Page 1

10 Sunnen Drive

St. Louis, MO 63143

telephone: 800-807-9054

fax: 314-781-2714

www.wellsbloomfield.com

BLOOMFIELD INDUSTRIES

672

OWNERS MANUAL

for

SS2 - SERIES

DUAL SATELLITE

COFFEE BREWERS

with

ELECTRONIC

PROGRAMMABLE

CONTROL

and

INTERNALLY HEATED

SATELLITE SERVERS

MODELS:

9520 9520FB

9521 9521FB

Includes:

Installation

Operation

Use & Care

Servicing Instructions

Model 9520 Dual Satellite Brewer

with optional 3901 Drip Tray

DD-74345 Rev.M M672 090804

Page 2

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory.

Upon acceptance of this shipment, the transportation

company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill

or express receipt, and that the note of loss or damage

is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

must be done within fifteen (15) days from the date the

delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

WARRANTY STATEMENT

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

SHIPPING DAMAGE CLAIMS PROCEDURE

1. Resetting of safety thermostats, circuit breakers,

overload protectors, or fuse replacements unless

warranted conditions are the cause.

2. All problems due to operation at voltages other than

specified on equipment nameplates; conversion to

correct voltage must be the customer’s responsibility.

3. All problems due to electrical connections not made in

accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Replacement of items subject to normal wear, to include

such items as knobs and light bulbs. Normal maintenance

functions including adjustment of thermostats, microswitches,

and replacement of fuses and indicating lights are not

covered under warranty.

5. All problems due to inadequate water supply, such as

fluctuating, or high or low water pressure.

6. All problems due to mineral/calcium deposits, or

contamination from chlorides/chlorines. De-liming is

considered a preventative maintenance function and is

not covered by warranty.

All electrical equipment manufactured by WELLS

BLOOMFIELD is warranted against defects in materials and

workmanship for a period of one year from the date of original

installation or eighteen (18) months from the date of shipment

from our factory, whichever comes first, and is for the benefit

of the original purchaser, except that:

a. airpots carry a 30 day parts warranty only.

b. dispensers; i.e., tea and coffee carry a 90 days parts

warranty only, decanters excluded.

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN IN

LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE HEREBY EXCLUDED.

BLOOMFIELD INDUSTRIES DIVISION / SPECIALTY

EQUIPMENT MANUFACTURING CORPORATION SHALL

NOT BE LIABLE FOR INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES FROM ANY

CAUSE WHATSOEVER.

This warranty is void if it is determined that upon inspection by

an Authorized Service Agency that the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God.

It also does not apply if the serial nameplate has been

removed or unauthorized service personnel perform service.

The prices charged by Wells Bloomfield for its products are

based upon the limitations in this warranty. Seller’s obligation

under this warranty is limited to the repair of defects without

charge by a Wells Bloomfield Authorized Service Agency or

one of its sub-agencies. This service will be provided on

customer’s premises for non-portable models. Portable

models (a device with a cord and plug) must be taken or

shipped to the closest Authorized Service Agency,

transportation charges prepaid, for services.

In addition to restrictions contained in this warranty, specific

limitations are shown below (Additional Warranty Exclusions).

Wells Bloomfield Authorized Service Agencies are located in

principal cities.

This warranty is valid in the United States and void elsewhere.

Please consult your classified telephone directory or your food

service equipment dealer; or, for information and other details

concerning warranty, write to:

Service Parts Department

Wells Bloomfield, LLC

10 Sunnen Dr. P.O. Box 430129

St. Louis, MO 63143 USA

Phone: 1-800-807-9054 Fax: 1-800-396-2677

7. Full use, care and maintenance instructions are supplied

with each machine. Those miscellaneous adjustments

noted are customer responsibility. Proper attention will

prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an

authorized Service Agency or one of its sub-agencies.

9. All labor shall be performed during normal working hours.

Overtime premium shall be charged to the customer.

10. All genuine Bloomfield replacement parts are warranted

for ninety (90) days from date of purchase on

non- warranted equipment.

Any use of non-genuine Wells Bloomfield parts

completely voids any warranty.

11. Installation, labor and job check-out are not considered

warranty.

12. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technicians ability

to perform services are not covered by warranty.

This includes institutional and correctional facilities.

xi

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 3

TABLE OF CONTENTS

Thank You for purchasing this

WARRANTY STATEMENT xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 4

AGENCY APPROVAL INFORMATION 4

INSTALLATION 5

OPERATING INSTRUCTIONS 7

CLEANING INSTRUCTIONS 10

PROGRAMMING INSTRUCTIONS 12

TROUBLESHOOTING SUGGESTIONS 17

SERVICING INSTRUCTIONS 18

EXPLODED VIEWS / PARTS LISTS 20

WIRING DIAGRAM 24

9340 EXPLODED VIEW / PARTS LIST / WIRE DIA 25

Wells Bloomeld appliance.

Proper installation, professional

operation and consistent

maintenance of this appliance will

ensure that it gives you the very

best performance and a long,

economical service life.

This manual contains the

information needed to properly

install this appliance, and to use,

care for and maintain or repair the

appliance in a manner which will

ensure its optimum performance.

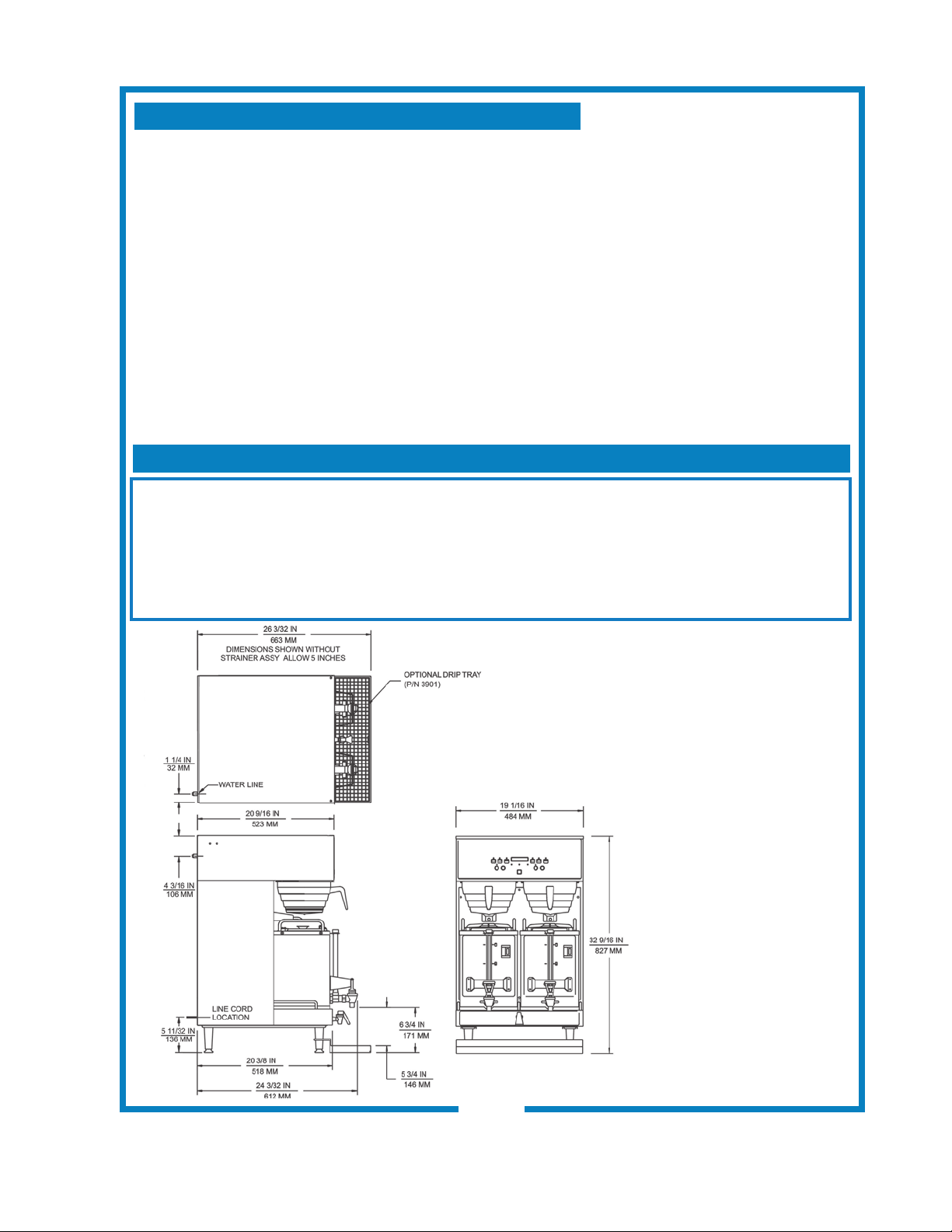

SPECIFICATIONS

MODEL VOLTS WATTS AMPS POWER

CORD

9520

9520FB

9521

9521FB

120/208 VAC

50/60 Hz 1ø

120/240 VAC

50/60 Hz 1ø

5655W 27A not provided

6680W 28A not provided

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Model 9520FB shown

Others are similar

1

Page 4

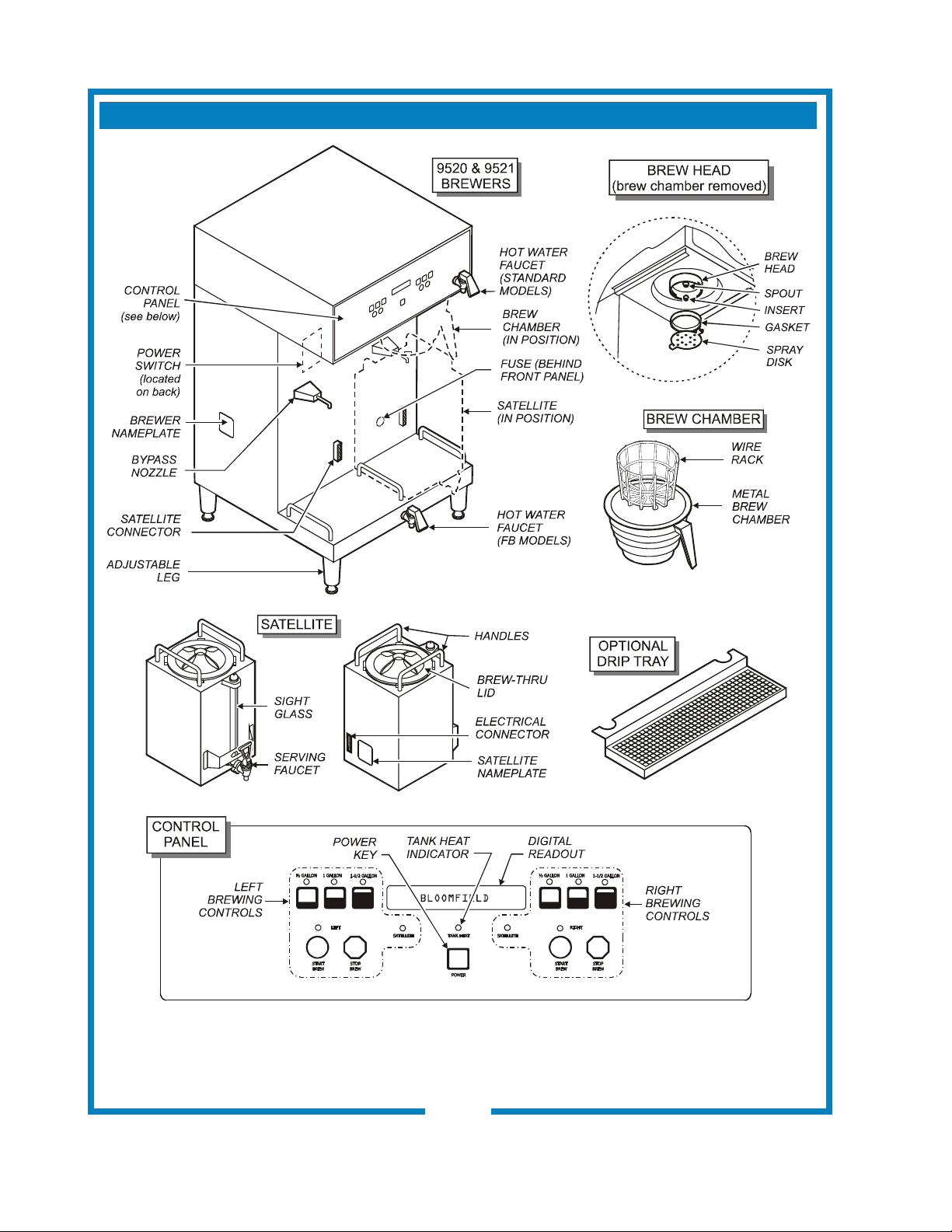

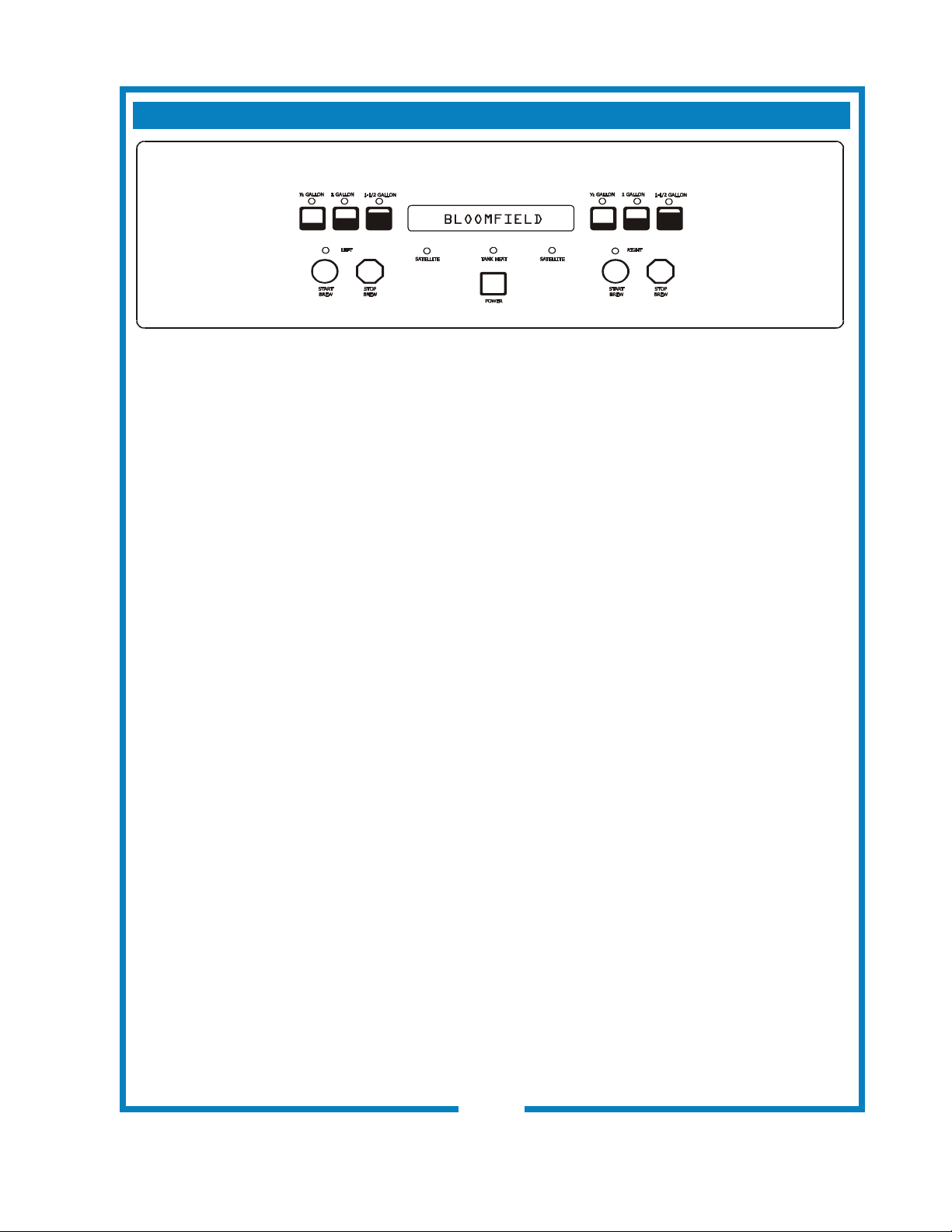

FEATURES AND OPERATING CONTROLS

Fig 1. SS-2 Satellite Brewing System Features & Operating Controls

2

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 5

FEATURES AND OPERATING CONTROLS (continued)

Brewer

Adjustable Legs

Brewing Controls

Connector

Digital Readout

Bypass Nozzle

Hot Water Faucet

Nameplate

Power Key

Power Switch

Brew Chamber

Brew Chamber

Wire Rack

Allows brewer to be leveled. Also allow clearance for cleaning

underneath brewer.

Start or stop brew and select brew volume. Right and left section

are independent. Also, used to program brewer in programming

mode.

Connects to satellite. Allows satellite heater to be energized.

Allows brewer to sense that a satellite is in place.

Displays information pertaining to brew cycle and status.

Displays programming information in programming mode.

Dilution water ows into satellite from here.

Hot water dispensed here. Mounted in base on FB models.

Lists manufacturer, model and serial number.

Also lists voltage and wattage rating of brewer.

Controls brewer ON MODE and OFF MODE.

Located on lower right rear of brewer. Turns main power to

brewer ON or OFF .

Holds coffee grounds during brew cycle.

Holds paper lter and coffee grounds in proper position in brew

chamber.

Satellite

Brew-Thru Lid

Connector

Handles

Nameplate

Serving Faucet

Sight Glass

Drip Tray (optional)

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Allows entry of brewed coffee and dilution water into satellite.

Minimizes splashing in the event satellite is tipped.

Connects to brewer. Allows heater to be energized. Allows

brewer to sense that a satellite is in place.

Allow the satellite to be safely carried.

Lists manufacturer, model and serial number.

Also lists voltage and wattage rating of satellite.

Fresh coffee dispensed from satellite here.

Check the level of coffee remaining here.

Optional drip tray catches drips and spills from serving faucet.

Easily removed for cleaning.

3

Page 6

GENERAL INFORMATION AND PRECAUTIONS

E9253

E9253

STD 4

This appliance is intended for use in commercial

WARNING:

SHOCK HAZARD

All servicing requiring access

to non-insulated electrical

components must be

performed by a factory

authorized technician.

DO NOT open any access

panel that requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

establishments only.

This appliance is intended

coffee, for human consumption. No other use is recommended or

authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance

use, limitations and associated restrictions. Operating instructions

must be read and understood by all persons using or installing this

appliance.

Cleanliness of this appliance is essential to good sanitation. Read

and follow all included cleaning instructions and schedules to ensure

the safety of the food product.

Surfaces of the brewer, brew chamber and satellite can be hot to the

CAUTION:

BURN HAZARD

touch, and may cause burns on contact.

Disconnect the brewer from electrical power before performing any

maintenance or servicing.

Surfaces of the brewer and

brew chamber may be hot

to the touch and can cause

burns on contact.

DO NOT submerge satellites in water.

DO NOT splash or pour water over, onto or into any controls,

control panel or wiring.

Any procedure which requires the use of tools must be performed

by a qualied technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics,

parts breakdown illustrations, notices and labels must remain with

the appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

to brew hot beverage, specically

AGENCY APPROVAL INFORMATION

This dual satellite brewing system is listed under E9253

and listed under E9253.

This dual satellite brewing system meets NSF Standard 4 only when

installed and maintained per the instructions in this manual.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

4

Page 7

INSTALLATION INSTRUCTIONS

SCREW INTO

BREWER

FRAM E

ADJUST

FOR

HEIGHT

ATTACH

RUBBER

FEET

INSTALL LEGS

The brewer is provided with adjustable legs and rubber feet. Be

sure the legs are securely screwed into the base of the brewer,

and that the rubber feet are properly installed.

LEVEL THE UNIT

The adjustable legs allow the brewer to be leveled. Set the brewer

in its ultimate operating location and check for level with a spirit

level Adjust the brewer for level from front-to-rear, and from side-

to-side. Be sure all four feet rest rmly on the counter.

PLUMBER’S INSTALLATION INSTRUCTIONS

IMPORTANT:

This equipment must be installed in accordance with the Basic

Plumbing Code of the Building Ofcials and Code Administrators

International (BOCA), and the Food Service Sanitation Manual

of the Food and Drug Administration (FDA). Also, this equipment

installation must comply with all local codes and ordinances.

Brewer must be installed on a water line with a full-ow pressure

between 20 psi and 90 psi.

NOTE: If water pressure varies greatly, or exceeds 90 psi at any

time, a water pressure regulator must be installed. Plumbing

installer must supply the regulator.

Brewer must be connected to a potable water supply. Bloomeld

recommends not less than 1/4” copper tubing for installations of

12’ or less, and not less than 3/8” copper tubing for installations

exceeding 12’. Brewer must be connected to a COLD water line.

NOTE: DO NOT use a saddle tap for this water line connection.

A shut-off valve must be installed between the main water supply

and the brewer. Plumbing installer must supply the shut-off valve.

A 1/4-turn ball valve is recommended.

Bloomeld recommends the use of a water strainer to help prevent

deposits in the brewing system.

Flush the water line before connecting to the brewer.

NOTE:

To enable the installer to make

a quality installation and to

minimize installation time, these

tests and suggestions should be

completed before the actual

installation is begun.

CAUTION:

UNSTABLE

EQUIPMENT HAZARD

Rubber feet must be installed

on each leg of the brewer. Legs

must be adjusted so that all four

feet rest rmly on the counter.

Failure to properly install the

feet can result in movement of

the brewer, which can cause

personal injury and/or damage

to the brewer.

CAUTION:

SHOCK HAZARD

Brewer must be properly

grounded to a reliable earth

ground to prevent possible

shock hazard. Do not assume

a plumbing line will provide

such a ground. Electrical shock

may cause serious injury.

ELECTRICIAN’S INSTALLATION INSTRUCTIONS

Brewer requires a dedicated single-phase circuit:

Model 9520

5655 Watts 30 Amps

Model 9521 120/240 Volt AC, 50/60 Hz 3-Wire + gnd

6156 Watts 30 Amps

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

120/208 Volt AC, 50/60 Hz 3-Wire + gnd

Fig. 2 Adjustable Legs

5

Page 8

INSTALLATION INSTRUCTIONS (continued)

IMPORTANT:

Initial set-up must be performed

by a qualied installer or

qualied service technician.

Improper set-up will damage the

brewer and void the warranty.

DO NOT CONNECT POWER

TO BREWER WITH

SATELLITES IN PLACE.

NOTE: If “NO WATER

SENSED” error message is

displayed:

* Disconnect brewer from

electrical power.

* Review Plumber’s

Installation Instructions

* Check inlet solenoid for

debris and verify proper

operation

NOTE: Brewer will not operate unless a satellite is properly

positioned on the brewer.

INITIAL SET-UP INSTRUCTIONS

Plumber’s and Electrician’s installation procedures must be

completed before proceeding with the set-up.

Be sure all electrical connections are secure, and that all

plumbing connections are secure and leak-proof.

1. CHECK BREWER FOR PROPER CONFIGURATION

Make sure spray disk gaskets are in place INSIDE of spray

heads.

Make sure spray disks are properly installed.

Check hot water faucet for proper operation and leaks.

2. START BREWER OPERATION

With the satellite servers removed, press the POWER

SWITCH to ON.

When power is rst applied to the brewer, the display will

read “BLOOMFIELD” briey, and a “beep” will sound.

Press the POWER key on the front panel.

The inlet valve will

energize and the tank will begin lling. The display will read

“Filling…” Fill time for the tank is approximately 13 minutes.

If water is not sensed at the water level probe within 20

minutes, the brewer will shut down and the display will read

“NO WATER SENSED” error message.

When tank has lled, TANK HEAT LED will glow and display

will read “Heating…”.

Slide satellites into position. Make sure satellites are prop-

erly aligned and the SATELLITE LEDs are lit.

Allow 30 minutes for initial water heat-up. Time will vary with

incoming water temperature. When the tank water is up to

the Precise Temperature for Brewing™, the TANK HEAT

LED will turn off.

3. FINAL CHECKS

After initial heat-up and before brewing, draw water from the

hot water faucet until the inlet solenoid actuates. This will

prevent volume differences to the initial brew caused by

water expansion.

Verify brew water temperature. It should be 198ºF ±5ºF.

Check and adjust water delivery volumes.

Disconnect brewer from electrical power. Inside top of the

brewer for leaks. Reassemble brewer and reconnect power.

6

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 9

OPERATING INSTRUCTIONS

Fig. 3 Control Panel

GETTING STARTED

Check the brewer and satellites:

Check that the brewer is clean and the drip tray (if used)

is empty.

Check that the satellites are empty and clean with lids

properly installed.

Check the spray heads:

Remove the brew chambers. Check the spray heads. Verify

that the spray disks are clean and properly installed. Verify

that the gaskets are properly installed inside the spray heads.

Check the brew chambers:

Check that the brew chamber is clean.

Check that the wire basket is properly installed in the

brew chamber.

DAILY START-UP

Press POWER KEY to enter ON mode:

Brewer water tank will begin lling. The message FILLING

will be displayed.

When the tank is full, TANK HEAT LED will glow, and the

message HEA

TING is displayed indicating that the tank

heater is ON.

When the tank is lled and up to temperature, time and date are

displayed. The brewer is ready to operate.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

NOTE:

If water is not sensed at the

water level sensor within 20

minutes:

Heater will be disabled

Error message NO WATER

SENSED will be displayed

7

Page 10

OPERATING INSTRUCTIONS (continued)

PAPE R

FILTER

WIRE

RACK

BREW

CHAMB ER

Fig. 4 Operating Controls

Fig. 5 Brew Basket

CAUTION:

BURN HAZARD

Basket and contents are hot to

the touch and may cause burns

on contact.

BREWING COFFEE

Prepare the Brew Baskets:

Make sure the wire rack is properly installed in each brew

chamber.

Insert one (1) Bloomeld paper lter into each brew chamber.

Make sure the lter is properly supported by the wire rack.

Add a measured amount of grounds to each brew basket.

Gently shake the basket to level the grounds.

Slide one brew chamber under each brew head.

Insert Satellites:

Slide one satellite under each brew chamber until it is fully

seated.

When the satellite is properly installed, SATELLITE LED for

left or right side will glow.

Select Brew Volume:

Press either the 1/2 GALLON, 1 GALLON or 1-1/2 GALLON

key. The corresponding LED will glow.

Start the Brew:

Press either the right or left START BREW key. The LED for

the selected side will glow.

NOTE: The brew can be cancelled at any time by pressing

the BREW STOP key.

At the end of the brew

, the brewer will beep. When the TANK

HEAT LED goes out, the brewer is ready to run another brew

cycle.

Empty the Brew Basket:

Discard the grounds and the paper lter. Rinse the brew

chamber under clear water.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

8

Page 11

OPERATING INSTRUCTIONS (continued)

WATER FLOW

Fig. 6 Water Flow Diagram

INLET

The INLET VALVE is controlled by a signal from the CONTROL

BOARD. If the WATER LEVEL PROBE does not detect water, the inlet

solenoid is opened until water is again sensed.

BREW

The BREW VALVE fed by gravity from the hot water tank, and is

controlled by a signal from the CONTROL BOARD. The brew valve is

opened for a length of time as determined from programmed values.

The brew valve discharged through the BREW HEAD. Each half of the

brewer is independently controlled.

BYPASS

The BYPASS VALVE fed by gravity from the hot water tank via a

standpipe, and is controlled by a signal from the CONTROL BOARD.

The bypass valve is opened for a length of time as determined from

programmed values. The bypass valve discharges through the

BYPASS NOZZLE into the satellite server. Each half of the brewer is

independently controlled.

HOT WATER FAUCET

The HOT WATER FAUCET is fed by gravity from the hot water tank.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

The faucet is spring-loaded closed and manually opened.

The SS-2 Brewer has

two independent brewer

systems sharing a common

hot water tank.

The hot water faucet is fed

by the hot water tank, but

is otherwise independent of

the brewing systems.

NOTE:

Use of the hot water faucet

during a brew cycle will

not change the delivered

volume. However,

excessive use of the faucet

during brew may lower the

brew water temperature.

9

Page 12

CLEANING INSTRUCTIONS

CLEANING INSTRUCTIONS

CAUTION:

BURN HAZARD

Brewing and serving

temperatures of coffee are

extremely hot.

Hot coffee will cause

serious skin burns.

WARNING:

SHOCK HAZARD

DO NOT immerse or submerge

satellites. Fluid may saturate

the insulation and short-circuit

the receptacle connectors.

Electric shock may cause injury

and property damage.

IMPORTANT:

DO NOT use steel wool, sharp

objects, or caustic, abrasive or

chlorinated cleansers to clean

the brewer, brew baskets or

satellites.

PROCEDURE: Clean Coffee Brewer

PRECAUTIONS: Press POWER key to OFF.

Allow brewer to cool.

FREQUENCY: Daily

TOOLS: Mild Detergent, Clean Soft Cloth or Sponge

Bristle Brush

1. Press POWER key to OFF.

Allow brewer to cool.

2. Remove satellites.

3. Remove and empty brew baskets.

4. Remove spray disks and gaskets from spray heads

5. Wipe inside of spray head and area around spray head with a

soft clean cloth or sponge moistened with clean water.

6. Wash spray disks in a sink using warm water and a mild

detergent. A bristle brush may be used to clear clogged

spray holes. Rinse spray disks with clean water and allow to

air dry.

7. Wash brew baskets in a sink using warm water and a mild

detergent. A bristle brush may be used to clean around the

wire rack. Rinse with clean water and allow to air dry. Be

sure wire racks are properly installed.

8. Remove and drain the drip tray. Rinse in a sink under warm

running water. Allow to air dry, then reinstall on brewer.

9. Wipe exterior of brewer and satellites with a soft clean cloth

or sponge moistened with clean water.

10. Reinstall gaskets INSIDE brew heads, and then reinstall

spray disks.

11. Reinstall brew chambers.

12. Reinstall satellites.

Procedure is complete

10

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 13

CLEANING INSTRUCTIONS (continued)

PROCEDURE: Clean Satellite

PRECAUTIONS: Drain Satellite before Cleaning

FREQUENCY: Twice Weekly

TOOLS: Sight Glass Brush, Sanitizer

Soft Clean Cloth, Bucket

1. Remove and drain satellites.

2. Place 1 packet of Sanitizer into 2-1/2 gallons of warm tap

water. Pour approximately 1 gallon of sanitizer solution into

each satellite. Allow to stand for 2 minutes.

3. Remove the shield cap (large vent) on top of the sight glass.

NOTE: It is not necessary to remove the sight glass unless it

is broken and replacement is required.

4. Run the sight glass brush up and down through the sight

glass at least 10 times.

5. Reinstall and tighten the shield cap.

6. Drain sanitizer solution from satellite into the bucket.

7. Disassemble faucet. Brush clean with sanitizer solution.

Reassemble faucet.

8. Install satellite on brewer.

9. Rinse satellites: With an empty brew chamber in place,

press the BREW key and run 1 full cycle into each satellite.

10. Drain water from satellites.

Procedure is complete

CAUTION:

BURN HAZARD

Brewing and serving

temperatures of coffee are

extremely hot.

Hot coffee will cause

serious skin burns.

WARNING:

SHOCK HAZARD

DO NOT immerse or submerge

satellites. Fluid may saturate

the insulation and short-circuit

the receptacle connectors.

Electric shock may cause injury

and property damage.

IMPORTANT:

DO NOT use steel wool, sharp

objects, or caustic, abrasive or

chlorinated cleansers to clean

the brewer, brew baskets or

satellites.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

11

Page 14

PROGRAMMING INSTRUCTIONS

Fig. 7 Function Keys

NEW MENU SETTINGS

NOTE:

Time is held in memory and is

battery-backed. Clock change

should only be necessary for

daylight saving time, or if the

brewer is moved to another time

zone.

For advanced programming

features and instructions, refer

to PROGRAMMING MANUAL,

p/n 74346.

This brewer can be

programmed with a personal

computer.

Please contact your Bloomeld

Representative for details

Menu Program:

Press POWER key to enter OFF mode.

Press and hold 3rd & 6th keys for 3 seconds

Advance thru menus by pressing the 1st key

Advance thru items by pressing the 3rd key

To exit, press 2nd key

Clock Settings:

Press POWER key to enter ON mode

Press 3rd & 4th keys at the same time

Check Tank Temperature:

Press POWER key to enter ON mode

Press 3rd & 6th keys at the same time

12

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 15

PROGRAMMING INSTRUCTIONS (continued)

FEATURES

1. Energizing the Brewer: Turn the brewer on by pressing

the POWER key. The brewer will start to ll the tank with the

message on the screen “lling…”. With the proper water

supply the tank should be lled in about 2½ minutes. Once

lled, the heating element will come on until the proper tank

temperature has been reached, (which will take about 20

minutes on 120-Volt models or about 12 minutes on 120/240

Volt models).

Brewing (Precise Temperature Brewing™ — PTB™): In

2.

regular operating mode, the Satellite Brewer maintains the

tank temperature within +/- 1ºF of the brew temperature.

Normally this will mean that a brew will be started as soon

as the BREW switch is depressed. However, there may be

a slight delay if the BREW switch is depressed immediately

after a brew has been completed (notably on 120v models).

If the tank temperature is below the brew temperature, the

brew will be delayed going into the “Brew Wait” mode, with

the brew light ashing, and the message on the screen

“heating…”. As soon as the correct temperature is reached

the brew will commence with the BREW LED on continuously

during the brew. The time remaining in the brew will count

down on the display. During the brew if the BREW switch is

depressed, it will be ignored. Only if the brew is complete

can another brew be started.

To over-ride the Brew Wait Mode, press and hold the

START BREW key for 3 seconds when the brewer is in Brew

Wait mode (i.e. when BREW LED is ashing). The brew will

proceed immediately regardless of water temperature. This

feature should only be used when testing water volume,

otherwise the brew will proceed with the water below the

precise brew temperature.

PRECISE BREWING

TEMPERATURE™:

The brew cycle will not start

until the water in the tank is at

the proper temperature.

If START BREW key is pressed

and held for 3 seconds during

“Brew Wait” the brew will

proceed immediately.

Note: the following safety

features prevent multiple

unattended brews:

When the BREW LED is on or

ashing, repeated pressing of

the START BREW switch will be

ignored, (there will be a beep

each time it is pressed).

3. Brew Cancel: To cancel a brew in progress, or to cancel a

brew waiting, depress the STOP BREW key: two beeps will

sound and the BREW LED will go out. Water owing to the

brew basket will be stopped immediately, but, if there is

already water in the brew basket, it will take a few moments

before this drips through as coffee

4. Normal Operation (Non Brewing): When the unit is not

brewing, the Brewer maintains the water temperature at the

Precise Temperature for Brewing™ (PTB™). The heating

element will cycle on and off automatically to maintain this

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

temperature. The TANK HEAT LED will glow any time the

heating element is energized.

13

A Brew will only be activated

or put in Brew Wait when the

BREW LED is off.

Only one brew can be stored in

“Brew Wait” at a time.

Page 16

PROGRAMMING (continued)

ON/OFF – Normal Operation

(Non Automatic Timer):

To turn the brewer OFF, press

the POWER key: 2 beeps will

be heard and the brewer will

be turned OFF, indicated by all

lights being off.

To turn the brewer ON, press

the POWER key: 2 beeps will

sound, all lights will ash once,

then the POWER LED will glow.

NOTE: The HEAT LED will glow

if the water temperature is too

low when the brewer is turned .

5. View Water Temperature in Tank: To view the water

temperature on the screen, the brewer must be ON, and not

brewing or in the lling mode. Press and hold the 4th key,

and depress the 6th key. The actual water temperature will

be displayed for 3 seconds.

6. ON/OFF – Automatic Timer Feature:

The factory programmed Satellite Brewer has the automatic

timer turned off. To set the automatic timer, refer to

“Time Functions” Menu. If the Automatic Timer feature is

programmed off, the brewer can be turned on and off by

pressing the POWER key, as noted at left.

When the Automatic Timer feature is programmed ON the

Brewer will turn on and off automatically, at a programmed

time, Monday to Friday; with a separate on and off

programmed time schedule for Saturday and Sunday.

Temporarily Overriding the Automatic On/Off function:

While in the automatic timed OFF mode, the brewer can be

started by depressing the POWER key. The brewer will

remain on until the automatic programmed OFF time, when it

will turn off and resume normal automatic timed functioning.

Similarly, if turned OFF during the automatic timed ON mode

the brewer will remain OFF until the next programmed ON

time, when it will turn on and resume normal automatic timed

functioning.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

14

Page 17

PROGRAMMING (continued)

7. Automatic Start-Up in Previous Mode:

If the Satellite Brewer automatic timer is OFF (the factory

setting) and power is disconnected, the brewer will start up

when power is restored, in the mode it had been in prior to

the power disconnection. If the Satellite Brewer has the

timer setting ON and power is disconnected, the brewer will

start up in the mode that it should be in at the time the power

is restored.

8. Brew Volume:

The Brewer can have up to 3 different brew volumes on each

side. When a volume other than the standard, or rst brew

volume, is selected, the Brewer will complete that volume

and then automatically reset to the standard, or rst brew

volume.

To view, press the individual volume key. The brew volume

will be displayed on the screen for 3 seconds. If there is

no brew volume for a specic key, the screen will read “no

volume prog”, (i.e. no volume programmed).

9. Clock

Time – Battery Backup. The Satellite Brewer has a battery

backup system which will maintain the proper time during

power failures, or when the brewer is unplugged (even for

very prolonged periods of time). Normally there will not be a

need to set the time except for Daylight Saving Time

changes, or moving the brewer to different time zones.

10. Changing Day and Time: To change time, in the OFF

mode, press the 2nd key twice followed by the 1st key twice

to access the time change mode. In the time change mode

he screen will read “Day:” followed by the current day

setting. Use the 6th key to advance the day, or the 5th key

to reverse.

When day has been properly set, press the 3rd key. The

screen will now read “Time:” with the set time on the screen,

the hour and am or pm ashing. Use the 6th key to advance

the hour, or the 5th key to reverse, making sure that the am

or pm is correct.

When the hour and am/pm is correctly set, press the 3rd key,

and the screen will read “Time:” with the set time on the

screen, minutes ashing. As previously, use the 5th or 6th

keys to adjust the minutes, and press the 3rd key when

complete. The Brewer will return to the off mode. (Changing

time can also be done in the regular programming mode.)

Brew Volume

The 1st key is the Standard

Brew Volume.

When a brew volume other

than standard brew volume is

selected, the Brewer will

complete that brew then return

to the standard brew volume

automatically.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

15

Page 18

PROGRAMMING (continued)

The factory programming has

the After Hours™ mode turned

OFF.

While in the After Hours mode,

the POWER LED will ash

continuously.

Keypadlock™ deters unauthorized

operation of the brewer. This

feature is OFF in the standard

factory settings.

12. After Hours™: The After Hours™ can be programmed to

come on from 1 to 6 hours after the last brew. When the

Brewer goes into the After Hours™ mode, the water in

the tank will be allowed to drop from the normal brewing

temperature and will reheat less frequently – this feature

saves energy and extend component life. When a START

BREW key is pressed the Brewer automatically reverts back

to normal operation, heating the water to the Precise

Temperature for Brewing™ (PTB™), before starting the

brew. (The POWER LED will be on continuously and the

BREW LED will ash until the correct water temperature is

reached.)

13. Pulse or Pre-Infusion Volume Options: If a particular brew

volume has utilized the pulse or pre-infusion option, that

volume will be displayed with an asterisk (*) after the volume.

As an example “Volume#2*” would indicate that the second

programmed brew volume has utilized the pulse or

pre-infusion program options.

14. Keypadlock™: If the Keypadlock™ feature is activated,

there will be no response by the brewer when the keys are

pressed (except for the beep after a key is pressed).

To temporarily “unlock” the keypad, press and hold the 2nd

key for 6 seconds. A beep will sound, indicating the keypad

is temporarily “unlocked”, — a brew can be initiated, etc.

The keypad will remain unlocked until the brew is completed,

then automatically return to keypadlock™ mode. If a brew is

not initiated 60 seconds after “unlocking”, the system will time

out and return to the “locked” position.

15. View Filter Statistics: To view lter statistics, from the OFF

mode, press and hold the 6th key, and touch the 3rd key to

viewTotal Water Volume (TotalVol.) Touch the 3rd key again

to view the lter life (FltrLife:). The percentage of the lter

that has been used will be displayed.

16

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 19

TROUBLESHOOTING SUGGESTIONS

DESCRIPTION OF

PROBLEM

No lights or heat

Unit not plugged in or circuit breaker tripped Restore electric power

Power switch OFF Turn power switch ON

POSSIBLE CAUSE SUGGESTED REMEDY

No heat Hi-limit safety tripped

Water level probe corroded Clean water level probe

Brewer overows

Poor ground connection Verify ground connection

Dirt in inlet valve or valve damaged Replace inlet valve

Brew valve damaged Replace brew valve

Too many paper lters or wrong lter used.

Brew chamber

overows

Chamber discharge hole plugged Clean brew chamber

Improper programming Correct programming

Connected to wrong voltage Verify supply voltage

Heats slow

Scale build-up on heating elements De-lime hot water tank

Damaged heating element Replace element

Slow to ll

Insufcient water pressure

Plugged water line strainer Clean strainer

Not properly seated Seat satellite in receptacle

Satellite does not heat

Fuse blown Correct problem, replace fuse

Damaged satellite receptacle or wiring Determine/repair damage to satellite

Damaged brewer receptacle Repair/replace receptacle

Satellite shorts out Wet insulation

Improper programming Correct programming

Also:

Poor coffee quality

Keep brewer and servers clean.

Install a taste and odor lter in water supply, and replace cartridges regularly.

Use a quality coffee with a consistent roast. Use proper grind and amount of coffee per brew.

Allow brewer to cool, verify water level, reset

hi-limit

Use one genuine Bloomeld paper lter per

brew

Brewer must be operated on a dedicated water

line. Other equipment on line may be robbing

water volume.

Disassemble satellite, allow to dry completely

before reassembly

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

17

Page 20

SERVICING INSTRUCTIONS

CAUTION:

CHEMICAL BURN

HAZARD

Deliming chemicals are caustic.

Wear appropriate protective

gloves and goggles during this

procedure.

Never siphon deliming

chemicals or solutions by

mouth.

This operation should only be

performed by qualied and

experienced service personnel.

IMPORTANT: DO NOT spill,

splash or pour water or deliming

solution into or over any internal

component other than the inside

of the water tank.

IMPORTANT: DO NOT allow

any internal components to

come into contact with the

deliming solution. Take care to

keep all internal components

dry.

NOTE: Repeat steps 4 and 7

as required to remove all buildup.

PROCEDURE: Delime the Water Tank

PRECAUTIONS: Disconnect brewer from electric power.

Allow brewer to cool.

FREQUENCY: As required (Brewer slow to heat)

TOOLS: Deliming Solution

Protective Gloves, Goggles & Apron

Mild Detergent, Clean Soft Cloth or Sponge

Bristle Brush, Bottle Brush

Large Sink (or other appropriate work area)

1. Disconnect brewer from the electrical supply.

2. Remove the brewer top panel, then remove the tank lid

assembly. Do not disconnect the tank assembly at this

time.

3. Siphon all water from the hot water tank.

4. Mix 10 gallons of deliming solution according to the

manufacturer’s directions. Carefully pour the deliming

solution into the water tank. Lower the lid assembly back

onto the tank. Allow to sit for 30 minutes, or as directed by

the chemical manufacturer.

5.

At end of soaking period, reconnect brewer to electrical

power. Install the brew chamber without lter paper or

grounds. Place an empty satellite under the brew

chamber. Force a 1-1/2 gallon brew:

a. Press the 1-1/2 gallon key

b. Press the brew key, then press and hold the brew key

until a brew is initiated.

Empty the satellite and repeat for the other side.

6. Disconnect brewer from electrical power and allow to cool.

7. Remove lid assembly from tank.

a. Using a stiff bristle brush, scrub internal components to

remove lime and calcium build-up.

b. Thoroughly rinse internal components of lid assembly

with clear water.

c. Store lid assembly in a safe location.

8. Using a stiff bristle brush, scrub exposed portions of the

heating element and the inside surfaces of the tank to

remove lime and calcium build-up.

9. Siphon all solution from the tank.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

18

Page 21

SERVICING INSTRUCTIONS (continued)

10. Reinstall tank lid assembly into hot water tank. Make sure

the lid gasket is properly in place, then reinstall the holddown clamps.

11. Remove spray disks and gaskets. Rinse both brew heads

with clean water. Using a stiff brush, scrub spray disk to

remove any lime or calcium build-up. Reinstall gaskets

and spray disks.

13. Reconnect brewer to electrical supply .

14. Install the brew chamber without lter paper or grounds.

15. Place an empty satellite under the brew chamber. Run at

least ve 1-1/2 gallon brew cycles and discard all water

generated at the end of each cycle.

Repeat for the other side.

16. Rinse satellite with clean water. Reinstall one empty

satellite under each brew chamber.

Brewer is ready to use.

NOTE: Normally, silicone

hoses do not need to be

delimed. Should deliming hoses

become necessary, Bloomeld

recommends replacing the

hoses.

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

19

Page 22

EXPLODED VIEW CABINET AND EXTERIOR COMPONENTS

20

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 23

PARTS LIST - CABINET AND EXTERIOR COMPONENTS

ITEM PART NO DESCRIPTION QTY

1 COVER TOP HOUSING SS2 1

2 TOP HOUSING WLD ASSY SS2 1

3 BODY WLD ASSY SS2 1

4 BASE WLD ASSY SDS-2 1

5 BTM PLATE WLD ASSY 1

6 PANEL BACK SS2 1

7 PANEL FRONT SS2 1

8

9 BRACKET TANK SUPPORT TOP SS2 2

10 2K-70229 BUSHING SHORTY HEYCO 3

11 D7-72738 SPOUT ASSY 2

12 2E-73046 CONNECTOR WIRED ASSY SDS- 2

13 DD-73077 HANDLE GUIDE L 3

14 2A-73098 LEG 4” BLK PLASTIC W/FLANGE 4

15 2A-73107 FEET RUBBER BLACK 4

16 2K-300102 STRAIN RELIEF 1NPT .375-1 1

17 DD-37512 PLUG HOLE 1 3/8” 1

18 SCREW, PAN, NI #8-32 X 1/4 4

2I-70139 GASKET SPRAY HEAD

19

2I-72215 GASKET SPRAY HEAD 1.5 ID

20 A6-72727 SPRAY HEAD DISC EMBOSSED 2

21 2E-40310 TERM BLOCK 4POLE 75AMP 1

22 DD-71265 FUSEHOLDER 1

23 DD-71266 FUSE 5A 1

24 DD-74323 POWER & CONTROL BOARD ASSY 1

25 DD-75239 KEYPAD SS2 1

26 BRACKET HEAT SINK SS2 2

27 2C-70379 SCREW 8-32X5/16 PH PAN MS 56

28 2C-48748 SCREW 4-40X3/8 PH PAN #F 4

29 2C-73457 NUT 8-32 HEX HEAD KEPS MS 25

30 2C-31243 SCREW 8-32X7/8 PH RD HD 4

31 2A-73362 SPACER .375 OD, .25L 4

32 DD-70049 SCREW 8-32X1/2 PH PAN HD 2

33 WASHER #8 EXT SEMS 6

34 2C-35313 NUT 10-32 HEX MS SS 1

35 2E-73392 HEAT SINK & TRIAC ASSY 1

BRACKET CONTROL BOARD MTG

SS2

1

2

ITEM PART NO. DESCRIPTION QTY

36

37 2E-72936 SWITCH ROCKEER ON-OFF .125 1

38 2E-37780 CONTACTOR 3P, 240V, 40A ALT3 1

39 2E-73552 WIRE ASSY WATER LEVEL PRO 1

40 LUG GROUND SOLDERLESS 6-14G 1

41 2B-70466 RACK WIRE BREW CHAMBER 2

42 2C-70115 SCREW 10-32X5/16 HEX HD M 2

43 2C-70467 CLIP BREW BASKET 2

44 2D-73101 CHAMBER BREW .187 HOLD NO 2

45 2R-70112 HANDLE BLACK 2

46 A6-73100 BREW CHAMBER ASSY SS1 .18 2

47 DD-73885 SHIELD DRIP CONTACTOR 1

48 WASHER, FLAT #4 .312 OD 2

49

50 A6-70888 DOOR ACCESS SOLENOID 1

51 DD-75235 PLUG BUTTON 1/2 DIA BLK 1

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

21

Page 24

EXPLODED VIEW INTERIOR COMPONENTS

22

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 25

PARTS LIST - INTERIOR COMPONENTS

ITEM PART NO DESCRIPTION QTY

1 DD-74427 SOLENOID SINGLE 120V 1.0 1

2 DD-73778 RETAINING CLIP TANK LID 4

3 2C-73457 NUT 8-32 HEX HEAD KEPS MS 16

4 2I-70147 GASKET TANK COVER 1

5 2K-70154 FTG UNION 1/4X1/4 1

6 2C-70155 NUT 7/16-20 HEX HD BRASS 1

7 DD-75846 TUBE INLET ASSY 9.62 1

8 2C-70512 WASHER SS .035X7/16IDX3/4OD 1

9 2U-71061 FAUCET HOT WATER 1

11 2J-72114 PROBE 8783MCD 1

12 2I-72115 GROMMET 1/4 ID TRANSLUENT 1

13 2I-72390

14 A6-72661 TUBE SIL .312 ID X 27 1

15 2K-73152 ELBOW SPRAYER 1/4 ID 2

16 TANK WELD ASSY 1

DD-73287 ELEM 230V 3000W 2

17

DD-73424UL ELEM HEATING 208V 2750W 2

18 BRACKET SOLENOID VALVE SS2 1

19 SCREW PAN SLT SS 4mm X 8mm 2

20 2I-73309 GASKET TANK HEATER SS2 1

DD-73572 BRKT BYPASS DOUBLE 1

21

N.L.A. BRKT BYPASS DELTROL 1

22 2V-73311 TUBE FILL 90DEG BEND L=22 1

23 DD-73312 THERMO HI-LIMIT DBL POLE 1

24 2P-73318 PLUG TANK LID .510 DIA 2

25 2P-73319 PLUG TANK LID .298 DIA 1

26 2P-73320 PLUG TANK LID .687 DIA 1

27 DD-73325 TANK LID WELDED ASSY SS2 1

28 D7-73314

29 2K-47662 FTG STR BRS 3/8NPT X 3/8IN 1

30 2O-46575 VALVE DRAIN 3/8NPT 1

31 DD-83605 ELBOW MALE 5/8 X 3/8 90 DEG 1

32 DD-73380 TUBE ASSY COPPER TUBE 1

33 DD-83381 KIT DRAIN VALVE ASSY 1

34 2C-73359 WASHER FLARE TANK DRAIN 1

35 DD-73358 PLUG TANK DRAIN SS2 1

36 DD-73357 NUT TANK DRAIN PLUG SS2 1

37 DD-73553 TUBE SIL .375 ID X 72” 1

38 2K-70103 ELBOW OUTLET 2

GROMMET .375 ID TRANSLUCENT

TUBE, TANK TO VALVE, SIL .50

ID 7.3

1

2

ITEM PART NO DESCRIPTION QTY

39 2A-73384 TUBE SPRAY HEAD 2 3/8” LG 2

40 A6-73537 TUBE SIL .312 ID X 9” LG 3

41 2V-73388 VALVE ADJUST WATER OUTLET 2

42 D7-70699

43 BRACKET BYPASS VALVE 2

44 2C-72148 WASHER LOCK 1/2 ID INT SE 1

45 SCREW 10-32 X 1/2 PH PAN 4

46 2C-35485 NUT 1/4-20 HEX FINISHED 1

48 DD-76934 FTG ELBOW W/EXTENSION 2

49 F4-70409 WASHER BEVELLED 2

50 2I-70152 GASKET ELEM HTG 2

51 2C-73147 WASHER GYLON 1/2 ID 3/4 OD 2

52 2C-72739 NUT TANK FITTING #304 3/4 2

53 2J-73313 PROBE THERMISTOR PASSSIVAT 1

54 D7-73414 SHIELD HI-LIMIT 1

55 2C-73415 NUT 6-32 HEX 1.00 LG ALUM 2

56 2V-70111 TUBE FORMED INLET ASSY 1

57 2V-73027 STRAINER ‘Y’ PLASTIC W/FT 1

58 DD-73571 INSERT SPRAY HEAD SS2 2

WS-83617 VALVE SOL BYPASS ASSY 120V 2

2V-72729 VALVE ADJUST DISPENSING 1

2I-73570 INSERT BYPASS REG SS2 1

A6-73537 TUBE SIL .312 ID X 9 LG 1

59

WS-83618 VALVE SOL DISP ASSY 120V 2

2V-73388 VALVE ADJUST WATER OUTLET 1

2I-73570 INSERT BYPASS REG SS2 1

A6-73537 TUBE SIL .312 ID X 9” LG 1

60 2C-70379 SCREW 8-32X5/16 PH PAN MS 6

61 WASHER FLAT SS #8 2

62 2C-70405 SCREW 6-32X1/4 RD HD M 2

63 DD-74063 GROMMET .510 OD X 250 ID 1

64 2C-72681 WASHER FLT 15/32X1 1/8 1

65 RETAINING TUBE 1

66 BOTTOM PLATE TUBE RETAINER 1

67 DD-74434 TUBE FORMED SS 1

68 DD-74433 TUBE SIL .312 X 6” 1

69 DD-74435 INSUL LYTHERM FAUCET TUBE 1

70 DD-74650 TUBE SIL .312 ID 4.8L 1

TUBE INLET HOSE, SIL .375 ID

X 17.25

1

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

23

Page 26

EXPLODED VIEWWIRING DIAGRAM

24

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

Page 27

SATELLITE EXPLODED VIEW, PARTS LIST & WIRING DIAGRAM

L1

N E UT.

45W

SCHEMATIC P/N 73061

SATELLITE ASSEMBLY 9340 120V

ITEM PART NO DESCRIPTION QTY

1 2L-73863 TANK LID ASSY, SRL-DP 1

2 2R-73099 HANDLE SATELLITE TOP 9105 2

5 SCREW, 8-32X3/8” BLK OXIDE 8

6 STIFFENER BRACKET LEFT 1

7 2L-73558 TOP COVER SATELLITE 1

8 FRAME, DECAF (PART OF #9) 1

9 DD-83092 DOOR DECAF & FRAME 1

10 2U-73112 FAUCET W/SG 10” 1

10.01 WS-8600-17 CAP SHIELD VENT HL 1

10.02 WS-8700-25J WASHER UPPER TUBE 1

10.03 WS-8705-11C TUBE SIGHT-GLASS 10IN 1

10.04 WS-8600-20 SHIELD 10 GAUGE 1

10.05 WS-8705-11B WASHER 79ES GASKET W/1/16H 1

10.06 WS-8705-11G SHIELD BASE 1

DD-74345-M672 OP MANUAL DUAL SATELLITE BREWERS

10.08 WS-8600-26 C RING 1

10.09 WS-8600-27 NUT WING #17 ANY B 1

10.10 2U-71460 SEAT CUP TEA DISP FAUCET 1

10.20 WS-8705-11D SHANK ASSEMBLY

12 DD-74326 HANDLE FAUCET GUARD 1

MODEL VOLTS WATTS

9340 120 45

ITEM PART NO DESCRIPTION QTY

13 WS-83172 RECEPTACLE PIN WIRED ASSY 1

14 N.L.A. ELEM HTR SILICON 45W W/TAPE 1

15 D7-73117 INSUL LYTHERM TANK BTM 1

16 2L-73057 BASE POLYPROP INJECT MOLD 1

17 PLATE STIFFENER 1

18 WELDMENT, SATELLITE BODY 1

19 TANK SUB ASSY w/FITTINGS 1

20 TAPE GLASS CLOTH 33

21 THREADLOCK RED A/R

22 2I-70801 SEAL DRAIN FITTING 2

23 TAPE TEFLON 1.74

24 LABEL SATELLITE 1

25 SCREW, PAN PHL 8-32X1/2” 4

26 STIIFENER BRACKET RIGHT 1

27 SCREW, TRS PHL SS 10-32X3/8” 4

28 2I-70812 O-RING 7IDX7 1/4OD X1 1

30 WASHER #10 4

33 2C-73457 NUT 8-32 HEX HEAD KEPS MS 3

34 2M-73132 LABEL CAUTION DO NOT IMMERSE 1

25

Page 28

10 SUNNEN DRIVE, P.O. BOX 430129, St. Louis, MO 63143

telephone: 314-781-2777 fax: 314-781-2714

www.wellsbloomfield.com

Loading...

Loading...