Page 1

UHC

UNIVERSAL HOLDING CABINET

INSTALLATION -- OPERATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN 33555 Rev E (6/01)

E 2000 --- G.S.Blodgett Corporation

Page 2

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not storeor use gasolineor other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructionswill result in satisfactory baking results

and long,trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

Page 3

THE REPUTATION YOU CAN COUNT ON

Forover a century andahalf,The BlodgettOvenCompanyhas been building

ovensandnothingbut ovens. We’ve set the industry’s quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett;gas and electric, full-size,half-size, countertopand deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For moreinformation on thefull line of Blodgett ovens contact your

Blodgett representative.

Page 4

Your Service Agency’s Address:

Model:

Serial Number:

Your oven was installed by:

Your oven’s installation was checked by:

Page 5

Table of Contents

Introduction

Description 2......................................................

Installation

Delivery and Location 3.............................................

Assembly and Connection 4.........................................

Operation

Safety Information 7................................................

Control Panel Descriptions 8........................................

Operator Mode 9..................................................

Timer Operation 10..................................................

Meal Selection 12...................................................

Clean Mode 13.....................................................

Slot On/Off 14......................................................

Displaying Slot Temperature Information 15............................

Temperature Alarms 16..............................................

Product Selection for Each Slot 18....................................

Entering and Editing Product Information 23............................

More Product Prompt Time Feature 28................................

Display Adjustments 29..............................................

Operating Tips and Menus 30........................................

Maintenance

Cleaning and Preventative Maintenance 34.............................

Page 6

Introduction

Description

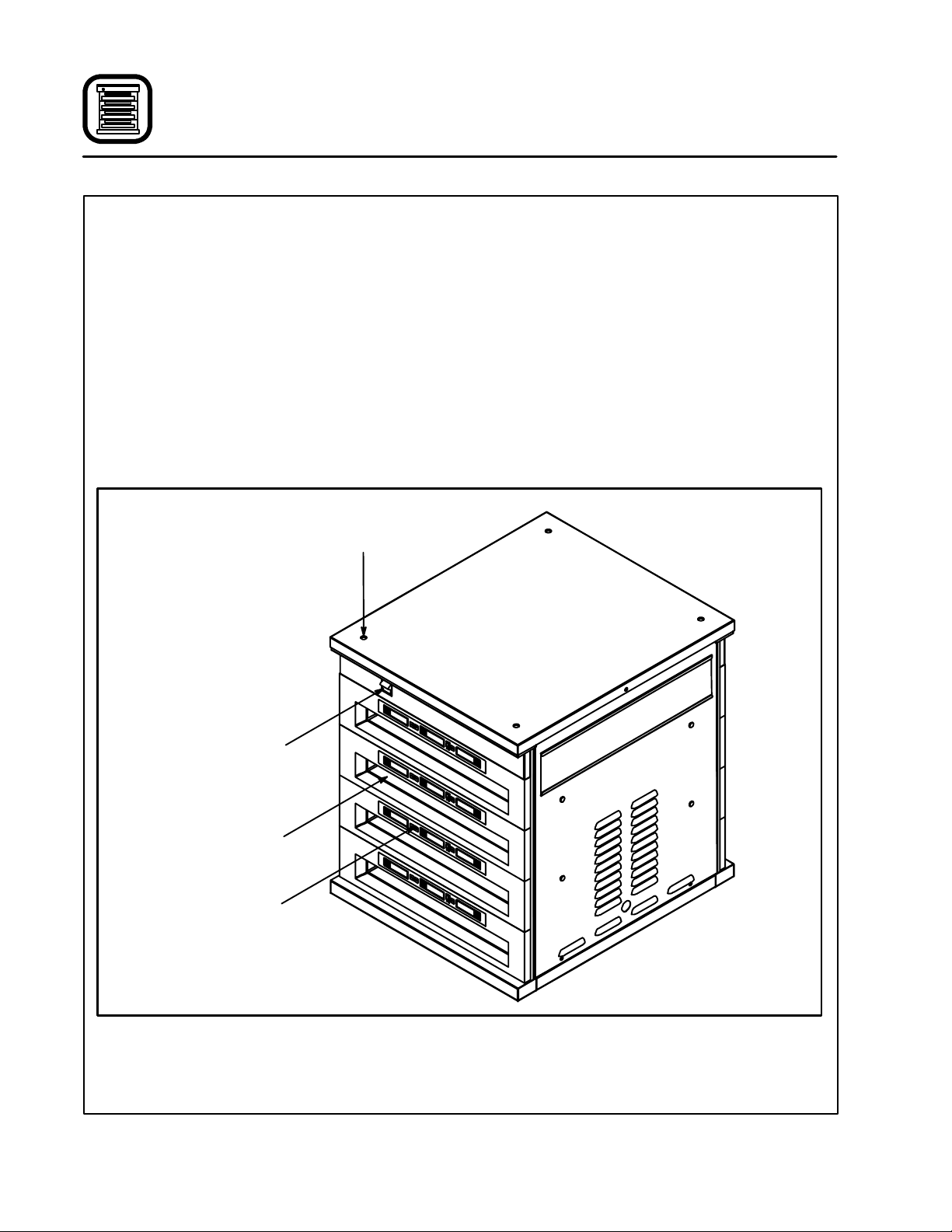

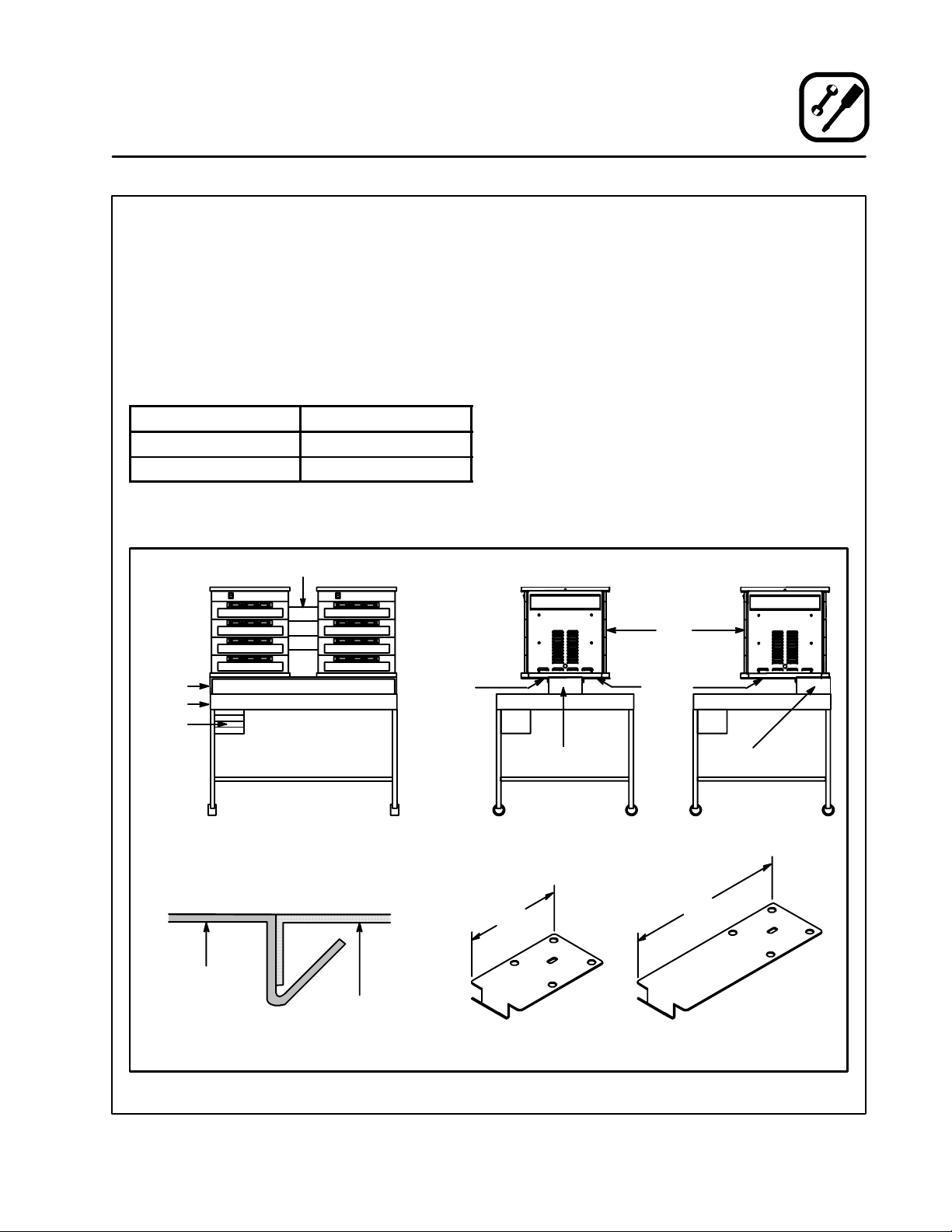

The Blodgett Universal Holding Cabinet is a short

term holding device designed to maintain the

freshness of a variety of food product. The UHC

contains four product slots which can be controlled independently. Control panels are located

above each slot on both the front and rear of the

cabinet. All operator mode selections can be

made from either the front or rear display.

Power Switch --- controls power to the cabinet.

Product Slot --- holds up tothreetrays ofproduct

per slot.

Control Panel --- indicates the holding time and

product selection for each tray position.

Knockouts for

Double Stacking

1/3 Size Product Tray - -- designed for all grilled

products (meat, eggs, chicken). This tray maintains the product’s moisture.

1/2 Size Crumb Tray with Wire Rack --- designed

for fried products (crispy chicken, nuggets, fillet).

The tray keeps the fried crumbs from dropping

through the racks. It also allows moisture to escape leaving the outside of the product crispy.

Full Size Product T ray --- designed for bread

products (biscuits and muffins). This tray allowsa

small amount of moisture to escape.

Power Switch

Product Slot

Control Panel

Figure 1

2

Page 7

Installation

Delivery and Location

DELIVERY AND INSPECTION

All Blodgett holding cabinets are shipped in containers to prevent damage. Upon delivery of your

new unit:

D

Inspectthe shippingcontainerforexternaldamage. Any evidenceof damage should be noted

onthedelivery receiptwhichmustbe signed by

the driver.

D

Uncratetheunit and checkforinternaldamage.

Carriers will accept claims for concealed damage if notified within fifteen days of delivery and

the shipping container is retained for inspection.

The Blodgett Oven Company cannot assume

responsibility for loss or dama ge suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a claim is necessary.

Each Universal Holding Cabinet is shipped with

the following:

D

Equipment manual

D

PM card

D

Training video

D

Quick-reference guide

D

Cleaning brush

At this time, please complete and return the

Service Tracking card shipped with your oven.

LOCATION

Thefollowing clearancesmustbeavailableforservicing.

D

Cabinet body sides --- 22” (56 cm)

D

Cabinet body back --- 25” (64 cm)

3

Page 8

Installation

Assembly and Connection

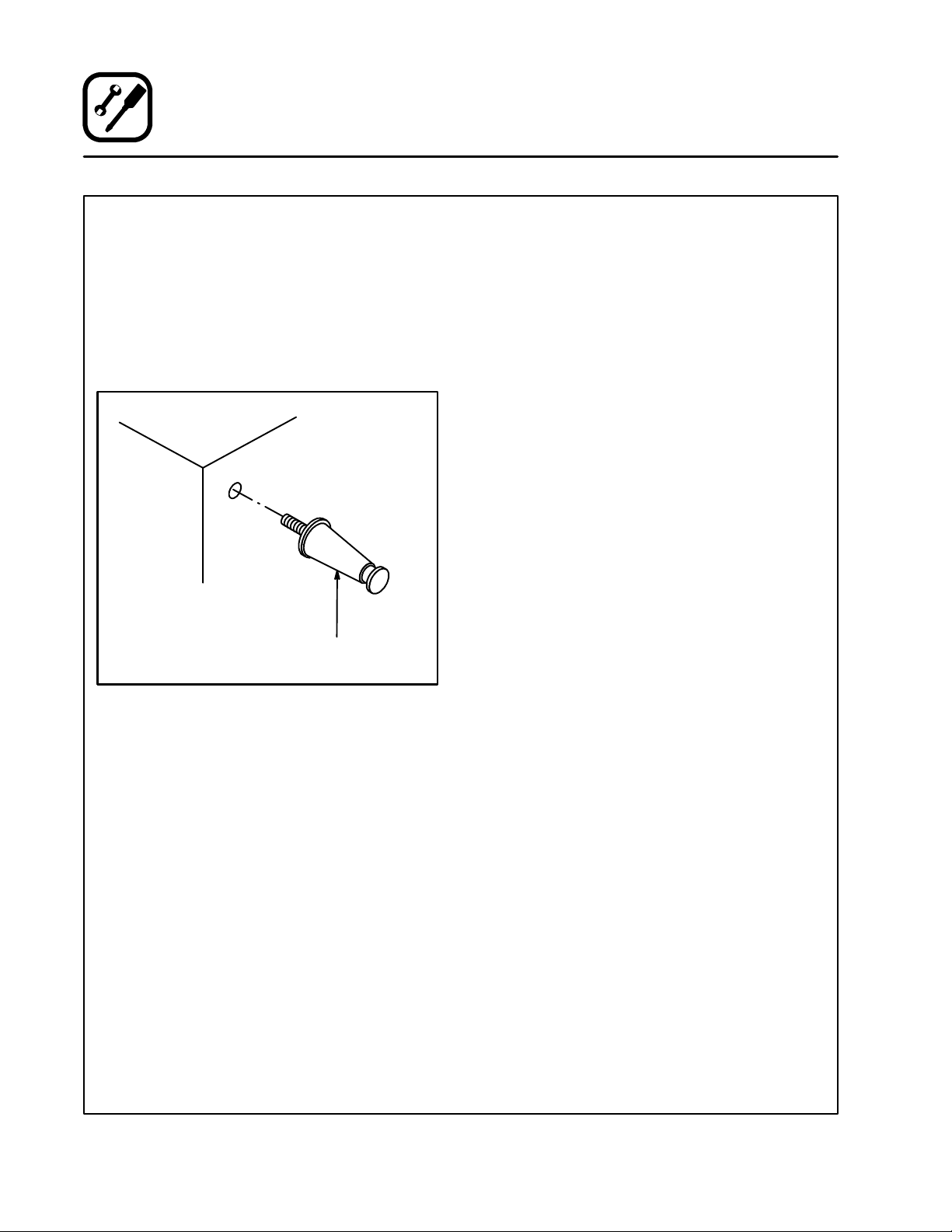

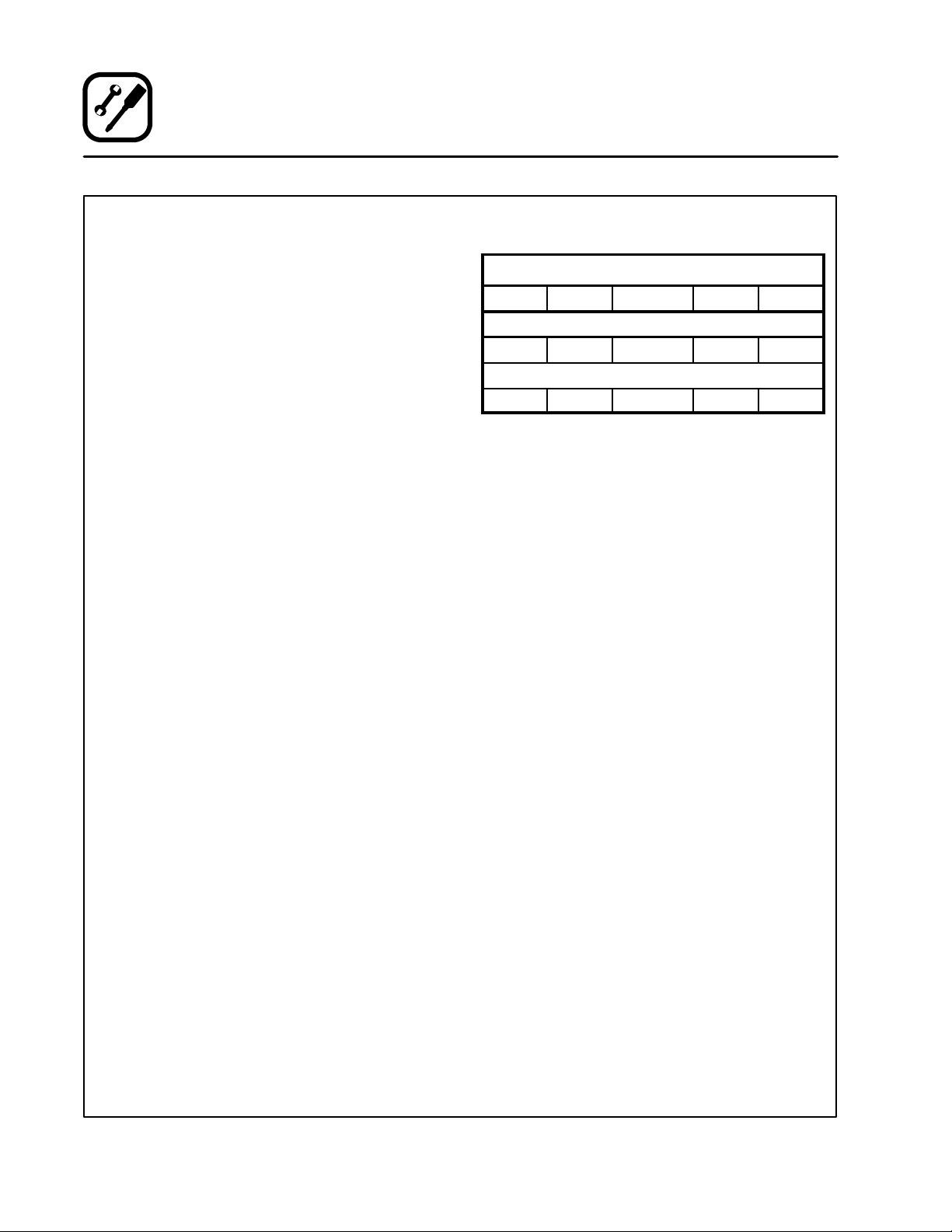

LEG ATTACHMENT

1. Lay the unit on its side.

2. Screw one 4” (10 cm) leg into each of the four

holes located near the corners on the bottom

of the UHC. See Figure 2.

3. Use a tool to tighten the hex nut at the top of

each leg.

4. Lift the unit onto the legs.

Bottom of

Cabinet

4” (10 cm)

Leg

ASSEMBLY TO STAND

1. Place the unit on top of the cart.

NOTE: Be surethelocking casters are facing

the front of the cabinet, the side with

the power switch.

2. Bolt the corners of the unit to the stand from

the underside of the stand top using 3/8” x

5/8” bolts provided.

Figure 2

4

Page 9

Installation

Assembly and Connection

ASSEMBLY TO DUAL UHC TABLE WITH RISER

TheUHCcanbemountedonthetableforeither

double or single sided access. See Figure 3. For

double sided access the unit is centered on the

table. Forsinglesided access the unit is mounted

flush to the back of the table.

Besurethat youhavethecorrect mountingbrackets for your configuration. Refer to t he following

table.

Mounting Style

Bracket Length

Double Sided Access Short (6”, 15.5 cm)

Single Sided Access Long (12”, 31 cm)

NOTE: The installation requires two brackets per

UHC.

Tool Accessory

Bench

Table

Shelves

Hold Down

Bracket

(See View A)

1. Place the unit on top of the riser of the dual

UHC table.

2. Line up the center hole on each hold down

bracket with a leg mounting hole on the bottomoftheunit.Bolttwobracketstothebottom

of each UHC using the 3/8” x 5/8” bolts provided.Besure the formedangleofthebracket

cups the underside edge of the bench. See

Figure 3.

For Double Sided Access

Installonebracket ontheouterfrontcornerof

eachUHC.Installtheother bracketon theouter back corner of each UHC.

For Single Sided Access

Installonebracket ontheouterfrontcornerof

each UHC. Install the other bracket on the inner front corner of each UHC.

UHC

Hold Down

Bracket

Hold Down

Bracket

RiserSupport

Front View Side View

UHC

Riser

View A

Side View

(Double Sided Access)

6” (15.5 cm)

Double Sided Access

Short Bracket

Figure 3

5

RiserSupport

Side View

(SingleSided Access)

12” (31 cm)

Single Sided Access

Long Bracket

Page 10

Installation

Assembly and Connection

DOUBLE STACKING

1. Remove the four knockoutsfromthetop of the

lower unit.

2. Place the upper unit in position on top of the

lower unit.

3. Remove the side panels from the lower unit.

4. Attach the lower unit to the upper unit using

four 3/8” x 5/8” long bolts provided.

NOTE: The holes in the bottom of the upper

unit are the same as the leg mounting

holes. Theholesinthetop of thelower

unit are knockouts.

5. Replace the side panels.

ELECTRICAL CONNECTION AND POWER UP

Electrical Specifications (per section)

KW Hz Volts Phase Amps

U.S. and Canadian installations

3.6 60 208/240 1 20

General Export installations

3.6 50/60 208-240 1 20

Installation must conform with local codes, or in

theabsenceoflocalcodes,withthe NationalElec-

trical Code, ANSI/NFPA 70---Latest Edition and/or

Canadian Electrical Code CSA C22.2 as applica-

ble.

Wiring diagrams are located inside the right side

panel.

This appliance is equipped with a three-prong

grounding plug for your protection against shock

hazard and must be plugged into a properly

groundedthree-prongreceptacle. DONOT cutor

remove the grounding prong from this plug.

1. Plug the UHC into the power source.

2. Togglethepowerswitchto ON.Allof the control displays illuminate.

3. Monitorthe temperatureof the slots. It should

take approximately15 minutes for the slots to

heat from room temperature to a 155_F

(68_C) setpoint. It should take approximately

25minutes forthe slotsto heatfromroomtemperature to a 200_F(93_C) setpoint.

THE BLODGETT OVEN COMPANY CANNOT ASSUMERESPONSIBILITYFORLOSSOR DAMAGE

SUFFEREDASA RESULTOFIMPROPERINSTALLATION.

6

Page 11

THE INFORMA TION CONTAINED IN THIS SECTIONIS PROVIDEDFORTHEUSEOFQUALIFIED

OPERATING PERSONNEL. QUALIFIEDOPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE UNIT AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOFTHE EQUIPMENTDESCRIBED.ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

andoperatinginstructions.Theyare the keytothe

successful operation of your Blodgett UHC.

Operation

Safety Information

SAFETY TIPS

For your safety read before operating

General safety tips:

D

DO NOT remove the control panels unless the

unit is unplugged.

D

DO NOT operate the UHC unless it has been

properly installed and checked.

D

DONOToperatetheU HC unlessallserviceand

access panels are in place and properly secured.

D

Use caution when operating the UHC to avoid

contact with heated surfaces.

7

Page 12

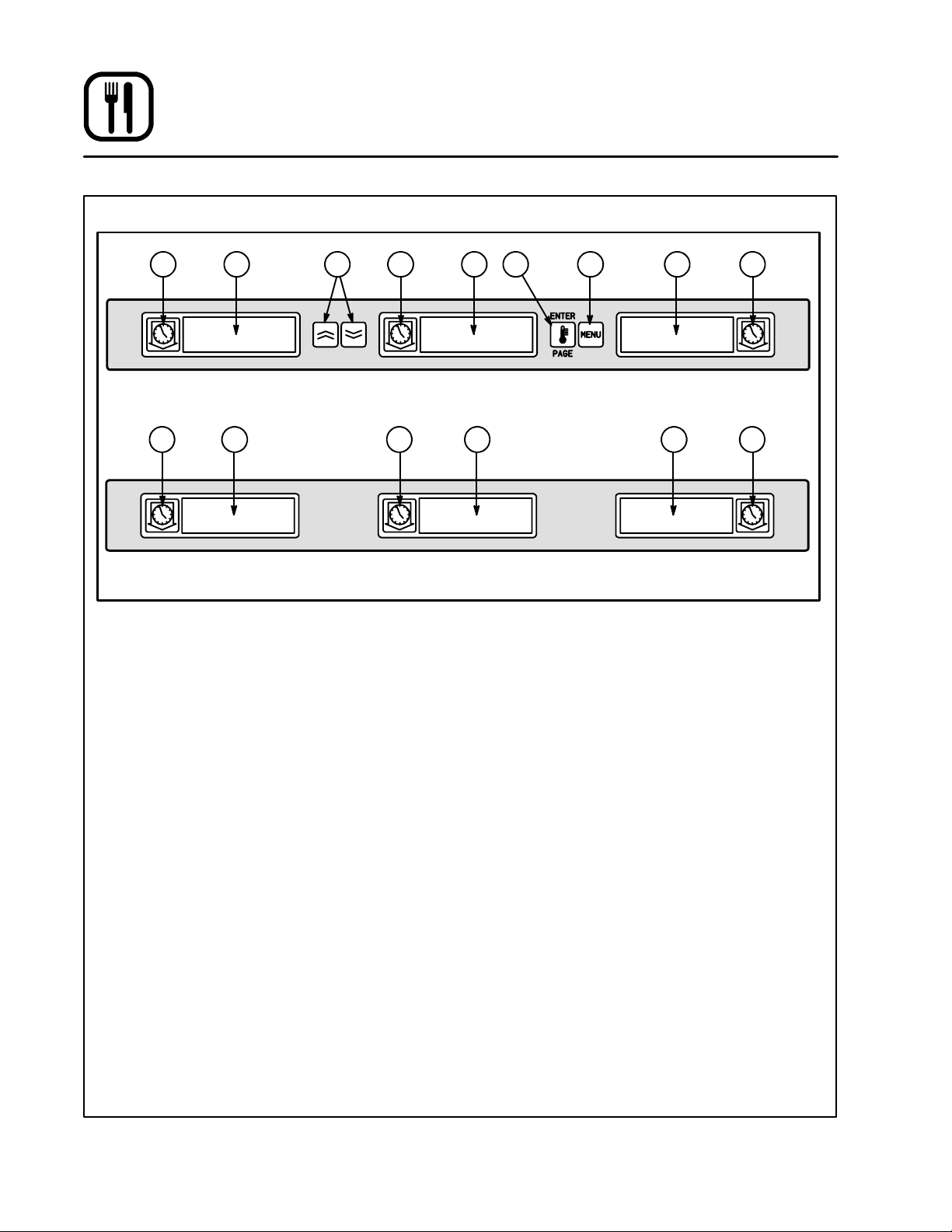

Operation

Control Panel Descriptions

1 1 12 2 25 4 3

1 1 12 2 2

UHC Front Control Panel

UHC Rear Control Panel

FRONT CONTROL PANEL

1. TIMER KEYS --- start and stopthe timer associated with each tray position. The timer keys

also turn off audible alarms. There are three

timerkeys oneachfrontpanel(left,centerand

right).

2. DISPLAYS --- show productselectionandhold

time for each tray position. The displays also

provide programming information in the program mode.Therearethreedisplaysoneach

front panel (left, center and right).

3. MENU KEY --- press to select meal transitions

(breakfast to lunch), clean mode operation

andtoturn individualslots onoroff. Themenu

key also provides access to the program

mode.

4. TEMPERATURE/ENTER/PAGE KEY --- this

key has three separate functions.

D

Display slot temperature information

D

Enter operationalchanges

D

Select page parameters in program mode.

5. UP and DOWN ARROW KEYS --- press to increase/decrease variables or change selections.

Figure 4

REAR CONTROL PANEL

NOTE: The rear panels are used for operational

functions only. All programming must be

performed from the front panels.

1. TIMER KEYS --- start and stopthe timer associated with each tray position. The timer keys

also turn off audible alarms. There are three

timerkeys oneachfrontpanel(left,centerand

right).

2. DISPLAYS --- show productselectionandhold

timeforeachtray position.Therearethreedisplays on each front panel (left, center and

right).

8

Page 13

Operation

Operator Mode

The operator mode is the normal operating mode

of the controller when all slots are at the proper

temperature and no alarm conditions exist. Product information and hold time are displayed.

SLOT TEMPERATURE CONTROL

Each product selection has its own temperature

setpoint and product hold time. All product timers

run independently.

Theslott emperature is controlledby the temperature setpoint ofthe leftmost productentry ineach

slot as viewed from the front of the cabinet (side

with the On/Off switch). Product selections that

have a hold temperature different than the left

most product selection will not be available for

entry into that slot’s configuration.

DISPLAY INFORMATION

In the operator mode the slot displaysprovidethe

following information:

D

The product selection for each tray location.

D

The hold time remaining (in minutes) for active

timers.

NOTE: An active timer alternately displays the

product selection and the time remaining.

Inactive timers displayonlyproduct selection.

DISPLAY IDENTIFICATION

Since there are three separate displays for each

slot it is important to identify product status for

each display. The operator mode indicates hold

time status by changing the display intensity.

There are three levels of display intensity used to

indicate product status.

D

USE FIRST DISPLAY --- indicates the product

with the least amount of hold time remaining.

This displayisidentified bythe brightestlevelof

intensity and running dots along the bottom of

the display.

D

ACTIVE TIMER --- indicates an active timer that

is not the product with the least amount of hold

time remaining. This display is identified by a

medium level of intensity.

D

INACTIVE TIMER --- only product selection is

displayed for inactive timers. This display is

identified by the lowest level of intensity.

SAUS

!.!.!

.

Use first timer

(highest intensity)

12

.!.!.!.

.

Running dots(decimal points)

Active timer

(medium intensity)

Figure 5

9

Inactive timer

(lowest intensity)

Page 14

Operation

Timer Operation

Starting a timer

1. Press the TIMER KEY above the desired t ray

position to start t he timer. The timer counts

down from a preset value and alternatelydisplays product selection and the hold time re maining.

2. Wait a minimumof3seconds beforepressing

another timer key t o initiate a secondary timing function.

NOTE: If more than one tray of product is timing,

the tray with the least hold time remaining

is indicated by the Use First display.

Adjusting a timer

1. Press the TIMER KEY to initiate the product

timer (if not already activated).

2. Press the TIMER KEY again within 3 seconds

to decrease the hold time by 5 minutes.

NOTE: The hold time will be decreased by 5

minutes each time the product key is

pressed.

3. The timer becomes active 3 seconds afterthe

lastkeypress.Thedisplayindicates themaximum holding time for the product and

changestoDisplayIntensity3 (brightest).The

display alternately displays the remaining

hold time and product mnemonic.

Stopping a timer

1. Press the TIMER KEY above the slot position to

turn off an active timer. The timer stops timing.

The display changes to the inactive status.

Timing out

1. Thetimeoutalarm alerts the operator that the

productholdtimehasexpired.Whenthehold

timeremainingreacheszeroan audiblealarm

sounds and the display reads --- 00 --- .

All other active displays in the cabinet switch

to the lowest intensity level until the audible

alarm is turned off.

2. Press the TIMER KEY to clear the timed out

display and silence the alarm.

If other timers in the cabinet have timed out,

theaudiblealarmremainsonuntilalltimedout

displays are cleared.

3. When all timers are cleared, active timers return to normal status. The Use First status is

switched to the next timer with the least hold

time remaining.

10

Page 15

SAUS

.!.!.!.

45

!.!.!

.

SAUS

.!.!.!.

.

Display alternately indicates hold time and

product selection for active timers.

Operation

Timer Operation

Press timer key to start a timer

--- 00 ---

Press timer key to stop or silencea timer

!.!.!

.

Use First indication changes to the next active timer

SAUS

.!.!.!.

Figure 6

.

11

Page 16

Operation

Meal Selection

Selecting breakfast and lunch

NOTE: The following example is for selecting

breakfast.Thesameprocedureappliesfor

selecting lunch.

1. Press the MENU KEY to change the product

selectionofthe slotfrombreakfastto lunch.All

displays are highlighted.

2. Press the ENTER KEY to activate the meal

selection. The displays switch to the inactive

mode.

NOTE: If the enter key is not pressed within

fiveseconds,theproductselectionreturns to the breakfast meal selection.

Changing meal selections

Active timers will not change to the new meal

selection until the timer(s) are stopped or time out

and are reset. Activetimersarestoppedbypressing the timer key.

If the product selection for the meal has a hold

temperaturedifferentthanthe currentmeal,a high

or low temperature alarm is displayed to alert the

operator that the hold temperature is being

changed.Shouldthehigh orlowtemperaturecondition remain for two or more minutes, an audible

alarmsounds.Tosilencethealarmpressanytimer

key.Thisdoesnotaffectthetimeroperationunless

the timer key is pressed again. The display alternately indicates the product selection and the

alarm message until the slot temperature is within

the preset limits.

If no keys are pressed, the alarm message automaticallyresets wh en the slot temperature is within the preset limits.

NUGG

Press menu key to display inactive

meal selection

NUGG NUGG

Press enter key to enter meal selection

and return to normal displaymode

Figure 7

12

Page 17

Operation

Clean Mode

The clean mode changes the temperature setpoint of all slots in the cabinet to 125_F(52_C).

To start the clean mode

1. PresstheMENUKEYtoscrolltotheclean

mode message, CLN MODE.

2. Press the ENTER KEY to activate the clean

mode. All slots change to clean mode.

NOTE: If the enterkeyis not pressed within 5

seconds thecontrolreturnstotheprevious meal selection.

If the t emperature is above 125_F(52_C),the

display alternately reads SLOT CLN MODE

CLN MODE

and NOT SAFE YET. The display reads SAFE

TO CLN when the slot is 125_F(52_C).

To ex it clean mode

1. Press the MENU KEY to display CLN MODE.

2. Press the ENTER KEY to exit the clean mode

and return to normal operation. The slot alternately displays SLOT TEMP LOW and the

productselectionuntilthetemperature iswithin the normal operating limits.

NOTE: If the enter key is not pressed within 5

seconds the slot returns to the clean

mode.

Press menu key to scroll to clean

mode message

Press enter key to start clean mode

SAFE TO CLN

CLN MODE

To exit clean mode press menu key

to display clean mode message

EXIT CLN MODE

Press enter key to return to normal

displaymode

Figure 8

13

Page 18

Operation

Slot On/Off

To turn slot off

1. Press the MENU KEY to scroll to the slot off

message, TURN SLOT OFF.

2. Press t he ENTER KEY to enter the selection.

The display reads SLOT IS OFF.

NOTE: If the enter key is not pressed within

five seconds the product selection returns to the operator mode.

TURN SLOT OFF

To turn slot on

1. Press the MENU KEY to scroll to the slot on

message, TURN SLOT ON.

2. Press the ENTER KEY to enter the selection

and return to the operator mode. The display

alternately reads SLOT TEMP LOW and the

productselectionuntilthetemperature iswithin normal operating limits..

NOTE: If the enter key is not pressed within

fiveseconds the slot returnstoslotoff

status.

Press menu key to scroll to slot off

message

Press enter key to turn slot off

SLOT IS OFF

SLOT IS OFF

Press menu key to scroll to slot on

message

TURN SLOT ON

Press enterkey to turn sloton and return

to normal display mode

Figure 9

14

Page 19

Operation

Displaying Slot Temperature Information

1. Press t he TEMPERATURE KEY to scroll the

following temperature information for each

slot:

D

Top plate actual temperature

D

Bottom plate actual temperature

D

Top plate setpoint temperature

D

Bottom plate setpoint temperature

TOP TEMP 155

BOT TEMP 155

2. Pressthe TEMPERATUREKEYagaintoreturn

the display to operator mode.

NOTE: The display automatically returns to

operator mode if no keyispressed for

five seconds.

Press temperature key to display top

platetemperature

Press temperature key to display

bottom plate temperature

Press temperature key to display top

platesetpoint temperature

TOP TSET 155

Presstemperaturekey to display bottom

platesetpoint temperature

BOT TSET 155

Press temperature key to turn return to

normal display mode

Figure 10

15

Page 20

Operation

Temperature Alarms

There are five temperature alarm functions.

D

High temperature alarm

D

Low temperature alarm

D

FDA alarm

D

Sensor alarm

D

Rise time alarm

Ifalarmconditionsoccuranaudible alarmsounds

and the displays alternately give the product

selection and an alarm message. Timers cannot

be started when a slot is in alarm condition.

Hi and Low Temperature alarm

Ifthe slottemperatureisaboveorbelowthe preset

limitsfor a product selection, the controllerenters

the high orlow alarm condition. The display reads

either SLOT TEMP HIGH or SLOT TEMP LOW.

Should the high or low temperature condition remain for two or more minutes, an audible alarm

sounds. To silence the alarm press any timer key.

HIGH/LOW TEMPERATURE ALARM

1. The displays alternately display the product

selection and the alarm messageuntil the slot

temperature is within the preset limits.

NOTE: The low temperature audible alarm is in-

hibited at powerup.TheSLOTTEMP LOW

messageisdisplayed until theslotiswithin the preset limits.

Food and Drug Administration (FDA) alarm

The FDA alarm indicates the slot temperature is

belowthe preset limit toholdthe product. The audible alarm sounds and the display reads TEMP

UNDR FDA. Active timers are automaticallyreset.

1. Toturn off the audible alarm press any TIMER

KEY. The alarmmessageremains untiltheslot

temperature is within the preset limits. If no

keysarepressedtheaudiblealarmand alarm

message remain.

A timer key must be pressed to clear an FDA

alarm.

FDA ALARM

SLOT TEMP LOW

Press any timer key to silence audible alarm

SLOT TEMP HIGH

Press any timer key to silence audible alarm

TEMP UNDR FDA

Press any timer key to silence audible alarm

Figure 11

16

Page 21

Operation

Temperature Alarms

Sensor Range alarm

The sensor fail alarm indicates a sensor temperature value above or below the operating limits of

the slot, 50---250_F (10-121_C).

1. Toturn off the audible alarm press any TIMER

KEY. The alarm message isdisplayeduntil the

slot temperature is within the operating limits.

Power to the slot’s heaters is turned off until

the sensor is repaired.

Service is required to correct a sensor alarm.

SENSOR RANGE ALARM

SENS ALRM

Press any timer key to silence audible alarm

RISE TIME ALARM

Rise Time alarm

Therisetimealarmindicates thattheslottemperature failed to reach operating temperature within

the preset time limits of the system at power up.

1. Toturn off the audible alarm press any TIMER

KEY.

Service is required to correct a rise time alarm.

SLOT RISE RATE

Press any timer key to silence audible alarm

Figure 12

17

Page 22

Operation

Product Selection for Each Slot

Program mode is used to select the products for

each slot. All entries are made through PAGE and

MENUselections.Eachslothas apageofconfiguration menus. The topslot in the cabinet is Slot 1.

D

The PAGE key selects the slot (1-4) pages.

D

The MENU key selects the configuration menu

items (meal and tray location).

D

The UP/DOWN arrow keys select the available

products for each meal.

PROG MODE

To enter Program Mode

1. Pressand holdthe MENU KEY forat least five

seconds. The display reads PROG MODE.

To enter Page Selections

Eachslotpage(1-4)containsproductselectionfor

each meal.

1. PressthePAGEKEYtoscrolltotheslot(1-4)

pages.

Press and holdmenu key to enter

program mode

Press page key to scroll slot page

selections

SLOT 1

SLOT 2

SLOT 3

SLOT 4

Figure 13

Press page key to scroll slot page

selections

Press page key to scroll slot page

selections

Press page key to scroll slot page

selections

18

Page 23

Meal Selection and Tray Position

1. Press the MENU KEY to scroll the meal and

tray position in the left and center displays.

SLOT 1 PAGE

BFST LEFT SAUS

Operation

Product Selection for Each Slot

The current product selection is indicated in

the right display.

Press menu to key to scroll

meal selection and tray position

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

BFST CENT SAUS

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

BFST RGHT SAUS

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

LNCH LEFT 10-1

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

LNCH CENT 10-1

Meal Selection Tray Position

Press menu to key to scroll

meal selection and tray position

LNCH RGHT 10-1

Meal Selection Tray Position

Figure 14

19

Press menu to key to scroll

meal selection and tray position

Page 24

Operation

Product Selection for Each Slot

To enter Product Selection

1. Press the UP/DOWN ARROW KEYS to scroll

the availableproduct selectionsfor each meal

and tray position.

The product selection for the left tray position of

each meal determines the hold temperature for

the slot. Only products that have hold temperatures within 5_F(2.8_C) of the left most product

selection willbe displayedfor selection inthe center and right tray position. If the left most product

selection is changed, the center and right posi-

PRODUCT SELECTION

BFST LEFT SAUS

Pressup/down arrow keysto

scroll product selections

BFST LEFT ROUN

Pressup/down arrow keysto

scroll product selections

tions must be reentered. If the product selection

for an active timer is changed, the timer is automatically reset.

To exit Program Mode

1. Press and hold the MENU KEY for five seconds.

NOTE: The controller automatically exits the

program mode if no entries are made

for five minutes.

Product Selections

BFST LEFT FOLD

BFST LEFT SCRA

EXITING PROGRAM MODE

BFST LEFT SCRA

Pressup/down arrow keysto

scroll product selections

Figure 15

20

Product Selections

Product Selections

Press and hold the menu key for

five seconds to exitprogram mode

Page 25

Sample product selection change

Thisexamplechangesthelunchproductselection

in the left position of slot 3 from 10-1 to NUGG.

Since the hold temperature for NUGG is different

than 10-1, the center and right product selections

PROG MODE

Operation

Product Selection for Each Slot

are cleared. Only items with hold temperatures

within5_F(2.8_C)ofthe left product selectioncan

be entered for the center and right position.

Press menu to key for five seconds

to enter the program mode

Press page key to scroll slot page

selections

SLOT 1

Press page key to scroll slot page

selections

SLOT 2

Press page key to scroll slot page

selections

SLOT 3

Press menu key to scroll meal

selection and tray position

BFST LEFT SAUS

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

21

Page 26

Operation

Product Selection for Each Slot

BFST CENT SAUS

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

BFST RGHT SAUS

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

LNCH LEFT 10-1

Meal Selection Tray Position

Press menu key to scroll meal

selection and tray position

LNCH LEFT 4-1

Pressup/down arrow keysto scrollproduct selections

LNCH LEFT NUGG

Figure 16

22

Press and holdmenu key for five

seconds to exit program mode

Page 27

Operation

Entering and Editing Product Information

Changing or entering new product selections,

hold timer and temperature setting are password

protected functions.

To enter the password

1. Press and hold the MENU KEY for five seconds. The display reads PROG MODE.

2. Press the PAGE KEY to scroll to VIEW PAGE.

3. Press the MENU KEY to select the security

lock, SECRLOCK.UsetheUPandDOWNARROW KEYS to enter the security code 1 2 3.

ENTERING THE PASSWORD

PROG MODE

A new product entry requires entry of:

D

the product name,

D

hold time,

D

hold temperature from 55-250_F (13-121_C),

D

meal selection

The following example enters a new product,

named XXY, with a hold time of 25 minutes, and

hold temperature of 180_F(82_C).

Press and holdmenu key to enter

program mode

Press page key to scroll view page

VIEW PAGE

Press menu key to scroll to the

security lock

SECR LOCK 156

Press up/down arrow keys to enter password

SECR LOCK 123

Figure 17

23

Page 28

Operation

Entering and Editing Product Information

ENTERING THE PRODUCT NAME

SECR LOCK 123

EDIT PAGE SAUS

PROD NAME .

Press page key to scroll to the edit page

Press menu key to scroll to an

unused product(blank) mnenonic

Press up arrowkey to

scroll to the letter X

NOTE: The decimal point indicates which

display segment is beingentered.

PROD NAME X.

Press down arrow key to scroll to the next display segment

PROD NAME X.

Press up arrow key to scroll to the letter X

PROD NAME XX.

Press down arrow key to scroll to the next display segment

PROD NAME XX.

Press up arrow key to scroll to the letter Y

PROD NAME XXY.

Figure 18

24

Page 29

ENTERING THE PRODUCT HOLD TIME

PROD NAME XXY.

TIME PAGE XXY

XXY TIME 20

Operation

Entering and Editing Product Information

Press page key to scroll to the edit page

Press menu key to scroll to product

time selection

Press up/down arrow key to change time to 25 minutes

XXY TIME 25

Figure 19

25

Page 30

Operation

Entering and Editing Product Information

ENTERING THE PRODUCT HOLD TEMPERATURE

XXY TIME 25

TEMP PAGE XXY

XXY Ttop 155

Press up/down arrow key to change top plate temperature

Press page key to scroll to the temp page

Press menu key to scroll to product

top plate temperature selection

XXY Ttop 180

Press menu key to scroll to product

bottom plate temperature selection

XXY Tbot 155

Press up/down arrow key to change bottom plate temperature

XXY Tbot 180

Figure 20

26

Page 31

ENTERING MEAL USAGE

XXY Tbot 180

MEAL PAGE XXY

XXY MEAL ALL

Operation

Entering and Editing Product Information

Press page key to scroll to the meal page

Press menu key to scroll to product

meal selection

Press up/down arrow keys to select BFST

XXY MEAL BFST

Figure 21

27

Page 32

Operation

More Product Prompt Time Feature

A cook more time may be entered for each product type that will alert the operator to cook more

product before the holding time reaches zero.

When the product timer equals the cook time the

audible alarm will chirp for 3 seconds and the display message will alternately display PRODUCT

NAME,TIMERTIME,COOKand MORE until the

timer times out. If more than one tray of a product

type is active the cook more alarm will not occur

until allactive timers reach the cook time.If a position is indicating, COOK MORE and another timer

of the same product is started, the COOK MORE

message will be cleared. During transition from

breakfast to lunch the COOK MORE indication is

disabled. Use the following procedure to change

or enter the cook time of a product svelection:

DEFAULT SELECTIONS FOR THE PROMPT TIME

MNEMONICS

Left Center Right*

COOK PAGE Cook Page

SAUS COOK 4 Product 1 Cook Time 0 --- 30 Minutes 3

ROUN COOK 4 Product 2 Cook Time 0 --- 30 Minutes 3

1. Press and hold the menu key for 5 seconds.

2. Pressthepagekeytoscrolltoviewpage.

3. Press the menu key to scroll to the security

lock.

4. Pressthe upanddown arrowkeysto enterthe

manager security code: 3 3 1.

5. Press the page key to scroll to cook page.

6. Pressthemenu key to scrollto productselection.

7. Pressthe up anddownarrowkeys toincrease

ordecreasetheprompttime(inminutes)to

cook more product.

8. Whencomplete,pressandholdthemenukey

for 5 seconds to return to normal operation.

Description Available

Settings Level

Access

FOLD COOK 3 Product 3 Cook Time 0 --- 30 Minutes 3

SCRA COOK 3 Product 4 Cook Time 0 --- 30 Minut es 3

RBAC COOK 0 Product 5 Cook Time 0--- 30 Minutes 3

CBAC COOK 1 Product 6 Cook Time 0 --- 30 Minutes 3

MUFF COOK 3 Product 7 Cook Time 0 --- 30 Minutes 3

BISC COOK 22 Product 8 Cook Time 0 --- 30 Minutes 3

BURR COOK 0 Product 9 Cook Time 0 --- 30 Minutes 3

10 --- 1 COOK 2 Product 10 Cook Time 0 --- 30 Minutes 3

4 --- 1 COOK 4 Product 11 Cook Time 0 --- 30 Minutes 3

GRCK COOK 5 Product 12 Cook Time 0 --- 30 Minutes 3

NUGG COOK 5 Product 13 Cook Time 0 --- 30 Minutes 3

FISH COOK 5 Product 14 Cook Time 0 --- 30 Minutes 3

McCK COOK 7 Product 15 Cook Time 0 --- 30 Minutes 3

NOTE: Therightdisplaygivesthetimein minutes.

28

Page 33

Operation

Display Adjustments

Changing the Display Time

The rate at which an active timer alternately displays product selection and hold time may be adjusted as follows:

1. Press and hold the MENU KEY for five seconds.

2. Press the PAGE KEY to scroll to VIEW PAGE.

3. PresstheMENUKEYtoscrolltothesecurity

lock, SCR LOCK.

4. Pressthe UPandDOWNARROW KEYStoenter the security code 1 2 3.

5. PresstheMENUKEYtoscrolltoproductdisplay time, PROD TIME.

6. Press the UP and DOWN ARROW KEYS to

change the product display time.

7. PresstheMENUKEYtoscrolltotimerdisplay

time, TIMR TIME.

8. Press the UP and DOWN ARROW KEYS to

change the timer display time.

9. Press and hold the MENU KEY for five seconds to return to normal operation.

Changing from _Fto_C

The followingchanges the temperature units from

_Fto_C.

NOTE: Your UHC is factory programmed with the

proper temperature units. Access to level 3

programming is required to change the

units. Should you need to change the units

contact your local service agent for assistance.

1. Press and hold the MENU KEY for five seconds.

2. Press the PAGE KEY to scroll to VIEW PAGE.

3. PresstheMENUKEYtoscrolltothesecurity

lock, SCR LOCK.

4. Pressthe UPandDOWNARROW KEYStoenter the security code.

5. PresstheMENUKEYto scrolltodisplayunits.

6. Press the UP and DOWN ARROW KEYS to

change from _Fto_C.

7. Press and hold the MENU KEY for five seconds to return to normal operation.

Changing the Display Intensity

The brightnessofeachof the three intensitylevels

used for product status may be adjusted as follows:

1. Press and hold the MENU KEY for five seconds.

2. Press the PAGE KEY to scroll to VIEW PAGE.

3. PresstheMENUKEYtoscrolltothesecurity

lock, SCR LOCK.

4. Pressthe UPandDOWNARROW KEYStoenter the security code 1 2 3.

5. PresstheMENUKEYtoscrolltodisplayintensity level. The display reads DISP IntX.There

are three display intensity levels.

Level #

1 (dimmest) Int1 10---25 10

2 (mid-level) Int2 10---25 10

3(brightest) Int3 67-100 100

6. Press the UP and DOWN ARROW KEYS to

change the intensity level.

7. Press and hold the MENU KEY for five seconds to return to normal operation.

Display Range Default

29

Page 34

Operation

Operating Tips and Menus

Correct heat and moisture levels are important to

the proper operation of the UHC. There are no

doors inthe cabinet.Thetrays act as doors,therefore it is important that they be positioned correctly. The trays must be inserted to the stop line. The

stop line is clearly marked on the handle of all

three tray styles.

Product Slots

The UHC has four slots that can hold up to three

trays of product per s lot.

Slot 1

Slot 2

Slot 3

Slot 4

Baked Products

Thefullsizetrayisdesignedtoholdallbaked

products such as biscuits and muffins.

D

UseaUHCtraylinerwiththefullsizetray.

D

After biscuits have been removed from the biscuit oven, remove the wrapper and open the

cardboard box. Slide the biscuits onto the tray

liner.

D

Fullsize trayscan hold up to 30 frozen biscuits,

20 scratch biscuits or 20 muffins.

Grilled Products

The 1/3 tray is designed to hold all grilled products.

D

Product shouldnot be drained when picked up

from the grill.

D

Use a UHC tray liner with the 1/3 tray.

D

Product should be stacked when placed in the

lined1/3 sizetray.10:1and sausagepattiescan

be stacked up to six high. Eggs (except

scrambled), grilled chicken and 4:1 patties can

bestackeduptothreehigh.

D

Productshould be placedtowardsthecenterof

the tray.

Figure 22

Fried Products

The 1/2 crumb tray with the wire rack is designed

to hold all fried products.

D

Product should be held in the wire rack which

is placed in the crumb tray.

D

UHC tray liners are not necessary when using

thewirerackforfriedproduct.

Figure 23

30

Page 35

Operation

Operating Tips and Menus

Thefollowing arecopiesof the ProductionControl

Charts for the breakfast and regular menus. The

laminated charts can be ordered through O’Brien

Budd, Inc. The ordering numbers are:

D

Breakfast UHC card #MCD 63102

D

Regular Menu UHC card #MDC 63102A

WEEKEND(S) REGULAR MENU

Recommended Tray Size/

Recommended Stack

Ultra High Volume 18 / 6 15 / 3 15 / 3 1/1 10 / 1 14 / 1

Units Trays Trays #Pieces Bags #Pieces #Pieces

Time Period 10:1 4:1 GRCK NUGG McCK FISH

WEEKEND(S) BREAKFAST MENU

9/3 9/3 8/3 1/1 8/1 8/1

Ultra high volume should be used when the grills

and fryers are set up in such as way that they can

cook all the items that can fit in one tray at the

same time. For example, a restaurant cooks two

runs of 9 patties of 10:1 at the same time. In this

case the 18 pattiescan be staged in one tray and

stackeduptosixhigh.

These charts indicate how may pieces of each individual menu items fit in the trays.

Recommended Tray Size/

Recommended Stack

Ultra High Volume 30 / 1 24 / 6 18 / 3 6/1 18 / 3 30 / 3 20 / 1 9/1

Units Trays Trays Trays Trays Trays Trays Trays Trays

Time Period BISC SAUS FOLD SCRA ROUN CBAC MUFF BURR

30 / 1 12 / 3 6/3 6/1 6/3 15 / 3 5/1 9/1

31

Page 36

Operation

Operating Tips and Menus

LUNCH (REGULAR) MENU

Stack

Product

10:1 6 18 Trays Yes 1/3 size

4:1 3 15 Trays Yes 1/3 size

Grilled

Chicken

Deluxe

Nuggets 1 1Bag Bags No 1/2 size wire 20

Crispy

Chicken

Deluxe

Fish Fillet

Deluxe

(maximum)

3 15 #Pieces Yes

1 10 #Pieces No 1/2 size wire 20

1 12 #Pieces No 1/2 size wire 30

Tray

Amount

(maximum)

Units Liner Tray Type

plastic

plastic

1/3 size

plastic

Maximum

Hold

25

25

30

NOTE: All products reflect maximum holding time in the UHC. All products can be heldfor an additional

10 minutes in the transfer bin.

32

Page 37

BREAKFAST MENU

Operation

Operating Tips and Menus

Stack

Product

Biscuits 1 30 Trays Yes Full size

Sausage 6 24 Trays Yes 1/3 size

Folded

Egg

Scrambled

Egg

Round Egg 3 18 Trays Yes 1/3 size

Canadian

Bacon

(maximum)

3 18 Trays Yes 1/3 size

1 6 Trays Yes 1/3 size

3 30

Tray

Amount

(maximum)

(10 rows of 3

overlapped)

Units Liner Tray Type

plastic

plastic

plastic

plastic

plastic

Trays Yes 1/3 size

plastic

Maximum

Hold

***50

60

20

20

20

*60

Muffins 1 20 Trays Yes Full size

plastic

Burritos

mix/rolled

NOTE: All products reflect maximum holding time in the UHC. All products can be heldfor an additional

10 minutes in the transfer bin.

* Time reflects UHC only. Carter Hoffman Cabinet still remains at 90 minutes.

** Burrito mix cannot be held in the Carter Hoffman Cabinet.

*** Testing to increase holding from 50 to 60.

1 1batch

9 burritos

single layer

Batch/Tray No 1/3 size

plastic

33

20

**30/20

Page 38

Maintenance

Cleaning and Preventative Maintenance

DAILY CLEANING

1. At the end of the operating day, turn the unit

to clean mode. Refer to page 13.

2. Remove all plastic and wire trays. Take the

trays to the sink for cleaning.

Wash the trays in a hot McD All PurposeSu-

per Concentrate (APSC) (HCS) solution as

drawn throughthe sink proportioneror mix0.3

fl. oz. McD APSC (HSC) for each gallon of

solution.

Rinse the trays thoroughly under hot water.

Sanitize the trays by immersing in McD Sink

Sanitizer (HCS) solution, (1 pack per 10 gallons of water) or McD Sanitizer (HCS) solution (4 packs per 10 gallons of water), for at

least 1 minute.

Remove from the sanitizer solution and allow

to air dry.

NOTE: DO NOT use MCD Sink Sanitizer

(HCS)to cleantheexterioroftheUHC.

3. Let the unit cool until the display reads SAFE

TOCLN.Use the cabinetcleaningbrush to re-

move any remaining buildup on the slot surface.

NOTE: DO NOT use any other tool other than

the cabinet cleaning brush to clean

the cabinet shelves. Wire brushes,

abrasive pads, or metal scrapers will

permanently damage the surface of

the cabinet slot.

4. With the cabinet cleaning brush, remove all

loose particles by pushing the debris out the

opposite end of the cabinet.

5. Wrap a cloth soaked with McD APSC (HCS)

around the cabinet cleaning brush. Use to

wipe excess grease from the shelves, control

panel and bottom of the unit.

6. Wipe clean all exterior cabinet surfaces witha

clean,sanitizedtowelthathas been soaked in

McD APSC (HCS).

PREVENTATIVE MAINTENANCE

The best preventativemaintenancemeasures are

theproperinstallationof the equipmentandaprogram for routinely cleaning the unit.

If maintenance or repairs are required, contact your

local Blodgett service company at 800-298-1862, a

factory representative or the Blodgett Oven company at 800-331-5842.

Weekly Maintenance

Verifythe calibration of the heatedplates.Usethe

Atkins Temperature sensor along with the following procedure in the morning:

1. Turn on power to the unit.

2. Face the front of the unit. Place your hand on

the left access panel to verify motor operation.

Air should be circulating if the motors are operational. Be sure the louvers are not blocked

with debris. If any blockage exists, use the

brush provided to scrape and remove debris.

3. Allow eachshelf to stabilize at the holding temperature (approximately20minutes). Slide the

sensor into the cavityto the center of theplate.

4. Allow three minutes for the sensor to equilibrate in temperature and proceed to read the

temperature using the calibrated temperature

sensor. If the temperature varies from the set-

point by more than ¦5_F(3_C), contact your

Blodgett service company at 800-298-1862.

WARNING!!

Alwaysdisconnecttheappliancefromthe

power supply before servicing or cleaning.

WARNING!!

DO NOT use any other cleaner than McD

APSC(HCS).Usin goth e rcompounds may

result in damage to control components.

34

Page 39

MCDONALD’S UHC

ORIGINAL EQUIPMENT WARRANTY

(For U.S. and Canada)

The BlodgettOvenCompany warrants to each originalBuyerthatits UniversalHolding Cabinet will be free

from defects in materialand workmanship for two yearsfromthe earlier of thedate of installationor90days

after shipment. Blodgett Oven Company’s obligation under this warranty shall be limited to replacing or

repairing, at its option, any part found to be defective within the specified warranty period.

Anylaborexpense or part failureincurred after the warranty periodwillbe the responsibilityof the enduser.

Blodgett Oven Company agrees to pay any authorized Blodgett service agency within the United States

or Canada for any labor required torepair or replace, at Blodgett Oven Company’s option, any part which

provestobedefectivedue to defects in materialorworkmanshipduring the warrantyperiod.Thiswarranty

includestravel timenotto exceed two(2) hours andmileagenot to exceedonehundred(100) miles, round

trip.

Thiswarrantydoesnotcovera ny defect due to, or resulting from, ordinarywearandtear, handling, abuse,

misuse, improper ventilation, or harsh chemical action, nor shall it extendto any unit from which the s erial

numberhas beenremovedoraltered, ormodificationsmade byunauthorizedservicepersonnelordamage

byflood, fireor other acts ofGod.Adjustmentssuch as calibrations,leveling,or tighteningoffastenersnormally associated with original installation are the responsibility of the dealer or installer and not that of the

Blodgett Oven Company.

Blodgett OvenCompanyshallnotbeliable,directlyor indirectly,under anycircumstances forconsequentialorincidentaldamages, including,butnotlimitedto:(i) anyloss ofbusiness orprofits; and (ii)labor ,material or other charges, claims losses or damages incurred or suffered from, in connection with or in conse quence of the workingupon, alteration,or repairof anysuch defectiveproducts orparts bypersons orfirms

other than Blodgett Oven Company.

THIS WARRANTY AND THEOBLIGATIONSASSUMED BYBLODGETT OVEN COMPANYAREEXCLUSIVE

AND IN LIEU OF ALL OTHER LIABILITIESANDWARRANTIES,EXPRESS OR IMPLIED.BLODGETT OVEN

COMPANYMAKES NO REPRESENTATION OR WARRANTY OFANY KIND, EXPRESSOR IMPLIED, AS TO

MERCHANTABILITY,FITNESSFORAPARTICULARPURPOSE,ORANYOTHERMATTERWITHRESPECT

TO THE PRODUCTS SOLD HEREUNDER, WHETHER USED ALONEORIN COMBINATION WITH OTHER

EQUIPMENT. This warranty gives buyer specific legal rights, and buyer may have other rights which vary

from state to state.

IMPORTANT NOTICE

The end-user purchasing a Universal Holding Cabinet is urged to return the purchaser registration card

included in the owner’s documentpackage. By returning the registrationcard, the end-user can establish

the date of installation in the end-users’premisesforpurposes of determining the warranty period. If such

registrationcardisnotreturned, then thewarranty periodwillbedeemed tohave commenced on the date

of invoice for the particular oven to the dealer or other intermediate customer, w hich may have the effect

of reducing substantially the duration of the warranty period.

BLODGETT OVEN COMPANY

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA

T el ephone (802) 860-3700 FAX: (802) 864-0183

Loading...

Loading...