Blodgett ZEPHAIRE-E User Manual

ZEPHAIRE-E

ELECTRIC CONVECTION OVEN

INSTALLATION -- OPERATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN 90147 Rev H (10/06)

E 2006 --- G.S. Blodgett Corporation

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructions will result in satisfactory baking re sults

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

THE REPUTATION YOU CAN COUNT ON

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We’ve set the industry’s quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, full-size, half-size, countertop and deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Your Service Agency’s Address:

Model:

Serial Number:

Your oven was installed by:

Your oven’s installation was checked by:

Tab l e o f C o n t e n t s

Introduction

Oven Description and Specifications 2................................

Oven Components 3...............................................

Installation

Delivery and Location 4.............................................

Utility Connections --- Standards and Codes 5.........................

Oven Assembly 6..................................................

NSF Bolts 6....................................................

Leg Attachment 7...............................................

Caster Assembly 7..............................................

Double Section Assembly 8......................................

Oven Leveling 8................................................

Operation

Single Speed Blower 9.............................................

Single Speed Blower with Cavity Lights 10.............................

Dual Speed Blower 11...............................................

Dual Speed Blower with Cavity Lights 12...............................

General Guidelines for Operating Personnel 13.........................

Suggested Times and Temperatures 14................................

Maintenance

Cleaning and Preventative Maintenance 15.............................

Troubleshooting Guide 16............................................

Introduction

KW/

S

VoltsP

h

C

localcode

Oven Description and Specifications

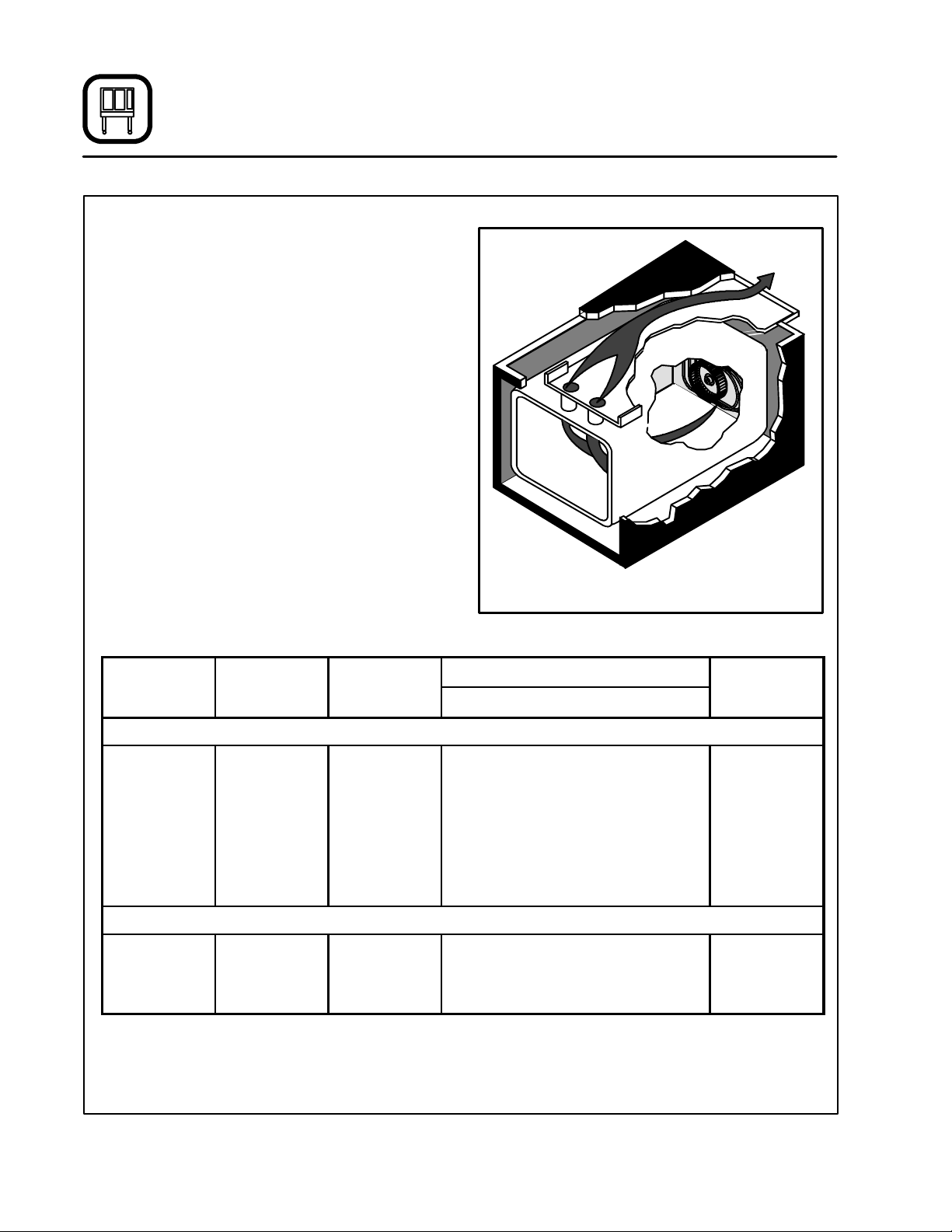

Cooking in a convection oven differs from cooking

in a conventional deck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. The moving air continually strips aw ay the layer of cool air surrounding the product, quickly allowing the heat to penetrate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgett convection ovens represent the latest advancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recirculated within the cooking chamber before being

vented from the oven: resulting in substantial reductions in energy consumption and enhanced

oven performance.

Blodgett Electric Convection Ovens

Amperes

ection

60 HZ UNITS

11 208 1 51 0 51 --- 6

11 208 3 31 29 29 --- 8

11 220-240 1 44 0 4 4 --- 6

11 220-240 3 26 24 24 --- 8

11 440 3 15 14 14 --- 12

11 480 3 14 13 13 --- 12

50 HZ UNITS

11.0 220/380 3 18 16 16 2

11.0 240/415 3 18 14 14 8

11.0 230/400 3 18 15 15 3

ase

L1 L2 L3 N

Air Flow Pattern for

Figure 1

Electrical

onnection

AWG*

Size per

* Electric connection wiring is sized for 90_C copper wire at 125% of rated input.

2

Introduction

Oven Components

Heating Elements --- located in the back of the

oven, the elements provide heat to the baking

chamber on electric ovens.

Control Panel --- contains wiring and components

to control the oven operation.

Oven Racks --- five racks are provided standard.

Additional racks are available.

Rack Supports --- h o l d o v e n r a c k s .

Baffle --- located on the back interior wall of the

oven. Protects the blower wheel.

Blower Wheel --- spins to circulate hot air in the

baking chamber.

Blower Motor --- provides power to turn the blower wheel.

Oven Lights - -- provide lighting inside the baking

compartment.

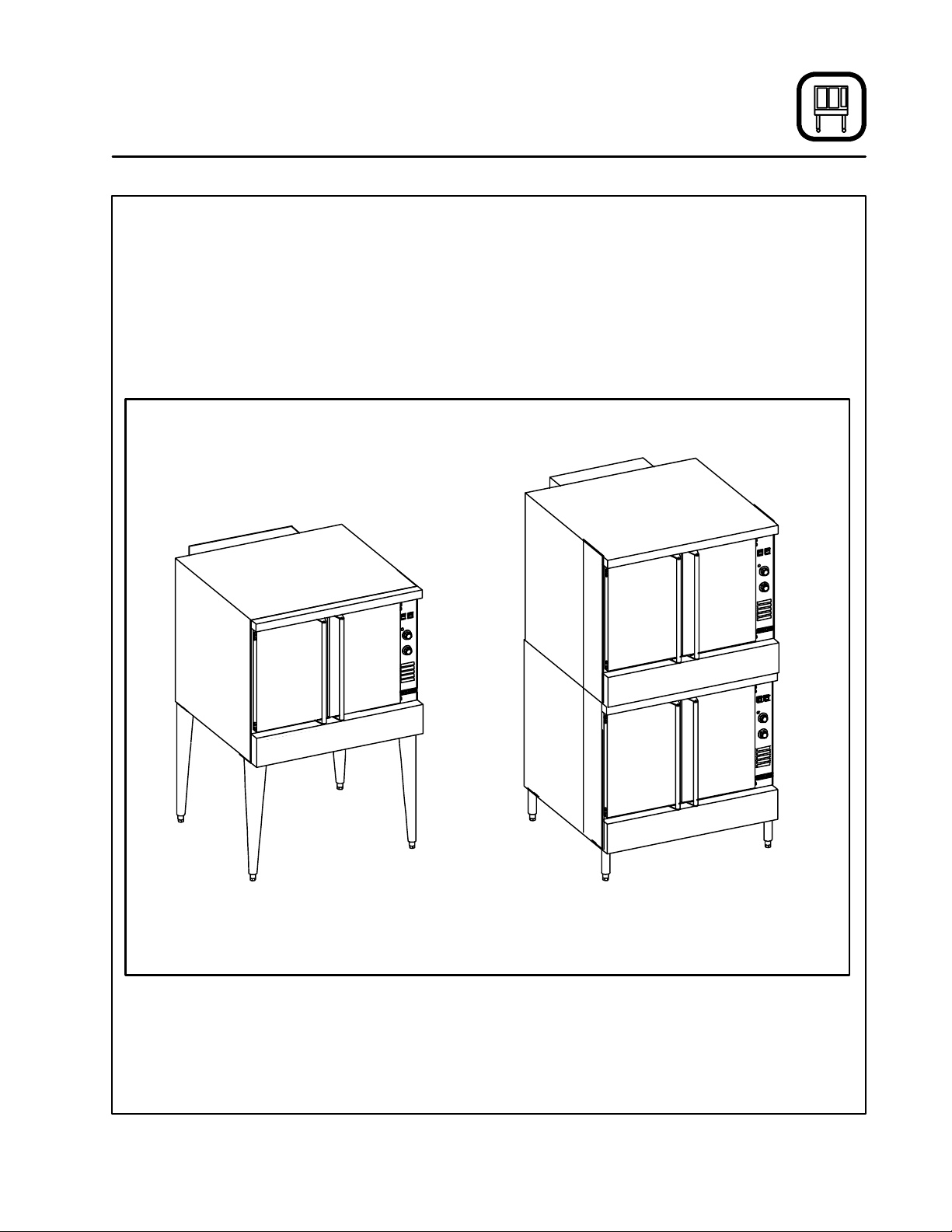

ZEPHAIRET--- E

Single

Figure 2

3

ZEPHAIRE

Double Stacked

T

--- E

Loading...

Loading...