Page 1

OWNER'S MANUAL

71239

OPERATING INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

and PARTS LIST

Model 8702 Coffee Brewing System

with

Model 8703 Satellites

TWIN SATELLITE BREWING SYSTEM

BLOOMFIELD INDUSTRIES

2 ERIK CIRCLE, P.O. BOX 280

VERDI, NEVADA 89439

FAX (800) 356 -5142

8702-M

Page 2

INDEX

INTRODUCTION 3

PRE-INSTALLATION INSTRUCTIONS 4

CONNECTING THE WATER SUPPLY 5

ELECTRICAL INSTALLATION 6

INITIAL OPERATION INSTRUCTIONS AND

BREWING OF COFFEE 7

PARTS IDENTIFICATION LIST 8, 9, 10

SOLENOID VALVE REPLACEMENT PARTS 10

EXPLODED VIEW-MODEL 8702 BREWER . 11

EXPLODED VIEW-MODEL 8703 SATELLITE . 12

REPLACEMENT PARTS LIST-MODEL 8703 SATELLITE 13

HOT WATER FAUCET PARTS LIST 14

WATER FLOW DIAGRAM 14

DAILY OPENING & CLOSE DOWN PROCEDURES 15

TROUBLE SHOOTING GUIDE 16 thru 21

SERVICE INSTRUCTIONS 22 thru 26

BY-PASS VALVE ADJUSTMENT & SETTING 27

WIRING DIAGRAM & ORDERING INFORMATION 28

The INTEGRITY BREWERS have been designed with adjustment flexibility to cover a wide

spectrum of customer needs. Adjustments on the running thermostat and inlet

timer are simple adjustments easily accomplished by the purchaser, but

NOT COVERED UNDER ANY WARRANTY SERVICE AGGREEMENT

Brewers must be installed in accordance with installation instructions in the owner's manual for the

warranty to be valid.

WARNING:

DO NOT PLUG IN OR ENERGIZE THIS UNIT

UNTIL INSTALLATION INSTRUCTIONS ARE

READ AND FOLLOWED.

Page 2

Page 3

INTRODUCTION

MODEL 8702 SATELLITE COFFEE BREWER

WITH HOT WATER FAUCET, manufactured by

Bloomfield Industries, is designed to brew a

satellite of coffee at the press of a switch and to

hold 1 1/4 gallons of hot beverage at the correct

temperature for ser ving.

• Satellites are electrically heated —may be

"plugged into" the brewer to keep coffee at the

correct temperature for serving.

• Satellites may be moved and plugged into any

standard wall receptacle so fresh brewed coffee

may be kept hot and dispensed locally.

• Operates on 30 Amps, 5800 Watts, 115/230 or

120/208 Volts, 50/60 hz., single phase three (3)

wire service.

• Requires a water flow rate of one (1) gallon per

minute at a minimum pressure of 20 PSI.

• Brews 212 oz. of coffee in approximately 7

minutes.

• Is all Stainless Steel Construction.

• "Energy Saver" Tank Heater on/off switch

conserves energy.

• Hot Water Faucet on the front of the brewer

provides hot water for hot beverages at anytime

without affecting the coffee brew volume.

• "Ready to Brew" light to indicate proper water

temperature to insure uniform quality of brewed

coffee.

• Exclusive "Water Spray Disc" with 12 holes.

Water drips slowly and gently over the coffee

grounds, causing a floating action and complete

saturation of all the coffee grounds.

• Factory pre -set thermostat so brewer is ready for

operation on installation.

• 4-minute Solid State Timer.

• Low watt, density 5500 Watt heating ele ment for

longer life, more efficient operation.

• Teflon color coded wiring, keyed to co lor tabs at

connection points.

WARRANTY

For a period of one (1) year from date of installation, all defective parts on Bloomfield equip ment will

be replaced free of charge, providing parts did not

become defective through acci dent, neglect,

improper installation, mishandling or damage in

transit. The service necessary to replace these

defective parts will also be free of charge, provided

this service is performed by an authorized

BLOOMFIELD service station, wherever authorized

service is available.

BREWER WARRANTY IS VOID IF:

Other than genuine Bloomfield replacement parts

are used.

Brewer is plugged into voltage other than specified

on serial plate.

Tank heating element is energized before water

tank is filled.

Recommended Bloomfield set-up and servicing

procedures are not followed.

SAFETY

Knowledge of proper procedures is essential to the

safe operation of electrically energized equipment.

In accordance with generally accepted product

safety labeling guidelines for potential hazards, the

following f our signal words are used throughout this

manual.

DANGER - Danger is used to indicate the pre sence

of a hazard which will cause severe personal

injury, death, or substantial property damage in the

event the statement is ignored.

WARNING - Warning is used to indicate the

presence of a hazard which can cause severe

personal injury, death, or substantial property

damage in the event the statement is ignored.

Page 3

CAUTION - Caution is used to indicate the

presence of a hazard which will or can cause

minor personal injury or property damage in the

event the statement is ignored.

NOTE — Note is used to notify personnel of in stallation, operation or maintenance informa tion

which is important, but not hazard related.

Page 4

PRE-INSTALLATION INSTRUCTIONS

FOR MODEL 8702 TWIN SATELLITE

BREWING SYSTEM

WARNING:

DO NOT PLUG IN OR ENERGIZE THIS UNIT UNTIL INSTALLATION INSTRUCTIONS ARE READ AND

UNDERSTOOD.

CHECK THE ELECTRIC SOURCE THAT WILL FEED THE UNIT.

1. Check the female power receptacle and the circuit breakers.

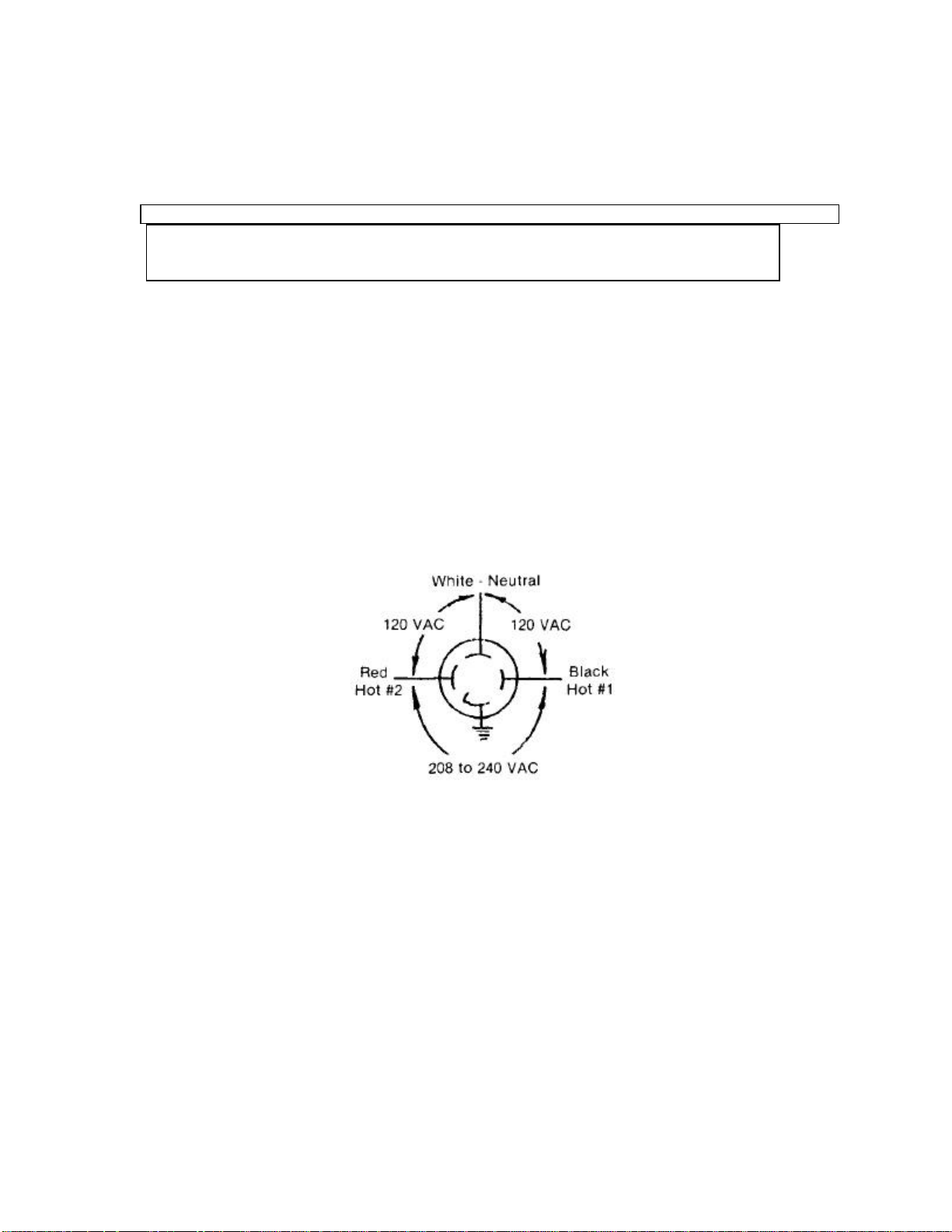

A. The power receptacle must be a 30 AMP, Single Phase, NEMA #L14-30 receptacle wired for 115/230

or 120/208 Volt to match the power requirements shown below.

B. Circuit Breakers in the control cabinet must be of 30 AMP rating.

Source Receptacle

NOW THE UNIT MAY BE SET IN PLACE.

1. Be Sure Tank Heater Switch is "Off."

2. Follow Plumber's Instructions.

3. Follow Electrician's Instructions.

YOU ARE NOW READY TO FILL THE TANK WITH WATER.

1. Follow initial operation instructions.

Page 4

Page 5

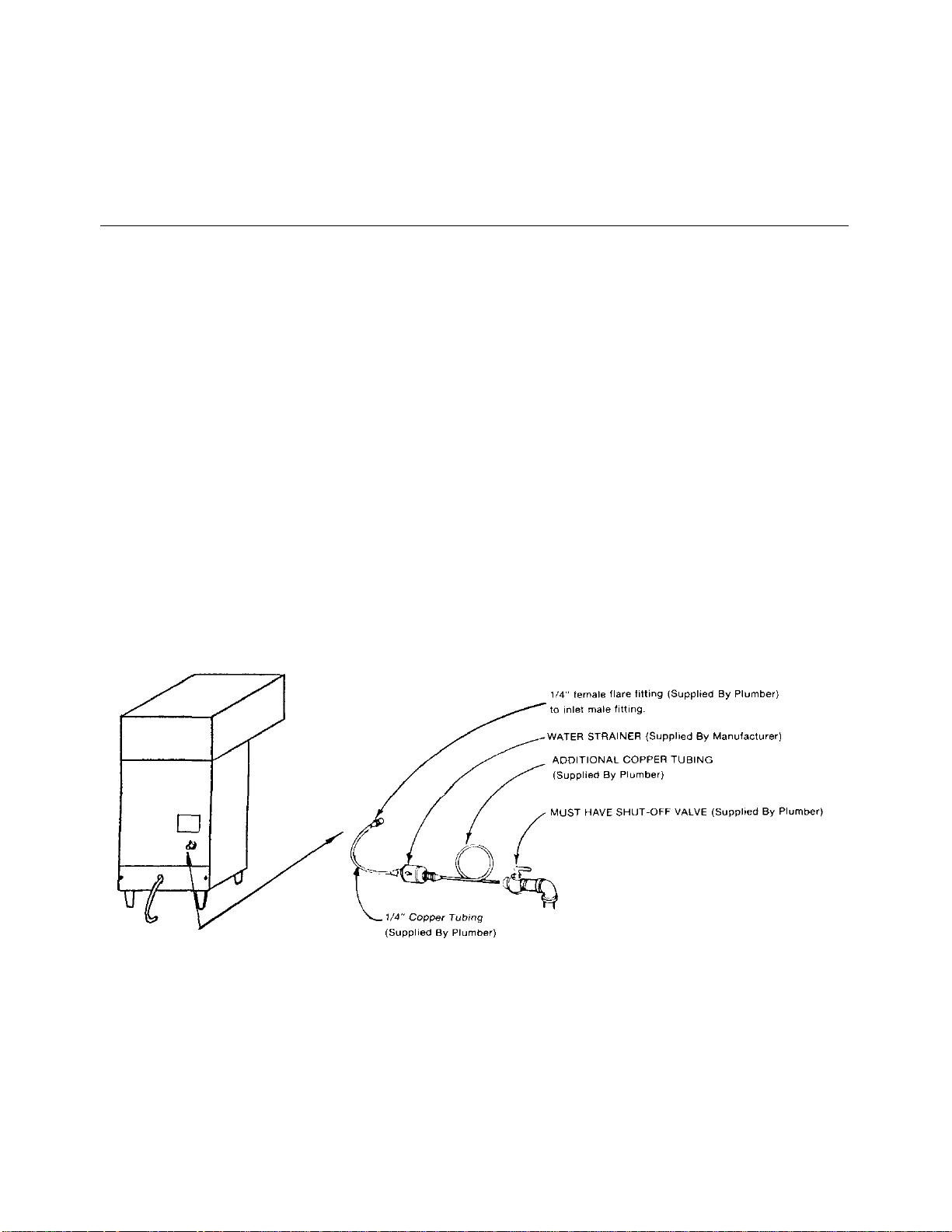

CONNECTING WATER SUPPLY LINE TO UNIT

WARNING:

DO NOT PLUG IN OR ENERGIZE THIS UNIT UNTIL INSTALLATION INSTRUCTIONS ARE READ AND

CAUTION: IF UNIT HAS BEEN CONNECTED TO

1. Flush water line before connecting to Brewer.

2. For less than 25' water run, use 1/4" line. For

3. A water shut-off valve must be installed on the

4. Water pressure should be at least 20 PSI and

UNDERSTOOD.

THE POWER SOURCE, UNPLUG IT

OR TURN OFF POWER AT

SOURCE.

Power to Brewer must be OFF before

proceeding with plumbing in stallation.

Brewer should be connected to COLD WATER

line.

more than 25' use 3/8" line.

incoming water line in a convenient location,

close to the unit.

flow at one gallon per minute.

NOTE: Unit must be installed on a water line with

pressure between 20 PSI and 90 PSI. If water

pressure varies greatly or does not fall into this

range, a pressure regulator should be installed.

NOTE: Line connections to machine must conform

to local codes.

5. Connect the incoming water line coupler

assembly to the 1/4" male end of the water

strainer. Observe arrow direction for water

flow.

6. To delay build up of lime deposits in water tank,

we recommend the use of a Water Conditioner

such as Everpure QC7-MH.

Page 5

The National Sanitation Foundation requests a

provision be made in the incoming water line for

flexibility. This is necessary to allow tilting or moving

the machine for proper cleaning underneath, etc. A

tightly coiled length of copper tubing located on either

side of the water strainer would help comply with this

request.

Page 6

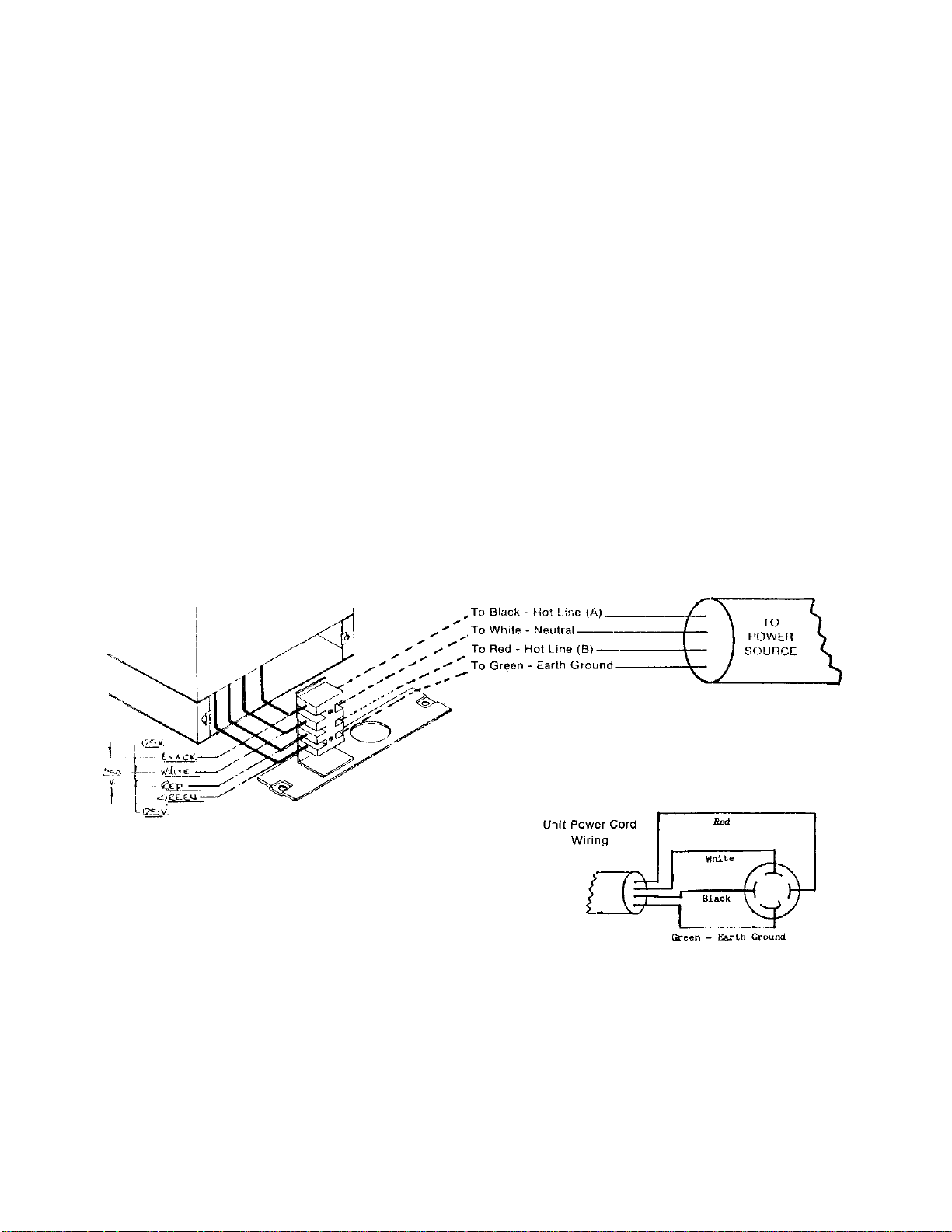

ELECTRICAL INSTALLATION

Electrical requirements: 115/230 (120/208) Volts

A.C. 50/60 hertz, 4 wire with ground, single phase,

30 amp wiring required.

Warranty is void if Brewer is connected to any

voltage other than specified above.

WARNING: Brewer must be properly grounded to

prevent possible shock haz ard. DO

NOT assume a plumbing line will

provide such a ground.

1. Energy Saver Tank Heater Switch on front of

Brewer must remain in OFF position until

plumbing is connected and Brewer is initially

filled with water. The switch must NOT be turned

on until after Step 6 is completed in the initial

operation instruction, See Page 7.

2. Electrical service line cord and NEMA

Plug and receptacle, or equivalent, must be

furnished by installer. Use copper wire on ly of

#10AWG wire size.

3. Plug power cord to power source.

4. After connecting service as specified, test the

voltages on the field wired side with a volt

meter. Do not turn on tank heater switch.

5. If plumbing connection has been made, the

Brewer is now ready for "Initial Operation

Instructions." If plumbing is to be done later, be

sure power is "OFF" and Brewer is not plugged

into outlet.

NOTE: Line connection to machine must conform to

local codes. See Diagram above.

Page 6

Page 7

INITIAL OPERATION INSTRUCTIONS

Electrician's and Plumber's Instructions should be

followed carefully before proceeding with Initial

Operating Instructions.

Be sure all electrical and plumbing connec tions are

tight.

1. Open water inlet valve.

2. Make sure Energy Saver Switch is in OFF

position.

3. Connect electricity.

4. Place empty Satellite in brewing position.

5. Place empty Brew Funnel into brew rails and

turn left or right so that handle is over receiving

Satellite.

NOTE: Handle must be turned all the way to left

or right so Micro Switch is engaged.

6. Press "Brew" Switch. Repeat a second time,

allowing five (5) minutes between cycles. Water

will begin to flow through brew funnel into

Satellite during third cycle.

7. Turn Energy Saver Switch to ON. On initial

warm up, some water may flow into the brew

funnel due to expansion of cold water in the

Tank.

8. Allow 20 minutes for initial water heat up. Time

will vary with incoming water temperature.

9. When correct brewing temperature is reached,

READY LIGHT will come on. Make sure

Satellite is empty. Press Brew Switch and run a

cycle of hot water only. At the end of

this cycle, Brewer will be ready for checking

timer adjustment.

10. Check a cycle of water ONLY to determine

water volume delivery. Appro ximately one (1)

inch down from the top of the Sight Glass

Assembly, on the shield, there are two (2) lines

stamped in the metal. The water should rise in

the Sight Glass, to a level between those lines

to be considered as a full delivery volume.

11. The Solid State Timer is pre-set at the fac tory to

run 146 seconds and allow 224 ounces of water

to flow into the Basin Pan. Timer adjustment is

located behind the 2 inch Plug Button in the

Front Panel in the upper left area. To adjust,

remove snap-in plug and turn dial clockwise to

increase timer cycle and water volume, or

counter-clockwise to decrease timer cycle and

water volume.

12. Replace snap-in plug.

13. The Thermostat is pre-set at the factory for

195°-205°. The Thermostat Adjustment is

located behind the Plug Button in the upper left

section of the Front Panel. To adjust, turn knob

clockwise to increase temperature, or counterclockwise to decrease temperature level of the

water in the tank.

14. Replace plug button.

15. Brewer is ready for use.

16 If water supplied to brewer is softened or

brewed coffee is too strong, see Adjustment

Tools and By -Pass Adjustment.

BREWING OF COFFEE

NOTE: To be sure water brewing temperature is

correct do not start a brewing cycle until

READY LITE is ON.

1. Slide brew chamber from the brew rails and

check to be sure wire rack (brew basket) is in

place in the brew chamber. Proper timing and

brewed coffee flow, through the brew chamber,

cannot occur without it.

2. Place one BLOOMFIELD filter paper into brew

chamber and add a pre -measured package

(standard package is 8. 0 ounces of grounds)

of URN GRIND coffee. Shake brew chamber to

level the filter paper and coffee bed.

3. Make sure satellite is empty before starting a

brewing cycle. Place empty Satellite in brewing

position and plug Satellite Cord into receptacle

inside of unit. Turn ON Satellite Heater Switch.

4. Slide brew chamber into brew rails and turn to

LEFT or RIGHT so micro-switch is engaged by

actuator tab on front of brew chamber.

5. Press BREW SWITCH - this action activates the

timer and water solenoid to automatically

complete a brew.

6. When the brew is finished and coffee flow has

stopped remove the brew chamber and discard

the used coffee grounds and filter paper.

Page 7

Page 8

PARTS IDENTIFICATION LIST

MODEL NO. 8702

REF.

PART NO. DESCRIPTION QTY. FUNCTION

NO.

1 8543- 52 #8 x 3/8 phillips head "B" screw. 2 Fastens top cover.

2 8706- 46 Top cover. 1 Covers basin body.

3 8706- 5 Outlet tube, to faucet. 1 Water faucet line.

4 8706- 4 Formed inlet tube ass'y. 1 Water faucet line.

5 8551- 30 1/4" male flare x 1/8"FPT. connector. 1 Connects water faucet line.

6 8514- 26 Needle valve. 1 Adjust water flow to faucet.

7 8706- 3 Inlet tube ass'y. 1 Water faucet line.

8 8706- 97 T fitting. 1 Connects water & cushion lines.

9 8706- 24 Straight tube. 1 Main water line connection.

10 8706- 1 Snubber tube assembly. 1 Water line cushion.

11 8706- 23 Snubber inlet tube. 1 Connects water.

12 SA-9052 Strainer. 1 Filters incoming water.

13 8702- 17 Outlet, snap -in. 2 Provides power to satellites.

14 8543- 52 #8 x 3/8 phillips "B" screw. 4 Accepts cover plate.

15 8706- 41 Cover plate, water tank body. 1 Access door.

16 8706- 13 Thermostat. 1 Controls water temperature.

17 9700- 377 Terminal block c ontact. 4 Protects wires.

18 7200- 6X #8-32 x 5/16" Ig. screw. 2 Attaches terminal block.

19 8700- 378 Terminal block end. 1 Protects wires.

20 8710- 10 #7/16-20 x 1/8" brass hex nut. 2 Secures water line.

21 8706- 156 Back cover sub -ass'y- 1 Access to electrics.

22 8942- 92 #8- 32 keps hex nut. 2 4

23 8700- 517 Relay, 120 v. 1 Transmit power.

24 18-126 #1/4-20 hex nut. 2 Fastens relay bracket & fastens locator bar.

25 8706- 166 Relay mounting bracket. 1 Accepts relay.

26 8705- 37 #8- 32 x 5/8" Ig. screw. 2 Accepts relay.

27 8706- 22 Locator bar. 1 Positions satellites.

28 8706- 64 #1/4-20 x 1" Ig. screw. 2 Fastens locator bar.

29 7200- 6X #8-32x5/16" Ig. screw. 4 Fastens basin body.

30 3543- 23 Tinnerman nut. 2 To accept top cover screw.

31 8941- 20 Adaptor fitting. 2 Connects water line for brewing.

32 8881- 8 Washer. 2 Accepts gasket.

33 8043- 30 Gasket. 3 Prevents leakage.

34 8873- 12 Male elbow 1/4" pipe x 1/4" male flare. 1 Connects water brewing line.

35 8706- 57 Basin pan sub-ass'y. 1 Holds water for brewing.

36 8706- 65 #6- 32 x 7/8" Ig. screw. 4 Holds micro switch.

37 8706- 19 Switch, micro. 2 Insures brew funnel placement.

Fastens relay & fuse holder to body. Fastens basin

Page 8

Page 9

REF.

PART NO. DESCRIPTION

NO.

38A 8875-68 Fuse holder 1 Holds fuse.

38B 8875-C9 Fuse—15 Amp. 1 Electric line protection.

39 8861-16 #6-32 Keps hex nut. 4 To accept a screw.

40 8704-5 Basin sub -assembly. 1 Houses components.

41 8706-186 Pilot tight assembly. 1 Shows water is ready for brewing.

42 8551-100C Hex lock nut. 1 To accept faucet.

43 8551-100B 7/16" External tooth lock washer. 1 To accept faucet.

44 8551-100A Washer. 1 To accept faucet.

45 8706-169 Faucet assembly. 1 Dispenses hot water.

45A 8706-169A Faucet spout ass'y. 1 Connects to faucet.

46 8706-28 Switch, brew. 2 Starts brew cycle.

47 8707-34 Switch, 120 v. 1 Energizes tank heater.

48 8706-17 Timer, includes knob, faceplate & screws. 1 Controls coffee timing.

49 3-100 #6-32 x 1/4" Ig. screw. 2 Holds thermostat.

50 8706-96 Thermostat knob. 1 Adjust thermostat.

51 8706-21 Water inlet tube. 1 Water line for brewing.

52 8706-76 Plug button 1- 1/8". 1 Access to thermostat adjustment.

53 8706-75 Plug button 2". 1 Access to timer adjustment.

54 8700-591 Leg. 4 Elevates unit.

55 8541-48a Elbow. 1 Water line for brewing.

56 8551-35 "T" coil inlet fitting. 1 Transfers water.

57 8706-102 Reducer, adapter. 1 Path of water.

58 8541-120 Solenoid valve 120 v. 1 Turns water on & off, flow control.

58A 8541. 122 Screw, 10 -32 x 1/2" Pn. Hd. 2 Secures solenoid valve.

59 8706-9 Wire rack, brew chamber. 1 Holds filter paper.

60A 8706-107 Brew funnel, cup only. 1 Holds coffee grounds, and directs brew to satellite tank.

60S 8706-60 Brew funnel complete with wire rack & handle. 1 Promotes brewing.

61 8707. 3 Screw. 1 Fastens handle to brew funnel.

62 8707-2 Handle, brew funnel. 1 Lifting and turning brew funnel.

63 8706-54 Front cover sub-assembly. 1 Covers internal components.

64 18- 302 #8-32 hex cap nut. 2 Accepts hold strap.

65 8043-47 #10- 32 x 1 " Ig. screw. 1 Seals tank cover.

66 8043-5 Hold down strap. 1 Holds tank cover on.

67 8512-41 Seal washer. 3 Seals thermostat, water coil.

68 8043-28 1/2-20 hex nut. 2 Fastens heating element.

69 8514-68 Tank cover sub-assembly. 1 Seals tank.

70 8043-12 Tank cover gasket. 1 Seals cover to hot water tank.

71 8706-8 Hot water coil assembly. 1 Transports water.

72 8535-2 Heating element 5500 w., 230 v. 1 Heats water.

73 8706-20 Vent tube. 1 Air Vent.

74 8706-6 Inlet elbow. 1 Water tine from tank to pan.

QTY. FUNCTION

Page 9

Page 10

REF.

ACCESSORY AND IT

EMS NOT SHOWN

8702-18

Label, for 65 Watt Outlet

NO.

75 8043-83 Hi-limit thermostat. 1 Prevents over heating.

76 8043-11 Outlet elbow. 1 Water line from tank to sprayer disc.

77 8706-25 "T" by-pass flow tube. 1 Path of water.

78 8706-188 Tubing connector. 1 Path of water.

79 8942-33 Gasket. 2 Seals water coil.

80 8551-53 7/16" I. D. x 3/4" O. D. 2 Seals water coil.

81 8706-111 Nylon screw (by -pass). 1 Adjust water flow.

82 8706-26 By-pass valve body. 1 Path of by-pass water.

83 8043-13 Spray elbow. 1 Water outlet to sprayer disc.

84 8543-42 Spray head gasket. 1 Seals sprayer disc.

85 8543-44 Sprayer disc. 1 Control spray pattern into coffee.

86 8543-74 #4-40 hex nut. 1 Accepts screw.

87 8543-73 #4-40 x 1-1/2" Ig. screw. 1 Fastens water tube-

88 8706-68 Water inlet tube. 1 Deposits cold water at bottom of hot water tank.

89 8706-49 Water tank assembly. 1 Holds water.

90 6541-39 #1/4-20 x 3/4" Ig. screw. 2 Fastens front cover panel to body.

91 8543-69 Heyco bushing. 3 Protects wires.

PART NO. DESCRIPTION QTY. FUNCTION

8704-1

8704-2

8704-3

8705-44

8706-205

8706-110

Label, Front

Label, Front Right Side

Label, Front Left Side

Faucet Shield

By-Pass Set Kit

Filter Papers -Box of 500.

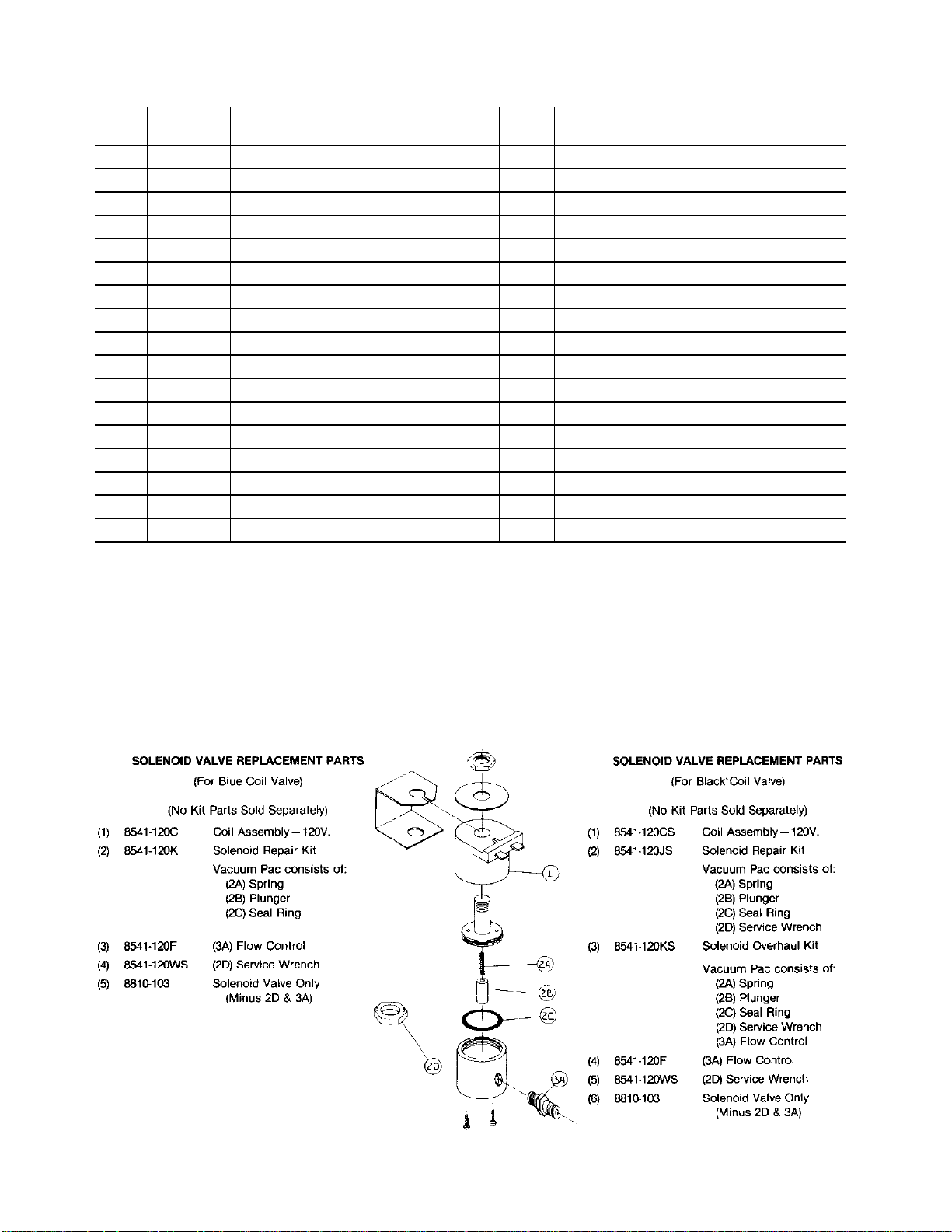

REF. #58 COLD WATER ENTRANCE SOLENOID VALVE PART NO. 8541 -120

(Consists of Valve and Flow Control)

Page 10

Page 11

EXPLODED VIEW

MODEL NO. 8702

Page 11

Page 12

REPLACEMENT PARTS LIST

MODEL NO. 8703 SATELLITE

Page 12

Page 13

REPLACEMENT PARTS LIST

2. 8705-21 Satellite Cover Only

3.

8705-4 Handle

-

Rod 4. D20002

-

3 Screw, 10

-

32 5. 8942-92 Hex Nut,

8-32, Keps

6. 8705-37 Screw, 8

-

32 x 5/8

7.

8705-6 Locating Block

8.

8705-7 Locating Block Seal

9.

8705-1 Spacer, Tank Cover Retainer

10. 8705-5 Retainer Spring

12. 35-110 Cord Grip

—

Strain Relief

13. 8596-43 On/Of

f Lighted Switch

14. 8703-8 Satellite Body S/A

15. 8703-3 Heat Sink Plate

17. 8703-26 Retainer

18. 8705-60 Spacer Tube

19. 8703-27 Access Door

20. 8705-45 Foot 21. 8706-64 Screw, 1/4

-

20 x 1 22. 8705-40 Drip Tra

y Cover

23. 8705-41 Drip Tray Body

24. 8705-22 Satellite Tank Assembly

25. 8705-26 Seal Drain Fitting

26. 8705-33 0 Ring

—

Tank Top Seal

27. 18-126 Hex Nut

-

1/4-20

8706-110 Box of 500 Filter Papers

8706-205 By-Pass Set Kit

2. 8700-25J Upper Washer

for Sight Glass 1/8" Standard

8700-25K Upper Washer for Sight Glass 1/16' Special

3.

8600-20 Shield

-

10" x 3/4" O.

D. - Aluminum

4.

8705-11C Sight Glass

-

10 x 5/8 O.

D. - Polysulpnone

5.

8705-11B Lower Sight Glass Washer

-

w/ 1/16" Hole

8700-25H Lower Sight Glass Washer

-

w/5/16" Hole

6.

8705-11G Shield Base

7.

8705-11D Shank Assembly w/Wing Nut

8.

9.

8705-11L Upper Assembly

—

Black Bonnet

10. 8700-25L Seat Cup

11. 8705-11K Washer for Clean Out C

ap 12. 8705-11J Clean Out Cap with Washer

MODEL NO. 8703 SATELLITE

REF. NO. PART NO.

1. 8705- 18 Cap Sub-Assembly

DESCRIPTION

11.

16.

28. 8705- 11 Faucet and Sightglass Assembly

8703- 11

8703- 25

8705- 44 Faucet Shield

Cord and Cap Assembly

Heating Element, 60 Watt

ACCESSORY AND ITEMS NOT SHOWN

REPLACEMENT PARTS LIST

FOR FAUCET ASSEMBLY ONLY - PART NO. 8705-11

REFERENCE NO. 28 ABOVE

REF. NO. PART NO. DESCRIPTION

1.

8600-17

Shield Cap

8705-11F

Faucet only w/o Shank & Sight Glass

Page 13

Page 14

HOT WATER FAUCET

PART

Page

14

REPLACEMENT PARTS LIST

REF. NO. PART NO. DESCRIPTION

1. 8551-275 Repair Kit (sold as Kit only)

A.

B.

C. " Valve Disc

D. Kit "0" Ring - #6, #7 & #8

E. Contains Tee Nut

F. J L

G.

H.

A. 8706. 1698 Faucet Handle, Red

2. 8551. 275B Stream Straightener

3. 8551. 100A Washer Rubber

4. 8551. 100B 7/16 External Tooth Lock

5. 8551. 100C Hex Lock Nut

SEALS AVAILABLE

6. 8551-200B "0" Ring Stem Seal 5/16" O. D

7. 8551-200A "0" Ring Seal 1/4" O. D.

8. 8551-200C "0" Ring Spout Seal 3/8" O. D.

C. 8551. 275A Valve Disc

TOOL AVAILABLE

9. 8551. 200E Adaptor Tool - Service

10. 8706-169A Flexible Spout

Handle (Color -Red)

Valve —Stem

Spring

Guide

Bushing

Insulation Card (Not Shown)

(Not Shown)

Washer

Wrench

WATER FLOW DIAGRAM

Sequence of Operations:

WATER FLOW FOR BREWING OPERATION

1. Pushing brew Start Switch energizes the Timer. The Timer

then energizes the Solenoid Valve, allowing water to flow

into the Basin Pan and then into the Hot Water Tank. The

length of time the Solenoid Valve is energized is controlled

by the Timer setting.

2. The water entering the Hot Water Tank from the Basin Pan,

flows to the bottom of the Tank through the Water Inlet

Tube.

3. The addition of water into the bottom of the Hot Water Tank

causes the hot water at the top of the Tank to flow out

through the Outlet Elbow of the Tank Cover, to the Spray

Head.

(Both Brewing Sections)

PART II

Sequence of Operations:

WATER FLOW FOR FAUCET OPERATION

(Faucet Section O niy)

1. The incoming cold water supply connects to a "T" Inlet

Fitting on the Unit. Water flows from the "T" Inlet

Fitting through the Inlet Tube, Needle Valve and

Formed Inlet Tube into the input connection of the

Water Coil.

2. The Water Coil is submerged in the Hot Water Tank

and draws heat from the surrounding hot water.

Water flowing into the Water Coil is then heated and

flows out through the Formed Outlet Tube to the

Faucet. (The water flowing through the Water Coil,

which feeds the Faucet is not controlled by the

Solenoid Valve. This portion of the system is always

under pressure and is con trolled by the Faucet.

Opening the Faucet allows the water to flow through

the Water Coil system.)

3. The Needle Valve, in the system, controls the

volume of flow from the Faucet and is adjusted to

allow a gentle stream of water to be dispensed

through the Faucet, without splashing into the

cup. (The Faucet is intended as a cup to cup hot

water supply.)

NOTE: Drawing hot water from the Faucet,

during a Brewing Cycle DOES NOT affect the

volume of the finished brew.

Page 15

EQUIPMENT SET-UP AND CLOSE PROCEDURES

Daily Start Up Procedure

3. Rinse brew funnel and satellites thoroughly.

1. Turn tank heater switch ON.

2. Wait for "Ready to Brew" light to come on.

(Approximately 10 minutes.)

3. Brewer is now ready for use.

Daily Close Down Procedures

1. Turn tank heater swit ch OFF.

2. Pour out any left over coffee in satellites and

clean inside of satellites and brew fun nel

with a solution of Sanitizer.

Do Not Immerse Satellite in Water.

TROUBLESHOOTING

It is very imp ortant when servicing equipment to:

1. Define the basic Problem.

4. Wash spray disc in sanitizer solution; rinse

thoroughly, and replace.

5. Use a damp cloth and clean the entire brew head

area to remove any accumulated coffee

residue.

NOTE: DO NOT USE ABRASIVE CLEANERS THAT

MAY DAMAGE THE EXTERIOR FINISH OF THE

BREWER.

Should the problem remain after exhausting the

troubleshooting steps suggested, refer to the

Order/Service Information section of this Manual.

2. Isolate the Probable Cause.

3. Take Corrective Action, regarding those items

hampering proper operation of the equipment.

It is usually relatively easy to define the basic

problem, but sometimes very difficult to pin point the

precise cause.

A Trouble-shooting Guide is provided in this

Manual to suggest probable causes and corrective

actions for each. Obviously, if the cause is not

isolated and corrected, proper operation of the

equipment cannot be restored.

Warning: Inspection, testing and repair of electrical

equipment should be performed only by qualified

service personnel. The brewer should be

unplugged when servicing, except when electrical

tests are required.

Danger: Use extreme care during electric circuit

tests. Live circuits will be exposed.

Page 15

Page 16

PROBLEM

clean screen filter or replace

A. No water from the Spray Disc.

(Brew Switch is activated.)

TROUBLE SHOOTING GUIDE

PROBABLE CAUSE

A. 1. No Water

A. 2. No Power Check line fuse or circuit breaker. If OFF, turn ON, or replace fuse.

A. 3. Loose Wire or Connection Remove unit top cover and Body Column Front Cover.

A. 4. Screen Filter and QC7-MH Screen filter or QC7-MH may be plugged—

A. 5. Start Switch

A. 6. Timer

A. 7. Solenoid Valve Check Solenoid Valve for continuity at the terminals of the Solenoid

CORRECTIVE ACTION

Push brew funnel totally to the left or right to activate the micro-switch.

Be sure water shut-off valves are open. Check continuity of microswitch, if switch does not make and break contact, replace microswitch. See micro-switch replacement, non -scheduled maintenance.

Make certain unit is alone on its own electrical lines.

If fuses or circuit breaker continue to "open," call Qualified

Serviceman.

Check all wires and connections, be certain none are loose or

disconnected.

Repair loose connections, and/or wires and reattach.

QC7-MH.

Check switch continuity. If switch does not make and break contact,

replace Start Switch. See Start Switch replacement — non-scheduled

maintenance.

When start button is pressed, the timer should acti vate. The timer

should continue to operate until the cycle is completed. If it does not,

replace the timer.

Valve Coil. If no continuity, replace either the Solenoid Coil or the

Complete Solenoid Valve.

B. Too much water or too little

water, satellite short or

overflows.

A. 8. Water Supply Tubing (from

Solenoid to Basin.)

B. 1. QC7 Filter is clogged.

B. 2. Timer needs adjustment. Turn Timer Adjustment clockwise to increase the water or

B. 3. Flow Restrictor in output end of

Water Solenoid Valve (dirty, missing,

damaged or inoperative)

Check for twist or "kink" in water supply tubing, blocking water flow into

basin pan.

Replace QC7 cartridge.

counterclockwise to reduce the water.

Clean or replace flow restricter or replace the Water Solenoid Valve.

Clean or replace the flow Restrictor or the complete solenoid.

Page 16

Check timer cycle several times with a stopwatch. If times are

irregular replace the timer.

Particles in the water solenoid valve may partially clog the orifice of

the flow restrictor.

Page 17

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

B. Too much water or B. 4. All Automatic Brewers require a constant water pres

too little water, Water Pressure sure between 20 PSI and 85 PSI for consistent, troublesatellite short or Variations free operation.

overflows.

(Continued) (Water pressure rises Wide swinging water pressures lead to erratic delivery.

above 85 PSI or falls A pressure regulator may be needed to stabilize high

below 20 PSI) running pressures.

A water source that falls below 20 PSI may result in

short pots or erratic volume delivery.

C. Water keeps run C. 1. Check and clean inside of the water solenoid valve,

ning into Fill Basin. Water Solenoid Valve and plunger.

(Will not shut off (Plunger stuck open)

with Power Plug

pulled.)

Check inside surface of water solenoid port, if it is

scored, chipped or damaged, replace the water sole

noid valve.

(Shuts off when C. 1A. Check with switch continuity, replace if defective.

Power Plug is Start Switch

pulled.)

C. 2A. Timer is defective, will not cycle to "OFF" condition.

Timer Replace timer.

D. Water fails to heat D.. 1 Check if power cord is plugged into wall outlet.

and brewer does No Power to Unit

not work.

(Water from the

faucet is cold.)

Check line fuse or circuit breaker— if off, turn it on or

replace.

If circuit continues to be open, call a Qualified Service

man.

Defective cord or plug —repair or replace.

Loose wires—remove front and top panels and check

for loose connections, screws or terminals. Tighten

screws, repair or replace terminals.

E. Water fails to heat, Unit has power, the

but brewer does failure is due to:

operate. E. 1. Switch in off position—turn on.

Heater Switch Defective switch, replace switch.

(Water from the

faucet is cold.) E. 2. Check for loose wire or connection. Repair or

Tank Heater reconnect.

Check for proper voltage at Tank Heater Terminals.

If voltage is present, element is defective, replace ele

ment.

E. 3. Check for a loose wire or connection. Repair and/or

High Limit Safety Control reconnect.

Disconnect wires and check for continuity on both ter

minals of the High Limit Safety Control.

If continuity is present, the control is functioning prop

erly, if not, replace Hi limit.

E. 4. Check for loose wire or connection feeding into Ther-

Thermostat stat.

If READY light is ON turn the thermostat adjusting

(READY Light ON is a shaft clockwise to the full ON position.

guide.) If READY light goes out, water should begin to heat-

adjust to proper water temperature.

If READY light stays ON, replace the Thermostat.

Page 17

Page 18

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

voltage condition exits, an electrician should be consulted. A low voltage

F. READY light fails to glow

when water reaches brew

temperature.

F. 1. READY light is defective. If thermostat cycles on and off and READY Iight does not glow, replace

READY light.

G. Water heats, but is not hot

enough.

H. Water heats, but longer than

12 minutes. (Slow recover)

I. Water temperature too hot.

ALSO CALLED: • STEAMING •

BOILING • HEAT NEVER

SHUTS OFF

G. 1. Thermostat adjustment. If water from the water outlet tube (with spray disc re-

moved) is less than 195°F., and thermostat cycles the Tank Heater OFF,

adjust the Thermostat to a higher setting. 1/4 turn equate approximately

18°F (10°C) temperature change. To increase the tank temperature, turn

the adjustment shaft in a clockwise direction.

G. 2. Thermostat defective. If adjusting Thermostat to a higher setting does not correct the problem,

G. 3. High Limit Safety Control

(READY light does not come on.)

H. 1. High Lime Deposits Delime unit.

H. 2. Low voltage at source. Check voltage. 11 should be within 110% of unit rating plate, if a tow

H-3. Low voltage at Tank Heater. Voltage Rating and Power Source must be the same. Cneck wiring

1. 1. Thermostat Thermostat out of calibration or defective. Adjust or replace. it.

the thermostat is defective, replace it.

High Limit Safety Control is defective. Replace it.

condition. can and does cause frequent service calls, as well as extending water heating time.

diagram and name plate.

J. Dry coffee remain ing in the

brew fun nel after a brew has

been completed.

K. Coffee Grounds do not get

wet — water stays in the basin.

Coffee Grounds do not get wet

— water leaks out of the bottom

of the unit.

J. I. Spray Disc missing The Spray Disc must be in place to break up the water stream.

J-2. Filter Paper Use

J. 3. Improper loading of the Brew

funnel.

K. 1. No syphon action. Check elbow connection from basin to tank, it may be twisted and not

K. 2. Leak in Water Path from basin

to final outlet.

Filter should be centered in the brew funnel and the coffee bed should

toe! level.

open to water flow.

Check for correct fit and at: A. Elbow from. basin to tank cover. B. Tank

Cover Gasket. C. Output eitelbowand tube assembly.

Page 18

Page 19

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

L. Weak Coffee

L. 1. Too much water. Verify water level on sight glass. Adjust timer if necessary.

L. 2. Water temperature too low. Adjust thermostat to a higher setting.

M. Strong Coffee

N. Brew Time exceeds 8

minutes for full satellite.

L. 3. Improper loading of brew

funnel.

L. 4. Not enough coffee in brew

funnel.

M. 1. Not enough water. Verify water level on sight glass. Adjust timer if necessary.

M. 2. Too much coffee in brew

funnel.

M. 3. Two (2) Filter Papers or

improper filter paper used.

M. 4. Coffee being drawn d uring a

brew cycle.

M. S. By- Pass Valve improperly set

or unit connected to softened water

source.

N. 1. Water Supply has been

softened.

Filter paper must be centered in brew funnel. Coffee bed must be level

when starting a brew cycle.

Verify package weight.

Verify package weight.

Use only one (1) recommended Filter Paper. Improper Filter Paper can

restrict water flow.

At beginning of a brew cycle coffee is very strong, you must wait until

cycle is completed before drawing to serve.

Insufficient water being by-passed or unit is brewing with softened

water—see adjustment section of manual.

Brewer was shipped with soft water valve set of 25%. If soft water

conditions exist valve must be opened slightly. See Non- Scheduled

Maintenance.

N. 2. Use of two (2) Filter Papers or

improper Paper Filters.

Use only one (1) recommended Filter Paper. Two (2) Paper Filters or the

use of foreign papers can cause brew chamber run-over.

Page 19

Page 20

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

0. 1. Incoming water source shut- off. Check and turn ON the water source valves. 0. No Water from water faucet.

0. 2. "T" Valve (Between Water

Solenoid and water tank.)

P. Faucet keeps dripping. P. 1. Foreign matter inside the

valve, holding the valve seat from

closing completely.

Q. Overflowing Satellite. Q. 1. Receiving Satellite not empty

when a b rew cycle is started.

R. Satellite does not keep coffee

hot.

R. 1. Not plugged into power source. Plug Power Cord into electric source.

R. 2. Switch not turned on. Turn on Satellite Power Switch.

The "T" Valve must be open to permit water flow from the faucet.

It may be partially closed to control the force of the water stream

from the faucet.

Shut off water, disassemble and clean the faucet seat. If faucet still leaks

or drips, install a complete repair kit (part #8551-275). If faucet continues

to drip, the seat has been damaged, replace the faucet assembly.

Always start with an empty receiving Satellite when a brew is started.

R. 3. Switch defective. Check switch, if it does not make and break continuity change switch.

R. 4. Loose or disconnected wire. Reconnect loose wire or replace loose connector.

R. 5. Heating element electrically

"open."

Check heating element for continuity. If "open" replace element.

Page 20

Page 21

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

when making level adjustments. Level the unit from left to right and front

S. Satellite Faucet keeps

dripping. (Dripping and/or bitter

taste.)

S. 1. Seat cup clogged with residue. The faucet seat cup should be removed and freed of all coffee oils and

residue. It must seat properly on the faucet opening. The seat cup

should be kept clean to prevent build-up of oils that may turn rancid and

result in bitter taste to the coffee.

T. Water drips from basin head

unit.

T. 1. Unit not level. Level the unit. For proper unit operation, it is very im portant that the unit

be level when it is standing in its proper operating position. A spirit level

should be placed on the top plate of the unit, at the edge, as a guide

to back by turning the ad justable feet that support the unit.

Page 22

SERVICE INSTRUCTIONS DETAILED ILLUSTRATIONS

MODEL 8702 SATELLITE COFFEE BREWER

NON. SCHEDULED MAINTENANCE

Under normal conditions and with proper use and

care, very little non-scheduled maintenance will be

required for this coffee brewer. However, this

section provides procedures for removal and

replacement of various major components used in

the brewer in the event that servicing becomes

necessary. Before replacing any component, refer

to the Trouble -shooting Section for assistance in

determining the cause of any problem and to verify

that removal is required.

Recommended Tools

1-Flat Head 1/4" Blade Screwdriver

1—Phillips Head Screwdriver

1 —9" Adjustable Wrench

1 —6" Adjustable Wrench

1—Thermometer/Digital Pyrometer

1 —Voltmeter

1 —Continuity Tester

Component Access

All components are accessible by the removal of

two (2) panels. The top panel provides access to

the Tank Lid Assembly which includes the Heating

Element and Water Coil; Tank Body, Switches,

Ready to Brew Light, Faucet and Needle Valve

(#6).

The front panel provides access to the Solid State

Timer and the Solenoid Valve.

The screen filter/strainer (#12), is located in the

rear, outside the brewer.

CAUTION: Always disconnect brewer electric

sources before servicing.

To remove front panel for service, remove two (2)

screws located under front of brewer.

To remove top plate for service, remove two (2)

screws and lift up.

Thermostat Replacement

WARNING: Turn off Tank Heater Switch and un-

plug the brewer before removal of any panel or

replacement of any component.

1. Remove front panel and top cover.

2. Loosen the two (2) screws (#49) fastening the

thermostat body to the bracket.

3. Remove wires to thermostat (#16).

4. Remove the thermostat bulb by loosening hold

down nut and pull up firmly.

5. Lift thermostat and probe from brewer.

6. Install new thermostat in reverse order, steps 2-

5.

Page 22

Page 23

7. Place empty brew funnel into the funnel rails

and place an empty satellite in position.

3. Disconnect wires from all fittings on Tank Lid

(#69).

8. Plug in brewer.

9. Press Brew Switch. If Tank is full of water, the

water will flow from the spray disc through the

funnel and into the satellite. If the tank is not full

it may be necessary to repeat this operation

one more time to fill the Tank with water.

10. Turn on Tank Heater Switch.

11. Check temperature calibration.

12. When thermostat is calibrated, unplug brewer

and replace top cover panel and front panel.

(49) (16)

Heating Element Replacement

4. Lift out Tan k Lid with all components attached.

5. Remove two (2) hex nuts securing Heating

Element to Tank Lid and remove Element.

6. Install new Heating Element to Tank Lid.

7. Return Tank Lid Assembly to tank and re connect,

reversing steps 1 - 4.

8. Place empty brew funnel into the funnel rails and

set an empty satellite in place.

9. Plug in brewer and turn on water.

10. Press Brew Switch. If Tank is full of water, the

water will flow from the spray disc through the

funnel and into the satellite. If the tank is not full

it may be necessary to repeat this operation one

more time to fill the Tank with water.

11. When the water flow from the funnel stops,

unplug brewer and replace top cover.

12. Turn on Tank Heater Switch.

WARNING: Turn off the water and the Tank Heater

Switch and unplug brewer before removal of any

panel or replacement of any com ponent.

1. Remove the two (2) screws in the rear cor ners

of the top panel. Slide panel back and up to

remove.

2. Remove Thermostat (#16) Seal Nut, located on

tank cover and gently lift out the thermostat

sensing tube and bulb from the fitting.

Disconnect Outlet Tube (#77) from Outlet Elbow

(#76). Remove Inlet Elbow (#74) and Vent Tube

(#73) from Water Basin Pan (#35). Lift basin

pan from brewer. Unscrew Hold Down Strap

(#66) and slide free. Disconnect Water Lines

(#3 and #4) at flare fittings on tank lid.

Timer Replacement

WARNING: Turn off Tank Heater Switch and unplug

the brewer before removal of any panel or

replacement of any component.

1. Remove two (2) Front Panel Mounting Screws.

2. Remove Front Panel.

3. Remove all wires connected to Timer (#48

4. Unscrew Timer from the Mounting Bracket.

Page 23

Page 24

5. Remove Timer from the brewer.

6. Fasten new timer to the Mounting Bracket.

7. Reinstall wires to Brew Solenoid Valve and

Wiring Harness (follow color codes).

8. Reinstall Front Panel, reversing steps 1-2.

9. Plug in Brewer and turn on Heater Switch.

10. Check and adjust water volume.

Solenoid Valve/Flow Restrictor Replacement

WARNING: Turn off the Tank Heater Switch and

unplug Brewer before removal of any panel or

replacement of any component.

1. Shut off water supply to the Brewer.

2. Remove two (2) Front Panel Mounting Screws.

3. Remove Front Panel.

4. Remove the wires to the Solenoid Valve (#58).

5. Remove the Hex Nut at the outside rear in let

port.

6. Remove flare fitting from the tee inlet.

7. Remove Solenoid from brewer.

To replace Flow Restrictor:

1. Use two (2) wrenches, remove Outlet Fit tings

from outlet side of Solenoid Valve. Restrictor

is located inside the 5/8" fitting. Replace the

complete Restrictor Fit ting Assembly.

2. Replace Restrictor into Outlet Elbow, use

pipe thread tape around threads to pre vent

leaks.

Hi-Limit Safety Control Replacement

WARNING: Turn off T ank Heater Switch and un-

plug the brewer before removal of any panel or

replacement of any component.

1. Remove two (2) screws and top cover.

2. Remove the wires from the Hi-Limit Safety

Control (#75).

3. Lift the Retaining Spring to remove the Hi-Limit

Safety Control.

4. Replace the new Hi -Limit Safety Control by

sliding it into place under the Retaining Spring.

5. Reinstall the two wires to the Hi -Limit Safety

Control.

6. Make sure that Hi-Limit Safety Control is

securely mounted and that all electrical

connections are tight.

7. Plug in Brewer and turn on Tank Heater Switch.

3. Replace the Assembly into the Solenoid after

wrapping the threads with pipe tape. Do not

use liquid or paste pipe seals, as they tend to

creep into the Sole noid and will result in

improper opera tion.

8. Install new Solenoid, reversing order of Steps 1-

6.

9. Plug in Brewer and turn on Tank heater Switch.

Page 24

Page 25

Switches and "Ready to Brew" Light

Page 25

WARNING: Turn off the Tank Heater Switch and

unplug brewer before removal of any panel or

replacement of any component.

Whenever switch replacement becomes necessary,

proceed as follows:

1. Remove two screws from top cover.

2. Lift off cover.

3. Lift Water Basin to reveal switches and lights.

4. The switches (#47, #46) and the "Ready to

Brew" Light (#41) are removable through the

front of the Brewer. Compress the spring clip

located on the inside of the Brewer and push

forward.

5. Remove wires from the old switch and con nect

them to the new switch or light. Follow color

code on wire to color code on switch or light.

6. Re-insert switches and replace top reversing

steps 1-4.

7. Plug Brewer into electric outlet.

4. Remove wires from defective switch.

5. Remove screws holding switch in place.

6. Replace Micro-Switch reversing Steps 1-5.

7. Plug Brewer into electric outlet and turn on Tank

Heater Swi tch.

HEATED SATELLITE Service and

Part Replacement

Micro-Switch Replacement

WARNING: Turn off the Tank Heater Switch and

unplug brewer before removal of panel or

replacement of any component.

Whenever Micro -Switch replacement becomes

necessary, proceed as follows:

1. Remove two screws from top cover.

2. Lift off cover.

3. Lift Water Basin to reveal Micro-Switches (#37).

WARNING: Prior to doing any service work on a

heated Satellite be sure the Satellite is completely

empty of fluid and to disconnect the Satellite Power

Cord from the power source receptacle.

1. Turn the Satellite to a position where the

bottom access plate can be removed. See

exploded view of the Satellite.

A. Turn each of the four (4) feet (#20) counter -

clockwise until loose and set them aside.

B. Remove the large slotted head screw (#21)

located in the center of the bottom access

plate (#19) and remove the access plate.

2. The heating element (#16) and the power cord

(#11) may be tested and/or replaced through

this access opening without disassembling the

unit any further.

3. The On/Off power switch (#13) also can be

tested for make and break of continuity, when

the switch is activated to each position. If it

does not make and break the circuit, replace it.

A. The switch may be removed through the front

of the cabinet by depressing the plastic clips

on the switch from inside the cabinet and

pushing the switch out the front.

Page 26

B. Remove the wires from the original switch

and place them in the same position on the

replacement switch.

C. Depress the plastic mounting clips on the

switch and push the switch wires through and

into position in the cabinet hole.

4. The Satellite Reservoir Tank (#24) may be

removed or replaced, in the following order.

A. Remove the faucet assembly (#28) from the

Satellite.

B. Remove the bottom access plate (#19) see

step #1 above.

C. Disconnect wire connections at the heater

element (#16) terminals.

D. Lift the reservoir tank (#24) out of the top of

the Satellite Body.

E. Reassemble in reverse order—steps 4D

through 4A.

NOTE: The faucet assembly periodically MUST be

disassembled and thoroughly cleaned of coffee oil

and residues. If this is not done com -plaints of

strong, bitter coffee may result.

To properly clean the faucet use a solution of urn

cleaner and a brush.

1. Remove sight tube cap (#1) and lift out the

polysulphone sight tube. Use care not to lose

the lower sight tube washer (#5) if it comes out

with the tube.

2. Remove the lower sight washer (#5).

3. Unscrew the faucet bonnet assembly (#19) and

lift it from the faucet body.

4. Remove the seat cup (#10) from the faucet

bonnet assembly (#9).

5. Remove the clean out cap (#12).

6. Clean all par ts with an urn cleaner solution

including the inside of the satellite reservoir

tank and rinse thoroughly.

7. Reassemble in reverse order—steps 5 through

1.

To Delime Brewer:

WARNING: Turn off the Tank Heater Switch and

unplug brewer before removal of any panel or

replacement of any component.

1. Shut off water to brewer.

2. Remove two (2) screws and top cover.

3. Remove Water Basin.

4. Remove all wires to Tank Lid.

5. Remove all water connections to Tank Lid.

6. Remove hold down strap and lift out Tank Cover

which has heating element, inlet tube and hot

water faucet coil attached.

7. Remove approximately 1 gallon (1/4) of water

from tank and replace with Deliming Agent such

as "Lime Away."

8. Replace Tank Lid Assembly and parts and let

stand for one hour. (It is not necessary to fasten

in place.)

9. Remove Tank Lid Assembly and syphon all

liquid from tank.

10. Reassemble entire unit and connect all

plumbing and electrical connections.

11. Plug in Brewer and turn on water.

NOTE: Heater Switch must be OFF.

12. Place empty Satellite in brewing position.

13. Place empty Brew Funnel in brewing position

over empty Satellite.

14. Press "Brew" Switch. Repeat a second time,

allowing five (5) minutes between cycles. Water

will begin to flow through brew funnel into

Satellite during third cycle.

15. Turn Energy Saver Switch to ON. On initial

warm up, some water may flow into the brew

funnel due to expansion of cold water in the

Tank.

16. Allow 20 minutes for initial water heat up. Time

will vary with incoming water temperature.

17. Run at least 4 cycles of water only before

brewing coffee.

NOTE: The outside stainless steel surface of the

Satellite can be cleaned with urn solution on a

sponge, rinsed clean and wiped dry to maintain its

original stainless beauty.

Do not use abrasive cleaners to polish the outer

Satellite surfaces as they may scratch and mar the

surface.

Page 26

Page 27

IMPORTANT ADJUSTMENT TOOLS

(Do Not Discard Them)

Supplied with this Model#8702 Coffee Brewing

Unit are:

1. Part #8706-200, By -Pass Test Hose Assembly

(used for checking the By -Pass Water volume).

2. Part #8706-202, Flow Set Gauges (used for

setting the By -Pass Water Valve).

The unit leaves the factory with the By-Pass Valve

set at the 25% by-pass volume which is the smaller

of the flow set gauges, however, if the location has:

A. Softened Water:

1. supplied by their community water source or

2. their own water softener, or

B. The finished brew is too strong:

1. the correct amount of coffee grounds is

used, approximately 8 to 10 ounces and,

2. the correct volume (224 ounces) of water

flows into the satellite,

the by-pass valve must be re -adjusted or opened

toward the larger gauge and size which is

approximately a 50% by-pass water volume.

Re-adjustment of the by -pass valve prevents the

coffee bed from rising above the filter paper and

flooding into the finished brew. Re-adjustment also

aids in setting the level of finished brew strength for

local coffee drinking quality.

NOTE: THIS ADJUSTMENT MUST NEVER BE MADE

UNLESS SOFT WATER CONDITION EXISTS OR AN

ADJUSTMENT FOR COFFEE STRENGTHS IS TO BE

MADE.

To adjust soft water valve: Brewer was shipped

with soft wat er valve set for 25%. If soft water

conditions exist the soft water valve should be

opened to 50%.

WARNING: Turn off the Tank Heater Switch and

unplug Brewer before removal of any panel or

replacement of any component.

1. Remove the two (2) screws holding the top

panel. Slide panel back and up to remove.

2. Lift Water Basin Pan (#35) and move aside.

3. Remove soft water valve (#82) and turn screw

counter-clockwise enough to accept large end

of Flow Set Gauge.

4. Replace soft water valve in brewer.

5. Replace water basin and top cover.

6. Plug in Brewer and turn on Tank Heater Switch.

NOTE: Brewing time should be between 6 and 8

minutes. If brew time exceeds 8 minutes after

opening valve to 50% open soft water valve 1/8

turn further and re-time brew cycle. If brew time still

exceeds 8 minutes, contact Bloomfield Industries.

To measure By-Pass Water Volume, use the ByPass Test Hose. Insert By -Pass Test Hose into ByPass Valve Outlet (located behind Spray Head).

Insert Brew Chamber, to catch Spray Head flow,

and collect By -Pass Flow from hose in a one (1)

gallon container. Press both the Brew Switch and

manually press the Micro -Switch Actuator Pin, at

the same time, to start a brew cycle. When brew

cycle is finished, measure the By-Pass water

volume. The perce nt of By -Pass is the volume of

water in ounces from the hose, versus a volume of

224 ounces of water in a full brewing cycle.

Page 27

Page 28

ORDERING/SERVICE PROCEDURE

Service Information - To obtain service

assistance in addition to that contained in

this manual, call Bloomfield's toll free

number (800) 621-8556.

Be prepared to give the Model and Serial Numbers

of your brewer, as well as the problem and the

trouble-shooting steps already taken, to the service

technician when calling for assistance.

How to Order-

Individual users and owners must order re-

placement parts thru their distributors or the local

authorized service station.

Terms: Prices, terms, designs, materials, weights,

specifications and dimensions for equipment or

parts are subject to change without notice.

BLOOMFIELD INDUSTRIES 2

ERIK CIRCLE

P.O. BOX 280 VERDI, NV

89439 FAX (800) 356-5142

Page 29

REPLACEMENT PARTS LIST #8772-100

HEATED SATELLITE

Parts that differ because of change voltage requirements between

Model #8703 covered in #8702 Owner's manual and Model #8772-100 unit are shown below.

SEE PAGE

NO.

13

REF.

NO.

13 8596-43 ON/OFF LIGHTED SWITCH 8563-100

PART NO. DESCRIPTION MODEL 8772 —100

UNIT MUST USE

PART NO.

——NOT SHOWN

NOTE: ALL OTHER PARTS ARE COMMON IN USE.

------------ RECTIFIER 8772-102

Page 30

REPLACEMENT PARTS LIST

MODEL 8703 SATELLITE

Page 31

REPLACEMENT PARTS LIST

3. 70820

Handle, Rod

4. 70123

Screw.

#8-32, Keps

5. 70378

Hex. Nut-

32, Keps

15. 71278

Heat Sink Plate

17. 71220

Retainer

19. 71275

Access Door

20. 70819

Foot

22. 70821

Drip Tray Cover

1. 8600-17 Shield Cap

3. 8600-2D Shield 10" x 3/4" O.

D. Aluminum

8700-25H Lower sight Glass Washer 5/16" Hole

6.

8705-11G Shield Base

MODEL NO. 8703 SATELLITE

REF. NO PART NO. DESCRIPTION

1. 70805 Cap Sub Assembly

2. 76762 Satellite Cover Only

6. 70813 Screw. #8-32 x 5/8

7. 70814 Locating Block

Locating Block Seal 8. 70818

9.

10.

11. 70293 Cord and Cap Assembly

12. 70215 Cord Grip, Strain Relief

13. 70138 On/Off Lighted Switch

14. 71278 Satellite Body Sub Assem bly

16. 71274 Heating Element. 60 Watt

18. 70815 Spacer Tube

70781 Spacer, Tank Cover Retainer

70823 Retainer Spring

21. 70817 Screw. 1/4-20 x 1 LG

23. 70822 Drip Tray Body

24. 70794 Satellite Tank Assembly

25. 70801 Seal Drain Fitting

26. 70812 0 Ring, Tank Top Seal

27. 70792 Faucet and Sight Glass Assembly

ACCESSORY AND ITEMS NOT SHOWN

70324 Box of 500 Filter Papers

2. 8700-25J Upper Washer 1/8" Standard

8700-25K Upper Washer 1/16" Special

4. 8705-11C Sight Glass 10x5/8 O. 0. Polysulphone

5. 8705-11B Lower Sight Glass Washer 1/16" Hole

7. 8705- 11D Shank Assembly w/ Wing Nut

8. 8705-11F Faucet only w/o Shank & Sight Glass

9. 8705- 11L Upper Assembly, Black Bonnet

10. 8700-25L Seat cup

11. 8705-11K Washer for dean Out Cap

12. 8705-11J Clean Out Cap with Washer

70824 Faucet Shield

70938 By-Pass Set Kit

FOR FAUCET ASSEMBLY ONLY ( PART NO. 8705-11)

Loading...

Loading...