Page 1

TBG36-CM, TBG36-FM AND TBG36-S

ELECTRIC CONVEYOR GRILL

STARTUP AND CALIBRATION GUIDE

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA T elephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN G0172 Rev A (7/01)

E 2001 --- G.S. Blodgett Corporation

Page 2

Table of C o n t e n t s

Introduction

Blodgett Conveyor Grill Description 2.................................

Specifications and Utility Requirements 3.............................

Controls Identification 4.............................................

Startup Procedures

Platen Alignment 5.................................................

Height Calibration 7................................................

Thermocouple Continuity Test 8.....................................

Assembly for Testing 9.............................................

Complete Functional Testing 10.......................................

Page 3

Introduction

Blodgett Conveyor Grill Description

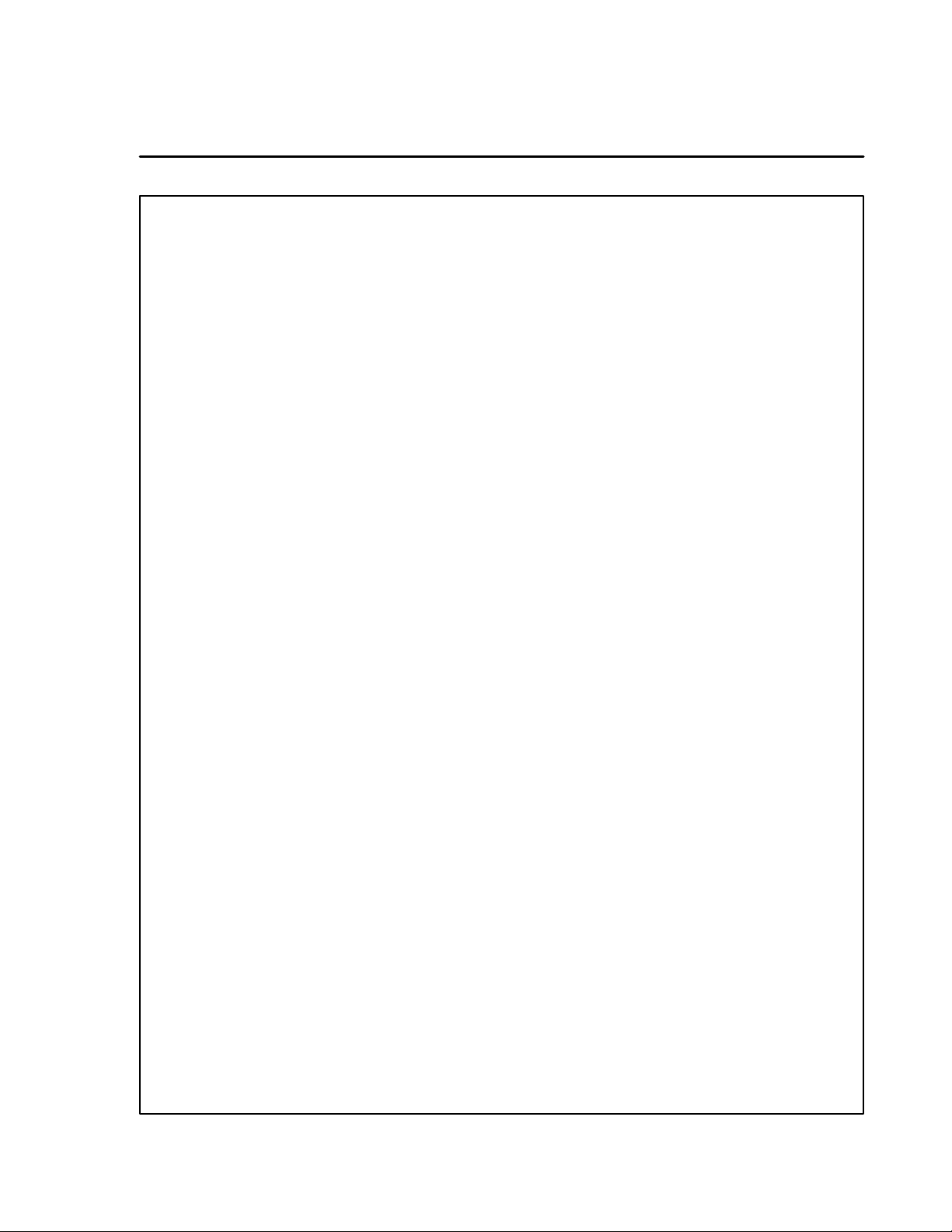

TheBlodgettConveyorGrillisamicroprocessor

controlled conveyorized belt cooking grill built by

Blodgett. The Blodgett Conveyor Grill uses two

Tef lon coated woven fiberglass belts each encircling an electrically heated aluminum cooking

platen. Food placed on the lower belt travels over

a preheat zone where the food is slightly thawed

(in the case of frozen food) and then between the

upper and lower platens where it is cooked on

both sides simultaneously. After cooking, the food

slides into a receiving pan. During the cooking

process, wipers remove excess grease from the

belts and collect it in a grease pan in the bottom

of the unit continuously.

The conveyor cooking technique assures consistent, dependable results. By closely controlling all

the variables --- cooking time, temperature, belt

speed and product contact pressure --- the possibility of improper cooking due to operator error or

inconsistency is greatly minimized. For the most

consistent cooking results use a portion controlled/consistent food product. The microprocessor controls six easy to use programmable menu

selections at the push of a button. It is the responsibility of the person(s) operating the machine to

periodically check that the food is properly

cooked.

TBG36-FM

Floor Model

TBG36-CM

Counter Model

TBG36-S

Stack Capacity

Model

2

Page 4

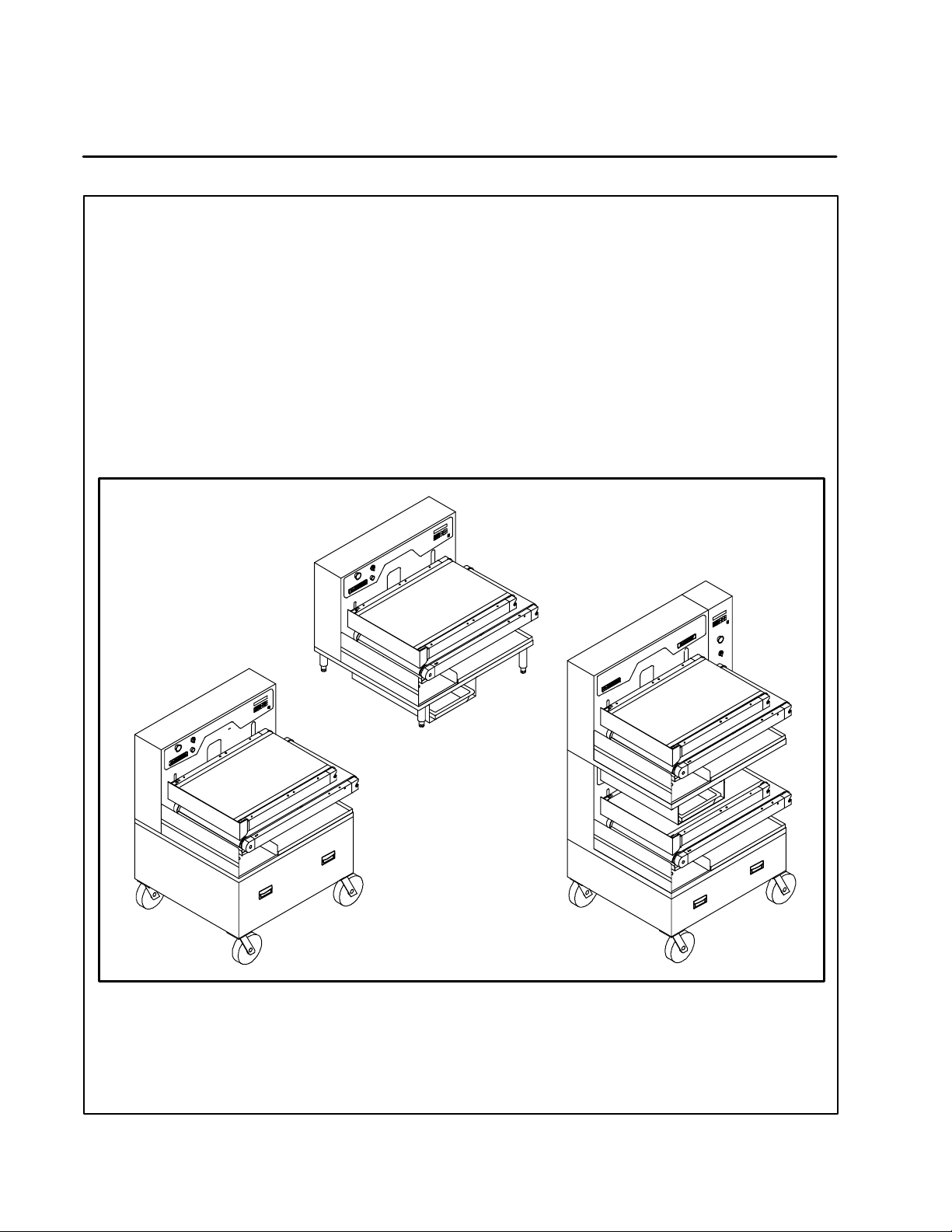

Specifications and Utility Requirements

DIMENSIONS AND WEIGHT SPECIFICATIONS

Introduction

TBG36-CM/AA

Counter Model

Width 35.75” (91 cm) 35.75” (91 cm) 43” (109 cm)

Height 31.5” (80 cm) 49.5” (126 cm) 69” (175 cm)

Depth 33.75” (86 cm)* 33.75” (86 cm)* 33.75” (86 cm)*

Weight

Crated

Uncrated

NOTE: * Includes 1.5” ( 3.81 cm) box on rear cover.

TBG36-CM/AA, TBG36-FM/AA and TBG36-S/AA ELECTRICAL SPECIFICATIONS

Hz Volts Phase Amps

60/50 208 3 50

60/50 220 3 47

60/50 240 3 43

60/50 440 3 24

680 lbs (308 kg)

580 lbs (263 kg)

TBG36-FM/AA

Floor Model

790 lbs (353 kg)

690 lbs (313 kg)

TBG36-S/AA

Stack Capacity Model

1545 lbs (701 kg)

1445 lbs (655 kg)

60/50 480 3 22

60/50 380 3 27

60/50 415 3 25

A 3 phase, 50/60 Hz, 3-wire grounded equipment branch circuit, permanently connected in accordance with applicable articles of ANSI/NFPA 70 (NEC code), is required. The stack capacity unit

requires tw o identical circuits.

Provision is made for 1-1/2” trade size conduit for incoming power. UL Listed reducing seals (donut

washers) will be required if a smaller size fitting is used.

Stack capacity (TBG36-S) model requires (2) power feeds, (1) for each cooking section. The stack

capacity design is not currently UL listed in Canada.

3

Page 5

Introduction

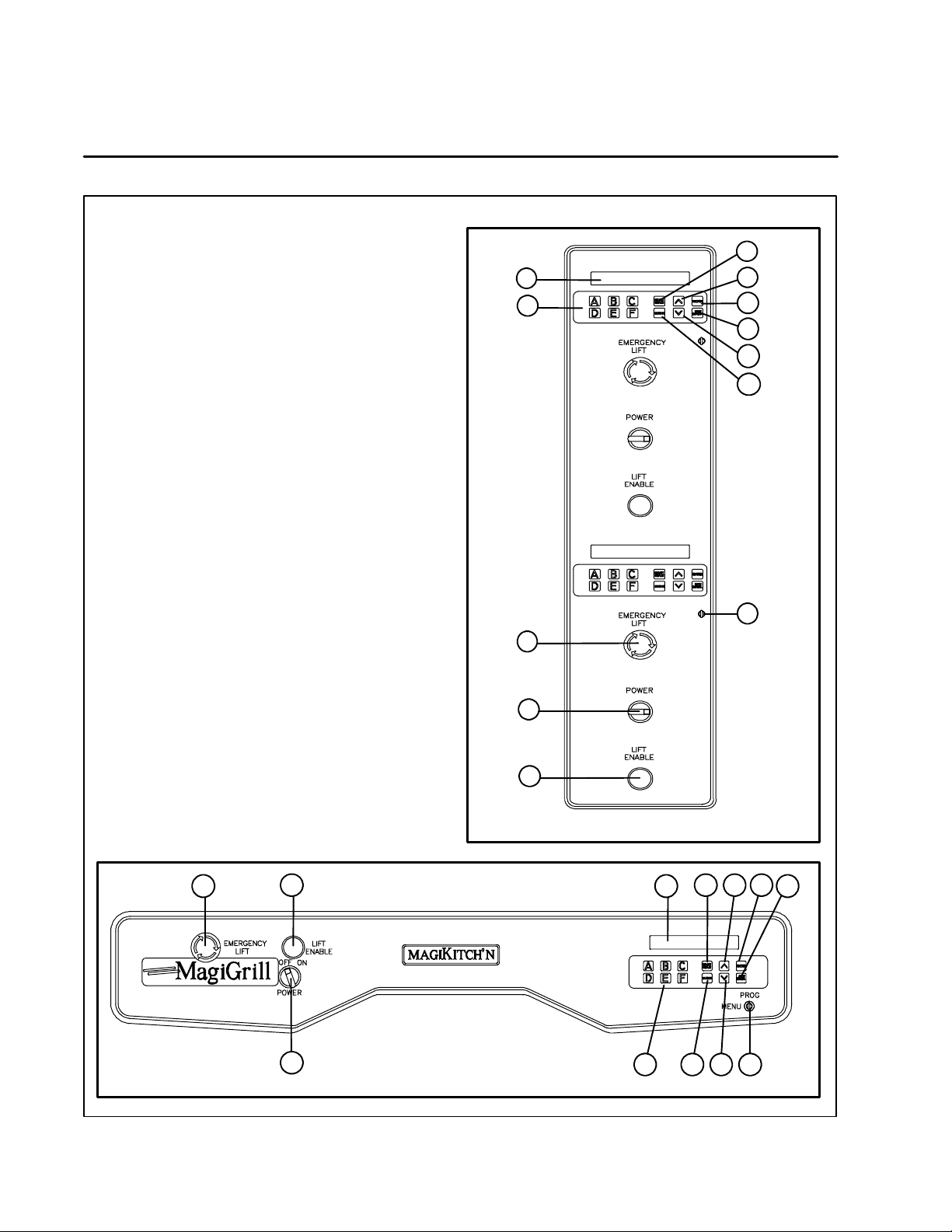

Controls Identification

1. SELECT/DISPLAY --- used to select the dis-

play information.

2. UP and DOWN ARROW --- u s e d i n p r o g r a m -

ming to increase/decrease selection choices.

3. ENTER --- used to enter a menu selection into

the current program.

4. OFF/CANCEL --- cancels the current menu so

another may be entered.

5. KEYSWITCH --- requires a key to change from

MENU mode to PROGRAM mode.

6. CLEAN --- raises the upper platen for thor-

ough cleaning.

7. MENU buttons --- used in the MENU mode to

load programming for products A through F.

Used in PROGRAM mode to select menu designations and product descriptions.

8. DISPLAY --- displays the menu a nd program

mode information selected.

9. EMERGENCY LIFT --- immediately raises the

upper platen to the clean position. Push and

turn to re-set/release button.

10. LIFT ENABLE --- a safety feature requiring the

operator to hold the button in while movingthe

platen to a cooking position after a programming adjustment or menu change.

11. MAIN POWER SWITCH --- An ON-OFF rotary

switch for emergency or convenience use

which controls all electrical power inside the

unit. When power is on, the display lights up.

8

7

9

11

10

1

2

3

4

2

6

5

TBG36-S Control

10

NEED NEW ARTWORK

11

TBG36-CM and TBG36-FM Control

4

1 2 3

89

7

4

526

Page 6

Startup Procedures

Platen Alignment

MECHANICAL INSTALLATION OR SERVICING

OF THIS MACHINE TO BE CARRIED OUT ONLY

BY PERSONNEL WHO HAVE BEEN AUTHORIZED BY BLODGETT TECHNICAL SERVICE.

NON-AUTHORIZED REPAIR OR INSTALLATION

WORK MAY VOID THE WARRANTY COVERAGE.

CALL BLODGETT TECHNICAL SERVICE AT

888-992-6624 TO CONFIRM AUTHORIZATION OF

SERVICE PERSONNEL TO WORK ON THIS UNIT,

TO CHECK THAT THE UNIT’S ELECTRICAL SUPPLY WIRING HAS BEEN COMPLETED BY A

QUALIFIED ELECTRICIAN PRIOR TO INSTALLATION OR TO SCHEDULE ANY INSTALLATION OR

SERVICE WORK ON THIS UNIT.

CHECKING SUPPLY VOLTAGE

Touch the multimeter probes to all three poles of

the definite purpose contactor to be sure all legs

are at the correct voltage and are reasonably

equal. Check each pole to ground the same way.

✍

Enter readings on startup form.

PLATEN ALIGNMENT

NOTE: Be sure the teflon belts are not installed

before performing the platen alignment.

After shipping, the unit will require checking and

may need re-squaring of the platens. Re-calibration of the linear potentiometer may also be necessary.

To check platen alignment

1. Place the unit in the clean mode as follows:

a.) Turnonthemainpowerswitchonthefront

panel.

b.) Check that the red Emergency Lift button,

on the left side of the unit, is released. Release the Emergency Lift button by turningittotherightasindicatedbythearrows on the button face.

c.) Place the keyswitch in the menu mode.

The key should be in the horizontal position. The display briefly flashes, scrolls

through several programming messages

and then reads [MENU?A].

d.) Press the CLEAN button. This raises the

upper platen approximately 4” to t he

clean position.

e.) Remove any remaining packaging from

between the platen.

2. Place the unit in the password mode (PSWD)

as follows:

a.) Turn the keyswitch to the PROGRAM posi-

tion. The key should be in the verticalposition. The display reads [PROG?A].

b.) Press the SELECT/DISPLAY button. The

display reads [PSWD?]

c.) Press the E NTER button and then press

the A button. The display reads [0:SE-

LECT MODEL].

d.) Press ENTER. Use the ARROW keys to

toggle the display to [TBG36”]. Then

pressENTER.Thisoperationisnecessary

to set the belt speed time constant since

thesamecontrollerisusedontwodifferent size models of TBG.

3. Set the calibration height as follows:

a.) Press the UP ARROW key once. The dis-

play reads [1:LIFT CAL].

b.) Press ENTER. The display reads [H=X.XXX],

the current position value.

NOTE: With the platen in the CLEAN posi -

tion this number will be greater

than 1.900.

c.) Adjust this value to .500 using the ARROW

keys while holding in the LIFT ENABLE

button. The last digit of this number may

fluctuate slightly.

5

Page 7

Startup Procedures

Platen Alignment

4. Test the spacing between the platens using

the 1/2” calibration rod (included with the

parts and accessories). If the gap is too small

for the rod to fit anywhere between the platens

adjust as follows:

a.) REMOVE THE ROD.

b.) While holding the LIFT ENABLE button,

use the ARROW keys to adjust the gap until the 1/2” rod just fits at the tightest point.

UP

1/2”

Calibration

Rod

DOWN

Figure 1

5. If the variation in the gap, using the 1/2” rod,

is no greater than ±0.016” (±1/64”) between

the front and the back of the platens or any of

the corners, no further alignment a djustment

is necessary and you may move to the Height

Calibration procedure.

To adjust platen al ignment if necessary

1. If platen alignment is necessary, use two 7/16”

wrenches as shown in Figure 1 to turn the nut/

bolt assemblies on each of the four corners of

the upper and lower platen assemblies until

the platens are aligned.

2. If you are unable to align the platens satisfactorily at the 1/2” setting, it may be necessary

to carry out a rough alignment at a 3” height.

When aligning at the 1/2” setting it is difficult

or impossible to adjust the two rear bolt/nut

pairs on the upper platen, so setting the alignment at this larger gap allows hand access to

all of the nut/bolt pairs.

a.) Use a piece of 3” rigid plastic pipe cut

squarely or other block of material of the

right size. Adjust all the nut/bolt pairs so

they are in the middle of their travel range.

b.) Raise the upper platen to allow the 3”

gauge to fit in and follow the instructions

for t he 1/2” rod.

c.) When the 3” gauge fits uniformly every-

where between the platens, repeat the

calibration with the 1/2” rod to fine tune.

d.) When the 1/2” rod fits uniformly at allspots

between the platens, the alignment process is complete.

NOTE: DO NOT discard the 1/2” rod, it may be

necessary for future servicing of the unit.

✍

Check off platen alignment on startup form

upon completion of procedure.

Tips for platen alignment

D

Make small adjustments (1/2 turns). Re-check

the entire platen for squareness frequently.

D

Always turn the nut and bolt together as a unit

wherepossible(youwillonlybeabletoturnthe

assembly using nut on the inner nut/bolt assemblies).

D

It may be necessary to use two wrenches to

loosen the nut slightly while holding the bolt

head if the nut/bolt assembly is too tight to turn.

D

If the nut/bolt will not turn as an assembly, try replacing the locking nut with a new one.

D

Always make sure the bolt heads and nuts

are both tight against the platen frame mem bers during adjustment and are snug after final alignment.

D

Do not continue to turn a nut/bolt assembly if it

has bottomed out at it’s limit in the frame assembly or you may break the adjusting bolt assembly.

6

Page 8

ADJUSTING PLATEN HEIGHT AND LINEAR

POTENTIOMETER

!

NOTE: If the display still reads .500

016”, then

no linear potentiometer calibration is necessary, and you may move on to checking

the thermocouples.

To adjust the platen height

1. Removetherearcover.

2. Loosen the two locknuts on the potentiometer

shaft using the 5/16” combination wrenches.

3. When you lower the locknuts on the shaft, the

display value goes down. When you raise the

locknuts the display value goes up. When the

display reads .500 ± 010”, hold the bottom nut

still and tighten the top nut against it.

NOTE: Check the display while tightening to

ensure that the value doesn’t change.

✍

Check off Height Calibration on startup form

upon completion of procedure.

Startup Procedures

Height Calibration

Linear

Potentiometer

Plunger Shaft

Plunger Weight

Adjustment Nuts

Moving

Reference Bracket

Figure 2

WARNING!!

Be very careful, you will be working with

metal wrenches in a live voltage area. If

the unit y ou are working on does not have

a protective plastic sheet over the definite

purpose contactor area, you should make

one out of plastic,cardboardor some other non-conductive material.

7

Page 9

Startup Procedures

Thermocouple Continuity Test

1. De-energize the unit.

2. Remove the 18 pin Molex plug from connector

J-4 of the controller board.

3. Check for continuity across each of the pairs

of thermocouples. If a thermocouple is open

(no continuity), check all connections and replace/repair the thermocouple a s necessary.

4. Check each of the pins for a short to ground.

If there is a short to ground, replace or repair

the thermocouple in question.

✍

Check off Thermocouple Continuity Test on

startup form upon completion of procedure.

J Type Thermocouple

(ambient)

Bottom Heat, Oufeed, Red ( --- )

Bottom Heat, Infeed, Red (--- )

Top Heat, Oufeed, Red (--- )

Top Heat, Infeed, Red (---)

Pinout Diagram for the Thermocouple Connector J4

Figure 3

Bottom Heat, Oufeed, White (+)

Bottom Heat, Infeed, White (+)

Top H eat, Oufeed, White (+)

Top H eat, Infeed, White (+)

Figure 4

8

Page 10

Startup Procedures

Assembly for Testing

IDLE ROLLERS

1. Replace the rear covers if they were previously

removed and energize the Blodgett Conveyor

Oven.

2. Slip the idle roller into the slots on the idle roller

adjustment blocks.

Idle Roller

Figure 5

COOKING BELTS

1. Slide the cooking belts over the roller on the

platen deck s. The longer belt goes on the lower platen deck. See Figure 6.

2. After the belts are installed, back the adjusting

bolts out until there is at least a 1/8” gap between the bolt head and the plastic idle roller

bearing block. See Figure 7. The belts will now

have tension on them.

3. Re--check periodically after use to see that

there is still a 1/8” gap, since the belts may

stretch slightly over time.

Upper

Belt

Lower

Belt

3. The idle roller adjustment blocks are spring

loaded. The adjusting bolts must be turned in

all t he way in order to install or remove the

cooking belts on the platen a ssemblies. Use

the Tee Handle Tool supplied for this adjustment.

Figure 6

End view of idle roller

Approximately 1/8” gap

between bolt head and

idle roller tension block

during normal operation

Figure 7

9

Page 11

Startup Procedures

Complete Functional Testing

PROGRAMMING FLOW CHART

Power Switch

ON

Turn

KEYSWITCH

to vertical

position

Display reads

PROG?A

NO

YES

ARROW KEYS

Belt Speed

Press ENTER

display reads

A

Press

to set

PH = BH

UP

T=XX.XX

DOWN

CHANGE SPELLING

Select letter

with

ARROW KEYS

L E T T E R K E Y A --- F

youwishto

Top H e a ter

Press ENTER

display reads

ARROW KEYS

to set temp

Bottom Heater

Press ENTER

display reads

TBG60

ARROW KEYS

to set temp

Press the

program

TH = XXX

Press

BH = XXX

Press

UP

DOWN

TBG36

DOWN

ARROW KEYS

to set time

Height Between

Platens

Change

Food Product

Descriptions

Press ENTER

display reads

H=XX.XX

ARROW KEYS

to set height

Press ENTER

display reads

FOOD PRODUCT

Press

Press

Change

product

spelling?

UP

UP

DOWN

DOWN

YES

CONTINUE

SPELLING

Press

ENTER to lock

in letter

DONE

Press

SELECT DISPLAY

Display reads

SAVE A>F

Press ENTER

display reads

SAVING

Display reads

PROG?A

Finished

programming

Preheater

Press ENTER

display reads

PH = XXX

A

UP

NO

NOTES:

_

All temperature setting must be less than or equal to 450

Platen height (H = X.XXX) must be less than or equal to 1.900” and greater than or

equal to 0.100”

Belt speed (T = X.XXX) must be less than or equal to 4 minutes and great than or equal

to 35 seconds.

F

10

Page 12

START/POWER

switch on

Turn KEY to program

(vertical position)

Press SELECT DISPLAY

Display reads PSWD?::

Unlocks Display

Press ENTER then A

Startup Procedures

Complete Functional Testing

CALIBRATION FLOW CHART

Page 1 of 3

Display reads

0:SELECT MODEL

Press ARROW key

to continue

programming

display reads

1:LIFT CAL

Press ARROW key

to continue

programming

2:CJ CAL

Press ARROW key

to continue

programming

Display reads

3:TEMP CAL

Press

A button

Display

reads

Change linear pot

calibration

Calibrate thermocouple

cold junctions

When finished press

OFF/CANCEL

Calibrate 3 platens

to external reference

Press ENTER

display reads

TBG36 or TBG60

When finished

Press ENTER

Press ENTER

display reads

H=X.XXX

When finished

Press

OFF/CANCEL

Press ENTER

display reads

CJ=XX

Press ENTER

to save

Press ENTER

display reads

SET = 400

Press ARROW

keys to

select

Press ARROW keys

and LIFT ENABLE to

set height. Calibrate with

known dimension

Press ARROW keys

to adjust. Use external

meter for calibration

Press ARROW

keys to set

temperature

Press ARROW key

to continue

programming

A

Press

OFF/CANCEL

Set

TH = SET

BH = SET

PH = SET

with ARROW keys

Set each

temperature by

pressing ENTER

11

Scroll display with

SELECT DISPLAY

compare

temperature with

external meter

Press ENTER

3 platens heat

to temperature

and stabilize

Page 13

Startup Procedures

Complete Functional Testing

CALIBRATION FLOW CHART

A

Change all cooking

menu parameters while

operating

Display reads

4:TEST COOK

Page 2 of 3

Press ENTER

then a menu key

A --- F

Press ENTER and

LIFT ENABLE

release ENTER

(hold LIFT ENABLE

until platen stops moving)

Display reads

T = XX:XX

(counts down until up

to temperature)

belts start moving

Press ARROW key

to continue

programming

Display reads

5:SET TOPHEAT

Press ARROW key

to continue

programming

Display reads

6:SET BOT HEAT

Press ARROW key

to continue

programming

Display reads

7:SET PREHEAT

Change top

platen temperature

(actual platen temp)

Press OFF/CANCEL

Change bottom

platen temperature

(actual platen temp)

Press OFF/CANCEL

Change preheat

platen temperature

(actual platen temp)

Default to old setting

Press OFF/CANCEL

Save changes

press ENTER

Press ENTER

display reads

T = XXX

twice to exit

Press ENTER

display reads

T = XXX

twice to exit

Press ENTER

display reads

T = XXX

When

done

press

OFF/CANCEL

Press OFF/CANCEL

display reads

TH XXX

(current platen temp)

Press OFF/CANCEL

display reads

BH XXX

(current platen temp)

Press OFF/CANCEL

display reads

PH XXX

(current platen temp)

Press SELECT/DISPLAY

Use ARROW keys to select

parameter to change

TH BH PH T H

(change to desired setting)

Press ARROW keys

to adjust temperature

Press ENTER

display reads

T = XXX

(showns platens temp)

Press ARROW keys

to adjust temperature

Press ENTER

display reads

T = XXX

(showns platens temp)

Press ARROW keys

to adjust temperature

Press ARROW key

to continue

programming

Press OFF/CANCEL

twice to exit

Press ENTER

display reads

T = XXX

(showns platens temp)

B

12

Page 14

B

Display reads

8:SET TIME

FOR TECHNICIAN ONLY

Shows main control board is

picking up magnetic speed

control output

Press ENTER

display reads

T = X:XX

(shows a time value)

Startup Procedures

Complete Functional Testing

CALIBRATION FLOW CHART

Page 3 of 3

Press ENTER

display reads

S=XXXXX

(shows fluctuating number)

pick up is working “OK”

Press ARROW key

to continue

programming

Display reads

SET HEIGHT

Press ARROW key

to continue

programming

Display reads

10:STOP ALL

Press ARROW key

to continue

programming

Display reads

11:DEFAULT MENU

Press ARROW key

to continue

programming

Obsolete Function

LIFT CAL does the

same function

Discontinues all

password setting

8through10

Only to change all

menus to preset variables

(current position)

Press

OFF/CANCEL

twice to exit

Press ENTER

display reads

P=X.XXX

When finished

display reads

Press ENTER

to change

Press ENTER

to change

P = X.XXX

Press OFF/CANCEL

twice to exit

Press OFF/CANCEL

display reads

P = X.XXX

(adjust to desired height)

Press ENTER

platen will adjust

Press OFF/

CANCEL

to exit

Scroll through the

following

12:EE WORD

13:EE BYTE

14:SET CHECKSUM

FINISHED

RESTRICTED

DO NOT ACCESS

FOR ENGINEERING

ONLY

13

Page 15

Startup Procedures

Complete Functional Testing

OPERATIONAL FLOW CHART

Turn on

MAIN POWER

SWITCH

(turn knob to right)

A

Release

EMERGENCY LIFT

if set

(turn knob to right)

Turn

KEYSWITCH

to Menu

(horizontal position

display reads

MENU?A

Press (1) desired

menus selection

button A --- F

Press and hold

ENTER and LIFT ENABLE

buttons at the same time

oven beeps

Release ENTER

hold LIFT ENABLE

until upper platen lowers

to cooking height and

stops

Push Red

EMERGENCY LIFT

button

Cooking cycle

complete

T=00:00

Push OFF/CANCEL

display reads

remaining time

T=XX:XX

Push

OFF/CANCEL

Finish

select new program

Display reads

STANDBY

platens preheat and

counts down from 15 min.

T=XX:XX

Roller and belts start

moving

Blodgett Conveyor Oven

ready to cook

(display scrolls cooking

description)

A

14

Page 16

Startup Procedures

Complete Functional Testing

Checking the cooking consistency

1. Press OFF/CANCEL twice.

2. Press A and ENTER.

3. Place the 9 fresh bread slices on the infeed of

the lower platen (3 rows and 3 columns). See

Figure 8.

4. All nine slices should emerge evenly done on

all sides with no variations in appearance. A

variation in appearance between the tops and

bottoms of the slices indicates a possible

problem with temperature control or height

calibration. A variation between columns or

rows indicates a possible platen alignment

problem.

✍

Report on cooking performance on startup

form upon completion of test.

Back of Unit

BELT TRAVEL

Exiting the functional testing

1. Press OFF/CANCEL.

2. Wait for the cooking cycle to time out.

3. Press CLEAN.

4. Turntheredpowerswitchtotheoffposition,

and disconnect the power.

Installation checklist

Complete and return the startup form to Blodgett

Technical Service.

OUTFEED

Back Row

Middle Row

INFEED

Front Row

Lower Belt Test Cooking Pattern for Sliced Bread

Figure 8

15

Loading...

Loading...