Page 1

BLOOMFIELD INDUSTRIES

10 SUNNEN DRIVE

St. Louis, MO 63143

telephone: 314-781-2777

fax: 314-781-2714

www.wellsbloomfield.com

PROGRA MMING MANUAL

SATELL I T E BREWI NG SYSTEM

675

for

SS-2

PROGRAMM I NG for SS-2 Series Dual Sat el lite Brewer s

Models SS-2: 9421

9520 9520FB

9521 9521FB

SS-2EX: 9521EX 9522HK

p/n 2m- 74346 Rev.C ECN-13385 M675 090408 rm s

Page 2

TA BLE O F CO NTE NT S

Thank You for purchasing

thi s Wells Bloomfield

appliance.

Proper installation,

pr ofessiona l op er at io n and

consistent maintenance

of this appliance will ensure

that it gives you the very best

performance and a long,

economical service life.

PRECAUTIONS & GENERAL INFORMATION 1

OPERATION 2

PROGRAMMING

CO NTROL PANEL CONFIGURAT IONS 6

PROGRAMMING CHART 7

PROCEDURES

BREW SETTINGS 10

T IME FUNCT IONS 10

SERVICE & COUNT ERS 10

M ACHI NE SET TINGS 11

FACTORY SETTINGS 12

CALIBRATION 12

PULSE BREW , PRE-INFUSIO N AND BYPASS 13

DIAGNOSTICS - TEST PROGRAM 15

FAULT PROTECTION 19

APPLICATION

Proper setup i s essential to

achievi ng the optimum

performance this appli ance

can pr ov i de .

This m anual contains the

infor mation nee ded to perfor m

oper a tor level pr o gr am m in g,

and to setup initial program

parameters for this appliance.

This manual applies to the following domestic satellite brewers:

9421

9520

9520FB

9521

9521FB

This manual also applies to the following export satellite brewers:

9521EX

9522HK

xi

675 p/n 74346 SS-2 Programming Manual

Page 3

PRECAUTIONS AND GE NE RAL INFORMA TI ON

WAR NING: ELE C T RI C SHO CK HA Z A R D

All servi cing requiring access to non-i nsulated components must be performed by qualified

service personnel. Do not open any access panels which requi re the use of tools. Failure to

heed this warning can result in electrical shock.

WAR NING: I NJ URY HAZARD

All installati on procedures m ust be performed by qualified personnel with full knowledge of all

applicable electrical and pl umbi ng codes. Failure could result in property damage and

per s onal in jury .

WAR NING: ELE C T RI C SHO CK HA Z A R D

Brewer must be properly grounded to prevent possible shock hazard. DO NOT assum e a

plumbi ng line will provide such a ground. Electrical shock will cause death or serious Injury.

WAR NING: BURN HAZ A RD

This appliance dispenses very hot liquid. Serious bodil y injury from scalding can occur from

contact with d is pensed liqu i ds .

This appliance is i ntended for commercial use only.

This appliance is i ntended for use to brew beverage products for

hum an consumption. No other use is recom mended or

authorized by the manufacturer or its agents.

This appliance is i ntended for use i n commercial establishm ents,

where all operators are familiar with the appliance use,

limi tations and associated hazards. Operating instructions and

warnings in the c orr espo nding Serv ice M anual must be read and

understood by all operators and users.

Except as noted, this piece of equipment is made in the USA

and has American sizes on hardware. Please note: Metric

hardware is used to mount the inlet (Fill) solenoid. All metric

conversions are approximate and can vary in si ze.

Any trouble shooting, com ponent views and parts lists included

in this manual are for general reference, and are intended for

use by qualifi ed servi ce personnel.

This m anual should be considered a permanent part of this

app l ia nce. Th e man ual must rema in wit h the ap pl i ance i f it is

s old or moved to an oth er location.

675 p/n 74346 SS-2 Programming Manual

CAUTION:

EQUIPMENT DAMAGE

DO NOT plug in or energize this

app l ia nce un t i l all In stallation

Instructions are read and followed.

Damage to the Brewer will occur if

these instruc ti ons are not fo l lowed.

CAUTION:

BURN HAZARD

Exposed surfaces of the

appliance, brew chamber and

decanter may be HOT to the

touch, and can cause serious

burns.

CAUTION:

BURN HAZARD

To avoid splashi ng or overfl owing

hot liquids, ALWAYS use an

empty decanter before starting the

brew cycle.

CAUTION:

BURN HAZARD

After a brew cycle, brew basket

contents are HOT. Rem ove the

brew basket and dispose of used

grounds with care.

1

Page 4

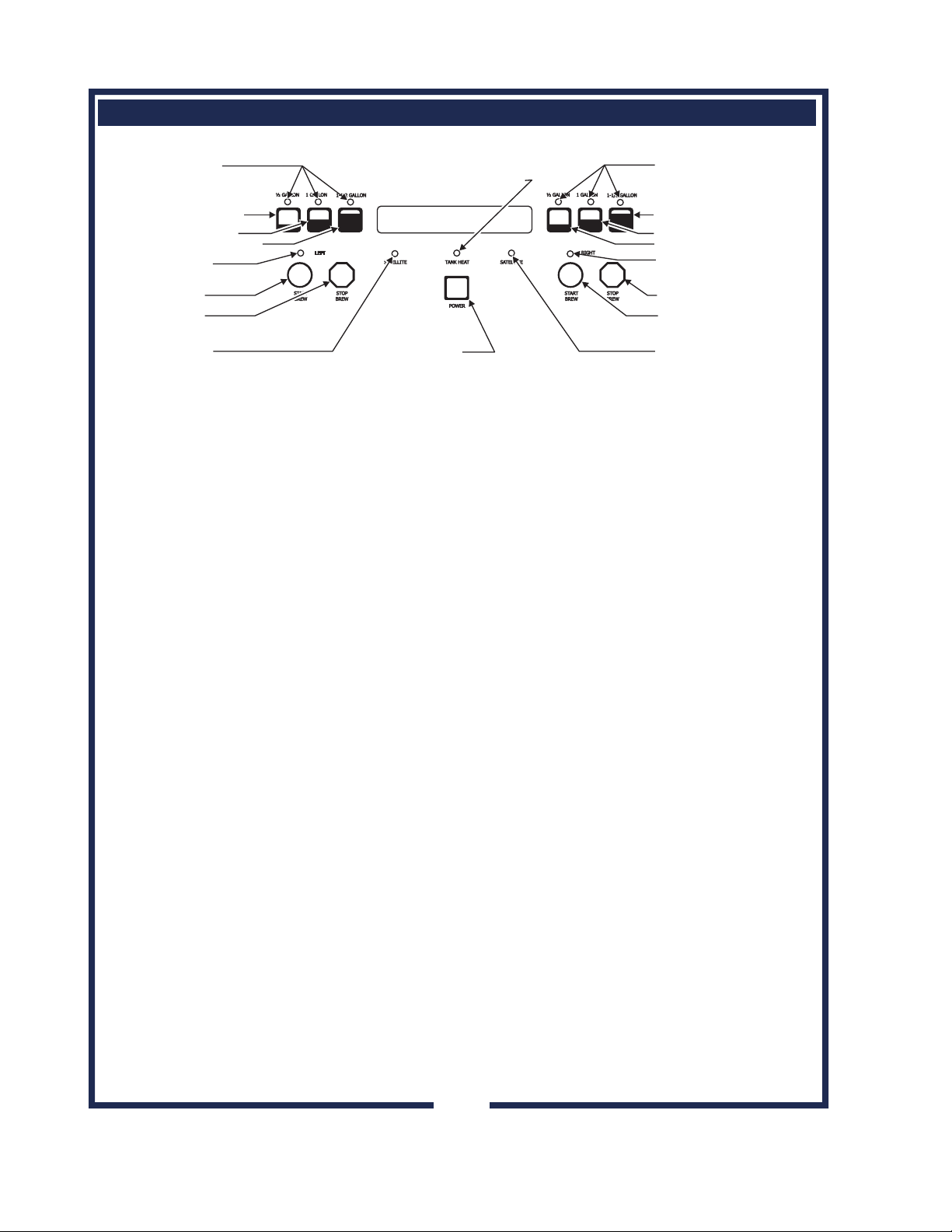

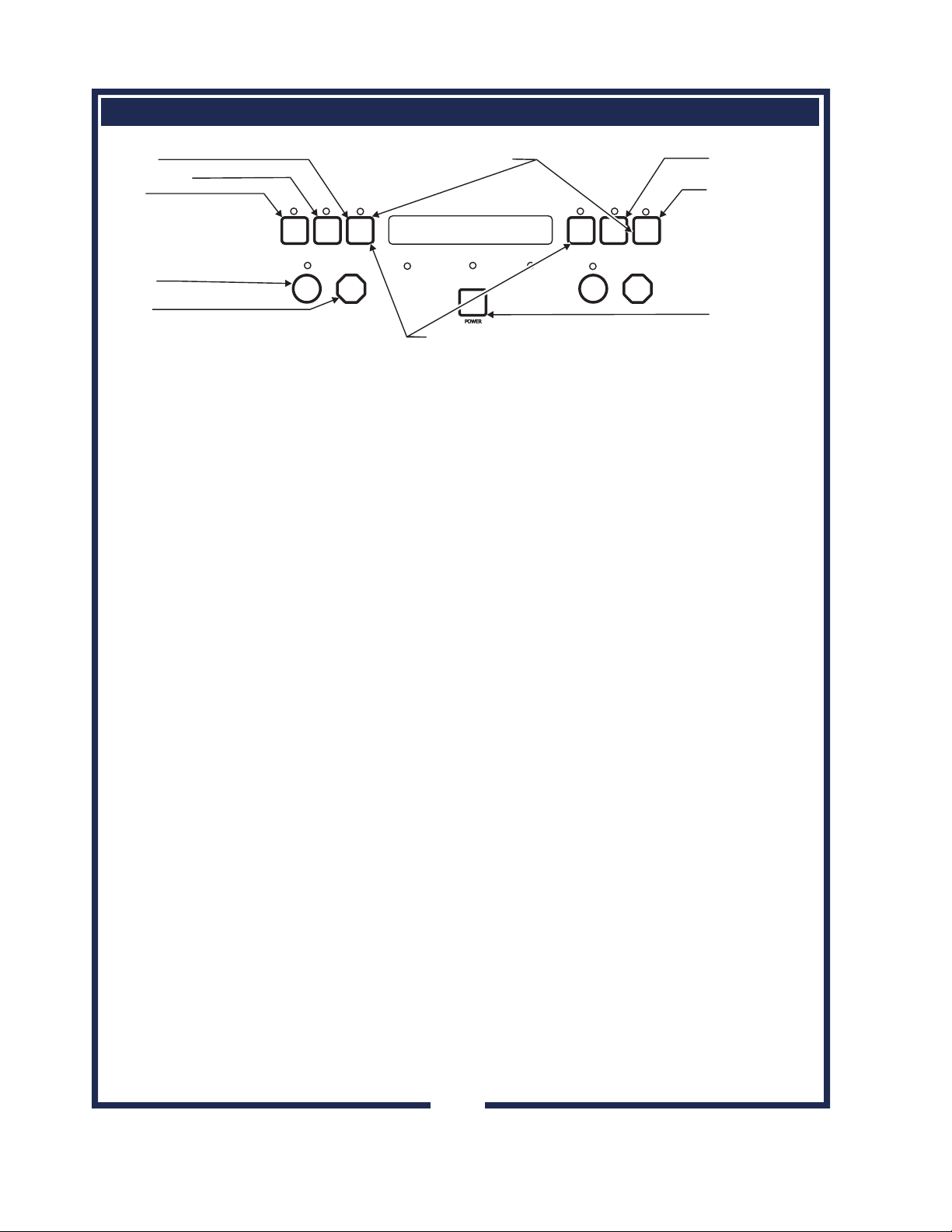

OPERATION

Mon 09:12am

LEFT SIDE

LED INDICATORS

(selection)

LED INDICATOR

(heating element energized)

RIGHT SIDE

LED INDICATORS

(selection)

SELECT ½ GAL (2 liter)

SELECT 1 GAL (4 liter)

SELECT 1-1/2 GAL (6 liter)

LED INDICATOR

(brew)

BREW INITIATE BREW INITIATE

BREW CANCEL BREW CANCEL

LED INDICATOR

(satellite installed)

NOTE:

If water is not sensed at the

water level sensor wi thin 20

minutes:

Heater will be disabled

Error m essage "NO WATER

SENSED" will be displa y ed .

NOTE:

If the keypad lockout i s enabled,

pressi ng a key will hav e no

effect. To tempo rari ly bypa ss

the lockout, press and hold the

LEFT BREW CANCEL key for

six seconds. The keyboard is

un locked unt il the next brew .

To enter Brew mode from On

mode, press the Left or Ri ght

Mon 09:12am

ON-OFF KEY

GETTING STARTED

1. In the OFF MODE, val ves and heaters are turned OFF, and

no m essage is di splayed.

2. Press the POWER key to turn the brewer ON.

a. When the brewer is first turned ON, the digi tal readout

will display "BLOOMFIELD'" and a beep will sound. The

POWER L ED will gl ow.

b. The brewer will attempt to fill the tank with wa ter. The

readout will display "Filling…".

c. When the tank is filled to the level of the water level

probe the tank heaters will be energized. The TANK

HEAT LED will glow and the readout displays "Heating".

3. When the water i n the tank is up to the set tem perature, the

T ANK HEAT LED tu rns o ff and the readout d ispla ys th e ti me

and day.

4. From the ON MODE, the user can press a BREW VOLUM E

key on left or right side to select a brew amount, the left or

right START key to initiate a brew, or the POWER key to turn

the system OFF (thi s enters the OFF MODE).

SELECT ½ GAL (2 liter)

SELECT 1 GAL (4 liter)

SELECT 1-1/2 GAL (6 liter)

LED INDICATOR

(brew)

LED INDICATOR

(satellite installed)

Start key. A beep is heard each

tim e a key is pressed. In Brew

Mo de, th e Lef t or R i ght Br ew

LED i s ei ther on or flashing.

To ensure high quality coffee,

water volume and temperature

considerations have to be met

before initiating a brew. If such

conditions are not m et, the

system wai ts until water

temperature and volume

conditions are met before

brewing can begin.

675 p/n 74346 SS-2 Programming Manual

2

Page 5

OPERATION (continued)

R

BREWING

In regular operating mode, the SS-2 maintains the temperature of

the water i n the tank within ± 1ºF of the brew tem perature.

Normall y , the brew will start as soon as the BREW START key is

pressed. However, there may be a slight delay if a second brew i s

started immediatel y after a brew is completed. If the tank temperature is below the Preci se Temperature Brewing™ poin t , the brew

will be delayed going into the "Brew Wait" mode, with the brew light

flashing and the display message "heating…". As soon as the

PTB™ is rea c hed, th e brew will start . The brew light will remain on

for the duration of the brew, and the time remain ing will be

displayed.

NOTE: The foll owi ng safety features have been i ncorporated to

prevent multiple unattended brews.

A. When the brew light is on or flashing, repeated pressing of the

BREW S TART ke y will be i gnored (however , an beep will

sound each time the key is pressed).

B. A brew will only be initiated, or placed in "brew wait" when the

brew light is off.

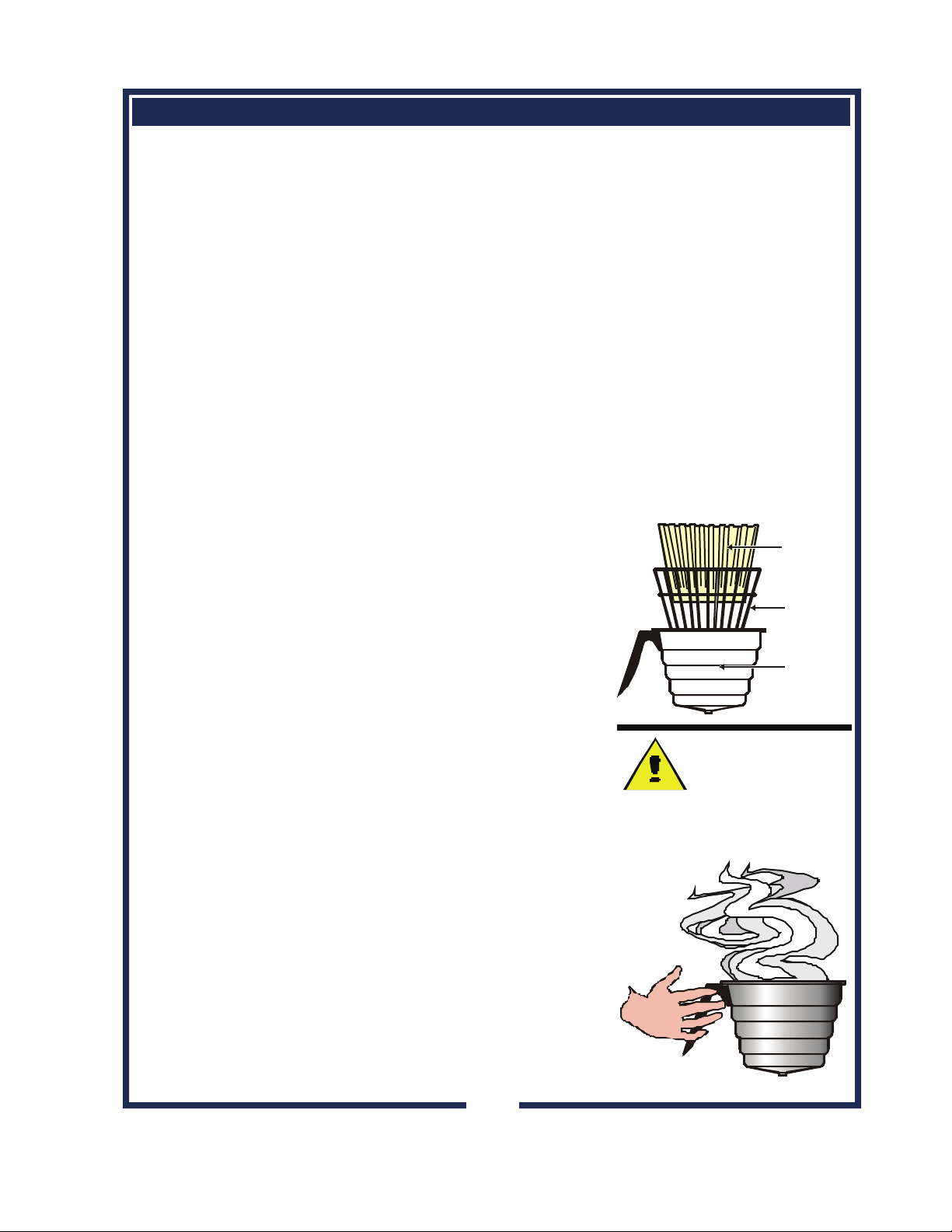

BREWI NG COFFEE

Prepare the Brew Baskets:

Make sure the wire rack is properly installed in each brew

chamber.

Insert one (1) Bloomfield paper filter into each brew chamber.

Make sure the filter i s properly supported by the wire rack.

Add a measured amount of grounds to each brew basket.

Gently shake the basket to level the grounds.

Slide one brew cham ber under each brew head.

Inse rt Satellites:

Slide one satellite under each brew chamber until i t is fully

seated. When the satellite is properly installed, SATELLITE

LED for left or righ t side wil l glo w.

Se lect Brew Vol u me:

Press either the 1/2 GALLON, 1 GALLON or 1-1/2 GALLON

key. The corresponding LED will glow.

Start the Brew:

Press either the right or left START BREW key. The LED for

the selected side will gl ow. At the end of the brew, the brewer

will beep. When the TANK HEAT LED goes out, the brewer i s

ready to run another brew cycle.

675 p/n 74346 SS-2 Programming Manual

Empty the Brew Basket:

Discard the grounds and the paper filter. Rinse the brew

chamber under cl ear water.

To bypass the BREW WAIT ,

press and hold the BREW

START key for thr ee seconds.

The b rew will start , even t ho ugh

the wate r may not be up to the

Precise Temperature Brewing™

point. This feature is most

useful when adj usti ng volumes

and i s not generally used for

normal brewi ng.

Dur in g a brew , if the br ew key is

pressed, i t will be ignored. Onl y

when a brew is com plete can

ano ther br ew beg in .

NOTE: The brew can be cancel le d at any ti me by pr ess ing

the BREW STOP key.

PAPER

FILTER

WIRE

RACK

BREW

CHAMBE

CAUTION:

BURN HAZARD

Basket and contents are hot to

the touch and may cause burns

on contact.

3

Page 6

OPERATION (continued)

View Water Temperature in

Tank:

To view the water temperature

on the screen, the SS2 brewer

must be ON, and not brewing or

in the filling mode. Press and

hol d the 3rd key, and depress

the 6th ke y. The actu al wate r

t emperature wi ll be disp l aye d for

3 seconds.

Tempora r i ly Ove r riding the

Automatic On/ Off function :

While in the autom ati c timed

OFF mode the brewer can be

started by depressing the ON/

OFF swi tch . The brewer will

remain on unti l the aut om atic

programmed o ff time, when it will

turn off and resu me no rmal

automati c timed functi oning.

Si milarly, if tu rned OFF du ri ng

the automatic timed ON m ode

the brewer will remain OFF until

the next pr o gr am m ed on time ,

when it will turn on and resume

normal automatic timed

functioning.

NOTE:

W hen br ew ing both s id es at

same ti me or one side onl y,

countdown timer on time remaining for brew complete wi ll

be shown in minutes and seconds.

Brew Cancellation

Br ew ing c an be canc el ed at any ti m e by pr ess ing t he St o p key or

another Brew Batch switch. Once canceled, there will not be any

indication as to when it will be safe to begin another brew. If

brewin g is cance led, the valves close and the Brew LED turns off,

two beeps are heard and "Cncl" is displayed on the appropriate

side. In addition, the S atellite indic ator lig ht will flash.

Norma l Operation (Non Brewing)

When the unit is not brewi ng, the SS2 m aintains the water temperature at the Precise Temperature for Brewing™ (PTB ™). The

heatin g el ement will cycle on and off autom a ticall y to maintain this

temperature.

ON/O FF - Non Automa tic Ti m er:

To turn the brewer OFF, press the ON/OFF switch: 2 beeps will be

heard and the brewer wi ll be turned OFF, indicated by all lights

bei ng off. To turn the brewer ON, press the ON/OFF switch: 2

beeps-wi ll sound, all lights will flash once, then the "Power" li ght

will remain on, (the "Heat' light may come on if water temperature

is t oo low).

ON/OFF - Automatic Timer Feature:

The f actor y pr ogr a m me d SS 2 h as the au tomat ic ti mer tur ned off.

T o se t the automatic timer, re fer to the Programming section in

this manual, "Time Functions" Menu. If the Automatic Tim er

feature i s programmed off, the brewer can be turned on and off by

depressing the ON/OFF switch, as noted above.

When the Automatic Timer feature is programmed ON the SS2 will

turn on and off automatically, at a programmed time, Monday to

Friday; with a separate on and off programmed time schedule for

Saturday and Sunday.

Automatic Sta rt-UP in P revious Mod e:

If the SS2 automatic timer is OFF (the factory setting) and power

is di sco nn ected, the brewer will st art up when po wer is restored , in

the mo de it had been in prior to th e pow er dis c on nection. I f the

SS2 has the timer setting ON and power is disconnected, the

brewer will start up in the mode that it sho uld be in at the time the

power i s restored.

Brew Volume - View i ng Programmed Brew Volume :

The SS2 can have up to 6 different brew volumes, see

programming table to change.

Clock:

Time - Battery Backup. The SS2 has a battery backup system

which will mai nt ain the prope r tim e during power fail ures, or when

the brewer is unplugged (even for very prolonged periods of time).

Normally there will not be a need to set the time except for Day-

light Saving Time changes, or moving the brewer to different time

zones.

675 p/n 74346 SS-2 Programming Manual

4

Page 7

OPERATION (continued)

Refer to page 2 for key designations

Changi ng Day and Time:

To change time, (Brewer in on mode.) Press the 3rd and 4th key at

the same time to access the time change mode. In the time change

mode the screen will read 'Day :" followed by the current da y

setting. Use the 6th key to advance the day, or the 5th key to re-

verse. When day has been properly set press the 3rd key. T he

screen wil l now read "Time:" with the set tim e on the screen, the

hour and am or pm flashing. Use the 5th key to go back or the 6th

key to advance the hour, making sure that the am or pm is correct.

When the hour and am/pm is correctly set press the 3rd key,

and the screen will read "Time:" with the set time on the screen,

minutes flashi ng. As previously, use the 5th or 6th keys to adjust

the minutes, and press the 3rd key when complete. )

Afte r Hour ™:

The factory programming has the After Hours™ mode turned ON.

The After Hours™ can be programm ed to com e on f r om 1 to 6

hours after the last brew. When the SS2 goes into the After

Hours™ mode, the water in the tank wil l be allowed to drop from

the norm al brewing tem perature and wi ll reheat less frequently.

This feature saves energy and extends component life. When the

BREW switch is pressed the SS2 automatically reverts back to

normal operation, heating the water to the Precise Tem perature for

Brewing™ (PTB™), before starting the brew. The Brew light wi ll

flash until the correct water temperature is reached.

Countdown Quality Timer ™:

The SS2 factory programming has the Countdown Quality Timer™

turned ON fo r satellite brewi ng.

Keypadlock™:

This feature is OFF in the standard factory settings. If the

Keypadlock™ feature is act ivated , there will be n o respon se by the

brewer when the keys are depressed (except for the beep after a

key is depressed).

To temporarily "unlock" the keypad, press and hold the CANCEL

key f or 6 seconds. A beep will be heard indi cati ng the keypad is

now "unloc ked" , - a brew can be initiated, etc . Th e keypad will

remain unlocke d until the brew is completed, then au tomatically

re turn to Keypadlock™ mode. If a brew is not initiated 60 seconds

after "unlocking", the system will time out and return to the "locked"

position.

Pulse or Pre -infusion V olume System:

To set these features, refer to the Programming section in thi s

manual , Brew Settings Menu. Thi s feature maybe set for any

volume key.

Bypass Valve System:

675 p/n 74346 SS-2 Programming Manual

Refer to programming section under brew settings menu item . This

feature may be set for any volume key.

Changing time can also be

done i n the regula r

pr ogr a mm ing mo de.

Consult the Programming

secti o n in thi s manual to set

the After Hours™ mode.

Consult the Programming

sect ion i n this ma nual to

chan ge t h e Countdown Quality

Timer™ feature:

T o se t the Keypadlock™ refer

to the Programm ing secti on in

thi s manual, M a chine S etti ngs

Menu.

5

Page 8

PROGRAMMING - CO NTROL PANEL CONF IG URA TI ONS

Mon 09:12am

MENU PROGRAM

MENU

MENU EXIT

ITEM

PRESS AT SAME TIME

(POWER OFF)

DECREASE (-)

INCREASE (+)

START

STOP

The brewer can be

prog r amm ed w ith a

personal computer.

Please contact your

lo cal Bloomfield

Representative for

more i nformat i on.

NOTE:

Brewer will not b rew

while in the FILLING

mode.

123 4

8

7

QUICK NAVIGATION TIP S

Mon 09:12am

9

CLOCK SET

PRESS AT SAME TIME

(POWER ON)

5

10 11

6

ON-OFF KEY

1. T o ente r PROGRAMMING mode:

a. Press ON-OFF (POWER) key until the brewer is OFF

b. Press and hold 3rd and 6th keys for 3 seconds

2. Advance thr u MENU S by pr ess ing 1st key

a. Access and advance thru ITEMS by pressi ng 3rd key

b. Advance thr u SU B- MEN U and SUB- ITE MS by pr ess ing 3r d key.

3. To EXIT PROGRAMMING mode:

Press 2nd key

4. For clock settings:

a. Press ON-OFF (POWER) key until the brewer is ON

b. Press 3rd and 4th keys

5. To check tank temperature

a. Press ON-OFF (POWER) key until the brewer is ON

b. Press 3rd and 6th keys

675 p/n 74346 SS-2 Programming Manual

6

Page 9

PROGRAMMING CHART

To enter Programming Mode, turn brewer OFF, then press 3rd and 6th key. Hol d until "Brew Settings"

appears on readout.

Advance thr u MENU S by pr ess ing 1s t key

Access and advance thru ITEMS by pressing 3rd key

See ITEM DESCRIPTION for procedure to access SUB-MENUS and SUB-ITEMS.

Advance thr u SU B- MENU and SU B- ITE MS by pr essing 3r d key.

Change setti ngs by pressing 5th key (decrease) or 6th key (increase).

Press 2nd key at any time to EXIT programming m ode.

See pa ge 10 for detail ed expla nation of al l program m in g topics.

ME NU

LEFT 1/2

GAL (key 1)

MENU

1

BREW

S ETTIN G S

Brew

Change

Type1

TotalValve Number of seconds brew valve is open. Press RIGHT

InitVlvTime Initial Valve Time. Number of seconds Brew Valve open

PulseDelay Number of seconds i n pulse cycle to delay before

PulseValve Number of seconds in pulse cycle Brew Valve is open 2- 255 sec. 0

Bypass

Bypass

Brew

Set R=L? Set RIGHT side volumes to the same settings as LEFT

Change

When display returns to " Wat erTemp", press 1st key to advance to next MENU

675 p/n 74346 SS-2 Programming Manual

ITEM

LEFT 1-1/2

GAL (key 3)

WaterTemp Actual wate r temp is displayed i n ºF or ºC none N/A

BrewTemp Brew Temperature. Must be 5ºF below MaxTemp

Volumes

LVols?

Right?

SUB-MENU SUB-ITEM DESCRIP TION

Press LEFT 1-1/2 GAL (key 3) to advance thru items

Calculate volume of water delivered both thru b rew

Change Left Volumes Y (yes) or N (no)

Satellite

Dela y1

PULSE BR EW SYSTEM

Time1

Complete1

Left B rew Vo lumes 2 (Type2...) and 3 (Type3…) appear in order and are set as above

Change RIGHT Volumes

Righ t Brew Volumes 4 (Type4...), 5 ( Type5…) and 6 (Type6 …) appear in orde r and are set as above

Press LEFT 1 GAL (key 2) to EXIT menu

See Machine Settings Menu

chamber and b ypass

"y" advance s to Type1… "N" advance s to Ser R=L?

Select container for 1st (1/2 GAL) Brew Airpot

1/2 GAL (key 4) to ac cess Pulse Brew S etti ngs

initially before beginning pulses

opening Brew Valve

Number of seconds afte r brew starts to open Bypass

Valve.

Number of seconds Bypass Valve is open 0-540 sec. 0

Number of seconds afte r Brew Valve closes for all

product to drip out of brew chamber

"Y" advance s to MENU "N" advance s to "ChangeRight?

"Y" advance s to Type4… "N" advances to MENU

RANGE

Key 5 dec.

Key 6 inc.

185-205ºF

85-96ºC

Y / N N

Satellite

0 - 655 sec. see Factory

0 - 540 sec. N/A

0 - 255 sec. 0

0-540 sec. 0

0 - 255 sec. see Factory

Y / N N/A

Y / N N

DEFAUL T

197ºF

Satellite

Settings

Settings

7

Page 10

PROGRAMMING CHART (continued)

ME NU

LEFT 1/2

GAL (key 1)

MENU

2

TIME

FUNCTIONS

Quality

TIMER Activa tes various timed fun ction s If "On" access Wkday

Wkda y on Hour

Minute Set minute for brewer to turn on - Wee kdays 00 - 59 07:00A

Wkda y off Hour

Minute Set minute for brewer to turn off - Weekda ys 00 - 59 07:00P

Wkend on Hour

Minute Set minute for brewer to turn on - Wee kend 00 - 59 07:00A

Wkend off Hour

Minute Set minute for brewer to turn off - Weekend 00 - 59 07:00A

SET DAY

Day Set today's day of week Mon - Sun none

Time: Hour Set hour and AM or PM

Time - Min Set minute 0 - 60 none

ITEM

LEFT 1-1/2

GAL (key 3)

After-Hours Puts brewer into low energ y mode if unused for a time 0 (off) or 1

Time

AND TIME

SUB-MENU SUB-ITEM DESCRIP TION

Press LEFT 1-1/2 GA L (key 3) to advan ce thru item s

Countdown Quality Timer flashe s satellite LED after a

AM or PM

AM or PM

AM or PM

AM or PM

Set brewer for today's time and date. Setting is battery

Press LEFT 1 GAL (key 2) to EXIT menu

tim e .

On. If "Off" a ccess Day

Set hour and AM/PM for brewer to tu rn on - Weekda ys

Set hour and AM/PM for brewer to tu rn off - Weekda ys

Set hour and AM/PM for brewer to tu rn on - Weekend

Set hour and AM/PM or brewer to turn off - Weekend

Set same on and off times to have brewer remain off

backed. Change for daylight savings or time zone move

RANGE

Key 5 dec.

Key 6 inc.

- 6 (hours)

0 (off) or

0-180 min.

On or Off Off

01 - 12

AM/PM

01 - 12

AM/PM

01 - 12

AM/PM

01 - 12

AM/PM

01- 12

AM/PM

DEFAUL T

3

45 min.

07

:00A

07

:00P

07

:00A

07

:00A

none

Press 1st key to advance to ne xt MENU

MENU

3

SER VICE

&

COUNTERS

Filter

Reset Totals Reset volume and cycl es counter to 0 N/A none

Call for

Trac ks usage totals

TotalVol Displays Total Volum e of water in Gallons or Liters 000000 G/L none

BrewCy cs Total num ber of brew cycles performed 000000 none

FltrLife Filter life in 100 gallon increments. "0" di sables 0-10000 0

Message

Select one of 3 message s for filter problem, or 0 for off.

A message to be displayed on readout may be

Service

Press 1st key to advance to ne xt MENU

Program m able with personal compute r.

programmed wi th a personal computer

1, 2 or 3

or 0 for off

N/A none

0

675 p/n 74346 SS-2 Programming Manual

8

Page 11

PROGRAMMING CHART (continued)

ME NU

LEFT 1/2

GAL (key 1)

MENU

4

MAC HIN E

S ETTIN G S

KeyPad

MaxWt

Brew Wait "Y" = Wait to initiate brew until water temperature is at

Beeper Y = Beeper on N = B eeper off Y or N Y

Load

HIDDEN

MENU

FACTORY

S ETTIN G S

TotalVol. Independent volume total - not re-settable 000000 none

BrewCycs Independent cycle counter - not re-settable 000000 none

ITEM

LEFT 1-1/2

GAL (key 3)

Temp.Unit Select temperature units as ºF or ºC F or C ºF

Vol.Unit Select volume unit as ounces or liters Oz or L Oz

Lock

Temp

Defaults?

InflRa te Inflow Rate. Number required to calculate volumes. 0.00 to 1.00

Calibration To change: press 4th ke y when "Calibrati on" is displ ayed

SUB-MENU SUB-ITEM DESCRIP TION

Select measurement units and default functions

Locks keypad. When ON hold LEFT BREW STOP key

for 6 sec. to unlock m om enta rily

Maximum water temperature. Must be 5ºF o ver Brew

Temperature

Preci se Tempe rature for Brewing™.

"N" = brew regardless of temperature

Y = Reload factory default setti ngs Y or N N

To access from Machine Settings press and hold 3rd and

6th keys unti l "Factory Settings" is displayed

Offset required to make temp sensor readi ng match

actual temperature

RANGE

Key 5 dec.

Key 6 inc.

On or Off Off

195 - 210 208

Y or N Y

gallon/min.

-20ºF to

+20ºF

DEFAUL T

Fa cto r y set

@ 0.75

none

Press 2nd key to EXIT or 1st key to scroll thru MENUS.

See page 10 for detailed explanation of all programming topics.

675 p/n 74346 SS-2 Programming Manual

9

Page 12

PROGRAMMING PROCED URES

All 6 volumes are set

Independentl y.

Left and right side may

be set the same or

dif fer e nt . Se e pro gr am

chart.

Maximum Water temp i s

factory set at 20 8ºF. It

may be ad j usted fr o m

195ºF to 210ºF.

Maximum Brew Temp.

can be s et no hi gh er than

5ºF below the M aximum

Water Temperature.

W hen using the timer be

sure to allow at least 30

minutes for the brewer to

r each pr op er te mp er ature

from the ti m e it is t urned

on.

Brew Settings Me nu

• "Water Temp:" is actual water temperature in the tank.

• "Brew Temp:" i s desi red brew temperature. This temperature +/-IºF will

be maintained in the tank. Adjust by pressing 5th or 6th keys. The

brew temperature cannot be set any higher than 5ºF below the

Maximum Water Temperature, which i s factory set at 208ºF. Thi s

m eans maximum brew tem perature will be 203ºF. If a higher

temperature is req uired, first increase the Maxi mum Wa te r

T emperature in Machine settings (maximum is 210ºF), then increase

brew tem perature (maximum brew temperature is 205'F if Maximum

Water Temperature i s increased to 210ºF).

• Pul se Brew. To access the pulse or pre-infusi on program s, see Pulse

Brew System detail s.

• "Total Valve:". This is the number of seconds the dump (or brew) val ve

will remain open and dete rmines to tal water volume.

• Brew Type for each volume can be set as ai rpot or satellite container.

• Note: "Airpot" brew typ e bypasses any sa te llite in te rlock system .

• "Brew Complete...:" (Dripout Time)- Thi s i s the num ber of seconds after

the dump valve i s closed that is required until all of the water flows

through the brew basket. If different weights of coffee or tea are used,

this num ber may ne ed t o be increas ed or dec r e ased.

Ti m e Functions Menu

• "After Hours:" When A fter Hours™ is activ ated, the b rewer will allow the

water temperature to drop by 20'F before reheating. Can be turned off

by s etting to "0".

• "Quality Time:" - Countdown Quality Timer™. Flashes SATELLITE

LED after a set time to remind server that coffee is aged. Can be

turned off by settin g to "0", or se t fro m 0 mi n utes to 180 minute s. See

program ta ble.

• "Timer:" Turn the timer on if automatic startup and stop is required.

Time fo r t he brewe r is main tained wit h a batte ry ba c kup system that will

last up to 20 years. This system also handles power fl uctuations by

maintai ning the power tim e during power outages. When setti ng times,

make sure that the AM or PM is set properly to activate the timer at the

correct time. On and Off ti mes for weekdays and weekends are set

individually. Weekend may be turned "OFF" by setting the start and

stop tim e at the same ti me.

• "Day:" Set the day of the week by using the 5th and 6th keys.

• "Time:" Use the 5th and 6th keys to set Hour, AM or PM and Minutes.

Service & Counters Menu

• "TotalVol:" - Total Volume. Indicates total water volume processed by

the brewer.

• "Brew Cycs:" - Brew Cycles. Displays total number of brew cycles since

last r eset.

• "Filter Message" - Select one of three messages to be displayed if filter

exceeds life expectancy, or "0" to turn filter message "OFF".

• "FltrLi fe:" - Filter Life. If a filter is used, input the number of gallons of

expected filter life capacity, in increments 100 gallons.

• "Message" T rouble message to be displayed. Programmed with

personal computer.

675 p/n 74346 SS-2 Programming Manual

10

Page 13

PROGRAMMING PROCEDURES (continued)

Ma chine Settings Menu

• "Temp. Unit:" - Tempe rature Unit. Set to "F" for ºF and "C" for ºC.

• "Vol. Unit:" - Vo lume Uni t. Set to ei ther "Oz" fo r ounce s or " L" for lite rs.

• "KeyPadLock:" Turn to "On" or "Off". If "On" the keypad switches can

only be activated by pressing and holding the LEFT BREW STOP key

for 6 seconds.

• "MaxWt.Temp.:" - Maximum Water Tem perature. The maximum water

temperature i s factory set at 208'F degrees, but can be adjusted up as

high as 210ºF. The brew temperature cannot be set any higher than

5ºF bel ow the m aximum tem perature. Maximum temperature shoul d

be set at least 2ºF degrees below the local boi ling point. T he brewer

will di spl ay "overheat error' if the water tem perature in the tank is

sensed to be at or above the Maxim um Water T emperature. Therefore

in highe r altitude loc ations, adjust the Max. Wate r Temp accordi ngly:

• "Brew Wait:" The Preci se Temperature Brewing™ feature can be

overridd en by se tting Bre w Wai t to "N" for No .

• "Load De buits?" Reloading o f def ault setti ng s will reset many of the

program med settings to those outlined i n the programming table. In the

ta ble t hose ite ms with "none" no ted in the Default column would n ot be

reset when defaults are re@-loaded. Where a value is noted, thi s

would be the re-loaded value if defaults are loaded. Re-loading of

defaults should be used only if major program ming problems have

675 p/n 74346 SS-2 Programming Manual

occurre d and it is necessary to return to factory se ttings.

The keypadlock can be

momentarily bypassed by

pressing and holdi ng the

LEFT BREW STOP ke y

for 6 seconds. The keys

wil l be active unti l a br ew

has been completed. Or

if a brew is not started,

the keypad will revert to

the locked mode after 60

seconds.

By setting "Brew Wait" to

"N", the brewer will start

a brew regardless of the

water temperature. There

will be no delay to heat to

the pr op er temp er ature.

T his is not the

recommended setting.

"Brew Wait" is facto ry set

at "Y" for yes. In this

mode the brewer will only

start a brew at the

Precise B rew

Temperature™.

11

Page 14

PR OGRAMMING PROCED URE S (continued)

The factory settings

menu can only be

accessed by going into

the pr ogr a m m ing m ode,

and pressi ng the 1st key

until "Machine Settings"

is di splayed. Then press

and hold the 3rd and 6th

keys for three seconds

unt i l "Factor y S ett i ngs" is

displayed.

IMPORTANT:

Only quali fied personnel

should make changes to

these Factory Settings.

NOTE:

The probe has been

factory calibrated. If a

contr oller board is

changed it is

r ecom me nd ed t ha t t he

previous calibration be

checked and entered on

the new bo ar d.

If thi s is not possi bl e, or if

a new probe is used,

cali brati on should be

completed as at right:

Factory Settings Menu

• "Infl Rate:" - Inflow Rate. The inflow rate i s factory set at 0.75 gall ons

per minute. This value is required to cal culate the water volume.

Genera lly the . 75 setting will be qui te accurate unle ss t here is

unusually low or high water pressure and vol ume, in whi ch case the

Inflow Rate can be changed.

• "Calibration". To access the calibration program, press the 4th key

when "Calibration" is displayed. The probe i s factory set and should

not ne ed resett i ng, un less the co ntr o l ler board or pr obe is chang ed .

See Calibration Instructions below for detailed i nstructions.

• " TotaiVol:" - Total Volume . Total water volume is stored in the

Factory Settings menu as well as in the Service & Counters m enu.

T his to tal is not re -settable.

• "B re wCvcs:" - Brew Cycles. Total brew cycles is stored in the

Factory Settings menu as well as in the Service & Counters m enu.

T his to tal is not re -settable.

Calibration Ins tructions:

1. Turn brewer on and allow to heat to proper temperature, and the

heat light will go out.

2. Turn brew er off .

3. Access the programming mode, go to Factory Settings, go to

Calibration and press the 4th key to access calibrati on.

4. Usi ng an accurate thermometer, determine the actual tank

tem per a tur e by me asuring th e tem per ature of t he water comin g out

of the faucet. It is important to run the water over the thermostat long

enough to get a proper reading. (An alternate m ethod of establishing

water temperature i s to remove the top cover of the brewer, then pull

out the level sensor. Insert the thermometer into the brewer. Allow

tim e for the thermometer temperature to stabilize.)

5. Once the actual tank temperature has been established, look at the

values on the screen. As an exampl e, it may read "199F Corr. + 0"

This woul d indicate that the water temperature in the tank is 199ºF

with no correcti on (or calibration) of the probe. If the actual

temperature according to the thermostat was:

a. HIGHER by 3F (i.e. 202ºF i n thi s exam ple), press the 6th key 3

tim es until the screen reads as follows: "202F Corr. + 3".

b. LOWER by 3F (i.e. 196F i n this exampl e), press the 5th key 3

tim es until the screen reads as follows: "196F Corr. - 3".

6. Make sure the temperature on the left of the screen agrees with the

actua l tempe ratu re of the wate r determ ined with the accurate

thermostat. Once this has been completed the SS2 wi ll maintain the

cali brated setti ng.

7. Once calibrated, press the 3rd key to continue in the Factory

Settings menu, press the 1st key to return to Brew Settings menu, or

press the 2nd key to exit programming.

675 p/n 74346 SS-2 Programming Manual

12

Page 15

PROGRAMMING PROCED URES (cont inued )

PULSE BREW PRE-INFUSION CAPABILITY

BYPASS SYSTEM

Applications:

1. Pre-infuse (or Pre-soak) the Bed of Coffee or Tea.

The brew valve can be opened for a -short peri od of time to

allow the bed of coffee or tea to be pre-i nfused. After a delay

while the pre-soaking is taking place, the brew valve can be

opened to start and complete the brew.

2. Extend Contact Time With the Coffee.

The brew valve can be programm ed to "pulse" by opening

and closing for programm ed periods during the brew. This

ca pability will allo w for longer contact with the coffee or tea if

higher extraction rates are required.

3. Prevent Brew Chamber Overflow.

The pulse feature allows the delivery time of the water to be

extended. Over flow pr ob le ms can als o be ex p er ie nced if

particul arly fi ne grind coffee i s used. The SS2 can be

programmed to extend the delivery of the water over a longer

period of time, thus preventing any overflow problems.

Access the Pulse System:

1. Se lect th e Brew Vo lu me that will be us in g t h e "pu lse" br ew

system. (i.e. Brew Volume 1, 2, 3 etc.)

2. With the selected volume on the screen (e.g.: BrewVoI1:),

chan ge v ol um e if necessar y (must not be "0 ") and pr ess t he

4th ke y (whi le in to tal valve time displa y) to go to the Pulse

Programming options (as opposed to pressi ng the 3rd key

which would bypass Pulse Programming).

3. T he fi rst three menu item s below wi ll appear in this order.

a. InitVlv Time: Initial Val ve Time (seconds) to open before

pulse cycle(s) begin.

b. Pulse Delay: Number of seconds valve i s closed

beginning pulse cycle(s).

c. Pulse Valve On: Number of second's valve is open

during pulse cycle(s).

d. Total Valve: Total num ber of seconds valve i s to be open

(pulse + initial). This determines your total volume out of

brew chamber, which must be set i f total vol ume changes

from fa ctory se ttings.

e. D r ip O ut T im e: T ime after va lve is closed be for e all wat er

drips through brew cham ber as brewed product and the

brew is complete.

Pre-infusi on is used to pre-wet

the bed of grounds or tea leaves

prior to the actual brew. T his may

be used to improve the brew

quality in certain situatons.

Pul si ng the delivery of brew water

exten d s the time th e water is i n

contact wi th the coffee grounds or

tea leaves. This can be adjusted

to optimi ze extraction rates.

Pul si ng the delivery of brew water

a llows more time for the wat er to

drip out of the brew chamber.

This can be set to prevent brew

chamber overfl ow when very fine

grind coffee i s used.

Bypass System delivers a portion

of th e total volume of wa te r

directly to the container. This i s

used in situations where del i very

of all water through the coffee

grounds or tea leaves would

result in too strong a product.

675 p/n 74346 SS-2 Programming Manual

13

Page 16

PR OGRAMMING PROCED URE S (continued)

The pulse feature will be active

on ly if it has be en pr ogr am me d.

See pa ge 13 .

The b rewe r will calcula te the

num ber of seconds for the full

br ew and display it on t h e LC D

to begi n t he brew. I t will also

calculate how many pulse

cycl es are required to compl ete

the brew. (If a final partial "Pulse

Valve On" is required this will

al so be calculate d

automati cally.)

Vol

total

= (T

(T

byp ass

bre w

x R

x R

spray hea d

bypass

) +

)

or

Total deli vered volume is equal to:

Brew Valve Time times

Sprayhead Flow Rate

Plus

B ypa ss V al ve Ti me ti me s

Bypass Flow Rate

Pulse Feature Operation:

When the pulse brew begins, the brew valve will be opened for

the number of seconds programmed for "Initial Valve Ti me"

(Ini t Vlv Time). The valve will then clo se f or the num be r of

seconds in "Pulse Delay", then open for the number of seconds

i n "Pulse Valve On". The pulse cycle (Pulse Delay plus Pulse

Valve ) will be repeated con tinuously un til the brew valv e has

been opened for the time program med as "Total Val ve ".

Water Outfl o w (Deliv ery) Rate s:

T he ou tflo w rate of wa te r from the sprayhea d is required to

calculate valve time for different volumes. Sprayhead outflow

rates are based on the standard 64-ounce coffee brew requi ring

approximately 117 seconds of the brew valve being open. T his is

an outflow rate of approximately .50 ounces per second.

To calculate Total Valve time, the total ounces required should be

divi ded by .50 oz/second. Each brewer may have a slightly

different flow rate based on whether the brewer is level, scale

bui ld up on lines, etc. Minor adjustments m ay be required to get

precise volume.

Bypass Valve System:

Access the Bypass System from the "Brew Setti ngs" menu,

"Total Valve" sub-menu (sam e as Pulse Brew).

1. Bypass delay: Number of seconds after brew starts valve will

open.

2. Bypass Valve Tim e: Num ber of seconds valve i s on.

3. Bypass Flow Rate is approximately 0.27 oz/seconds.

675 p/n 74346 SS-2 Programming Manual

14

Page 17

SA MPLE PROGRAM

PROGRAMMING PROCED URES (cont inued )

Position 1 & 4 Position 2 & 5 Position 3 & 6

Type Satellite Type Satellite Type Satellite

Total Valve 142 Total Valve 215 T otal Val ve 322

Press 4th Key Press 4th Key Press 4th Ke y

Intit Valve Time 30 Intit Valve Time 3 0 In tit Valve Time 30

Pulse De lay 5 Pulse Delay 5 P ulse Delay 5

Pul se Valve On 10 Pulse Valve On 10 Pulse Valve On 25

Bypass Dly 30 Bypass Dly 30 Bypass Dly 30

Bypass Time 50 Bypass Tim e 150 Bypass T ime 200

Brew Complete 30 Brew Complete 45 Brew Complete 60

Appr oximate Flow Rates

To determine brew time for a volume di vide ounces by flow rate:

EX: 1 64oz (1/2 Gallon) ¸ .50oz Sec = 128 Sec. (approx.)

EX: 2 192oz (1 ½ Gal w/bypass) ¸ .27oz Sec = 249 Sec. (approx.)

Factory Settings

With “MACHINE SETTINGS” di splayed, press and hold keys 3 & 6

• Infl. Rate 0.75 G.M.

• Calibration

• Press Key #4

• Core + 0°F

• Total Val: 000000G

• Brew Cycl e: 000000

Press #2

• Check Compl ete

Brew Setting s

Water Tem p :

Brew Temp: 195°F

Brew Volumes

Change L. Vol. Y

Set R=L Y

Change R. Vol s N

Ti m e Functions

• After Hours: Off

• Q ua l ity T im e 180 m

• Ti mer: ON

• Day:

• Time: Hours

• Ti me: Mi n.

3 Serv ice Count

• Total Volume 000000G

• Brew Cycl e 000000

• Filter Life 10000

• F il ter Mes sage

• Reset Total : N

• Service Number:

888-492-2782

Ma chi ne Set t i ng s

• Temp. Unit: F

• Vol. Unit: G

• Key Pad Lock: Off

• Max Tem p.: 2 08F

• Brew Wait: Y

• Beeper: Y

• Load Defaults? N

675 p/n 74346 SS-2 Programming Manual

15

Page 18

PROGRAMMING - DI AGNOS TIC TEST

T his is a built-in test of the

following system components:

a) Ver ificatio n of Firmware/

EEPROM data

b) Keypad switches / interlock

switches

c) Vol ume, brew start/stop,

po we r and sa tellite LEDs

d) Inlet v a lve, lef t an d ri ght

dum p val ves, left and right

bypass valves, solenoid

valves (optional)

e) Heater

f) Water level probe,

temperature probe

If a key or toggle switch i s not

detected withi n 5 seconds, then

the "Switch Er r or " mess age will

be di splayed followed by 2

beeps. If an error occurred with

the correct key pressed, the

control board has failed the test.

DUAL SATELLITE SYSTEM BUILT-IN DIAGNOSTIC TEST

Ente r i ng Tes t Mode:

1. Press POWER key OFF .

2. Press and hold the 3rd (Left 1-1/2 GAL) key and the 4th

(Right 1/2 GAL) key, then POWER key ON.

3. At the sound of the beep, release the keys.

If successful, a m essage containing the revisi on of the

firmwa re will b e on the display . (e.g. "WW 291 Rev. 3 .1)

Verify that the revision of the software is correct, and then

press the POWER key. Each key press should be followed

by an audible beep.

Check Date Revision:

The next displ ay contains the revisi on number of the data

programmed into the EEPROM. (e.g. "Data Rev 3.0"). Ensure

that the co rrect version has bee n loaded into the EEPROM , then

press POWER key to continue.

Switch Test:

1. Press th e le ft 1/2 GAL key. Y ou will he ar a beep, and the

di spla y will change to: "Test Swi tch 2".

2. Press the left 1 GAL key. You wi ll hear a beep, and the

di spla y will change to: "Test Swi tch 3".

3. Continue testing keys in order:

Test Switch 1 Left 1/2 GAL key

Test Switch 2 Left 1 GAL key

Test Switch 3 Left 1-1/2 GAL key

Test Switch 4 Right 1/2 GAL key

T e st S witch 5 Right GAL ke y

Test Switch 6 Right 1-1/2 GAL key

Te st Swi tch 7 Left BREW START ke y

Te st Swi tch 8 Left BREW STOP key

Te st Swi tch 9 POWER key

Te st Swi tch 10 Right BREW START key

T e st S witch 11 Right BREW STOP ke y

4. Check the safety interlock switches (if equipped):

Toggle the left interlock by removing and rei nstalling the left

brew chamber when the controller displ ays "L Interlock".

Check the right interlock i n the sam e way when the control ler

di spla ys " R Interlock".

675 p/n 74346 SS-2 Programming Manual

16

Page 19

PROGRAMMING - DI AGNOS TIC TEST ( con t inued )

LED Test

Displ ay will read: "Testing LEDs"

1. The top left LED should turn on first. After one second, the

LED immediately right o f it will turn on and t he top left LED

will turn off. Obse rve th a t the LEDs turn on in o rder - movi ng

from left to right al ong the top row, then left to right al ong the

bottom row. Ensure that only one LED i s on at a time and

that each of the eleven LEDs turn on.

2. Al so ensure that the color of each LED is correct:

GREEN

YELLOW

GREEN

GREEN

3. Press the POWER key to advance to the next test.

Valves/Heater Test

T he display will read: "Valvc I Off"

1. Verify that all the valves are o ff, and that the he ater is off.

Val ve I corresponds to the inlet valve.

2. Press the POWER key and the inlet valve should turn on with

the mes sage: "Va lve I On"

3. Press the POWER key to advance to Valve 2 (left dump

valve). Conti nue testing components. Each of the following

components should turn on then off in the following order:

Valve I Inflow

Val ve 2 Left Brew

Val ve 3 Right Brew

Val ve 4 Left Bypass

Val ve 5 Right Bypass

Heater Heater - DO NOT leave on for an

extended period of time.

L Sole noid Lock Out Solenoid (op tional)

R Solenoid Lo ck Out Sole noid (optional)

4. If each one of the components turn on i n order, and if only

one of them is on at any time, then the controll er has passed

thi s test. In this case, press the POWER ke y to advance to

the next test.

If any one of the LEDs does not

turn on , if more than on e LED

turns on at any gi ven time

during this test, or if the LEDs

do not turn on in the correct

order then the controller has

failed the test.

If a -Valve Fault" message

appears on the displ ay during

thi s test, the contro ller fail s the

test.

675 p/n 74346 SS-2 Programming Manual

17

Page 20

PROGRAMMING - DI AGNOS TIC TEST ( con t inued )

The m essage "Test Done"

should be on the display.

Pr ess the POWER key to reset

the controller. T he controller

should restart with the message

"BLOOMFIELD" and date.

Probe Test:

Two numbers will be displayed:

1. The left numbe r determines whether the WATER-sensing

probe i s in contact with water.

a. A number of "0" (or close to 0) means that water is i n

contact with the probe.

b. A number of "255" (or close to 255) means water i s not in

contact wi th the probe.

2. The right numbe r represents what the T EMPERATURE-

sensing probe reads. The table below is an approximate

correlation between the value and the tem perature the probe

is sensing:

a. A nu m ber less than "10" in dicates that t he pr obe is not

properl y connected to the board

b. A number higher than "155" indicate a defective probe.)

Testing Co mplete!

Number

(Right Side)

Approximate

Water Temp.

≤ 10

20 74ºF

25 83ºF

30 92ºF

↓ ↓

120 181ºF

125 186ºF

130 191ºF

135 196ºF

140 201ºF

150 206ºF

≥ 155

Probe not

connected

Defective

Probe

675 p/n 74346 SS-2 Programming Manual

18

Page 21

F A UL T D ETECTI ON

Faul t De tection:

Software-level fault detection is performed usi ng the temperature

probe, and the water level sensor.

In the event of a fault, solenoid valves are closed, the heater

tri ac is turned off, all LEDs fl ash, an error message is displayed

and the system halts by entering Error Mode.

The system can be reset by removing the power to the system or

by holdi ng down the 8th (Left Stop Brew key) for 2 seconds.

These errors are moni tored at all times:

1. Probe/Heater Error

If the temperature of the water does not i ncrease 4ºF in 4

minutes with the heater on, then ei ther there i s a probe and/

or heating element failure, or the water is boiling. In either

case, the system halts with a "probe/heater err" message.

2. M aximum Temperature Reached

If the temperature exceeds a l imit, then an overheat error

message is produced. This error can occur if the heater triac

fails "on". The maximum temperature shoul d be set in the

menu system as to prevent boil ing.

3. Water Level Sensor Timeout

If the inflow valve is opened and water is not detected within

30 minutes, the message no water sensed is produced.

This can be caused by level sensor failure or water i nflow

valve failure . After the tank is filled to full capaci ty, the time

limi t varies with the state of the outflow val ves:

a. Two sides brewing: 5 minutes

b. One side brewing: 3 minutes

c. No brewi ng being performed: 1 minute

4. Internal Component Fault

The controll er is al so capable of verifying the proper

functioning of internal components:

a. "Keypad locked" message i ndicates that a key has been

hel d down for an extended amount of time. This i s

perceived as a faul t in the keypad controller.

b. "Valve faul t" message indicates that the val ves are not

responding properly.

Fault detectio n is perfo r m ed at

all tim e s, excep t in Off mode.

IMPORTANT:

The boiling temperature of

water will vary with al titude.

See chart, page 11.

675 p/n 74346 SS-2 Programming Manual

19

Page 22

Page 23

Page 24

10 SUNNEN DRIVE, P.O. BOX 430129, St. Louis, MO 63143

telephone: 314-781-2777 fax: 314-781-2714

www.wellsbloomfield.com

Loading...

Loading...