WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5707

fax: 775-689-5976

www.wellsbloomfield.com

600

INSTALLATION INSTRUCTIONS

SOLENOID RETROFIT FOR MODEL NUMBERS

8541 8573

9001 9013

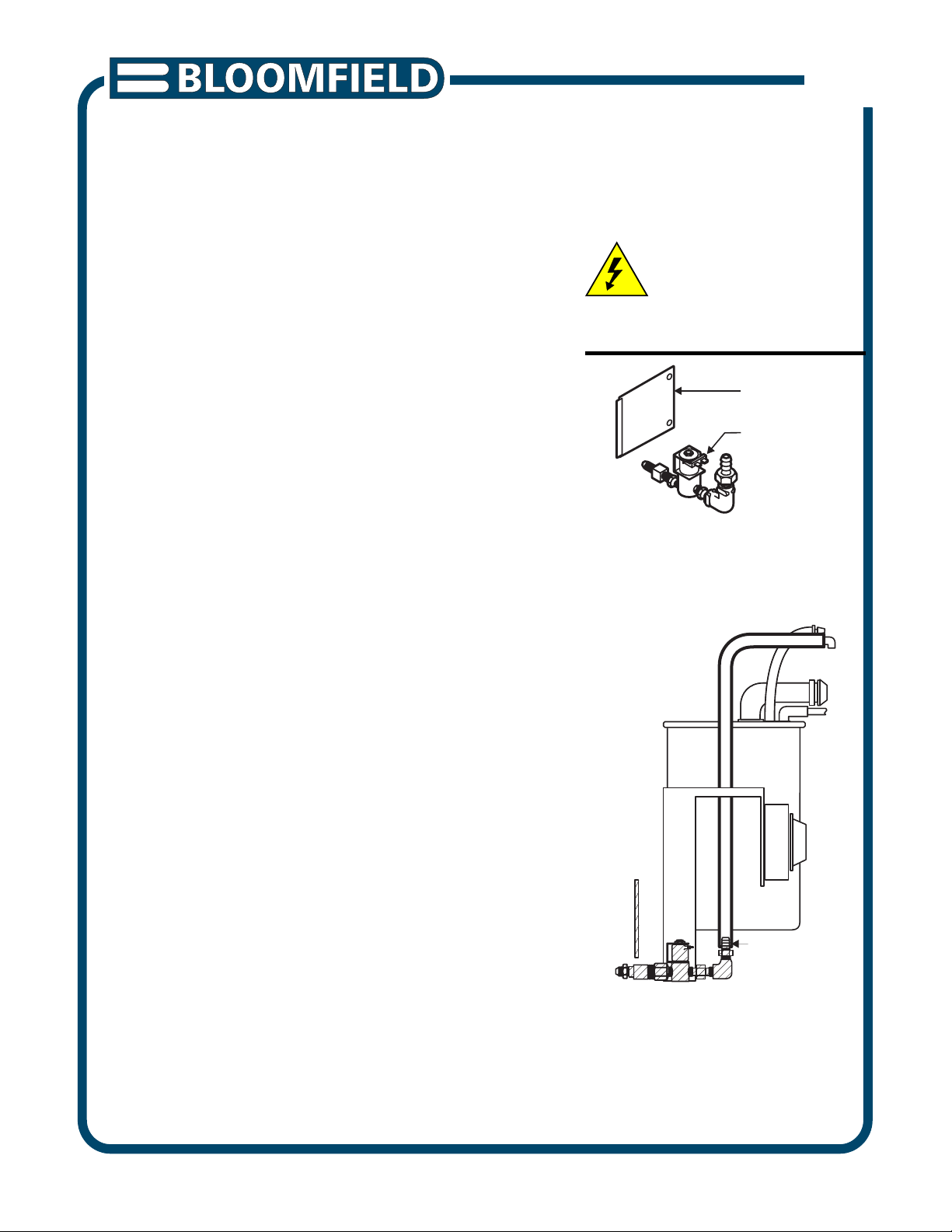

1. REMOVE EXISTING SOLENOID (See figures 1 and 2)

a. Disconnect brewer from electric power and shut off water

supply.

b. Remove TOP PANEL, FRONT PANEL and SOLENOID

ACCESS DOOR.

c. Disconnect wires to solenoid. Remove silicone SUPPLY

HOSE from solenoid.

d. Remove BRASS NUT from INLET FITTING.

Lift solenoid / timer / bracket assembly from mounting clip.

e. Loosen screws on bottom of solenoid and separate solenoid

from bracket.

Remove solenoid and fittings from cabinet.

CAUTION:

ELECTRIC SHOCK

HAZARD

Unplug brewer before beginning

conversion.

Fig. 1

NOTE: TYPICAL INSTALLATION

SHOWN. ALL INSTALLATIONS ARE

SIMILAR. DETAILS MAY VARY.

ACCESS

DOOR

SOLENOID

ASSEMBLY

BRACKET

SILICONE SUPPLY HOSE

ACCESS DOOR

TIMER

DISCONNECT

Fig. 2

REMOVE SHADED COMPONENTS

* SOLENOID ACCESS DOOR

* SOLENOID AND FLOW CONTROL

* INLET FITTING, TEE & ADAPTERS

PRINTED IN UNITED STATES OF AMERICA

p/n 75910 Rev. A ECN-13394 I 600 080211 cps

1 of 3

CAUTION:

ELECTRIC SHOCK

HAZARD

Unplug brewer before beginning

conversion.

JUMPER

WIRES

BROWN

TO TIMER

WHITE

85089

ACCESS

DOOR

8810-12

BUTTON

PLUG

SOLENOID

TO TIMER

WHITE

TO TANK

HEATER

REMOVE

PIGGY-BACK

PORTION

EXISTING

WHITE

WIRES

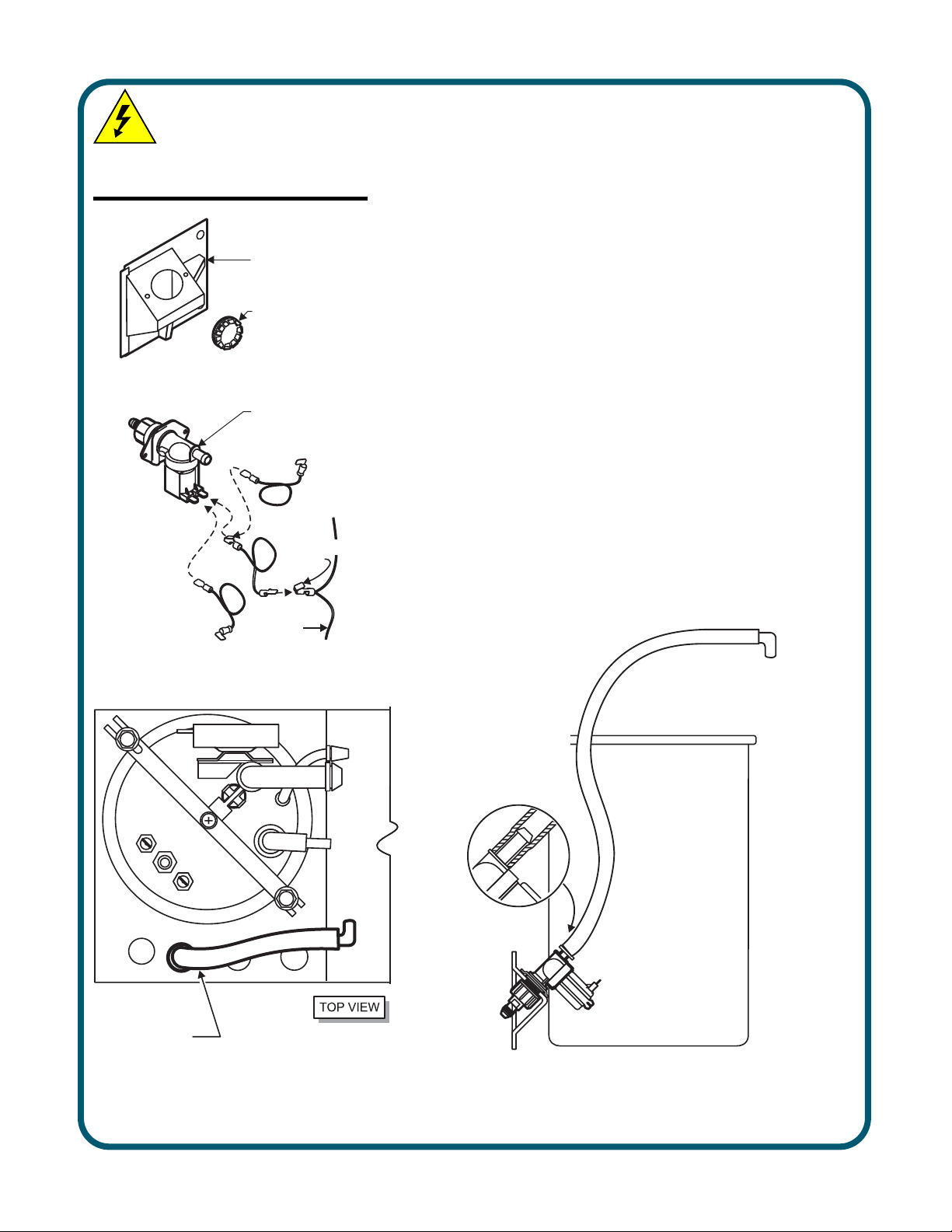

2. INSTALL NEW SOLENOID (See figs. 3, 4 and 5)

a. Assemble the SOLENOID to the new ACCESS DOOR.

Coil should be at the bottom as shown in fig. B.3.

b. Route the silicone SUPPLY TUBE through the 3rd hole

(from the front). Attach tube to SOLENOID. Push tube

fully onto the outlet of the solenoid coil.

c. Remove "piggy-back" flag from female spade terminal

on existing wiring. Connect jumper wires to the solenoid

and existing white wire as shown.

d. Assemble the ACCESS DOOR / SOLENOID to the

cabinet.

e. Turn water supply ON. Check for leaks.

f. Insert BUTTON PLUG in the hole formerly occupied by the

inlet fitting.

g. Reinstall TOP PANEL and FRONT PANEL.

Reconnect unit to electric power and test for proper operation.

LINE

Fig. 3

ROUTE HOSE

AS SHOWN

Fig. 4

ATTACH PLASTIC

HOSE TO OUTLET

WITH SOLENOID:

* PUSH HOSE

FULLY AGAINST

VALVE BODY

600 p/n 75910 Instr Retro Solenoid Valve

Fig. 5

2 of 3

Loading...

Loading...