Page 1

BLOOMFIELD INDUSTRIES

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

telephone: 888-492-2782

fax: 888-492-2783

www.wellsbloomfield.com

727

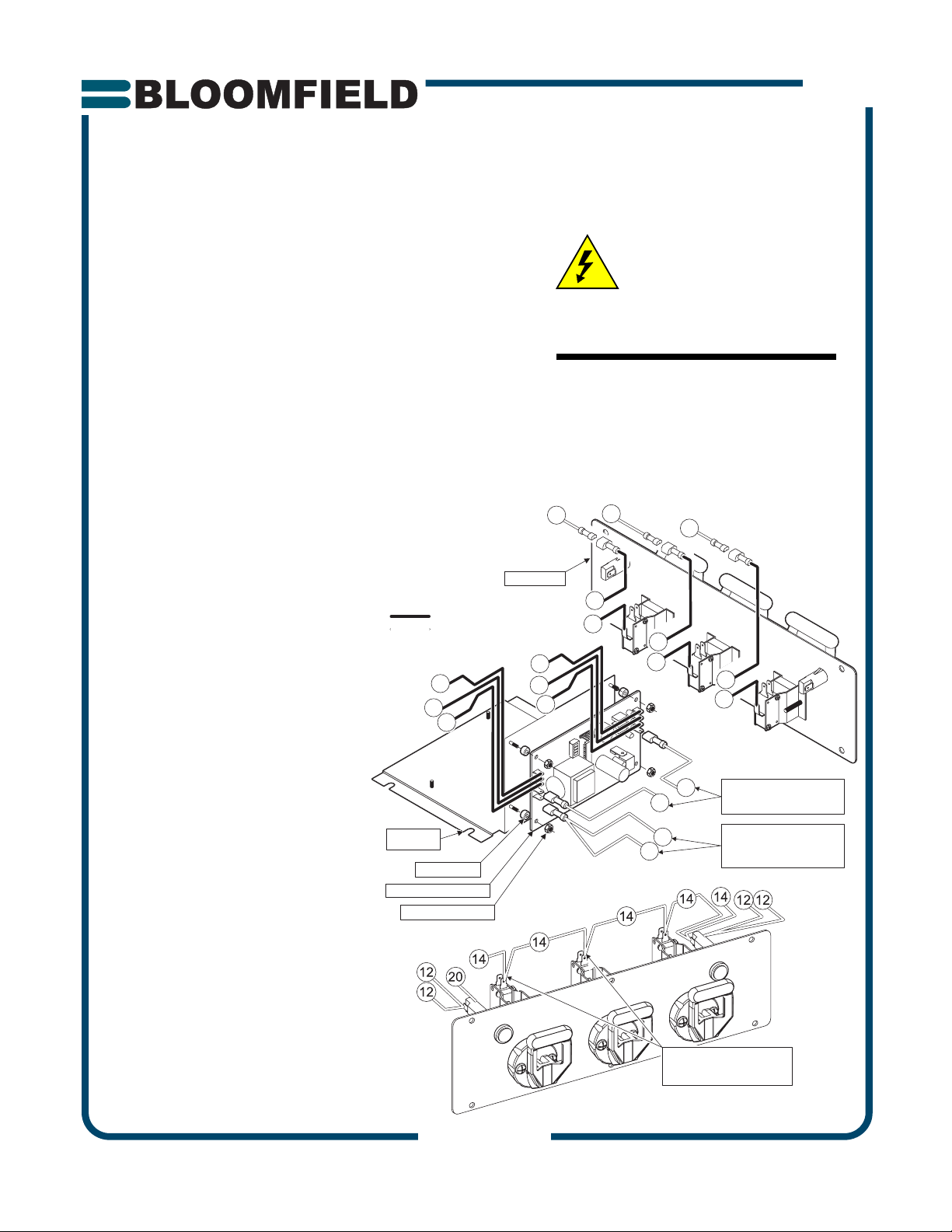

CONVERSION INSTRUCTION

Convert Model 9465 KFT to

Mechanical Switches

KIT # 87439 - Convert Model 9465KFT Electronic Portion

Control to Mechanical Switches with Portion Control

1. Disconnect unit from electric power.

2. Remove portion control assembly from front of unit.

3. Refer to 9465KFT Wiring Diagram, page 2. Mark wires to

control board, then disconnect wires from board. Discard

old board.

4. Unfasten contactor from mounting bracket. Remove and

discard old bracket. Install new bracket and remount

contactor. Mount portion control board to new bracket.

5. Locate red wire #12 and blue wire #13. Determine a

position on each wire that will comfortably reach the

portion control board.

Cut wire #12 at the determined

location, strip insulation and

crimp a provided female terminal

(small barrel) to each wire.

Connect to L2 and VALVE

COMM on portion control

board.

NEW WIRING HARNESS

EXISTING WIRES

SWITCH PANEL

Cut wire #13 at the determined

53

51

55

RED

BROW

BLUE

N

location, strip insulation, twist

both wires together and crimp on

provided female terminal ( large

barrel). Connect to L1 on portion

control board.

6. Locate 2 ea. blue wires #14 near

front of unit and remove tape

from terminals.

7. Connect provided wiring harness

to switch panel and portion

control board.

8. Refer to revised 9465 Wiring

Diagram, page 3. Connect

CONTACTOR

BRACKET

SPACER 4 places

PORTION CONTROL BOARD

NUT 10-32 KEPS 4 places

existing wires to new switch

panel and portion control

board per diagram.

9. Assemble switch panel to unit.

RED

WHITE

Connect unit to electric power

and test for proper operation.

10. Program portion control

option as required.

(see page 4)

CAUTION

ELECTRIC SHOCK HAZARD

Disconnect appliance from electric

power before beginning this

conversion.

IMPORTANT:

This procedure must be performed by

factory authorized personnel. All wiring

terminal attachment must be performed

in accordance with the wire terminal

manufacturer’s specifications using

correct tooling.

23

RED

N

W

52

51

BRO

W

N

RED

RED

54

53

BROW

BRO

W

33

BLUE

N

N

BLUE

56

BLUE

55

R

ED

RED

12

12

BLUE

BLU

E

13

13

REMOVE TAPE FROM 2 TERMINALS

ON BLUE WIRE #14

CONNECT TO CONNECTOR

OF LEFT AND CENTER SWITCHES

CUT RED WIRE #12

CRIMP ON 2 FEMALE TERMINALS

CONNECT TO &

ON PORTION CONTROL BOARD

CUT BLUE WIRE #13

CONNECT ENDS AND CRIMP ON

FEMALE TERMINAL

CONNECT TO ON

PORTION CONTROL BOARD

FRONT

52

54

32

RED

BRO

BLUE

56

BLUE

L2 VALVE COMM

L1

RED

Page 1 of 4

p/n 87439A Rev. (-) ECN-12956 I727 051114 cps

Page 2

Page 2 of 4

12

RED

BREW

LIGHT

20

WHITE

WHITE

32

ORANGE

DISPENSE

VALV E

(LEFT)

32

RED

LEFT SWITCHES

CONTROL BOARD

BLACK

YELLOW

LEADS

AUGER MOTOR

(LEFT)

+

-

12

21

RED

22

CENTER SWITCH

LIQUID LEVEL

BLACK

208/240V

LEFT

TRANSFORMER

24V

CONTROL

RED

SOLENOID VALVE

ON/OFF SWITCH

BROWN

RIGHT SWITCHES

COM

MAX

NC

L1

L2

26

ORANGE

25

SPEED

BOARD

-++

-

RED

27

28

WHITE

4

1

2

5

WHITE

SERVE

SANITIZE

DISPENSE

(CENTER)

23

PORTION CONTROL BOARD

GREEN/YELLOW

NO

BLACK

208/240V

RIGHT

TRANSFORMER

24V

BROWN

RED

29

30

4

1

2

5

BLUE

14

VALV E

BLUE

33

CUT WIRE #13

TWIST TOGETHER

ADD TERMINAL

18

WHITE

19

LIQUID

LEVEL

PROBE

BROWN

BLACK

YELLOW

LEADS

AUGER MOTOR

(RIGHT)

+

-

WHITE

24

12

RED

BLUE

14

L2

L1

17

31

BLUE

BLACK

DISPENSE

TERMINAL

BLOCK

13

33

VALV E

(RIGHT)

14

BLUE

JUMPER

BLUE

12

POWER

LIGHT

INLET

L2 RED

L1 BLACK

VALV E

BLACK

12 GA

DISPENSE TEMP

THERMOSTAT (LEFT)

WHITE

20

3

2

1

RED

12

RED

ILLUMINATED

5

HTG ELEMENT

(LEFT)

240V 3000W

FAN

RED

DOOR

RED

12 GA

12 GA

BLACK

BLACK

BLACK FAN LEADS

12

RED

14

BALLAST

RED

LAMP

6

BLUE

15

BLUE

(2) WIRE NUTS

WHITE

BLACK

WIRE NUT

YELLOW

L2

LINE

L1

LINE

POWER

SWITCH

1

HTG ELEMENT

(RIGHT)

240V 3000W

13

BLUE

13

BLOWER

T2

LOAD

T1

LOAD

RED

12 GA

TANK TEMPERATURE

THERMOSTAT (RIGHT)

14

BLUE

7

12 GA

RED

BLACK

12 GA

2

10

RED

12 GA

9

RED

12 GA

8

4

BLACK

12 GA

BLACK

12 GA

T1

3

2

1

3

4

HI-LIMIT

RED

11

T2

CONTACTOR

L2

1

2

12

RED

11

RED

HEATER

SWITCH

RED

12

CUT WIRE #12

ADD TERMINALS

L1

16

BLACK

14

BLUE

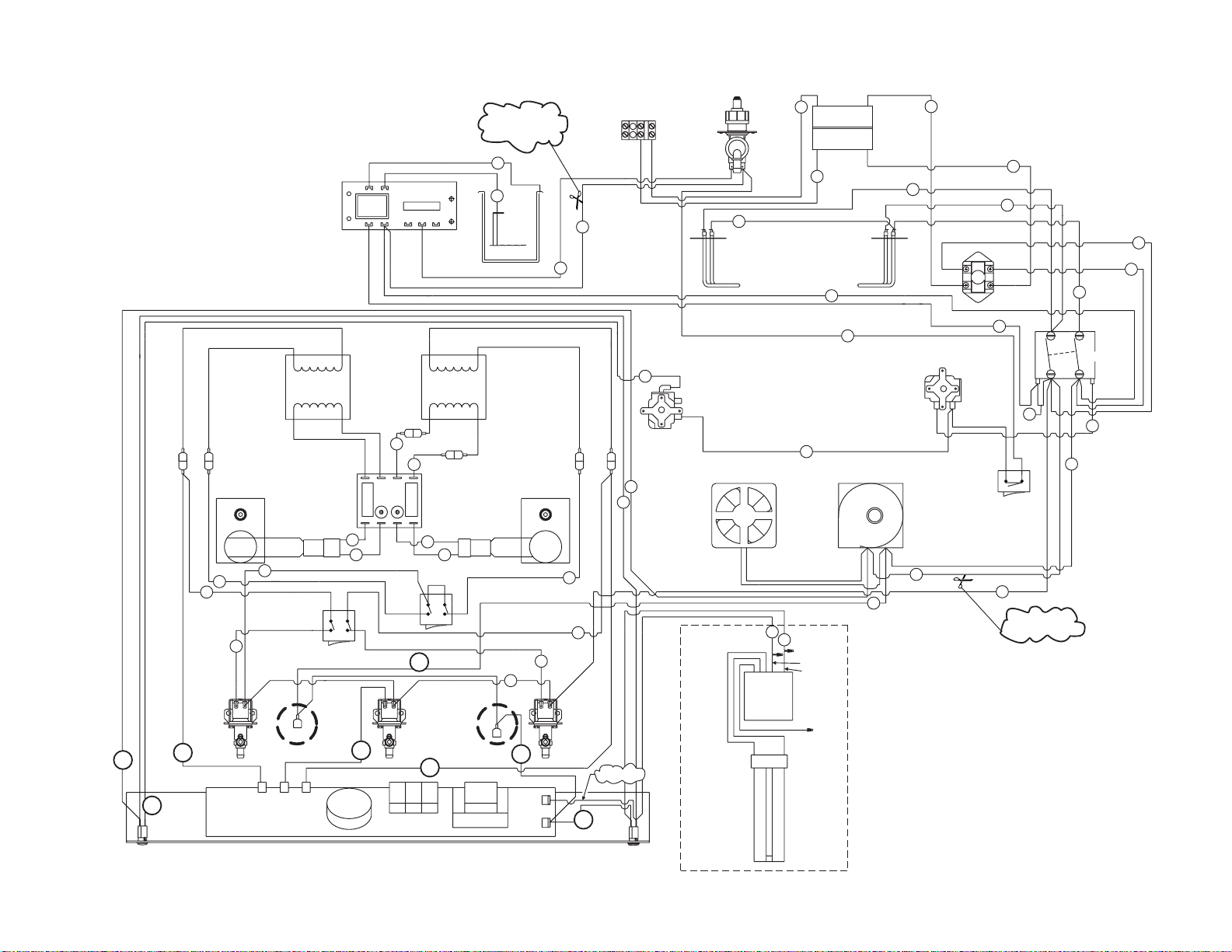

WIRING DIAGRAM

9465KFT

P/N 76312

Page 3

Page 3 of 4

12

BREW

LIGHT

RED

BLACK COM

32

20

WHITE

RED 208V

RED

DISPENSE

BLUE 240V

AUGER MOTOR

(LEFT)

+

-

WHITE

21

32

RED

ORANGE

22

VALV E 1

(LEFT)

DISPENSE SWITCH 1

(LEFT)

LIQUID LEVEL

CONTROL BOARD

208/240V

TRANSFORMER

(LEFT)

12V

RED

12

4

5

SOLENOID VALVE

ON/OFF SWITCH

BROWN

51

14

BLUE

MAX

COM

L1

L2

-

RED

+

27

28

1

SANITIZE

2

23

52

RED

DISPENSE SWITCH 2

(CENTER)

GREEN/YELLOW

NC

NO

17

TRANSFORMER

26

ORANGE

25

BROWN

CONTROL

-

+

29

WHITE

SERVE

4

5

BLUE

14

DISPENSE

VALV E 2

(CENTER)

53

14

BROWN

208/240V

(RIGHT)

12V

SPEED

BOARD

RED

30

1

2

RED

12

BLUE

18

WHITE

19

LIQUID

LEVEL

PROBE

AUGER MOTOR

(RIGHT)

BROWN

54

BROWN

DISPENSE SWITCH 3

+

-

WHITE

24

(RIGHT)

BLUE

BLACK

RED

TERMINAL

BLOCK

13

BLUE 240V

31

33

DISPENSE

VALV E 3

(RIGHT)

BLUE

RED 208V

BLACK COM

12

WHITE

12

RED

L2 RED

L1 BLACK

BLACK

12 GA

20

RED

POWER

LIGHT

INLET

VALV E

BLACK

5

HTG ELEMENT

LEFT

240V 3000W

DISPENSE TEMPERATURE

THERMOSTAT (LEFT)

FAN

13

13

BLACK FAN LEADS

BLUE

33

RED

52

RED

51

53

55

BLUE

7

RED

12 GA

BLACK

12 GA

6

L2

LINE

LINE

1

HTG ELEMENT

240V 3000W

BLUE

BLUE

15

LI

13

RIGHT

13

T2

LOAD

POWER

SWITCH

T1

LOAD

RED

12 GA

10

TANK TEMPERATURE

THERMOSTAT (RIGHT)

RED

BLACK

RED

1

2

12 GA

12 GA

RED

12 GA

9

3

4

HI-LIMIT

11

BLOWER

HEATER

SWITCH

12

RED

VALVESW1

VALVESW2

VALVESW3

L2

L1

54

BROWN

14

56

VALVEOUT 1

VALVEOUT 2

VALVEOUT 3

VALVECOM

12

BLUE

BLUE

12

PORTION CONTROL BOARD

WIRING DIAGRAM (REVISED)

9465KFT w/MECHANICAL SWITCHES

& PORTION CONTROL

P/N 77455

2

RED

11

RED

4

T2

CONTACTOR

L2

14

ILLUMINATED

DOOR

BLACK

12 GA

BLACK

12 GA

T1

L1

16

BLUE

RED

RED

12 GA

BLACK

12

BALLAST

RED

LAMP

3

14

8

BLUE

2 WIRE

NUTS

WHITE

BLACK

WIRE

NUT

YELLOW

RED

Page 4

PROCEDURE: Program Portion Control 9465 KFT

PRECAUTIONS: Possible exposed electrical circuits

FREQUENCY: When needed

TOOLS: #2 Phillips Screwdriver

Small pointed stylus (or ballpoint pen)

1. Turn dispenser power switch OFF.

2. Remove drip pan and splash shield to access portion control

board.

3. Enable adjustment program by moving switch #4 to ON.

To adjust “coffee” portion control, move switch #1 to ON.

To adjust “hot water” portion control, move switch #2 to ON.

To adjust “decaf” portion control, move switch #3 to ON.

4. Turn dispenser power switch ON.

5. Place an empty container under the nozzle of the valve to

be set. Pull the handle to start product flow. When the

desired volume is reached, release the handle to stop the

flow and enter this volume into memory. This process may

be repeated any number of times until the exact desired

volume is achieved.

6. Repeat for all valves to be set.

7. Turn dispenser power switch OFF.

8. Move switch #4 to OFF. Leave switches #1, #2 and/or #3 in

the ON position if portion control is desired for that dispenser.

9. Reinstall Splash Shield and Drip Tray. Turn dispenser power

switch ON.

Procedure is complete

CAUTION -

ELECTRIC SHOCK

Panels removed for this

procedure may expose live

electrical circuits. Use due

caution around wiring and

connectors.

Switch #1, #2, or #3 can be

turned ON to enable portion

control for that dispensing

nozzle.

#1 - COFFEE

#2 - HOT WATER

#3 - DECAF

To return to manual dispensing:

1. Turn power switch OFF.

2. Remove drip tray and

splash shield.

3. Move switch for desired

position to OFF.

4. Reinstall Splash Shield and

Drip Tray. Turn dispenser

power switch ON.

HAZARD

Page 4 of 4

Loading...

Loading...