or immerse

brewer in water. Do not pour or

splash water into or over air

vents, control panel or warmer

plates.

IMPORTANT:

DO NOT use steel wool, sharp

objects, or caustic, abrasive or

chlorinated cleansers to clean

the brewer or decanters.

PROCEDURE: Clean Coffee Brewer

PRECAUTIONS: Disconnect brewer from electric power.

Allow brewer to cool.

FREQUENCY: Daily

TOOLS: Mild Detergent, Clean Soft Cloth or Sponge

Bristle Brush

1. Disconnect brewer from electric power.

Allow brewer to cool before cleaning.

2. Remove decanters.

3. Remove and empty brew chamber.

4. Remove the spray disk from the brew head:

Press up on the spray disk ears, then turn the disk to the left

to unlatch. Remove the gasket from inside the brew head.

5. Wipe inside of brew head and area around the brew head

with a soft clean cloth or sponge moistened with clean water.

6. Wash the spray disk in a sink using warm water and a mild

detergent. A bristle brush may be used to clear clogged

spray holes. Rinse the spray disk with clean water and allow

to air dry.

7. Wash the brew chamber in a sink using warm water and a

mild detergent. A bristle brush may be used to clean the

inside. Rinse with clean water and allow to air dry.

8. Wipe all warmer plates and the exterior of the brewer with a

soft clean cloth or sponge moistened with clean water.

10. Reinstall the gasket INSIDE the brew head, then reinstall the

spray disk.

11. Reinstall the brew chamber.

12. Decanters may be washed in a sink or dishwasher. Be sure

decanters are well rinsed and dry before use.

Procedure is complete

8

Page 11

SERVICING — OPERATIONAL ADJUSTMENTS

BREW

TIMER

(IN SECONDS)

210

AB

BREW

TEMP

(IN °F)

194

185

320100

QUALITY

TIMER

(IN 5 MIN INCR)

70

20

205OFF

CDE

120OFF

DRIPOUT

TIMER

(IN SECONDS)

9030

AFTER HOURS

TIMER

(IN ONE HR INCR)

360

6OFF

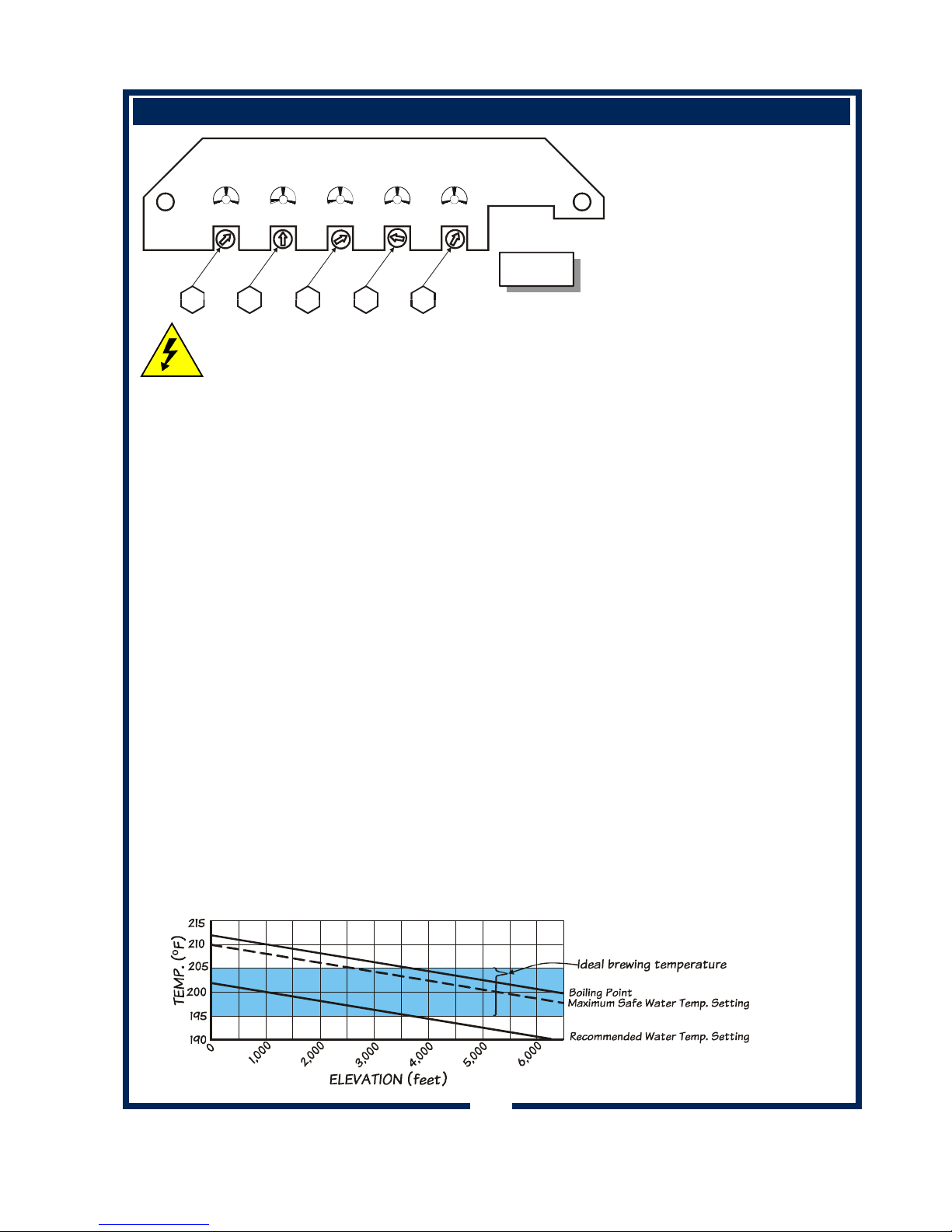

CAUTION:

Electric Shock Hazard

Unplug or disconnect the brewer from electric

power before removing the top cover

IMPORTANT: Adjustments must be performed

by qualified service personnel ONLY.

1. Access the Controls: All adjustments on

the E-Max™ LX may be accessed by

removing the top cover or top warmer station

from the brewer. The adjustments are

directly behind the front panel.

2. Adjust Brew Time: The time the brew

solenoid is open maybe adjusted by turning

the shaft of the left-most control (A). Turning

the shaft clockwise increases the time. Ten

degrees of rotation is approximately equal to

seven seconds change. Adjust until a

complete brew is achieved without

overflowing the decanter.

3. Adjust Brew Temperature: Ideal brewing

temperature is 195ºF to 205ºF. Realistically,

the maximum brew temperature is the local

boiling temperature minus 10ºF. To adjust

the temperature, turn the shaft of the second

control (B). Turning the shaft clockwise

increases temperature. Fifteen degrees of

rotation is approximately equal to 1-1/4ºF.

WATER

TEMP

LEVEL

PROBE

PROBE

A. Adjust Brew Time

B. Adjust Brew Temperature

UNDER

TOP COVER

4. Adjust Quality Timer: When a brew is

completed, the timer begins counting down.

At the end of the set time, the warmer

indicators will blink continuously until reset

(push to turn off, push again to turn back

on). The length of time may be adjusted by

turning the shaft of the third control (C).

Turning the shaft clockwise increases the

time. Turning the shaft fully counter clockwise turns the Quality Time function off.

Adjustment is in five minute increments.

5. Adjust Dripout Timer: This feature

disables the brew switch for an amount of

time after the brew solenoid closes to allow

all water to finish dripping through the

grounds. The length of time may be adjusted

by turning the shaft of the fourth control (D).

Turning the shaft clockwise increases the

time. Ten degrees of rotation is

approximately equal to 2-1/2 seconds.

6. Adjust After Hours Timer: This feature

places the brewer into an energy-saver

mode if no brew has been initiated for a

length of time. Time may be adjusted by

turning the shaft of the fifth control (E).

Turning the shaft clockwise increases the

time. Turning the shaft fully counter clockwise turns the After Hours function off.

Adjustment is in one hours incremen

C. Adjust Quality Timer

D. Adjust Dripout Timer

E. Adjust After Hours Timer

ts.

9

Page 12

SERVICING INSTRUCTIONS — ELECTRICAL

OPERATION

SEE PAGE 11 FOR COMPONENT NAMES / NUMBERS

1. Pressing the POWER key energizes the unit. The

POWER LED will glow whenever the unit is ON.

2. Automatic fill is accomplished via a FILL SOLENOID

(32) and a WATER LEVEL PROBE (7). The probe

FILL

CONTROLLER

WATER

LEVEL

PROBE

FILL

SOLENOID

senses ground through the water in the tank. When the

BREW

TIME

CONTROLLER

DRIP OUT

TIME

BREW

SOLENOID

water level falls below the probe and ground is no longer

sensed, the CONTROLLER (20) energizes the fill

solenoid until the water level again reaches the water

level probe.

3. Pressing the BREW key begins the brew cycle.

BREW

BREW

CANCEL

Pressing the CANCEL key at any time during the

BREW

brew cycle terminates the brew. The BREW SOLENOID

LINE

VOLTAGE

HI-LIMIT

STAT

TRIAC

HEATING

ELEMENT

BREW

TEMP

T

CONTROLLER

WATER TEMPERATURE

QUALITY

TIMER

CONTROLLER

WATER

TEMP

PROBE

WARMER

ELEMENT

(18) is energized by the CONTROLLER (20) for a time

determined by the setting of the BREW TIME

CONTROL. A second brew can be started only after the

brew time plus the time set on the DRIP OUT TIMER

has elapsed.

4. Brew water temperature is controlled via a water

temperature sensor and a HEATING ELEMENT (15)

controlled by a TRIAC (17) electronic switch. The

element is energized according to the sensed water

temperature and the desired temperature setting of the

BREW TEMP control. An over-temperature condition

WARMER

PLATES

WARMER

will trip the HI-LIMIT THERMOSTAT (4), de-energizing

the heating element.

5. Individual WARMER PLATES (27) are heated by

WARMER ELEMENTS (28), which are controlled by the

WARMER keys. Pressing a warmer key will turn ON or

OFF the corresponding warmer and LED.

Because coffee loses its freshness after sitting on a

warmer, a quality time function is included. The

WARMER LEDS will begin to flash some time after the

last brew cycle, based on the setting of the QUALITY

TIMER. Note: QUALITY TIMER does not turn off the

warmer elements.

6. The unit will revert to the energy-saver mode some

time after the last brew, based on setting of the AFTER

HOURS TIMER.

10

Page 13

27

28

WARMER

MOUNTING

SERVICING INSTRUCTIONS — ELECTRICAL

3 PROBE, TEMPERATURE

(THERMISTOR)

4 THERMOSTAT, HI-LIMIT

5 GROMMET

7 PROBE, WATER LEVEL

8 SLEEVE, WATER LEVEL PROBE

15 ELEMENT, WATER HEATING

17 ASSEMBLY, TRIAC & HEAT SINK

18 BREW SOLENOID

20 CONTROLLER

27 COVER PLATE, WARMER

28 ELEMENT, WARMER

32 FILL SOLENOID

120/240V

UNITS

7

8

15

17

4

E-MAXLX

ELECTRICAL

COMPONENT

3

5

4

18

20

32

120V

UNITS

11

Page 14

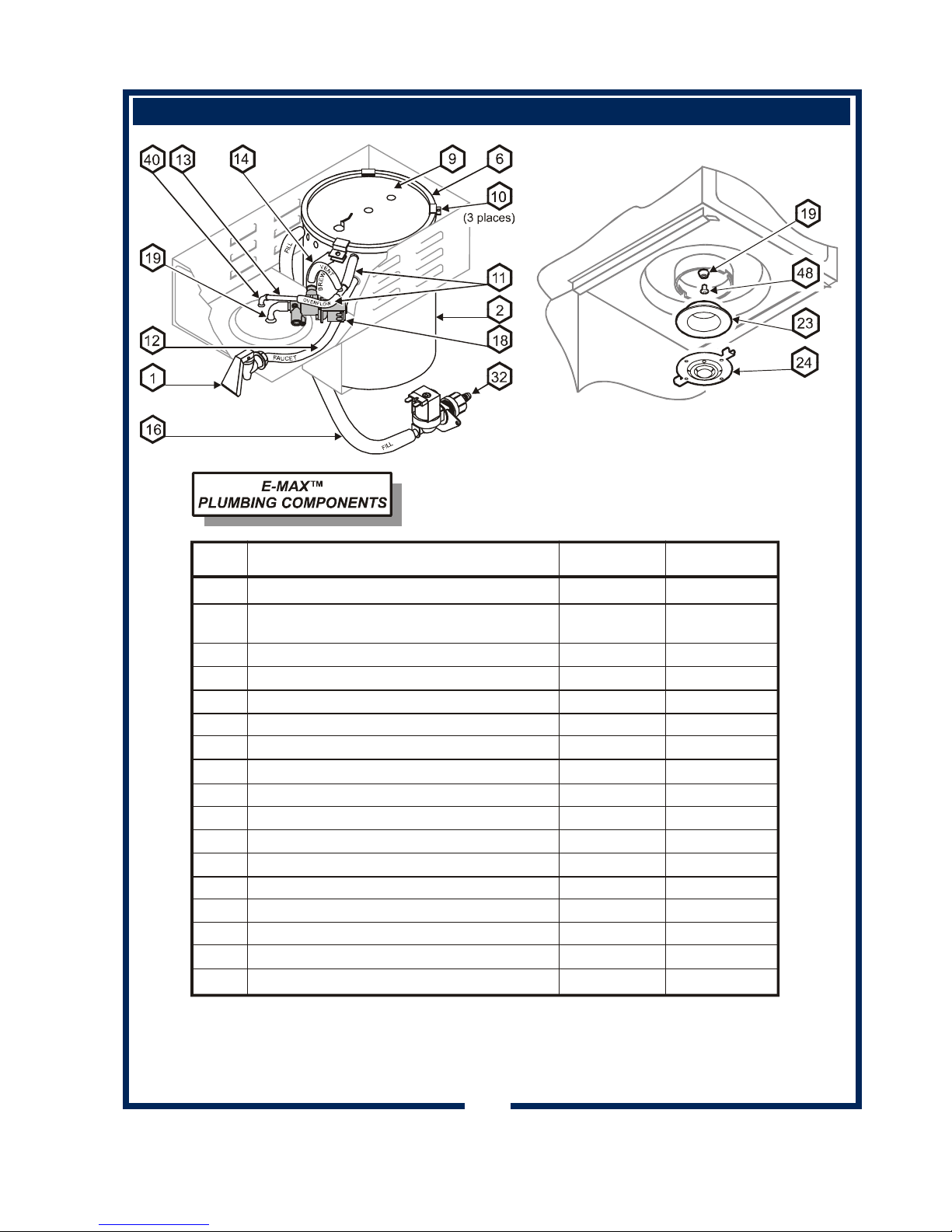

(

SERVICING INSTRUCTIONS — PLUMBING

OPERATION

SEE PAGE 13 FOR COMPONENT NAMES/NUMBERS

1. Water enters at the inlet fitting of the fill solenoid (32). The

solenoid admits water via a command from the controller.

NOTE: The solenoid has an internal strainer. To clean the

strainer: Shut off water supply. Unscrew the plastic cap

protruding from the rear of the brewer. Remove the cap,

inlet fitting and washer. With pliers, grasp the bar of the

strainer and pull straight out. Wash any debris from the

strainer. Note orientation - DO NOT reverse strainer.

Reassemble and reinstall. Turn water supply back on.

2. Water enters the tank (2) thru the fill tube (16). Water is

heated in the tank by the heating element (15).

3. The tank lid (9) is sealed around the edge with a gasket

(6), and is secured by 3 clips (10).

4. Heated water is dispensed to the brew head through the

brew tube (14), brew solenoid (18), and spout of the brew

fitting (19). The brew solenoid is energized during the brew

cycle by the controller.

NOTE: The flow rate of the brew solenoid is factory set.

DO NOT adjust.

5. Hot water is sprayed over the coffee grounds by the spray

disc (24), which is sealed to the brew head by a gasket (23).

6. The tank is vented through the vent fitting (40) and vent

tubes (12 & 13).

7. Water for the hot water faucet (22) is supplied from the tank

through the faucet supply tube (11).

SOLENOID

STRAINER

(note orientation

DO NOT REVERSE)

WASHER

INLET

FITTING

CAP

FLOW

CONTROL

installed)

FILL

SOLENOID

12

LID

TANK

LID GASKET

GASKET

CLIP

Page 15

SERVICING INSTRUCTIONS — PLUMBING

ITEM DESCRIPTIO N PART N0. USED ON

1

2 ASS EMBLY, WATER TANK (1 20V) 83500 2212, 2272

6 GASKET, TANK LID 83499 ALL

9 TAN K LID 83504 ALL

10 RETAINING CLIP, TANK LID 83506 ALL

11 HOSE, OVERF LOW (2 pc SILICONE 4.5” LO NG) 86014 ALL

12 HOSE, FAUCET SUPPL Y (SILICONE, 10” LONG) 83538 ALL

13 TUBE, VENT (METAL, 2.3” LONG) 83384 ALL

14 TUBE, BREW SUPPLY VENTED ASSEMBLY

16 TUBE, FILL (SILICONE, 83540 ALL

18 SOLENOID, BREW (DUMP) 83388 ALL

19 ELBOW, BREW 83152 ALL

23 GASKET, SPRAY HEAD 82215 ALL

24 SPRAY DISK 82727 ALL

32 SOLEN O ID, FILL 83612 ALL

40 ELBOW, VENT 8043-11 ALL

48 INSERT, SPRAY HEAD 83571 ALL

FAUCET, HOT WATER 8783-1 ALL

ASSEMBLY, WAT ER TANK (240V) 83753 2216

86013 ALL

13

Page 16

SERVICING INSTRUCTIONS — DE-LIMING HEATER TANK

CAUTION - CHEMICAL

BURN HAZARD

De-liming chemicals are caustic.

Wear appropriate protective gloves

and goggles during this procedure.

Never siphon de-liming chemicals

or solutions by mouth.

This operation must only be

performed by qualified and

experienced service personnel.

IMPORTANT: DO NOT spill,

splash or pour water or de-liming

solution into or over any internal

component other than the inside of

the water tank.

IMPORTANT: DO NOT allow any

internal components to come into

contact with the de-liming solution.

Take care to keep all internal

components dry.

NOTE: Repeat steps 4 thru 7 as

required to remove all scale and

lime build-up.

NOTE: Normally, silicone hoses

do not need to be de-limed.

Should de-liming hoses become

necessary, Bloomfield Industries

recommends replacing the hoses.

1. Disconnect brewer form the electrical sup ply. Turn off

the water supply and disconnect water supply from the

brewer inlet fitting.

2. Remove the top panel or top warmer section to gain

access to internal components.

3. Disconnect water level sensor and water temperature

sensor from the controller. On 120V units, slip hi-limit

thermostat from under its holder clip. Disassemble the

three lid clips and lift the lid off of the water tank. Store

lid assembly in a safe location.

4. Mix de-liming solution according to the manufacturer’s

directions. Add the de-liming solution to the water tank.

Set lid assembly back on tank. Allow to sit for 30

minutes, or as directed by the manufacturer.

5. At end of soaking period, remove lid assembly from tank.

Thoroughly rinse interior components of lid assembly

with clear water. Wipe temperature sensor and water

level sensor with a clean, soft cloth. Store lid assembly

in a safe location.

6. Using a stiff bristle brush, scrub the coils of the heating

element and the interior surfaces of the water tank.

7. Siphon the used solution and loose lime/scale into an

appropriate container. Dispose of the used solution as

required by local ordinances.

8. Fill the water tank with clean tap water. Rinse

thoroughly, then siphon the rinse water into an

appropriate container for disposal. Again, take care to

keep all internal components dry.

9. Reassemble the tank lid to the water tank. Make sure

the gasket is properly attached to the lid before

assembling the lid clips. Re-connect the water level and

temperature probes, then reinstall the hi-limit thermostat

(if removed). Verify that all internal components are dry,

then reinstall the top panel.

10. Reconnect brewer to water and electrical. Run and

discard at least three full decanters from the faucet.

Install the brew chamber without filter paper or grounds,

then run and discard at least three full decanters as

normal brew.

11. Brewer is ready to use.

14

Page 17

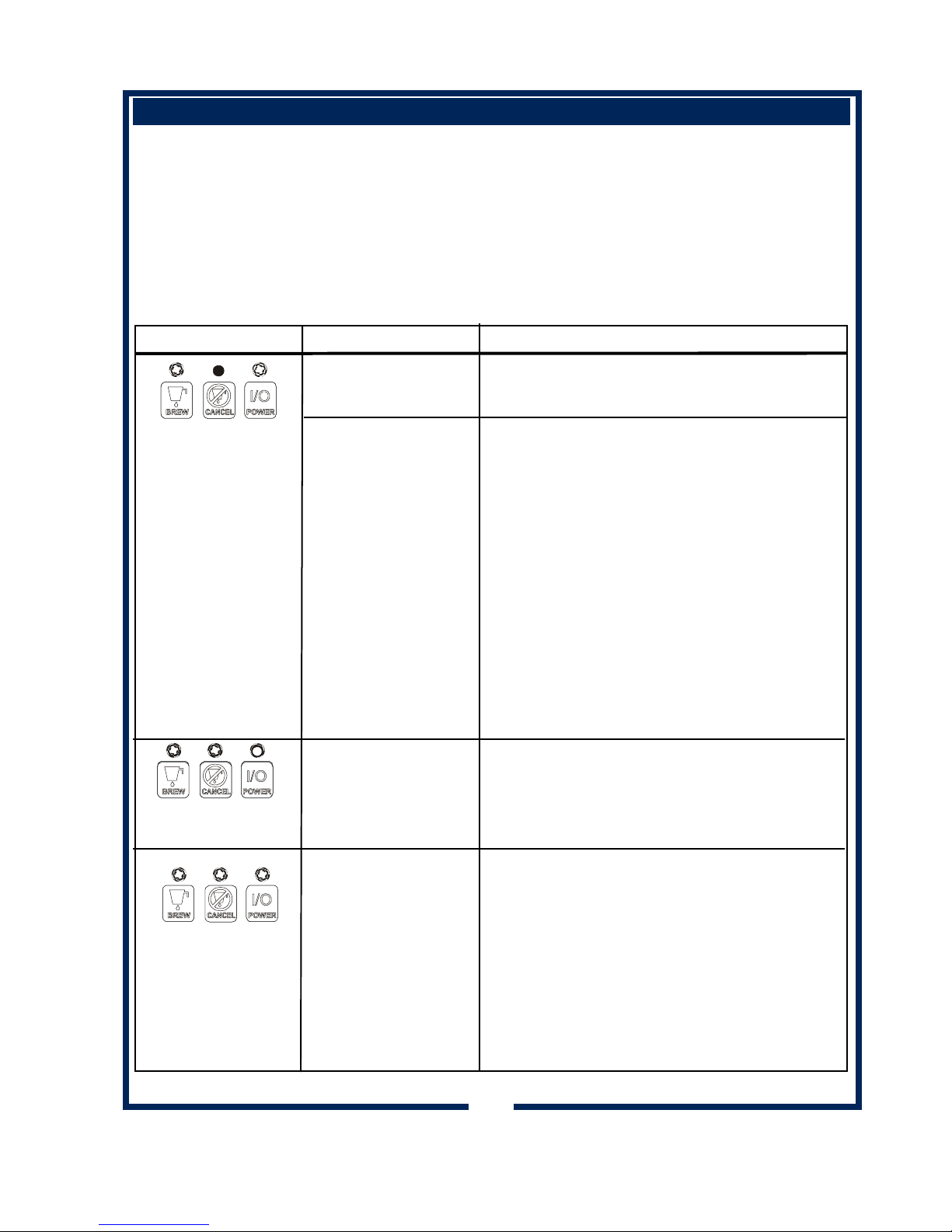

SERVICING INSTRUCTIONS — DIAGNOSTICS & TROUBLESHOOTING)

If the E-Max™ LX goes into an error mode as outlined below, it

will probably be necessary to reset the brewer in order to test

individual components. Note the reset procedure below:

* FOR “LOW WATER” OR “OVERHEAT” ERRORS:

PRESS & HOLD CANCEL FOR 3 SECONDS, OR

RE-ENERGIZE THE BREWER (i.e. unplug for a few

seconds, the plug in again.)

* FROM “VALVE FAULT” ERROR: THE BREWER MUST

BE RE-ENERGIZED Using the CANCEL button will not

reset the brewer from “Valve Fault”.

FLASHING LIGHTS

BREW light and

POWER light

flashing

BREW light and

CANCEL light flashing

BREW light, CANCEL

light and POWER light

flashing

ERROR

LOW WATER TEMP

(Not an error)

LOW WATER LEVEL:

Inlet valve has been on

and no water sensed:

a. During regular

operation for 60

sec., or

b. during startup for

4-1/2 min.

VALVE FAULT:

Detection of a problem

with the wiring to the

valve or of the valve

switching system.

OVERHEAT:

Water temperature has

exceeded 210ºF

POSSIBLE PROBLEM & CORRECTIVE ACTION

1. Water has not reached Precise Temperature

for Brewing™. WAIT UNTIL WATER

TEMPERATURE HAS RECOVERED.

1. Sleeve on level sensing probe gasket is too

long or sensor not pushed down fully. Sensor

should protrude beyond sleeve 1/4”.

REMOVE TANK LID, CUT SLEEVE TO

PROPER LENGTH. MAKE SURE SENSOR

IS FULLY PUSHED DOWN.

2. Level sensor may be pulled out of tank.

REINSTALL SENSOR.

3. Wiring to sensor may be disconnected or

faulty. REPAIR WIRING

4. Level sensor may be encrusted with scale or

lime build-up. CLEAN SENSOR (use chemical

de-liming. Scraping or sanding will damage

the sensor.

5. Water supply may be shut off, or is incapable

of filling the tank in the allotted time.

RESTORE WATER SUPPLY.

1. Wiring to either inlet or dump valve not properly

connected. CHECK WIRING / CONNECTORS.

2. Controller has two switches for each valve, one

or both has been detected as failing on.

REPLACE CONTROL BOARD.

1. Brew temperature may be too close to max.

temp. Brew temperature should be no higher

than 205ºF. LOWER BREW TEMPERATURE

SETTING.

2. Triac may have failed on, and water continues

to heat even after controller has tried to turn

heating element off. CHECK TRIAC,

REPLACE IF REQUIRED.

3. Probe may be defective. TEST ACTUAL

TEMPERATURE TO VERIFY. REPLACE

PROBE OR REPAIR WIRING AS REQUIRED.

IMPORTANT: The following

troubleshooting suggestions are for

operator reference only.

All servicing and/or repairs must be

performed by qualified service

personnel.

15

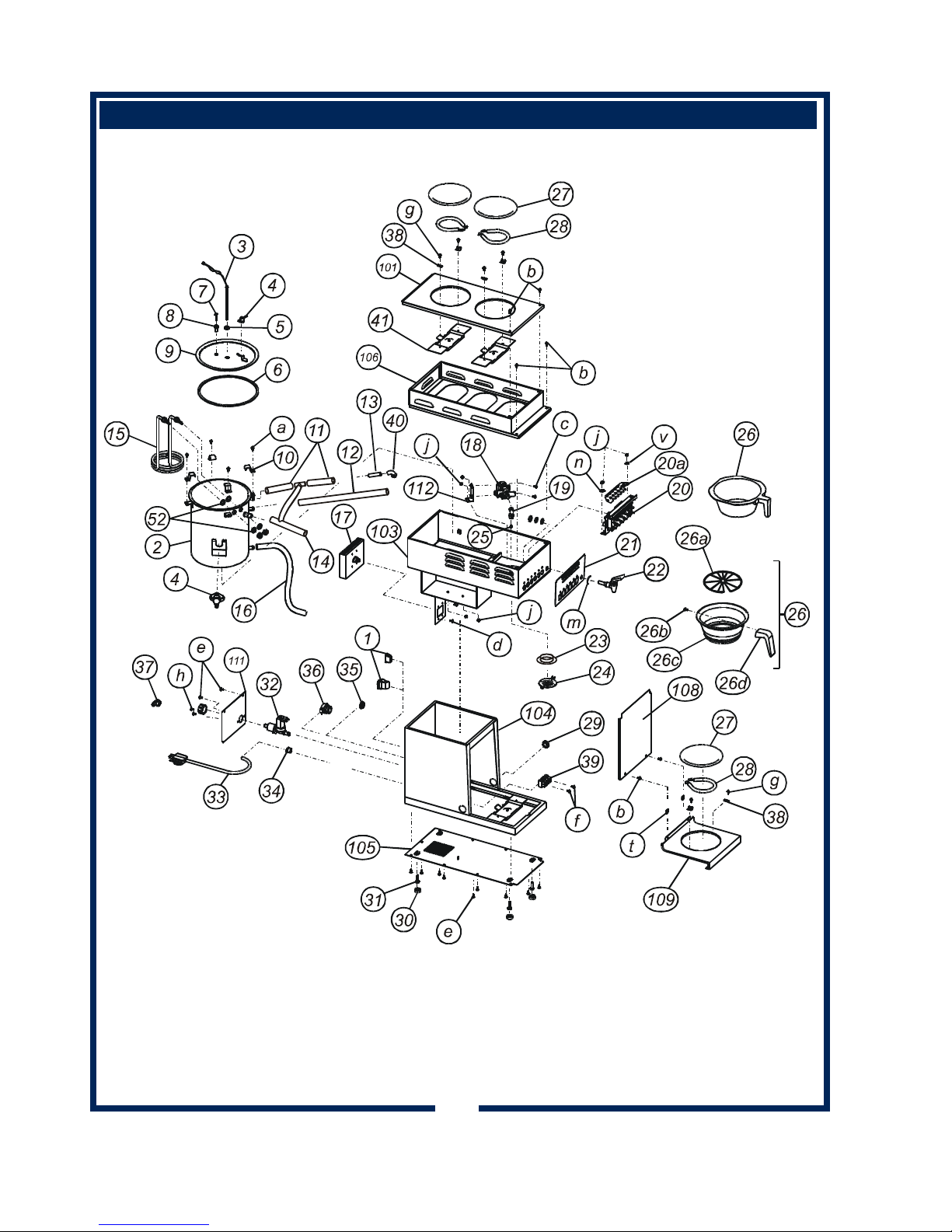

Page 18

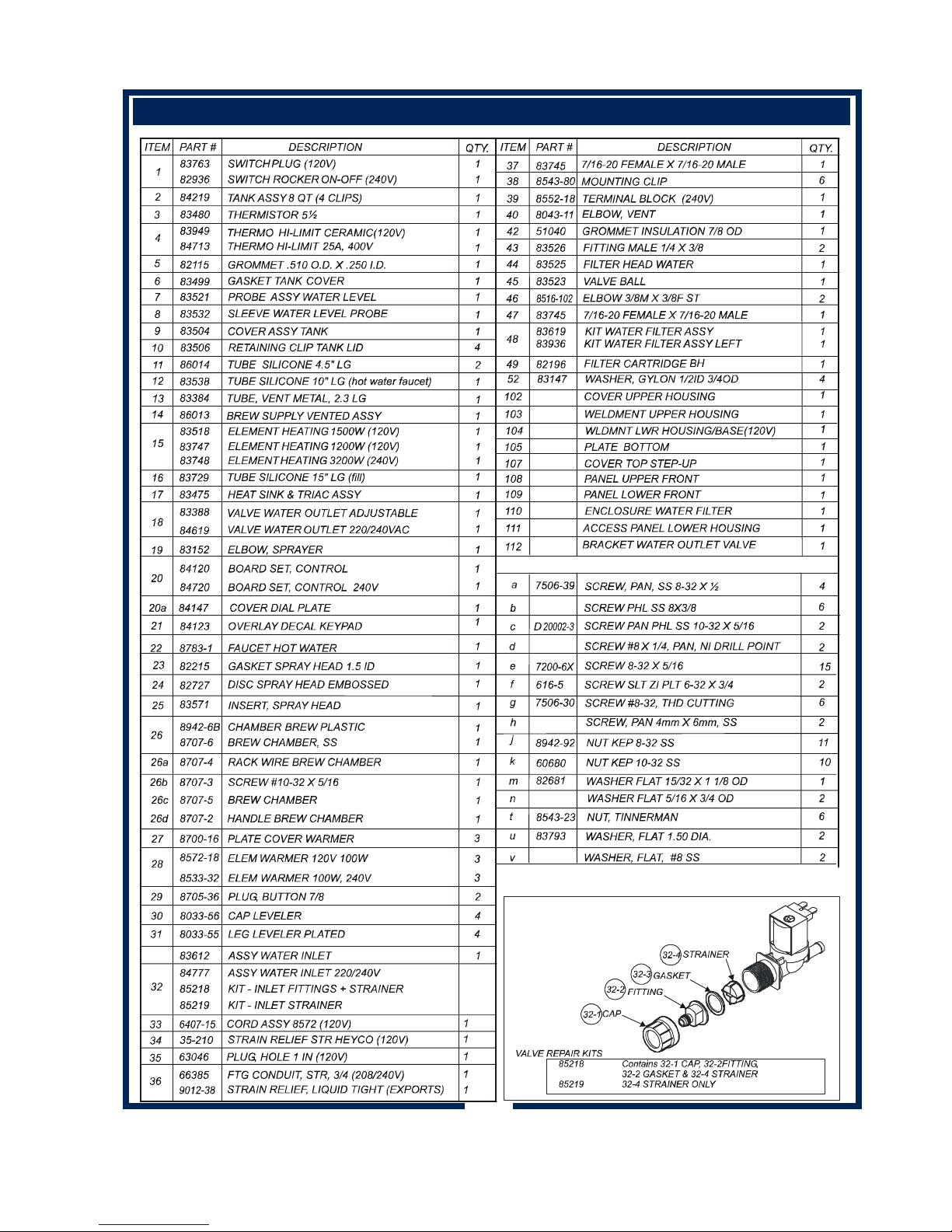

EXPLODED VIEW — IN-LINE MODELS

16

Page 19

PARTS LIST — IN-LINE MODELS

17

Page 20

EXPLODED VIEW — STEP-UP MODELS

18

Page 21

PARTS LIST — STEP-UP MODELS

19

Page 22

WIRING DIAGRAM — IN-LINE MODELS

20

Page 23

WIRING DIAGRAM — IN-LINE EXPORT MODEL

21

Page 24

WIRING DIAGRAM — STEP-UP MODEL

White #11

White #11

Rear Warmer

Inlet

Valve

Plate #3

120V

100 Watt

Brown #1

Orange #7

Line

Load

Gate

Triac

Front Warmer

Plate #2

120V

100 Watt

Blue #4

Brown #5

White #11

White #12

Main Warmer

Plate 120V

White #11

Outlet

Valve

100 Watt

Blue #2

120 Volt

1500 Watt

Tan k He ate r

B

l

a

Red #6 Red #6

c

k

#

9

White #10

Orange #8

Hi-Limit

W

W

h

i

t

h

e

i

t

e

#

1

#

0

1

1

White #10

Black #9

Orange #3

Brown #1

Blue #2

Black #9

White #12

White #10

White #11

CONTROL BOARD

1 WP3

2 WP2

3 WP1

1 Heater (Line)

2 Inlet (Line)

3 Dump Line

4 Power (Line)

5

6 Dump (Neut)

7 Power (Neut)

8 Heater (Neut)

22

Page 25

WIRING DIAGRAM — STEP-UP EXPORT MODEL

23

Page 26

Bloomfield Industries proudly supports CFESA

Commercial Food Equipment Service Association

Bloomfield Industries, Inc.

Division of Carrier Refri ge rat io n

In US

PO Box 280, Verdi, NV 89439

Telephone: 775-345-0444

Service: 888-492-2782 Fax: 888-792-2783

website: www.wellsbloomfield.com

In Canada

Telephone: 877-507-1700

Service: 905-507-1700 Fax: 905-507-1777

website: www.bloomcan.com

Loading...

Loading...