Page 1

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5703

fax: 775-689-5976

www.wellsbloomfield.com

OPERATION

MANUAL

BUILT-IN

ELECTRIC

CHAR

162

for

Model B-406

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS U S ING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

BROILERS

Models:

B-406

B-446

B-506

includes:

INSTALLATION,

Model B-446

IMPORTANT: DO NOT DISCARD THIS MANUAL

this appliance. Additional manuals are available from your WELLS DEALER.

questions concerning installation, operation or maintenance of this equipment.

USE and CARE

PRINTED IN UNITED STATES OF AMERICA

p/n 303673 Rev. D ECN-13371 M162 071025 cps

Page 2

LIMITED WARRANTY STATEMENT

Unless otherwise specified, all commercial cooking

equipment manufactured by WELLS BLOOMFIELD, LLC is

warranted against defects in materials and workmanship for

a period of one year from the date of original installation or

18 months from the date of shipment from our factory,

whichever comes first, and is for the benefit of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW OR IN

FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE, AND/OR FOR DIRECT,

INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS BLOOMFIELD PRODUCTS.

This warranty is void if it is determined that, upon inspection

by an authorized service agency, the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or

if service is performed by unauthorized personnel. The

prices charged by Wells Bloomfield for its products are

based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of

defects without charge by a Wells Bloomfield factory

authorized service agency or one of its sub-service

agencies. This service will be provided on customer’s

premises for non-portable models. Portable models (a

device with a cord and plug) must be taken or shipped to

the closest authorized service agency, transportation

charges prepaid, for service. In addition to restrictions

contained in this warranty, specific limitations are shown in

the Service Policy and Procedure Guide. Wells Bloomfield

authorized service agencies are located in principal cities.

This warranty is valid in the United States and Canada and

void elsewhere. Please consult your classified telephone

directory, your foodservice equipment dealer or contact:

Service Department, Wells Bloomfield, LLC

P.O. Box 280, Verdi, Nevada 89439

phone (775) 689-5707 or fax (775) 689-5976

for information and other details concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

162 303673 OpManual for Built-In Electric Charbroilers

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 4

AGENCY LISTING INFORMATION 4

INSTALLATION 5

OPERATION 7

BROILER CHART 9

TROUBLESHOOTING SUGGESTIONS 10

CLEANING INSTRUCTIONS 11

PARTS & SERVICE 13

CUSTOMER SERVICE DATA 13

Thank you for purchasing this

Wells Bloomfield appliance.

Proper installation, professional

operation and consistent

maintenance of this appliance

will ensure that it gives you the

very best performance and a

long, economical service life.

This manual contains the

information needed to properly

install this appliance in a

manner which will ensure its

optimum performance.

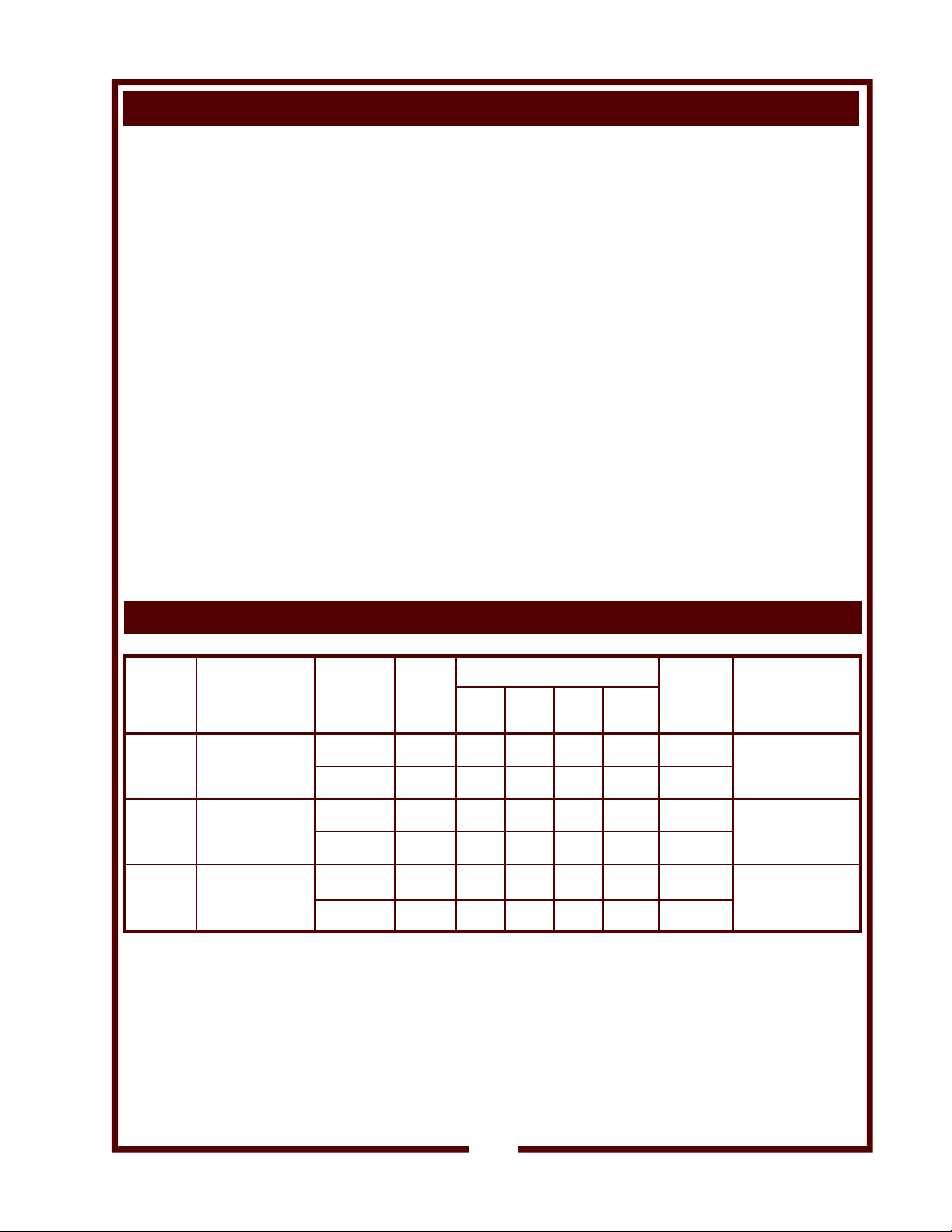

SPECIFICATIONS

AMPS PER LEG 3ø

NEUT

MODEL ELEMENT VOLTS KW

B-406

B-446

B-506

162 303673 OpManual for Built-In Electric Charbroilers

NOTE: Refer to appropriate Installation Instructions for equipment dimensions, cut-out dimensions,

clearances, etc.

SINGLE

ASSEMBLY

SINGLE

ASSEMBLY

DUAL

ASSEMBLIES

208 5.5 12.9 12.9 22.4 N/A 26.0 3ø 10 ga.

240 5.5 11.2 11.2 19.4 N/A 22.5

208 5.5 11.5 22.4 14.4 N/A 26.0 3ø 10 ga.

240 5.5 10.0 19.5 12.5 N/A 22.5

208 11.0 30.0 30.0 30.0 N/A - 3ø 8 ga.

240 11.0 26.0 26.0 26.0 N/A 45.0

AMPS

.

1ø

1ø 8 ga.

90 g

1ø 8 ga.

90 g

1ø 4 ga.

90g

FIELD

WIRING L1 L2 L3

1

Page 4

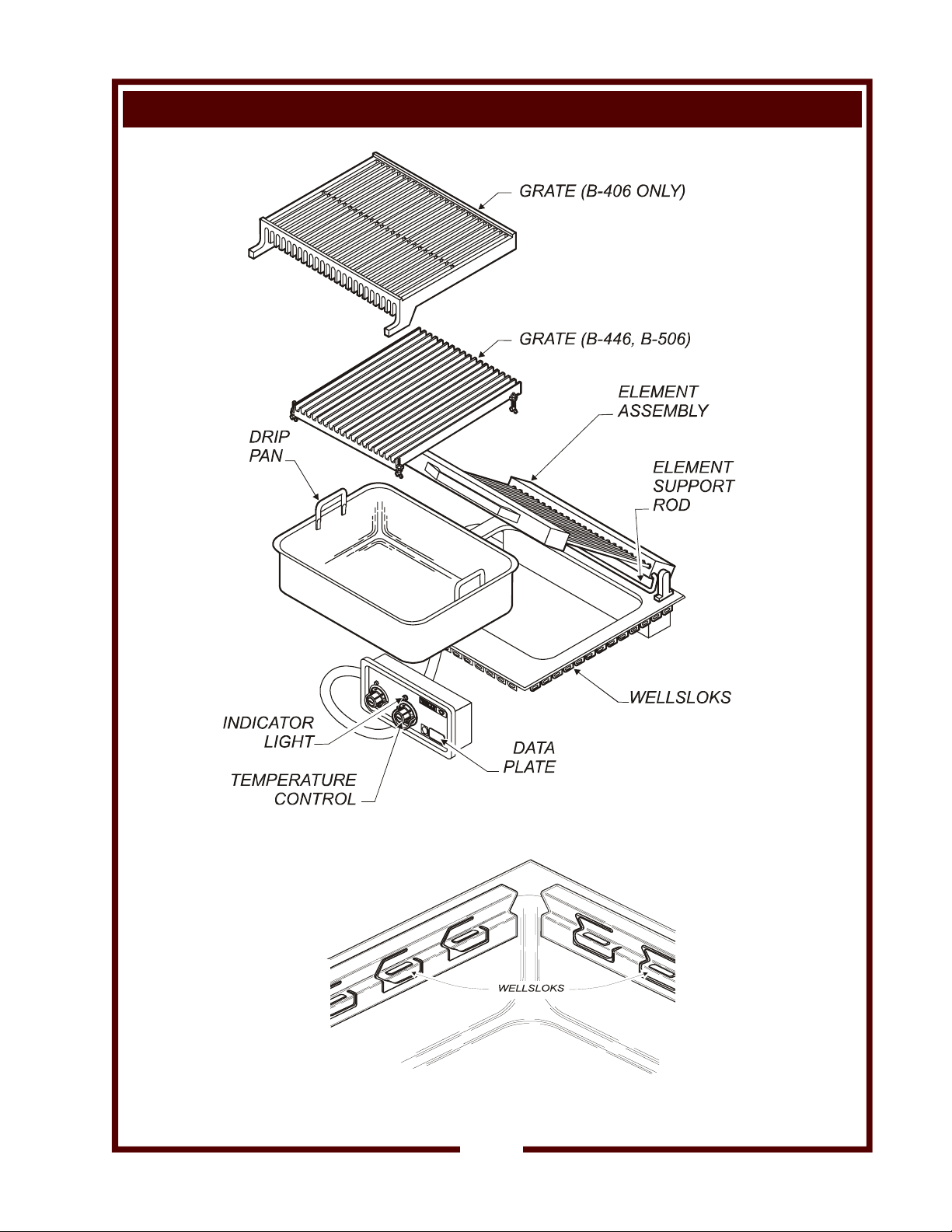

FEATURES & OPERATING CONTROLS

ITEM

TEMPERATURE CONTROL

INDICATOR LIGHT

HEATING ELEMENT

ASSEMBLY

ELEMENT GUARD / GRATE

ELEMENT SUPPORT ROD

DRIP PAN

DATA PLATE

WELLSLOKS

COMMENT

The char-broiler is INFINITE SWITCH CONTRO LLED. Power is

applied to the heating elements based on the control knob position and

the amount of energy used.

Light will glow when the infinite switch is in any position other that OFF.

The char-broiler element assembly may be raised for cleaning, or to

add water to the drip pan. It is held the “up” position by a support rod

which automatically engages as the element is raised.

The grate is designed to protect the individual elements from food

contact and spatula abrasion, resulting in prolonged element life and

reduced carbonization. The grate is easily removed for cleaning.

IMPORTANT: Always remove the grate before lifting the element

assembly.

Hold element assembly in up position. Engages automatically when the

element assembly is raised.

IMPORTANT: Remember to dis-engage the support rod before

lowering element assembly

The heavy-duty removable drip pan is located under the element

IMPORTANT: DO NOT pour water over elements to refill drip pan.

assembly. The drip pan catches food particles and grease drippings

during broiler operation. Maintain 2 inches of water in the drip pan at all

times during operation of the broiler. The drip pan is easily removed for

cleaning.

Gives manufacturer, make, model and serial number. Also voltage and

phase information, and agency approvals.

The broiler is equipped with WELLSLOKS, uniquely designed turnout

tabs, which help secure the broiler to the countertop. (See Installation

Instructions supplied with the particular appliance for details.)

162 303673 OpManual for Built-In Electric Charbroilers

2

Page 5

FEATURES & OPERATING CONTROLS (continued)

162 303673 OpManual for Built-In Electric Charbroilers

Fig. 1 Built-In Electric Charbroiler

Fig. 2 Wellsloks

3

Page 6

PRECAUTIONS AND GENERAL INFORMATION

WARNING:

Electric Shock

Hazard

All servicing requiring access

to non-insulated electrical

components must be

performed by a factory

authorized technician.

DO NOT open any access

panel which require the use of

tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

Risk of Damage

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

Broilers are intended for use to cook food products for human

consumption. No other use is recommended or authorized by the

manufacturer or its agents.

Broilers are intended for use in commercial establishments, where all

users are familiar with the appliance limitations, use and associated

hazards. Operating instruction and warnings must be read and

understood by all operators and users.

Do not submerge broilers in water. Do not splash, or pour water onto

controls, control panels or wiring.

Disconnect the broiler from electrical power before performing any

service or maintenance.

Allow drip pan to cool before removing from broiler. Do not operate

broiler without the drip pan installed. Do not operate the broiler without

2” of water in the drip pan.

Any parts replacement, maintenance procedure or servicing procedure

requiring the use of tools must be performed by an Authorized Service

Agency.

Any troubleshooting guides, component view, parts lists or installation

guides provided with this equipment are intended for the use of the

qualified technical personnel only.

Except where otherwise noted, this piece of equipment is made in the

USA and has American sizes on hardware.

This manual should be considered a permanent part of this appliance.

This manual and all supplied instructions, diagrams, schematics, parts

break downs, notices and labels must remain with the appliance if it

sold or moved to another location.

162 303673 OpManual for Built-In Electric Charbroilers

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

STD 4

E6070

installed in accordance with the supplied Installation Instructions.

This appliance is Underwriters Laboratory recognized ( ). Since

this appliance is only a single component of a complete installation, the

finished installation of this unit requires additional evaluations to

Underwriters Laboratory standards.

Refer to Installation Instructions included with the broiler for

Underwriters Laboratories conditions of acceptability, electrical

4

Page 7

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic film, packing materials and accessories from the appliance

before connecting electrical power or otherwise performing any

installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before discarding

packing materials. Store all accessories in a convenient place for later

use.

CUT-OUT AND INSTALLATION

Cutouts

a. Broilers may be installed in METAL COUNTERS ONLY.

b. Cutout dimensions for broilers and control panels are listed on

the Installation Instructions provided with the broiler.

c. Refer to the Installation Instructions for Underwriters

Laboratories Conditions of Acceptability.

Mounting the broiler:

a. Verify that provided sealants are applied to the under side of

the broiler top flange prior to setting the unit into the cutout.

b. After installation, verify that the tabs on the Wellsloks are

turned out to lock the broiler into the counter (see Fig. 3).

c. Apply a thin bead of food-grade silicone sealant around the

flange to seal it to the counter.

Refer to the Installation Instructions for required clearances. Maintain

required clearances between the appliance and adjacent combustible

and non-combustible surfaces.

Sufficient overhead clearance must be provided to allow the element

assembly to be raised. Refer to the Installation Instruction Sheet for

required clearances.

Install drip pan and element guard/grate prior to heating or using broiler.

162 303673 OpManual for Built-In Electric Charbroilers

Avoid storing flammable or combustible materials near the appliance.

This includes gasoline and other fuels, mops, rags and wrapping pa per.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

IMPORTANT: This is a

GENERAL GUIDE. For

specific equipment and cutout

dimensions, and other

installation details, refer to

the Installation Instructions

supplied with the broilers.

Fig. 3 Set the Wellslloks

IMPORTANT: Water

damage caused by failure to

set Wellsloks, failure to install

gasket, or failure to seal

flange to counter is NOT

covered by warranty.

5

Page 8

INSTALLATION (continued)

WARNING:

Risk of personal

injury

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

CAUTION:

Electrical Shock

Hazard

The broiler must be

electrically grounded.

Connect the terminal marked

“GND” or “ ” to a suitable

building ground.

IMPORTANT: Contact a

licensed electrician to install

and connect electrical power

the broiler.

Electrical installation must be

performed by a licensed

electrician in compliance with

all local ordinances and code

requirements.

IMPORTANT: Damage due

to being connected to the

wrong voltage or phase is

NOT covered by warranty.

ELECTRCAL HOOK-UP

Refer to the nameplate. Verify the electrical service power. Voltage

and phase must match the nameplate specifications. Connecting the

griddle to the wrong voltage can severely damage the unit or cause

noticeable decreased performance.

Use copper wire suitable for a minimum of 90°C for electrical supply

connections.

Broilers are factory wired three-phase (3ø). For single-phase (1ø)

wiring, refer to the wiring diagram attached to the broiler. Conversion to

1ø must be performed by a licensed electrician.

This broiler is not fused. Protect the circuit with properly sized fuses or

circuit breaker.

An electrical disconnect must be installed readily accessible to the

operator of the broiler.

162 303673 OpManual for Built-In Electric Charbroilers

6

Page 9

OPERATION

PREPARE THE CHAR-BROILER FOR USE

When using the broiler for the first

time, wipe the entire unit with a clean

damp cloth or sponge and mild

detergent. Rinse thoroughly clean

water. Dry with a soft clean cloth.

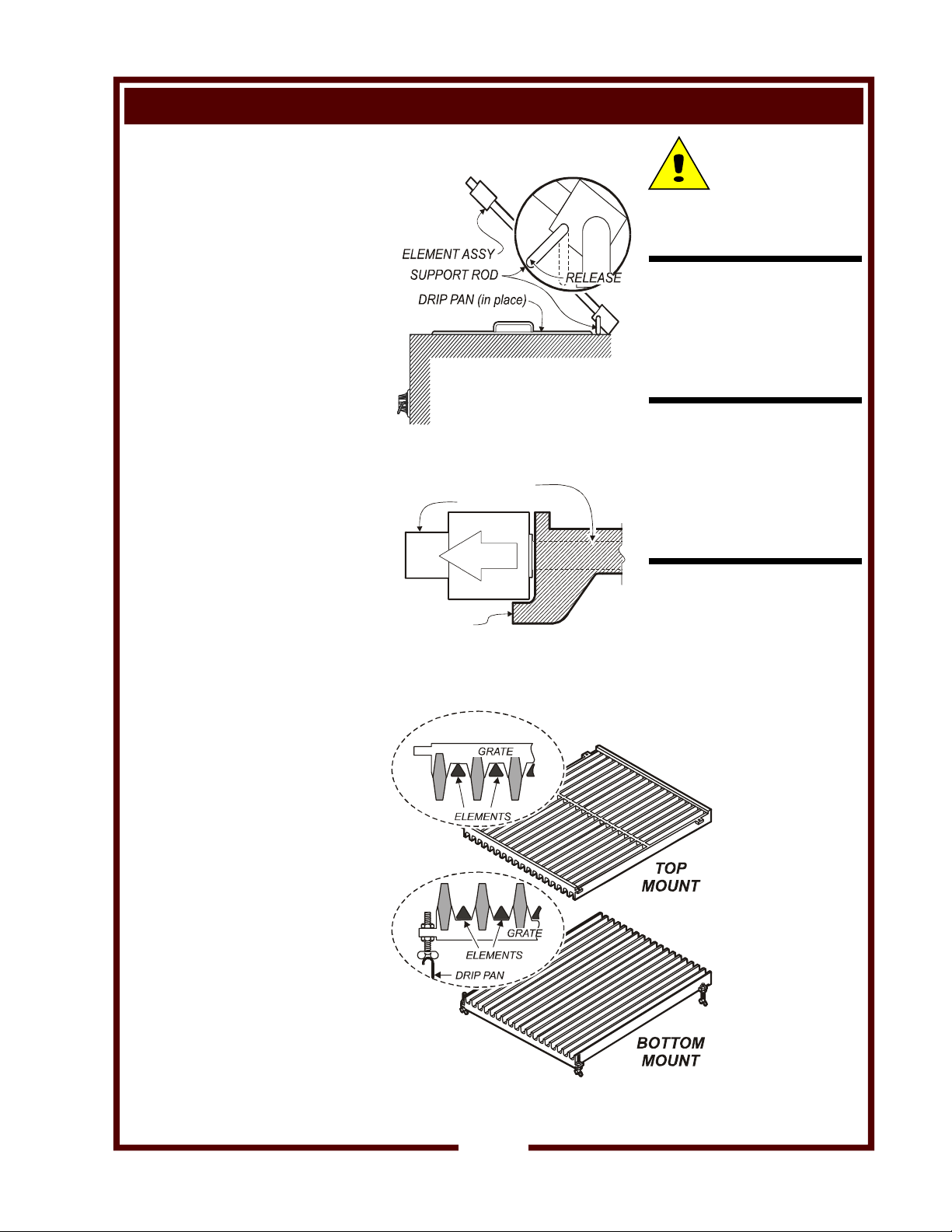

Remove the GRATE and raise the

ELEMENT ASSEMBLY.

Install the DRIP PAN and add

2” (5cm) of tap water.

Release the ELEMENT SUPPORT

ROD by lifting the element assembly

slightly, then pulling the lower portion

of the support rod forward. Lower the

ELEMENT ASSEMBLY gently.

MODEL B-406: Grate must be

installed ABOVE elements.

Install the GRATE, front edge first.

The TANGS of the grate go DOWN

and point toward the FRONT. The

grooves on the underside of the

grate align with the elements. The

rear edge of the grate can be

lowered until it rests firmly on the

elements.

MODELS B-446 and B-506: Grate(s)

can be installed above or below the

elements.

ABOVE: Gently lower grate over

elements. The end with flush tabs

goes toward the front.

BELOW: Install one wing bolt in

each tab. The notch in the wing

rests on the lip of the drip pan. The

end with flush tabs must go toward

the front Adjust the wing bolts so

that , when the element assembly is

lowered, the top of the element is

162 303673 OpManual for Built-In Electric Charbroilers

1/4" (6mm) below the top of the

grate fins.

Fig. 4 ELEMENT SUPPORT ROD

ELEMENT

HANDLE

FRONT

GRATE TANG

Fig. 5 B-40 GRATE INSTALLATION

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

IMPORTANT: DO NOT

attempt to raise the element

assembly without first

removing the grate. Damage

to the hinges will result. Such

damage is NOT covered by

warranty.

IMPORTANT: Allow drip pan

to cool before removing from

the broiler.

DO NOT operate the broiler

without the drip pan installed.

DO NOT operate the broiler

without 2” (5cm) of water in

the drip pan.

IMPORTANT: DO NOT

attempt to lower the element

assembly without first

releasing the support rod.

Damage to the hinges will

result. Such damage is NOT

covered by warranty.

Fig. 6 B-44 and B-50 GRATE INSTALLATION

7

Page 10

OPERATION (continued)

CAUTION:

Hot Surface

Exposed surfaces

can be hot to the touch and

may cause burns.

Fig. 7 TEMPERATURE CONTROL

IMPORTANT: DO NOT

POUR WATER OVER

ELEMENTS TO REFILL

PAN.

DO NOT splash or pour water

onto controls, control panels

or wiring.

TEMPERATURE CONTROLS

Each section of the broiler is equipped with an individual temperature

control. The desired temperature is controlled by rotating the

TEMPERATURE CONTROL KNOB. Any time the control is turned

“ON”, the adjacent indicator light will glow. Each section of the broiler

may be set to a different temperature setting.

“OFF” removes power from the element., allowing the element to cool.

Use OFF to turn the broiler off at the end of the cooking day.

“LO” is the lowest temperature settings. Use LO for stand-by operation.

“2” thru “8” are temperature settings. Higher number indicate higher

temperature.

“HI” is a continuous ON setting. Use HI for pre-heating the broiler.

USING THE CHAR-BROILER

Pre-Heat the broiler ten (10) minutes by turning the TEMPERATURE

CONTROL to “HI”.

After the pre-heat period, turn the TEMPERATURE CONTROL to the

desired setting (refer to the Broiler Chart at right for recommended

settings).

After every order, use the brush provided to brush any remaining food

particles from grate and elements. Keeping the cooking surfaces clean

will help in maintaining food taste.

Visually check the water level in the drip pan during operation. Add

water as required to maintain 2 inches (5cm) water depth in the drip

pan.

162 303673 OpManual for Built-In Electric Charbroilers

8

Page 11

OPERATION (continued)

BROILER CHART

RECOMMENDED COOKING TIMES AND DIAL SETTINGS

NOTE: The times and dial settings in this chart are suggestions only. Your own

experience with your own menu items will be your best guide to achieving the best food

product.

PRODUCT

Condition

BEEF Frozen 1/2” Rare 8 4 - 6

“ 1/2” Medium 8 7 - 9

“ 3/4” Rare 7 7 - 9

“ 3/4” Medium 7 8 - 10

“ 1” Rare 7 12 - 14

“ 1” Medium 7 14 - 16

“ 1-1/4” Rare 6 23 - 25

“ 1-1/4” Medium 6 25 - 27

BEEF Non-Frozen 3/4” Rare HI 4 - 6

3/4” Medium HI 5 - 7

1” Rare HI 7 - 9

1 Medium HI 8 - 10

1-1/4” Rare HI 12 - 14

THICKNESS COOKING

SETTING

DIAL TIME

Minutes Total

162 303673 OpManual for Built-In Electric Charbroilers

1-1/4” Medium HI 13 - 15

1-1/2” Rare HI 14 - 16

1-1/2” Medium HI 18 - 20

9

Page 12

TROUBLESHOOTING SUGGESTIONS

SYMPTON POSSIBLE CAUSE SUGGESTED REMEDY

Won’t heat- - no indicator

lights

One or more section

won’t heat—or not hot

enough

One or more section too

hot

Element assy loose, or

difficult to raise or lower

Element assy does not

latch in up position

Electric disconnect OFF

Circuit breaker tripped

Temperature control not set

Check / turn disconnect ON

Check / reset circuit breaker

Set temperature control knob to

desired temperature

240V unit run on 208V Verify proper voltage

Damaged component or wiring

Temperature control not set

Contact an Authorize Wells

Service Agency for repairs

Set temperature control knob to

desired temperature

208V unit run on 240V Verify proper voltage

Damaged component or wiring

Damaged hinge

(see page 7 for precautions)

Damaged support rod assembly

Contact an Authorized Wells

Service Agency for repairs

Contact an Authorized Wells

Service Agency for repairs

Contact an Authorized Wells

Service Agency for repairs

NOTE: There are no user

serviceable components in

this appliance. In all cases of

damage or component

malfunction, contact your

Authorized Wells Service

Agency for repairs.

162 303673 OpManual for Built-In Electric Charbroilers

10

Page 13

CLEANING INSTRUCTIONS

PREPARATION

Turn both temperature control knobs OFF.

Allow broiler to cool completely.

Disconnect broiler from electric power.

FREQUENCY

Daily.

TOOLS

Steel Brush with Scraper

Plastic Scouring pad, Soft-Bristled Fiber Brush

Mild Detergent, Non-Abrasive Cleanser

Clean Soft Cloth / Sponge

CLEANING

1. Remove the grate from the broiler. Clean grate:

a. Use the supplied steel brush with scraper to remove food

particles and residue from grate surfaces.

b. Grate may be washed in sink or dishwasher.

c. Dry the grate and apply a light coating of cooking oil.

2. Raise the element assembly until it latches. Remove and clean

the drip pan:

a. Stubborn food particles maybe removed with a plastic scouring

pad.

b. Drip pan may be washed in a sink or dishwasher.

3. Clean the element assembly:

a. Use a soft-bristled fiber brush to remove any remaining food

particles from the elements.

b. Clean the element rods with a soft damp cloth or sponge and

mild detergent. Rinse by wiping with a soft cloth moistened

with clean water. Dry with a soft cloth.

4. Clean the control panel with a soft damp cloth or sponge and mild

detergent. Rinse by wiping with a soft damp cloth moistened with

clean water. Dry with a soft cloth.

5. Reassemble broiler:

a. Reinstall drip pan.

b. Unlatch element support rod and carefully lower the element

assembly.

c. Reinstall the grate.

162 303673 OpManual for Built-In Electric Charbroilers

Procedure complete.

CAUTION:

Electric Shock

Hazard

Disconnect appliance from

electric power before

cleaning.

CAUTION:

Burn Hazard

Allow appliance to cool

completely before cleaning.

CAUTION:

Electric Shock

Hazard

Do not submerge appliance

in water.

IMPORTANT:

DO NOT spill or pour water

into controls, control panel or

wiring. Damage to internal

components will occur.

Damage to internal

components from water

damage is NOT covered by

warranty.

11

Page 14

THIS PAGE BLANK

162 303673 OpManual for Built-In Electric Charbroilers

12

Page 15

PARTS & SERVICE

DESCRIPTION SERVICE

PART NO.

GREASE PAN, B-446 (1 PER UNIT)

B-506 (2 PER UNIT) 20174

GREASE PAN, B-406 20202

GRATE, B-446 (1 PER UNIT)

B-506 (2 PER UNIT) 21706

GRATE, B-406 21707

BRUSH, BROILER 21708

IMPORTANT: Use only

factory authorized service

parts and replacement

filters.

For factory authorized

service, or to order factory

authorized replacement parts,

contact your Wells authorized

service agency, or call:

Wells Bloomfield, LLC

2 Erik Circle

P. O. Box 280

Verdi, NV 89439

Service Parts Dept.

phone: (775) 689-5707

fax: (775) 689-5976

Service Parts Department can

supply you with the name and

telephone number of the

WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

CUSTOMER SERVICE DATA

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

162 303673 OpManual for Built-In Electric Charbroilers

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

VOLTAGE: (check one) 208 240

please have this information available if calling for service

13

Page 16

Genuine Parts

Protect - YOU - All - Ways

SERVICE TRAINING - QUALITY SERVICE

CUSTOMER SATISFACTION

Commercial Food Equipment Service Association

Wells Bloomfield proudly supports CFESA

Commercial Food Equipment Service Association

SERVICE TRAINING - QUALITY SERVICE

CUSTOMER SATISFACTION

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5703

fax: 775-689-5976

www.wellsbloomfield.com

PRINTED IN UNITED STATES OF AMERICA

Loading...

Loading...