Page 1

OPERATING INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

and

PARTS LIST

DUAL BREWERS WITH WARMING UNITS

BREWER Model Nos. 8516 and 8518

INTEGRITY

Brewing Systems

OWNER'S MANUAL

COVERING

Page 2

INDEX

MODEL NO.

8516

SKETCH

2 INTRODUCTION and PRE

-

INSTALLATION

3 ELECTRICAL INSTRUCTIONS

4 CONNECTING TO WATER

5 INITIAL BREW CYCLE SET UP

6

BREWING OF COFFEE

7

SERVICING INS

IDE THE BREWER

8

WATER FLOW DIAGRAM IN THE UNIT

8

EXPLODED VIEW

9 REPLACEMENT PARTS LISTING

10,11, 12

ITEMS NOT SHOWN and ACCESSORIES

12

CAUSE and EFFECT CHART

13, 14, 15, 16, 17,18, 19

WIRING DIAGRAM

— MODELS

8516

and

8518

20

ADDITIONAL SERVI

CE INFORMATION, SOLENOID

&

FAUCET

21, 22

CONTENT PAGE NO.

MODEL NO. 8518 SKETCH FRONT COVER

The INTEGRITY BREWERS have been designed with adjustment flexibility to cover a wide

spectrum of customer needs. Adjustments on the running thermostat and inlet timer are simple

adjustments easily accomplished by the purchaser, but NOT COVERED UNDER ANY

WARRANTY SERVICE AGREEMENT.

Brewers must be installed in accordance with installation instructions in the owner's manual for the

warranty to be valid.

WARNING:

DO NOT PLUG IN OR ENERGIZE THIS UNIT

UNTIL INSTALLA TION INSTRUCTIONS ARE READ

AND FOLLOWED.

2

Page 3

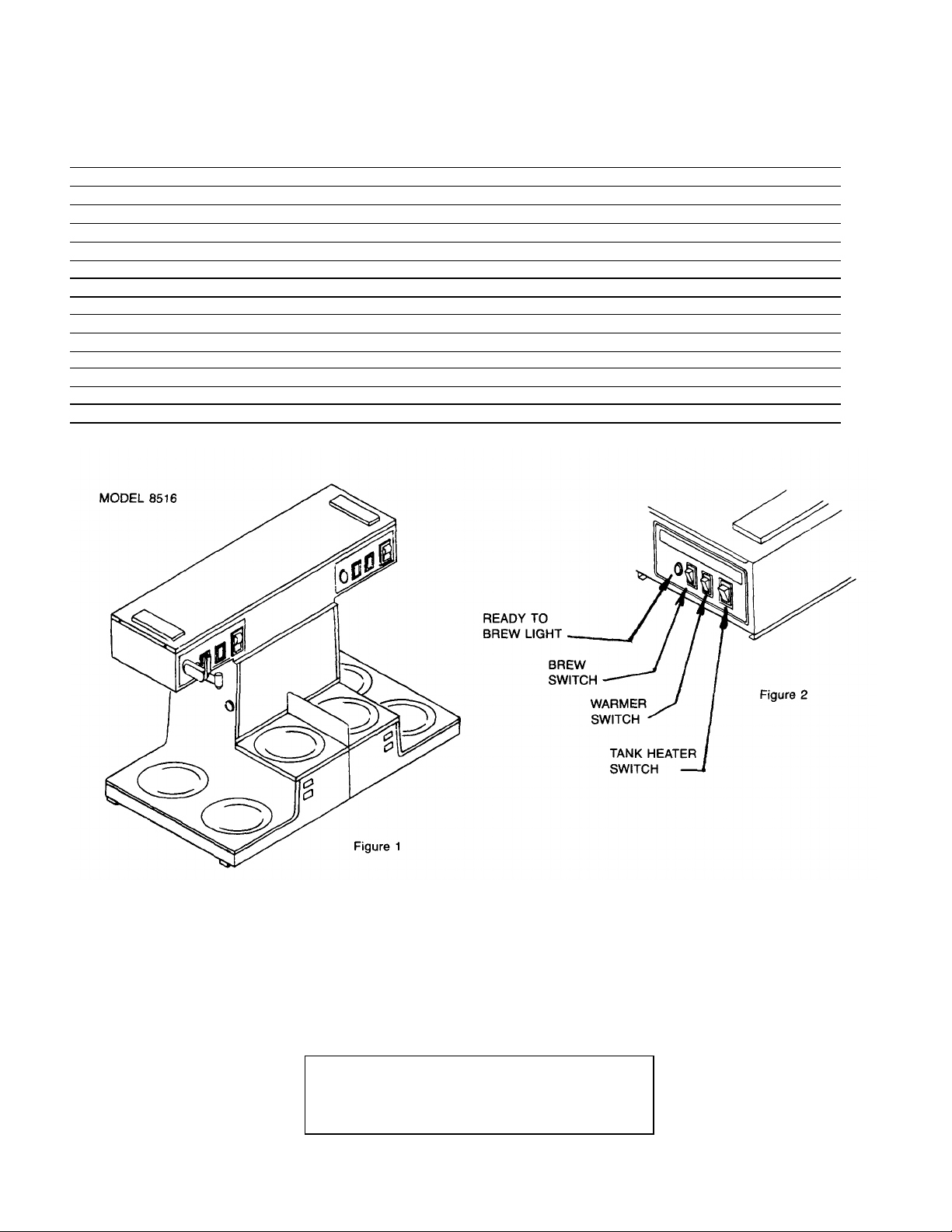

INTRODUCTION TO THE UNITS

There are two (2) styles of brewers covered in this

manual.

The "front loading" MODEL 8516 is a unit that positions to the rear of the counter and is completely

operated by store personnel. All operations such as

brewing, keeping coffee warm, serving coffee and

drawing of hot water are performed from the front of

the unit.

A companion "rear loading" MODEL 8518 is a unit

that may be positioned at the front of a counter. This

unit differs from MODEL 8516, as the hot water faucet

and the warmer stations remain at the front of the unit,

while the brewing and control functions have been

placed in the back of the brewer making operation of

the unit easily available, and a step saver for store

personnel.

MODEL 8516 and 8518 UNITS:

A. Bot h units have two (2) independent brewing

sections in each brewer,

1. One brewing section has a water faucet

for drawing cups of hot water while the

other section is for brewing only.

2. In either unit, one brewing section can be

used alone or both may be used at the

same time.

3. Each unit has six (6) warmer stations for

keeping decanters of coffee hot and

available.

4. All Brew Chambers and Decanters are

readily interchangeable between section

to section of a brewer or from brewer to

brewer.

5. Each brewing station of a unit requires a

separate:

a. Power source of 115/230 Volts, A.C.,

60 Hertz, SINGLE PHASE, Four(4)

Wire Supply capable of handling a

20 AMP load.

b. Water input line connected to a single

water source hose line of 3/8"

minimum size.

PRE-INSTALLATION INSTRUCTIONS

GUIDE TO THE INITIAL INSTALLATION and TANK FILLING SEQUENCE.

1. Check the Tank Heater Switch in both brewing sec tions of the unit to be sure it is in the OFF position.

They must remain OFF from Step 1 thru Step No.

9. A Tank Heater Switch controls the main heating

element in each brewing section of the unit, and it

must not be energized before the tank is filled with

water, thru Step No. 5. The Tank Heater Switch

also serves to de-energize the Brew Start Switch,

preventing brew cycles of cold water while the

Tank Heater Switch is in the OFF position.

2. Connect each brewing section of the unit to a

power source, see Electrical Installation on Page 4.

3. Connect each brewing section of the unit to the

water supply line, see instructions on Page 5.

4. Slide both Brew Chambers in place and SET AN

EMPTY DECANTER UNDER EACH BREW

CHAMBER.

5. Pour a full decanter of water thru the pour-in

door on top of each brewing section of the unit.

Wait two (2) minutes and repeat. Repeat a third

time for the non-faucet brewing section of the

unit. Water will start flowing into the decanter

during the third cycle (second cycle from water

faucet brewing sec tion) indicating that the tank

is filled with water.

6. After water flow stops, remove, empty and

replace the decanter under each brew chamber.

7. Plug in both power cords to the source

receptacles. Water should be connected to the

unit and ready to go. Recheck and correct any

leaks.

8. Turn on electric and water at source.

9. NOW — PRESS BOTH TANK HEATER

SWITCHES TO ON position and leave them

ON.

10. Proceed with initial Brew Cycle Set -up

Instruction on Page 6, and then to Brewing of

Coffee.

3

Page 4

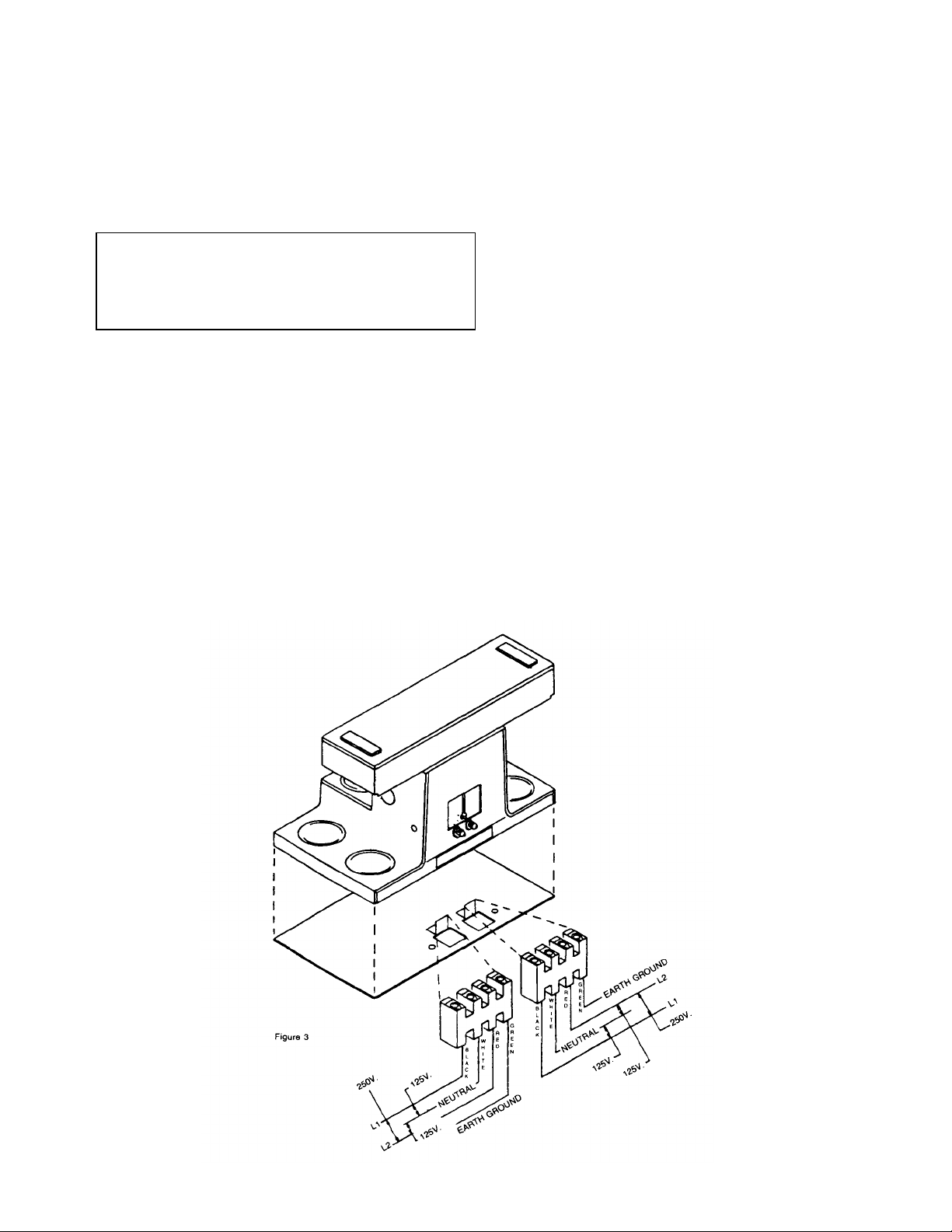

ELECTRICAL INSTALLATION for MODELS 8516 and 8518

IMPORTANT: Prior to starting the electrical hook-up, check

power source and electrical receptacle for proper single

phase voltage supply. Figure 3 details the power

requirements of each brewing section of a unit.

CAUTION: DO NOT CONNECT TO A THREE (3) PHASE

POWER SOURCE OR ANY OTHER THAN AS NOTED

IN FIGURE 3, AS DAMAGES TO THE UNIT CAN

OCCUR THAT ARE NOT THE RESPONSIBILITY OF

THE MANUFACTURER OF THE UNIT

There are two (2) independent brewing sections in each

unit, and each brewing section draws 20 AMPS of power.

Each brewing section must be connected to a separate

power source, capable of supplying:

115/230 Volts, A.C. 60 Hz., Single Phase, four (4) Wire, 20

AMP service.

For power line cord, use #12 gauge wire suitable for 75

degrees C. All wiring must be in accordance with local

electrical codes.

1. Do not assume the GREEN earth ground wire

can be used as a neutral. The GREEN earth

ground is a protection circuit not intended as

part of the power lines.

2. Recheck at this point — the tank heater and

operation switch, on the front panel of each

brewing sec tion of the unit, must be in the OFF

position.

3. To install power cords, remove rear and bottom

cover panels of the unit for access to the power

junction blocks. See Figure 3. A separate

power cord must be wired into each junction

block thru either the rear or thru the bottom

opening. If bot tom access is to be used,

remove the two (2) snap-in Plug Buttons, and

transfer them to the power cord entrance holes

in the rear of the unit.

4. Recheck the Tank Heater Switch in each

section — it must be in the OFF position. Plug

in both power cords, check voltages at both

terminal blocks to be certain each conforms to

Figure 3 designations.

NOTE: At this point, unplug each power

cord and go to Step 3 of Initial

Installation Instruction Guide.

4

Page 5

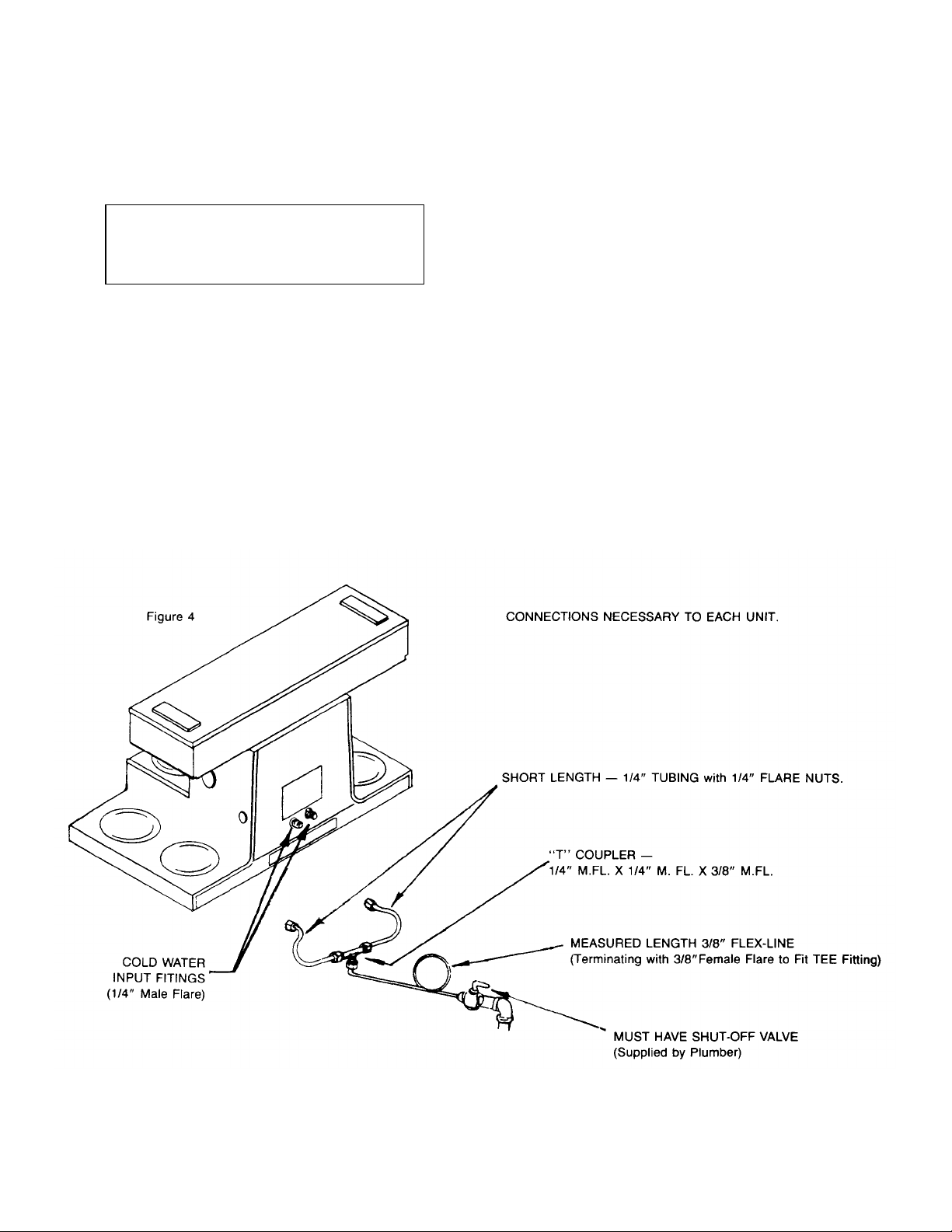

CONNECTING WATER SUPPLY LINE TO THE UNIT

Complete the electrical installation

before starting the water connections.

WARNING:

DO NOT PLUG IN OR ENERGIZE THIS UNIT

UNTIL INSTALLATION INSTRUCTIONS ARE

READ AND FOLLOWED.

Before starting water hook-up, check to be sure both power

cords of the unit are unplugged.

Unit must be installed on a water line with a flowing

pressure between 20 PSI and 90 PSI. If water pressure

does not fall into this range, or varies greatly a pressure

regulator should be installed.

IMPORTANT: Flush the water line a minimum

of three (3) minutes before connecting to the

unit. The unit should be connected to COLD

WATER.

Each brewing section connects to a short length

of 1/4" O.D. tubing, preformed to go beneath the

unit. Each preformed tube connects to a 1/4"

Male Flare leg of a "TEE" fitting. The remaining

leg of the "TEE" fitting is a 3/8" Male Flare that

connects to a single 3/8" incoming water supply

line, as shown in Figure 4.

After water hook -up is completed, continue to

follow Pre-lnstallation Guide Instructions No. 4

thru 10.

5

Page 6

INITIAL BREWING CYCLE SET-UP

and OPERATION GUIDE

1. Unit is now connected to power and water. Both

water tanks have been filled. The Tank Heater

Switch on each brewing section is in the ON position and the water is heating in both brewing

sections.

2. On Water Faucet Section of each unit, draw off an

ounce or two of water from the faucet, two or

three times during the initial tank heating process,

to relieve air and expansion pressure in the hot

water faucet lines. This relieves "spitting with

pressure," when a cup of hot water is drawn from

a newly installed unit.

3. Initial heating time, at start up, will range from six

(6) to eight (8) minutes. The GREEN signal light

will turn ON when the water reaches brewing

temperature.

4. When GREEN signal light turns ON, press brew

start switch. Hot water will start to flow

immediately and assure that the tank and system

are full of water.

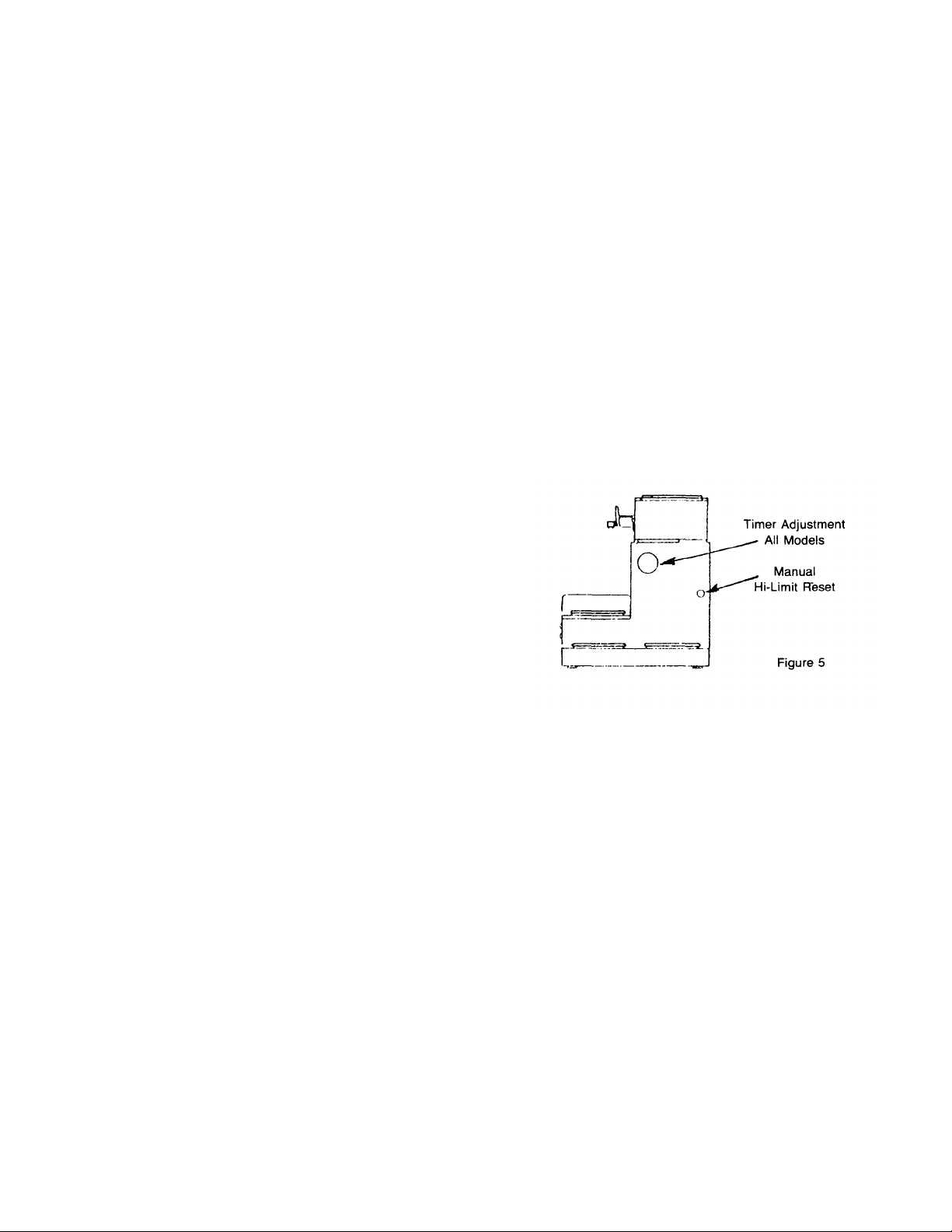

C. Turn Timer adjusting knob: The Timer is

very sensitive, so make adjustments one

(1) mark on the dial at a time. A one (1)

mark change on the dial approximates

three (3) ounces of water delivery change.

The factory timer set ting is 38 seconds

when the unit is operated on a flow

pressure of 35 PSI to receive a 60 ounce

water delivery.

1. Clockwise to INCREASE water

volume, delivered during a brewing

cycle or

2. Counter-clockwise to DECREASE the

delivery.

D. Repeat Steps 4 and 5 until desired amount

of water is dispensed during a brewing cycle.

5. Repeat Step 4. After water stops flowing, you

should have a full decanter of water — 60

ounces. In each brewing sec tion, a water flow

control valve and factory preset timer, control the

exact amount of water to be delivered during

each brewing cycle. If, after completing Step 4

the second time, the decanter is not full — 60

ounces of water, or tends to overflow, proceed as

follows:

A. Check water supply line flowing pressure.

Brewer will not operate properly if the line

pressure is below 20 PSI. (You may obtain

your PSI pressure by inserting a gauge in the

incoming water line at the back of the unit).

B. Remove the 2" Plug Button from access hole in

the cabinet front panels. Timer Knob and Face

Plate are in clear view for easy adjustment.

LEVELING THE UNIT

A very important installation operation that must

not be overlooked or ignored, is the "Leveling of

the Unit." For proper unit operation, it is very

important that the unit be level when it is standing

in its proper operating position.

After adjustment of both brew-sections is

completed and the GREEN signal lights have

turned ON, you are ready to brew coffee.

6

Page 7

BREWING OF COFFEE

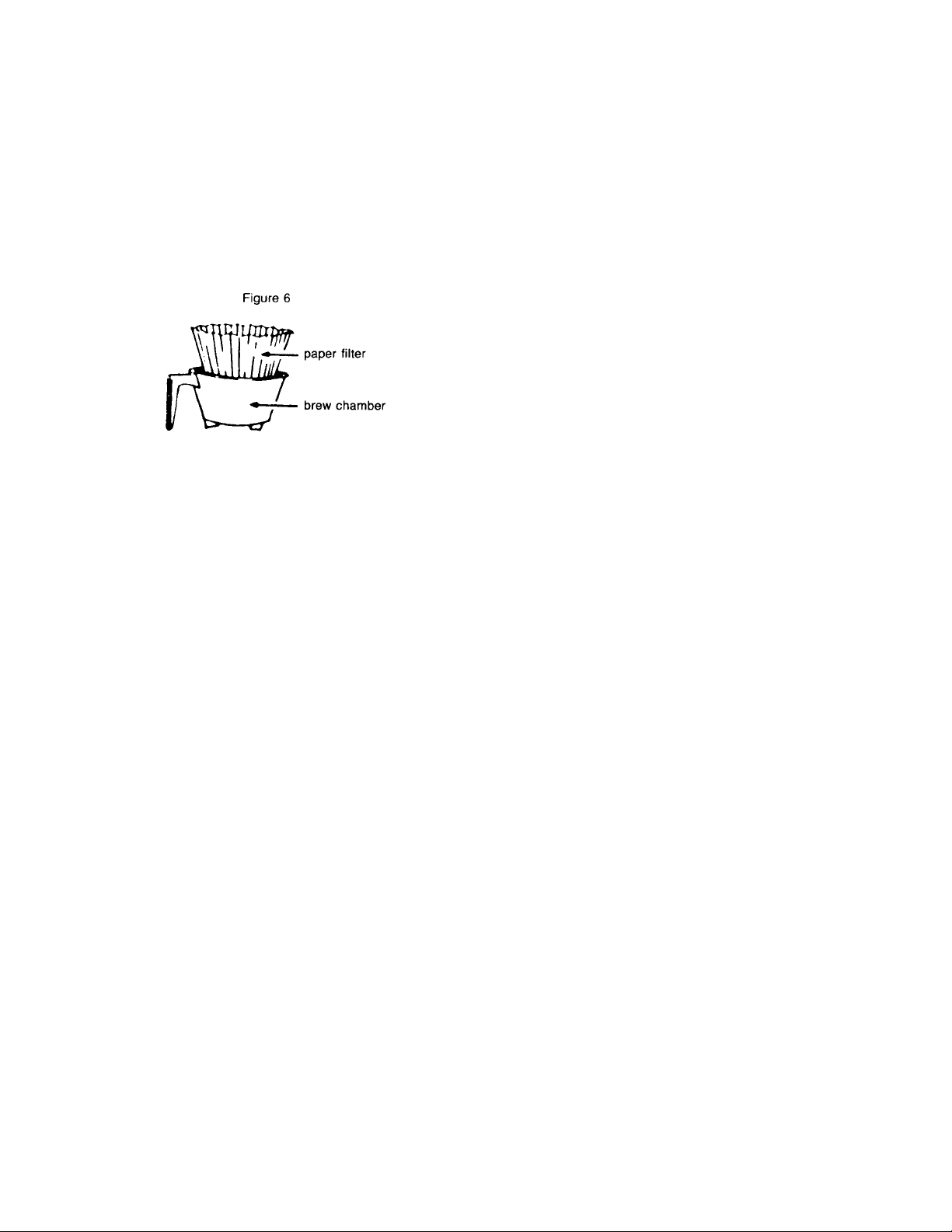

1. Remove brew chamber from under Spray Head

and place one (1) Paper Filter into Brew

Chamber. Add your choice of a premeasured

package of FINE GRIND coffee. Shake Brew

Chamber to level off coffee.

NOTE: Use 1-1/2 to 2-1/2 ounces to begin

brewing. Then, if stronger coffee is desired,

use more (to taste) of fine grind coffee. Slide

Brew Chamber in place.

3. Press Brew Switch. Hot water will start

spraying over coffee grounds in Brew

Chamber and coffee will start filling the

decanter. When coffee stops flowing, the

freshly brewed coffee is completed.

IMMEDIATELY remove Brew Chamber and

discard paper filter and used grounds.

4. When GREEN signal light relights again,

Brewer will be ready for another brewing

cycle.

To keep your coffee warm, the Brewers are

equipped with electric warmers which are

activated by a switch. A Red signal light will glow,

indicating WHICH warmer is ON.

2. Place empty decant er under Brew Chamber.

IMPORTANT: ALWAYS USE EMPTY

DECANTER BEFORE STARTING A BREW

CYCLE.

IMPORTANT:

1. Warmers should be turned OFF when not in

use.

2. Do not leave empty decanter on warmer that is

ON.

Page 8

SERVICING INSIDE THE UNIT

To expose the timer, high limit thermostat, switches

and wiring, etc. inside a unit section, the front panel

must be removed.

To Remove Front Panel:

A. Turn the two (2) pedestal warmer cover plates

counter-clockwise to remove them.

B. Remove the two (2) screws and clips from each

warmer well that holds the front panel in place.

C. Gently pull the front panel forward and lift it off

exposing the unit inside.

WATER FLOW DIAGRAM

PART I

Sequence of Operations:

WATER FLOW FOR BREWING OPERATION

(Both Brewing Sections)

1. Pushing brew Start Switch energizes the Timer.

The Timer then energizes the Solenoid Valve,

allowing water to flow into the Basin Pan and then

into the Hot Water Tank. The length of time the

Solenoid Valve is energized is controlled by the

Timer setting.

2. The water entering the Hot Water Tank from the

Basin Pan, flows to the bottom of the Tank

through the Water Inlet Tube.

3. The addition of water into the bottom of the Hot

Water Tank causes the hot water at the top of the

Tank to flow out through the Outlet Elbow of the

Tank Cover, to the Spray Head.

PART II

Sequence of Operations:

WATER FLOW FOR FAUCET OPERATION

(Faucet Section Only)

1. The incoming cold water supply connects to a "T"

Inlet Fitting on the Unit. Water flows from the "T"

Inlet Fitting through the Inlet Tube, Needle Valve

and Formed Inlet Tube into the input connection of

the Water Coil.

2. The Water Coil is submerged in the Hot Water

Tank and draws heat from the surrounding hot

water. Water flowing into the Water Coil is then

heated and flows out through the Formed Outlet

Tube to the Faucet. (The water flowing through the

Water Coil, which feeds the Faucet is not controlled by the Solenoid Valve. This portion of the

system is always under pressure and is controlled

by the Faucet. Opening the Faucet allows the

water to flow through the Water Coil system.)

3. The Needle Valve, in the system, controls the

volume of flow from the Faucet and is adjusted to

allow a gentle stream of water to be dispensed

through the Faucet, without splashing into the cup.

(The Faucet is intended as a cup to cup hot water

supply.)

NOTE: Drawing hot water from the Faucet,

during a Brewing Cycle does not affect the

volume of the finished brew.

8

Page 9

EXPLODED VIEW

for

MODEL NOS. 8516 and 8518

9

Page 10

REPLACEMENT PARTS LIST — MODELS 8516 and 8518

includes

#12, #13,

and #14

35 8881-8 Washer

2

L & R L & R

NOTE: FACING THE OPERATOR CONTROLS, DETERMINES LEFT

OR RIGHT BREWER DESIGNATION.

EXPL.

VIEW

REF.

PART DESCRIPTION

1 8707-4 Filter Support Frame 2 L& R L & R

2 8707-3 Screw, #10-32x5/16 Hex Hd. 2 L & R L & R

3 8707-2 Bakelite Handle, Black 2 L & R L & R

4 8516-131 Basin Cover, Sub-Assembly 1 Common Common

5 8543-46 Hinge Cover 2 L & R L & R

6 8543-49 Hinge Cover Wire 2 L& R L & R

7 8543-52 Screw, #8-3/8" Ph. Hd. "B" 30 L & R L & R

8 8043-506 #8-32 Hex Cap Nut 4 L & R L & R

9 8043-5 Hold Down Strap 2 L & R L & R

10 8043-47 Screw, Ph. Hd. #10-32x1" 2 L & R L & R

11 8551-250 Faucet Assembly, 1 L R

12 8551-100A Washer 1 L R

13 8551-100B Ext. Toothed Lockwasher 7/16 1 L R

14 8551-100C Hex Lock Nut 1 L R

15 8516-130 Formed Outlet Tube, to Faucet 1 L R

16 8718-31 Green Pilot Light 2 L & R L & R

17 8707-28 Brew Start Switch 2 L & R L & R

18 8516-25 Main Switch-Lighted Style Series 2 L & R L & R

19 6710-23 ON/OFF Lighted Switch, Black 6 L & R L & R

20 8540-4 Formed Inlet Tube Assy., to Input. 1 L R

21 8551-30 1/4" M. Flare to 1/8" FPT Connector 1 L R

22 8514-26 Needle Valve 1 L R

23 8543-23 Tinnerman Nut 30 L & R L & R

24 8516-136 Formed Tube Assy., to Needle Valve 1 L R

25 8516-142 Water Inlet Hose 2 L & R L & R

26 8941-20 Adaptor Fitting 4 L & R L & R

27 8541-48A 1/4" M. Flare x 1/4" FPT Elbow 2 L & R L & R

28 8541-120F Flow Control, 1/4" MPT x 1/4" MPT 2 L & R L & R

29 8541-120 Solenoid Valve, incl. #28 2 L & R L & R

29A D 20002-3 Screw, #10-32 x 5/16" 4 L & R L & R

30 8706-102 Reducer Adaptor 1/8 M x 3/8 FPT 2 L & R L & R

31 8516-102 Street Elbow 3/8 P.T. 1 L R

32 8551-35 "T" Fitting 2 x 1/4" M. Flare x 3/8 MPT 1 L R

33 8710-10 Hex Nut, 7/16-20 x 1/8" 2 L & R L & R

34 8541-93 Inlet Fitting 1/4" M. Flare x 3/8 MPT 1 R L

QTY.

PER

UNIT

MODEL USED ON

8516

BREWER

LEFT/RIGHT

BREWER

LEFT/RIGHT

8518

36 8043-30 Gasket 6 L & R L & R

37 8873-12 M. Elbow 1/4" Pipe x 1/4" M. Flare 2 L & R L & R

38 8541-21 Basin Pan 2 L & R L & R

39 8512-41 Seal Washer 2 L & R L & R

40 3-100 #6-32 x 1/4" Rd. Hd. Screw 4 L & R L & R

41 8512-51 Thermostat 2 L & R L & R

10

Page 11

73 8516-101 Front Panel

1 R L

REPLACEMENT PARTS LIST — MODELS 8516 and 8518

NOTE: FACING THE OPERATOR CONTROLS. DETERMINES LEFT

OR RIGHT BREWER DESIGNATION.

EXPL.

VIEW

PART DESCRIPTION

REF.

42 8043-8 Inlet Elbow 2 L & R L & R

43 8043-15 Vent Tube 2 L & R L & R

44 8043-11 Outlet Elbow 2 L & R L & R

45 8043-26 Water Outlet Tube 2 L & R L & R

46 8043-13 Sprayer Elbow 2 L & R L & R

47 8543-42 Sprayhead Gasket 2 L& R L & R

48 8543-44 Sprayer Disc 2 L & R L & R

49A 8514-68 Tank Cover Plate ONLY, Watercoil Style 1 L R

49B 8552-180 Tank Cover Plate ONLY, Non-Watercoil 1 R L

50 8043-12 Tank Cover Gasket 2 L & R L & R

51 8543-73 #4-40 x 1-1/2" Pan Hd. Screw 2 L & R L & R

52 8043-24 Water Inlet Tube 2 L & R L & R

53 8543-74 #4-40 Hex Nut 2 L & R L & R

54 8716-1 Heat'g Element 3500W, 230 V 2 L & R L & R

55 8043-28 1/2-20 Hex Nut 4 L & R L & R

56 8941-21 7/16-20 Hex Nut 1/8" thick 2 L R

57 8942-33 Seal Gasket 2 L R

58 8551-53 7/16" I.D. x 3/4" O.D. Stainless Steel Washer 2 L R

59 8540-6 Hot Water Coil 1 L R

60 8043-10 Tank Body 2 L & R L & R

61 7200-6X #8-32 x 5/16" Screw 2 L & R L & R

62 8861-16 #6-32 Hex Nut 4 L & R L & R

63 8718-48 Hi-Limit Bracket 2 L & R L & R

64 8552-50 Safety Thermostat 2 L & R L & R

65 8718-1 Timer w/Knob & Dial — 2 min. 2 L & R L & R

66 8718-1 A Timer Knob 2 L & R L & R

67 8700-16 Warmer Cover Plate, Black 6 L & R L & R

68 8572-18 Calrod Warmer Element, 100W, 120V. 6 L & R L & R

69 8033-60 Dot Plug Button, 3/8" Diameter 2 L & R L & R

70 8706-75 Plug Button, 2" Diameter 2 L & R L & R

71 7506-30 #8-32 x 3/8" Thread Cutting Screw 8 L & R L & R

72 8543-80 Front Panel Mount'g Clips 8 L & R L & R

QTY.

PER

UNIT

MODEL USED ON

8516

BREWER

LEFT/RIGHT

8518

BREWER

LEFT/RIGHT

74 616-5 #6-32 x 1-1/4" Rd. Hd. Screw 4 L & R L & R

75 8552-18 Terminal Block 2 L & R L & R

76 8516-116 Bottom Plate 1 Common Common

77A 8033-55 Leveler Leg 4 L & R L & R

77B 8033-56 Leveler Leg Cap 4 L & R L & R

78 8516-119 Warmer Top Assembly 1 Common Common

79 8516-100 Front Panel 1 L

80A 8516-105 Body Assembly 1 Common Common

81A 8516-122 Basin Sub-Assembly 1 Common —

81B 8518-102 Basin Sub-Assembly 1 — Common

11

Page 12

REPLACEMENT PARTS LIST — MODELS 8516 and 8518

2

1

8541

-

120JS

Solenoid Repair Kit

8544

4"

Leg Kit (Set of

4)

NOTE: FACING THE OPERATOR CONTROLS, DETERMINES LEFT

OR RIGHT BREWER DESIGNATION.

MODEL USED ON

EXPL.

VIEW

PART DESCRIPTION

REF.

82 8518-3 Front Label w/Faucet Hole 1 L 83 8516-2 Front Label without Faucet Hole 1 R L & R

84 8707-160 Brew Chamber Cup ONLY 2 L & R L & R

8707-6

85 8705-36 Plug Button, 7/8" Diameter 2 L & R L & R

86 8543-69 Heyco Bushing 8 L & R L & R

87 8516-107 Tank Support Bracket 1 Common Common

88 8516-134

89 8516-133 Access Door, Wiring 1 Common Common

90 8516-135 Bottom Access Door, Wiring 1 Common Common

Complete Brew Chamber, includes #1,

#2, #3, and #84

Solenoid Access Door

QTY.

PER

UNIT

8516

BREWER

LEFT/RIGHT

L & R

Common

BREWER

LEFT/RIGHT

L & R

Common

OPTIONAL ACCESSORIES (not shown)

8518

8551-275 Faucet Repair Kit

8707-6

8717-300 Complete Tank Lid Assembly, w/AII Components mounted onto it, FOR NON-FAUCET STYLE

8716-300 Complete Tank Lid Assembly, w/AII Components mounted onto it, FOR FAUCET STYLE BREWER

— Connector Kit — to attach both Brewing Sections of a Unit to a Single 3/8" Cold Water Source, FLEX— Connector Kit — to attach both Brewing Sections of a Unit, to a Single 3/8" Cold Water Source FLEX-

Complete Brew Chamber Assembly, w/wire rack

BREWER SECTION.

SECTION.

LINE. (For Unit without 4" legs).

LINE (For under the Unit Coupling, Unit stands on 4" legs).

12

Page 13

TROUBLESHOOTING GUIDE

plug in power

ed, reset breaker or

must

Check switch continuity, if switch does not make and

but blows fuses

AMP power

replace fuses

It is very important, when servicing equipment, to:

1. Define the basic Problem.

2. Isolate the Probable Cause.

3. Take Corrective Action regarding those items

hampering proper operation of the equipment.

It is usually relatively easy to define the basic

problem, but sometimes very difficult to pinpoint the

precise cause.

A TROUBLESHOOTING GUIDE is provided in this

chapter to suggest probable causes and corrective ac

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

tions for each. Obviously, if the cause is not

isolated and corrected, proper operation of the

equipment cannot be restored.

Should the problem remain after exhausting the

troubleshooting steps suggested, refer to the

Order/ Service Information section of this

chapter.

WARNING: Inspection, testing and repair of

electrical equipment should be performed only by

qualified service personnel. The brewer should

be unplugged when servicing, except when

electrical tests are required.

DANGER: Use extreme care during electrical

circuit tests. Live circuits will be exposed.

1. Unit electrically dead. No

power in unit or at terminal

block.

2. Unit has power but will not

start a cycle.

3. Unit has power but will

operate only while "Brew

Button," is held in contact.

Cycle stops when button is

released.

A. Power Cord. 1. Power cord not plugged into source —

cord.

B. Source Circuit Breaker or

Fuse.

C. Source receptacle miswired. 1. Check receptacle for proper power distribution at

A. Unit connected to wrong

power source.

B. Loose wire or connection. 1. Check for loose wire or connection.

C. Main Switch. 1. Switch is in OFF position — turn ON.

D. Brew "START" Switch. 1.

A. Loose wires. 1. Timer not being energized due to a loose wire —

B. Timer. 1. Timer blown due to hookup to wrong power —

1. Blown fuse or circuit breaker tripp

replace blown fuse.

terminals.

1. Check power source — correct wire hookup —

be A.C., 120Volt/208 to 240Volt, Single Phase.

Reattach loose wire or tighten connection,

2. Electrically open — replace.

3. Switchbutton stuck — replace.

break when activated — replace.

reattach wire.

correct power supply — replace timer.

2. Timer defective — replace.

4. Unit operates

or trips circuit breaker.

A. Under rated fuses or circuit

breakers.

1. Each unit must operate on a separate 20

line. 15 AMP fusing will not operate —

or circuit breakers, use 20 AMP rated line protectors.

13

Page 14

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

4. Unit operates but blows fuses

Remove extra appliances, each brewer requires a 20

straighten the line or replace line

clockwise to reduce the water dump

movement of the timer knob One (1) mark on the dial

or trips circuit breaker.

flows into the basin pan or

from the faucet.

flows into basin pan. Water

does flow from the faucet.

B. Too heavy a load on the line.

(Excessive demand).

A. Water Supply. 1. Water supply line valve shut off — turn on. 5. Unit activates but no water

B. Line filter such as QC7

and/or strainer.

C. Restricted water line. 1. Water line to unit plugged — clear blockage or

A. Loose Wire. 1. Locate loose wire and attach. 6. Unit activates but no water

B. Solenoid Valve (not

opening).

1. Other appliances added onto same power line.

AMP power line

1. Water line filter plugged up — replace filter.

2. Strainer plugged up — back flush or replace.

replace line.

2. Kink in water line —

section

3. Water line in cold area, water frozen in the line —

warm up the line so water flows freely,

1. Solenoid valve coil electrically open — replace coil.

2. Foreign material in solenoid — clean inside of

solenoid valve.

3. Shut off piston seat or spring damaged — replace

both or complete solenoid.

7. Too little water or too much

water. (Decanter short or

overflows)

C. Twisted or Kinked Hose

(from solenoid to basin pan).

A. Strainer or water filter

cartridge is clogged.

B. Timer Adjustment (Timer

needs to be adjusted).

C. Flow Restricter in Output

End of Water Solenoid

Valve. (Dirty, missing,

damaged or inoperative)

1. Relieve twist or kink in hose — reposition on basin

pan fitting.

1. Back flush strainer or replace. 2. Replace water filter

cartridge.

1. To receive a full decanter, adjust the timer to run a

shorter or longer time cycle. To increase water

volume, turn timer knob clockwise for a longer cycle

time, or countercycle time.

NOTE: At 35 PSI water flow, into the unit, a change of

three (3) ounces in delivery occurs with each

face.

2. Check timer cycle with a stop watch, if cycle time is

irregular — change timer.

1. Particles of foreign material may partially or

completely clog the orifice of the flow restricter.

Clean or replace flow regulator or change complete

solenoid valve assembly.

14

Page 15

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

free operation. Wide varying water pressures

Starting with some liquid in

versa

1/2 minutes, therefore a second

Check inside surface of water solenoid valve port.

Basin Pan. (Water flow stops

7. Too little water or too much

water. (Decanter short or

overflows)

8. Water keeps running into

Basin Pan. (Will not shut off

with Power Cord unplugged)

D. Water Pressure Variations

(Water pressure rises

above 85 PSI or falls below

20 PSI.)

E. Decanter —

1) Wrong Size

2)

decanter.

3) Correct decanter used

but second brew cycle

initiated before first run

off is completed.

A. Water Solenoid Valve

(Plunger stuck open)

1. All automatic brewers require a constant water

pressure between 20 PSI and 85 PSI for consistent

[roublelead to erratic delivery. A pressure regulator may be

needed to stabilize high or fluctuating running

pressures. A water source that falls below 20 PSI

may result in short pots or erratic water volume

delivery.

1. Customer using a foreign decanter too small to

hold volume of liquid being delivered or vice— use correct decanter.

2. Start with an empty decanter every cycle, as any

coffee left in decanter will cause overflow.

3. Water flow into basin pan takes approximately 38

seconds but the run, thru the coffee to complete a

brew, takes 3 to 3brew cycle must not be started until the first cycle

has been completed.

1. Check and clean inside of water solenoid valve

and plunger.

2.

If it is scored, chipped or damaged, replace the

complete solenoid valve.

9. Water keeps running into

when Power Cord is

unplugged.)

10. Water keeps running or

dripping from Spray Disc

(Solenoid Valve not leaking

into Basin Pan).

A. Brew "START SWITCH" 1. Check brew switch for operation. If switch does not

B. Timer 1. Check timer for TIME CYCLE operation. If timer

C. Shorted Wiring (Wires from

start switch shorted

together).

A. Tank Temperature (Set too

high).

3. Check plunger seat surface if worn or damaged,

replace the plunger and spring or replace complete

solenoid valve.

make and break contact, replace switch

does not cycle to OFF condition and brew "Start

Switch" is good, replace timer.

1. Locate and remove the contact — replace wire

where necessary.

1. Adjust thermostat to lower temperature. Tank

temperature should be between 195 and 204

degrees F. To decrease tank temperature, turn the

thermostat adjusting shaft counter-clockwise.

NOTE: A 10 degree turn of thermostat shaft is

equal to a 4 degree F temperature change in the

water. Always run 2 or 3 cycles to climatize water

temperature and new thermostat setting.

15

Page 16

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Brewer does operate. Water

must go out indicating thermostat is calling for heat.

replace

locate and reconnect.

clockwise to decrease the temperature. A 10

nd

10. Water keeps running or

dripping from Spray Disc

(Solenoid Valve not leaking

into Basin Pan).

is cold.

B. Hot Water Coil leaking.

(Faucet side only)

A. Loose Wire. 1. Check for loose connection — locate and reattach. 11. Water fails to heat, but

B. Thermostat adjust ment.

(Ready Light is ON)

C. Tank Heater 1. Check for voltage at Tank Heater Terminals. Voltage

1. Shut off needle valve controlling water to Hot Water

Coil. If running or dripping from Spray Disc stops,

replace Hot Water Coil.

1. Thermostat adjustment shaft turned down. Turn

thermostat shaft clockwise to the stop, Ready Light

If Ready Light does not go out — replace thermostat.

2. If Ready Light does go out, allow water to heat and

then adjust thermostat for a water temperature

between 190 to 200 degrees F, as it exits directly

under the Brew Chamber, taking it about one (1)

minute into the cycle.

should be between 208 Volts and 240 Volts,

depending on source. If voltage is present —

element.

12. Ready Light fails to glow

when water reaches

brewing temperature.

13. Water heats but does not

get hot enough.

D. Source Fuse or Circuit

Breaker.

A. Ready Light 1. Check for disconnected wire —

A. Thermostat. (Out of

adjustment, Ready Light

does come ON)

2. If voltage is not present on element terminals, check

Items 11 A, 11B and 11D.

1. One (1) fuse or circuit breaker is open, not

completing the Heater Element circuit — change

fuse or activate circuit breaker.

2. If thermostat cycles ON and OFF and Ready Light

does not glow — replace ready light.

1. Temperature of water out of the brew chamber must

be 190 to 200 degrees F. Turn thermostat shaft

clockwise to increase the water temperature or

counterdegree turn of the thermostat shaft makes a 4

degree F water temperature change.

2. If thermostat shaft is turned clockwise to the stop a

temperature is still too low — replace thermostat.

16

Page 17

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

terminals. It should be within 10% of unit rating plate.

adjust or

e Brew

14. Water heats, but takes a

long time. (Slow Recovery)

15. Water Temperature

TOO Hot.

Also Called:

• Steaming

• Boiling

• Overheating

16. Dry Coffee Grounds, All

grounds not getting wet in

Brew Chamber (after a

brew cycle has been

completed.)

A. High Lime Deposits. 1. Delime unit. (Consult a qualified service technician.)

B. Low Voltage at Source. 1. Check voltage at receptacle and at heater element

If a low voltage condition exists, an electrician

should be consulted. A low voltage condition can

and does cause frequent service calls, as well as

extending the water heating time.

A. Thermostat 1. Thermostat out of calibration or defective —

replace. To decrease tank temperature, turn the

adjustment shaft counterclockwise. If Ready Light

does not come ON, the thermostat is defective,

replace it.

A. Spray Disc and/or Gasket

missing.

B. Filter Paper (Paper weave

too porous).

1. Check Spray Disc. The Spray Disc and Gasket must

be properly in place to break up the water stream

and completely wet coffee grounds.

1. Use proper filter papers to insure correct time for

contact of water and coffee in the Brew Basket.

C. Improper loading of th

Chamber.

17. Coffee Grounds do not get

wet. Water stays in Basin

Pan or Pan overflows,

and/or water leaks out of

the bottom of brewer body.

18. Weak Coffee A. Too much water. 1. V erify water level in decanter. Delivery should be 60

A. No Siphon Action. 1. Check for obstruction in elbow connections from

B. Leak in Water Path from

Water Input to final outlet at

Spray Disc.

1. Filter should be centered in the Brew Chamber and

the bed of coffee grounds should be level.

Basin Pan to Tank Cover and Outlet Elbow and

Tube to Spray Disc. 2. Check Tank Lid openings for

lime buildup restricting water flow.

1. Check for correct fit and/or leakage at:

a. Solenoid Valve and Fitting.

b. Water Input Tubing from Solenoid Valve to Basin

Pan.

c. Tank Cover Gasket.

d. Elbows and Tube connections from Basin Pan to

Spray Disc.

Oz. Adjust Timer for correct water delivery — (see

Installation Instructions.)

17

Page 18

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

(should be between 190 and 200 degrees F). Adjust

1. Filter Paper must be centered in Brew Chamber and

Improper Filter Paper can restrict water flow through

proximately three (3)

r drips, install a

18. Weak Coffee.

19. Strong Coffee.

B. Temperature of water too

low.

C. Improper loading of Brew

Chamber.

D. Not enough coffee grounds

in Brew Chamber.

A. Not enough water. 1. Verify water level in decanter. Delivery should be 60

B. Two (2) Filter Papers or

improper Filter Paper.

1. Check temperature of water out of Spray Disc

thermostat to proper temperature. (See Thermostat

Adjustment Procedure.)

Coffee ground bed must be level.

1. Verify coffee ground weight. Be sure to use the

proper measure of coffee grounds.

Oz. — adjust Timer for correct water delivery. (See

Installation Instructions).

1. Use only one (1) recommended Filter Paper.

coffee bed, causing over extraction, resulting in

strong, bitter coffee.

C. Too much coffee grounds in

Brew Chamber.

20. Overflowing Decanter.

Occasionally, not every

time.

22. Faucet keeps dripping. A. Foreign material inside the

A. Receiving Decanter not

empty when a brew cycle is

started.

B. Water pressure is fluctuating. 1. See: 7D "Water Pressure Fluctuations."

A. Incoming water source shut

off.

B. Needle Valve Shut -off

(between water inlet "T"

fitting and water tank.)

faucet valve seat preventing

faucet seat from shutting off

water flow completely.

1. Verify coffee ground weight. Be sure to use the

proper measure of coffee grounds. Average volume

is 1-1/4 to 3 ounces of cof fee grounds.

1. Always start a brew with an empty receiving

Decanter under Brew Chamber.

1. Check and be sure the water source valve is open. 21. No Water from Faucet.

1. The needle valve must be open to permit water flow

through the faucet, setting is ap

full turns from a closed condition. (The needle valve

is also used to adjust the force of the water stream

from the faucet.)

1. Shut off water supply, disassemble and clean the

faucet valve seat. If faucet still leaks o

complete repair kit. If faucet continues to drip, the

seat has been damaged, replace Faucet Assembly.

18

Page 19

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

1. Check Warmer Element for continuity. If no continuity

minutes.

24. Warming Plates will not

heat.

does not light.

A. Use of two (2) Filter Papers

or improper Filter Paper.

B. Lime Deposits in Brewer. 1. Check Elbows and Water Outlet Tube for lime

A. Warmer Switch. 1. Switch OFF, turn ON.

B. Warmer Element.

A. Loose Wire. 1. Locate loose wire and re-attach Terminal. 25. Glow Light inside Switch

B. Burned out Neon Glow

Lamp. (Switch works, but

light does not glow.)

1. Use only one (1) recommended Filter Paper. 23. Brew Time Exceeds 4-1/2

deposits or BLOCKAGE.

2. Check tank lid openings for lime deposit or foreign

material blockage.

3. Delime Elbows and/or Unit. (Consult a qualified

Service Technician.)

2. Check Warmer Switch for proper operation. If it

does not make and break load circuit — replace

Switch.

is present, replace Warmer Element.

1. Remove complete lighted Switch and replace.

19

Page 20

WIRING DIAGRAM

For

MODEL NOS. 8516 and 8518

NOTE: All wiring 16 gauge, except where noted.

This diagram is the same for Models 8516 and 8518, and covers both brewing sections of the units.

20

Page 21

ADDITIONAL SERVICE INFORMATION

Vacuum Pac consists of:

Ref. #29 COLD WATER ENTRANCE SOLENOID VALVE PART NO. 8541-120

Consists of Valve and Flow Control

SOLENOID VALVE REPLACEMENT PARTS

(For Blue Coil Valve)

(1) 8541-120C Coil Assembly — 120V.

(2) 8541-120K Solenoid Repair Kit

(3) 8541-120F (3A) Flow Control

(4) 8541-120WS (2D) Service Wrench

(5) 8810-103 Solenoid Valve Only

(No Kit Parts Sold Separately)

(2A) Spring

(2B) Plunger

(2C) Seal Ring

(Minus 2D & 3A)

(1) 8541-120CS Coil Assembly — 120V.

SOLENOID VALVE REPLACEMENT PARTS

(For Black Coil Valve)

(No Kit Parts Sold Separately)

(2) 8541-120JS Solenoid Repair Kit

(3) 8541-120KS Solenoid Overhaul Kit

(4) 8541-120F (3A) Flow Control

(5) 8541-120WS (2D) Service Wrench

(6) 8810-103 Solenoid Valve Only

Vacuum Pac consists of:

(2A) Spring

(2B) Plunger

(2C) Seal Ring

(2D) Service Wrench

Vacuum Pac consists of:

(2A) Spring

(2B) Plunger

(2C) Seal Ring

(2D) Service Wrench

(3A) Flow Control

(Minus 2D & 3A)

21

Page 22

ADDITIONAL SERVICE INFORMATION (Cont'd.)

HOT WATER FAUCET

REPLACEMENT PARTS LIST

Ref.

No. Part No. Description A. 8706-169B Handle, Red

1. 8551-275 Repair Kit (sold as Kit only) 3. 8551-100A Washer Rubber

A.

B.

C.

D. Kit "0" Ring — #6, #7 & #8 6. 8551-200B "0" Ring Stem Seal 5/16" O.D.

E. Contains Tee Nut 7.

F.

G.

H.

Handle (Color — Red) 4. 8551-100B 7/16 External Tooth Lock Washer

Valve-Stem 5. 8551-100C Hex Lock Nut

Valve Disc

Spring 8.

Guide C. 8551-275A Valve Disc

Bushing

Instruction Card (Not Shown) 9. 8551-200E Adapter Tool — Service Wrench

2. 8551-275B Stream Straightener (Not Shown)

8551-200A "0" Ring Seal 1/4" O.D.

8551-200C "0" Ring Spout Seal 3/8" O.D.

SEALS AVAILABLE

TOOL AVAILABLE

22

Loading...

Loading...