Page 1

VIB SERIES

VENTILATION SYSTEM

INSTALLATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN M10590 Rev C (11/03)

E 2001--- G.S. Blodgett Corporation

Page 2

Table o f Contents

Installation

Agency Approvals 2................................................

Delivery and Inspection 3...........................................

VIB3240 Parts List 4................................................

VIB3855 Parts List 6................................................

VIB3870 Parts List 8................................................

Airflow Requirements 10.............................................

Oven Preparation 11................................................

Oven Assembly and Stacking 11...................................

Cooling Fan Exhaust Plenum Mounting Brackets 11..................

Oven/Vent Alignment Holes 12.....................................

AMU Installation 13..................................................

AMU Alignment Pins 13...........................................

Corner Support Bracket(s) 14.....................................

AMU Support brackets 17.........................................

AMU Installation 18...............................................

Exhaust Installation 19...............................................

Vertical Exhaust Plenum Assembly 19..............................

Cooling Fan Exhaust Plenum 20...................................

Exhaust Plenum Hanging Pin 21...................................

Top O v e n Br a c k e t 22.............................................

Filters 23........................................................

Right Exhaust Plenum and Heat Shield 24...........................

Left Exhaust Plenum and Heat Shield 25............................

Duct Connection 26.................................................

Maintenance

Cleaning 27........................................................

Servicing 28........................................................

Page 3

Installation

Agency Approvals

The InVentr Hood Systems are Listed by Underwriters Laboratories Inc. (UL) in category YYCW as

Exhaust Hoods Without Exhaust Dampers. They

are intended to be installed in accordance with

NFPA 96, the Standard for Ventilation Control and

Fire Protection of Commercial Cooking Operations. The basic Standard used by UL to investi-

gate products in this category is UL 710, the Standard for Exhaust Hoods for Commercial Cooking

Equipment.

These hoods are considered to be Type 1 according to the International Mechanical Code (IMC);

thatis,theyare,“installedatoraboveallcommercial food heat-processing equipment that produces grease vapors or smoke.” IMC is published

by the International Code Council, Inc. and is compatible with codes written by the Building Officials

and Code Administrators International, Inc.,

(BOCA), the International Conference of Building

Officials (ICBO), and Southern Building Code

Congress International, Inc. (SBCCI). The Uniform

Mechanical Code (UMC) published by ICBO defines a Type I Hood as, “a kitchen hood for collecting and removing grease and smoke.” A “Type II

Hood is a general hood for collecting and removing steam, vapor, heat or odors.” The hood type is

determined by the intended use. UL tested and

approved the InVentsr foruseintheTypeIenvironment.

These hoods are NSF approved to ANSI/

NSF2-1992, Food Equipment

requires that all materials used be corrosion resistant. Furthermore, that there be no sharp corners

or open seams where food, residue or soil collect.

. ANSI/NSF2-1992

2

Page 4

Installation

Delivery and Inspection

All VIB ventilation systems are shipped in containers to prevent damage. Upon delivery of your new

In-Ventr:

D Inspect the shipping container for external dam-

age. Any evidence of damage should be noted

on the delivery receipt which must be s igned by

the driver.

D Uncrate the In-Ventr, preferably at the installa-

tion site, and check for damage. Carriers will ac cept claims for concealed damage if notified

within fifteen days of delivery and the shipping

container is retained for inspection.

The Blodgett Oven Company cannot assume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a claim is necessary.

Check the following parts lists to be sure all items

were received.

NOTE: The reference numbers given in the parts

lists also appear in brackets within the assembly sections of this document.

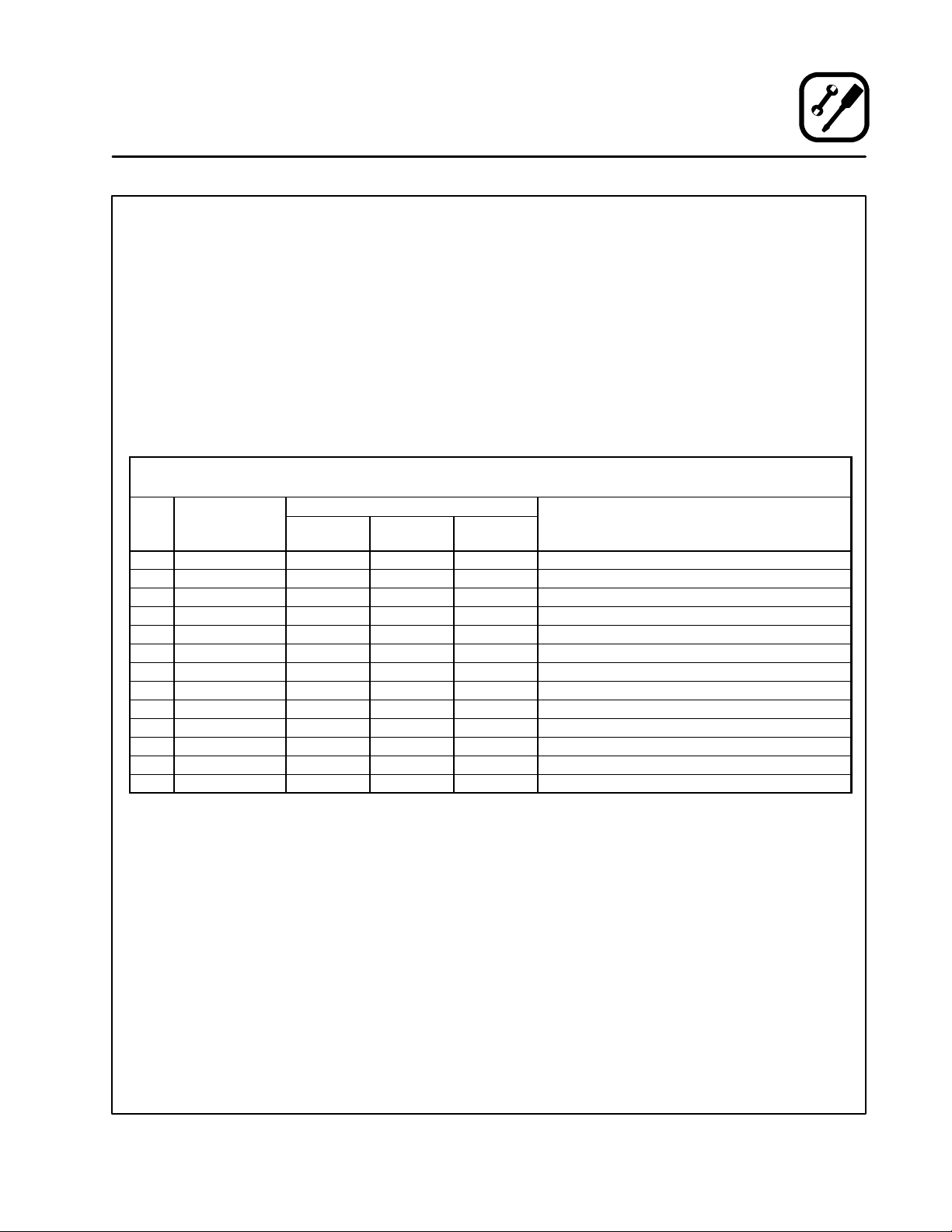

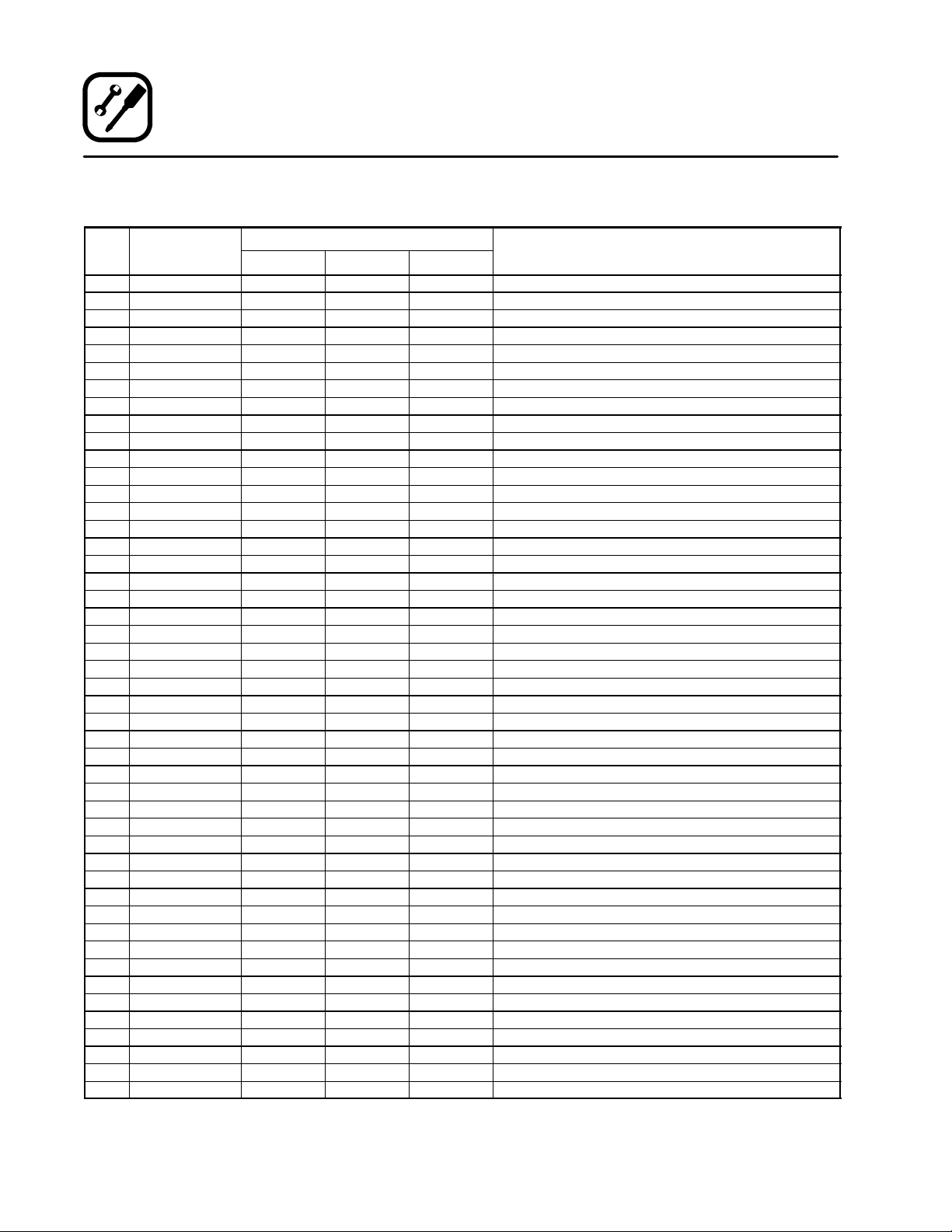

HARDWARE KIT (All Models)

Single Model: P/N ASVIBHDKIT -1, Double Model: P/N ASVIBHDKIT-2, Triple Model: P/N ASVIBHDKIT-3

REF

# P/N

K1 1 1 1 Installation Instructions, VIB Series

K2 FASCW0011 2 7 12 Screw, #10x1/2 Sheet Metal (Self drilling)

K3 FABLT5121 4 4 4 Screw, Hex Head, 3/8---16 x 1”

K4 FAWSH073 4 4 4 Washer, Flat 3/8

K5 FAWSH072 4 4 4 Washer, Lock 3/8

K6 FABLT4092 4 10 12 Screw,HexHead1/4---20x1”S/S

K7 FAWSH046 8 20 24 Washer, 1/4 Flat

K8 FAWSH045W 4 10 12 Washer, Lock 1/4

K9 FANUT0400 4 9 12 Nut, 1/4 ---20

K10 M3828 2 2 2 Stacking Pins

K11 FABLT0001 4 4 4 S c r e w , # 1 0 --- 2 4 x 3 / 8 ” P h i l i p s H e a d

K12 RPBLT0001 0 1 2 Shoulder Bolt, 1/4 --- 20 x 1 1/2” S/S

K13 FANUT0416 0 2 2 Nut, 1/4 --- 20 Lock

ORDERING

Single

Models

QUANTITY DESCRIPTION

Double

Models

Trip l e

Models

01=Top Oven, 02=Second Oven Down

03= Bottom Oven of a Triple Stack

3

Page 5

Installation

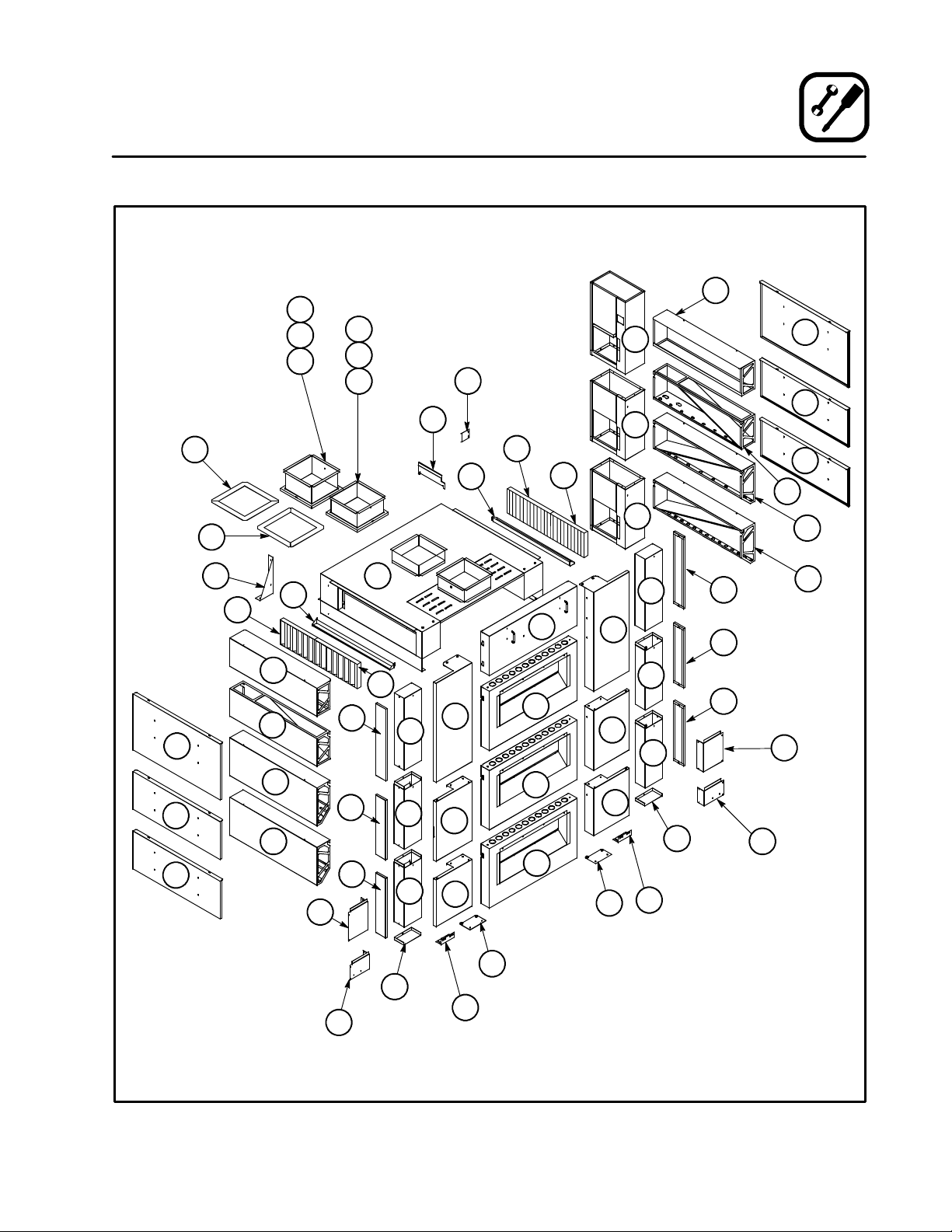

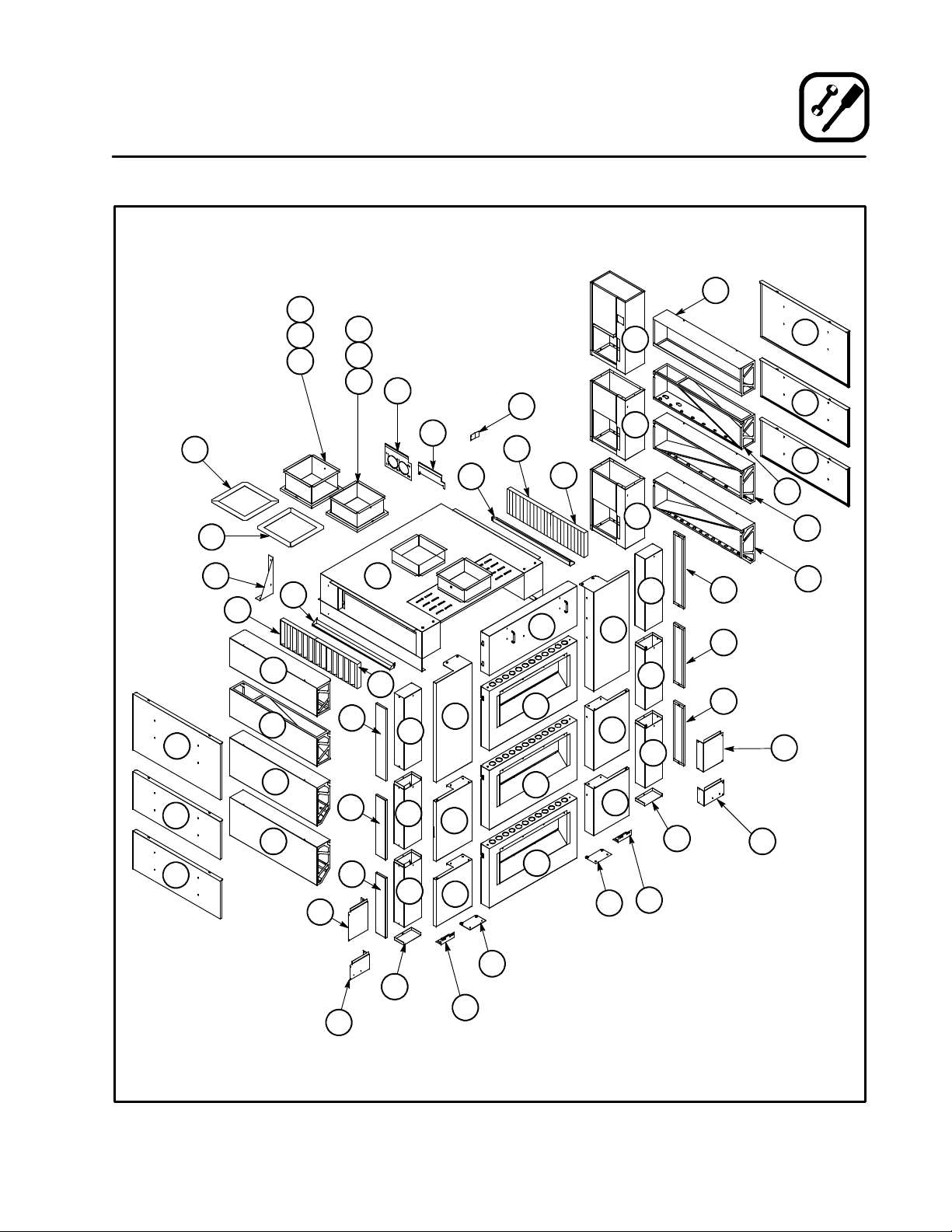

VIB3240 Parts List

REF

# P/N

01 VIB3240--- 001 1 1 1 Assy, AMU Support Bracket, O1 LH

02 VIB3240--- 002 1 1 1 Assy, Vertical Exh Plenum O1 LH

05 VIB3240--- 005 2 2 0 Bracket, AMU Bottom Support O1+O2

06 VIB3240--- 006 1 1 0 Back Plate, AMU Support Bracket O1+O2 LH

07 VIB3240--- 007 1 1 1 Assy,UpperExhPlenum,O1LH

08 VIB3240--- 008 1 1 1 Assy,UpperExhPlenum,O1RH

09 VIB3240--- 009 1 1 1 Assy, Heat Shield, O1 LH

10 VIB3240--- 010 0 1 1 Assy, AMU Support Bracket, O2 LH

11 VIB3240--- 011 1 1 1 Bracket, O1, Left Hand

12 VIB3240--- 012 1 1 1 Assy, Vertical Exh Plenum O1 RH

15 VIB3240--- 015 2 2 2 Plate, Block Off, Vert Exh Plenum, LH+RH

16 VIB3240--- 016 1 1 0 Back Plate, AMU Support Bracket O1+O2 RH

17 VIB3240--- 017 1 1 1 Assy,LowerExhPlenum,O1LH

18 VIB3240--- 018 1 1 1 Assy,LowerExhPlenum,O1RH

19 VIB3240--- 019 1 1 1 Assy, Heat Shield, O1 RH

20 VIB3240--- 020 0 1 2 Assy, Vertical Exh Plenum O2+O3 LH

22 VIB3240--- 022 0 1 2 Assy, Vertical Exh Plenum O2+O3 RH

23 VIB3240--- 023 1 1 1 PlenumAssy,AMU,Upper

25 VIB3240--- 025 1 2 3 PlenumAssy,AMU,O1+O2+O3

27 VIB3240--- 027 0 1 1 Assy,ExhPlenum,O2LH

28 VIB3240--- 028 0 1 1 Assy,ExhPlenum,O2RH

29 VIB3240--- 029 0 1 2 Assy, Heat Shield, O2+O3 LH

31 VIB3240--- 031 1 1 1 Assy, AMU/Exhaust Manifold

37 VIB3240--- 037 0 0 1 Assy,ExhPlenum,O3LH

38 VIB3240--- 038 0 0 1 Assy,ExhPlenum,O3RH

39 VIB3240--- 039 0 1 2 Assy, Heat Shield, O2+O3 RH

40 VIB3240--- 040 1 1 1 Assy, Cooling Fan Exh Plenum O1

44 VIB3240--- 044 1 1 1 Assy, Mounting Bracket, Cooling Fan Exh Plenum

45 VIB3240--- 045 0 1 2 Assy, Cooling Fan Exh Plenum O2+O3

47 VIB3240--- 047 2 2 2 Filter Trough / Receptacle

50 VIB3240--- 050 1 1 1 Assy, AMU Support Bracket, O1 RH

51 VIB3240--- 051 0 0 2 Bracket, AMU Bottom Support O3

57 VIB3240--- 057 1 1 1 Assy, AMU Duct Extension

60 VIB3240--- 060 0 1 1 Assy, AMU Support Bracket, O2 RH

61 VIB3240--- 061 1 1 1 Assy,MountingBracket,Ver.A,CoolingFanExhPlenum

67 VIB3240--- 067 1 1 1 Assy, Exhaust Duct Extension

70 VIB3240--- 070 2 2 2 Assy, Heat Sheild, Vert Exh Plenum O1

71 VIB3240--- 071 0 2 4 Assy, Heat Sheild, Vert Exh Plenum O2+O3

72 VIB3240--- 072 2 2 2 Trim,Ceiling,AMUDuct

73 VIB3240--- 073 2 2 2 Trim,Ceiling,ExhaustDuct

80 VIB3240--- 080 0 0 1 Assy, AMU Support Bracket, O3 LH

86 VIB3240--- 086 0 0 1 Back Plate, AMU Support Bracket O3 LH

90 VIB3240--- 090 0 0 1 Assy, AMU Support Bracket, O3 RH

91 VIB3240--- 091 1 1 1 Assy,MountingBracket,Ver.B,CoolingFanExhPlenum

96 VIB3240--- 096 0 0 1 Back Plate, AMU Support Bracket O3 RH

F1 ASFLT1016AL 4 4 4 Filter, 10” x 16

ORDERING

QUANTITY DESCRIPTION

VIB3240---1 VIB3240---2 VIB3240---3

01=TopOven, 02=SecondOven Down

03= Bottom Oven of a Triple Stack

4

Page 6

73

72

67

87

98

57

77

97

91

44

47

F1

F1

Installation

VIB3240 Parts List

8

40

45

45

19

39

39

18

28

29

29

11

47

F1

7

17

9

27

37

6

86

71

70

71

31

F1

15

20

20

12

23

1

2

10

80

51

25

25

25

5

60

5

50

22

22

90

51

70

71

71

15

38

16

96

5

Page 7

Installation

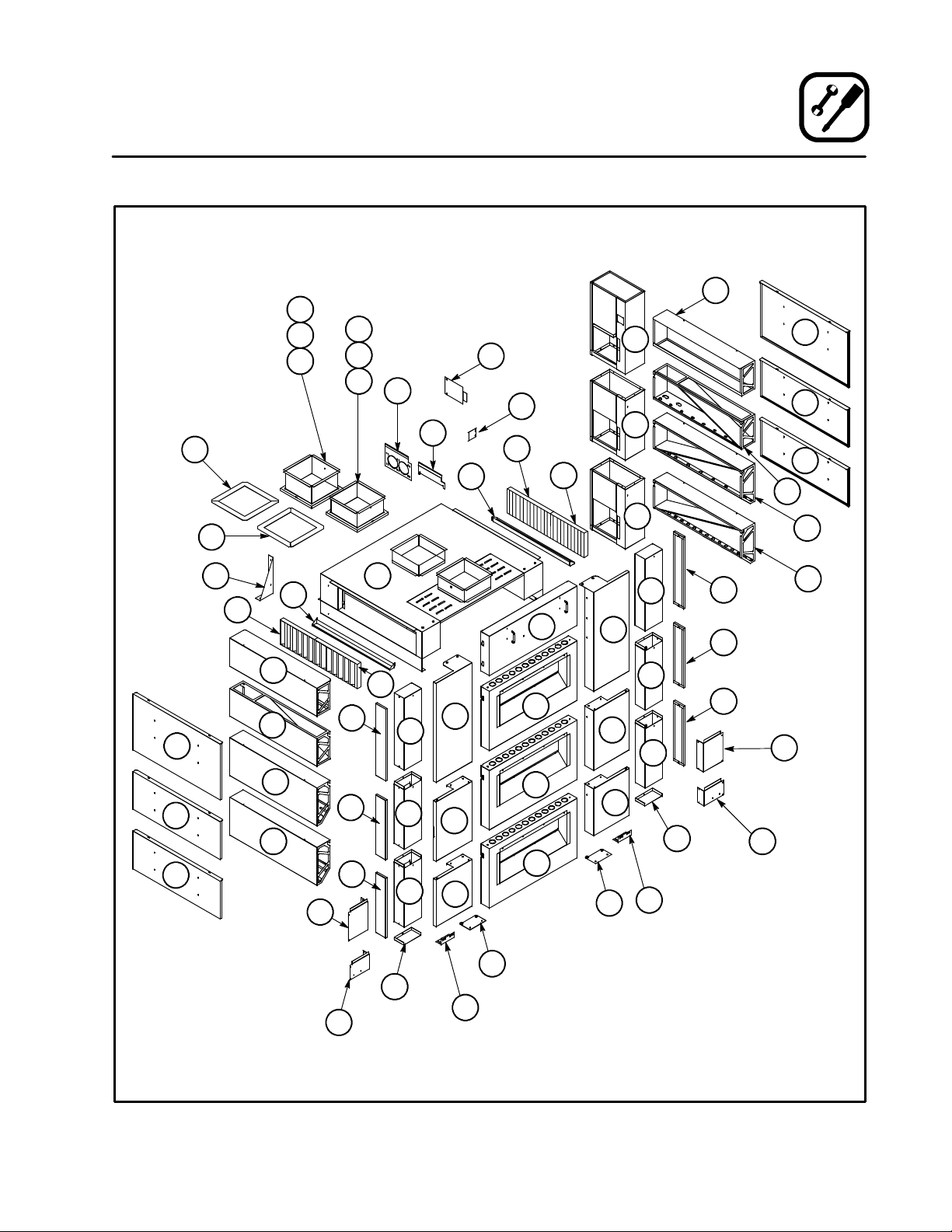

VIB3855 Parts List

REF

# P/N

01 VIB3855--- 001 1 1 1 Assy, AMU Support Bracket, O1 LH

02 VIB3855--- 002 1 1 1 Assy, Vertical Exh Plenum O1 LH

05 VIB3855--- 005 2 2 0 Bracket, AMU Bottom Support O1+O2

06 VIB3855--- 006 1 1 0 Back Plate, AMU Support Bracket O1+O2 LH

07 VIB3855--- 007 1 1 1 Assy,UpperExhPlenum,O1LH

08 VIB3855--- 008 1 1 1 Assy,UpperExhPlenum,O1RH

09 VIB3855--- 009 1 1 1 Assy, Heat Shield, O1 LH

10 VIB3855--- 010 0 1 1 Assy, AMU Support Bracket, O2 LH

11 VIB3855--- 011 1 1 1 Bracket, O1, Left Hand

12 VIB3855--- 012 1 1 1 Assy, Vertical Exh Plenum O1 RH

15 VIB3855--- 015 2 2 2 Plate, Block Off, Vert Exh Plenum, LH+RH

16 VIB3855--- 016 1 1 0 Back Plate, AMU Support Bracket O1+O2 RH

17 VIB3855--- 017 1 1 1 Assy,LowerExhPlenum,O1LH

18 VIB3855--- 018 1 1 1 Assy,LowerExhPlenum,O1RH

19 VIB3855--- 019 1 1 1 Assy, Heat Shield, O1 RH

20 VIB3855--- 020 0 1 2 Assy, Vertical Exh Plenum O2+O3 LH

22 VIB3855--- 022 0 1 2 Assy, Vertical Exh Plenum O2+O3 RH

23 VIB3855--- 023 1 1 1 PlenumAssy,AMU,Upper

25 VIB3855--- 025 1 2 3 PlenumAssy,AMU,O1+O2+O3

27 VIB3855--- 027 0 1 1 Assy,ExhPlenum,O2LH

28 VIB3855--- 028 0 1 1 Assy,ExhPlenum,O2RH

29 VIB3855--- 029 0 1 2 Assy, Heat Shield, O2+O3 LH

31 VIB3855--- 031 1 1 1 Assy, AMU/Exhaust Manifold

37 VIB3855--- 037 0 0 1 Assy,ExhPlenum,O3LH

38 VIB3855--- 038 0 0 1 Assy,ExhPlenum,O3RH

39 VIB3855--- 039 0 1 2 Assy, Heat Shield, O2+O3 RH

40 VIB3855--- 040 1 1 1 Assy, Cooling Fan Exh Plenum O1

44 VIB3240--- 044 1 1 1 Assy, Mounting Bracket, Cooling Fan Exh Plenum

45 VIB3855--- 045 0 1 2 Assy, Cooling Fan Exh Plenum O2+O3

47 VIB3855--- 047 2 2 2 Filter Trough / Receptacle

50 VIB3855--- 050 1 1 1 Assy, AMU Support Bracket, O1 RH

51 VIB3855--- 051 0 0 2 Bracket, AMU Bottom Support O3

57 VIB3855--- 057 1 1 1 Assy, AMU Duct Extension

60 VIB3855--- 060 0 1 1 Assy, AMU Support Bracket, O2 RH

61 VIB3855--- 061 1 1 1 Assy,MountingBracket,Ver.A,CoolingFanExhPlenum

67 VIB3855--- 067 1 1 1 Assy, Exhaust Duct Extension

70 VIB3855--- 070 2 2 2 Assy, Heat Sheild, Vert Exh Plenum O1

71 VIB3855--- 071 0 2 4 Assy, Heat Sheild, Vert Exh Plenum O2+O3

72 VIB3855--- 072 2 2 2 Trim,Ceiling,AMUDuct

73 VIB3855--- 073 2 2 2 Trim,Ceiling,ExhaustDuct

80 VIB3855--- 080 0 0 1 Assy, AMU Support Bracket, O3 LH

81 VIB3855--- 081 0 0 0or1* Plate, Block Off, Cooling Exh Plenum*

86 VIB3855--- 086 0 0 1 Back Plate, AMU Support Bracket O3 LH

90 VIB3855--- 090 0 0 1 Assy, AMU Support Bracket, O3 RH

91 VIB3855--- 091 1 1 1 Assy,MountingBracket,Ver.B,CoolingFanExhPlenum

96 VIB3855--- 096 0 0 1 Back Plate, AMU Support Bracket O3 RH

F1 ASFLT1016AL 2 2 2 Filter, 10” x 16

F2 ASFLT1020AL 2 2 2 Filter, 10” x 20

* = only included in Conversion Kit VIB3855 --- B3 for converting an AB2B to a VIB3855 --- 3

ORDERING

QUANTITY DESCRIPTION

VIB3855---1 VIB3855---2 VIB3855---3

01=TopOven, 02=SecondOven Down

03= Bottom Oven of a Triple Stack

6

Page 8

73

72

67

87

98

57

77

97

61

91

47

81

F2

44

F1

Installation

VIB3855 Parts List

8

40

45

45

19

39

39

18

28

29

29

11

47

F1

7

17

9

27

37

6

86

71

70

71

31

F2

15

20

20

12

23

1

2

10

80

51

25

25

25

5

60

5

50

22

22

90

51

70

71

71

15

38

16

96

7

Page 9

Installation

VIB3870 Parts List

REF

# P/N

01 VIB3855--- 001 1 1 1 Assy, AMU Support Bracket, O1 LH

02 VIB3855--- 002 1 1 1 Assy, Vertical Exh Plenum O1 LH

05 VIB3855--- 005 2 2 0 Bracket, AMU Bottom Support O1+O2

06 VIB3855--- 006 1 1 0 Back Plate, AMU Support Bracket O1+O2 LH

07 VIB3855--- 007 1 1 1 Assy,UpperExhPlenum,O1LH

08 VIB3855--- 008 1 1 1 Assy,UpperExhPlenum,O1RH

09 VIB3855--- 009 1 1 1 Assy, Heat Shield, O1 LH

10 VIB3855--- 010 0 1 1 Assy, AMU Support Bracket, O2 LH

11 VIB3855--- 011 1 1 1 Bracket, O1, Left Hand

12 VIB3855--- 012 1 1 1 Assy, Vertical Exh Plenum O1 RH

15 VIB3855--- 015 2 2 2 Plate, Block Off, Vert Exh Plenum, LH+RH

16 VIB3855--- 016 1 1 0 Back Plate, AMU Support Bracket O1+O2 RH

17 VIB3855--- 017 1 1 1 Assy,LowerExhPlenum,O1LH

18 VIB3855--- 018 1 1 1 Assy,LowerExhPlenum,O1RH

19 VIB3855--- 019 1 1 1 Assy, Heat Shield, O1 RH

20 VIB3855--- 020 0 1 2 Assy, Vertical Exh Plenum O2+O3 LH

22 VIB3855--- 022 0 1 2 Assy, Vertical Exh Plenum O2+O3 RH

23 VIB3870--- 023 1 1 1 PlenumAssy,AMU,Upper

25 VIB3870--- 025 1 2 3 PlenumAssy,AMU,O1+O2+O3

27 VIB3855--- 027 0 1 1 Assy,ExhPlenum,O2LH

28 VIB3855--- 028 0 1 1 Assy,ExhPlenum,O2RH

29 VIB3855--- 029 0 1 2 Assy, Heat Shield, O2+O3 LH

31 VIB3870--- 031 1 1 1 Assy, AMU/Exhaust Manifold

37 VIB3855--- 037 0 0 1 Assy,ExhPlenum,O3LH

38 VIB3855--- 038 0 0 1 Assy,ExhPlenum,O3RH

39 VIB3855--- 039 0 1 2 Assy, Heat Shield, O2+O3 RH

40 VIB3870--- 040 1 1 1 Assy, Cooling Fan Exh Plenum O1

44 VIB3870--- 044 1 1 2 Assy, Mounting Bracket, Cooling Fan Exh Plenum

45 VIB3870--- 045 0 1 2 Assy, Cooling Fan Exh Plenum O2+O3

47 VIB3855--- 047 2 2 2 Filter Trough / Receptacle

50 VIB3855--- 050 1 1 1 Assy, AMU Support Bracket, O1 RH

51 VIB3855--- 051 0 0 2 Bracket, AMU Bottom Support O3

57 VIB3855--- 057 1 1 1 Assy, AMU Duct Extension

60 VIB3855--- 060 0 1 1 Assy, AMU Support Bracket, O2 RH

61 VIB3870--- 061 1 1 1 Assy,MountingBracket,Ver.A,CoolingFanExhPlenum

67 VIB3855--- 067 1 1 1 Assy, Exhaust Duct Extension

70 VIB3855--- 070 2 2 2 Assy, Heat Sheild, Vert Exh Plenum O1

71 VIB3855--- 071 0 2 4 Assy, Heat Sheild, Vert Exh Plenum O2+O3

72 VIB3855--- 072 2 2 2 Trim,Ceiling,AMUDuct

73 VIB3855--- 073 2 2 2 Trim,Ceiling,ExhaustDuct

80 VIB3855--- 080 0 0 1 Assy, AMU Support Bracket, O3 LH

86 VIB3855--- 086 0 0 1 Back Plate, AMU Support Bracket O3 LH

90 VIB3855--- 090 0 0 1 Assy, AMU Support Bracket, O3 RH

91 VIB3870--- 091 1 1 1 Assy,MountingBracket,Ver.B,CoolingFanExhPlenum

96 VIB3855--- 096 0 0 1 Back Plate, AMU Support Bracket O3 RH

F1 ASFLT1016AL 2 2 2 Filter, 10” x 16

F2 ASFLT1020AL 2 2 2 Filter, 10” x 20

ORDERING

QUANTITY DESCRIPTION

VIB3870---1 VIB3870---2 VIB3870---3

01=TopOven, 02=SecondOven Down

03= Bottom Oven of a Triple Stack

8

Page 10

73

72

67

87

98

57

77

97

61

91

47

F2

44

F1

Installation

VIB3870 Parts List

8

40

45

45

19

39

39

18

28

29

29

11

47

F1

7

17

9

27

37

6

86

71

70

71

31

F2

15

20

20

12

23

1

2

10

80

51

25

25

25

5

60

5

50

22

22

90

51

70

71

71

15

38

16

96

9

Page 11

Installation

Airflow Requirements

MODEL PRESSURE SUPPLY EXHAUST

VIB3240-1

Duct size 7”x12”

(17.8 x 305 mm)

VIB3240-2

Duct size 7”x12”

(17.8 x 305 mm)

VIB3240-3

Duct size 7”x12”

(17.8 x 305 mm)

VIB3855-1 CFM 1100 CFM 1500 CFM

Duct size 12” x 12”

(305 x 305 mm)

VIB3855-2

Duct size 12”x12”

(305 x 305 mm)

VIB3855-3

Duct size 12”x12”

(305 x 305 mm)

CFM 500 CFM 875 CFM

STATIC PRESSURE 0.04” W.C. (10 Pa) 0.7” W.C. (174 Pa)

CFM 750 CFM 1150 CFM

STATIC PRESSURE 0.07” W.C. (17 Pa) 1.0” W.C. (249 Pa)

CFM 1050 CFM 1450 CFM

STATIC PRESSURE 0.14” W.C. (35 Pa) 1.5” W.C. (373 Pa)

STATIC PRESSURE 0.02-0.03” W.C.

(5-7 Pa)

CFM 1450 CFM 1850 CFM

STATIC PRESSURE 0.09” W.C. (22 Pa) 1.4” W.C. (348 Pa)

CFM 1800 CFM 2200 CFM

STATIC PRESSURE 0.12” W.C. (30 Pa) 1.8” W.C. (448 Pa)

1.5” W.C. (373 Pa)

VIB3870-1 CFM 1100 CFM 1500 CFM

Duct size 12” x 12”

(305 x 305 mm)

VIB3870-2

Duct size 12”x12”

(305 x 305 mm)

VIB3870-3

Duct size 12”x12”

(305 x 305 mm)

STATIC PRESSURE 0.02-0.03” W.C.

(5-7 Pa)

CFM 1450 CFM 1850 CFM

STATIC PRESSURE 0.09” W.C. (22 Pa) 1.4” W.C. (348 Pa)

CFM 1800 CFM 2200 CFM

STATIC PRESSURE 0.12” W.C. (30 Pa) 1.8” W.C. (448 Pa)

10

1.5” W.C. (373 Pa)

Page 12

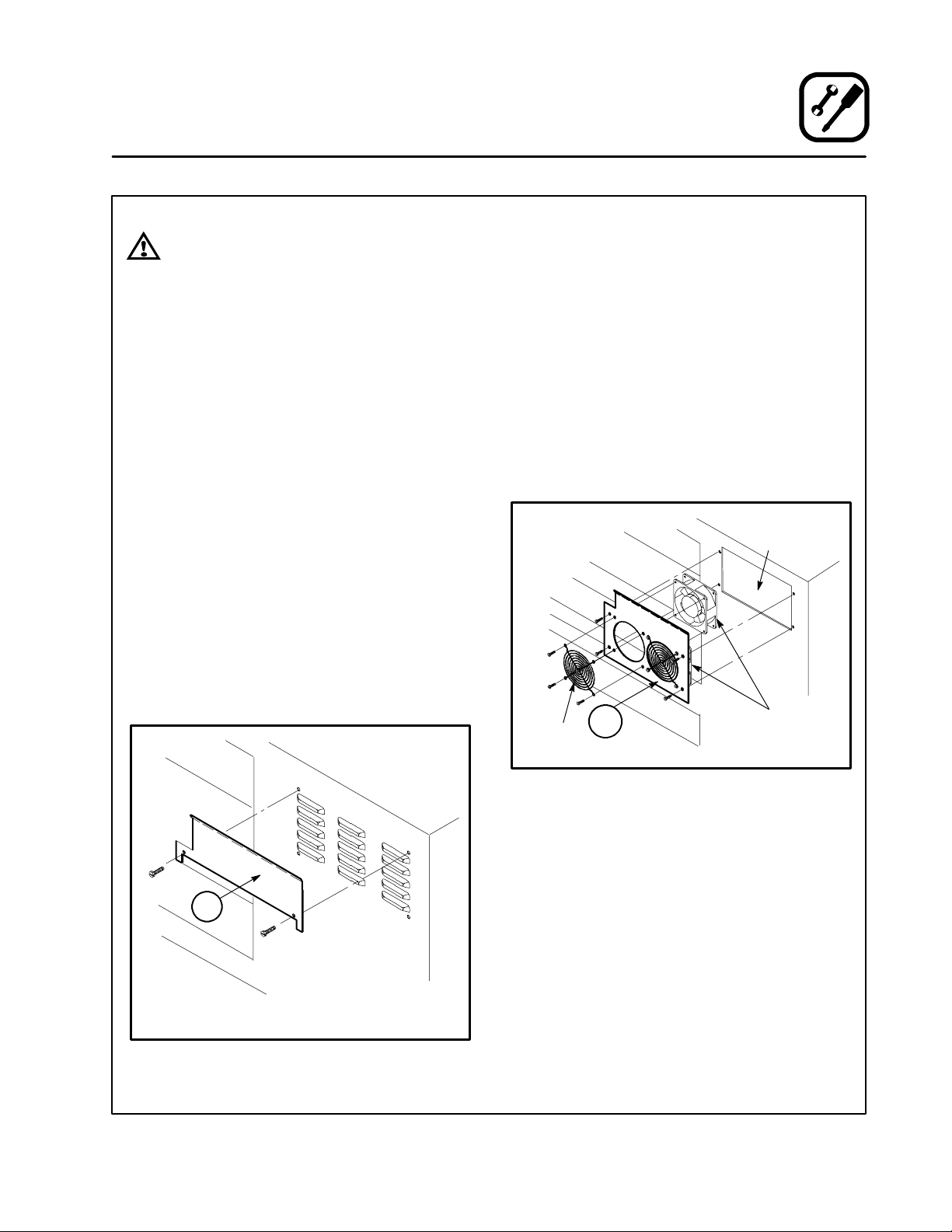

WARNING!!

Be sure that the ovens are unplugged and

the gas disconnected (if applicable).

OVEN ASSEMBLY AND STACKING

1. Assemble the oven(s) as described in the

Owner-Operator Manual provided with the appliance(s).

2. If applicable, stack the units as follows:

SG3240 Ovens --- Use the stacking pins pro-

vided with the oven to secure the decks together and prevent shifting.

MT3855 and MT3870 Ovens --- Attach the

stacking rail between each oven on the back to

secure the decks together and prevent shifting.

COOLING FAN EXHAUST PLENUM MOUNTING

BRACKETS

For Ovens with Cooling Fan Exhaust Louvers

1. Install the Mounting Bracket Version B [91] using two #10-24 x 3/8 screws provided. See

Figure 1.

NOTE: Mount with the offset going away from

theoven.Theshapeofbracket91varies with the model of the oven.

Installation

Oven Preparation

For Ovens with Plate Mounted Cooling Fans

(VIB3855 with o l der MT3855 ovens or VIB3870

with older MT3870 ovens)

1. Remove the plate in the top oven that holds the

exhaust fans in place. Disconnect the wiring.

NOTE: The plate is located on the right side

of the oven.

2. Remove the fans from the original plate and

install them, along with the grills, on the Version A Mounting Bracket [61] using the original hardware. See Figure 2.

3. Reconnect the fan motors to the wiring harness and install the assembly to the top oven

using the original screws.

OVEN

CUTOUT

EXHAUST

FAN

GRILL

61

91

Rear of Right Side of MT3855

shown with VIB3855-091 Bracket

Figure 1

Figure 2

11

Page 13

Installation

Oven Preparation

OVEN/VENT ALIGNMENT HOLES

For SG3240 and Ovens With Stacking Align-

ment Knockouts

1. Use a hammer to remove the two front knockouts. The location of the knockouts should

match t he two shown in Figure 3.

For Ovens Without Stacking Alignment Knockouts

1. Locate the front, top edge of the upper oven.

2. Drill two 7/16” diameter holes in the top of the

oven at the locations shown in Figure 3. The

holes should penetrate both the top “skin” of

the oven as well as the angle frame member.

There is no need to penetrate the top of the

oven by more than 7/8”.

3/4

2-7/16”

FRONT OF OVEN

Figure 3

12

7/16” (2 PLCS)

3/4

2-7/16”

Page 14

AMU ALIGNMENT PINS

1. Thread the two Alignment Pins [K9] into the fittings on the bottom of the AMU / Exhaust Manifold Assembly [31].

31

Installation

AMU Installation

2. Carefully lift the assembly and place it on top

of the oven(s). Insert the alignment pins into

the alignment holes to prevent the assembly

from shifting on top of the oven. See Figure 4.

ALIGNMENT

PIN

Figure 4

ALIGNMENT

HOLE

13

Page 15

Installation

AMU Installation

CORNER SUPPORT BRACKET(S)

For VIBXXXX-01 (Single Ovens)

1. Right Corner Support Bracket Assembly:

a.) A ttach Bracket [16] to the bottom rear of

Corner Support Bracket [50] using four

#10 x 1/2” self drilling screws [K2].

b.) Attach Bracket [5] to the bottom of Corner

Support Bracket [50] using two #10 x 1/2”

self drilling screws [K2].

c.) Hang the assembly on the right side of the

AMU/Exhaust Manifold Assembly [31]

leaving the two 3/8-16 hex head screws

[K6]loose.SeeFigure6.

2. Left Corner Support Bracket Assembly:

a.) A ttach Bracket [6] to the bottom rear of

Corner Support Bracket [1] using four

#10 x 1/2” self drilling screws [K2].

b.) Attach Bracket [5] to the bottom of Corner

Support Bracket [1] using two #10 x 1/2”

self drilling screws [K2].

c.) Hangtheassemblyontheleftsideofthe

AMU/Exhaust Manifold Assembly [31]

leaving the two 3/8-16 hex head screws

[K6]loose.SeeFigure6.

3. Loosen the front two leg bolts on both the front

legs enough to slide Brackets [5] under the

washers. See Figure 6. Center the Corner Support Brackets and tighten at the top and bottom

holding the brackets against the oven. Refer to

the following table for the correct distance between the brackets.

Model

VIB3240 37-5/8” (956 mm)

VIB3855 40-1/8” (1019 mm)

VIB3870 55-1/8” (1400 mm)

Distance

For VIBXXXX -02 (Double Stacked Ovens)

1. Right Corner Support Bracket Assembly:

a.) A ttach Bracket [16] to the bottom rear of

Corner Support Bracket [60] using four

#10 x 1/2” self drilling screws [K2].

b.) Attach Bracket [5] to the bottom of Corner

Support Bracket [60] using two #10 x 1/2”

self drilling screws [K2].

c.) Attach Corner Support Bracket [60] to

Corner Support Bracket [50] using 1/4-20

x 1” hex head bolts[K6], 1/4” flatwashers

[K7], 1/4” lockwashers [K8], and 1/4-20

nuts [K9]. Tighten securely while aligned.

d.) Hang the assembly on the right side of the

AMU/Exhaust Manifold Assembly [31]

leaving the two 3/8-16 hex head screws

[K6]loose.SeeFigure6.

2. Left Corner Support Bracket Assembly:

a.) A ttach Bracket [6] to the bottom rear of

Corner Support Bracket [10] using four

#10 x 1/2” self drilling screws [K2].

b.) Attach Bracket [5] to the bottom of Corner

Support Bracket [10] using two #10 x 1/2”

self drilling screws [K2].

c.) Attach Corner Support Bracket [1] to Cor-

ner Support Bracket [10] using 1/4-20 x 1”

hex head bolts[K6], 1/4” flatwashers [K7],

1/4” lockwashers [K8], and 1/4-20 nuts

[K9]. Tighten securely while aligned.

d.) Hangtheassemblyontheleftsideofthe

AMU/Exhaust Manifold Assembly [31]

leaving the two 3/8-16 hex head screws

[K6]loose.SeeFigure6.

3. Loosen the front two leg bolts on both the front

legs enough to slide Brackets [5] under the

washers. See Figure 6. Center the Corner Support Brackets and tighten at the top and bottom

holding the brackets against the oven. Refer to

the following table for the correct distance between the brackets.

Model

Distance

14

VIB3240 37-5/8” (956 mm)

VIB3855 40-1/8” (1019 mm)

VIB3870 55-1/8” (1400 mm)

Page 16

Installation

AMU Installation

For VIBXXXX-03 (Triple Stacked Ovens)

1. Right Corner Support Bracket Assembly:

a.) A ttach Bracket [96] to the bottom rear of

Corner Support Bracket [90] using four

#10 x 1/2” self drilling screws [K2].

b.) Attach Bracket [51] to the bottom of Cor-

ner Support Bracket [96] using two #10 x

1/2” self drilling screws [K2].

c.) Attach Corner Support Bracket [50], Cor-

ner Support Bracket [60] and Corner Support Bracket [90] using 1/4-20 x 1” hex

head bolts[K6], 1/4” flatwashers [K7],

1/4” lockwashers [K8], and 1/4-20 nuts

[K9]. Tighten securely while aligned.

d.) Hang the assembly on the right side of the

AMU/Exhaust Manifold Assembly [31]

leaving the two 3/8-16 hex head screws

[K6]loose.SeeFigure6.

2. Left Corner Support Bracket Assembly:

a.) A ttach Bracket [86] to the bottom rear of

Corner Support Bracket [80] using four

#10 x 1/2” self drilling screws [K2].

b.) Attach Bracket [51] to the bottom of Cor-

ner Support Bracket [86] using two #10 x

1/2” self drilling screws [K2].

c.) Attach Corner Support Bracket [1], Cor-

ner Support Bracket [10] and Corner Support Bracket [80] using 1/4-20 x 1” hex

head bolts[K6], 1/4” flatwashers [K7],

1/4” lockwashers [K8], and 1/4-20 nuts

[K9]. Tighten securely while aligned.

d.) Hangtheassemblyontheleftsideofthe

AMU/Exhaust Manifold Assembly [31]

leaving the two 3/8-16 hex head screws

[K6]loose.SeeFigure6.

3. Loosen the front two caster bolts on both the

right and left sides enough to slide Brackets [5]

under the washers. See Figure 6. Center the

Corner Support Brackets and tighten at the top

and bottom holding the brackets against the

oven. Refer to the following table for the correct

distance between the brackets.

Model

VIB3240 37-5/8” (956 mm)

VIB3855 40-1/8” (1019 mm)

VIB3870 55-1/8” (1400 mm)

Distance

15

Page 17

Installation

AMU Installation

50

80

10

1

60

90

LOCATION OF

BRACKET,

AMU BOTTOM

SUPPORT

(if single oven)

DOUBLE DECK

BRACKET

LOCATION

50

5

60

90

Figure 5

16

Page 18

AMU SUPPORT BRACKETS

For VIBXXXX -1 (Single Ovens) and

VIBXXXX-2 (Double Stacked Ovens)

1. Secure the AMU Bottom Support Bracket

01-02 [5] below the right front support leg

mounting flange. Use the same inner, front

bolt and washer that secures the leg in place.

2. Repeat STEP 1 for the left front support leg.

NOTE: Both AMU support brackets should be

parallel and square and held firmly against

the front of the oven(s).

Installation

AMU Installation

For VIBXXXX-3 (T riple Stacked Ovens)

NOTE: The AMU Bottom Support Bracket is at-

tached to the AMU Bottom Support Bracket Back Plates at the factory.

1. Secure the Right AMU Bottom Support Bracket 03 [51] to the caster plate on the oven as follows:

e.) Loosen the two outer bolts on the caster

plate.

f.) Slide the assembly between the plate and

washers.

g.) Re-tighten the bolts.

2. Repeat STEP 1 for the Left AMU Bottom Support Bracket 03 [51].

Figure 6

6

51

Figure 7

80

17

Page 19

Installation

AMU Installation

AMU INSTALLATION

1. Place the Lower AMU Plenum Assembly 02

[25] on the pins of the AMU Support Bracket

01 [50 right, 1 left].

2. Place the Middle AMU Plenum Assembly 02

[25] on the pins of the AMU Support Bracket

01[60right,10left].

3. Place the Upper AMU Plenum Assembly 02

[25] on the pins of the AMU Support Bracket

01 [50 right, 1 left].

4. Place the Plenum Assembly [23] on the upper

pins of the AMU Support Bracket 01 [50 right,

1left].

23

25

Figure 8

18

25

25

Page 20

VERTICAL EXHAUST PLENUM ASSEMBLY

NOTE: For VIBXXXX-1 (single ovens) complete

steps1,4and6.ForVIBXXXX-2(double

stacked ovens) complete steps 1, and 3 - --6.

For VIBXXXX-3 (triple stacked ovens) completeallofthesteps.

Use the following instructions to install the left and

right Vertical Exhaust Plenums.

1. All Models --- Attach the Block Off Plate [15

right and left] to bottom of [2 and 12 if

VIBXXX-1] [20 and 22 if VIBXXXX- 2 or

VIBXXXX-3] using #10-24x3/8” Phillips Head

Screws. See Figure 9.

2. Triple Stacked Ovens Only --- Attach the

Lower Vertical Exhaust Plenum Assembly 03

[22 right, 20 left] to the AMU Support Bracket

Assembly 02 [60 right, 10 left] by aligning the

pin on the vertical exhaust plenum to the slot

on the back of the right AMU support bracket.

3. Double and Triple Stacked Ovens Only --- A t -

tach the Middle Vertical Exhaust Plenum As-

Installation

Exhaust Installation

sembly 02 [22 right, 20 left] to the AMU Support Bracket Assembly 01 [50 right, 1 left] by

aligning the pin on the vertical exhaust plenum

to the slot on the back of the AMU support

bracket.

4. All Models --- Attach the Vertical Exhaust Ple-

num Assembly 01 [12 right, 2 left] to the AMU

Support Bracket Assembly 01 [50 right, 1 left]

by aligning the pin on the vertical exhaust plenum to the slot on the back of the AMU support brack et.

5. Double and Triple Stacked Ovens Only --- A t -

tach the Heat Shield 02-03 [71 right and left]

to the Vertical Exhaust Plenum 03 [22 right, 20

left] by aligning the slots in the heat shield with

the pins on the vertical exhaust plenum.

6. All Models --- Attach the Heat Shield 01 [70

right and left] to the Vertical Exhaust Plenum

Assembly 01 [12 right, 2 left] by aligning the

slots in the heat shield with the pins on the vertical exhaust plenum.

70

LOCATION OF

[15] FOR

VIBXXXX-1

71

LOCATION OF

[15] FOR

VIBXXXX-2

71

15

12

40

22

45

22

45

LOCATION OF [ 15] FORVIBXXXX-3

Figure 9

19

Page 21

Installation

Exhaust Installation

COOLING FAN EXHAUST PLENUM

For VIBXXXX-3 (T riple Stacked Ovens)

1. Attach the lower Cooling Fan Exhaust Plenum

Assembly [45] to the upper Cooling Fan Exhaust Plenum Assembly [45] using #10x1/2”

self drilling screws [K10].

2. Attach the Cooling Fan Exhaust Plenum Assembly 01 [40] to the oven by aligning the

flange on cooling fan exhaust plenum with the

Mounting Bracket Assembly [61 or 91].

3. Install Bracket (44) to the rear of the top oven

to hold the lower Cooling Fan Exhaust Plenum Assembly [45] and the upper Cooling

Fan Exhaust Plenum Assembly [45] forward.

For VIBXXXX-2 (Double Stacked Ovens)

1. Attach the Upper Cooling Fan Exhaust Plenum Assembly [40] to the Cooling Fan Exhaust Plenum Assembly 01 [45] using

#10x1/2” s elf drilling screws [K10].

2. Attach the Cooling Fan Exhaust Plenum Assembly 01 [40] to the oven by aligning the

flange on cooling fan exhaust plenum with the

Mounting Bracket Assembly [61 or 91].

3. Install Bracket (44) to the rear of the top oven

to hold the lower Cooling Fan Exhaust Plenum Assembly [45] and the upper Cooling

Fan Exhaust Plenum Assembly [45] forward.

For VIBXXXX-1 (Single Ovens)

1. Attach the Cooling Fan Exhaust Plenum Assembly 01 [40] to the oven by aligning the

flange on cooling fan exhaust plenum with the

Mounting Bracket Assembly [61 or 91].

40

45

44

Figure 10

FLANGE

40

31

61

91

20

Page 22

EXHAUST PLENUM HANGING PIN

WARNING!!

The hole location described below

should not interfere with any oven control

center components. Care must be taken

when locating and drilling this hole to

avoid damage to internal components.

Use the following procedure to install the exhaust

plenum hanging pins on VIBXXXX-02 (double

stacked ovens) and VIBXXXX- 03 (triple stacked

ovens).

1. On the first and second decks drill one 1/4” diameter hole into the upper control cabinet.

SeeFigure11.

NOTE: The distance from the top of the upper

oven to the center line of the hole

should be the same as the distance

from the top of the upper oven center

lineofthepinweldedinthesurfaceof

the Left Vertical Exhaust Plenum Assembly 01 [2].

2. Remove the electrical box cover.

3. Remove the chain guards from the ovens.

4. Insert one 1/4”-20 Custom Shoulder Bolt

[K12] through the hole. Secure the bolt in

place with one 1/4” Flat Washer [K3] and one

1/4”-20 Lock Nut [K13].

5. Reinstall the chain guards in the electrical box.

6. Reinstall the electrical box cover.

Installation

Exhaust Installation

1

15-19/32

FRONT VIEW

21

Figure 11

Page 23

Installation

Exhaust Installation

TOP OVEN BRACKET

1. Locate Left Bracket 01[11] at the junction of

the AMU Exhaust Manifold Assembly [31] and

the forward inboard edge of the upper oven

electrical box. The forward edge of the bracket

should be vertical.

2. Attach the bracket using #10x1/2” Self Drilling

Screws [K10].

11

Figure 12

22

Page 24

FILTERS

1. Install one Filter Trough/Receptacle [47] into

the opening in each end of the AMU Exhaust

Manifold Assembly [31].

NOTE: The tabs in the filter trough/receptacle fit

into the slots on the sides of the openings in the AMU exha u st manifold.

For VIB3240

1. Insert one 10” x 16” Filter [F1] into each end

of the AMU Exhaust Manifold Assembly [31]

as follows:

a.) Install the top of the filter into the channel

in the top of the AMU Exhaust Manifold

first.

b.) Then allow the bottom of the filter to drop

into the Filter Trough/Receptacle [47].

2. Repeat on the other end of the oven.

Installation

Exhaust Installation

For VIB3855 and VIB3870

1. Insert one 10” x 16” (254 x 406.4mm) Filter

[F1] and one 10” x 20” (254 x 508mm) Filter

[F2] into each end of the AMU Exhaust Manifold Assembly [31] as follows:

a.) Install the top of the filters into the channel

in the top of the AMU Exhaust Manifold

first.

b.) Then allow the bottom of the filters to drop

into the Filter Trough/Receptacle [47].

2. Repeat on the other end of the oven.

Figure 13

47

23

Page 25

Installation

Exhaust Installation

RIGHT EXHAUST PLENUM AND HEAT SHIELD

Use the following instructions to installthe right Exhaust Plenums and Heat Shields.

To p D e c k

1. Mount the Right Lower Exhaust Plenum Assembly 01 [18] in place. The slots on t he sides

towards the rear of the lower exhaust plenum

fit over the pins in the Cooling Fan Exhaust

Plenum Assembly 01 [40] and the Vertical Exhaust Plenum Assembly 01 [12].

2. Mount the Right Upper Exhaust Plenum Assembly 01 [8] in place. See Figure 14.

3. Mount the Right Heat Shield 01 [19] by aligning the slots over the pins on the upper exhaust plenum assembly.

Second Deck (if applicable)

1. Mount the Right Exhaust Plenum Assembly 02

[28] in place. The slots on the sides towards

the rear of the exhaust plenum fit over the pins

in the Cooling Fan Exhaust Plenum Assembly

[45] and the Vertical Exhaust Plenum Assembly [22].

2. Mount the Right Heat Shield 02 [39] by aligning the slots over the pins on the exhaust plenum assembly.

Third Deck (if applicable)

1. Mount the Right Exhaust Plenum Assembly 03

[38] in place. The slots on the s ides towards

the rear of the exhaust plenum fit over the pins

in the Cooling Fan Exhaust Plenum Assembly

[45] and the Vertical Exhaust Plenum Assembly [22].

2. Mount the Right Heat Shield 03 [39] by aligning the slots over the pins on the exhaust plenum assembly.

39

39

8

40

19

18

45

28

45

38

Figure 14

24

Page 26

LEFT EXHAUST PLENUM AND HEAT SHIELD

Use the following instructions to install the left Exhaust Plenums and Heat Shields.

To p D e c k

1. Mount the Left Lower Exhaust Plenum Assembly 01 [17] in place. The slots on the sides towards the rear of the lower exhaust plenum fit

over the pins in the Left Bracket 01 [11] and

the Left Vertical Exhaust Plenum Assembly 01

[2].

2. Mount the Left Upper Exhaust Plenum Assem bly 01 [7] in place. See Figure 15.

3. Mount the Left Heat Shield 01 [9] by aligning

the slots over the pins on the upper exhaust

plenum assembly.

Second Deck (if applicable)

1. Mount the Left Exhaust Plenum Assembly 02

[27] in place. The slots on the sides towards

Installation

Exhaust Installation

the rear of the exhaust plenum fit over the Custom Shoulder Bolt [K12] in the oven’s electrical box and the Left Vertical Exhaust Plenum

Assembly [20].

2. Mount the Left Heat Shield 02 [29] by aligning

the slots over the pins on the left exhaust plenum assembly.

Third Deck (if applicable)

1. Mount the Left Exhaust Plenum Assembly 03

[37] in place. The slots on the s ides towards

the rear of the exhaust plenum fit over the Custom Shoulder Bolt [K12] in the oven’s electrical box and the Left Vertical Exhaust Plenum

Assembly [20].

2. Mount the Left Heat Shield 03 [29] by aligning

the slots over the pins on the exhaust plenum

assembly.

29

29

7

9

17

27

37

Figure 15

25

Page 27

Installation

Duct Connection

WARNING!!

The duct collar extensions are designed

to remain in place when the oven is rolled

away for maintenance or cleaning. Therefore, they should be rigidly fastened to

the ceiling structure as they are not intended to support the weight of the ductwork and/or fans.

1. Roll the oven into its operating location.

2. Install the Exhaust Duct Extension as follows:

a.) Locate the Exhaust Duct Extension As-

sembly [98, 87 or 67] on top of the exhaust

duct collar. The collar is part of the AMU

Exhaust Manifold Assembly [31].

b.) Secure the duct extension in place with

the two over-center latches. The exhaust

duct extension is designed to penetrate 8’

tall ceilings by approximately 2”.

c.) Connect the duct from the exhaust fan to

the exhaust duct extension.

3. Install the AMU Duct Extension as follows:

a.) Locate the AMU Duct Extension Assem-

bly [97, 77 or 57] on top of the air make up

duct collar. The collar is part of the AMU

Exhaust Manifold Assembly [31].

b.) Secure the duct extension in place with

the two overcenter latches. The AMU duct

extension is designed to penetrate 8’ tall

ceilings by approximately 2”.

c.) Connect the duct from the air makeup to

the AMU duct extension.

The oven(s) can now be connected to electric and

gas (if applicable) supplies.

NFPA 96, Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations,re-

quires that “hoods, grease removal devices, exhaust fans, and ducts shall have a clearance of at

least 18” (457.2 mm) to combustible material, 3”.

(76.2mm) to limited combustible material, and 0”

(0mm) to non-combustible material”. The VIB Series exhaust hood is equipped with louvers on the

top of the hood which supply make-up air to the

general vicinity of the oven help cool the area

around the oven. DO NOT store or place items

on top of hood.

EXHAUST DUCT

WALL

AMU DUCT

98 87 67 57 77 97

31

Figure 16

26

FINISHED CEILING

Page 28

WARNING!!

The oven and the ventilation system get

hot during operation. Allow the oven/ventilation system assembly to cool to avoid

possible injury.

MONTHLY

1. Remove the heat shields and exhaust plenums by lifting up and pulling away from the

oven.

2. Remove the filters by lifting up then swinging

the bottom out and down.

3. Remove the filter trough receptacles.

4. Run the parts through a dishwasher or wash

by hand with hot, soapy water. DO NOT use

scouring pads (plastic or metal) on the exterior surfaces; they will scratch and mar

the finish.

5. Rinse the panels in warm water and dry.

6. InstallthepartsasdescribedintheExhaust

Installation section of this manual.

Maintenance

Cleaning

QUARTERLY

1. Remove the heat shields and exhaust plenums by lifting up and pulling away from the

oven.

2. Remove the filters by lifting up then swinging

the bottom out and down.

3. Remove the filter trough receptacles.

4. Run the parts through a dishwasher or wash

by hand with hot, soapy water. DO NOT use

scouring pads (plastic or metal) on the exterior surfaces; they will scratch and mar

the finish.

5. Wipe out the exhaust channel portion of the

AMU exhaust manifold.

6. Brush a nd clean the guards of the cooling

fans.

7. Rinse the panels in warm water and dry.

8. Install the parts as described in the Exhaust

Installation section of this manual.

NOTE: This regular maintenance is in addition to

the daily, quarterly, semi-annual and annual cleaning schedule included in the oven

operation manual.

27

Page 29

Servicing

WARNING!!

Be sure that the ovens are unplugged and

the gas disconnected (if applicable) before servicing.

Maintenance

To move the oven/ventilation system for servicing:

1. Release the over-center latches on the exhaust and air make-up duct collars.

2. Slide the clamping collars up and secure them

out of the way .

3. Release the brakes on the front locking casters of the oven.

4. Roll the oven out and away from the w a ll.

EXHAUST

CLAMPING

COLLAR

DUCT

AMU DUCT

CLAMPING COLLAR

Figure 17

28

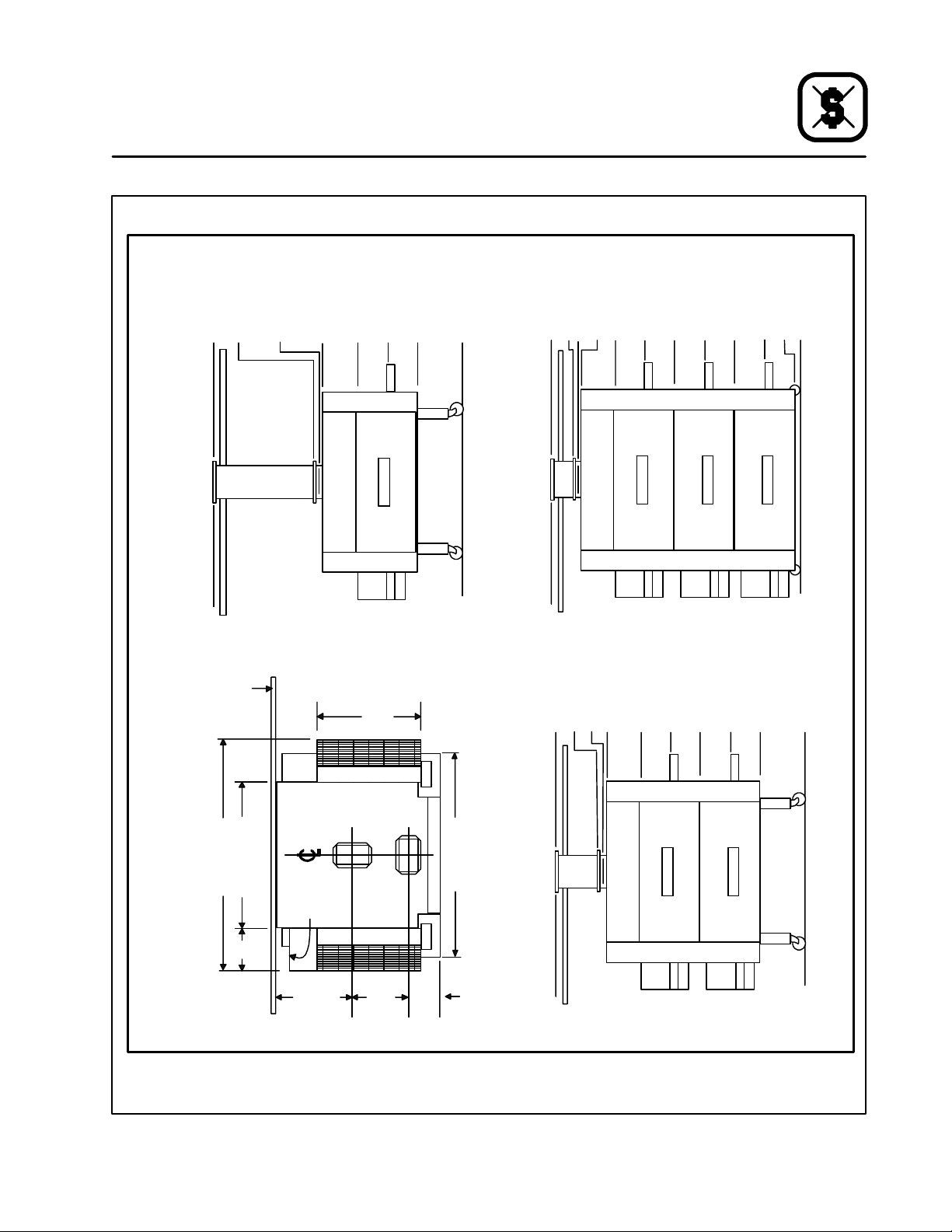

Page 30

99” (2515mm)

68.5” (1740mm)

Suppy (AMU)

67.5” (1715mm)

Quick Disconnect

Exhaust Quick

63.5” (1613mm)

Disconnect

37.69” (957mm)

47.5” (1207mm)

top ofoven only

23.5” (597mm)

0” (0mm)

FRONT VIEW (VIB3240 - -- 1)

Maintenance

49.5” (1257mm)

63.68” (1618mm)

73.5” (1867mm)

top ofoven only

89.5” (2273mm)

93.5” (2375mm)

94.5” (2400mm)

99” (2515mm)

25.5” (648mm)

39.68” (1008mm)

Servicing

0” (omm)

15.68” (398mm)

1.5” (38mm)

VIB3240

8’ C EILING

0” (0mm)

FROM WALL

CLEARANCE

77” (1956mm)

40” (1016mm)18”

GAS

INPUT

(457mm)

*Ductwork should be terminated 99” (2515mm) above the finished floor (2” (51mm) above an 8’ ceiling). All other connections will be supplied with the hood.

(660mm

26” or 34.8”*

or

EXHAUST

883mm)

33.25”

(845mm)

19”

(483mm)

99” (2515mm)

86.5” (2197mm)

85.5” (2172mm)

SUPPLY

TOP VIEW

58” (1473mm)

14”

(356mm)

* 34.8” (883mm) for VIB3240-3, 26” (660mm) for VIB3240-1 or VIB3240-2

65.5” (1664mm)

81.5” (2070mm)

55.69” (1415mm)

top ofoven only

41.5” (1054mm)

31.69” (805mm)

17.5” (445mm)

FRONT VIEW (VIB3240 - -- 3) WITH CASTER CRADLES

0” (0mm)

FRONT VIEW (VIB3240 - -- 2)

Figure 18

29

Page 31

Servicing

Maintenance

99” (2515mm)

68” (1727mm)

Suppy (AMU)

Quick Disconnect

67” (1702mm)

Exhaust Quick

Disconnect

63” (1600mm)

47” (1194mm)

top of oven only

37.5” (953mm)

23.5” (597mm)

0” (0mm)

FRONT VIEW (VIB3855 - -- 1)

99” (2515mm)

92” (2337mm)

93” (2362mm)

72” (1829mm)

top of oven only

88” (2235mm)

48.5” (1232mm)

62.5” (1588mm)

39” (991mm)

25” (635mm)

15.5” (394mm)

1.5” (38mm)

0” (0mm)

VIB3855

8’ C EILING

0” (0mm)

FROM WALL

CLEARANCE

91.12” (2314mm)

55.12” (1400mm)

18”

*Ductwork should be terminated 99” (2515mm) above the finished floor (2” (51mm) above an 8’ ceiling). All other connections will be supplied with the hood.

(457mm)

16.75”

(425mm)

(737mm

29” or 32”*

Gas Input

or

Exhaust

813mm)

39.6”

(1006mm)

21”

(533mm)

Supply

TOP VIEW

73” (1854mm)

12.3”

(312mm)

99” (2515mm)

85.5” (2172mm)

84.5” (2146mm)

* 32” (813mm) for VIB3855-3, 29” (737mm) for VIB3855-1 or VIB3855-2

80.5” (2045mm)

64.5” (1638mm)

top of oven only

41” (1041mm)

55” (1397mm)

31.5” (800mm)

17.5” (445mm)

FRONT VIEW (VIB3855 - -- 3) WITH CASTER CRADLES

0” (0mm)

FRONT VIEW (VIB3855 - -- 2)

Figure 19

30

Page 32

99” (2515mm)

68” (1727mm)

Suppy (AMU)

Quick Disconnect

67” (1702mm)

Exhaust Quick

Disconnect

63” (1600mm)

37.5” (953mm)

47” (1194mm)

top of oven only

23.5” (597mm)

0” (0mm)

FRONT VIEW (VIB3870-1)

92” (2337mm)

93” (2362mm)

99” (2515mm)

Maintenance

25” (635mm)

39” (991mm)

48.5” (1232mm)

62.5” (1588mm)

72” (1829mm)

top of oven only

88” (2235mm)

Servicing

0” (0mm)

15.5” (394mm)

1.5” (38mm)

VIB3870

8’ C EILING

0” (0mm)

FROM WALL

CLEARANCE

70” (1780mm)

105.8” (2685mm)

18”

*Ductwork should be terminated 99” (2515mm) above the finished floor (2” (51mm) above an 8’ ceiling). All other connections will be supplied with the hood.

(457mm)

22.5”

(572mm)

33” or 36”

Gas Input

914mm)

(838mm or

39.6”

(1006mm)

21”

(533mm)

Supply

TOP VIEW

88” (2235mm)

12.3”

(312mm)

Exhaust

99” (2515mm)

85.5” (2172mm)

84.5” (2146mm)

* 36” (914mm) for VIB3870-3, 33” (838mm) for VIB3870-1 or VIB3870-2.

80.5” (2045mm)

64.5” (1638mm)

top of oven only

41” (1041mm)

55” (1397mm)

31.5” (800mm)

17.5” (445mm)

FRONT VIEW (VIB3870-3) WITH CRADLE CASTERS

0” (0mm)

FRONT VIEW (VIB3870-2)

Figure 20

31

Loading...

Loading...