Page 1

UNIVERSAL HOLDING CABINET

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN 33954 Rev B (6/01)

Duplication of the information in this manual is prohibited without the consent of the Blodgett Service Department.

E 1998 --- G.S. Blodgett Corporation All rights reserved.

Page 2

TABLE OF CONTENTS

1. INTRODUCTION

Description 1 --- 1......................................................................

Specifications 1 --- 2....................................................................

2. OPERATION

Control Panel Descriptions 2--- 1.........................................................

Operator Mode 2 --- 2...................................................................

Timer Operation 2 --- 3..................................................................

Meal Selection 2 --- 4...................................................................

Clean Mode 2 --- 5......................................................................

Slot On/Off 2 --- 6.......................................................................

Displaying Slot Temperature Information 2--- 7.............................................

Operating Tips 2 --- 8...................................................................

Sequence of Operation 2 --- 9............................................................

3. PROGRAMMING AND CALIBRATION

Store Manager Programming 3--- 1......................................................

Product Selection for E ach Slot 3--- 1.................................................

Entering and Editing Product Information 3--- 6........................................

More Product Prompt Time Feature 3--- 11.............................................

Changing the Display Time 3--- 12.....................................................

Changing the Display Intensity 3--- 13..................................................

Service Programming and Calibration 3--- 14...............................................

To Access Service Programming 3--- 14................................................

Offset Calibration 3 --- 1 5.............................................................

Display Test Mode 3 --- 1 5............................................................

Timer Fast Test 3 --- 1 5...............................................................

Changing from _Fto_C 3 --- 1 9......................................................

Programming Alarms 3--- 20..........................................................

4. TROUBLESHOOTING

Troubleshooting Elements and Warning Alarms 4---1......................................

Troubleshooting Flow Diagrams 4---4....................................................

Troubleshooting a Locked Out Slot 4---10.................................................

Troubleshooting Sensor Alarms 4---11....................................................

Troubleshooting the Driver Board and Control 4--- 12........................................

i

Page 3

TABLE OF CONTENTS

5. PARTS REPLACEMENT

Element or Probe Assembly 5--- 1........................................................

Cooling Blower 5 --- 2...................................................................

Bezel Assembly 5 --- 3..................................................................

Membrane Switch 5 --- 4................................................................

LED Board 5 --- 4.......................................................................

Driver Board 5 --- 5.....................................................................

Temperature P r o b e 5 --- 5...............................................................

Mother Board 5 --- 5....................................................................

Bezel Gasket 5 --- 6.....................................................................

Chip Replacement 5 --- 7................................................................

6. TECHNICAL APPENDIX

Schematic 6 --- 1.......................................................................

Wiring Diagram 6 --- 2...................................................................

Temperature P r o b e 6 --- 3...............................................................

ii

Page 4

CHAPTER 1

INTRODUCTION

Page 5

UHC

DESCRIPTION

The Blodgett Universal Holding Cabinet is a short

term holding device designed to maintain the

freshness of a variety of food product. The UHC

contains four product slots which can be controlled independently. Control panels are located

above each slot on both the front and rear of the

cabinet. All operator mode selections can be made

from either the front or rear display.

Power Switch --- controls power to the cabinet.

Product Slot --- holds up to three trays of product

per slot.

Control Panel --- indicates the holding time and

product selection for each tray position.

1/3 Size Product Tray --- designed for all grilled

products (meat, eggs, chicken). This tray maintains the product’s moisture.

Knockouts for

Double Stacking

1/2 Size Crumb Tray with Wire Rack --- d e s i g n e d

for fried products (crispy chicken, nuggets, fillet).

The tray keeps the fried crumbs from dropping

through the racks. It also allows moisture to escape leaving the outside of the product crispy.

Full Size Product Tray --- designed for bread products (biscuits a nd muffins). This tray allows a small

amount of moisture to escape.

Each Universal Holding Cabinet is shipped with

the following:

D

Equipment manual

D

PM card

D

Training video

D

Quick-reference guide

D

Cleaning brush

Power Switch

Product Slot

Control Panel

FIGURE 1

1 --- 1

Page 6

SPECIFICATIONS

INTRODUCTION

OVEN CLEARANCES

The following clearances must be available for servicing.

D

C a b i n e t b o d y s i d e s --- 2 2 ” ( 5 6 c m )

D

C a b i n e t b o d y b a c k --- 25 ” ( 6 4 c m )

ELECTRICAL SPECIFICATIONS

Electrical Specifications (per section)

KW Hz Vol ts Phase Amps

U.S. and Canadian installations

2.5/3.3 50/60 208/240 1 20

General Export installations

2.5/3.3 50/60 208/240 1 20

TABLE 1

Installation must conformwith local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 --- Latest Edition and/or Canadian Electrical Code CSA C22.2 as applicable.

Wiring diagrams are located inside the right side

panel.

This appliance is equipped with a three-prong

grounding plug for your protection against shock

hazard and must be plugged into a properly

grounded three-prong receptacle. DO NOT cut or

remove the grounding prong from this plug.

CONTROL SPECIFICATIONS

Operating Voltage

Input Voltage 264 VAC maximum

Load Requirements

(heaters)

System Operating

Environment

Required Handling

Precautions

208 VAC +10/ ---15% or

240 VAC+10/--- 15%

50 or 60 Hz

177 VAC minimum

400 watt maximum at

240 VAC, resistive load,

8 heaters per cabinet max.

50-104_F(10-40_C) with

400 ft/minute airflow over

circuit board assemblies

Circuits contain sensitive

electronic components.

DO NOT ship or store

near strong electrostatic,

electromagnetic, magnetic or radioactive field.

CAUTION: Due to electrostatically sensitive

components. All technicians performing service

work must be grounded.

Grounding may be accomplished using a

grounding strap or other

suitable means. Connect

to another grounded unpowered piece of equipment. (ie. equipment other than the one you are

currently working on.)

1 --- 2

TABLE 2

Page 7

UHC

This page intentionally left blank.

1 --- 3

Page 8

CHAPTER 2

OPERATION

Page 9

UHC

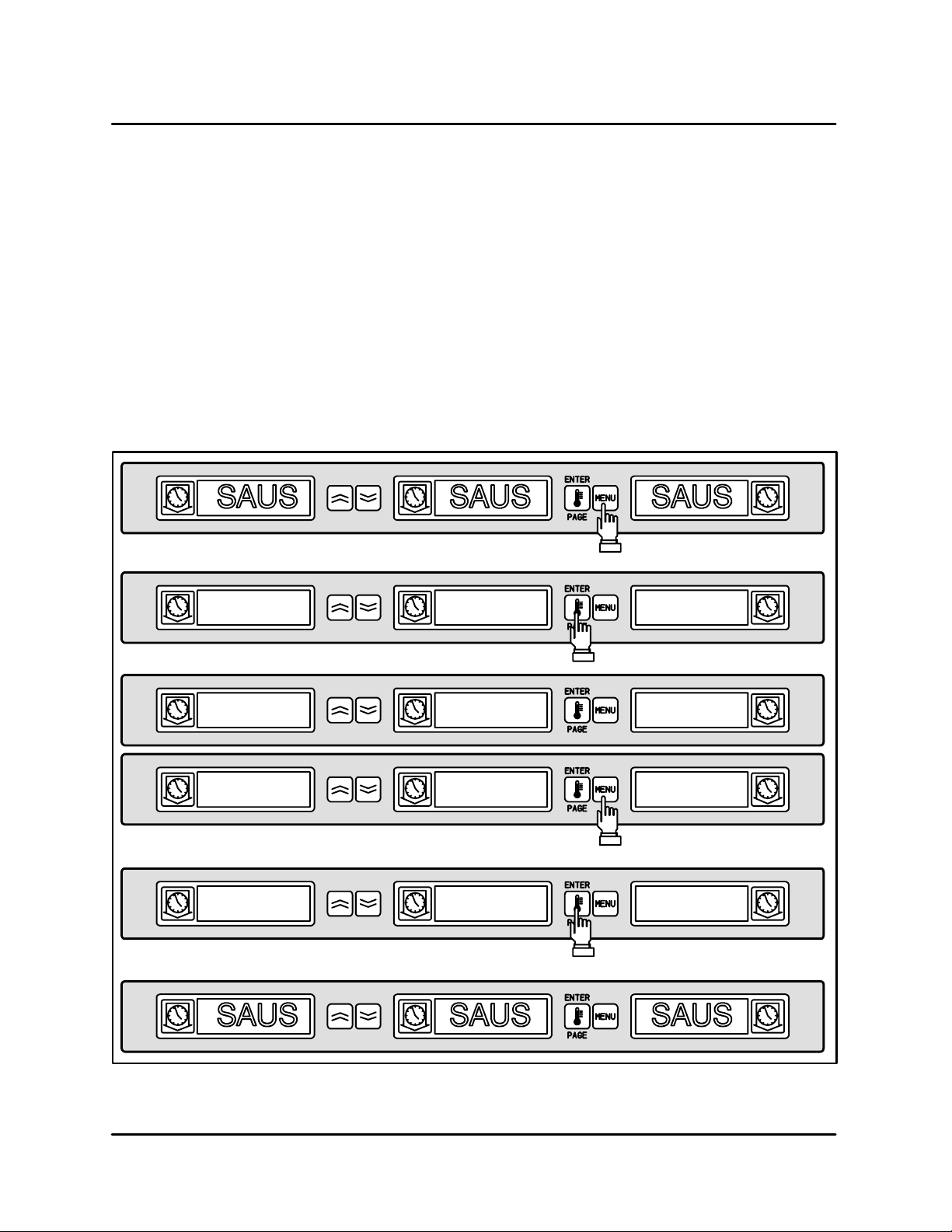

CONTROL PANEL DESCRIPTIONS

1 1 12 2 25 4 3

UHC Front Control Panel

1 1 12 2 2

UHC Rear Control Panel

FIGURE 1

FRONT CONTROL PANEL

1. TIMER KEYS --- start and stop the timer associated with each tray position. The timer keys

also turn off audible alarms. There are three

timer keys on each front panel (left, center and

right).

2. DISPLA YS --- show product selection and hold

time for each tray position. The displays also

provide programming information in the program mode. There are three displays on each

front panel (left, center and right).

3. MENU KEY --- press to select meal transitions

(breakfast to lunch), clean mode operation

and to turn individual slots on or off. The menu

key also provides access to the program

mode.

4. TEMPERATURE/ENTER/PAGE KEY --- this key

has three separate functions.

D

Display slot temperature information

D

Enter operational changes

REAR CONTROL PANEL

NOTE: The rear panels are used for operational

functions only. All programming must be

performed from the front panels.

1. TIMER KEYS --- start and stop the timer associated with each tray position. The timer keys

also turn off audible alarms. There are three

timer keys on each front panel (left, center and

right).

2. DISPLA YS --- show product selection and hold

time for each tray position. There are three displays on each front panel (left, center and

right).

D

Select page parameters in program mode.

5. UP and DOWN ARROW KEYS --- press to increase/decrease variables or change selections.

2 --- 1

Page 10

OPERATOR MODE

OPERATION

The operator mode is the normal operating mode

of the controller when all slots are at the proper

temperature and no alarm conditions exist. Product information and hold time are displayed.

SLOT TEMPERATURE CONTROL

Each product selection has its own temperature

setpoint and product hold time. All product timers

run independently.

The slot temperature is controlled by the temperature setpoint of the left most product entry in each

slot as viewed from the front of the cabinet (side

with the On/Off switch). Product selections that

have a hold temperature different than the left most

SAUS

!.!.!

.

Use first timer

(highest intensity)

.

(medium intensity)

product selection will not be available for entry into

that slot’s configuration.

DISPLAY INFORMATION

In the operator mode the slot displays provide the

following information:

D

The product selection for each tra y location.

D

The hold time remaining (in minutes) for active

timers.

NOTE: An active timer alternately displays the

product selection and the time remaining.

Inactive timers display only product selection.

Active timer

Inactive timer

(lowest intensity)

12

.!.!.!.

Running dots (decimal points)

FIGURE 2

2 --- 2

Page 11

UHC

TIMER OPERATION

NOTE: If more than one tray of product is timing,

the tray with the least hold time remaining

is indicated by the Use First display.

Starting a timer

1. Press the TIMER KEY above t he desired tray

position to start the timer. The timer counts

down from a preset value and alternately displays product selection and the hold time remaining.

Stopping a timer

1. Press the TIMER KEY above the slot position

to turn off an active timer. The timer stops timing. The display changes to the inactive status.

Timing out

1. The time out alarm alerts t he operator that the

product hold time has expired. When the hold

SAUS

.!.!.!.

time remaining reaches zero an audible alarm

sounds and the display reads --- 0 0 --- .

NOTE: The audible alarm is indicated by a

modulating tone. A continuous tone

signals a warning alarm.

All other active displays in the cabinet switch to

the lowest intensity level until the audible alarm

is turned off.

2. Press the TIMER KEY to clear the timed out display and silence the alarm.

If other timers in the cabinet have timed out,

the audible alarm remains on until all timed out

displays are cleared.

3. When all timers are cleared, active timers return to normal status. The Use First status is

switched to the next timer with the least hold

time remaining.

45

!.!.!

.

SAUS

.!.!.!.

.

Display alternately indicates hold time and

product selection for active timers.

--- 0 0 ---

Press timer key to stop or silence a timer

Press timer key to start a timer

!.!.!

.

SAUS

.!.!.!.

.

Use First indication changes to the next active timer

FIGURE 3

2 --- 3

Page 12

MEAL SELECTION

OPERATION

Selecting breakfast and lunch

NOTE: The following example is for selecting

breakfast. The same procedure applies for

selecting lunch.

1. Press the MENU KEY to change the product

selection of the slot from breakfast to lunch. All

displays are highlighted.

2. Press the ENTER KEY to activate the meal

selection. The displays switch to the inactive

mode.

NOTE: If the enter key is not pressed within

five seconds, the product selection returns to the breakfast meal selection.

Changing meal selections

Active slots with active timers will not change to the

new meal selection until the timer(s) are stopped

or time out and are reset. Active timers are stopped

by pressing the timer key.

If t h e product selection for the meal h a s a hold temperature different than the current meal, a high or

low temperature alarm is displayed to alert the operator that the hold temperature is being changed.

Should the high or low temperature condition remain for two or more minutes, an audible alarm

sounds. (See page 4--- 1 of the Troubleshooting

section.) To silence the alarm press any timer key.

This does not affect the timer operation unless the

timer key is pressed again. The display alternately

indicates the product selection and the alarm message until the slot temperature is within the preset

limits.

If no keys are pressed, the alarm message automaticallyresets when the slot temperature is within

the preset limits.

NUGG

Press menu key to display inactive

meal selection

NUGG NUGG

Press enter key to enter meal selection

and return to normal display mode

FIGURE 4

2 --- 4

Page 13

UHC

CLEAN MODE

The clean mode changes the temperature setpoint

of all slots in the cabinet to 125_F(52_C).

To s t a r t the clean mode

1. PresstheMENUKEYtoscrolltotheclean

mode message, CLN MODE.

2. Press the ENTER KEY to activate the clean

mode. All slots change to clean mode.

NOTE: If the enter key is not pressed within 5

seconds the control returns to the previous meal selection.

If the temperature is above 125_F(52_C), the

display alternately reads SLOT CLN MODE

CLN MODE

and NOT SAFE YET. The display reads SAFE TO

CLN when the slot is 125_F(52_C).

To exit clean mode

1. Press the MENU K E Y to display CLN MODE.

2. Press the ENTER KEY to exit the clean mode

and return to normal operation. The slot alternately displays SLOT TEMP LOW and the prod uct selection until the temperature is within the

normal operating limits.

NOTE: If the enter key is not pressed within 5

seconds the slot returns to the clean

mode.

Press menu key to scroll to clean

mode message

Press enter key to start clean mode

SAFE TO CLN

CLN MODE

To exit clean mode press menu key

to display clean mode message

EXIT CLN MODE

Press enter key to return to normal

display mode

FIGURE 5

2 --- 5

Page 14

SLOT ON/OFF

OPERATION

To turn slot off

1. Press the MENU KEY to scroll to the slot off

message, TURN SLOT OFF .

2. Press the ENTER KEY to enter the selection.

The display reads SLOT IS OFF.

NOTE: If the enter key is not pressed within

five seconds the product selection returns to the operator mode.

TURN SLOT OFF

To turn slot on

1. Press the MENU KEY to scroll to the slot on

message, TURN SLOT ON.

2. Press the ENTER KEY to enter the selection

and return to the operator mode. The display

alternately reads SLOT TEMP LOW and the

product selection until the temperature is within normal operating limits.

NOTE: If the enter key is not pressed within

five seconds the slot returns to slot off

status.

Press menu key to scroll to slot off

message

Press enter key to turn slot off

SLOT IS OFF

SLOT IS OFF

Press menu key to scroll to slot on

message

TURN SLOT ON

Press enter key to turn slot on and return

to normal display mode

FIGURE 6

2 --- 6

Page 15

UHC

DISPLAYING SLOT TEMPERATURE INFORMATION

1. Press the TEMPERATURE KEY to scroll the following temperature information for each slot:

D

Top plate actual temperature

D

Bottom plate actual temperature

TOP TEMP 155

BOT TEMP 155

D

Top plate setpoint temperature

D

Bottom plate setpoint temperature

2. The display automatically returns to operator

mode if no key is pressed for five seconds.

Press temperature key to display top

plate temperature

Press temperature key to display

bottom plate temperature

Press temperature key to display top

plate setpoint temperature

TOP TSET 155

Press temperature key to display bottom

plate setpoint temperature

BOT TSET 155

Press temperature key to turn return to

normal display mode

FIGURE 7

2 --- 7

Page 16

OPERATING TIPS

OPERATION

Correct heat and moisture levels are important to

the proper operation of the UHC. There are no

doors in the cabinet. The trays act as doors, therefore it is important that they be positioned correctly.

The trays must be inserted to the stop line. The

stop line is clearly marked on the handle of all three

tray styles.

Product Slots

The UHC has four slots that can hold up to three

trays of product per slot.

Slot 1

Slot 2

Slot 3

Baked Products

Thefullsizetrayisdesignedtoholdallbakedproducts such as biscuits and muffins.

D

Use a UHC tray liner with the full size tray.

D

After biscuits have been removed from the biscuit oven, remove the wrapper and open the

cardboard box. Slide the biscuits onto the tray

liner.

D

Full size trays can hold up to 30 frozen biscuits,

20 scratch biscuits or 20 muffins.

Grilled Products

The 1/3 trayis designed to hold all grilled products.

D

Product should not be drained when picked up

from the grill.

D

Use a UHC tray liner with the 1/3 tray.

D

Product should be stacked when placed in the

lined 1/3 size tray. 10:1 and sausage patties

can be stacked up to six high. Eggs (except

scrambled), grilled chicken and 4:1 patties can

bestackeduptothreehigh.

D

Product should be placed towards the center

of the tray.

Slot 4

FIGURE 8

Fried Products

The 1/2 crumb tray with the wire rack is designed

to hold all fried products.

D

Product should be held in the wire rack which

is placed in the crumb tray.

D

UHC tray liners are not necessary when using

thewirerackforfriedproduct.

FIGURE 9

Production control charts

Laminated charts can be ordered through O’Brien

Budd, Inc. The ordering numbers are:

D

Breakfast UHC card #MCD 63102

D

Regular M enu UHC card # MDC 63102A

2 --- 8

Page 17

UHC

SEQUENCE OF OPERATION

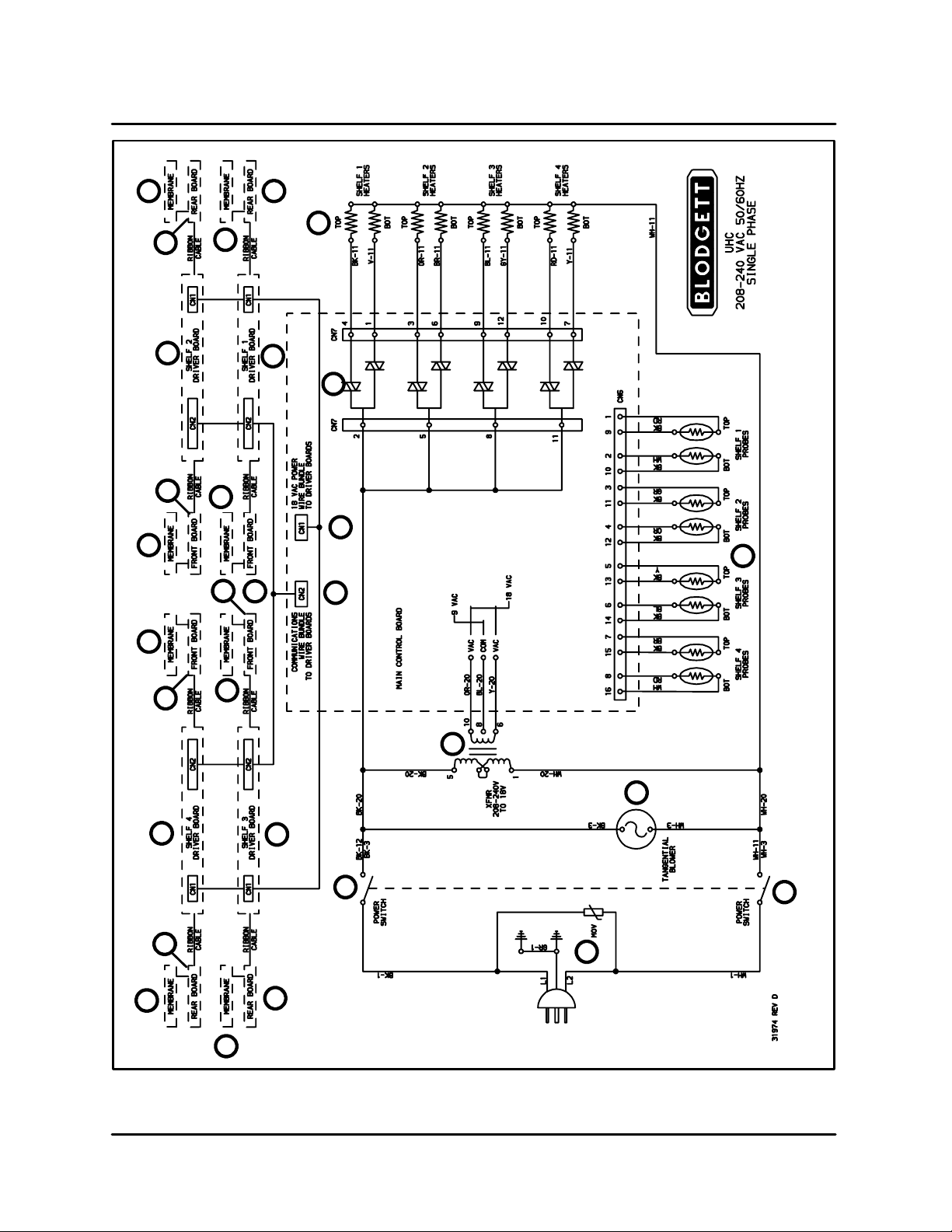

COMPONENT REFERENCE

NOTE: Refer to FIGURE 10 page 2 ---10 for compo-

nent locations.

1. METAL OXIDE VARISTOR

2. DPST POWER SWITCH

3. TANGENTIAL BLOWER

4. TRANSFORMER 200-240V

5. HEATER TRIAC

6. HEATER ELEMENTS

7. SHELF PROBES

8. SHELF 1 DRIVER BOARD

9. SHELF 2 DRIVER BOARD

10. SHELF 3 DRIVER BOARD

11. SHELF 4 DRIVER BOARD

12. SHELF 1 FRONT DISPLAY ASSY.

13. SHELF 2 FRONT DISPLAY ASSY.

14. SHELF 3 FRONT DISPLAY ASSY.

15. SHELF 4 FRONT DISPLAY ASSY.

16. SHELF 1 REAR DISPLAY ASSY.

17. SHELF 2 REAR DISPLAY ASSY.

18. SHELF 3 REAR DISPLAY ASSY.

19. SHELF 4 REAR DISPLAY ASSY.

20. SHELF 1 FRONT MEMBRANE

21. SHELF 2 FRONT MEMBRANE

22. SHELF 3 FRONT MEMBRANE

23. SHELF 4 FRONT MEMBRANE

24. SHELF 1 REAR MEMBRANE

25. SHELF 2 REAR MEMBRANE

26. SHELF 3 REAR MEMBRANE

27. SHELF 4 REAR MEMBRANE

28. CN-1 CONNECTOR

29. CN-2 CONNECTOR

OPERATION

1. Apply power to the unit. The input voltage is

applied to t he DPST POWER SWITCH (2), the

TANGENTIAL BLOWER (3) and the primary

side of the 200-240V TRANSFORMER (4). The

input power is also applied to pins 2, 5, 8, and

11 of CN-7 on the mother board and to one

side of each HEATER ELEMENT (6) on WH-11.

2. 18VAC is applied to the mother board through

the secondary side of the TRANSFORMER (4)

between OR-20 a nd Y-20. 9VAC is applied to

the mother board from the secondary of the

TRANSFORMER (4) between BL-20 and

OR-20 and between BL-20 and Y-20. The mother board applies 18VAC to each shelf driver

board through the wire bundle at CN-1 (28)

while continuously exchanging operational

logic signals with each shelf driver board

through the wire bundle attached to CN-2 (29).

After the individual SHELF DRIVERS (8--- 11)

receive power and communications from the

mother board they send power and logic sig nals to its FRONT and REAR DISPLAY AS SEMBLIES (12--- 19) and their respective MEMBRANE SWITCH/DISPLAY DECALS (20--- 27).

3. The main control board uses the inputs from

the eight individual RTD PROBES (7) to determine if any of the eight HEATERS (6) need to

be energized to bring their respective shelf

sections to the proper temperature.

NOTE: The eight probes react independently

and sense temperature by resistance.

Refertothetableonpage6---3ofthe

Technical Appendix.

4. If the main control decides that an individual

shelf section is not at the correct temperature

it energizes the proper TRIAC (5) and sends

power t hrough CN-7 to the respective heater.

NOTE: If the main control senses that the tem-

perature of an individual shelf section

is much lower than the setpoint it will

pulse the voltage to the heater to maintain a consistent temperature with a

minimum overrun.

5. When the main control determines that all individual shelf sections are within their programmed setpoints it maintains these temperatures with a continual pulsing of the input

voltage to each shelf section independently.

NOTE: If the main control senses that a heater

is not performing to its programmed

specifications it can display a variety of

failure conditions. See page 4---1 of

the Troubleshooting section.

2 --- 9

Page 18

OPERATION

25

21

23

17

913

20

14

24

12

16

6

8

5

28

7

29

27

11

15

19

22

26

18

10

4

3

2

1

2

FIGURE 10

2 --- 1 0

Page 19

UHC

This page intentionally left blank.

2 --- 1 1

Page 20

CHAPTER 3

PROGRAMMING

AND CALIBRATION

Page 21

UHC

STORE MANAGER PROGRAMMING

PRODUCT SELECTION FOR EACH SLOT

Program mode is used to select the products for

each slot. All entries are made through PAGE and

MENU selections. Each slot has a page of configuration menus. The top slot in the cabinet is Slot 1.

D

The PAGE key selects the slot (1-4) pages.

D

The MENU key selects the configuration menu

items (meal and tray location).

D

The UP/DOWN arrow keys select the available

products for each meal.

PROG MODE

To e n t er P rogram M o d e

1. Press and hold the MENU KEY for at least five

seconds. The display reads PROG MODE .

To enter Page Selections

Each slot page (1-4) contains product selection for

each meal.

1. Press the PAGE KEY to scroll to the slot (1-4)

pages.

Press and hold menu key to enter

program mode

Press page key to scroll slot page

selections

SLOT 1

SLOT 2

SLOT 3

SLOT 4

FIGURE 1

Press page key to scroll slot page

selections

Press page key to scroll slot page

selections

Press page key to scroll slot page

selections

3 --- 1

Page 22

PROGRAMMING AND CALIBRATION

Meal Selection and Tray Position

1. Press the MENU KEY to scroll the meal and

tray position in the left and center displays. The

current product selection is indicated in the

right display.

SLOT 1 PAGE

BFST LEFT SAUS

Press menu to key to scroll

meal selection and tray position

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

BFST CENT SAUS

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

BFST RGHT SAUS

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

LNCH LEFT 10-1

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

LNCH CENT 10-1

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

LNCH RGHT 10-1

Meal Selection Tray Position

FIGURE 2

3 --- 2

Press menu to key to scroll

meal selection and tray position

Page 23

UHC

To enter Product Selection

1. Press the UP/DOWN ARROW KEYS to scroll

the available product selections for each meal

and tray position.

The product selection for the left tray position of

each meal determines the hold temperature for the

slot. Only products that have hold temperatures

within5_F(2.8_C) of the left most product selection

will be displayed for selection in the center and

right tray position. If the left most product selection

PRODUCT SELECTION

BFST LEFT SAUS

Press up/down arrow keys to

scroll product selections

BFST LEFT ROUN

Press up/down arrow keys to

scroll product selections

is changed, the center and right positions must be

reentered. If the product selection for an active timer is changed, the timer is automatically reset.

To exit Program Mode

1. Press and hold the MENU KEY for five seconds.

NOTE: The controller automatically exits the

program mode if no entries are made

for five minutes.

Product Selections

BFST LEFT FOLD

BFST LEFT SCRA

EXITING PROGRAM MODE

BFST LEFT SCRA

Press up/down arrow keys to

scroll product selections

FIGURE 3

Product Selections

Product Selections

Press and hold the menu key for

five seconds to exit program mode

3 --- 3

Page 24

PROGRAMMING AND CALIBRATION

Sample product selection cha nge

This example changes the lunch product selection

in the left position of slot 3 from 10- 1 to NUGG.

Since the hold temperature for NUGG is different

PROG MODE

SLOT 1

than 10-1, the center and right product selections

are cleared. Only items with hold temperatures

within 5_F(2.8_C) of the left product selection can

be entered for the center and right position.

Press menu to key for five seconds

to enter the program mode

Press page key to scroll slot page

selections

Press page key to scroll slot page

selections

SLOT 2

Press page key to scroll slot page

selections

SLOT 3

Press menu key to scroll meal

selection and tray position

BFST LEFT SAUS

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

BFST CENT SAUS

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

3 --- 4

Page 25

UHC

BFST RGHT SAUS

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

LNCH LEFT 10-1

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

LNCH LEFT 4-1

Press up/down arrow keys to scroll product selections

LNCH LEFT NUGG

Press and hold menu key for five

seconds to exit program mode

FIGURE 4

3 --- 5

Page 26

PROGRAMMING AND CALIBRATION

ENTERING AND EDITING PRODUCT INFORMATION

Changing or entering new product selections, hold

timer and temperature setting are password protected functions.

To enter the password

1. Press and hold the MENU KEY for five seconds. The display reads PROG MODE .

2. Press the ENTER/PAGE KEY to scroll to VIEW

PAGE.

3. Press the MENU KEY to select the security

lock, SECR LOCK.

4. Press the UP and DOWN ARROW KEYS to enter the security code 123.

ENTERING THE PASSWORD

5. Press ENTER/PAGE KEY..

A new product entry requires entry of:

D

the product name,

D

hold time,

D

hold temperature from 55-250_F (13-121_C),

D

meal selection,

The following example enters a new product,

named XXY, with a hold time of 25 minutes and hold

temperature of 180_F(82_C).

Press and hold menu key to enter

program mode

PROG MODE

Press enter/page key to scroll view page

VIEW PAGE

Press menu key to scroll to the

security lock

SECR LOCK 156

Press up/down arrow keys to enter password

SECR LOCK 123

FIGURE 5

3 --- 6

Page 27

UHC

ENTERING THE PRODUCT NAME

SECR LOCK 123

EDIT PAGE SAUS

PROD NAME .

Press page key to scroll to the edit page

Press menu key to scroll to an

unused product (blank) mnenonic

Press up arrow key to

scroll to the letter X

NOTE: The decimal point indicates which dis

play segment is being entered.

PROD NAME X.

Press down arrow key to scroll to the next display segment

PROD NAME X.

Press up arrow key to scroll to the letter X

PROD NAME XX.

Press down arrow key to scroll to the next display segment

PROD NAME XX.

Press up arrow key to scroll to the letter Y

PROD NAME XXY.

FIGURE 6

3 --- 7

Page 28

ENTERING THE PRODUCT HOLD TIME

PROD NAME XXY.

TIME PAGE XXY

XXY TIME 20

PROGRAMMING AND CALIBRATION

Press page key to scroll to the time page

Press menu key to scroll to product

time selection

Press up/down arrow key to change time to 25 minutes

XXY TIME 25

FIGURE 7

3 --- 8

Page 29

UHC

ENTERING THE PRODUCT HOLD TEMPERATURE

XXY TIME 25

TEMP PAGE XXY

XXY Ttop 155

Press up/down arrow key to change top plate temperature

XXY Ttop 180

Press page key to scroll to the temp page

Press menu key to scroll to product

top plate temperature selection

Press menu key to scroll to product

bottom plate temperature selection

XXY Tbot 155

Press up/down arrow key to change bottom plate temperature

XXY Tbot 180

FIGURE 8

3 --- 9

Page 30

ENTERING MEAL USAGE

XXY Tbot 180

MEAL PAGE XXY

XXY MEAL ALL

XXY MEAL BFST

PROGRAMMING AND CALIBRATION

Press page key to scroll to the meal page

Press menu key to scroll to product

meal selection

Press up/down arrow keys to select BFST

FIGURE 9

3 --- 1 0

Page 31

UHC

MORE PRODUCT PROMPT TIME FEATURE

A cook more time may be entered for each product

type that will alert the operator to cook more product before t he holding time reaches zero. When the

product timer equals the cook time the audible

alarm will chirp for 3 seconds and the display message will alternately display PRODUCT NAME, TIM-

ER TIME, COOK and MORE until the timer times

out. If more than one tray of a product type is active

the cook more alarm will not occur until all active

timers reach the cook time.If a position is indicating, COOK MORE and another timer of the same

product is started, the COOK MORE message will

be cleared. During transition from breakfast to

lunch the COOK MORE indication is disabled. Use

the following procedure to change or enter the

cook time of a product svelection:

DEFAULT SELECTIONS FOR THE PROMPT TIME

MNEMONICS

Left Center Right*

COOK PAGE Cook Page

SAUS COOK 4 Product 1 Cook Time 0 --- 3 0 M i n u t e s 3

1. Press and hold the menu key for 5 seconds.

2. Pressthepagekeytoscrolltoviewpage.

3. Press the menu key to scroll to the security

lock.

4. Press the up and down arrow keys to enter the

manager security code: 3 3 1.

5. Press the page key to scroll to cook page.

6. Press the menu key to scroll to product selection.

7. Press the up and down arrow keys to increase

or decrease the prompt time (in minutes) to

cook more product.

8. When complete, press and hold the menu key

for 5 seconds to return to normal operation.

Description Available

Settings Level

Access

ROUN COOK 4 Product 2 Cook Time 0 --- 3 0 M i n u t e s 3

FOLD COOK 3 Product 3 Cook Time 0 --- 3 0 M i n u t e s 3

SCRA COOK 3 Product 4 Cook Time 0 --- 3 0 M i n u t e s 3

RBAC COOK 0 Product 5 Cook Time 0 --- 3 0 M i n u t e s 3

CBAC COOK 1 Product 6 Cook Time 0 --- 3 0 M i n u t e s 3

MUFF COOK 3 Product 7 Cook Time 0 --- 3 0 M i n u t e s 3

BISC COOK 22 Product 8 Cook Time 0 --- 3 0 M i n u t e s 3

BURR COOK 0 Product 9 Cook Time 0 --- 3 0 M i n u t e s 3

1 0 --- 1 COOK 2 Product 10 Cook Time 0 --- 3 0 M i n u t e s 3

4 --- 1 COOK 4 Product 11 Cook Time 0 --- 3 0 M i n u t e s 3

GRCK COOK 5 Product 12 Cook Time 0 --- 3 0 M i n u t e s 3

NUGG COOK 5 Product 13 Cook Time 0 --- 3 0 M i n u t e s 3

FISH COOK 5 Product 14 Cook Time 0 --- 3 0 M i n u t e s 3

McCK COOK 7 Product 15 Cook Time 0 --- 3 0 M i n u t e s 3

NOTE: The right display gives the time in minutes.

3 --- 1 1

Page 32

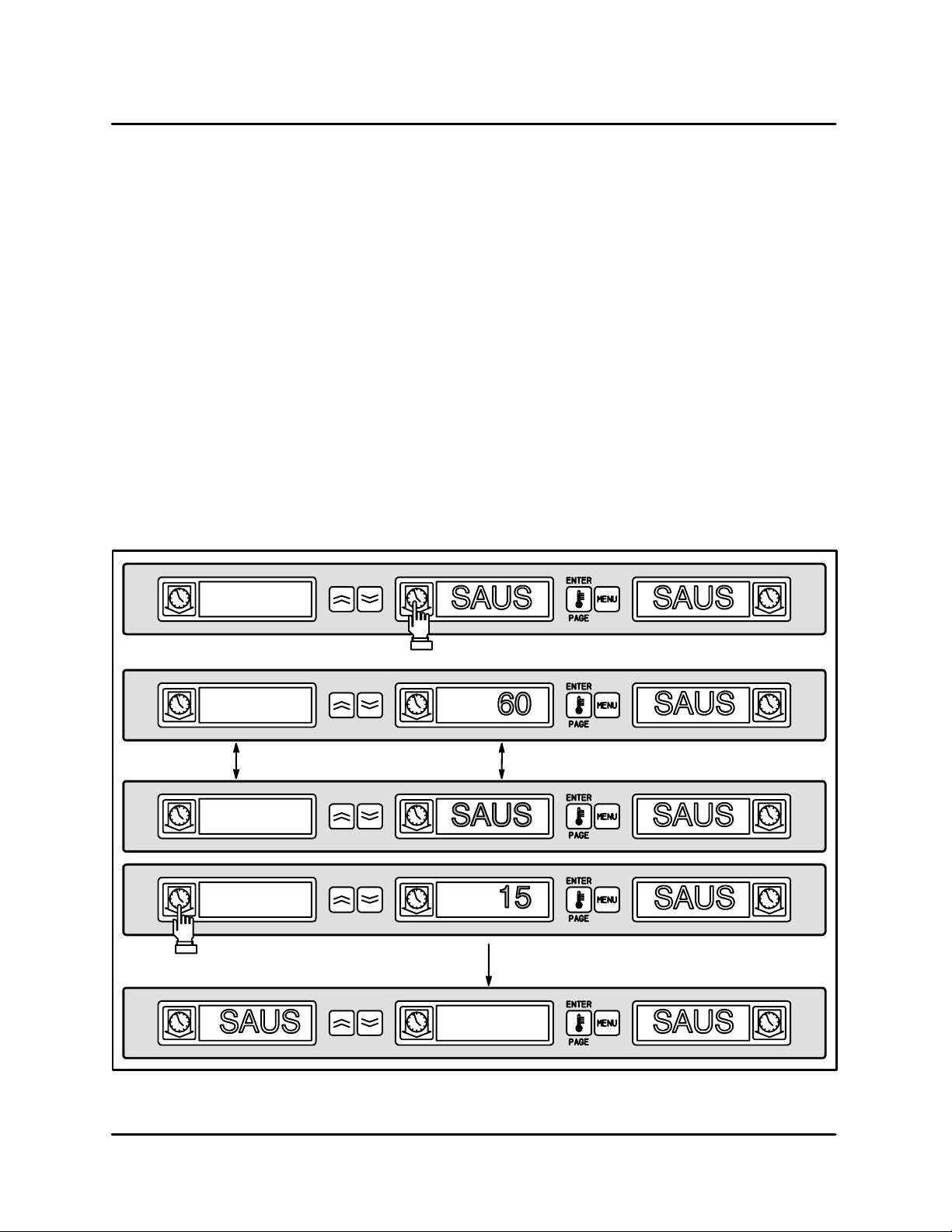

CHANGING THE DISPLAY TIME

PROGRAMMING AND CALIBRATION

The rate at which an active timer alternately displays product selection and hold time may be adjusted as follows:

1. Enter the manager programming security

code. See page 3 ---6.

2. PresstheMENUKEYtoscrolltoproductdisplay time, PROD TIME.

3. Press the UP and DOWN ARROW KEYS to

change the product display time.

CHANGING THE DISPLAY TIME

SECR LOCK 123

Press and hold menu key scroll to PROD TIME

PROD TIME 10

Use the arrow keys to change product display time

4. PresstheMENUKEYtoscrolltotimerdisplay

time, TIMR TIME.

5. Press the UP and DOWN ARROW KEYS to

change the timer display time.

6. Press and hold the MENU K EY for five seconds

to return to normal operation.

TIMR TIME

Press menu key to scroll to TIMR TIME

TIMR TIME 10

Use the arrow keys to change timer display time

Press and hold the menu key to return to normal operation

FIGURE 10

3 --- 1 2

Page 33

UHC

CHANGING THE DISPLAY INTENSITY

The brightness of each of t he three intensity levels

used for product status may be adjusted as follows:

1. Enter the manager programming security

code. See page 3 ---6.

2. PresstheMENUKEYtoscrolltodisplayintensity level. The display reads DISP IntX.There

are three display intensity levels available.

Level #

1 (dimmest) Int1 10--- 25 10

2 (mid-level) Int2 10--- 25 10

3(brightest) Int3 67-100 100

CHANGING THE DISPLAY TIME

Display Range Default

TABLE 1

SECR LOCK 123

3. Press the UP and DOWN ARROW KEYS to

change the intensity level.

4. Press and hold the MENU K EY for five seconds

to return to normal operation.

Press and hold menu key scroll to DISP Int1

DISP Int1 10

Use the arrow keys to change product display intensity

DISP Int1 20

Press and hold the menu key to return to normal operation

FIGURE 11

3 --- 1 3

Page 34

PROGRAMMING AND CALIBRATION

SERVICE PROGRAMMING AND CALIBRATION

THE FOLLOWING PROGRAMMING AND CALIBRATION INFORMATION IS FOR AUTHORIZED

SERVICE PERSONNEL ONLY.

TO ACCESS SERVICE PROGRAMMING

Service programming is password protected. Use

the following procedure to enter the password and

access service programming (level 3 programming).

ENTERING THE PASSWORD

PROG MODE

1. Press and hold the MENU KEY for five seconds.

2. Press the ENTER/PAGE KEY to scroll to VIEW

PAGE.

3. PresstheMENUKEYtoscrolltothesecurity

lock, SCR LOCK.

4. Press the UP and DOWN ARROW KEYS to enter the security code 247 or 331.

5. Press ENTER/PAGE KEY.

Press and hold menu key to enter

program mode

Press enter/page key to scroll view page

VIEW PAGE

Press menu key to scroll to the

security lock

SECR LOCK 156

Press up/down arrow keys to enter password

SECR LOCK 331

Use 331 or 247

FIGURE 12

3 --- 1 4

Page 35

UHC

OFFSET CALIBRATION

The offset value is the difference between the setpoint and the actual temperature. If the actual temperature is lower than the setpoint a n egative offset

is needed. If the actual temperature is higher than

the setpoint a positive offset is needed.

Use the surface probe to compare the top a nd bottom t emperatures to the setpoint value of 155_F

(68_C). Takeall measurements from the s lot center

position. Record the value. Repeat for all slots. If

the actual temperature varies from the setpoint by

¦

5_F(3_C) adjust the temperature offset as follows:

1. After accessing the service level programming, press the ENTER/PAGE key to scroll to

the slot number requiring adjustment.

NOTE: It is possible to access all slots from

any display.

2. Press the MENU key to advance to top or bottom of offset selection. Use the ARROW keys

to select the offset value. Press the ENTER k ey

to advance to the next slot. Repeat for all slots.

3. Press the MENU key for five seconds to exit

service programming.

NOTE: It is not necessary to exit the program-

ming mode if you wish to advance to

Display Test or Timer Test.

plays have been checked, turn the unit off and

back on again to exit the display test mode.

4. After verifying all slot display segments illuminate, press the ARROW KEY to stop the test.

The display reads DISPLAY TEST OFF.

5. Press the MENU key for five seconds to exit

service programming.

NOTE: It is not necessary to exit the program-

ming mode if you wish to advance to

the Timer Test.

TIMER FAST TEST

This test changes the timing on the TIMER KEYS

from minutes to seconds t o allow for quick test of

the timer keys. Access service level programming

to execute the timer test.

1. Press the ENTER/PAGE key to scroll to TEST

PAGE.

2. Press the MENU KEY to scroll to FAST TEST

OFF.

3. Press the ARROW KEY to toggle to FAST TEST

ON.

4. It is necessary to exit the service programming

level to test the timer keys. Press the MENU

KEY for five seconds to exit service programming and test the timer keys.

DISPLAY TEST MODE

The display test verifies all display segments are

operational.

NOTE: Executing the display test requires access to

level 5 programming. Contact Blodgett Service to acquire the necessary password.

1. Press the ENTER/PAGE key to scroll to TEST

PAGE.

2. Press the MENU KE Y to scroll to DISPLAY TEST

OFF.

3. Press and hold the bottom two outside timers

until the displays change. All segments should

illuminate and stay lit to give the operator time

to check both sides of the UHC. After the dis-

5. Press any TIMER KEY to activate and verify the

timer count down while in seconds mode. The

timer counts down a nd an alarm sounds. To silence the alarm press the TIMER KEY.

6. To cancel TIMER FAST TEST re-enter the service level programming. See page 3 ---14.

7. Press the ENTER/PAGE key to scroll to TEST

PAGE.

8. Press the MENU KEY to scroll to FAST TEST

ON.

9. Press the MENU KEY to toggle to FAST TEST

OFF.

10. Press the MENU KEY for five seconds to exit

the service level programming.

3 --- 1 5

Page 36

OFFSET CALIBRATION

SLOT #

Press the enter key to scroll to the slot # requiring offset calibration

TOP OFST 0

TOP OFST 10

BOT OFST 0

PROGRAMMING AND CALIBRATION

Press the menu key to advance to top offset display

Use arrow keys to select offset value

Press the menu key to advance to bottom offset display.

Press the Enter/Page key to advance control to next slot

BOT OFST 0

Press the menu key for five seconds to exit service programming

FIGURE 13

3 --- 1 6

Page 37

UHC

DISPLAY TEST

TEST PAGE

Press the enter key to scroll to the display test

DISP TEST OFF

Press the menu key to advance to DISP TEST OFF

DISP TEST ON

Press the arrow keys to begin the test

Segments light individually

DISP TEST OFF

Press the arrow keys to end the test

Press the menu key for five seconds to exit service programming

FIGURE 14

3 --- 1 7

Page 38

PROGRAMMING AND CALIBRATION

TIMER FAST TEST

TEST PAGE

Press the enter key to scroll to the display test

FAST TEST OFF

Press the menu key to advance to FAST TEST OFF

FAST TEST ON

Press the arrow keys to toggle to FAST TEST ON

FAST TEST ON

Press the menu key for 5 seconds to exit service programming and test timer keys

Press any timer key to activate and verify the timer count down while

in seconds mode. Press the menu key for 5 seconds to re-enter the

program mode. Access the service level programming.

TEST PAGE

Press the enter key to scroll to TEST PAGE.

FAST TEST ON

Press the menu key to advance to FAST TEST ON

FAST TEST OFF

Press the arrow keys to toggle to FAST TEST OFF

Press the menu key for five seconds to exit service programming

FIGURE 15

3 --- 1 8

Page 39

UHC

CHANGING FROM _FTO_C

The following changes the temperature units from

_Fto_C.

1. Enter the service programming security code.

Seepage3---14.

2. Press the MENU KEY to scroll to display units.

CHANGING TEMPERATURE UNITS

SECR LOCK 331

Press and hold menu key to scroll to display units

DISP UNIT F

Press arrow keys to toggle units

DISP UNIT C

3. Press the UP and DOWN ARROW KEYS to

change from _Fto_C.

4. Press and hold the MENU K EY for five seconds

to return to normal operation.

Press menu key for 5 seconds to return to normal operation

FIGURE 16

3 --- 1 9

Page 40

PROGRAMMING ALARMS

PROGRAMMING AND CALIBRATION

FOOD AND DRUG ADMINISTRATION (FDA)

ALARM

The FDA alarm indicates the slot temperature is below the FDA temperature setpoint (140_F) for a

time greater than the FDA time setting.

1. Enter the service programming security code.

Seepage3---14.

2. Press the MENU KEY to scroll to FDA PAGE.

FDA ALARM

SECR LOCK 331

Press and hold menu key to scroll to the FDA page

FDA PAGE

Press the Enter/Page key to advance to the FDA time

3. Press the ENTER key to advance the control.

Use the ARROW keys to enter FDA time from

0-5 minutes. The default is 2 minutes. Press the

ENTER k ey to advance the control.

4. Use the ARROW keys to enter FDA temperature from 55-140_F. The defau lt is 140_F. P r e s s

the ENTER key to advance the control.

5. Press and hold the MENU key to exit programming.

FDA TIME 2

Use the arrow keys to enter FDA time from 0-5 minutes

FDA TIME 3

Press Enter/Page key to advance control

FDA TEMP 140

Use the arrow keys to enter FDA temperature from 55-140_F

Press Enter/Page key to advance control

FIGURE 17

3 --- 2 0

Page 41

UHC

HI AND LOW TEMPERATURE ALARMS

If the slot temperature is above or below the preset

limits for a product selection, the control enters the

high or low alarm condition. The alarm setpoints

can be programmed from the ALRM PAGE. They

are entered as _F offsets from the product setpoint.

The default settings are 10_F.

NOTE: When switching menus or products the

temperature alarm is displayed if the new

product or menu requires a holding temperature outside of the current alarm band.

If the condition remains for two or more

minutes an audible alarm sounds. Press

any timer key to silence the alarm. The display returns to normal when the new hold

temperature has been reached.

1. Enter the service programming security code.

Seepage3---14.

2. Press the MENU KE Y to scroll to ALRM PAGE.

3. Press the ENTER KEY to advance the control.

The display reads ALRM ENBL ON.

NOTE: Selecting ALRM ENBL OFF disables

the visual and/or audible product

alarms for all slots.

4. Use the ARROW KEYS to toggle bewteen off

and on. Press the MENU KEY to advance the

control.

5. The display reads ALRM LoSP X. Use the ARROW KEYS to enter the desired low temperature alarm from 1 -10_F. P r e s s t h e M E N U K E Y

to advance the control.

6. The display reads ALRM HiSP X. Use the ARROW KEYS to enter the desired high temperature alarm from 1 -10_F. P r e s s t h e M E N U K E Y

to advance the control.

7. The display reads ALRM TIME X. The alarm

time allows an alarm condition to exist for up to

5 minutes before activating the audible alarm.

The default setting is 2 minutes.

Use the ARROW KEYS to enter the desired

alarm time from 0-5 minutes. Press the ENTER

KEY to advance the control.

8. Press and hold the MENU key to exit programming.

HIGH AND LOW TEMPERATURE ALARM

SECR LOCK 331

Press and hold menu key to scroll to the alarm page

ALRM PAGE

Press the Enter/Page key to advance the control

ALRM ENBL ON

ALRM ENBL ON

Use the arrow keys to toggle from ON to OFF

Press Menu key to advance control

3 --- 2 1

Page 42

HIGH AND LOW TEMPERATURE ALARM

ALRM LoSP 10

ALRM LoSP 10

Press the Enter/Page key to advance the control

ALRM HiSP 0

ALRM HiSP 10

PROGRAMMING AND CALIBRATION

Use the arrow keys to enter desired low temperature alarm

(the range is 1-10 with a default of 10)

Use the arrow keys to enter desired high temperature alarm

Press the Menu key to advance the control

ALRM TIME 0

Use the arrow keys to enter alarm time

ALRM TIME 2

Press the Enter/Page key to advance the control

ALRM PAGE

Press and hold the menu key to exit programming

FIGURE 18

3 --- 2 2

Page 43

UHC

This page intentionally left blank.

3 --- 2 3

Page 44

CHAPTER 4

TROUBLESHOOTING

Page 45

UHC

TROUBLESHOOTING ELEMENTS AND WARNING ALARMS

CAUTION: Due to electrostatically sensitive

components. All technicians performing service work must be grounded. Grounding may

be accomplished using a grounding strap or

other suitable means. Connect to another

grounded unpowered piece of equipment. (ie.

equipment other than the one you are currently

working on.)

During initial heat from a cold start, the unit applies

full voltage to the elements. A s the shelf approaches the setpoint temperature, the control

pulses the output of the elements. This allows for

an accurate set point response with minimum temperature overrun.

NOTE: The control also pulses output during nor-

mal operation to provide an even temperature response.

To Troubleshoot an Element

1. Verify offset calibration. Refer to page 3--- 15. If

correct continue with step 2.

2. Attach an amp clamp to the input. Observe the

steady amp draw during the initial startup and

the subsequent pulsing of this input at temper atures close to set point.

The main control applies voltage to the element assemblies by way of a TRIAC solid state device. This

circuit normally fails in the closed position and can

result in an overheat condition. If the elements do

not receive the pulse input, the main control is de-

fective. To replace a defective element, the upper

and lower portion of the shelf must be replaced

whichever is defective.

Several w arning alarms can result from a defective

element:

D

High and low temperature alarm

D

FDA alarm

D

Sensor alarm

D

Rise time alarm

If an alarm conditions occurs, a display alarm appears. An audible alarm may sound depending on

the alarm condition. Press the timer key to silence

the audible alarm. Timers cannot be started w hen

aslotisinanalarmcondition.

HI AND LOW TEMPERATURE ALARM

If the slot temperature is above or below the preset

limits for a product selection, the controller enters

the high or low alarm condition. The display reads

either SLOT TEMP HIGH or SLOT TEMP LOW.

1. An audible alarm sounds if the alarm condition

remains for two or more minutes.

NOTE: The low temperature audible alarm is inhib -

ited at power up. The SLOT TEMP LOW

message is displayed alternately with the

product selection until the slot is within the

preset limits.

HIGH/LOW TEMPERATURE ALARM

SLOT TEMP LOW

SLOT TEMP HIGH

Press any timer key to silence audible alarm

Press any timer key to silence audible alarm

FIGURE 1

4 --- 1

Page 46

TROUBLESHOOTING

FOOD AND DRUG ADMINISTRATION (FDA)

ALARM

The FDA alarm indicates the slot temperature is below the preset limit to hold the product. The audible

alarm sounds and the display reads TEMP UNDR

FDA. Active timers are automatically reset.

1. To turn off the audible alarm press any TIMER

KEY. The alarm message remains until the slot

temperature is within the preset limits. If no

keys are pressed the audible and visual alarm

remain.

See page 4--8 for troubleshooting.

FDA ALARM

SENSOR RANGE ALARM

The sensor fail alarm indicates a sensor tempera ture value above or below the operating limits of

the slot, 50--- 250_F (10-121_C).

1. To turn off the audible alarm press any TIMER

KEY. The alarm message is displayed until the

slot temperature is within the operating limits.

2. Press the temp/enter key to display the error

message HHHH or LLLL. HHHH indicates high

resistance, high temperature or open/shorted

probe. LLLL indicates low resistance, low temperature or open/shorted probe. Measure the

resistance of the probe, see page 5 ---5.

3. Scroll through the menu key until TURN SLOT

OFF is displayed. Press the enter k ey within

five seconds.

Service is required to correct a sensor alarm.

Refer to the flow diagrams in this chapter f or

troubleshooting.

TEMP UNDR FDA

SENSOR RANGE ALARM

SENS ALRM

Press any timer key to silence audible alarm

Press any timer key to silence audible alarm

FIGURE 2

4 --- 2

Page 47

UHC

RISE TIME ALARM

Therisetimealarmindicatesthattheslottemperature failed to reach operating temperature within

the preset time limits of the system at power up.

The system measures the time that each plate

takes to go from 100--- 125_F. If this time is greater

than 15 minutes the alarm is activated and SLOT

RISE RATE is displayed.

1. To turn off the audible alarm press any TIMER

KEY.

Service is required to correct a rise time alarm.

See page 4--8 for troubleshooting.

RISE TIME ALARM

SLOT RISE RATE

Press any timer key to silence audible alarm

SLOT RISE RATE

Use the following procedure to view the rise times

for each plate:

1. Press and hold the MENU key to enter the program mode.

2. PressthePAGEkeytoscrolltotheTESTPAGE.

3. Press the MENU key to scroll the time recorded

foreachslotatstartup.

Press any menu key to enter the program mode

TEST PAGE

Press any menu key to scroll the recorded rise times

RATE TOP1 12:00

FIGURE 3

4 --- 3

Page 48

TROUBLESHOOTING FLOW DIAGRAMS

Problem:

Unit fails to power up.

TROUBLESHOOTING

Verify input power

to terminal block

Yes

Turn on power switch.

Verify blower operation

and power on primary

transformer

Yes

Is there voltage on the

secondary transformer?

Yes

Replace main board.

Problem:

Segment out in display.

Enter the display test

mode. See page 3 ---15.

Verify faulty segment

location. Swap front and

rear display driver cables.

No

No

No

Check

branch circuit

Replace

power switch

Replace transformer.

Leave secondary wiring disconnected.

Verify voltage on secondary transformer.

Isolate any shorts between transformer leads.

Replace effect ed components

No

Replace the driver board.

Is the segment still out?

Yes

Visually and electrically

check the suspect

display cable.

Is the cable ok?

Yes

Replace the display.

No

Replace the display cable.

FIGURE 4

4 --- 4

Page 49

UHC

Problem:

Unit does not heat

Is the unit plugged in?

Yes

Is the power switch on?

Yes

Is the breaker on? Turn breaker on

Yes

displayoneachshelf

Yes

Disconnect OR-20, BL-20 & Y-20 from the main board.

Is there approx. 18V output from the secondary of the

Is there approx. 9V output from the secondary of the

transformerbetweenBL-20&OR-20andBL-20&Y-20?

Reconnect OR-20, BL-20 &

Y-20 to the main board.

Is there approx. an 18V and

9V on the secondary?

No

No

No

NoIs there an illuminated

transformer between OR-20 & Y-20?

Yes

Yes

Plug unit in

Turn swit c h on

primary of the transformer?

Yes

NoIs 208 or 240V applied to the

Disconnect CN -1 (AC power

No

in) to each driver board.

Is there approx. 18V and 9V

on the main board?

Yes

Check power switch for failure

and wires from power switch to

primary of transformer for

continuity. Replace if necessary.

No

Replace the

transformer

No

Replace the

main board.

Is the heating problem

on all shelves?

Yes

Replace the

mother board

Replace the

main board

Is the resistance value of the probe correct

No

for the effected shelf (see TABLE 1 on

page 6---3 of the Technical Appendix)

Successively plug in driver board no 4, 3, 2 & 1. Verify

the secondary voltage at each step. If the secondary

voltage is lost, replace effected driver board.

Yes

Visually and electrically check RTD

and heater harness. Are they ok?

Yes

Is there input voltage (208 or 240)

applied to the effected element?

Yes

Replace the effected shelf assembly

FIGURE 5

4 --- 5

No

No Replace effected

No Replace the

Replace the

shelf assembly

harness

motherboard

Page 50

Problem:

An individual shelf display will not

change from breakfast to lunch or

will not allow the operator to set

or reset the timers.

TROUBLESHOOTING

Is the problem on

all three display

sections?

Yes

Are ribbon cable connections

from the display to the shelf

driver connected to their ap-

propriate driver board?

No

membrane to the

membrane switch

Are connections

from the control

LED display

proper and in

good condition?

Yes

Replace control

assembly.

Problem fixed.

Done

Connect the ribbon

No

cables to their

appropriate driver

No

board.

Clean or reinstall

ribbon connection.

Problem still exists.

Replace LED

display assembly

Problem fixed.

Done

Problem still exists.

Replace shelf

driver board.

Done

Yes

Replace LED

display assy.

Problem fixed.

Done

Problem still exists.

Replace the

driver board.

Done

FIGURE 6

4 --- 6

Page 51

UHC

Problem:

An individual shelf is in

an overheat or

underheat situation.

Is the resistance vs.

temperature on the

probe correct?

R e f e r t o p a g e 5 --- 5 f o r

procedure.

(see TABLE 1 on page

6 --- 3 o f t h e

Technical Appendix for

conversions)

Yes

No

Replace shelf assembly .

Does the input voltage

to the element cycle on

and off and pulse when

close to set point?

Yes

Replace

shelf assembly.

No

Is the programming

correct for this shelf?

(see Programming and

Calibration section)

Yes

Replace the

main board.

No

Correct the programming.

(see Programming and

Calibration section)

FIGURE 7

4 --- 7

Page 52

Problem:

Unit displays

sensor alarm.

Is the resistance vs.

temperature on the

probe correct?

R e f e r t o p a g e 5 --- 5 f o r

procedure.

(see TABLE 1 on page

6 --- 3 o f t h e

Technical Appendix for

conversions)

Yes

Does the resistance of

the probe and harness

approx. match TABLE 1

o n p a g e 6 --- 3 of t h e

Technical Appendix?

Yes

No

No

TROUBLESHOOTING

Replace the

shelf assembly.

Replace the

RTD harness.

Replace the

mother board.

Problem:

Unit displays

FDA or rise time alarm

Is the effected element

receiving 208 or 240

input voltage?

Yes

Bad probe or heater.

Replace the shelf

assembly.

No

Is the wiring harness

between the element and

mother board correct?

Yes

Replace the

mother board.

No

Correct the wiring.

FIGURE 8

4 --- 8

Page 53

UHC

Problem:

Keypad Timer, Enter/

Page or Menu keys

not working

Press problem key to

verify fa ult.

Is audible click heard?

Yes

Problem:

Keypad Arrow keys

not working

Enter service level

programming.

( S e e p a g e 3 --- 1 4 )

Press problem key to

verify fa ult.

Is audible click heard?

Yes

Swap suspect display

cable to same position

No

on different driver

board.

Press problem key. Is

audible click heard?

Yes

Replace driver board.No problem.

Swap faulty display cable

No

to same position on dif-

ferent driver board.

Press problem key. Is au-

dible click heard?

Yes

Replace membrane

No

switch.

Press problem key.

Is audible click

heard?

Yes

Problem fixed.

Done

No

No

Replace membrane

switch.

Press problem key.

Is audible click heard?

Yes

Replace

ribbon cable.

Replace driver board.No problem.

FIGURE 9

4 --- 9

Replace driver board.

Page 54

TROUBLESHOOTING A LOCKED OUT SLOT

TROUBLESHOOTING

1. Remove the rear ribbon cable from the driver

board.

If the front membrane starts to work, you have

now isolated the problem to one of three of the

rear components.

If the front is still locked up then remove the

front ribbon and try using the rear timers.

If they workthen you have isolated the problem

to one of three front components.

2. Before replacing the membrane switch,

Plug the new membrane into the display board

and try it in your hand. If it continues to lock up

then the problem is, in either the ribbon cable,

or the display board.

4 --- 1 0

Page 55

UHC

TROUBLESHOOTING SENSOR ALARMS

The following is a test procedure to be used on the

UHC-1 cabinet to determine the cause for many of

the sensor alarms we are experiencing. You will

need the probe resistance chart, found on page

6--- 3 to perform the following tests.

1. Determine the slot experiencing the “SENSOR

ALARM”.

2. Determinetheplatecausingthealarm.Todo

this you need to press t he ENTER key 4 times

in succession and read the displays.

A.) Push ENTER key once display reads: TOP

ACT ** HHHH.

B.) Push ENTER key again display reads: BO -

T ACT 200.

C.) PushENTER key again display reads: TOP

SET 200.

D.) Push ENTER key again display reads:

BOT SET 200.

This has now determined that the ”SENSOR

ALARM” is being caused by a high probe re sistance reading. (This example is indicative of

a potential probe problem on the top plate of

the slot experiencing the alarm).

3. Using a Pyrometer get the actual temp. of the

plate in question This is the temp you will be

referencing.

4. Remove the probe harness from the mother

board and get the resistance reading from the

correct probe leads (reference the schematic

on page 6 ---1). The resistance value a nd temperature should match according to the chart.

If the resistance reading did not coincide

proceed to STEP 5.

If the resistance coincides with the actual temp

the problem is either in the harness connection

or the mother board. Before replacing the

mother board check all the pins in the connec-

tor, reinstall the harness to the board, take a

tooth pick, snap it in half and insert each piece

into the back of the probe wires. Check the

temp displays again to see if the TOP ACT coincides with the actual temperature. If so the

problem was in the connection and the probe

harness should be replaced. If you still have

HHHH the problem is in the mother board and

it should be replaced.

A.) ** HHHH = high resistance or open probe

B.) LLLL = low resistance or shorted probe

5. Disconnect the probe from the harness on the

side of the unit and read the resistance through

the probe while verifying the actual plate temperature. If the resistance reading at the probe

does not match the temperature according to

the chart, make sure you have a good connec tion with your meter. If probe proves faulty, replace the liner assembly. The probe and element are vulcanized to the liner and cannot be

replaced separately.

If the plate temperature and probe resistance

match according to the chart, check and tighten connections at the side probe harness then

read resistance at top of harness again. If the

resistance now coincides with the temperature, the problem was in the connection. If the

resistance is still incorrect the problem is in the

harness and should be replaced.

6. If the problem is intermittent or you cannot find

anything wrong test the probe. Shut the slot off

and cool it down with a pan of water then allow

it to reheat. As it’s heating note the top and bottom temps using your pyrometer. As you note

the temperatures, read the probes resistance

in 50 deg. increments. You should compare

these readings with your probe chart. If they do

not match run the test again. If they still do not

match the probe is going bad and the liner assembly should be replaced.

4 --- 1 1

Page 56

TROUBLESHOOTING

TROUBLESHOOTING THE DRIVER BOARD AND CONTROL

The following is a test procedure to be used on the

UHC-1 cabinet to determine if there is a problem

with driver board, the display control, the control

membranes, or the connecting harnesses.

1. Turn off power to the unit, locate the driver

board to the shelf to be tested, disconnect the

communications port (this being the 18 pin

connector with the blue j umper wire), turn the

power back on. The shelf should now read

”Display Test Mode”.

2. Starting with the front left timer push ALL buttons one at a time in order with the last one being the right rear timer. Each time you press a

key the four DOTS at the bottom of the display

will light up. If at any time during this test you

get a ”Key Press Error” reset the unit, by turning off then back on and start again. If the ”Key

Press Error” comes up at the same place, the

unit did not see the previous key activate and

the following procedure should be considered:

A.) Clean the ribbon cable connections at the

display control. If the problem persists

move on to next.

B.) Determine if the gray ribbon cable is good

by swapping it with one from another shelf

and running the test again. If the ”Key

Press Error” goes away replace the ribbon cable. If not move on to next.

3. After you hit the last key the shelf will go into an

LED test, at this time all led segments will light

up. If some of the segments do not light clean

the connection between the gray ribbon cable

and the display control, and check the gray ribbon for cuts or burns. If they still will not light

replace the control.

4. During the LED test look at all 6 displays. If the

same led segment is out in a ll 6 displays the

driver board is bad and should be replaced‘

C.) Remove the display control from the bezel

assy. and inspect both ribbon connection

areas for burns or corrosion. If control

looks bad you can prove it by swapping it

out with one from another shelf. If the ”Key

Press Error” goes away replace the display control. If not replace the membrane.

4 --- 1 2

Page 57

UHC

This page intentionally left blank.

4 --- 1 3

Page 58

CHAPTER 5

PARTS REPLACEMENT

Page 59

UHC

ELEMENT OR PROBE AS SEM BLY

1. Remove the right and left hand exterior panels

by removing the two lower phillips head screws.

2. Remove the top exterior panelby removing the

two upper phillips head screws.

3. Loosen the two hex head bolts located on either side of the bezel assembly.

4. Trace the ribbon cable from the bezel assembly to its associated driver board. Remove the

ribbon cable from the driver board.

NOTE: Mark the locationof the ribbon cable to

ensureit is replaced in the proper location.

5. Remove the ribbon cable clamps from the ribbon cable bundle on the right side of the unit.

6. Repeat steps 3 ---5 for the adjacent bezel assembly.

7. Remove both bezel assemblies to allow for unobstructed access to the shelf assembly.

8. Disconnect the two probes and element wire

connections from the affected shelf assembly.

9. Remove the four phillips head screws that attach the shelf assembly to the frame.

10. Remove the shelf assembly from the frame by

sliding it out from either side.

NOTE: If you are removing the #1 shelf as-

sembly, you must also remove the two

wire clamps attached to the right side

of the shelf assembly before removing

the shelf from the frame.

11. Remove the insulation cover from the shelf assembly by removing the two phillips head

screws on either side of the cover assembly.

12. Remove the four pieces of insulation from the

shelf assembly.

NOTE: The foil wrapped insulation is VERY

FRAGILE. Please use extra care when

handling.

13. Remove the twelve phillips head screws from

the top shelf section. See FIGURE 1.

Screw

Top S h elf S ect ion

Disassembling the Shelf Assembly

FIGURE 1

Bottom Shelf Section

5 --- 1

Page 60

PARTS REPLACEMENT

14. Discard the defective shelf section.

15. Install the new shelf section. Be sure to align

both the front and rear faces of the shelf assembly so that both the top and bottom shelf

sections are flush.

16. Install the foil wrapped shelf insulation and insulation cover assembly.

17. Insert the shelf assembly into the unit frame.

Install the four phillips head screws through

the shelf assembly into the unit frame.

18. Connect the two probe and element wire connections at the right side of the shelf assembly.

19. Feed the ribbon cables from the bezel assemblies over the top of the shelves to their associated driver boards.

NOTE: Be careful not to pinch the ribbon

cable between the bezel and the shelf

assembly.

20. Inspect the gasket assembly on the bezel. Re place if necessary. See Bezel Gasket Replacem e n t o n p a g e 5 --- 6 .

21. Install the front and rear bezel assemblies.

Tighten the four hex head bolts on either side

of the bezel assemblies.

COOLING BLOWER

1. Remove the right and left hand exterior panels

by removing the two lower phillips head screws.

2. Remove the top exterior panelby removing the

two upper phillips head screws.

3. Remove the black and white power connections from the blower motor.

4. Loosen the two phillips head screws holding

the blower bracket to the unit frame.

5. Remove the blower and bracket from the unit.

6. Remove theblower from the bracket by removing the three phillips head screws.

7. Install the new blower on the bracket with the

screws provided.

8. Install the blower and bracket into the unit

frame.

9. Connect the black and white power wires to

the blower motor.

10. Install the side and top exterior panels of the

unit.

11. Check the unit for proper operation.

22. Install the ribbon cable clamps on the ribbon

cable bundle located on the right side of the

unit.

23. Install the side and top panels.

24. Check the unit for proper operation.

5 --- 2

Page 61

UHC

BEZEL ASSEMBLY

1. Remove the right and left hand exterior panels

by removing the two lower phillips head screws.

2. Remove the top exterior panelby removing the

two upper phillips head screws.

3. Loosen the two hex head bolts at either side of

the bezel assembly. Remove the bezel from

the shelf.

4. Remove the two screws attaching the LED assembly to the bezel. Remove the ribbon cable

attaching the membrane switch to the LED assembly.

5. Discard the bezel assembly.

6. Install the gasket into the new bezel assembly.

See Bezel Gasket Replacement on page 5-- -6.

7. Install the membrane sw itch ribbon cable into

the LED assembly. Attach the LED assembly to

the bezel with the two screws provided. See

FIGURE 2 for proper placement and attachment of the membrane switch ribbon cable.

8. Install the bezel assembly on the frame by

tightening the two hex head bolts located on

either side of the bezel assembly.

NOTE: Be sure not to pinch the ribbon cable

between the bezel and the shelf assembly.

9. Install the side and top exterior panels.

10. Check the unit for proper operation.

Connect ribbon cables to the LED board

Flip the LED board as shown

Ribbon Cable

Mounting Screw Mounting ScrewBezel Insert

Slide LED board under metal insert on bezel. Align the screws holes and attach the LED board.

underneath board

FIGURE 2

5 --- 3

Page 62

PARTS REPLACEMENT

MEMBRANE SWITCH

1. Remove the right and left hand exterior panels

by removing the two lower phillips head screws.

2. Remove the top exterior panelby removing the

two upper phillips head screws.

3. Loosen the two hex head bolts located on either side of the bezel assembly. Remove the

bezel assembly.

4. Remove the two screws holding the LED assembly to the bezel. Remove the membrane

switch ribbon cable from the LED board.

5. Remove the defective membrane switch from

the bezel.

6. Clean all of the excess adhesive from the bezel.

7. Install the new membrane switch on the bezel.

8. Inspect the bezel gasket and replace if necessary. See Bezel Gasket Replacement on page

5 --- 6 .

9. Install the membrane sw itch ribbon cable to

the LED board. See FIGURE 2 on page 5 ---3

for proper placement and attachment of the

membrane switch ribbon cable.

10. Install the LED board into the bezel.

11. Install the bezel assembly on the frame by

tightening the two hex head bolts located on

either side of the bezel.

NOTE: Be sure not to pinch the ribbon cable

between the bezel and the shelf assembly.

LED BOARD

1. Remove the right and left hand exterior panels

by removing the two lower phillips head screws.

2. Remove the top exterior panelby removing the

two upper phillips head screws.

3. Loosen the two hex head bolts located on either side of the bezel assembly. Remove the

bezel assembly.

4. Remove the two screws holding the LED assembly to the bezel. Remove the membrane

switch ribbon cable from the LED board.

5. Remove the ribbon cable clamps from the ribbon bundle on the right side of the unit.

6. Trace the LED ribbon cable to its driver board.

Remove the ribbon cable.

7. Feed the new LED board ribbon cable to its

driver board.

8. Install the membrane sw itch ribbon cable to

the LED board. See FIGURE 2 on page 5 ---3

for proper placement and attachment of the

membrane switch ribbon cable.

9. Install the LED board into the bezel.

10. Install the bezel assembly on the frame by

tightening the two hex head bolts located on

either side of the bezel.

NOTE: Be sure not to pinch the ribbon cable

between the bezel and the shelf assembly.

11. Install the side and top exterior panels of the

unit.

12. Install the side and top exterior panels of the

unit.

13. Check the unit for proper operation.

12. Check the unit for proper operation.

5 --- 4

Page 63

UHC

DRIVER BOARD

The driver boards are static sensitive. Make

sure you use proper grounding procedures

when handling these boards.

1. Remove the right and left hand exterior panels

by removing the two lower phillips head screws.

2. Remove the top exterior panelby removing the

two upper phillips head screws.