Page 1

TBG36-CM, TBG36-FM AND TBG36-S

ELECTRIC CONVEYOR GRILL

INSTALLATION -- OPERATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA T elephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN G0171 Rev A (7/01)

E 2001 --- G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERA TION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this g rill. Adherence to these

procedures and instructions will result in satisfactory cooking results and long, trouble free service . Please read this manual carefully

and retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

Page 3

THE REPUTATION YOU CAN COUNT ON

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We’ve set the industry’s quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, full-size, half-size, countertop and deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Page 4

Your Service Agency’s Address:

Model:

Serial Number:

Your grill was installed by:

Your grill’s installation was checked by:

Page 5

Table of C o n t e n t s

Introduction

Blodgett Conveyor Grill Description 2.................................

Specifications and Utility Requirements 3.............................

Installation

Delivery and Inspection 4...........................................

Agency Approvals 6................................................

Grill Ventilation, Clearances and Installation Requirements 7.............

Blodgett Conveyor Grill Assembly 8..................................

Upper Grease Wiper Box 8.......................................

Lower Grease Wiper Box 8.......................................

Drain Pan 9....................................................

Optional Outfeed Slide and Receiving pan 9........................

Optional Infeed Slide 9..........................................

Grease Pan and Crumb Tray 10....................................

Operation

Control Panel 11....................................................

Program Mode 12...................................................

Menu Mode 14.....................................................

Menu Development 15...............................................

Grilling Tips 16.....................................................

Maintenance

Cleaning 18........................................................

Cleaning the Grill 18..............................................

Cleaning the Cooking Belts 19.....................................

Troubleshooting 20..................................................

Page 6

Introduction

Blodgett Conveyor Grill Description

TheBlodgettConveyorGrillisamicroprocessor

controlled conveyorized belt cooking grill built by

Blodgett. The Blodgett Conveyor Grill uses two

Tef lon coated woven fiberglass belts each encircling an electrically heated aluminum cooking

platen. Food placed on the lower belt travels over

a preheat zone where the food is slightly thawed

(in the case of frozen food) and then between the

upper and lower platens where it is cooked on

both sides simultaneously. After cooking, the food

slides into a receiving pan. During the cooking

process, wipers remove excess grease from the

belts and collect it in a grease pan or bucket in the

bottom of the unit continuously.

The conveyor cooking technique assures consistent, dependable results. By closely controlling all

the variables --- cooking time, temperature, belt

speed and product contact pressure --- the possibility of improper cooking due to operator error or

inconsistency is greatly minimized. For the most

consistent cooking results use a portion con trolled/consistent food product. The microprocessor controls six easy to use programmable menu

selections at the push of a button. It is the responsibility of the person(s) operating the unit to periodically check that the food is properly cooked.

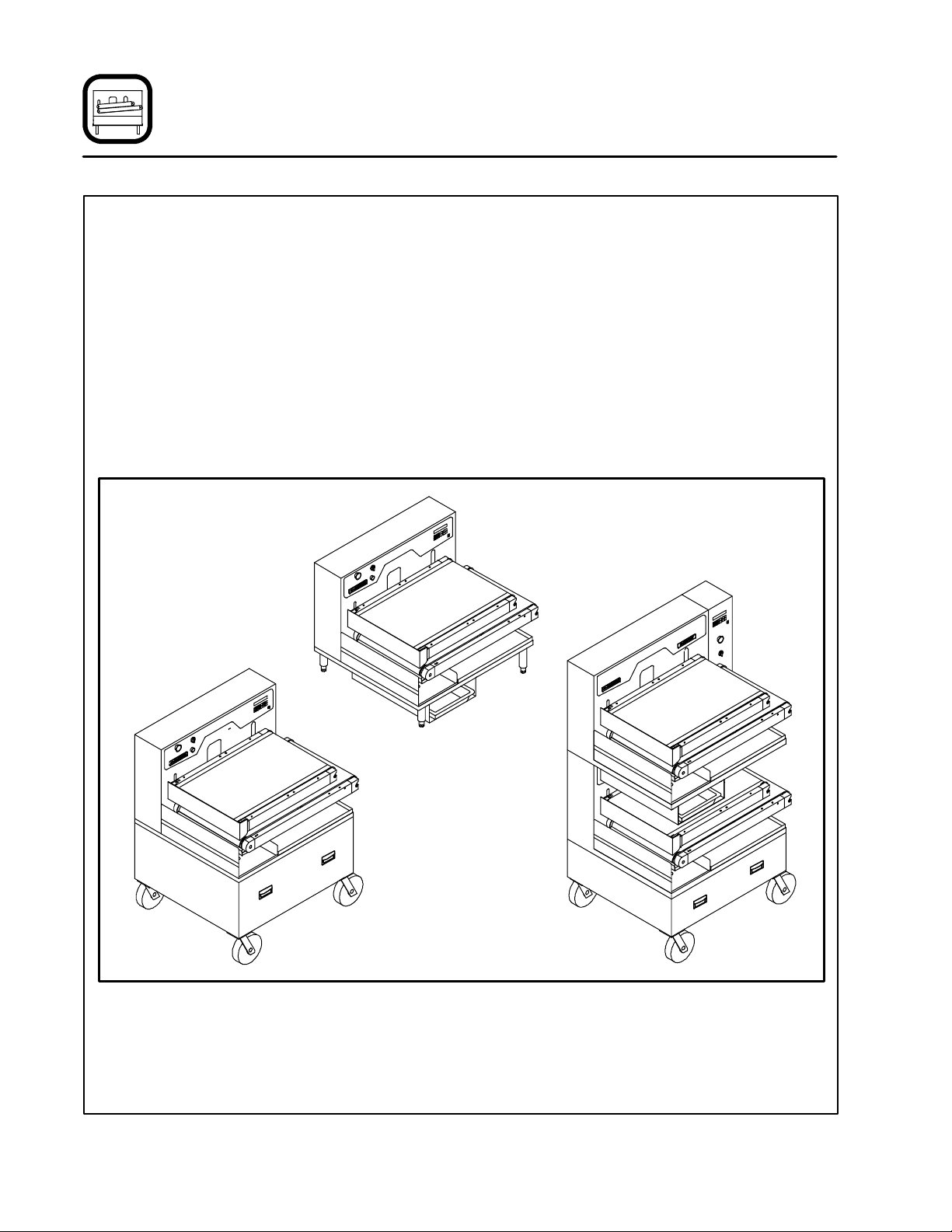

TBG36-FM

Floor Model

TBG36-CM

Counter Model

TBG36-S

Stack Capacity

Model

Figure 1

2

Page 7

Introduction

Specifications and Utility Requirements

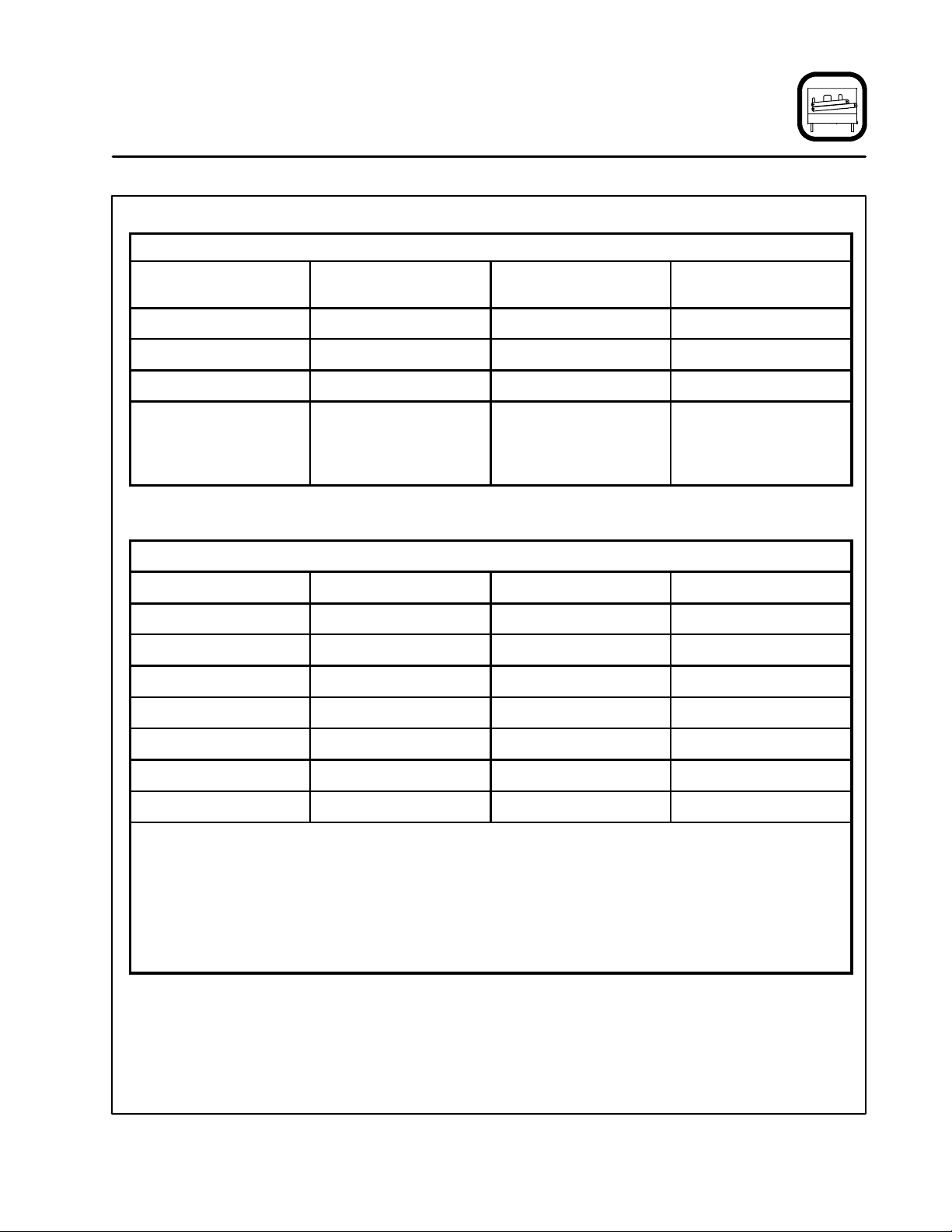

DIMENSIONS AND WEIGHT SPECIFICATIONS

TBG36-CM/AA

Counter Model

Width 35.75” (91 cm) 35.75” (91 cm) 43” (109 cm)

Height 31.5” (80 cm) 49.5” (126 cm) 69” (175 cm)

Depth 33.75” (86 cm)* 33.75” (86 cm)* 33.75” (86 cm)*

Weight

Crated

Uncrated

NOTE: * Includes 1.5” ( 3.81 cm) box on rear cover.

TBG36-CM/AA, TBG36-FM/AA and TBG36-S/AA ELECTRICAL SPECIFICATIONS

Hz Volts Phase Amps

60/50 208 3 50

60/50 220 3 47

60/50 240 3 43

60/50 440 3 24

680 lbs (308 kg)

580 lbs (263 kg)

TBG36-FM/AA

Floor Model

790 lbs (353 kg)

690 lbs (313 kg)

TBG36-S/AA

Stackable Model

1545 lbs (701 kg)

1445 lbs (655 kg)

60/50 480 3 22

60/50 380 3 27

60/50 415 3 25

A 3 phase, 50/60 Hz, 3-wire grounded equipment branch circuit, permanently connected in accordance with applicable articles of ANSI/NFPA 70 (NEC code), is required. The stack capacity unit

requires tw o identical circuits.

Provision is made for 1-1/2” trade size conduit for incoming power. UL Listed reducing seals (donut

washers) will be required if a smaller size fitting is used.

Stack capacity (TBG36-S) model requires (2) power feeds, (1) for each cooking section. The stack

capacity design is not currently UL listed in Canada.

3

Page 8

Installation

Delivery and Inspection

Upon delivery of your Blodgett Conveyor Grill:

Inspect the shipping container for external damage. Any evidence of damage should be noted on

the delivery receipt and the bill of lading, which

must be signed by the driver. Uncrate the Blodgett

Conveyor Grill a nd check for internal damage.

Inspect the unit immediately upon receipt. Do not

sign off on shipment until the packaging has been

removed and the unit has been inspected for damage. Blodgett cannot assume responsibil i ty for loss

or damage suffered in transit. The carrier assumed

full responsibility for delivery in good order when the

shipment was accepted. We are, however , prepared

to assist you in filing a claim if necessary.

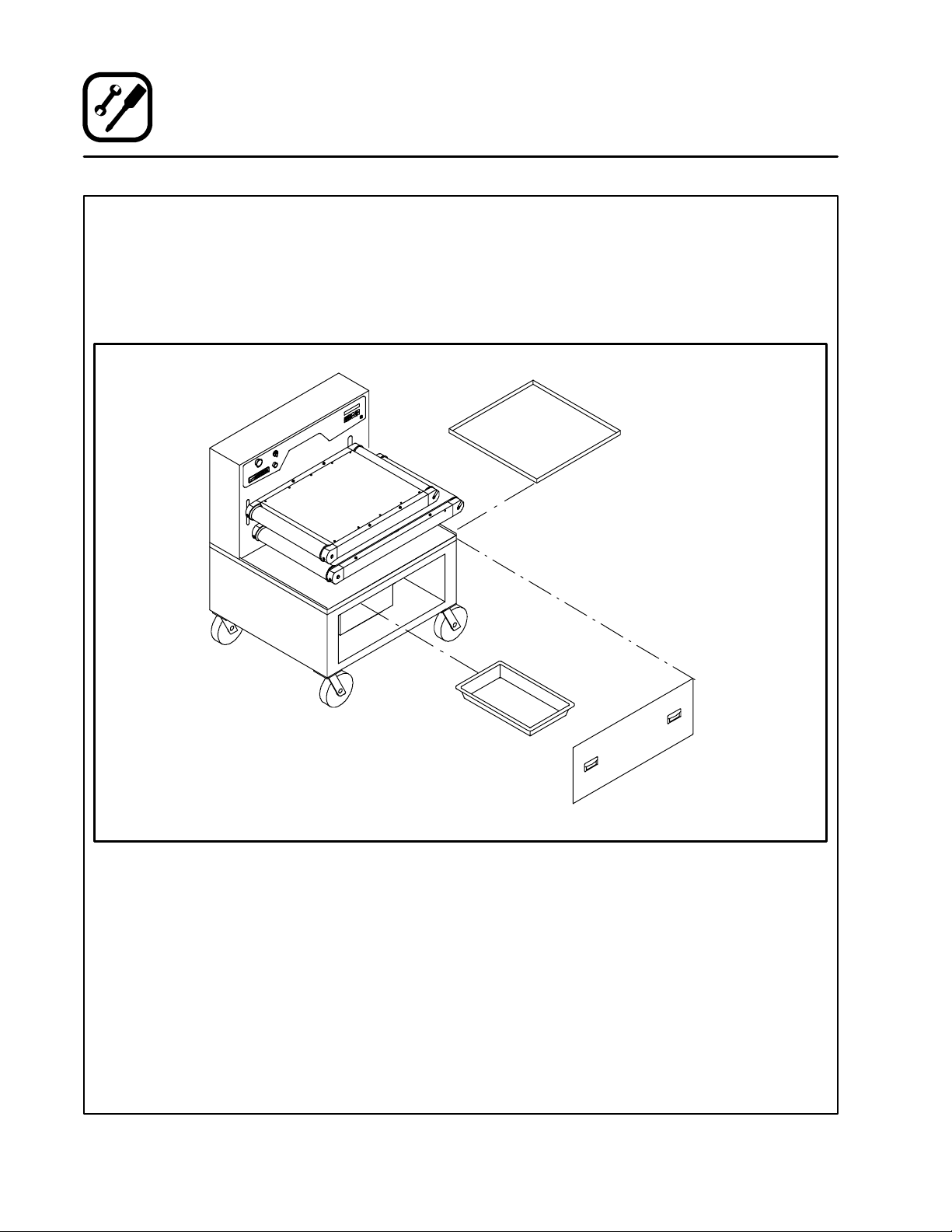

ITEM

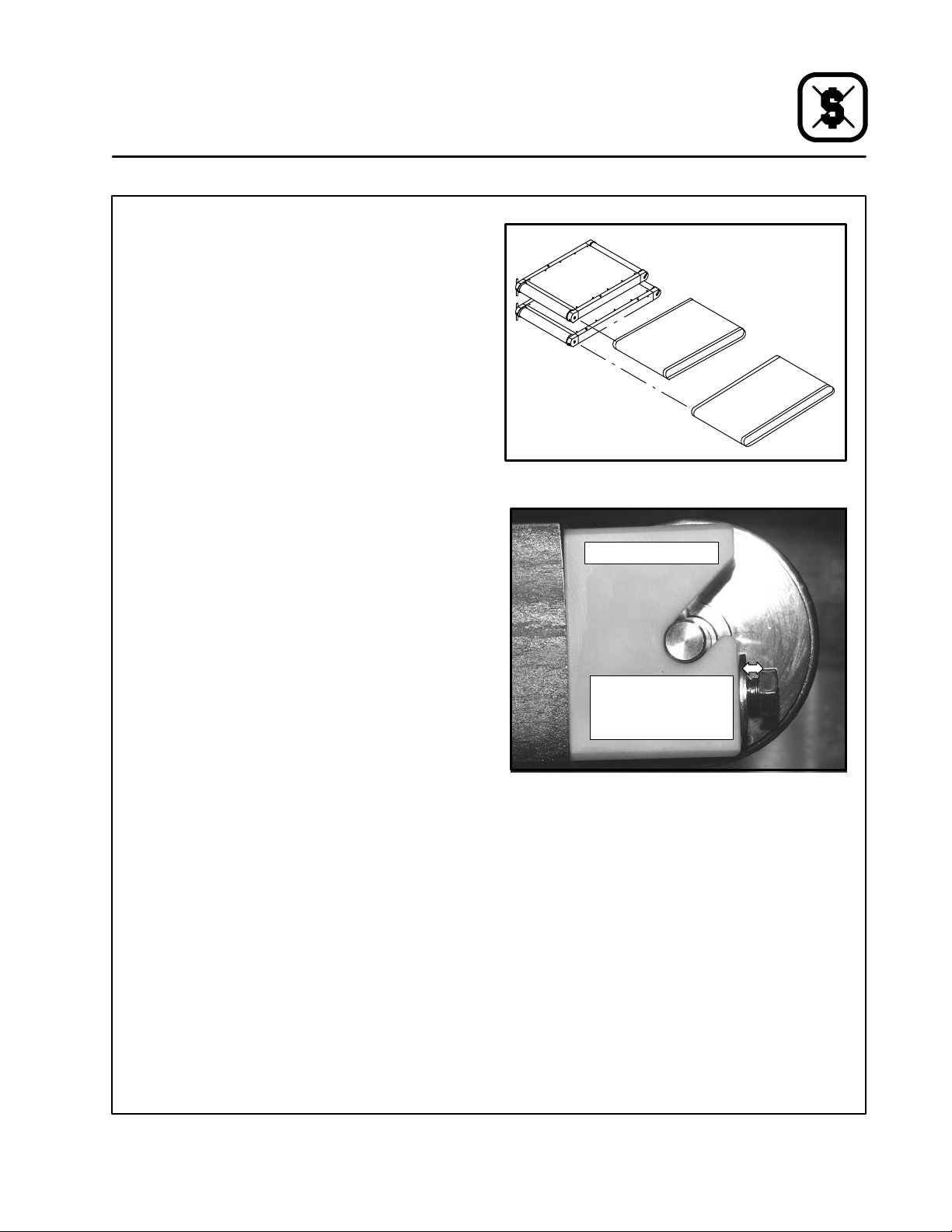

1 Blodgett Conveyor Grill, Model TBG36 (TBG36-FM shown) 1

2 Idle Rollers 2

3 UpperConveyorBelt 2

4 LowerConveyorBelt 2

5 Drain Pan 1

DESCRIPTION QTY.

Unpacking the unit:

Open all parts boxes carefully. DO NOT USE A

BLADECUTTERORKNIFE!One of the boxes

contains the woven glass Teflon impregnated

cooking belts which can easily be cut and damaged or destroyed. The warranty will not cover accidental cutting of belts during unpacking.

Remove all shipping bands and loose packaging

material from the unit. Remove all loose parts from

theupperandlowerplatenassemblies.Donot

discard the shipping crate or materials until installation is complete and unit is operating.

Check that all of the following parts have been received. Contact Blodgett immediately if any of the

components are damaged or missing.

6 Product Receiving Pan 1

7 Grease Pan / Bucket 1

8 Crumb Tray 1

9 Upper Wiper Box 1

10 Lower Wiper Box 1

11 Controller Programming Keys 2

12 Owner’s Manual 1

13 Door Panel (FM and S models only) 1

14 9/16” Tee Handle Wrench 1

15 1/2” Calibration Rod 1

Items not

shown

Wiper Blades 2

Bacon Scraper Blade 1

4

Page 9

Installation

Delivery and Inspection

TBG36-S has two platen sets for cooking on a single base with casters (quantities of all parts are doubled for TB G36 -S models)

TBG36 -FM floor model shown, TBG36-CM counter model has legs in place of the base with casters,

Figure 2

5

Page 10

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D

the installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experienced in such w ork, familiar with all precautions

required, and have complied with all requirements

of state, national and/or local authorities having jurisdiction.

U.S. and Canadian installations

The unit must be wired in compliance with ANSI/

NFPA 70 NEC (the National Electrical Code) and

all local codes and ordinances required where the

Blodgett Conveyor Grill is installed.

General export installations

Installation must conform with Local and National

codes and installation standards. Local installation codes a nd/or requirements may vary. If you

have any questions regarding the proper installation and/or operation of your Blodgett Conveyor

Grill, please contact your local distributor. If you do

not have a local distributor, please call Blodgett

Technical Service at 0011-888-992-6624.

117F LISTED

COMMERCIAL COOKING APPLIANCE

TBG36-S not currently listed in Canada

6

Page 11

Installation

Grill Ventilation, Clearances and Installation Requirements

VENTILATION

While the Blodgett Conveyor Grill requires less

ventilation than a conventional griddle, a power

vented hood of at least 525 CFM capacity is required for proper performance and safety of one

TBG36.

CLEARANCES

The unit is designed for 0” clearance on t he sides

and back, however, it is wise to allow more clearance for ease of operation, cleaning and maintenance.

INSTALLATION REQUIREMENTS

A UNIT INSTALLATION AND CALIBRATION SERVICE IS PROVIDED FOR AND IS REQUIRED BEFORE USING THE BLODGETT CONVEYOR

GRILL FOR THE FIRST TIME. UNIT INSTALLATION AND CALIBRATION IS TO BE CARRIED

OUT ONLY BY SERVICE AGENTS OR PERSONNEL AUTHORIZED BY BLODGETT TECHNICAL

SERVICE TO PERFORM THIS WORK. IF ONE

HAS NOT YET BEEN PERFORMED ON YOUR

UNIT, CONTACT BLODGETT TECHNICAL SUPPORT AT 888-992-6624 TO ARRANGE FOR AN

ASAP SERVICE VISIT.

WARNING!!

DO NOT use the unit befo re this service

has been performed. Use of the unit prior

to this or installation or servicing by other

than Blodgett Technical Service authorized service agencies or personnel may

void warranty coverage.

7

Page 12

Installation

Blodgett Conveyor Grill Assembly

UPPER GREASE WIPER BOX

1. Before installing the upper grease wiper box,

slidetherubberwiperbladeintoit’sslotinthe

wiper box. Slide the long edge in first. See

Figure 3.

Wiper

Blade

Figure 3

2. Snap the four spring fingers of the upper wiper

box over the screws in the end frame. See

Figure 4. The long fingers go on top.

NOTE: The wiper box opens towards the

back to allow the grease to flow to the

rear of the unit.

LOWER GREASE WIPER BOX

1. Before installing the lower wiper box, insert

the rubber wiper blades into their slots in the

wiper box. See Figure 5.

Figure 5

2. Install the lower wiper box by hanging the slots

in the mounting brackets onto the screw

heads on top of the deck. See Figure 6. The

wiper box rides against the belt by its own

slung weight.

Figure 4

Figure 6

8

Page 13

Installation

Blodgett Conveyor Grill Assembly

DRAIN PAN

1. Place the drain pan into position at the bottom

left of the unit .

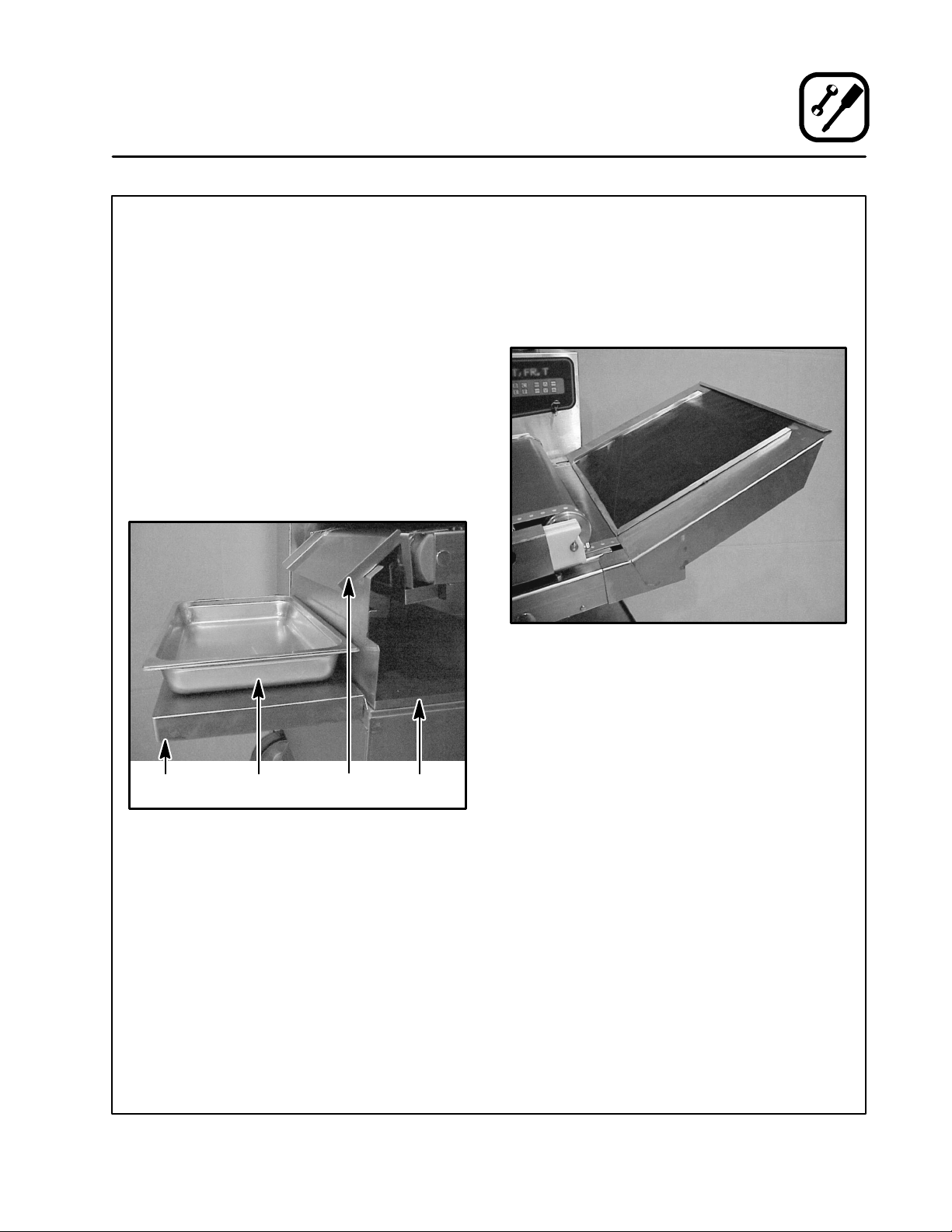

OPTIONAL OUTFEED SLIDE AND RECEIVING

PAN

1. Slide the outfeed slide onto the left hand edge

of the drain pan and push it to the back. Be

sure the slot on the baffle fits tightly onto the

side of the drain pan.

2. Attach the removable shelf to the left side of

thegrillbaseandseatitfirmlyontothebase

rim.

3. Place a product receiving pan up to 4-1/2”

deep on the shelf and under the lower edge of

the slide to collect the finished foods.

OPTIONAL INFEED SLIDE

The infeed slide option allows food product to be

loaded on a slide to feed by itself so other work

may be done while cooking.

1. Slip the infeed slide onto the lower platen rails

at the infeed end. Push until it seats fully.

Figure 8

Removable

Shelf

Receiving

Pan

Figure 7

Outfeed

Slide

Drain Pan

9

Page 14

Installation

Blodgett Conveyor Grill Assembly

GREASE PAN AND CRUMB TRAY

1. Place the grease pan (grease bucket for floor

models) in its compartment under the front of

the unit, making sure it is located beneath the

downspout tube of the drain trough.

2. Slide the crumb tray under the lower platen on

the right side of the unit.

3. Install the door panel on the front of the lower

compartment (TBG36-FM and TBG36-S only).

Crumb Tray

Figure 9

Grease Pan

Door Panel

10

Page 15

Operation

Control Panel

THE INFORMATION CONT AINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIF IED

OPERA TIN G PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE CAREFULLY READ THE INFORMATIO N CONTAINED IN

THIS MANUAL, ARE FAMIL IAR WITH THE FUNCTIONS OF THE OVEN AND/OR HAVE HAD PREVIOUS EXPERIENCE WITH THE OPERATION OF

THE EQUIPMENT DESCRIBED. ADHERENCE TO

THE PROCEDURES RECOMMENDED HEREIN

WILL ASSURE THE ACHIEVEMENT OF OPTIMUM

PERFORMANCE AND LONG, TROUBLE-FREE

SERVICE.

Please take the time to read the following operating instructions. They are the key to the successful

operation of your Blodgett Conveyor Grill.

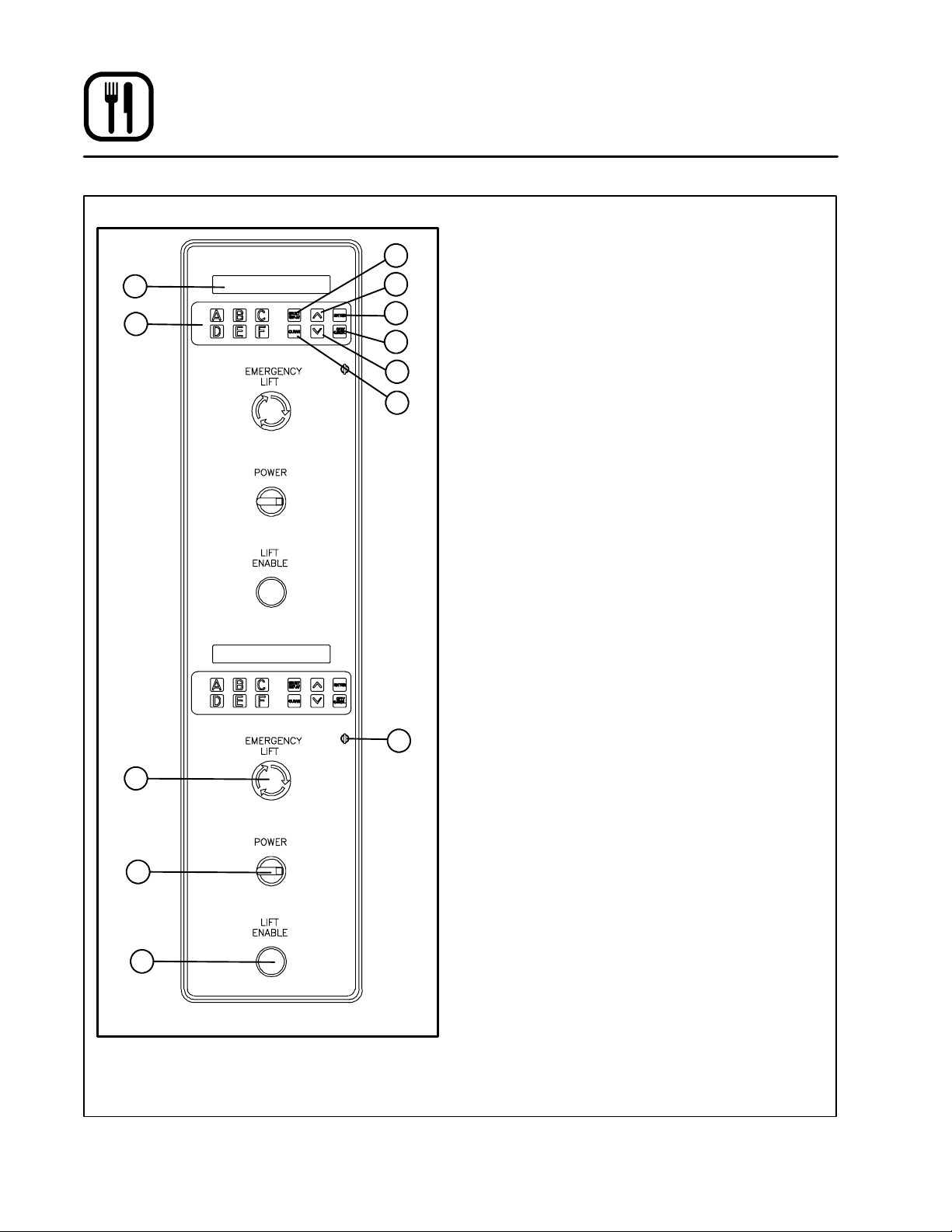

CONTROL DESCRIPTIONS

NOTE: For TBG36-CM and TBG36-FM, refer to

Figure 10. For TBG36-S, refer to Figure 11.

1. SELECT/DISPLAY --- used to select the dis -

play information.

2. UP and DOWN ARROW --- u s e d i n p r o g r a m -

ming to increase/decrease selection choices.

3. ENTER --- used to enter a menu selection into

the current program.

4. OFF/CANCEL --- cancels the current menu so

another may be entered.

5. KEYSWITCH --- requires a k ey to change from

MENU mode to PROGRAM mode.

6. CLEAN --- raises the upper platen for thor-

ough cleaning.

7. MENU buttons --- used in the MENU mode to

load programming for products A through F.

Used in PROGRAM mode to select menu designations and product descriptions.

8. DISPLAY --- displays the menu and program

mode information selected.

9. EMERGENCY LIFT --- immediately raises the

upper platen to the clean position. Push and

turn to reset/release button.

10. LIFT ENABLE --- a safety feature requiring the

operator to hold the button in while movingthe

platen to a cooking position after a programming adjustment or menu change.

11. MAIN POWER SWITCH --- An ON-OFF rotary

switch for emergency or convenience use

which controls all electrical power inside the

unit. When power is on, the display lights up.

10

11

NEED NEW ARTWORK

TBG36-CM and TBG36-FM Control

Figure 10

11

89

1 2 3

5267

4

Page 16

Operation

Program Mode

8

7

9

PROGRAMMING

1

2

3

4

2

6

5

PROGRAM mode is used to define six cooking

programs A through F. It can only be entered by

use of the keyswitch. To use the PROGRAM mode

follow the steps below:

Select Desired Menu to program:

1. Turn on the unit MAIN POWER SWITCH (11).

2. Turn the KEYSWITCH (5) to the PROGRAM

position. The display reads [PROG?A].

3. Press the letter of the desired MENU KEY (7).

4. Press ENTER (3) to select the desired menu.

NOTE: If the display reads [TBG36?], the

model size has not been selected.

Press ENTER (3) to select the 36”

model size.

Setting the Cooking Temperature

NOTE: The maximum cook temperature is 450

The minimum cook temperature is 70

1. The display reads [TH=xxx], indicating that the

top heater (TH=) is set for xxx_F. U s e t h e A R ROW (2) keys to raise or lower the temperature

setting for the upper platen.

2. Press ENTER (3) to choose that temperature

and enter it into the program.

3. The display now reads [BH=xxx], indicating that

the bottom heater (BH=) is set for xxx_F. U s e

the ARROW (2) keys to raise or lower the temperature setting for the upper platen.

4. Press ENTER (3) to choose that temperature

and enter it into the program.

Setting the Cook Time

_

_

F.

F.

11

10

TBG36-S Control

Figure 11

NOTE: The maximum cook time is 10:00 minutes.

The minimum cook time is 0:30 seconds.

NOTE: This is the actual cooking time (the time

spent between the upper and lower platens) not the total time to travel the length

of the lower conveyor belt.

1. The display now reads [T=xx.xx]. This indicates the current cooking time is xx.xx minutes/seconds. Use the ARROW (2) keys to enter the desired cooking time.

2. Press ENTER (3) to enter the new cooking

time into the program.

12

Page 17

Operation

Program Mode

Setting the Platen Height

NOTE: The maximum platen height is 1.900”. The

minimum platen height is 0.100”.

1. The display now reads [H=x.xxx]. This indi-

cates the current distance between platens in

inches and thousandths. Use the ARROW (2)

keys to change this value.

2. Press ENTER (3) to enter the new platen

height into the program.

Setting the Product Description

If you do not want to change the product description:

1. Press SELECT DISPLAY (1) followed by ENTER to save the program.

To change the product description:

1. If the display now reads [CHICKEN],thisisthe

product description for the menu you are now

modifying. The text is changed one letter at a

time using the ARROW (2) keys for the letter

that is blinking.

2. Press ENTER (3) to select t hat character and

move onto the next letter. Move from one char acter to the next using the ENTER (3) key until

you reach the end.

3. You will need to blank out any unwanted/extra

letters before saving. The blank space is located a few characters after the z.

4. Press SELECT DISPLAY (1) t o select and store

the whole word (product description).

Saving the New Menu Programming

1. When your menu programming session is

complete, press ENTER (3) to save the new

program. The display reads [SAVING].

PROGRAMMING TIPS

D

Once a setting has been entered, you cannot go

back to change it during the current programming session. If you make a mistake, finish programming any desired variables and save the

program. Go back into the programming mode

for that menu, cycle through the variables with

the ENTER (3) button and correct the desired

entry. Press ENTER (3) to save the program

again.

D

Do not enter a platen height of less than 0.100”

or grea ter than 1.900”.

D

Do not enter cooking t imes (belt speeds) of less

than 30 seconds or more than 10 minutes.

13

Page 18

Operation

Menu Mode

Menu mode allows the user to select one of the six

programmed product settings. To operate the unit

in the MENU mode simply follow the steps below:

Select Desired Menu to Run

1. Turn on the MAIN POWER SWITCH (11).

2. T urn the KEYSWITCH (5) to the MENU position.

3. The display reads [MENU?A].

4. Press the letter of the desired MENU (7) key.

5. Press ENTER (3) to select the desired menu

and press and hold the LIFT ENABLE (10) button until the display shows a countdown or the

menu description starts to scroll and the belts

begin t o turn.

Preheat Standby

1. Once the unit has reached the programmed

height, the display will count down from 15:00

while the unit is preheating to the programmed

temperature.

2. When the platens have reached the programmed temperature the menu description

starts to scroll and the belts begin to turn.

Cooking Process

1. The unit is now ready to begin cooking and the

product may be placed on the lower belt. Be

sure the product receiving pan, grease pan and

wiper boxes are in place.

2. During the cooking process the display will

show one of the following scrolling lists:

D

Tem p e r a t u r e [ TH/BH]

D

Height

D

Cook Time

D

Product Description

Press SELECT/DISPLAY (1) to toggle through

the list.

WARNING!!

During operation, check the contents of

the grease pan regularly. Do not allow the

pan to become so full that it is awkward to

handle and empty safely.

End Selected Menu

1. Press OFF/CANCEL(4) to exit from the current

menu.

2. The display reads [T=xx:xx] (programmed

cook time). The belts will continue to move until one cook cycle has finished. To exit before

the count down or cycle is complete, press

OFF/CANCEL (4) again.

Emergency Lift

1. Pushing the Emergency Lift (9) button will immediately raise the upper platen deck to the

clean position. To release the Emergency Lift

button, turn it to the right as indicated by the

arrows on the button.

NOTE: If the upper platen moves down, then

right back up when it attempts to posi tion in MENU mode, this button is

probably pushed and locked in. This

button must be released before the

platen height can be adjusted.

14

Page 19

Operation

Menu Development

Blodgett recommends setting the bottom platen

temperature 25_ to 50_F lower than the top platen

setting. This results in an even browning top and

bottom. The bottom of the food items have direct

contact with the belt throughout the baking process. The top of the food product may not have

continuous contact with the belt.

When creating menu settings, the items tested

should reach an internal temperature 25_Fhigher

than the minimum recommended temperature. This

allows for possible temperature variations under ex-

PROBLEM

SYMPTOM: Acceptable internal temperature but unacceptable results

S

Overdone tops

S

Underdone tops

S

Overdone bottoms

S

Underdone bottoms

SYMPTOM Unacceptable internal temperature

treme conditions such as colder than normal holding temperatures, improper product spacing on the

belt or a continuous load production.

It is important to check the internal product temperatures on the front, middle and back rows. These internal temperatures must be monitored continuously to ensure that safety guidelines are met.

Use the troubleshooting guide below to adjust your

menu settings if necessary.

SUGGESTED REMEDY

S

Lower the top platen temperature or raise the

platen height.

S

Raise the top platen temperature or lower the

platen height.

S

Lower the bottom platen temperature.

S

Raise the bottom platen temperature.

S

Internal temperature too low

S

Internal temperature too high

SYMPTOM: Uneven browning

S

Need more browning on top of food product

S

Need less browning on top of food product

S

Need a darker bottom

S

Need a lighter bottom

S

Raise t he temperature or increase the cook time.

S

Lowerthetemperatureordecreasethecooktime.

S

Lower the platen height or increase the

temperatureorcooktime.

S

Raise the platen height or decrease the

temperatureorcooktime.

S

Increase the bottom platen temperature.

S

Decrease bottom platen temperature.

15

Page 20

Operation

Grilling Tips

The following menus have been developed for various products a nd will serve as a starting point for your

menu development.

Portion To p

Product

MEATS (settings will vary greatly depending on product thickness)

Hamburger,

frozen

Hamburger,

fresh

Steak, fresh 6oz 450_F 425_F 0.73” 4:00 2 1:30

Pork Rib Cutlets,

boneless,

cooked

Minute Steak,

frozen

Bacon Strips,

fresh

10:1

(1.6 oz)

6:1

(2.7 oz)

4:1

(4 oz)

4:1

(4 oz)

6:1

(2.7 oz)

2 450_F 425_F 0.24” 1:00 3 440 Adjust height to obtain

sliced 450_F 425_F 0.15” 0:45 8-10 1840-

Heat

450_F

450_F

450_F

450_F 425_F 0.48” 1:40 3 700 For lighter burgers, lower

450_F 425_F 0.50” 1:45 3 530

Bottom

Heat

425_F

425_F

425_F

Height Time

0.35”

0.43”

0.54”

1:35

2:20

3:30

Qty

row

3

3

3

Qty

hr

850

500

330

2300

Comments

For lighter burgers, lower

temp. and extend time

For lighter burgers, lower

temp. and extend time

52 seconds per ounce

temp. and extend time

desired browning

Adjust height to obtain

desired browning

Bacon Strips,

frozen

POULTRY (settings will vary greatly depending on product thickness)

Chicken Breast,

fresh boneless

Chicken Patties,

cooked,

breaded, frozen

Chicken Fingers,

cooked,

breaded

sliced 450_F 425_F 1.15” 0:55 8-10 1500-

5oz 450_F 425_F 0.75” 4:00 3 200 G o ld e n b r o w n ---

2.5 oz 450_F 425_F 0.70” 5:30 3 210 G o ld e n b r o w n ---

450_F 425_F 0.58” 3:50 8 810 G o l d e n b r ow n ---

16

1800

Adjust height to obtain

desired browning

48 seconds per oz

48 seconds per oz

48 seconds per oz

Page 21

Operation

Grilling Tips

Portion To p

Product

BREAKFAST ITEMS

Toas t ,

Commercial

bread slices

Waffles, frozen 450_F 425_F 0.55” 1:05 3 860 For lighter waffles, lower

French Toast,

fresh

Sausage,

cooked frozen

patty

OTHER

Grilled Cheese 450_F 425_F 1:00” 1:15 3 750 It is not necessary to

Onions, sliced 450_F 425_F 0.25” 0:55 Lightly spray with oil

Quesadillas,

cheese

sliced 450_F 425_F 0.50” 0:40 3 1420

Heat

450_F 425_F 0.50” 0:50 3 1130 Buttersidedown

450_F 425_F 0.38” 1:45 3 530

450_F 350_F 0.68” 2:00 2 260

Bottom

Heat

Height Time

Qty

row

Qty

hr

temp. and extend time

butter the bread

before grilling

Comments

Fish Sticks,

frozen breaded

450_F 425_F 0.55” 3:15 10 960 Adjust height to obtain

desired crispness

17

Page 22

Cleaning

Maintenance

CLEANING THE GRILL

WARNING!!

The Blodgett Conveyor Grill WAS NOT designed for nor intended to be washed down

by water hose! Electric shock and/or severe injury to the operator and nearby personnel could result from allowing water to

run over an energized unit!

Water may also damage the internal mechanisms in the unit which may require major

service work to restore operation again.

Preparing the unit for cleaning

Place the unit in the clean position a nd shut it off

to cool down before cleaning.

1. Press the CLEAN key on the control panel. The

upper platen raises to the cleaning position.

2. Shut off the power to the unit at the disconnect

switch or circuit breaker panel.

Cleaning the unit

Cleaning intervals will vary depending upon the

types a nd quantities of foods prepared on the

Blodgett Conveyor Grill. As a rule, most users will

put the unit in the clean position and shut it down

at the end of the shift or workday. In the morning,

or when the unit is just warm clean as follows:

1. Remove the wiper boxes, drain pan, product

receiving pan, grease pan, crumb tray, outfeed slide and infeed slide (if applicable).

Wash these components using detergent and

hot w ater.

2. The platen assemblies, drive rollers and other

surfaces of the unit shouldbe washed by hand

with detergent and water, then rinsed.

3. The cooking belt should be cleaned in place

daily and removed for weekly cleaning. See

page 19 for belt cleaning information.

4. When grease build-up occurs, the unit surfaces may be sprayed with a non-caustic degreasing cleaner.

Reassemble after cleaning

NOTE: Refer to the Blodgett Conveyor Grill As -

sembly section of this manual for assembly instructions.

1. Reinstall all removed components.

2. Retension the belts when removed.

18

Page 23

CLEANING THE COOKING BELTS

To ensure longer life from the Teflon release material on your cooking belts, please follow these directions:

D

Never fold or crease the cooking belts; always

handle them carefully.

D

Neverallowsharpobjectsorabrasivestocome

in contact with either side of a cooking belt.

D

Machine w ashing is not recommended.

Daily Cleaning

1. DO NOT remove the belts. With the belts and

drive rollers turning, wash the cooking surface

of the belts w ith soap or detergent and warm

waterorwhitevinegar.

2. Rinse thoroughly.

3. If desired, use isopropyl alcohol afterward to

kill bacteria.

Weekly Cleaning

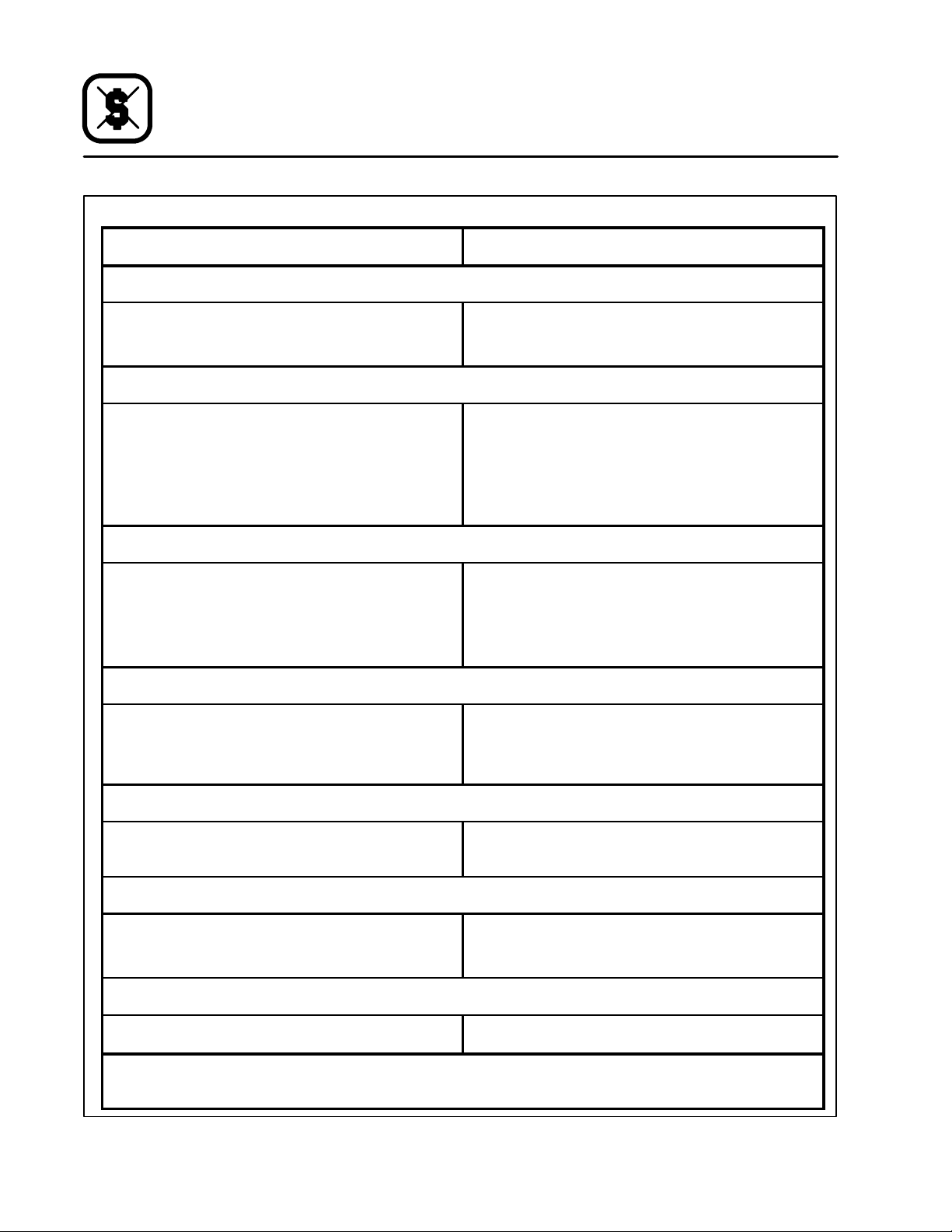

1. Use a wrench to tighten the adjusting bolts on

the end of the idle roller tension blocks. This

will release the tension on the belts so they

can be removed. See Figure 13.

2. Slide the cooking belts from the platens.

3. Wipe down both sides with warm water or

white vinegar and rinse thoroughly.

4. If desired, use isopropyl alcohol afterward to

kill bacteria.

5. Allow the belts to dry.

6. Reinstall the belts as follows:

a.) Slide the cooking belts over the rollers on

the platen decks. The longer belt goes on

the lower platen deck. See Figure 12.

b.) After the belts are installed, back the ad-

justing bolts out until there is at least a 1/8”

gap between the bolt head and the plastic

idle roller bearing block. See Figure 13.

The belts will now have tension on them.

c.) Re-check periodically after use to see that

there is still a 1/8” gap, since the belts may

stretch slightly over time.

Maintenance

Cleaning

Upper

Belt

Lower

Belt

Figure 12

End view of idle roller

Approximately 1/8” gap

between bolt head and

idle roller tension block

during normal operation

Figure 13

19

Page 24

Maintenance

Troubleshooting

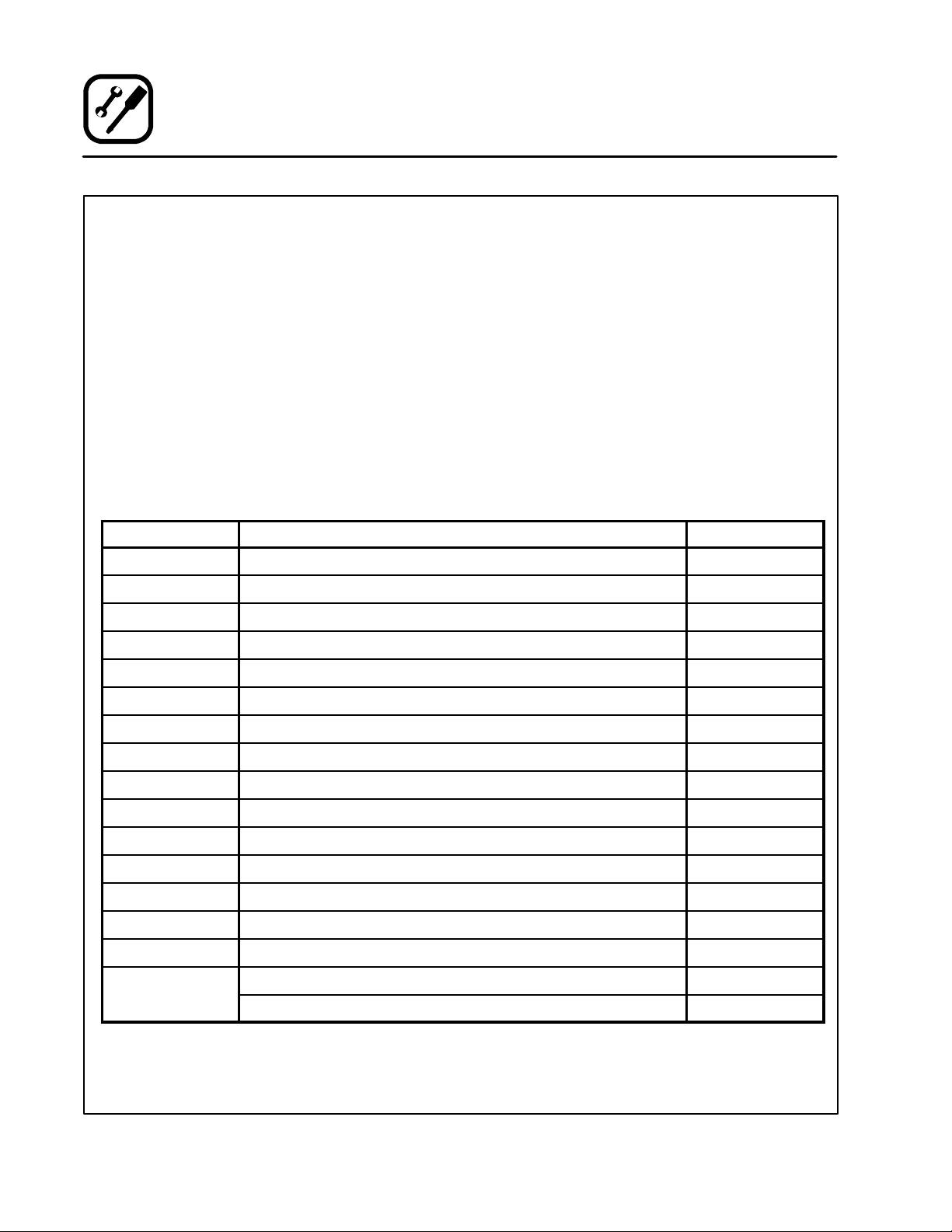

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Food items not moving through the belts

S

Food piles up the the infeed end

S

Food gets stuck betw een the belts

SYMPTOM: Belt not moving

S

The unit has not reached the preheat

temperature

S

Menu key not selected

S

Belt tension not adjusted properly

SYMPTOM: The platen height will not adjust

S

The emergency lift button is engaged.

S

The platen height is not adjusted.

S

The unit is in the program mode.

S

Check the variations in food product t hickness

S

Raise/adjust the height setting

S

Wait for the unit to reach the preheat temperature

S

Select the desired MENU key followed by the

ENTER k ey.

S

Loose or tighten the belt tensioners

S

Release the EMERGENCY button.

S

Hold the LIFT ENABLE to adjust the platen height.

S

Change to Menu mode. Select the desired

MENU k ey followed by the ENTER key.

SYMPTOM: Inconsistent cooking results

S

Inconsistent product thickness

S

Inconsistent final product temperature

SYMPTOM: Lightening under load

S

Product load too heavy

SYMPTOM: Front/middle/back rows bake differently

S

Uneven platen settings

S

Contact or element failure inside a platen

SYMPTOM: Cook time is not correct

S

The control is set for a 60” grill.

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that All

repairs and/or adjustmentsbe done by your local Blodgett service agency and not by the owner/operator. Blodgett cannotassume

responsibility for damage as a result of servicing done by unqualified personnel.

S

Maintain food item thickness

S

Maintain portion control and pre-cooked

temperatures.

S

Stagger food items. The products can be close

but not touching.

S

*

S

*

S

Change the default to 36”. Refer to page 12.

20

Loading...

Loading...