Page 1

Star

Manufacturing

International Inc.

Installation and

Operating Instructions

10 Sunnen Drive

St. Louis, MO 63143

Phone: (314) 678-6303

Fax: (314) 781-2714

Instructions d’installation

et d’opération

2M-Z16558 Rev. B 11/05/2013

ULTRA-MAX™ GAS GRIDDLE MODELS

GRILS A GAZ ULTRA-MAX MODELES

824MA 824TA 824TSA 824TCHSA 824TSCHSA

836MA 836TA 836TSA 836TCHSA 836TSCHSA

848MA 848TA 848TSA 848TCHSA 848TSCHSA

860MA 860TA 860TSA 860TCHSA 860TSCHSA

872MA 872TA 872TSA 872TCHSA 872TSCHSA

WARNING: Improper installation,

adjustment, alteration, service or

maintenance can cause property

damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing

or servicing this equipment.

AVERTISSEMENT: L’installation inexacte, le réglage,

le changement, le service ou l’entretien peuvent

causer des dégats matériels, des dommages ou la

mort. Lisez les instructions d’installation, d’opération

et d’entretien complètement avant d’installer ou

entretenir ce matériel.

FOR YOUR SAFETY: Do not store or

use gasoline or other ammable vapors or

liquids in the vicinity of this or any other

appliance.

POUR VOTRE SÛRETÉ: N’enregistrez pas ou

n’utilisez pas l’essence ou d’autres vapeurs ou

liquides inammables à proximité de ceci ou d’aucun

autre appareil.

WARNING: This appliance shall be

installed in accordance with current

regulations and used only in wellventilated space. Refer to instructions

before installing and using this

appliance.

AVERTISSEMENT: Cet appareil sera installé selon

des règlements actuels et utilisé seulement dans

l’espace bien-aéré. Référez-vous aux instructions

avant d’installer et utiliser cet appareil.

In addition, there should be posted, in a

prominent location, detailed instructions

to be followed in the event the operator

smells gas. Obtain the instructions from

the local gas supplier.

En outre, là devrait être signalé, dans un

emplacement en avant, des instructions détaillées

d’être suivi en cas que l’opérateur sent le gaz.

Obtenez les instructions du fournisseur local de gaz.

Page 2

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it

ready when you call to ensure a faster service.

Authorized Service Agent Listing

Model No.

Serial No.

Voltage

Purchase Date

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail customerservice@star-mfg.com

Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail customerservice@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

22

Page 3

32 3/8”

Width

(82.3 cm)

30 5/8”

(82.3 cm)

GAS INLET

2 3/16”

(5.5 cm)

13 9/16”

(34.4cm)

4”

7 7/16”

(13.8cm)

18”

(45.8cm)

IL2585

SPECIFICATIONS

Model Type Controls BTUH Griddle Area

824MA

836MA 3 90,000 860 sq. in. (5545 sq. cm) 36” (91.4cm) 321lbs (145.4kg) 366lbs (165.8kg)

848MA 4 120,000 1146 sq. in (7397 sq. cm) 48” (122cm) 428lbs (193.3kg) 488lbs (221.1kg)

860MA 5 150,000 1433 sq in (9242 sq cm) 60” (152.4cm) 535lbs (242.4kg) 610lbs (276.4kg)

Manual

Valve

(pilot)

2 60,000 573 sq in (3697sq. cm) 24” (61cm)

872MA 6 180,000 1719 sq in (11091 sq cm) 72” (182.9cm) 642lbs (290.9kg) 732lbs (331.7kg)

824TA

2 60,000 573 sq in (3697sq. cm) 24” (61cm)

836TA 3 90,000 860 sq. in. (5545 sq. cm) 36” (91.4cm) 321lbs (145.4kg) 366lbs (165.8kg)

848TA 4 120,000 1146 sq. in (7397 sq. cm) 48” (122cm) 428lbs (193.3kg) 488lbs (221.1kg)

T-Stat

(pilot)

Dimensions Approx Weight

Width Depth Height Installed Shipping

214lbs (97kg) 244lbs (110.6kg)

32 3/8”

(82.2cm)

18”

(45.7cm)

214lbs (97kg) 244lbs (110.6kg)

32 3/8”

(82.2cm)

18”

(45.7cm)

860TA 5 150,000 1433 sq in (9242 sq cm) 60” (152.4cm) 535lbs (242.4kg) 610lbs (276.4kg)

872TA 6 180,000 1719 sq in (11091 sq cm) 72” (182.9cm) 642lbs (290.9kg) 732lbs (331.7kg)

824TSA,

TSCHSA

836TSA,

TSCHSA

848TSA,

TSCHSA

860TSA,

TSCHSA

872TSA,

TSCHSA

Thermal

Spark

(no pilot)

2 80,000 573 sq in (3697sq. cm) 24” (61cm)

214lbs (97kg) 244lbs (110.6kg)

3 120,000 860 sq. in. (5545 sq. cm) 36” (91.4cm) 321lbs (145.4kg) 366lbs (165.8kg)

4 160,000 1146 sq. in (7397 sq. cm) 48” (122cm) 428lbs (193.3kg) 488lbs (221.1kg)

32 3/8”

(82.2cm)

18”

(45.7cm)

5 200,000 1433 sq in (9242 sq cm) 60” (152.4cm) 535lbs (242.4kg) 610lbs (276.4kg)

6 240,000 1719 sq in (11091 sq cm) 72” (182.9cm) 642lbs (290.9kg) 732lbs (331.7kg)

33

Page 4

CAUTION

GENERAL INSTALLATION DATA

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand the

units operation & safety before they use the unit.

Ultra-Max series griddles are equipped for use on either natural or propane gas. All units are shipped

for natural gas and can easily be converted to propane. See Propane Gas - Conversion.

-IMPORTANT-

Be sure to remove all paper protection and packing material from unit prior to

lighting. Remove the protective plastic from the griddle plate and thoroughly

clean the unit's exterior surfaces.

KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES! For

use on non-combustible countertops only. Combustible and non-combustible

material must be at least 48" (120cm) from the top of the appliance and at

least 6" (16cm) from the sides and back. Adequate clearance should also be

provided for proper operation and servicing.

The installation of the Appliance must conform to the NATIONAL FUEL GAS

CODE "ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY

RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE

CURRENT CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR

CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES

WHERE APPLICABLE.

NOTICE

When this appliance is installed with casters, it must be installed with the casters supplied, a connector

complying with either ANSI Z21.69 or CAN/CGA-6.16 and a quick-disconnect device complying with

either ANSI Z21.41 or CAN1-6.9. It must also be installed with restraining means to guard against

transmission of strain to the connector.

For your protection, we recommend a qualied installing agency install this appliance.

They should be familiar with gas installations and your local gas requirements. In any

case, your gas company should be called to approve the nal installation.

This appliance, its pressure regulator and its individual shutoff valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2

PSIG. This appliance and its pressure regulator must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 PSIG.

EXHAUST CANOPY

Griddles inherently create a good deal of heat and smoke and should be installed under an efcient

exhaust hood with ame proof lters. A vertical distance of not less than 48" shall be provided between

the top of the appliance and lters or any other combustible material. Exhaust installation must

conform to local codes.

CAUTION

AIR SUPPLY: Provisions for adequate air supply must be provided.

AIR INTAKES IN BOTTOM

Air for combustion enters from the bottom of the unit. Do not obstruct this area.

44

Page 5

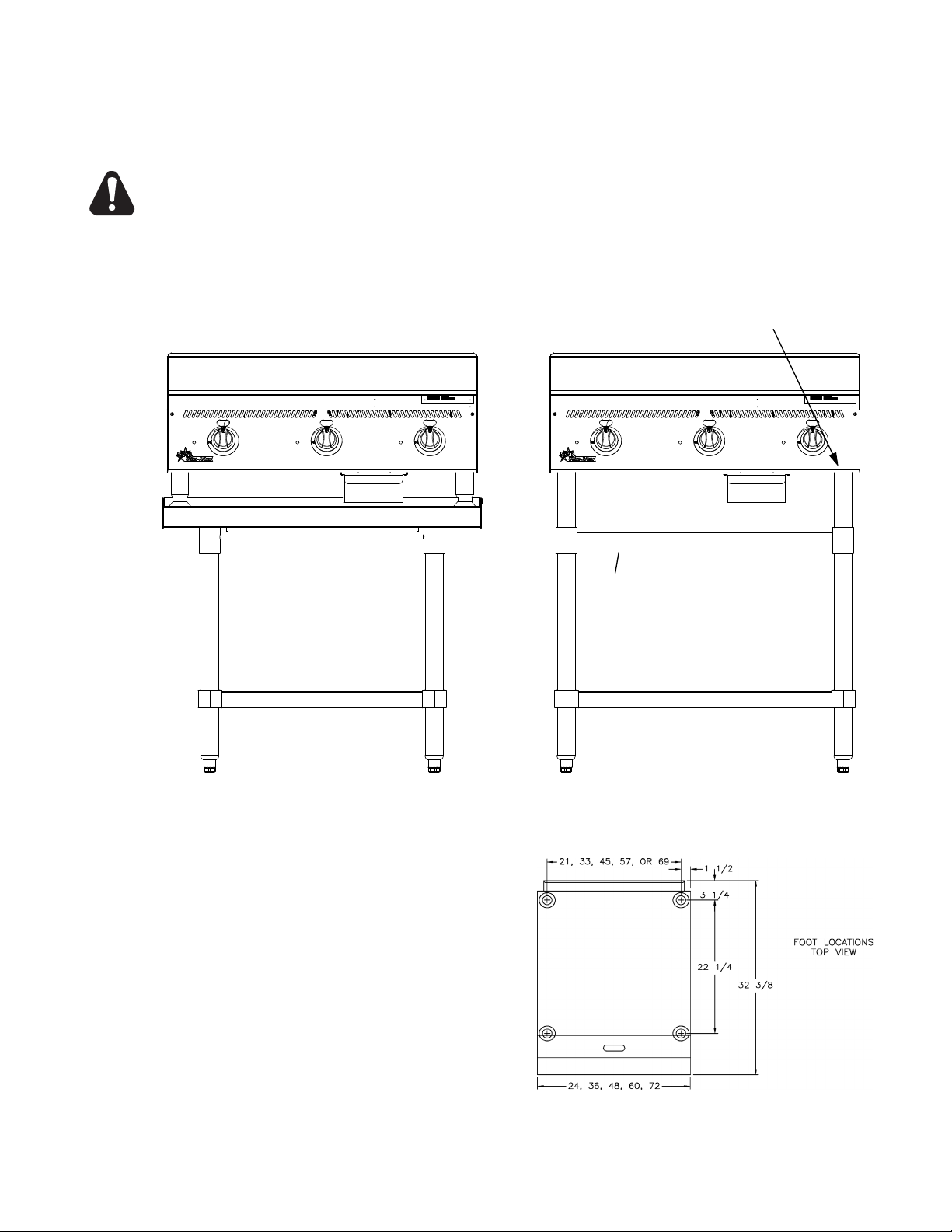

SCREW LEGS INTO

MOUNTING NUTS ON BOTTOM

FLOOR STAND SHELF

STIFFENING SUPPORTS FOR

860 & 872 MODELS ONLY

FLOOR STAND MODELCOUNTER TOP MODEL

ON OPTIONAL EQUIPMENT STAND

IL2586

CAUTION

LEVELING UNIT

This griddle is supplied with 4 feet or oor stand legs which must be screwed into the body. After

the griddle is in its nal position, adjust the legs to create 1/8 inch slant from back to front. This will

allow the grease to run into the grease gutter and provide the proper combustion air for the burners.

Adjusting the (4) feet which have an adjustment of 1-3/4" for accurate and perfect line-up with other

units.

DO NOT INSTALL WITHOUT ATTACHING FEET OR SUPPLIED STAND LEGS

AND SHELF - DO NOT REMOVE FEET.

Caster Kits: Casters can be used with oor

stand models or optional equipment stand.

For installation, carefully mark and cut off from

the bottom of each leg using a straight cutting

saw and de-burr the inside tube wall prior to

installing the caster. Cut leg should measure

19" tube length, not overall length. Casters

add about 6-1/4" of height to the unit. Be

sure to use approved strain relief means for

protecting gas line connection. If an appliance

is equipped with casters and is gas connected

with a quick connect coupling, all personnel

must be aware that there is a restraint on the

appliance and if disconnected for service or

cleaning it must be reconnected as originally

installed prior to use.

55

Page 6

GAS PIPING

PLUG

IL1199

Natural

Regulator

Propane / LP

Gas piping shall be of such size and so installed as to provide a supply of gas sufcient to meet the

full gas input of the appliance. If the appliance is to be connected to existing piping, it shall be checked

to determine if it has adequate capacity. Joint compound shall be used sparingly and only on the male

threads of the pipe joints. Such compounds shall be resistant to the action of L.P. gases. WARNING:

Any loose dirt or metal particles which are allowed to enter the gas lines on this appliance will damage

the valve and affect its operation. When installing this appliance, all pipe and ttings must be free from

all internal loose dirt.

GAS PRESSURE REGULATOR

A convertible pressure regulator is provided with each griddle. It should be connected to the inlet pipe

at the rear of the unit. The gas supply is then connected to it. The supply pressure to the regulator is

not to exceed 1/2 psig. If the gas pressure going to the regulator on the griddle exceeds 1/2 PSIG

then another regulator must be installed to lower the pressure going to it. This second regulator is not

supplied with the griddle and is the customers responsibility. All units are shipped for use with natural

gas. MA and TA Series Models are shipped set for 5" water column manifold pressure. TSA and

TSCHSA Series Models are shipped set for 5" water column manifold pressure.

MANUAL SHUT OFF VALVE

A manual shut off valve should be installed upstream from the manifold and within six feet of the

griddle. The shut-off valve is not supplied with the griddle and is the customers responsibility.

CONNECTING GAS SUPPLY LINE

The gas inlet of the griddle is sealed at the factory to prevent entry of dirt. Do not remove this seal until

the actual connection is made to the gas supply line.

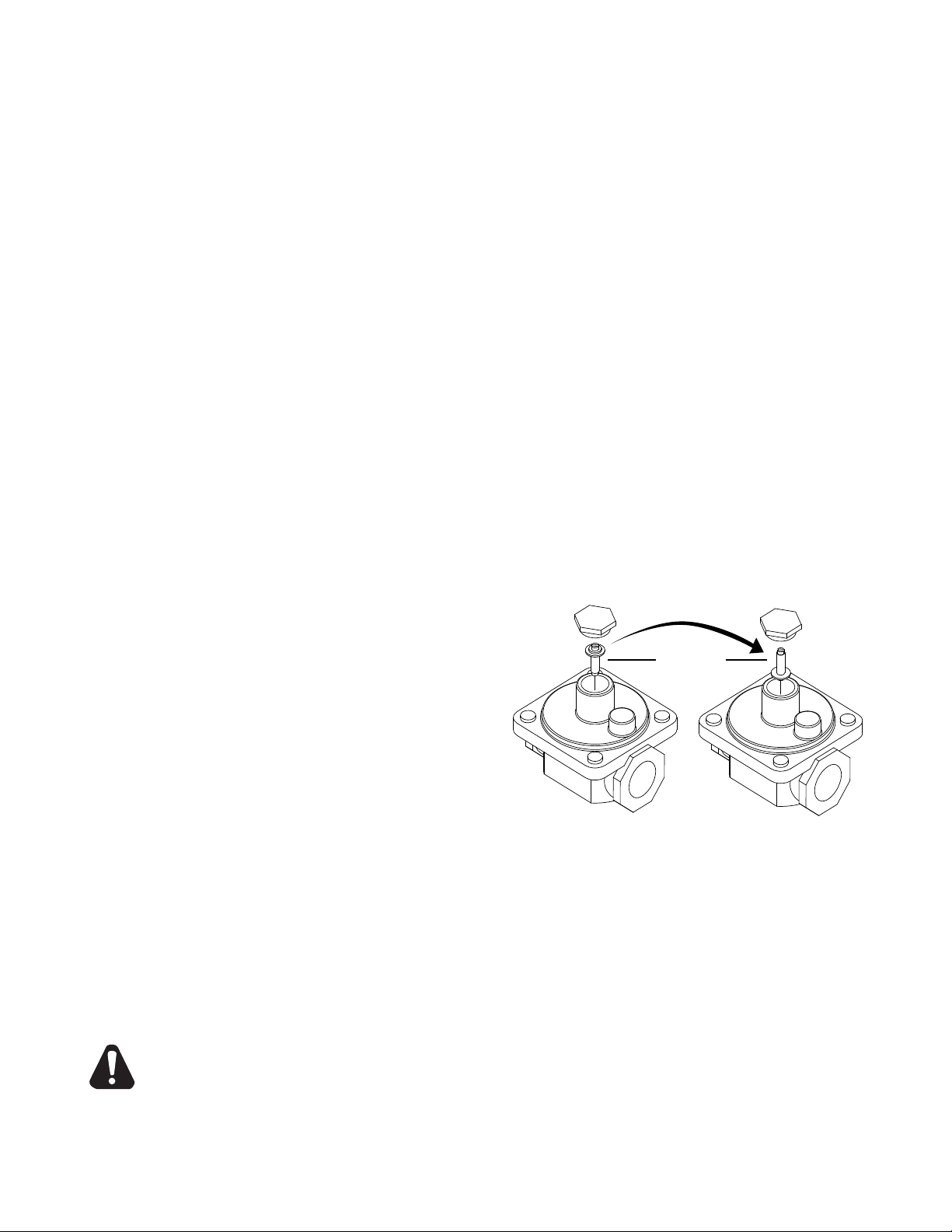

PROPANE GAS - CONVERSION

This griddle is equipped with xed orice hoods and is shipped from the factory for use with natural

gas. To convert to propane gas install the orice hoods located behind the front panel as follows:

1. Remove the front panel by removing the

screws located on the front and bottom.

2. Remove the burner mounting screws in the

center of the combustion chamber access

covers.

3. Slide the burners back off the orice hoods.

4. Remove the natural gas orice hoods and

install the propane orice hoods.

5. Slide the burners back over the orice hoods

and reinstall the burner mounting screws.

6. Reinstall the front panel.

7. Set the pressure regulator to 10" (25.4cm)

water column by removing the slotted or

hex cap from the center of the regulator.

Invert the plug and reinstall. The letters "LP"

will now be visible on the plug. Reinstall the cap. An 1/8" pipe plug is located on the manifold for

attaching a pressure gauge.

CHECKING FOR GAS LEAKS

Check entire piping system for leaks. Soap and water solution or other material acceptable for the

purpose, shall be used in locating gas leakage.

CAUTION

Matches, candle ame or other sources of ignition shall not be used for

locating gas leaks.

66

Page 7

PILOT FLAME ADJUSTMENT

The griddles are equipped with standing pilots and should be lit immediately after the gas is turned on.

MANUAL VALVE AND THROTTLING CONTROL MODELS

Adjust the ame as low as possible while still providing immediate burner ignition when the control

knob is turned to high.

LIGHTING INSTRUCTIONS

When the griddle is rst lit, it will smoke until the preservative oils and impurities are burned off.

The griddles are equipped with standing pilots and should be lit immediately after the gas is turned

on. Snap Action giddles do not have a standing pilot and do not require lighting. The Unit should

be properly leveled prior to lighting, with the rear of the griddle slightly higher than the front to allow

grease to roll off and ue gasses to escape out the rear..

DO NOT ATTEMPT TO LIGHT YOUR PILOT BURNER IF YOU EXPERIENCE A

STRONG GAS ODOR.

CAUTION

MANUAL VALVE AND THROTTLING CONTROL MODELS

1. Turn off the main valve to the unit and wait 5 minutes to clear gas.

2. Turn off all knobs and pilot valves.

3. Turn on main valve to unit and light all pilots.

4. Turn burner knobs to desired position.

5. To turn burners off, turn knobs to off.

ORIFICE ELEVATION COMPENSATION CHART

Orice @ sea level 2000 3000 4000 5000 6000 7000 8000 9000 10000

Manual Control Gas Griddles: 824ma thru 872MA

NAT 41 42 42 42 43 43 44 44 45 46

LP 52 52 53 53 53 53 53 54 54 54

Thermostatic Conrol Gas Griddles: 824TA thru 872TA

NAT 38 39 40 41 41 42 42 43 43 44

LP 52 52 53 53 53 53 53 54 54 54

Snap Action Gas Griddles: 824TSA thru 872TSA

NAT 34 35 36 36 37 37 38 39 40 42

LP 49 50 50 50 51 51 51 52 52 52

77

Page 8

CAUTION

BURNER AIR SHUTTER ADJUSTMENT

The burner air shutter has a locking screw on the bottom side of the venturi. Loosen this screw

to make any adjustment and tighten the screw to lock the air shutter in place after adjustment

is complete. Any adjustment must be made when the burner is at full input before the control

temperature setting has been satised.

1. Turn the control knob to the highest position and observe the burner ame.

2. Slowly decrease the air shutter opening until the ame is a soft blue with yellow tips, then increase

the opening until the yellow tips disappear and the ame is a hard blue.

3. Do not open the shutter to a point where the ame is unstable or lifting from the burner surface.

The ame must be steady and even across the entire burner.

The following was set at the factory and the adjustment should only be made

by an authorized installer and only if you are experiencing this specic

problem.

BYPASS ADJUSTMENT ON THROTTLING CONTROL MODELS ONLY

Throttling control models have a minimum ame setting that provides a steady uniform ame across

the burner when the control heat setting has been satised.

1. Set the control at the maximum setting and wait for the burner ame to throttle back.

2. Turn the dial to the 200 degree setting. A small steady ame should be visible on all the burner

ports. This ame should be approximately 1/8" high.

3. An adjustment screw is located either on the front or side of the control housing.

4. Turn clockwise to decrease the ame height; turn counterclockwise to increase the ame

CAUTION

CAUTION

ELECTRICAL CONNECTION FOR SNAP ACTION AND CHROME SURFACE

MODELS ONLY

Snap action and chrome surface griddles are equipped with a three-prong grounding plug. The unit

is designed for use on a 120 volt 15 amp 50/60 cycle AC single-phase circuit only. For protection

against electrical shock, the unit must be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from this plug.

Do not connect to any other type of current or serious damage will occur.

OPERATING INSTRUCTIONS

SEASONING THE GRIDDLE HEATING SURFACE (NON-CHROME SURFACES)

Clean the griddle surface thoroughly. After the griddle has been thoroughly cleaned, it should be

seasoned to prevent food from sticking. Before using and after each thorough scouring, season the

griddle heating surface in the following manner:

1. Turn the temperature control dial to 350°F (174.0°C).

2. Using a clean cloth, not a spatula, spread a thin lm of cooking oil or shortening over the griddle

cooking surface. This lm should remain on the hot griddle surface 1/2 hour.

3. Remove excess shortening and wipe clean.

4. Apply another lm of cooking oil over the hot cooking area for another 1/2 hour, and again remove

excess shortening and wipe clean. The griddle surface should now be ready for use.

Even with careful seasoning food may, to some extent, stick to the griddle cooking

surface until griddle plate is "broken in."

COOKING

Set the dial knob to the setting desired. After a 30 minute (minimum) preheating period, the griddle

will automatically maintain the selected temperature.

88

Page 9

GRIDDLE CARE (NON-CHROME SURFACES)

It takes very little time and effort to keep the griddle attractive and performing at top efciency. If

grease is permitted to accumulate, it will form a gummy cake and then carbonize into a hard substance

which is extremely difcult to remove. To prevent this condition, the following suggestions for

cleanliness should be followed:

1. After each use, scrape the griddle with a scraper or exible spatula to remove excess grease and

food. A waste drawer is provided for the scrapings. If there is an accumulation of burned-on grease

and food, the griddle should be thoroughly scoured and reseasoned. Use pumice or griddle stone

while the griddle is warm. Do not use steel wool because of the danger of steel slivers getting into

the food.

2. Use a clean cloth and good non-abrasive cleaner to clean the stainless steel body of the griddle.

Wipe the control panel front with a soft cloth.

3. At least once a day, remove the waste drawer and wash in the same way as an ordinary cooking

utensil. The drawer is removed by pulling forward and out.

GRIDDLE CARE (CHROME SURFACES)

(Chrome surface griddles are marked with "CHS" at the end of the model number designation on the

nameplate.) It takes very little time and effort to keep this Industrial Chrome griddle surface sparkling

clean and performing at top efciency. DO NOT allow grease to accumulate as it will carbonize and

become difcult to remove. To prevent this condition, the following cleaning suggestions should be

followed:

1. Remove excess oil and food regularly with a 4" (100mm) wide razor sharp type scraper and wipe

surface with a damp cloth if desired.

2. Following the scraping, for end of the day cleaning, a damp cloth and a non-silicated, non-abrasive,

non-chlorinated cleaner such as Bon-Ami may be used to wipe surface clean, followed by wiping

with clean wet cloth.

3. Follow steps 2 and 3 from Griddle Care (Non-Chrome Surfaces).

CAUTION

CAUTION

CAUTION

1. Never use pumice, griddle stones, or abrasives on the surface.

2. Never strike the griddle surface with a sharp instrument or spatula edge.

3. Never use steel wool.

4. Never use commercial liquid grill cleaner on the griddle surface.

5. Abusing the surface voids the warranty.

WASTE DRAWER

A waste drawer is located at the front and can be removed from the front for cleaning by pulling drawer

forward. This drawer should be checked and emptied when necessary or at least once per day.

EXERCISE EXTREME CARE IN HANDLING THE WASTE DRAWER CONTAINING

HOT GREASE.

OVERNIGHT SHUTDOWN

MANUAL VALVE AND THROTTLING CONTROL MODELS

Turn knobs to the off position to turn burners off.

SNAP ACTION AND CHROME SURFACE MODELS

Turn knobs to the lowest setting and turn power switch off.

99

Page 10

CHROME GRIDDLE SURFACE LIMITED WARRANTY EXCLUSIONS

Your chrome griddle has been designed to give you many years of cooking reliability and requires

minimum maintenance to keep the chrome surface in its original condition. All chrome griddle surfaces

are warranted for a period of 5 years against manufacturing defects to the original owner from the

date of installation. This limited warranty is void if it is determined by Star Manufacturing International

Incorporated or one of its authorized representatives that the chrome surface has been misused or

abused or subjected to the following situations:

1. Improperly installed.

2. By-pass adjustments not set properly on gas units allowing the appliance to overheat and discolor the

chrome surface. (See by-pass adjustment section.)

3. The misuse of any instrument or tool which scratches or makes indentations in the surface which could

cause the surface to peel, ake, or chip off.

4. The use of any chemical or abrasive cleaning solution, griddle brick, stone, screen or other cleaning

products which could damage and affect the performance of the chome surface.

5. The neglect of daily routine maintenance to the chrome surface.

1010

Page 11

SYMBOLE DE SÉCURITÉ

Ces symboles sont utilisés pour souligner à l’utilisateur les

instructions d’utilisation ou d’entretien importantes contenues

dans le manuel qui accompagne l’appareil.

CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE

L’utilisation de toute pièce autre que les pièces d’origine STAR dégage le fabricant de toute responsabilité.

Star se réserve le droit de changer les spécications et la conception du produit

sans préavis. Ces changements ne donnent pas le droit à l’acheteur d’obtenir

les changements, améliorations, ajouts ou remplacements correspondants pour

l’équipement acheté préalablement.

Dû aux modications périodiques de dessins, méthodes, procédures, règles

et régulations, les spécications contenues dans ce manuel sont susceptibles

de changer sans préavis. Quoique STAR Manufacturing exerce la bonne foi de

fournir le renseignement correct, STAR n’est pas responsable pour les erreurs

ou les omissions dans le renseignement pourvu ou les conclusions tirées à la

suite de l’utilisation des spécications. En utilisant le renseignement pourvu,

l’utilisateur assume tous les risques en relation avec telle utilisation.

AVIS

ENTRETIEN ET RÉPARATIONS

Contactez votre détaillent local pour les réparations ou l’entretien requis. Assurez-vous d’avoir le numéro de

modèle, le numéro de série, le voltage et la date d’achat pour un service plus rapide. Entrez l’information

requise ci-dessous pour référence rapide.

Agent de service autorisé

N° de modèle

N° de série

Voltage

Date d’achat

Voir la liste pourvue avec l’appareil

Ou

Pour une liste mise à jour voir :

Site web : www.star-mfg.com

Courriel : customerservice@star-mfg.com

1111

Page 12

DONNÉES GÉNÉRALES D’INSTALLATION

ATTENTION

Ce matériel est conçu et vendu pour l’usage commercial seulement par le personnel qualié et expérimenté en

son exécution et n’est pas vendu pour l’usage du consommateur dans et autour de la maison ni pour l’usage

directement par le grand public dans des emplacements de service de traiteur.

Des grils de série d’Ultra-Max sont équipés pour l’usage sur le gaz naturel ou de propane. Toutes les unités sont

expédiées pour le gaz naturel et peuvent facilement être converties en propane. Voir Le Propane Intoxiquer - La

Conversion.

-IMPORTANT-

Soyez sûr d’enlever tout le matériel de papier de protection et d’emballage à partir de l’unité avant l’éclairage.

Éliminez le plastique protecteur du plat de gauffreuse et nettoyez complètement les surfaces extérieures de

l’unité.

MAINTENEZ LA RÉGION D’CAppareils LIBRE ET CLAIRE DES COMBUSTIBLES! Pour l’usage sur les

countertops non-combustibles seulement. Le matériel combustible et non-combustible doit être au moins 48 “

(120cm) à partir du dessus de l’appareil et au moins 6 “ (16cm) des côtés et du dos. Le dégagement adéquat

devrait également être donné pour l’exécution appropriée et l’entretien.

L’installation de l’appareil doit se conformer au CODE NATIONAL DE GAZ COMBUSTIBLE "ANSI

Z223.1 - TOUTE DERNIÈRE ÉDITION" DES ÉTATS-UNIS ET À TOUTES LES RÈGLES ET

RÉGLEMENTATIONS DE LA COMPAGNIE DE GAZ LOCALE.

AU CANADA, L’INSTALLATION DOIT ÊTRE CONFORME AU CODE COURANT D’INSTALLATION

AU GAZ NATUREL CAN/CGA-B149.1 OU AU CODE D’INSTALLATION AU PROPANE CAN/CGAB149.2 ET AUX CODES LOCAUX, LE CAS ÉCHÉANT.

NOTIFICATION

Quand cet appareil est installé avec des roulettes, il doit être installé avec les roulettes fournies, un connecteur

étant conforme à la norme ANSI Z21.69 ou au CAN/CGA-6.16 et à un dispositif rapide étant conforme à la

norme ANSI Z21.41 ou au CAN1-6.9. Il doit également être installé avec des moyens retenants de garder

contre la transmission de la contrainte au connecteur.

Pour votre propre protection, on vous recommande de faire installer cet appareil par une agence d’installation

qualiée. Ils doivent connaître les installations de gaz et vos exigences de gaz locales. En tout cas, il faut

appeler votre société du gaz pour l’approbation de l’installation nale.

Cet appareil, son régulateur de pression et ses vannes d’arrêt individuelles doivent être débranchés de la

tuyauterie d’alimentation du gaz lors des essais de pression de la tuyauterie en question à des pressions en

dessus de ½ PSIG. Cet appareil et son régulateur de pression doivent être isolés de la tuyauterie d’alimentation

du gaz en fermant sa vanne d’arrêt manuelle individuelle lors des essais de pression de la tuyauterie

d’alimentation de gaz à des pressions égales à ou de moins que ½ PSIG.

ÉPUISEZ LE BALDAQUIN

Les grils créent en soi beaucoup de la chaleur et de la fumée et devraient être installés sous un capot efcace

d’échappement avec des ltres de preuve de amme. Une distance verticale pas moins de de 48 “ sera

fournie entre le dessus de l’appareil et les ltres ou n’importe quel autre matériel combustible. L’installation

d’échappement doit se conformer aux codes locaux.

LA PROVISION DE L'AIR

Les vivres pour provision de l'air adéquate doivent être fournis.

ATTENTION

PRISES D’AIR EN BAS

L’air nécessaire à la combustion entre par le bas de l’appareil. Ne bas boucher cette section.

1212

Page 13

IL2586-FR

Vissez les jambes dans des

écrous de support sur le bas

Étagère De Stand De Plancher

Raidissant des supports sur,

860 et 872 modèles seulement

Modèle de Stand de PlancherContre- Modèle Supérieur

Sur le Stand Facultatif de Matériel

RASANT DE L'UNITÉ

Cette plaque en fonte est fournie 4 pieds ou jambes

d'éventaire d'étage qui doivent être vissées dans le

corps. Après que la plaque en fonte est dans sa position

nale, régler les jambes pour créer le point de vue de

pouce 1/8 d'à l'envers. Cela permettra à la graisse

de heurter la gouttière de graisse et fournir l'air de

combustion nécessaire aux brûleurs. Le réglage (le 4)

les pieds qui ont un ajustage de 1-3/4" pour l'équipe

exact et parfait avec d'autres unités.

ATTENTION

N’INSTALLEZ PAS SANS ATTACHER ES

PIEDS OU DES JAMBES ET L'ETAGERE

FOURNIES DE STAND.

Lots de roulettes: Des roulettes peuvent être utilisées

avec les modèles de stand de plancher ou le stand

de matériel facultatif. Pour d’installation la marque

soigneusement et découpé le de bas de chaque jambe

en utilisant une scie et un de-burr droits de découpage

le mur intérieur de tube avant d’installer la roulette.

La jambe de coupe devrait mesurer 19 “ longueur

de tube, longueur hors-tout. Les roulettes ajoutent

environ 6-1/4 “ de taille à l’unité. Soyez sûr d’utiliser

des moyens approuvés de passe-ls pour protéger la

connexion de ligne de gaz. Si un appareil est équipé

des roulettes et est gaz lié à un rapide relient le

couplage, tout le personnel doit se rendre compte qu’il

y ait une contrainte sur l’appareil et si débranché pour

le service ou le nettoyage qu’il doit être rebranché

comme initialement installé avant l’utilisation.

1313

Page 14

TUYAUTERIE À GAZ

La taille de la tuyauterie à gaz et la façon dont elle est installée doivent être telles qu’elle fournisse une

alimentation sufsante de gaz pour répondre aux exigences d’admission de pleine puissance dans l’appareil.

S’il faut raccorder l’appareil à la tuyauterie existante, il faut vérier cette dernière pour déterminer si elle a la

capacité nécessaire. Il ne faut utiliser le composé combiné que modérément et seulement sur les letages mâles

des raccords à tuyaux. Ces composés doivent résister à l’action des gaz propanes. AVERTISSEMENT : Toute

impureté libre ou particule métallique qui entre dans les canalisations de gaz de cet appareil endommagera la

vanne et en affectera le fonctionnement. Lors de l’installation de cet appareil, tous les tuyaux et raccords doivent

être exempts de toute impureté interne libre.

RÉGULATEUR DE PRESSION DU GAZ

Un régulateur de pression convertible est équipé de chaque gauffreuse. Il devrait être relié dans le tuyau

d’admission à l’arrière de l’unité. L’offre de gaz est alors reliée à elle. La pression d’approvisionnement au

régulateur ne doit pas excéder 1/2 psig. Si la pression du gaz va vers le régulateur sur la sellette dépasse 1/2

PSIG, puis un autre régulateur doit être installé pour abaisser la pression allant jusqu'à lui. Cette deuxième

régulateur n'est pas fourni avec la crêpière et incombe aux clients. Toutes les unités sont expédiées pour l’usage

avec le gaz naturel. Les modèles de M et de séries de T sont positionnement expédié pour 5 “ pression de

tubulure de colonne de l’eau. Les modèles de série de SOLIDES TOTAUX et de TSCHS sont positionnement

expédié pour 5“ pression de tubulure de colonne de l’eau.

VANNE D’ARRÊT MANUELLE

Une valve coupée manuelle devrait être installée en amont de la tubulure et à moins de six pieds du gril. La

vanne d'arrêt est pas fourni avec la crêpière et incombe aux clients.

RACCORD DE LA CANALISATION DE GAZ

La prise de gaz du gril est scellée à l’usine pour empêcher l’entrée de la saleté. Ne retirez pas ce joint jusqu’à ce

que le rapport réel soit établi à la canalisation d’alimentation de gaz.

GAZ PROPANE - CONVERSION

Cette gauffreuse est équipée des capots xes d’orice et est expédiée de l’usine pour l’usage avec le gaz naturel.

Pour convertir en gaz de propane installez les capots de l’orice #52 situés derrière le panneau avant comme

suit:

1. Retirez le panneau avant en retirant les vis plac sur l’avant et le bas.

2. Retirez les vis de support de brûleur au centre de l’accès de chambre de combustion couvre.

3. Glissez les brûleurs dégagent les capots d’orice.

4. Retirez les capots d’orice de gaz naturel et installez les capots d’orice de propane.

5. Glissez les brûleurs en arrière au-dessus des capots d’orice et réinstallez les vis de support de brûleur.

6. Réinstallez le panneau avant.

7. Placez le régulateur de pression à 10 “ colonne de l’eau (de 25.4cm) en retirant le chapeau rainé ou d’hexa

du centre du régulateur. Inversez la prise et la réinstallez. Les lettres “ LP “ seront maintenant visibles sur la

prise. Réinstallez le chapeau. Un 1/8 “ prise de pipe est situé sur la tubulure pour attacher un indicateur de

pression.

LA VÉRIFICATION LE GAZ FUIT

Vérier l’étanchéité de toute la tuyauterie. Pour vérier l’étanchéité, il faut utiliser une solution de savon et d’eau

ou une autre matière acceptable pour ce but.

ATTENTION

Ne pas utiliser d’allumettes, la amme d’une chandelle ou d’autres sources d’allumage.

1414

Page 15

ALLUMER DES INSTRUCTIONS

Quand la gauffreuse est d’abord allumée, il fumera jusqu’à ce que les huiles et les impuretés de préservatif soient

consommation. Les gauffreuses sont équipées des pilotes debout et devraient être allumées juste après que le

gaz est allumé.

LA COMMANDE MANUELLE DE VALVE ET D’CÉtranglement MODÈLE

1. Arrêtez la valve principale à l’unité et attendez 5 minutes au gaz clair.

2. Arrêtez toutes les molettes et soupapes de commande.

3. Ouvrez la valve principale à l’unité et allumez tous les pilotes.

4. Tournez les molettes de brûleur à la position désirée.

5. Pour arrêter des brûleurs, tournez les molettes à hors fonction.

MODÈLES EXTÉRIEURS INSTANTANÉS DE THERMOSTAT ET DE CHROME D’CAction

1. Arrêtez la valve principale à l’unité et attendez 5 minutes au gaz clair.

2. Arrêtez le commutateur de puissance et tournez les thermostats à la plus basse conguration.

3. Ouvrez la valve principale.

4. Enfoncez et tenez le bouton pilote de remise de sûreté. Allumez le pilote. Tenez le bouton de remise pendant

60 secondes ou jusqu’ aux séjours pilotes s’est allumé. Répétition pour tous les pilotes.

5. Mettez en marche le commutateur de puissance et placez les thermostats à la position désirée.

6. Pour arrêter des brûleurs, arrêtez le commutateur de puissance.

RÉGLAGE PILOTE DE FLAMME

Les grils sont équipés des pilotes debout et devraient être allumés juste après que le gaz est allumé.

MODÈLES MANUELS DE COMMANDE DE VALVE ET D’CÉtranglement

Ajustez la amme aussi basse que possible tout en fournissant toujours l’allumage immédiat de brûleur quand le

bouton de commande est tourné à la haute.

MODÈLES EXTÉRIEURS INSTANTANÉS DE THERMOSTAT ET DE CHROME D’CAction Ajustez le pilote

tellement approximativement 3/8 “ de l’extrémité de thermocouple est entouré par la amme pilote.

RÉGLAGE D’CObturateur D’CAir DE BRÛLEUR

L’obturateur d’air de brûleur a une vis de blocage du côté inférieur du venturi. Desserrez cette vis pour faire

tout réglage et pour serrer la vis pour verrouiller l’obturateur d’air en place après que le réglage soit complet.

Tout réglage doit être fait quand le brûleur est à la pleine entrée avant que la conguration de la température de

commande ait été satisfaite.

1. Tournez le bouton de commande à la position la plus élevée et observez la amme de brûleur.

2. Diminuez lentement l’ouverture d’obturateur d’air jusqu’à ce que la amme soit un bleu mou avec des extrémités

jaunes, puis augmentez l’ouverture jusqu’à ce que les extrémités jaunes disparaissent et la amme est un

bleu dur.

3. N’ouvrez pas l’obturateur à un point où la amme est instable ou se soulevante de la surface de brûleur. La

amme doit être régulière et même à travers le brûleur entier.

LE RÉGLAGE DE DÉVIATION SUR LA COMMANDE D’CÉtranglement MODÈLE SEULEMENT

Les modèles de commande d’étranglement ont une conguration minimum de amme qui fournit une amme

uniforme régulière à travers le brûleur quand la conguration de la chaleur de commande a été satisfaite.

1. Placez la commande à la conguration et à l’attente de maximum la amme de brûleur à la commande de

puissance en arrière.

2. Tournez le cadran à la conguration de 200 degrés. Une petite amme régulière devrait être visible sur tous

les ports de brûleur. Cette amme devrait être approximativement 1/8 “ de haut.

3. Une vis d’approche est plac de l’avant ou du côté du logement de commande.

4. Tournez dans le sens des aiguilles d’une montre pour diminuer la taille de amme; tournez dans le sens

contraire des aiguilles d’une montre pour augmenter la amme.

1515

Page 16

CONNEXION ÉLECTRIQUE POUR L’CAction INSTANTANÉE ET LES MODÈLES EXTÉRIEURS DE CHROME

SEULEMENT

Des grils extérieurs instantanés d’action et de chrome sont équipés d’une trois-fourche fondant la prise. L’unité

est conçue pour l’usage sur 120 un circuit monophasé à C.A. de cycle de l’ampère 50/60 de volt 15 seulement.

Pour la protection contre le choc électrique, l’unité doit être branchée directement à un réceptacle correctement

fondé de trois-fourche. Ne coupez pas ou ne retirez pas la fourche fondante de cette prise.

INSTRUCTIONS DE FONCTIONNEMENT

EN ASSAISONNANT LA SURFACE de CHAUFFAGE de GRIL (SURFACES de NON-CHROME)

Nettoyez la surface de gril complètement. Après que le gril ait été complètement nettoyé, il devrait être

assaisonné pour empêcher la nourriture de coller. Avant utilisation et après chaque récurage complet,

assaisonnez la surface de chauffage de gril de la façon suivante:

1. Tournez le cadran de commande de la température à 350°F (174.0°C).

2. En utilisant un tissu propre, pas une spatule, a répandu une couche mince d’huile de cuisine ou de graisse

au-dessus du gril faisant cuire la surface. Ce lm devrait rester la demi-heure chaude de surface de gril.

3. Retirez gros excessif et le chiffon propres.

4. Appliquez un autre lm d’huile de cuisine au-dessus de la zone chaude de cuisine pour une autre demi-heure,

et encore retirez gros excessif et essuyez. La surface de gril devrait maintenant être opérationnelle.

Même avec la nourriture soigneuse d’assaisonnement peut, dans une certaine mesure, bâton au gril la

cuisine de la surface jusqu’à ce que le plat de gril "soit cassé dedans." CUISINE

Placez la molette de cadran à la conguration désirée. Après une période de préchauffage de 30 minutes

(minimum), le gril mettra à jour automatiquement la température choisie.

SOIN de GRIL (SURFACES de NON-CHROME)

Il prend le temps et l’effort très petits de maintenir le gril attrayant et exécutant en haut l’efcacité. Si la graisse

est autorisée pour s’accumuler, elle pour un gâteau gommeux et carboniser alors dans une substance dure il

est extrêmement difcile retirer que. Pour empêcher cette condition, les suggestions suivantes pour la propreté

devraient être suivies:

1. Après que chaque utilisation, éraent le gril avec un racleur ou une spatule exible pour enlever la graisse et

la nourriture excessives. Un tiroir de rebut est donné pour les raclures. S’ il y a une accumulation brûler-sur de

graisse et de nourriture, le gril devrait être complètement récuré et reseasoned. Utilisez la pierre de renovation

ou de gril tandis que le gril est chaud. N’utilisez pas les laines en acier en raison du danger des rubans en

acier entrant dans la nourriture.

2. Employez un tissu propre et un bon décapant non-abrasif pour nettoyer le corps d’acier inoxydable du gril.

Essuyez l’avant de pupitre de commande avec un tissu mou.

3. Du moins une fois par jour, retirent le tiroir de rebut et lavent de la même manière qu’une batterie de cuisine

ordinaire. Le tiroir est retiré en tirant en avant, vers le haut de et dehors.

1616

Page 17

SOIN de GRIL (SURFACES de CHROME)

(Des grils extérieurs de chrome sont identiés par “CHS“ à la n de la désignation de numéro de type sur la

plaque signalétique.) Elle prend le temps très petit et l’effort de maintenir ce scintillement extérieur de gril industriel

de chrome propre et exécuter en haut l’efcacité. Ne laissez pas la graisse s’accumuler car il carbonisera et

deviendra difcile de retirer. Pour empêcher cette condition, les suggestions suivantes de nettoyage devraient être

suivies:

1. Enlevez l’excédent d’huile et la nourriture régulièrement avec des 4 “ (100mm) racleur pointu de type de

rasoir large et essuyez la surface avec un tissu humide si désiré.

2. Après l’éraure, pour la n du nettoyage de jour, un tissu et un a humides non-silicated, décapant non abrasif

et non-chloré tel que la fève que l’ami peut être utilisé pour essuyer propre extérieur, suivi de l’essuyage avec

le tissu humide propre.

3. Suivez les étapes 2 et 3 du soin de gril (non surfaces de chrome).

ATTENTION

1. N’utilisez jamais la renovation, les pierres de gril, ou les abrasifs sur la surface.

2. Ne frappez jamais la surface de gril avec un instrument ou un bord pointu de spatule.

3. N’utilisez jamais les laines en acier.

4. N’utilisez jamais le décapant liquide commercial de gril sur la surface de gril.

5. Maltraiter la surface vide la garantie.

DE REBUT TIROIR

Un tiroir de rebut est situé à l’avant et peut être retiré de l’avant pour nettoyer en tirant le tiroir en avant. Ce tiroir

devrait être contrôlé et vidé si nécessaire ou au moins une fois par jour.

ATTENTION

PRENEZ LE SOIN EXTRÊME EN MANIPULANT LE TIROIR DE REBUT CONTENANT LA

GRAISSE CHAUDE.

ARRÊT DURANT LA NUIT MODÈLES

MANUELS DE COMMANDE DE VALVE ET D’CÉtranglement

Arrêtez les molettes à la position de repos aux brûleurs de tour.

CASSEZ L’CAction ET LES MODÈLES EXTÉRIEURS DE CHROME

Tournez les molettes à la plus basse conguration et arrêtez le commutateur de puissance.

EXCLUSIONS LIMITÉES DE GARANTIE DE SURFACE DE GRIL DE CHROME

Votre gril de chrome a été conçu pour vous donner beaucoup d’années de faire cuire la abilité et exige de

l’entretien minimum de maintenir la surface de chrome dans son état initial. Toutes les surfaces de gril de chrome

sont justiées pendant une période de 5 ans contre des défauts de fabrication au propriétaire initial de la date de

l’installation. Cette garantie limitée est vide si elle est déterminée par Star Manufacturing International Incorporated

ou un de ses représentants autorisés que la surface de chrome a été abusée ou maltraitée ou soumise aux

situations suivantes:

1. Incorrectement installé.

2. Sautez les réglages non réglés correctement sur des unités de gaz en permettant à l’appareil de surchauffer

et décolorer la surface de chrome. (Voir la section de réglage de déviation.)

3. L’abus de tout instrument ou outil qui rayent ou font des impressions dans la surface qui pourrait causer la

surface à la peau, s’écailler, ou ébrécher hors fonction.

4. L’utilisation de tout produit chimique ou solution abrasive de nettoyage, brique de gauffreuse, pierre, écran ou

d’autres produits de nettoyage qui pourraient endommager et affectent l’exécution de la surface de chome.

5. La négligence de l’entretien courant quotidien sur la surface de chrome.

1717

Page 18

1

17

18

19

20

21

3

4

5

6

9

8

7

29

24

23

22

6

25

27

28

26

2

3

6

10

11

12

13

16

Model: 836MA, Manual Control

Ultra-Max Gas Griddle

14

15

6

2M-Z16558; Ultra-Max Gas Griddle

SK2623, Rev. A 12/11/12

Page 19

PARTS LIST December 26, 2013, Rev B

Model: 824MA, 836MA, 848MA, 860MA, 872MA

Gas Griddle, Manual Control

Fig No Part No. Qty Description Application

G5-824037

G5-836037 836MA

1

G5-848037 848MA

G5-860037 860MA

G5-872037 872MA

2 G5-824012

3 2C-Z2893 AR NUT 10-24 HEX STL ZP

4 2F-Z4613

5 G5-Z16155

6 2C-8833 AR SCREW 8-18X1/2 HEX STL NP

7 2A-9369

2A-Z4930

8

2A-Z4931

9 G5-Z4798

G5-Z4812

G5-Z4813 FLUE 36” 836MA

10

G5-Z4814 FLUE 48” 848MA

G5-Z4815 FLUE 60” 860MA

2M-Z16558; Ultra-Max Gas Griddle

G5-Z4816 FLUE 72” 872MA

G5-Z4817 1 FLUE DIVIDER 824, 836, 848, 860

11

G5-Z4817 2 FLUE DIVIDER 872

12 2J-Z4686 1 REGULATOR-3/4 X 3/4

13 G5-Z4897

14 G5-824014

15 2R-Z19119 4 FOOT, TAPERED STEEL

GRIDDLE PLATE ASSY-

1

MANUAL

1

CHUTE ASSEMBLY

2 860, 872

2

3 836MA

BURNER 824 SERIES

4 848MA

5 860MA

6 872MA

2

3 836MA

BURNER COVER PLATE

4 848MA

5 860MA

6 872MA

2

3 836MA

ORIFICE-FITTING

4 848MA

5 860MA

6 872MA

2

3 836MA

ORIFICE #41

4 848MA

5 860MA

6 872MA

2

3 836MA

ORIFICE #52 BLK

4 848MA

5 860MA

6 872MA

1

2 836MA

BURNER BAFFLE

3 848MA

4 860MA

5 872MA

FLUE 24” 824MA

1

1

DRAWER SLIDE

2 860, 872

1

GREASE DRAWER ASSY

2 860, 872

824MA

824, 836, 848

824MA

824MA

824MA

824MA

824MA

824MA

824, 836, 848

824, 836, 848

Model: 824MA, 836MA, 848MA, 860MA, 872MA

Gas Griddle, Manual Control

Fig No Part No. Qty Description Application

16 2M-Z15805 1 ULTRA MAX LOGO

2

3 836MA

17 I4-Z15484

18 2M-Z15245

19 2C-200014 AR SCREW 8-32X3/8 THP SS

G5-Z16406

G5-Z15203 FRONT PANEL - 836TA 836MA

20

G5-Z16407 FRONT PANEL - 848 848MA

G5-Z16408 FRONT PANEL - 60” 860MA

G5-Z16409 FRONT PANEL - 72” 872MA

21 2C-8477 4 CLIP .125 PO STL PHOS

2K-Z15272

2K-Z15273 MANIFOLD - 836MA/TSA 836MA

22

2K-Z15274 MANIFOLD - 848MA/ISA 848MA

2K-Z15275 MANIFOLD - 860MA/ISA 860MA

2K-Z15276 MANIFOLD - 872MA/ISA 872MA

23 2V-6671

24 2V-Z15280

25 2V-Y8832

26 2A-Z0790

27 2K-Z4921

28 2P-1453 1 PLUG-PIPE 1/8NPT SQ HD 836MA

29 I5-Z16262 2 FRONT PANEL SIDE BRACKET

NI 2J-Z4686 1 RGLTR-GAS 3/4X3/4, CONVERTABLE

KNOB ASSEMBLY LG GAS

4 848MA

KEYB

5 860MA

6 872MA

2

3 836MA

KNOB LABEL ULTRAMAX

4 848MA

5 860MA

6 872MA

FRONT PANEL - 824MA 824MA

1

MANIFOLD - 824MA/ISA 824MA

1

2

3 836MA

VALVE-LINCOLN

4 848MA

BRASS#3817

5 860MA

6 872MA

2

3 836MA

PILOT BURNER MANUAL

4 848MA

5 860MA

6 872MA

2

3 836MA

VALVE-MANUAL GAS

4 848MA

5 860MA

6 872MA

2

3 836MA

FITTING-STRAIGHT

4 848MA

5 860MA

6 872MA

2

3 836MA

BURNER TUBE FLEX 3/8

4 848MA

OD

5 860MA

6 872MA

824MA

824MA

824MA

824MA

824MA

824MA

824MA

Star International Holdings Inc. Company

Page 20

1

3

2

4

19 23

21 22

20

25 26

24

5

6

7

8

9

29

6

27

28

9

31

30

32

33

37

36

35

34

14

18

6

13

3

10

11

3

6

12

15

Model: 848TA, T-Stat Control

Ultra-Max Gas Griddle

19

1616

16

17

6

2M-Z16558; Ultra-Max Gas Griddle

SK2631, Rev. - 12/11/12

Page 21

PARTS LIST December 26, 2013, Rev B

Model: 824TA, 836TA, 848TA, 860TA, 872TA

Gas Griddle, Thermostat Control

Fig No Part No Qty Description Application

G5-824032

G5-836032 836TA

1

G5-848032 848TA

G5-860032 860TA

G5-872032 872TA

2 G5-824012

3 2C-Z2893

4 2F-Z4613

5 G5-Z16155

6 2C-8833

2J-Z16923

7

2A-Z4931

8 2A-9369

2K-70104-

9

03

2M-Z16558; Ultra-Max Gas Griddle

10 G5-Z4817

G5-Z4812

G5-Z4813 FLUE 36” 836TA

11

G5-Z4814 FLUE 48” 848TA

G5-Z4815 FLUE 60” 860TA

G5-Z4816 FLUE 72” 872TA

12 2K-Z15231 1 PIPE SEG - 3/4x24.00 BI 848TA

13 2K-Z4611 1 ELBOW 3/4 NPT 848TA

GRIDDLE PLATE GAS

1

STEEL

1

CHUTE ASSEMBLY

2 860TA, 872TA

8

11 836TA, 848TA

NUT 10-24 HEX STL ZP

13 860TA

16 872TA

2

3 836TA

BURNER 824 SERIES

4 848TA

5 860TA

6 872TA

2

3 836TA

BURNER COVER PLATE

4 848TA

5 860TA

6 872TA

31

42 836TA

SCREW 8-18X1/2 HEX

45 848TA

STL NP

56 860TA

74 872TA

2

3 836TA

ORIFICE HOOD #38, NAT

4 848TA

5 860TA

6 872TA

2

3 836TA

ORIFICE #52 BLK, LP

4 848TA

5 860TA

6 872TA

2

3 836TA

ORIFICE-FITTING

4 848TA

5 860TA

6 872TA

4

6 836TA

FLEXIBLE TUBE 3/8OD

8 848TA

X 8

10 860TA

12 872TA

1

FLUE DIVIDER

2 872TA

FLUE 24” 824TA

1

824TA

824TA, 836TA, 848TA

824TA

824TA

824TA

824TA

824TA

824TA

824TA

824TA

824TA, 836TA, 848TA,

860TA

Model: 824TA, 836TA, 848TA, 860TA, 872TA

Gas Griddle, Thermostat Control

Fig No Part No Qty Description Application

2K-Z16583

2K-Z16584 MANIFOLD PIPE - 836TA 836TA

14

2K-Z16585 MANIFOLD PIPE - 848TA 848TA

2K-Z16586 MANIFOLD PIPE 860T 860TA

2K-Z16587 MANIFOLD PIPT 872TA 872TA

15 G5-Z4897

16 G5-824014

17

2R-Z19119 4

G5-Z16588

G5-Z16589 T-STAT BRKT 836TA 836TA

18

G5-Z16590 T-STAT BRKT 848TA 848TA

G5-Z16591 T-STAT BRKT 860TA 860TA

G5-Z16592 T-STAT BRKT 872TA 872TA

19 2C-200014 4

20 2M-Z15805 1 ULTRA MAX LOGO 848TA

21 G5-Z16532

22 2M-Z15214

G5-Z16516

G5-Z16515 FRONT PANEL 836TA 836TA

23

G5-Z16514 FRONT PANEL 48” TA 848TA

G5-Z16513 FRONT PNL 60” TA 860TA

G5-Z16512 FRONT PANEL 72” TA 872TA

24 2C-8477 2 CLIP .125 PO STL PHOS 848TA

25 2C-Z5883

26 2C-Z8547

27 2K-2675

MANIFOLD PIPE 824T 824TA

1

1

DRAWER SLIDE

2 860TA, 872TA

1

GREASE DRAWER ASSY

2 860TA, 872TA

FOOT, 4" TAPERED,

STEEL

T-STAT BRKT 824TA 824TA

1

SCREW 8-32X3/8 THP

SS

2

3 836TA

KNOB ASSY LG GS/K

4 848TA

KEYR

5 860TA

6 872TA

2

3 836TA

DIAL GRAPHIC - 550F TA

4 848TA

5 860TA

6 872TA

FRONT PNL 24” TA 824TA

1

6

8 836TA

10-24 X 1/2 FZA SCREW

12 848TA, 872TA

16 860TA

2

3 836TA

SCREW, 6-32

4 848TA

SHOULDER

5 860TA

6 872TA

4

6 836TA

ELL90 3/8MPTX3/8CC

8 848TA

BRASS

10 860TA

12 872TA

824TA, 836TA, 848TA

824TA, 836TA, 848TA

ALL

824TA

824TA

824TA

824TA

824TA

Star International Holdings Inc. Company

1717

Page 22

PARTS LIST December 26, 2013, Rev B

Model: 824TA, 836TA, 848TA, 860TA, 872TA

Gas Griddle, Thermostat Control

Fig No Part No Qty Description Application

2

3 836TA

28 2T-Z16593

29 G5-Z16703 2 FRNT PANEL BRKT ALL

30 2V-Z15281

31 2P-1453 1 PLUG-PIPE 1/8NPT SQ 848TA

32 2V-6671

33 2K-Z5106

34 2C-Z16361 2 HALF CLAMP 848TA

35 2C-Z5556 2 WASHER 1/4 FLAT SS 848TA

36 2C-Z5557 2 WASHER 1/4 SPLIT SS 848TA

37 2C-Z5555 2 BOLT 1/4-20 X .75 HEX 848TA

NI

2J-Z4686 1

T-STAT GAS GS 550F

4 848TA

5 860TA

6 872TA

2

3 836TA

PILOT BURNER

4 848TA

5 860TA

6 872TA

2

3 836TA

VALVE-LINCOLN

4 848TA

BRASS#3817

5 860TA

6 872TA

2

3 836TA

ELL, 1/8P-3/8T - BRASS

4 848TA

5 860TA

6 872TA

RGLTR-GAS 3/4X3/4

CONVERTABLE

824TA

824TA

824TA

824TA

Star International Holdings Inc. Company

1818

2M-Z16558; Ultra-Max Gas Griddle

Page 23

2M-Z16558; Ultra-Max Gas Griddle

1919

Page 24

1

3

4

5

6

7

2

32

31

33

34

35

29

30

36

37

40

39

38

37

8

43

42

41

3

20

21

26

27

28

19

18

22

23

24

25

11

10

9

17

16

12

15

Model: 848TSA, Snap Action / Thermal Spark

Ultra-Max Gas Griddle

2M-Z16558; Ultra-Max Gas Griddle

13

14

SK2650, Rev. B 3/12/15

Page 25

PARTS LIST November 5, 2013, Rev B

Model: 824TSA, 836TSA, 848TSA, 860TSA, 872TSA GAS GRIDDLE, SNAP ACTION

Fig No Part No. Description Qty Application

G5-824032 GRIDDLE PLATE GAS STEEL

G5-824033 GRIDDLE PLATE GAS CHROME 824TSCHSA

G5-836032 GRIDDLE PLATE GAS STEEL 836TSA

G5-836033 GRIDDLE PLATE GAS CHROME 836TSCHSA

G5-848032 GRIDDLE PLATE GAS STEEL 848TSA

1

G5-848033 GRIDDLE PLATE GAS CHROME 848TSCHSA

G5-860032 GRIDDLE PLATE GAS STEEL 860TSA

G5-860033 GRIDDLE PLATE GAS CHROME 860TSCHSA

G5-872032 GRIDDLE PLATE GAS STEEL 872TSA

G5-872033 GRIDDLE PLATE GAS CHROME 872TSCHSA

2 G5-824012 CHUTE ASSEMBLY

3 2T-Z15211 T-STAT 550F K-TYPE

4 2F-Z15290 GRIDDLE BURNER, 40K

2J-Z16497 HOOD, BURNER ORIFICE #34, NAT

5

2J-Z9288 ORIFICE #49, LP

6 G5-Z16155 BURNER COVER PLATE

7 2E-Z15213 IGNITOR/SENSOR

8 2A-9369 ORIFICE-FITTING

2M-Z16558; Ultra-Max Gas Griddle

9 G5-Z16732 FLUE DIVIDER - EXTENDED 1

G5-Z16733 FLUE 824TSCHSA 1 824TSCHSA

G5-Z16734 FLUE 836TSCHSA 1 836TSCHSA

10

G5-Z16735 FLUE 848TSCHSA 1 848TSCHSA

G5-Z16736 FLUE 860TSCHSA 1 860TSCHSA

G5-Z16737 FLUE 872TSCHSA 1 872TSCHSA

G5-Z16747 FLUE SHIELD 824TSA 1 824TSA

G5-Z16748 FLUE SHIELD 836TSA 1 836TSA

11

G5-Z16749 FLUE SHIELD 848TSA 1 848TSA

G5-Z16750 FLUE SHIELD 860TSA 1 860TSA

G5-Z16751 FLUE SHIELD 872TSA 1 872TSA

824TSA

1

1 824TSA, 836TSA, 848TSA

2 860TSA, 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2121

Page 26

PARTS LIST November 5, 2013, Rev B

Model: 824TSA, 836TSA, 848TSA, 860TSA, 872TSA GAS GRIDDLE, SNAP ACTION

Fig No Part No. Description Qty Application

12 G5-Z4897 DRAWER SLIDE

13 2C-8833 SCREW 8-18X1/2 HEX STL NP

14 G5-824014 GREASE DRAWER ASSY

15 2R-Z19119 FOOT, 4" TAPERED, STEEL 4

G5-824029 MANIFOLD ASSY-824TS(CHS)A 1 824TSA

G5-836029 MANIFOLD ASSY-836TS(CHS)A 1 836TSA

16

G5-848029 MANIFOLD ASSY-848TS(CHS)A 1 848TSA

G5-860029 MANIFOLD ASSY-860TS(CHS)A 1 860TSA

G5-872029 MANIFOLD ASSY-872TS(CHS)A 1 872TSA

17 2K-Z15231 PIPE SEG - 3/4x24.00 BI 1

18 2K-Z4611 ELBOW 3/4 NPT 1

2K-Z16511 MANIFOLD PIPE - 824TSA 1 824TSA

2K-Z16510 MANIFOLD PIPE - 836TSA 1 836TSA

19

2K-Z16509 MANIFOLD PIPE - 848TSA 1 848TSA

2K-Z16508 MANIFOLD PIPE - 860TSA 1 860TSA

2K-Z16507 MANIFOLD PIPE - 872TSA 1 872TSA

20 2P-1453 PLUG-PIPE 1/8NPT SQ HD 1

21 2K-Z5106 ELL, 1/8P-3/8T - BRASS

22 2E-Z12020 SWITCH-TOGGLE 2P ST 1

23 2K-H5417 BUSHING-HEYCO #SR-6P-3-4 1

24 2P-Z8478 HINGE, 2.5 U-MAX 3

25 2C-6349 SCREW #8X3/8 THP STL NP 12

26 Z1-70-07-0343 SWITCH GUARD 1

27 2M-12-07-0038 LABEL ON & OFF 1

28 2I-05-07-0013 BOOT SWITCH 1

29 2A-Z13272 KNOB GUARD AR -C UNITS CORA

30 2C-1516 SCREW 10-24X1 STL RH NP AR -C UNITS CORA

31 2M-Z15805 ULTRA MAX LOGO 1

32 G5-Z16680 KNOB ASSY LG GS/K KEYB

33 2M-Z15257 DIAL GRAPHIC - 550F TSA

34 2C-200014 SCREW 8-32X3/8 THP SS

1 824TSA, 836TSA, 848TSA

2 860TSA, 872TSA

39 824TSA

51 836TSA

64 848TSA

75 860TSA

86 872TSA

1 824TSA, 836TSA, 848TSA

2 860TSA, 872TSA

1 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

4 824TSA, 836TSA

6 848TSA, 860TSA, 872TSA

2M-Z16558; Ultra-Max Gas Griddle

2222

Page 27

PARTS LIST November 5, 2013, Rev B

Model: 824TSA, 836TSA, 848TSA, 860TSA, 872TSA GAS GRIDDLE, SNAP ACTION

Fig No Part No. Description Qty Application

G5-Z16402

G5-Z15215 836TSA

G5-Z16403 848TSA

G5-Z16404 860TSA

35

G5-Z16405 872TSA

G5-Z17263 836TSCHSA-C

G5-Z16764 848TSCHSA-C

G5-Z16765 860TSCHSA-C

G5-Z16766 872TSCHSA-C

36 2K-70104-03 FLEXIBLE TUBE 3/8OD X 8

37 2K-Y9472 FITG 3/8 CC X 3/8 MPT

38 2J-Z4610 SOLENOID VALVE

2E-Z15271-1 SPARK IGNITION CONTROL

2E-Z15271-2 SPARK IGNITION HARNESS

39

2E-Z15271-3 SPARK IGNITION WIRE

G5-Z16347 IGNITION SUPPORT 824TS 1 824TSA

G5-Z16212 IGNITION SUPPORT 836TS 1 836TSA

40

G5-Z16348 IGNITION SUPPORT 848TS 1 848TSA

G5-Z16349 IGNITION SUPPORT 860TS 1 860TSA

G5-Z16350 IGNITION SUPPORT 872TS 1 872TSA

41 2C-8833 SCREW 8-18X1/2 HEX STL NP AR

2M-Z16558; Ultra-Max Gas Griddle

42 G5-Z16703 FRONT PANEL BRACKET 2

G5-Z4798 BURNER BAFFLE 1 824TSA

G5-Z4798 BURNER BAFFLE 2 836TSA

G5-Z4798 BURNER BAFFLE 3 848TSA

43

G5-Z4798 BURNER BAFFLE 4 860TSA

G5-Z4798 BURNER BAFFLE 5 872TSA

NI N2-30409 LEAD IN CORD ASSY 120V 1

NI N2-Z13276 LEAD IN CORD ASSY 120V 1 -C UNITS CORA

NI 2J-Z16686 REGULATOR 3/4 HI FLOW 1 860TSA, 872TSA

NI 2J-Z4686 REGULATOR 3/4 X 3/4 1 824TSA, 836TSA, 848TSA

FRONT PANEL 1

824TSA

4 848TSA

6 848TSA

8 848TSA

10 860TSA

12 872TSA

3 824TSA

5 836TSA

7 848TSA

9 860TSA

11 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2 824TSA

3 836TSA

4 848TSA

5 860TSA

6 872TSA

2323

Page 28

Visit our Website at: www.star-mfg.com Email: customerservice@star-mfg.com

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in which

the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the transportation

company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of the unit.

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

LIMITED EQUIPMENT WARRANTY

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the Ultra-Max, Hot Plates, Griddles, Charbroilers is (3) years parts & labor.

* The warranty period for the Star-Max, Charbroilers, Griddles, Hot Plates, Fryers & Finishing Oven is (2) years parts & labor.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* ThewarrantyperiodfortheChrome-MaxGriddlesisve(5)yearsonthegriddlesurface.Seedetailedwarrantyprovidedwithunit.

* The warranty period for Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Dura-Teccoatingsfromimpropercleaning,maintenance,useofmetallicutensils,orabrasivecleaners,abrasivepads,productidentiersand

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted, the labor to replace the part is NOT warranted.

SERVICES NOT COVERED BY WARRANTY

1. Traveltimeandmileagerenderedbeyondthe50mileradiuslimit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damagesduetoimproperinstallation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

* TheModel510FD,510FFFryer.

* TheModel526TOAToasterOven.

* TheModelJ4R,4oz.PopcornMachine.

*TheModel518CMA&526CMACheeseMelter.

* TheModel12MC&15MC&18MCPHotFoodMerchandisers.

* TheModel12NCPW&15NCPWNachoChip/PopcornWarmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* AllQCS/RCSSeriesToastersexcept Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

PARTS WARRANTY

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resettingofcircuitbreakersorsafetycontrolsorresetbuttons

16. Replacementofbulbs

17. Replacementoffuses

18. Repairofdamagecreatedduringtransit,delivery,&

PORTABLE EQUIPMENT

FOR ASSISTANCE

installationORcreatedbyactsofGod

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

2424

2M-4497-2 11/21/14

Loading...

Loading...