Page 1

TBG36-CM, TBG36-FM AND TBG36-S

ELECTRIC CONVEYOR GRILL

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA T elephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN G0173 Rev A (7/01)

E 2001 --- MagiKitch’n Incorporated

Page 2

TABLE OF CONTENTS

1. INTRODUCTION

Unit Description 1 --- 1..................................................................

Specifications 1 --- 2....................................................................

Required Service Tools 1 --- 3............................................................

Electrical Safety 1 --- 3..................................................................

Wiring Diagrams 1 --- 4..................................................................

2. UNIT CONTROLS

Controls Identification 2 --- 1.............................................................

Programming Flow Chart 2---2..........................................................

Operation Flow Chart 2 --- 3.............................................................

Calibration Flow Chart 2 --- 4.............................................................

Controller Removal and Replacement 2---7...............................................

Switch Replacement 2 --- 9..............................................................

3. TEMPERATURE CONTROL

Description 3 --- 1......................................................................

Wiring Diagram 3 --- 2...................................................................

Troubleshooting 3 --- 3..................................................................

Thermostats 3 --- 3..................................................................

Overtemperature Safety Thermostat Circuit 3---4.......................................

Thermocouple Diagnostic Procedure 3---5................................................

Platen Contactor Diagnostic Procedure 3---7..............................................

4. PLATENS

Description 4 --- 1......................................................................

Platen Diagnostic Procedure 4---2.......................................................

Platen Removal and Replacement 4---3..................................................

Platen Removal 4 --- 3...............................................................

Platen Replacement 4 --- 5...........................................................

Platen Alignment 4 --- 6.................................................................

5. POSITION CONTROL

Description 5 --- 1......................................................................

Troubleshooting 5 --- 2..................................................................

Wiring Diagram 5 --- 3...................................................................

Lift Motor 5 --- 4........................................................................

Diagnostic Procedure 5---4..........................................................

Setting Lift Motor Limit Switches 5---4................................................

Removing and Replacing the Lift Motor 5---5..........................................

Linear Potentiometer 5 --- 6..............................................................

i

Page 3

TABLE OF CONTENTS

6. MISCELLANEOUS COMPONENTS

Hourmeter 6 --- 1.......................................................................

Drive Motor 6 --- 2......................................................................

Description 6 --- 2...................................................................

Drive Train Troubleshooting Guide 6--- 3..............................................

Drive Motor Removal and Replacement 6--- 4..........................................

Drive Motor Components Wiring Diagram 6--- 6........................................

Speed Sensor Removal and Replacement 6---7...........................................

Drive Roller and Bearing Block Removal and Replacement 6--- 8............................

Idle Roller T ension Blocks 6-- -10..........................................................

Wipers 6 --- 1 1..........................................................................

7. MAINTENANCE

Service Checks 7 --- 1...................................................................

ii

Page 4

CHAPTER 1

INTRODUCTION

Page 5

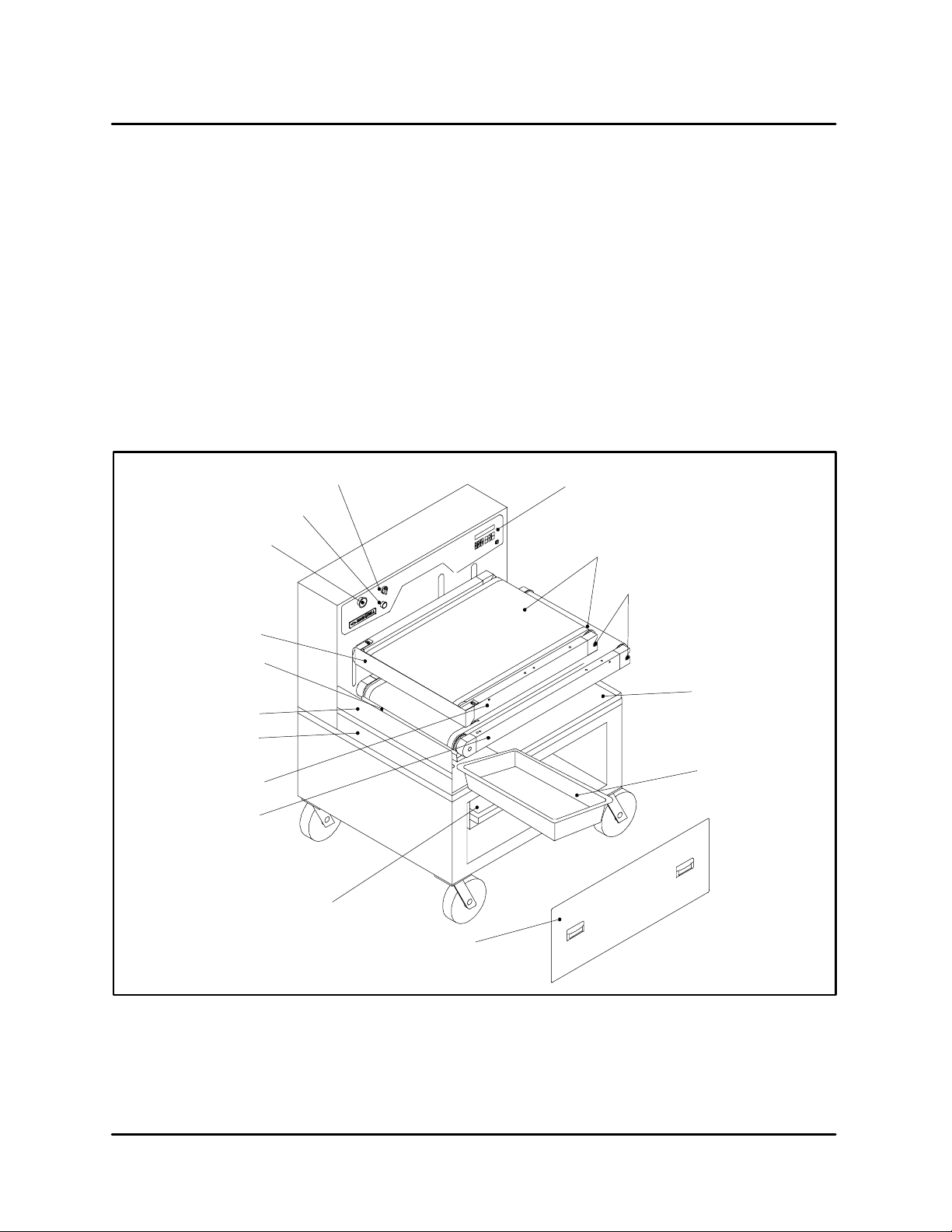

BLODGETT CONVEYOR GRILL

UNIT DESCRIPTION

The Blodgett Conveyor Grill is a microprocessor

controlled conveyorized belt cooking grill built by

Blodgett. The Blodgett Conveyor Grill uses two Teflon coated woven fiberglass belts each encircling

an electrically heated aluminum cooking platen.

Food placed on the lower belt travels over a preheat zone where the product is s lightly thaw ed (in

the case of frozen food) and then between the upper and lower platens where it is cooked on both

sides simultaneously. After cooking, the food falls

into a receiving pan. During the cooking process,

wipers remove excess grease from the belts and

collect it in a grease pa n or bucket in the bottom of

the unit.

Main Power Switch

Lift Enable Button

Emergency Lift Button

Upper Wiper Assembly

The conveyor cooking technique assures consistent, dependable results. By precisely controlling

all the variables --- cooking time, temperature, belt

speed and product contact pressure --- the possibility of improper cooking due to operator error or

inconsistency is greatly minimized. However, it is

still the responsibility of the person(s) operating the

machine to periodicallycheck that the food is properly cooked. The microprocessor controller provides six easy to use programmable menu selections at the push of a button.

Control Panel

Upper&LowerConveyorBelts

Idle Roller

Lower Wiper Assembly

Baffle & Pan Guide

Drain Trough

Upper Platen Deck

Lower Platen Deck

Crumb Tray

Food Receiving Pan

Grease Pan

Door Panel

FIGURE 1

1 --- 1

Page 6

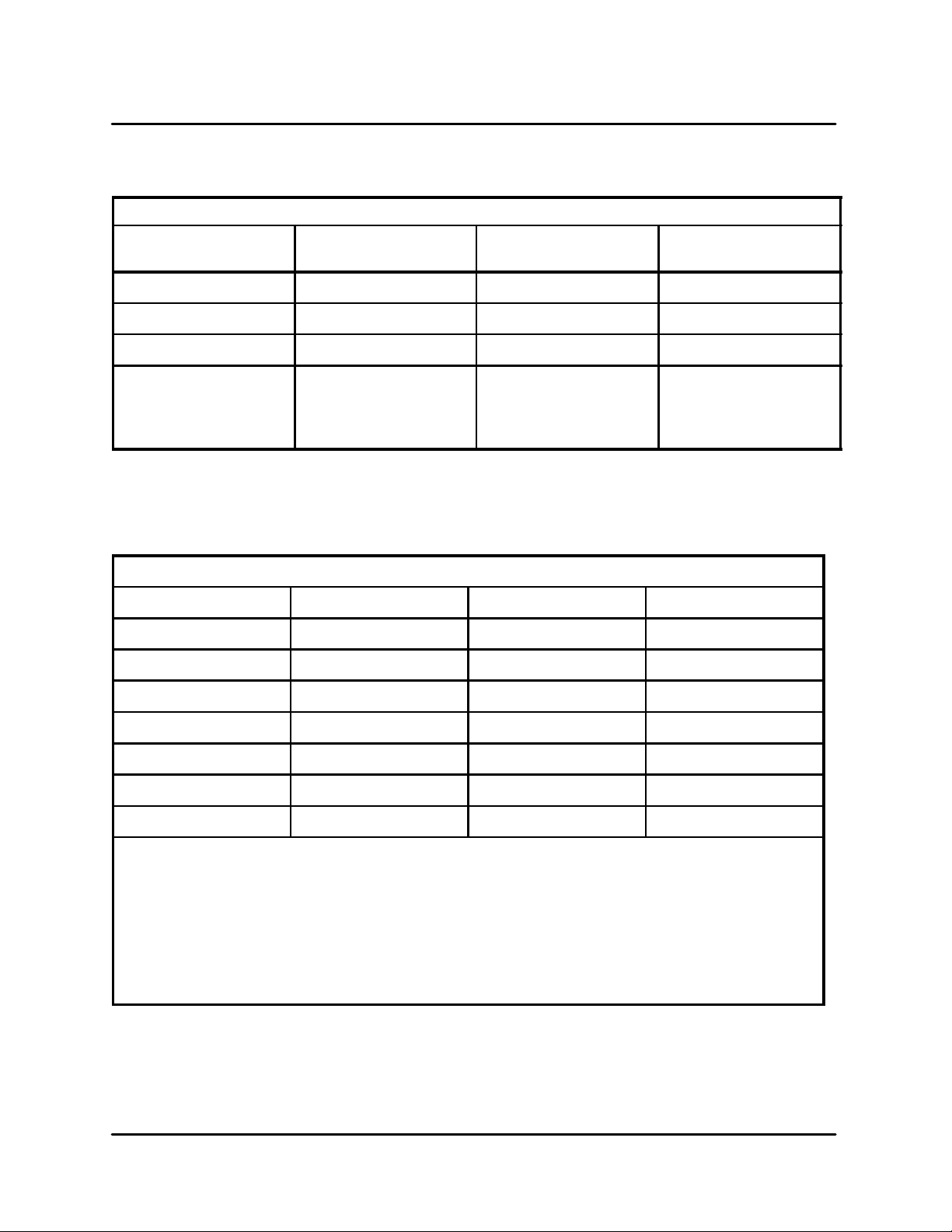

SPECIFICATIONS

INTRODUCTION

DIMENSIONS AND WEIGHT SPECIFICATIONS

TBG36-CM/AA

Counter Model

Width 35.75” (91 cm) 35.75” (91 cm) 43” (109 cm)

Height 31.5” (80 cm) 49.5” (126 cm) 69” (175 cm)

Depth 33.75” (86 cm)* 33.75” (86 cm)* 33.75” (86 cm)*

Weight

Crated

Uncrated

NOTE: * Includes 1.5” ( 3.81 cm) box on rear cover.

TBG36-CM/AA, TBG36-FM and TBG36-S/AA ELECTRICAL SPECIFICATIONS

Hz Vol ts Phase Amps

60/50 208 3 50

60/50 220 3 47

680 lbs (308 kg)

580 lbs (263 kg)

TABLE 1

TBG36-FM/AA

Floor Model

790 lbs (353 kg)

690 lbs (313 kg)

TBG36-S/AA

Stackable Model

1545 lbs (701 kg)

1445 lbs (655 kg)

60/50 240 3 43

60/50 440 3 24

60/50 480 3 22

60/50 380 3 27

60/50 415 3 25

A 3 phase, 50/60 Hz, 3-wire grounded equipment branch circuit, permanently connected in accordance with applicable articles of ANSI/NFPA 70 (NEC code), is required. The stack capacity unit

requires tw o identical circuits.

Provision is made for 1-1/2” trade size conduit for incoming power. UL Listed reducing seals (donut washers) will be required if a smaller size fitting is used. See the Electrical Installation Manual,

P/N 31-12-11343 for details.

Stack capacity (TBG36-S) model requires (2) power feeds, (1) for each cooking section. The stack

capacity design is not currently UL listed in Canada.

TABLE 2

1 --- 2

Page 7

BLODGETT CONVEYOR GRILL

REQUIRED SERVICE TOOLS

In addition to tools normally used when servicing

appliances, you may need the following tools:

These tools can be ordered individually from Blodgett Technical Service (888-992-6624 phone;

802-860-3784 fax) using the Blodgett part numbers shown or a complete kit of these items is available from Blodgett under part number G0235, TBG

Service Tools Kit. In either case, the tools will be

supplied at cost with no mark-up on a one-time ba-

QTY

1 Digital Multimeter Amprobe AM-1260 or similar;

1 Clamp-on ammeter Amprobe model RS-3 or similar;

1 24 VDC lift motor power supply (optional) Blodgett P/N G0239

1 Molex Mini fit crimping tool Molex 11-01-0197-P;

1 Molex Mini fit pin extraction tool Molex 11-03-0044;

DESCRIPTION P/N

sis. Replacement tools will be billed at the usual

dealer/agency price.

A Service Parts Replacement Kit (part number

G0236) is also available. This kit contains pa rt s that

normally require replacement and a few critical

components. This kit will be billed at full price with

replacements made for warranty usage when accompanied by complete documentation.

Blodgett P/N G0237

Blodgett P/N G0238

Blodgett P/N G0240

Blodgett P/N G0241

20 Molex Mini fit Jr. female pins Molex 39-00-0039;

Blodgett P/N G0242

1 Anti-seize compound, food grade, can McMaster 1404K11 or similar;

Blodgett P/N G0243

TABLE 3

ELECTRICAL SAFETY

De-energizing the unit

For servicing purposes throughout this manual,

two distinct operations are referred to frequently

and their meaning must be understood clearly for

your safety. One is the use of the Main Power

Switch and the other is “disconnect supplypower”.

The main power switch turns the Blodgett Conveyor Grill on and off for all user purposes. When working inside the machine, however, the main power

feed wires and over-temperature protection ther-

mostat wiring are very much alive and remain so

whetherthemainpowerswitchisonoroff.

To de-energize the machine completely, the

supply power must be disconnected at the circuit breaker or (fused) disconnect switch labeled for this unit.

NOTE: Stack capacity units have separate power

supplies. Be sure the power has been

turned off for the appropriate unit.

1 --- 3

Page 8

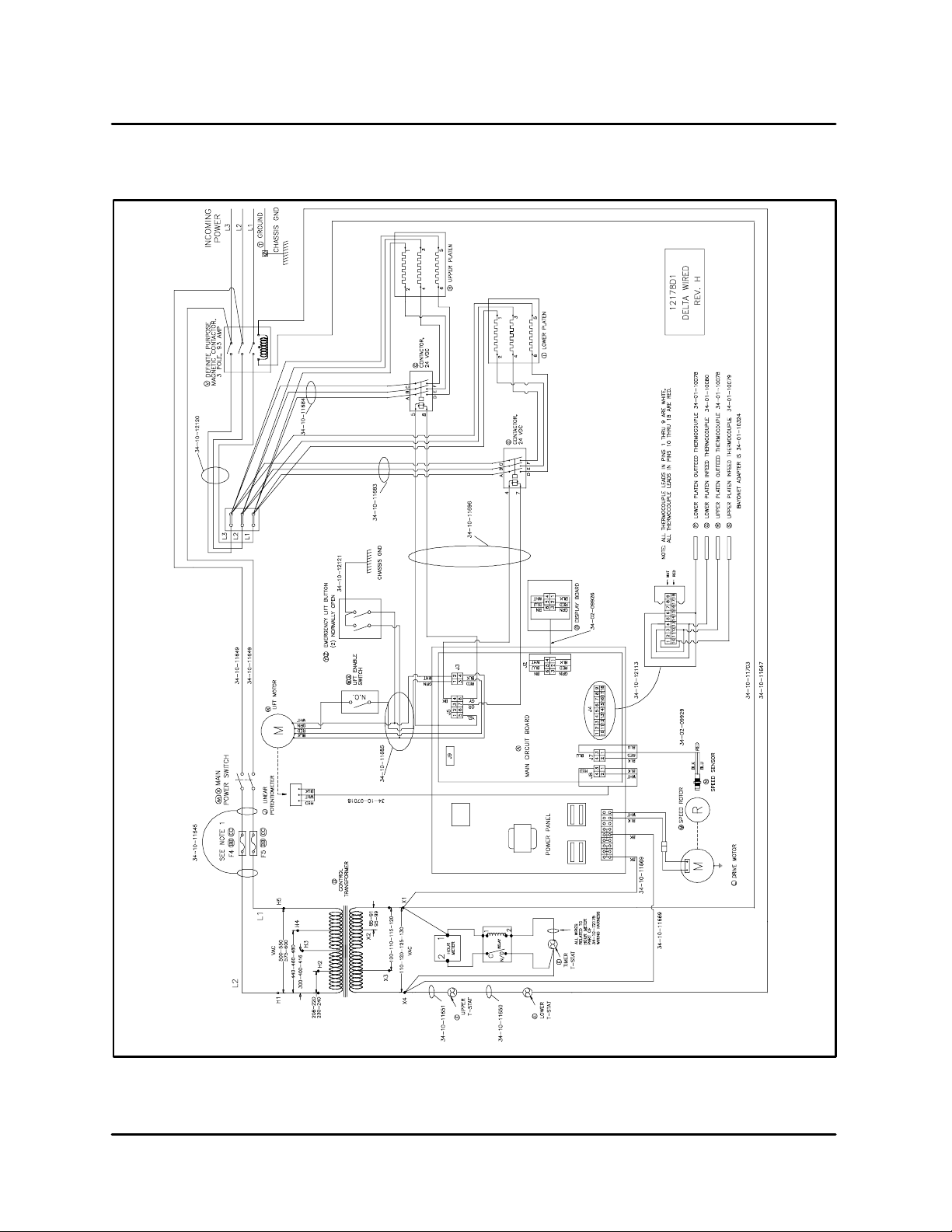

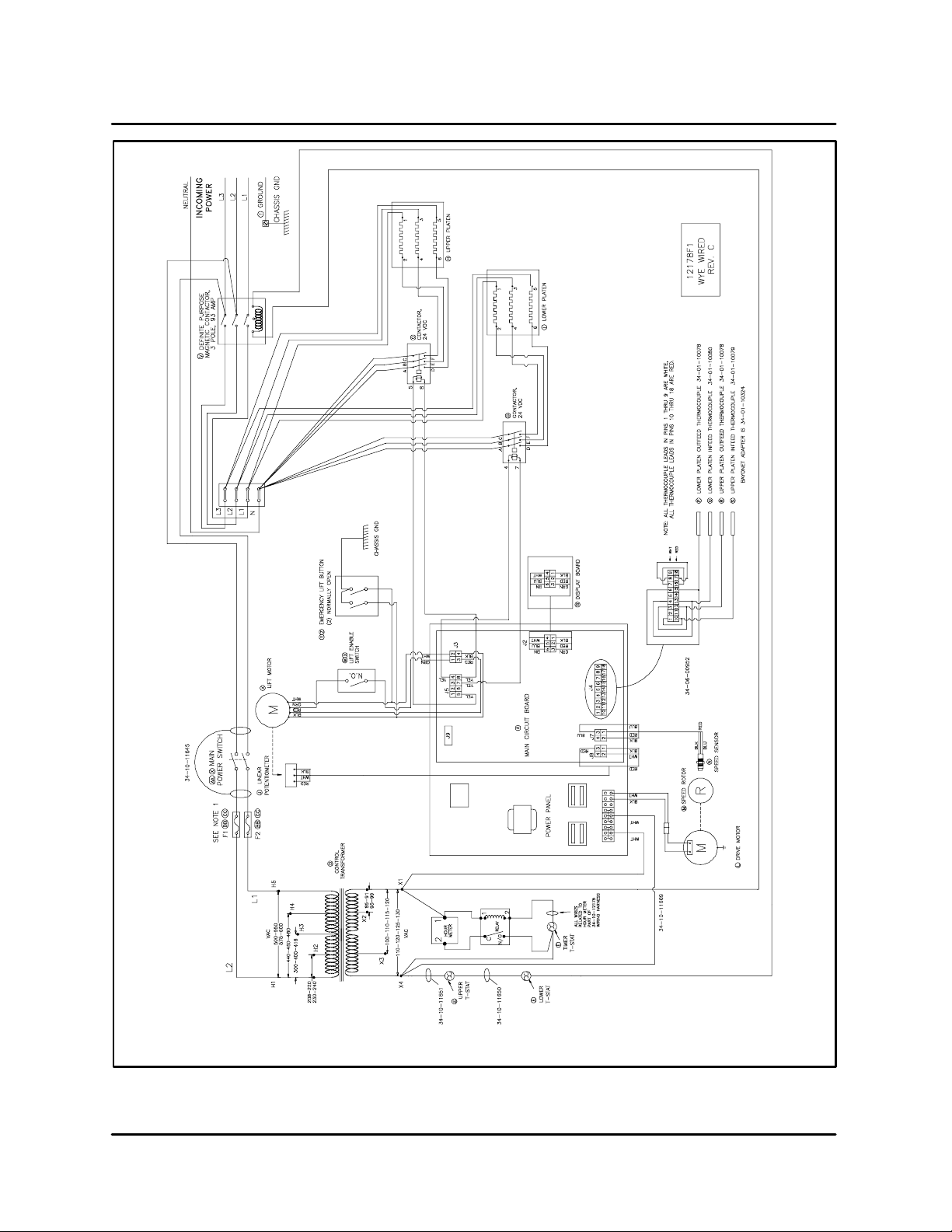

WIRING DIAGRAMS

INTRODUCTION

FIGURE 2

1 --- 4

Page 9

BLODGETT CONVEYOR GRILL

FIGURE 3

1 --- 5

Page 10

CHAPTER 2

UNIT CONTROLS

Page 11

BLODGETT CONVEYOR GRILL

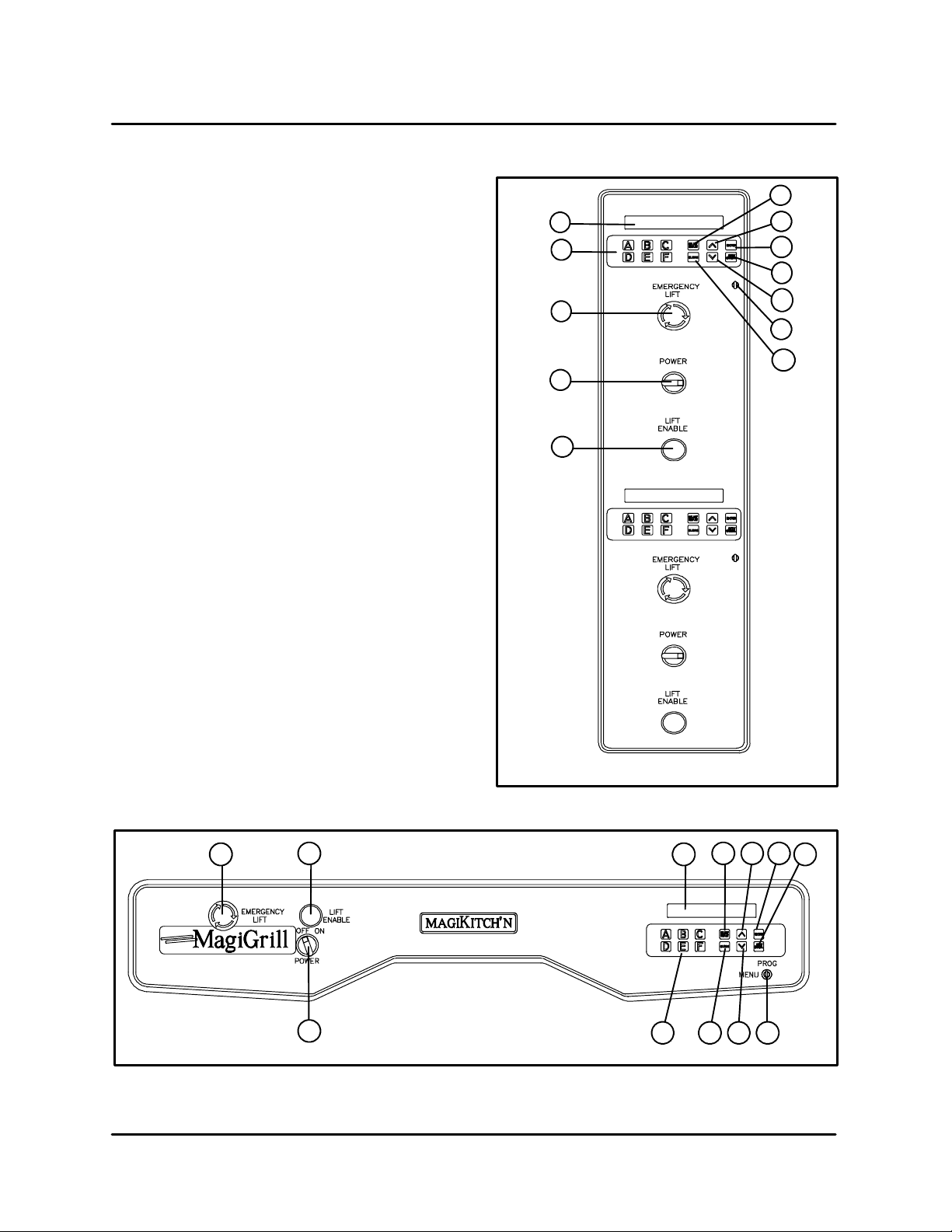

CONTROLS IDENTIFICATION

1. SELECT/DISPLAY --- used to select the display information.

2. UP and DOWN ARROW --- u s e d i n p r o g r a m ming to increase/decrease selection choices.

3. ENTER --- used to enter a menu selection into

the current program.

4. OFF/CANCEL --- cancels the current menu so

another may be entered.

5. KEYSWITCH --- requires a key to change from

MENU mode to PROGRAM mode.

6. CLEAN --- raises the upper platen for thorough

cleaning.

7. MENU buttons --- used in the MENU mode to

load programming for products A through F.

Used in PROGRAM mode to select menu designations and product descriptions.

8. DISPLAY --- displays the menu and program

mode information selected.

9. EMERGENCY LIFT --- immediately raises the

upper platen to the clean position. Push and

turn to reset/release button.

11

10

1

8

7

9

2

3

4

2

5

6

10. LIFT ENABLE --- a safety feature requiring the

operator to hold the button in while moving the

platen to a cooking position after a programming adjustment or menu change.

11. MAIN POWER SWITCH --- An ON-OFF rotary

switch for emergency or convenience use

which controls all electrical power inside the

unit. When power is on, the display lights up.

10

11

TBG36-CM and TBG36-FM Control

FIGURE 2

TBG36-S Control

FIGURE 1

89

7

1 2 3

526

4

2 --- 1

Page 12

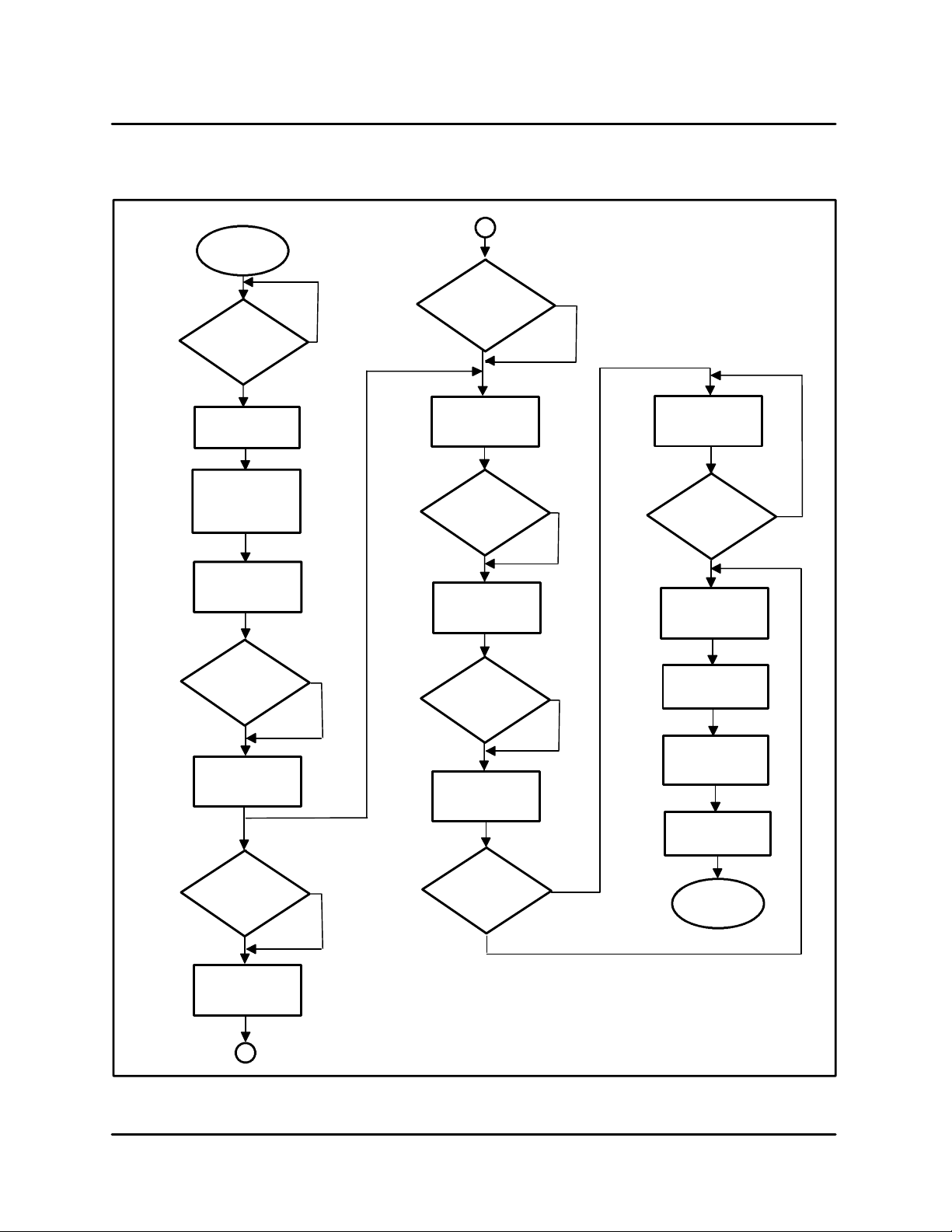

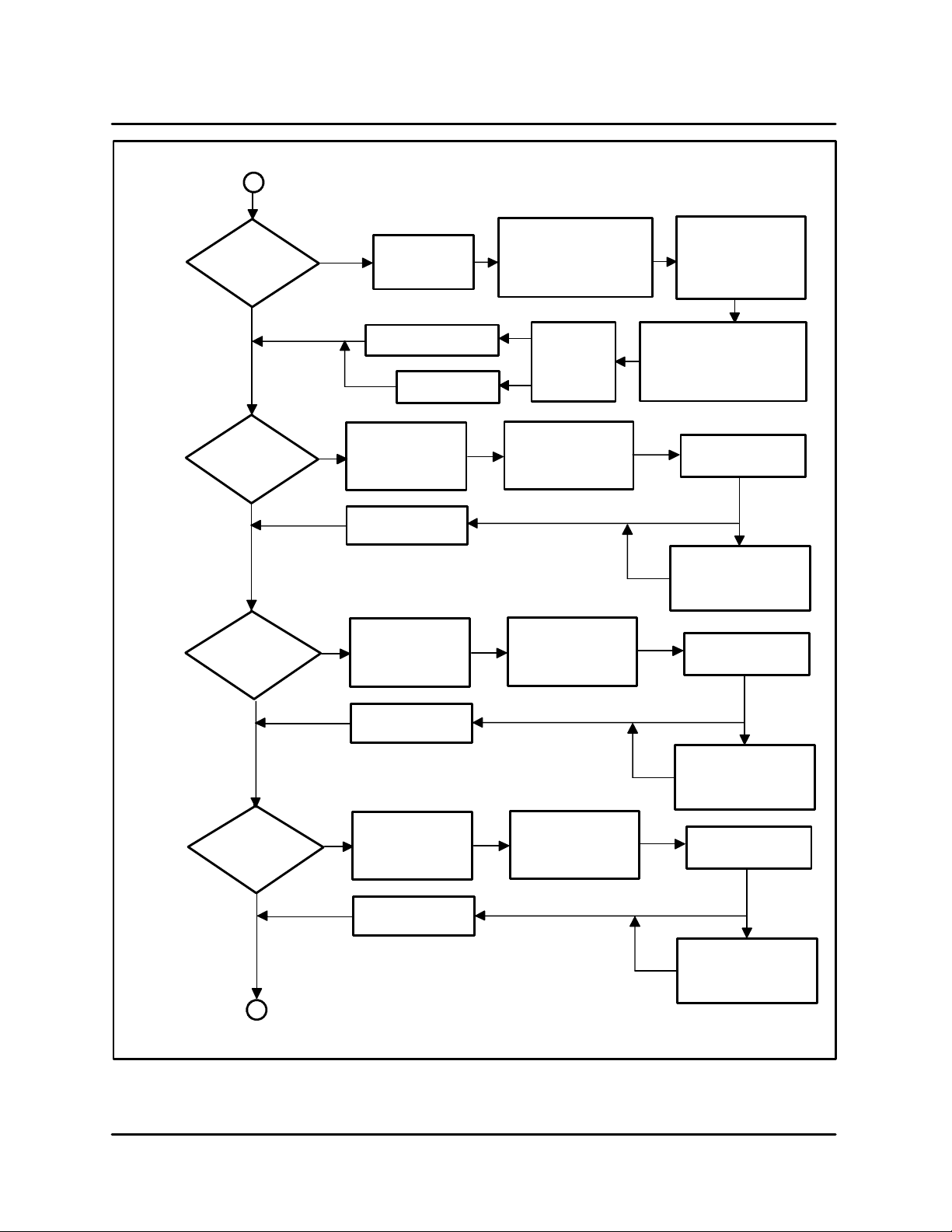

PROGRAMMING FLOW CHART

Power Switch

ON

Turn

KEYSWITCH

to vertical

position

Display reads

PROG?A

YES

NO

Belt Speed

A

Press

ARROW KEYS

to set

PH = BH

UP

Press ENTER

display reads

T=XX.XX

UNIT CONTROLS

DOWN

CHANGE SPELLING

Select letter

with

ARROW KEYS

L E T T E R K E Y A --- F

Top H e a ter

Press ENTER

display reads

ARROW KEYS

to set temp

Bottom Heater

Press ENTER

display reads

TBG60

ARROW KEYS

to set temp

Press the

youwishto

program

TH = XXX

Press

UP

BH = XXX

Press

DOWN

TBG36

DOWN

ARROW KEYS

to set time

Height Between

Platens

Change

Food Product

Descriptions

Press ENTER

display reads

H=XX.XX

ARROW KEYS

to set height

Press ENTER

display reads

FOOD PRODUCT

Press

Press

Change

product

spelling?

UP

UP

DOWN

DOWN

YES

CONTINUE

SPELLING

Press

ENTER to lock

in letter

DONE

Press

SELECT DISPLAY

Display reads

SAVE A>F

Press ENTER

display reads

SAVING

Display reads

PROG?A

Finished

programming

Preheater

Press ENTER

display reads

PH = XXX

A

UP

NO

NOTES:

_

All temperature setting must be less than or equal to 450

Platen height (H = X.XXX) must be less than or equal to 1.900” and greater than or

equal to 0.100”

Belt speed (T = X.XXX) must be less than or equal to 10 minutes and greater than or

equal to 30 seconds.

F

FIGURE 3

2 --- 2

Page 13

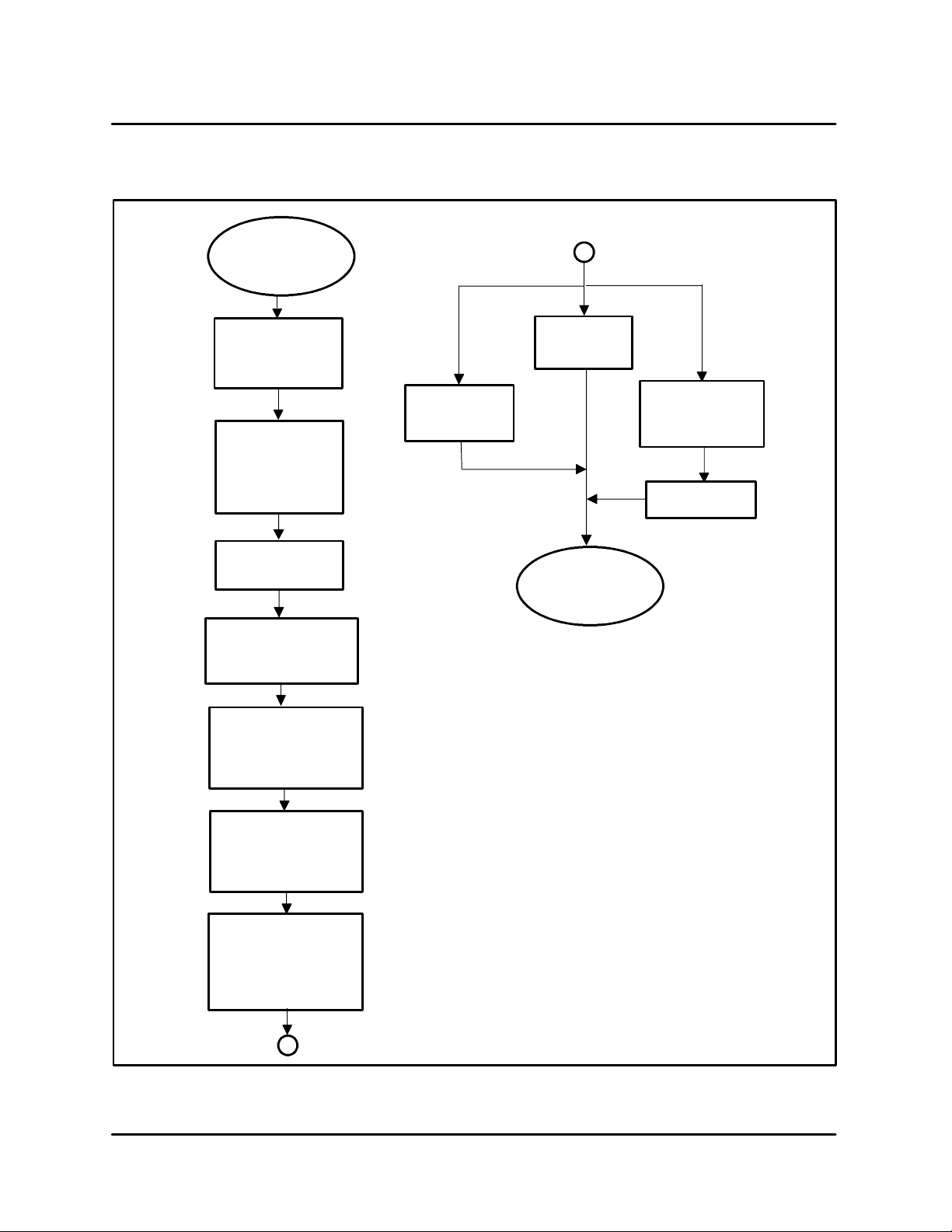

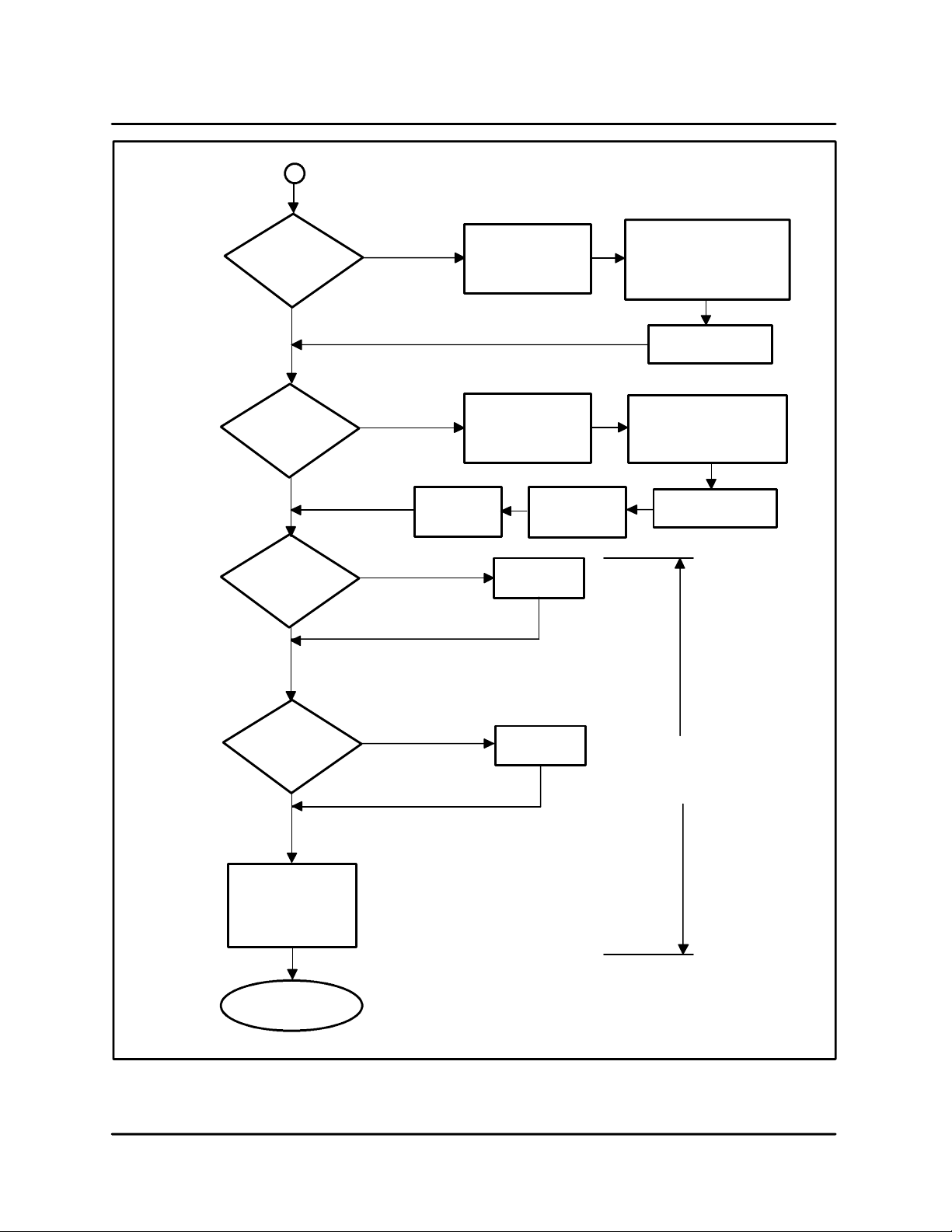

BLODGETT CONVEYOR GRILL

OPERATION FLOW CHART

Turn on

MAIN POWER

SWITCH

(turn knob to right)

A

Release

EMERGENCY LIFT

if set

(turn knob to right)

Turn

KEYSWITCH

to Menu

(horizontal position

display reads

MENU?A

Press (1) desired

menus selection

button A ---F

Press and hold

ENTER and LIFT ENABLE

buttons at the same time

oven beeps

Release ENTER

hold LIFT ENABLE

until upper platen lowers

to cooking height and

stops

Push Red

EMERGENCY LIFT

button

Cooking cycle

complete

T=00:00

Push OFF/CANCEL

display reads

remaining time

T=XX:XX

Push

OFF/CANCEL

Finish

select new program

Display reads

STANDBY

platens preheat and

counts down from 15 min.

T=XX:XX

Roller and belts start

moving

Blodgett Conveyor Grill

ready to cook

(display scrolls cooking

description)

A

FIGURE 4

2 --- 3

Page 14

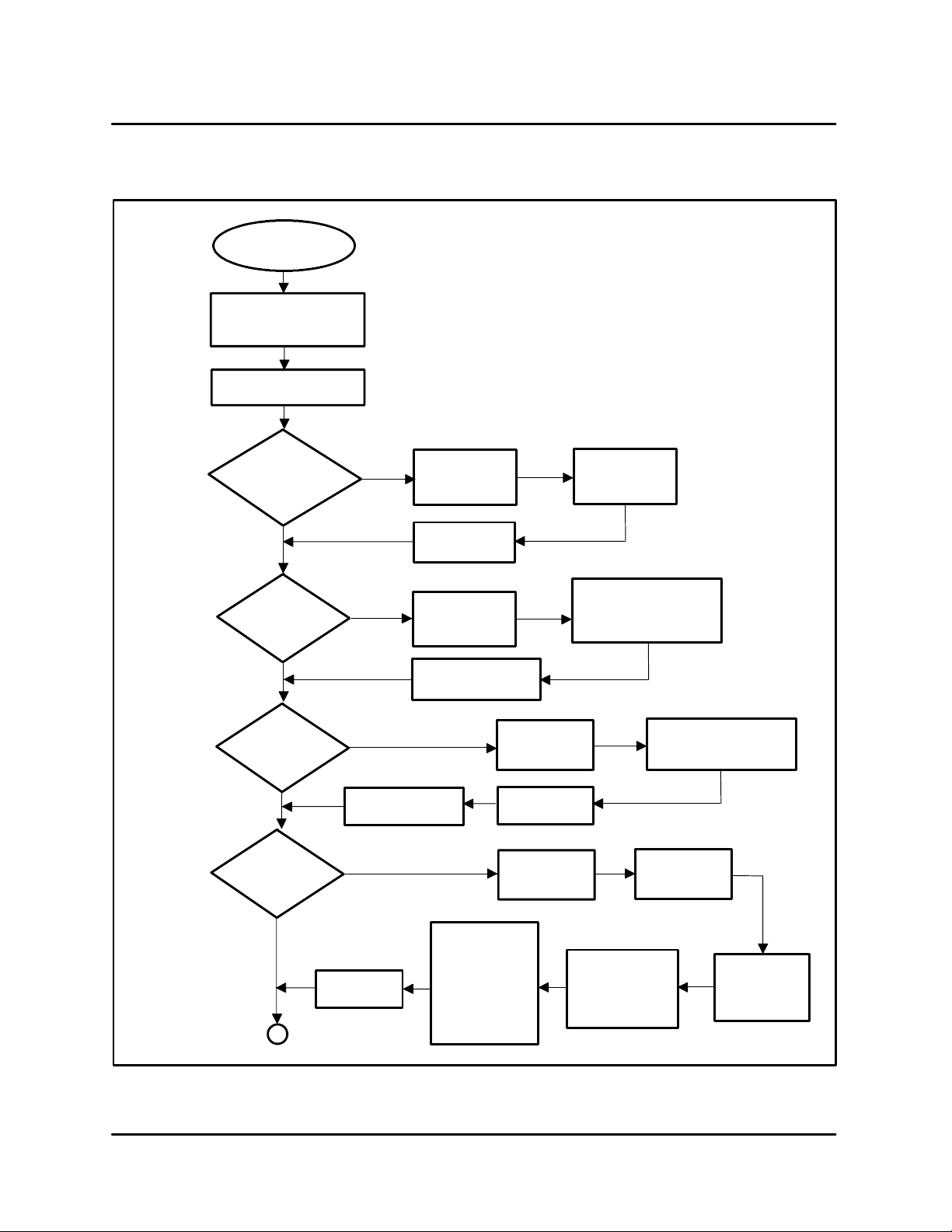

CALIBRATION FLOW CHART

UNIT CONTROLS

START/POWER

Turn KEY to program

(vertical position)

Press SELECT DISPLAY

Display reads PSWD?::

Unlocks Display

Press ENTER then A

Display reads

0:SELECT MODEL

Press ARROW key

to continue

programming

display reads

1:LIFT CAL

Press ARROW key

to continue

programming

2:CJ CAL

switch on

Press

A button

Display

reads

Change linear pot

calibration

Calibrate thermocouple

cold junctions

THE PASSWORD MODE ALLOWS ACCESS TO THE PROGRAMMING LOGIC AREA OF THE MICROPROCESSOR CONTROLLER.

DO NOT ATTEMPT TO ALTER A SETTING WITHOUT A COMPLETE

UNDERSTANDING OF THE CONTROLLER AND ITS PROGRAMMING AND A DIRECT CONSULTATION/APPROVAL FROM BLODGETT TECHNICAL SERVICE, 888-992-6624. THIS AREA IS USED

FOR INITIAL CALIBRATION, MENU DEVELOPMENT, TESTING

COMPONENT FUNCTION AND ADJUSTING PROGRAM VARIABLES BY A SERVICE TECHNICIAN. THIS AREA SHOULD NOT BE

ACCESSED BY THE USER.

Press ENTER

display reads

TBG36 or TBG60

When finished

Press ENTER

Press ENTER

display reads

H=X.XXX

When finished

Press

OFF/CANCEL

Press ENTER

display reads

CJ=XX

Press ARROW

keys to

select

Press ARROW keys

and LIFT ENABLE to

set height. Calibrate with

known dimension

Press ARROW keys

to adjust. Use external

meter for calibration

Press ARROW key

to continue

programming

Display reads

3:TEMP CAL

Press ARROW key

to continue

programming

A

When finished press

OFF/CANCEL

Calibrate 3 platens

to external reference

Press

OFF/CANCEL

Press ENTER

Press ENTER

display reads

SET = 400

Set

TH = SET

BH = SET

PH = SET

with ARROW keys

Set each

temperature by

pressing ENTER

FIGURE 5

2 --- 4

to save

Press ARROW

keys to set

temperature

Scroll display with

SELECT DISPLAY

compare

temperature with

external meter

Press ENTER

3 platens heat

to temperature

and stabilize

Page 15

BLODGETT CONVEYOR GRILL

A

Change all cooking

menu parameters while

operating

Display reads

4:TEST COOK

Press ENTER

then a menu key

A --- F

Press ENTER and

LIFT ENABLE

release ENTER

(hold LIFT ENABLE

until platen stops moving)

Display reads

T = XX:XX

(counts down until up

to temperature)

belts start moving

Press ARROW key

to continue

programming

Display reads

5:SET TOPHEAT

Press ARROW key

to continue

programming

Display reads

6:SET BOT HEAT

Press ARROW key

to continue

programming

Display reads

7:SET PREHEAT

Change top

platen temperature

(actual platen temp)

Press OFF/CANCEL

Change bottom

platen temperature

(actual platen temp)

Press OFF/CANCEL

Change preheat

platen temperature

(actual platen temp)

Default to old setting

Press OFF/CANCEL

Save changes

press ENTER

Press ENTER

display reads

T = XXX

twice to exit

Press ENTER

display reads

T = XXX

twice to exit

Press ENTER

display reads

T = XXX

When

done

press

OFF/CANCEL

Press OFF/CANCEL

display reads

TH XXX

(current platen temp)

Press OFF/CANCEL

display reads

BH XXX

(current platen temp)

Press OFF/CANCEL

display reads

PH XXX

(current platen temp)

Press SELECT/DISPLAY

Use ARROW keys to select

parameter to change

TH BH PH T H

(change to desired setting)

Press ARROW keys

to adjust temperature

Press ENTER

display reads

T = XXX

(shows platens temp)

Press ARROW keys

to adjust temperature

Press ENTER

display reads

T = XXX

(shows platens temp)

Press ARROW keys

to adjust temperature

Press ARROW key

to continue

programming

Press OFF/CANCEL

twice to exit

Press ENTER

display reads

T = XXX

(shows platens temp)

B

FIGURE 6

2 --- 5

Page 16

Display reads

Press ARROW key

to continue

programming

Display reads

SET HEIGHT

Press ARROW key

to continue

programming

B

8:SET TIME

Discontinues all

password setting

8through10

FOR TECHNICIAN ONLY

Shows main control board is

picking up magnetic speed

control output

Obsolete Function

LIFT CAL does the

same function

Press

OFF/CANCEL

twice to exit

Press ENTER

display reads

T = X:XX

(shows a time value)

Press ENTER

display reads

P=X.XXX

(current position)

When finished

display reads

P = X.XXX

UNIT CONTROLS

Press ENTER

display reads

S=XXXXX

(shows fluctuating number)

pick up is working “OK”

Press OFF/CANCEL

twice to exit

Press OFF/CANCEL

display reads

P = X.XXX

(adjust to desired height)

Press ENTER

platen will adjust

Display reads

10:STOP ALL

Press ARROW key

to continue

programming

Display reads

11:DEFAULT MENU

Press ARROW key

to continue

programming

Scroll through the

following

12:EE WORD

13:EE BYTE

14:SET CHECKSUM

FINISHED

Only to change all

menus to preset variables

RESTRICTED

DO NOT ACCESS

FOR ENGINEERING

ONLY

Press ENTER

to change

Press ENTER

to change

Press OFF/

CANCEL

to exit

FIGURE 7

2 --- 6

Page 17

BLODGETT CONVEYOR GRILL

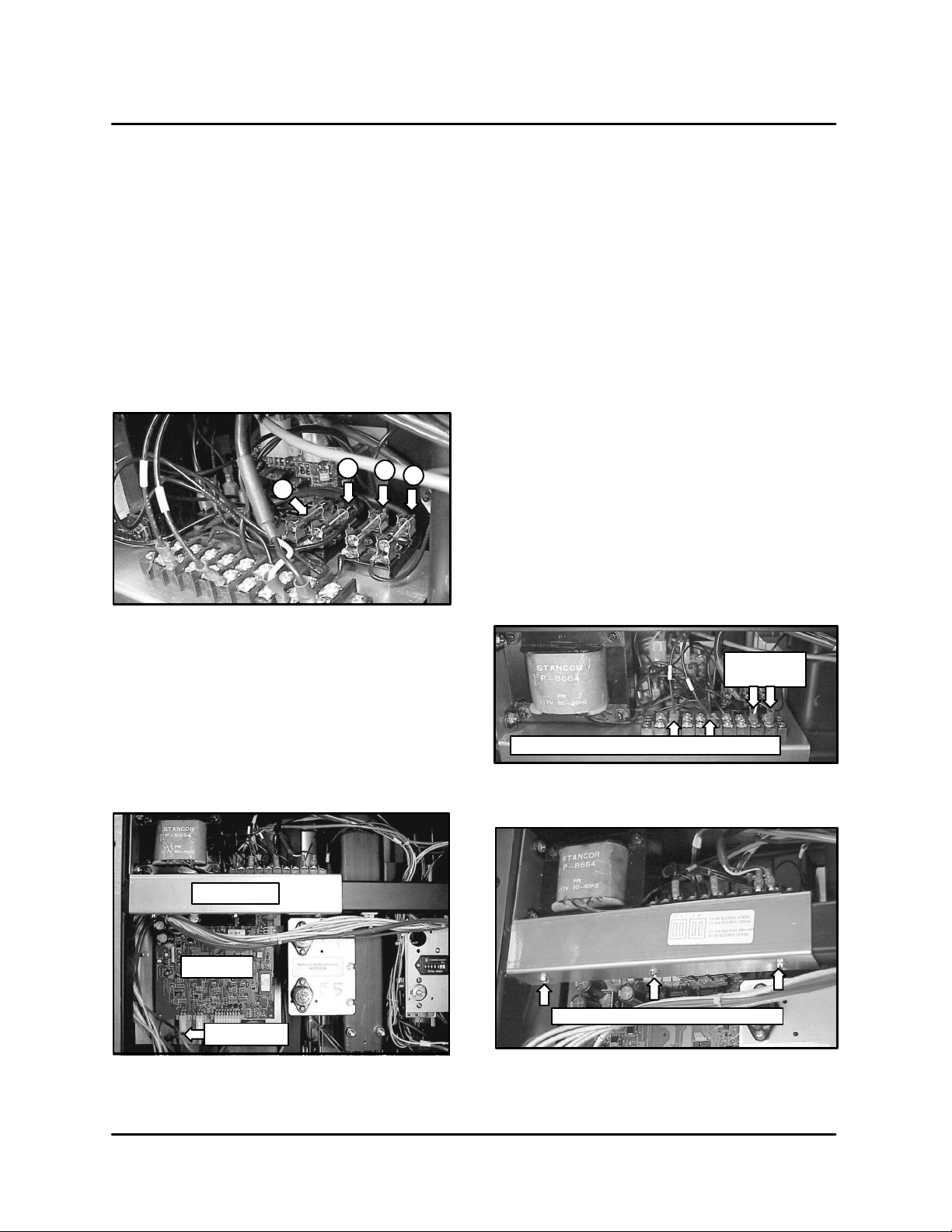

CONTROLLER REMOVAL AND REPLACEMENT

If repeated nuisance blowing of fuses persists, the

current rating of any of the fuses may be increased

to 5 amperes. The following are symptoms for a

blown fuse:

D

Definite Purpose Contactor pulls in but the display

remains blank. One of the following fuses has

blown. Fuse 1 (3A Slow-blo 24VDC), Fuse 2 (3A

Slow-blo 120VAC) or Fuse 4 (3A Slow-blo 24VAC)

D

Controller works but there is no belt drive motor operation. Fuse 3 (3A Slow-blo Drive Motor)

blown.

2

3

1

4

FIGURE 8

1. Remove the power supply as follows:

A.) Remove the three screw s securing t he

power supply mounting bracket to the

frame crossmember.

B.) Pull the power supply assembly/bracket

out of the unit about an inch to access the

screws on the terminal strip.

C.) Remove the two w ires from the drive motor

on the power supply terminal strip noting

which wire goes to which point on the terminal strip. If these are connected incorrectly the drive motor will run backwards.

D.) Remove the two wires supplying 120 VAC

from the 375 VA isolation transformer (located on the opposite side of the unit) to

the power supply terminal strip from the

terminal strip.

E.) Disconnect the power supply cable Molex

connector from plug J-9 on the main

board. Remove the power supply from the

unitandsetitaside.

The controller must be replaced as a set with the

following components:

D

Main board

D

Power supply board

D

Display

D

Display cable

Power Supply

Main Board

Display Cable

FIGURE 9

Drive Motor

Supply Wires

Wires from power transformer to power supply

FIGURE 10

Power supply bracket mounting screws

FIGURE 11

2 --- 7

Page 18

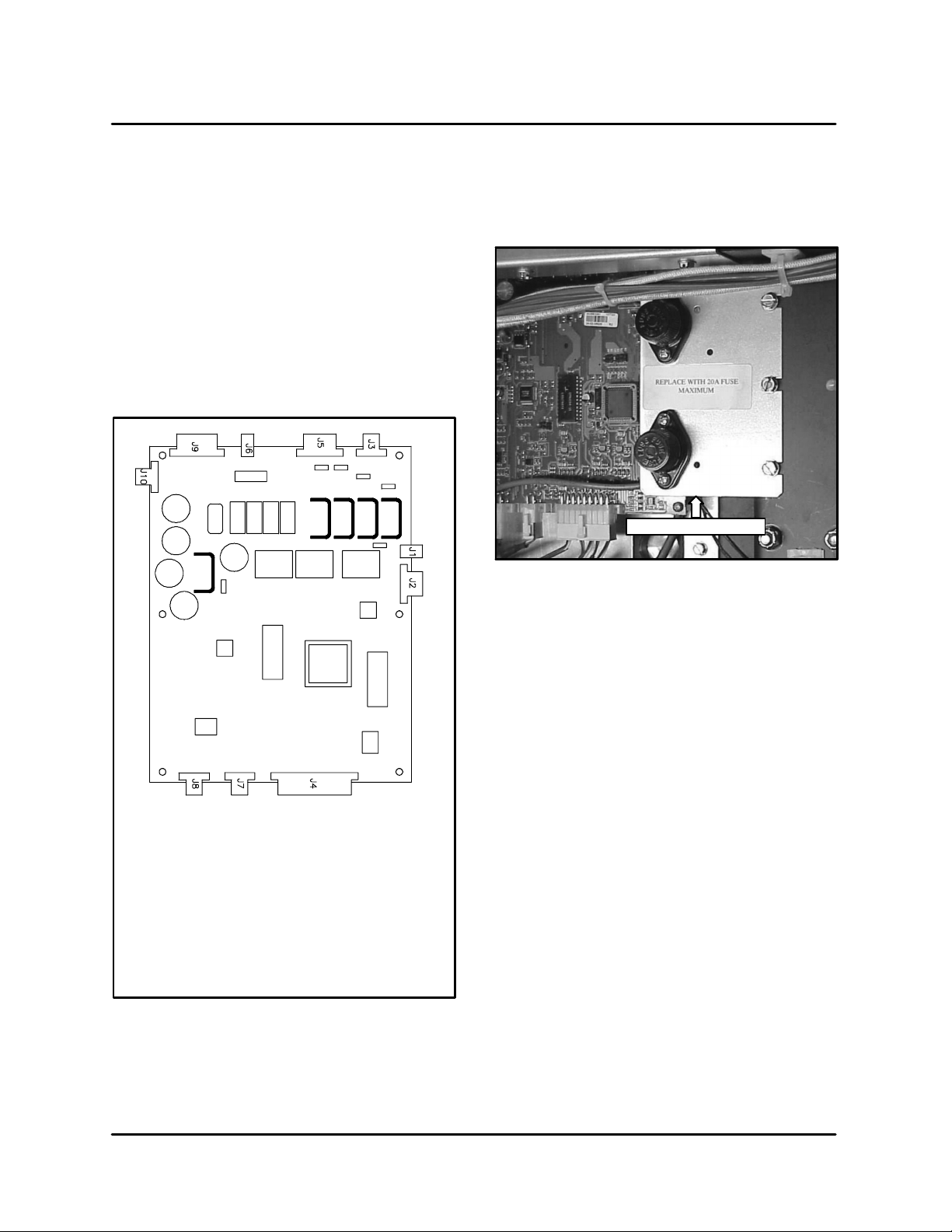

UNIT CONTROLS

2. Remove the main board as follows:

A.) Remove all other Molex connectors from

the main board. Note which connector

goes to which pin location on the board.

Be especially careful when removing/reconnecting the two 4 pin connectors from

J-7 and J-8 which are identical in appearance and are located a djacent to each other. If these are inadvertently switched the

display will show all segments lit when the

unit is energized. No damage to the board

will result, simply cycle the power off and

then switch the connectors to the correct

plugs before re-energizing.

B.) Remove the screws securing the fuse

mounting bracket and move this out of the

way to allow the main board mounting

panel and main board to be removed as an

assembly.

Fuse mounting bracket

FIGURE 13

Plug Designations

J1 Not used

J2 Display

J3 Lift Motor

J4 Thermocouples

J5 Heating Contactors

J6 Not Used

J7 Speed Sensor

J8 Linear Potentiometer

J9 Power Supply

J10 Not Used

FIGURE 12

C.) Remove the main board by loosening, but

not removing, the three screws securing it

to the upright frame member. Remove the

screw securing it to the horizontal frame

member.

3. Remove the display board a s follows:

A.) Remove the (5) small nuts securing the

display to its stand-offs.

B.) Remove the display board.

4. Installation of the display, power supply panel,

and main board is opposite of removal. A linear

potentiometer calibration must be run following replacement of the control board. See

p a ge 5 --- 6 o f t h e P OS I T I O N C O NT R O L s e ct i o n

of this manual.

2 --- 8

Page 19

BLODGETT CONVEYOR GRILL

SWITCH REPLACEMENT

The following procedure describes how to replace

the Emergency Lift, Power and Lift Enable switches.

1. Remove the drive motor to gain access to the

switches.

2. TheLIFTENABLEandPOWERswitcheshave

similar constructions. Replace as follows:

Lift Enable Actuator Components

Normally Open

Contact Block

(snaps into back

of mounting bracket)

Contact Block

Mounting Bracket

A.) Remove the wiring from the back of the

switches.

B.) Turn the black plastic tab securing the

switch to its actuator. If the actuator needs

to be removed, remove the plastic nut from

the barrel of the actuator and pull the actuator out through the front of the unit.

Plastic Nut

(secures actuator to

sheetmetal panel)

Actuator

Power Switch Components

Mounting bracket with

tab turned to unlock

bracket from actuator

(note that four notches

are open)

Mounting bracket with

tab turned to lock

bracket to actuator

FIGURE 14

2 --- 9

Complete switch/actuator

assembly

Page 20

Emergency Switch Components

UNIT CONTROLS

Contact Block

Assembly

Mounting Block

Complete Emergency Switch Assembly

(Note tips of screws protruding out of mounting block.

These screws must be tightened against the sheetme-

tal to secure the actuator in place before assembling

the contact block assembly to the mounting block.)

Actuator

FIGURE 15

2 --- 1 0

Page 21

BLODGETT CONVEYOR GRILL

This page intentionally left blank.

2 --- 1 1

Page 22

CHAPTER 3

TEMPERATURE CONTROL

Page 23

BLODGETT CONVEYOR GRILL

DESCRIPTION

The temperature control circuitry for the Blodgett

Conveyor Oven employs two (2) J -type thermocouples located at the infeed and outfeed ends of

each heating platen. The thermocouple outputs

are fed into the control board through the Molex

connector on J-4. When the platen t emperature

drops below the programmed set point, a controller relay energizes a three-phase power contactor.

The contactor energizes three heating elements in

the platen until the platen temperature passes a

With back cover

differential set point and reaches the correct cooking temperature. The controller de-energizes the

contactor, cutting power to the heating elements.

As the platen loses heat in cooking, this cycle repeats itself.

Over-temperature protection is provided by thermostats which are normally closed and designed

to open at 583˚F. These are wired in series with t he

coil of the definite purpose contactor which controls power to the entire unit.

With back cover removed

FIGURE 1

3 --- 1

Page 24

WIRING DIAGRAM

TEMPERATURE CONTROL

FIGURE 2

3 --- 2

Page 25

BLODGETT CONVEYOR GRILL

TROUBLESHOOTING

A problem with uneven cooking or undercooking

of food on the top and/or bottom surface may be

the result of a temperature control malfunction. It

is advisable to use the Cooking Troubleshooting

Guide in isolating the cause of the problem. Possible causes for improper cooking operation that

could be the fault of the temperature control include:

D

Broken thermocouple wiring.

D

Looseorbrokenwiresfromtheplatens.

D

Platen contactor failure.

D

Platen heating element failure.

Pillow Block

Upper Thermostat

THERMOSTATS

Theplatensareprotectedfromoverheatingby

bulb sensor type thermostats. The bulbs sensors

are located w ithin thermowells cast into the platens. These thermowells are located in the center of

the (6) element sheaths exiting the side of the platen castings.

Thermostat Sensor Capillary

(thin bare copper tube)

Linear Shaft

Mounting Plate

FIGURE 4

Lower Thermostat

FIGURE 5

FIGURE 3

3 --- 3

Page 26

TEMPERATURE CONTROL

OVERTEMPERATURE SAFETY THERMOSTAT CIRCUIT

A problem with the overtemperature safety circuit

is indicated when a hot grill shuts off for no apparent reason. There is a noticeable thunk sound from

the back of the unit, indicating that the definite purpose contactor has de-energized and dropped out

all power to the platens. No display warning is given. Power to the platens shuts down completely

until the temperature of the problem platen has

cooled enough to reset the thermostat, at which

time the unit restarts.

Overtemperature sa fety thermostat problem

If an overtemperature safety thermostat fails by actuating at too low a temperature (one within the

normal cooking temperature range of up t o 450˚F)

the grill will still shut off, even though there is no

temperature problem. If this condition occurs:

1. Disconnect supply power at the branch circuit

breakerandremovethebackcoverwhilethe

unit is still hot. Be certain the wiring is de-energized by testing with a voltmeter.

2. Remove one of the w ires from the thermostat

and measure across the wiring terminals of

each of the overtemperature thermostats with

an ohmmeter to find the open device. This

must be accomplished before the thermostat

cools down and resets itself. The open switch

is the thermostat that has actuated prematurely, the others will read closed (zero ohms).

3. When the platen cools down, the actuated

switch will close again automatically.

4. The safety thermostat is either out of adjustment or defective and in need of replacement.

Overtemperature safety circuit problem

If a grill does not start at all, and all the obvious requirements are met (cord plugged in, power available, etc.) then the O/T safety circuit may be suspect. To test with the unit at room temperature:

1. Open the supply power breaker and check for

continuity through the thermostats, definite

purpose contactor coil, and wiring.

2. If there is an open circuit, label and isolate the

wiring, connections, and components. Check

for device continuity with the wires removed.

3. Repair or replace defective wiring and/or components as necessary.

Overtemperature protection thermostat with shaft in

proper position (normally closed, continuity between

wires)

Note 12:00 position of microswitch actuating pawl.

Note that microswitch is closed. Microswitch is not part

of circuit.

Overtemperature protection thermostat with shaft in

wrong position (open circuit between wires).

Note 3:00 position of microswitch actuating pawl.

Note that microswitchis open. Microswitch is not part of

circuit.

FIGURE 6

3 --- 4

Page 27

BLODGETT CONVEYOR GRILL

THERMOCOUPLE DIAGNOSTIC PROCEDURE

1. Visually inspect for any broken wires. Check at

control board connector J-4 for any bare wires

touching one another or ground.

2. To test suspect thermocouples at room temperature, unplug the Molex connector from J-4

on the controller board and measure the thermocouple’s output (temperature) using the

digital thermometer and a pair of test leads (Jtype if available) from the connector pins.

3. Follow the Molex diagram and compare their

readings against the room ambient. If outputs

are not within +/ --- 10%, replace the thermocouple. The 18 pin Molex plug must be disconnected from the control board to take readings

from individual thermocouples s ince the infeed

and outfeed thermocouples are averaged together on the control board and must be separated for testing.

A small section of thermocouple wire must be

connected to pins 8 a nd 17.

NOTE: These pins correspond to a separate

preheat platen used on a larger version

of this appliance. While they are not

used on this unit, a thermocouple input

must be provided to these two locations or the resulting open channel will

cause a problem with the control.

A digital multimeter (preferably with a diode test feature) is required. Remove the 18-pin Molex connector from the controller before proceeding. See the illustrations below and complete these steps in order

until the problem is identified and corrected.

Plug Designations

J1 Not used

J2 Display

J3 Lift Motor

J4 Thermocouples

J5 Heating Contactors

J6 Not Used

J7 Speed Sensor

J8 Linear Potentiometer

J9 Power Supply

J10 Not Used

FIGURE 7

NOTE: All thermocouple leads in Pins 1 thru 9 are white

All Thermocouple l eads in Pins 10 thru 18 are red.

Bottom Outfeed Thermocouple

Bottom Infeed Thermocouple

Top Outfeed Thermocouple

Top Infeed Thermocouple

FIGURE 8

3 --- 5

Page 28

TEMPERATURE CONTROL

Ref. Figure Red + Probe Black -- Probe Result

FIGURE 9

(Rule out

thermocouple

wiring shorted to

ground)

FIGURE 10

(Test T/C

junction integrity)

NOTE: It is easier to connect meter leads to Molex sockets if a spare Molex pin or an opened paper clip

is temporarily placed in the plug socket under test and the meter lead connected to the pin or clip.

Each socket on the

white Molex plug,

one at a time*.

Molex pin for one

thermocouple w h ite

wire.

See FIGURE 8*.

Ground lug on unit*. Should read open (no continuity, no

beep). If it does not, note the socket

number and identify the faulty thermocouple from the diagram above. Trace

theleadwireandlookforplaceswhere

bare thermocouple wire may be touching grounded metal. Remove the thermocouple from the platen well tube and

check for bare conductors.

Molex pin for one

thermocouple red

wire.

See FIGURE 8*.

TABLE 1

Each thermocouple should have continuity from white to red. If not, the thermocouple is open and needs to be replaced.

FIGURE 9 FIGURE 10

3 --- 6

Page 29

BLODGETT CONVEYOR GRILL

PLATEN CONTACTOR DIAGNOSTIC PROCEDURE

1. Disconnect supply power by opening the circuit break er to de-energize the unit.

2. Remove back cover and label all t h e wires connected to the suspect heating contactor.

3. Disconnect all the wires on the contactor and

measure the coil resistance. The value should

be between 82 and 110 W; if not, the coil is

faulty and the contactor must be replaced.

Control

Board

Controller

Power

Supply

Primary

Transf ormer

Fuses

Linear

Potentiometer

4. Check that there is an open circuit (infinite resistance) across each of the pole pairs of the

contactor.

5. Connect a separate 24VDC power supply to

energize the contactor coil and recheck the

pole resistances again. When energized, they

should show almost zero resistance. If not, the

contactor is defective and must be replaced.

Hour

Meter

Top Pla t en

Safety

Thermostat

Drive

Roller

Sprockets

Drive

Chain

Power

Distribution

Block

Definite

Purpose

Contactor

Ground Lug Lift

Motor

Heat

Contactors

FIGURE 11

3 --- 7

Bottom

Platen

Safety

Thermostat

Main Power

Transf ormer

Page 30

CHAPTER 4

PLATENS

Page 31

BLODGETT CONVEYOR GRILL

DESCRIPTION

Theupperandlowerplatensaremadefromcast

aluminum with an electroless nickel coating. Three

incoloy sheathed elements are cast into each platen running lengthwise. A thermocouple is located

on the infeed and outfeed end of each platen to

provide accurate temperature monitoring. Sheet-

metal filler strips and a cover surround the platen

to protect the thermocouples and to improve

cleanability. The platens are aligned to each other

by means of adjusting bolts in the platen frame assemblies. No maintenance other than routine

cleaning is required.

FIGURE 1

4 --- 1

Page 32

PLATEN DIAGNOSTIC PROCEDURE

WARNING!!

Be careful! You will be working near LIVE

ACpowerof208voltsorgreater!

Stack capacity models have two services.

Check that the correct circuit has been

turned off! When working on a de-energized stack capacity unit, half the unit may

still be live (energized)! DO NOT accidentally reach into the wrong section! For

your safety, replace the back cover on an

energized unit that is not being serviced.

In normal operation, one side of each

heating element is alwa ys energized relative to ground whenever the supply power

breaker is on, regardless of the main pow er switch position!

1. Re-energize the unit and run it from a cold start

in Menu A. Set the temperatures above 375_F.

2. While the platens are heating, measure the

current draw through each branch conductor,

feeding power into the unit using a clamp-on

tester. Compare measurements to TABLE 1. If

the values do not agree, measure the draw of

the individual heating elements in the platens

at the contactors. Compare against TABLE 1.

3. If all three feed wires read about half normal

current, an entire platen is not working. If two

of three feed wires read a ppreciably lower than

normal, one or two heating elements in a platen may be defective. You can check the current draws of the individual platen elements by

PLATENS

locating and measuring the current draw on

the individual supply wires to each of the platens at their contactor. Be careful, you will be

working with a live, hi-voltage circuit. Refer to

TABLE1forcorrectlinedrawsfortheplaten.

4. To isolate the suspect heating element:

A.) Open the power disconnect to de-ener-

gizetheunitandletitcooldown.

B.) Label then disconnect the three high tem-

perature wires (fiber cloth covered) from the

top of the heating contactor of the platen.

C.) Label then disconnect all the high temper-

ature wires from the main power terminal

block. Separate wires to keep them from

touching each other.

D.) Isolate each of the three elements in the

platen and measure the cold resistance

through them. Refer to TABLE 1 for the

correct resistance value for the voltage

andplatenonwhichyouareworking.

E.) Checktheresistanceofeachwireleadto

ground; they should read infinite resistance (open circuit). If one or more elements fail to meet these criteria, the heating platen must be replaced. If the heating

elements are good, the problem lies in the

wiring associated with heating.

F.) Be careful removing or re-connecting wir-

ing. DO NOT twist (break) the terminals off.

Be sure that all connections are secure.

TBG36 CURRENT DRAWS

208 VAC 220 VAC 240 VAC 440 VAC 480 VAC 380 VAC 415 VAC

Branch Conductor Current Draw

50 A 47 A 43 A 24 A 22 A 27 A 25 A

Element Current Draw and Cold Resistance for Upper Platen (2600 W)

12.5 A 11.8 A 10.8 A 5.9 A 5.4 A 6.8 A 6.3 A

15.1---17.5 Ω 16.8---19.5 Ω 20.0---23.2 Ω 67.4---78.0 Ω 80.2 ---92.8 Ω 50.3---58.2 Ω 59.9---69.4 Ω

Element Current Draw and Cold Resistance for Lower Platen (3400 W)

16.4 A 15.5 A 14.2 A 7.7 A 7.1 A 9.0 A 8.2 A

11.5---13.3 Ω 12.9---14.9 Ω 15.3---17.8 Ω 51.5---59.7 Ω 61.3 ---71.0 Ω 38.4---44.5 Ω 45.8---53.1 Ω

TABLE 1

4 --- 2

Page 33

BLODGETT CONVEYOR GRILL

PLATEN REMOVAL AND REPLACEMENT

PLATEN REMOVAL

1. Removethewipersandbeltsfrombothplaten

assemblies. Clean the platen assemblies before proceeding with any disassembly.

2. Put the upper platen in the CLEAN position

3. Remove the front two platen adjusting bolts,

spacer washers, and nuts from the front and

rear frame members of the platen assembly.

If the upper platen is being removed, use

1:LIFT CAL in PSWD mode (refer to Unit Controls of this manual) to move the upper platen

assembly down until the upper platen is touching the lower platen.

If the lower platen is being removed, leave the

upper platen assembly in the CLEAN position.

4. Remove the sheetmetal cover from the platen

assembly. Remove the two large hole plugs

from t h e front frame member.

Arrangement of Supply Wire Exiting Platen Ca sting (cooking side down)

Platen Adjustment Nut,

Filler

Strip

Platen Adjustment Nut,

Bolt & Spacer Washer

Bolt & Spacer Washer

FIGURE 2

1/2-13

Mounting

Lug Bolts

Hole for Front

Mounting Lug Bolts

center element

Thermowell for

thermostat bulb

Bottom pair is for nearest element

Toppairisforfarelement

Center pair is for center elementCenter pair is for

FIGURE 3

4 --- 3

Page 34

PLATENS

5. Disconnect the unit from its power supply.

Note that there are three elements in each platen and six wires leading from these three elements on the replacement platen. These must

be connected properly to form a delta connection. The six wires must be grouped in sets of

2 per element with one set connected between

L1-L2, one set connected between L2-L3, and

the last set connected between L1-L3. Failure

to correctly connect these wires will lead to

an element that doesn’t heat o r an overloaded, unbalanced circuit.

Input Line 3

Input Line 1

Input Line 2

Load Line 1

Load Line 3

Load Line 2

7. Pull the safety thermostat sensor bulb from the

rear of the unit a nd out of its thermowell in the

platen side entry.

Thermostat Sensor Capillary

FIGURE 6

FIGURE 4

L3

L2

L1

FIGURE 5

6. Disconnect the thermocouples on the platen

infeed and outfeed. Remove the thermocouple

adaptors from the old platen and reinstall them

on the replacement platen.

FIGURE 7

8. Remove the two 1/2-13 bolts and nuts securing

thefrontframemembertotheplatenlugs.Removethefrontframememberandfillerstrip.Be

careful not to loose the spring washer from the

driverollerwhenremovingtheframemember.

9. Remove the two 1/2-13 bolts and nuts securing

the platen to the rear frame member. Remove

the platen. Carefully pull the wires through the

hole in the back of the unit while removing the

platen. Be careful not to loose the drive roller

spring washer. DO NOT remove the drive roller.

Unit with Upper Platen Removed

FIGURE 8

4 --- 4

Page 35

BLODGETT CONVEYOR GRILL

PLATEN REPLACEMENT

1. Assemble the frame members, filler strips,

drive roller, drive shaft, spring washers, and replacement platen in place on the unit. Secure

with the four 1/2-13 bolts and nuts removed.

Y o u will need to feed the wires through the rear

cover and engage the platen conduit with the rear

cover while pushing the platen into place. DO NOT

fully tighten them at this time, make them snug

enough to hold all the pieces in place.

The filler strips need to be bumped into position (using a wood block and hammer) so they

are even with one edge of the frame member.

Use the bottom edge on the top frame member, and the top edge on the bottom frame

member.

The platen cooking surface should be parallel

to the same frame member edge, but 1/8” taller. There are angles machined into the platen

mounting lugs that are 1/8”. If the edge of the

mounting lug is even with the edge of the frame

member, the platen should have the required

1/8” spacing relative to the frame member.

2. Re-connect the wiring and thermocouples as

follows:

3. Put the unit in MENU mode. Press the CLEAN

button to move the platen assemblies all the

way apart. Install the platen adjustment bolts,

nuts, and spacers. The bolt head must be to

the inside of the frame member with the nut

and spacer on the outside.

Nut

Spacer Washer

Platen adjusting bolt h ead

must be towards platen

cooking surface

A.) Push the thermostat bulb into its t hermo-

well in the replacement platen.

B.) Secure the wiring and sensor leads as

they were before disassembly. Make sure

the bare, copper thermostat capillary tube

can not contact a ny live metal electrical

connections.

C.) If the upper platen has been replaced,

make sure the sensor bulb moves with the

platen assembly and that no motion is

transmitted to the bulb. Repeated flexing

of this bulb will cause premature failure of

the part.

FIGURE 9

4 --- 5

Page 36

PLATEN ALIGNMENT

PLATENS

1. If a new platen is being aligned, turn all the upper and lower platen adjustment bolt/nut combinations, using two wrenches, until the support rods are centered in the holes in the frame

members.

FIGURE 10

2. Set the platen height as follows:

A.) Turn the keyswitch to the PROGRAM posi-

tion. The display reads [PROG?A].

B.) Press the SELECT/DISPLAY button. The

display reads [PSWD?].

C.) Press ENTER then press the A button. The

display reads [0:SELECT MODEL].

D.) Press the ARROW key. The display reads

[1:LIFT CAL].

E.) Press ENTER. The display reads [H=X.XXX],

the current position value. If the platen is in

the CLEAN position, this number will be

greater than 1.900.

3. Adjust the upper and lower platen bolts up and

down as necessary to align the platens to each

other using the 1/2” alignment rod. When the

alignment rod can just be slid across the entire

platen surface with only a slight drag and no

gaps, the platens are aligned.

4. When finished, tighten the acorn nuts securely

to the alignment bolts. You must not allow the

bolt to turn while tightening the nut or the adjustment will change.

5. Re-check the alignment and make slight adjustments as n eeded. Sometimes this process

goes quickly,but it usually requires some practice and patience.

UP

1/2”

Calibration

Rod

DOWN

FIGURE 11

F.) Use the ARROW keys while holding the

LIFT ENABLE button to change the value

to .500. The last digit of this number ma y

fluctuate slightly.

4 --- 6

Page 37

BLODGETT CONVEYOR GRILL

This page intentionally left blank.

4 --- 7

Page 38

CHAPTER 5

POSITION CONTROL

Page 39

BLODGETT CONVEYOR GRILL

DESCRIPTION

The positioning control uses a 24 VDC lift motor

(linear actuator) with internal limit switches and an

external 2000 W linear potentiometer with a 2-inch

stroke, which supplies positioning feedback to the

electronic controller. The lift motor attaches to the

upper platen sliding carriage by a bolt and notched

bracket. The sliding carriage houses four pillow

block bearings t hat ride on vertical polished shafts

bolted to the frame. The upper platen is carried by

two support rods that pass through the sliding

seals in the stainless cover and are bolted to the

sliding carriage.

The height of the upper platen deck over the lower

platen is measured by a linear potentiometer

mounted on the sliding carriage assembly inside.

Calibration is made by adjusting the resting position of the potentiometer shaft against it’s reference stop so that the display height reading agrees

with the actual measured distance between the

platens. Adjustment is accomplished by moving

the two locknuts on the potentiometer’s threaded

shaft. Re-calibration will be needed if the platens

have j ust been re-squared.

Linear Potentiometer

Plunger Shaft

Plunger Weight

Adjustment Nuts

Reference Stop

Limit

Switch

Access

Lift Motor

FIGURE 1

5 --- 1

Page 40

POSITION CONTROL

TROUBLESHOOTING

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Measured gap between platens never agrees w ith the display value --- too high or too low.

D

Unit not calibrated properly.

SYMPTOM: Measured gap between platens sometimes doesn’t agree with display value.

D

Check linear potentiometer shaft for freedom of

movement.

D

Check that the small donut weight is installed on

the end of the potentiometer shaft.

D

Check for any looseness of the sliding carriage

assembly.

D

Check for loose or broken wires/connectors on

cable from potentiometer.

D

Follow instructions to adjust jam nuts on the

linear potentiometer.

D

Clean shaft.

D

Install weight if missing.

D

Clean & lubricate vertical shafts.

D

Reconnect cable.

SYMPTOM: Unit can’t find it’s position

D

Linear potentiometer shaft sticking.

D

Linear potentiometer faulty.

D

Pillow block bearings not moving freely on

vertical shafts.

D

Check for loose or broken wires/connectors on

cable from potentiometer.

SYMPTOM: Lift motor does not move up or down

D

Liftmotororcontrollerfailure.

SYMPTOM: Unit fails to return from clean position.

D

Clean shaft.

D

Replace.

D

Clean and lubricate lightly.

D

Reconnect cable.

D

Unplug the red, white, green, and black wires to

the lift motor and check for 24 + VDC between the

red and black wires when the unit is put in the

“CLEAN” mode. If voltage is present, go to the “Lift

Motor Diagnostics” section. If not, check the lift motor supply harness for continuity and check the

control board Molex receptacle for 24 + VDC

(when the unit is in the “CLEAN” mode) between

the pins which correspond to the red and black

wires on lift motor supply harness Molex plug. Replace the harness or control board as necessary.

D

Lift motor limit switch failed or sticking.

D

TABLE 1

5 --- 2

Replace lift motor.

Page 41

BLODGETT CONVEYOR GRILL

WIRING DIAGRAM

FIGURE 2

5 --- 3

Page 42

LIFT MOTOR

POSITION CONTROL

NOTE: You may use the 24 VDC power supply avail-

able from Blodgett Tec h n ic al Support to perform these operations. This power supply

has connectors that plug into the lift motor

and an extend/retract switch allowing operation of the lift motor without power to the unit.

DIAGNOSTIC PROCEDURE

To test the lift motor for proper function, follow

these directions to use the existing lift motor power

supply and harness as a 24 VDC power source:

1. Shut off supply power at the circuit breaker or

disconnect and remove the rear cover.

2. Cut the wire tie securing the electrical supply

harness near the lower end of the lift motor.

Disconnect the connectors for the red, black,

white, and green wires in the supply harness.

3. Energize the unit again and place it in [MENU

A?] mode. Press the CLEAN button and check

for 24 VDC between the red and black wires

coming from the supply harness. If you do not

have 24 VDC, there is a problem with the controller or supply harness which must be corrected before you can test the lift motor.

4. If 24 VDC is present, de-energize the unit and

re-connect the black and red wires from the

supply harness to the black and red wires of

the lift motor . Connect the female bullet terminal from the short test wire coming from the

black wire on the supply harness to either the

white (for extend) or green (for retract) wire on

the lift motor. If the supply harness does not

have a short test wire attached to the black

wire, cut off the existing female bullet terminal

from the end of the harness wire and re-crimp

on a new female bullet terminal and a short (4”)

section of black wire with another female bullet

connector on the other end.

SETTING LIFT MOTOR LIMIT SWITCHES

NOTE: Complete the Lift Motor Diagnostics Pro-

cedure before setting the lift motor limit

switches.

Theliftmotorlimitswitchesmustbesetcorrectly.

A lift motor with an incorrectly set lower limit switch

may not allow movement of the upper platen to the

smaller height settings required for some products. An upper limit switch set higher than 4” will

cause damage to t he rear sheetmetal cover. The lift

motor limit switches are to be set so the lift motor

provides a total of 4” (+/ --- 1/16”) of travel from the

zero position. Set the switches as follows:

1. Remove the rubber plug beneath the wire inlet

into the motor to access the two small plastic

limit switch adjusting screws .

2. Turn the [retract length] screw to increase or

decrease the retracted position so the lift motor shuts off at the same point at which the platens are touching each other. This adjustment

is carried out in the CLEAN mode by disconnecting and connecting t he test jumper from

the green to the white wires repeatedly to establish the zero position. If this adjustment is

attempted with the lift motor removed from the

unit, the operating shaft must never be allowed

to rotate because the limit settings will be lost!

3. Repeat step 2 for the [extend length]. Set the

¦

upper limit to 4” (

extended.

4. Re-check the lower limit. Re-adjust if necessary.

1/16”) when the shaft is fully

5. Energize the unit and place in the CLEAN

mode. This causes the lift motor to extend or

retract depending on the lead the test wire was

connected to. Repeat for both extend and retract functions. If the motor fails to extend or retract, replace it and set the limit switches on the

new motor. If the motor does function properly,

check the limit switch settings to completely

test the lift motor.

FIGURE 3

5 --- 4

Page 43

BLODGETT CONVEYOR GRILL

REMOVING AND REPLACING THE LIFT MOTOR

1. Insert a 2” thick board or other non -marring objects between the platen assemblies to support the weight of the upper platen.

2. Energize the unit and go to the [1:LIFT CAL]

mode. Press ENTER and use the ARROW key

to lower the platen gently onto the board or

support object. Further lowering will withdraw

the lift motor shaft and cross bolt from the upper motor mounting bracket. If the lift motor is

totally non-functional, it will be necessary to

force boards between the platens to raise the

upper platen about 2” and free the upper lift

motor bracket.

4. Reverse the procedure to install the new lift

Upper Motor

Mounting

Bracket

Motor Shaft

Cross Bolt

motor:

A.) IntheLIFTCALmenuinPSWDmodeuse

Lower Lift Motor

Mounting Bolt

FIGURE 5

the ARROW keys to extend or retract the

cylinder shaft to fit it into position in the

cradle bracket. DO NOT allow the motor

shaft to rotate when extending or retracting the shaft, otherwise the limit switch settings w ill be lost.

FIGURE 4

3. Whentheuppershaftisfree,de-energizethe

unit and disconnect supply power in order to

work inside.

A.) Disconnect the four wires.

B.) Loosen and remove the lower lift motor

bolt.

C.) Remove the motor from the unit.

D.) Remove the upper shaft cross bolt and lock-

nut and re-install on replacement lift motor.

B.) Tighten the lower mounting bolt.

C.) The linear potentiometer will now need re-

calibrating and the limit switches will need

to be checked/reset. Failure to do so will

result in damage to the rear sheetmetal

cover of the unit if the lift motor extends

more t han 4”.

D.) Raise the platen using the ARROW keys in

[LIFT CAL] mode and remove the wooden

board from between the platens.

5 --- 5

Page 44

LINEAR P OTENTIOMETER

POSITION CONTROL

DIAGNOSTIC PROCEDURE

1. Disconnect the cable from J-8 on the control

board.

2. Check the resistance between each pair of

wiresandcomparewithTABLE2.Iftheresistance of the linear potentiometer you are working with does not approximately match these

values,itmustbereplaced.

LINEAR POTENTIOM ETER RESISTANCE IN

OHMS AT VARIOUS POSITIONS

Shaft fully

Red-

Green

open (1) open (1) closed (0)

Green-

Black

Red-

Black

extended

Shaftat1” open (1) open (1) 1.01

Shaft fully

open (1) open (1) 2.02

compressed

TABLE 2

REMOVAL AND REPLACEMENT

1. Turn the main power switch to de-energize the

unit and remove the rear covers.

2. Disconnect the 3-wire potentiometer cable

from J-8 on the controller board and cut any

wire tie wraps to free the cable from the rest of

the wiring harness.

CALIBRATION

NOTE: Before calibrating the potentiometer the

platen alignment must be checked and revised as necessary. Refer to Platen section

for procedures.

¦

If the display still reads .500

.016” then no calibration is necessary, and you may move on to temperature calibration. If not, calibrate as follows:

1. Loosen the two locknuts on the potentiometer

shaft using the two 5/16” combination

wrenches. When youlower the locknuts on the

shaft, the display value goes down, and when

you raise them the display value goes up.

¦

2. When the display reads .500

010”, hold the

bottom nut still and tighten the top nut against

it. Check the display while tightening to ensure

that the value doesn’t change when the nuts

are tightened. Be sure that the sliding shaft

and weight move smoothly up and down and

come to rest positively on the reference angle.

WARNING!!

Be very careful as you will be working with

metal wrenches in a live voltage area. If

the unit you are working on does not have

a protective plastic sheet over the definite

contactor area, you should make one out

of plastic, cardboard or some other nonconductive material.

3. Remove the two screws securing the potentiometer brackets to the sliding carriage assembly.

4. Remove the faulty linear potentiometer from

the mounting bracket and install the replacement unit. Reverse the procedure to install the

new assembly. The new unit MUST be calibrated before use.

5 --- 6

Potentiometer Shaft Weight Ring

Reference

Angle

Lock Nuts

FIGURE 6

Page 45

BLODGETT CONVEYOR GRILL

This page intentionally left blank.

5 --- 7

Page 46

CHAPTER 6

MISCELLANEOUS

COMPONENTS

Page 47

BLODGETT CONVEYOR GRILL

HOURMETER

The Blodgett Conveyor Grill is equipped with a 120

VAC hourmeter wired in parallel with the control

board power supply . A normally closed bulb sensor

thermostat set to approximately 200_F controls a

normally open relay which energizes/de-energi zes

the hourmeter. The thermostat opens above 200_F,

causing the relay to close and the hourmeter to record elapsed time.

The purpose of the hourmeter is to record the

elapsed time the unit is in use. The hourmeter only

records time when the unit’s power switch is on

and the platen temperature is over 200_F.

If the hourmeter does not function properly:

1. Run the unit in MENU mode with temperature

settings of 450_F for at least 15 minutes to heat

up the platens.

2. Shut off the power supply to the unit. Disconnect the wire (E) from the hourmeter to the

relay. Make and connect a wire from the output

side of the transformer (X2) to the open side of

the hourmeter (2). Secure and tape off any

bare wires.

3. Turn the unit power supply back on. The display should be lit and the hourmeter should be

running. If it does not, the hourmeter is faulty

and must be replaced. If it does record time,

the problem is with the thermostat, relay, or associated wiring.

4. Shut off the power supply and while the platens are still heated to over 200 degrees, check

that there is an open circuit across the thermostat. Reconnect the hourmeter to the relay.

If not open, the thermostat is either faulty or improperly set. If it is closed, turn the power sup ply to the unit back on and check for 120 VAC

across the hourmeter. If there is no voltage

across the hourmeter, it is likely that the relay

is faulty.

5. With the power supply off, disconnect the wire

from the relay to the thermostat (F). Make and

connect a wire from the relay (2) to the other

side of the transformer (X2) to deliver 120 VAC

across the relay coil. When the power supply

is re-connected and the power s witch turned

on, check for continuity across the contacts of

the relay(C to N/O). If there is no continuity, t he

relay is faulty and must be replaced.

6. If the problem persists after completing the

previous steps, check the individual wires for

continuity and properly crimped terminals. As

a last resort replace all wires and components

in the circuit.

FIGURE 1

6 --- 1

Page 48

DRIVE MOTOR

MISCELLANEOUS COMPONENTS

DESCRIPTION

The belt drive system consists of a 130 VDC gearmotor, a magnetic speed sensor and disk rotor, a

microprocessor controller board and power supply, and a chain drive train. Power is supplied to the

gearmotor by the controller through a cable connected to the terminal block mounted on the power

supply board of the controller. The speed of rota-

Upper Idle Sprocket

(not visible)

Speed Rotor

Speed

Sensor

tion is reported by a 60-pole magnetic disk rotor on

the gearmotor tail shaft and measured by a hall effect sensor connected to the controller by a cable

connected to J-7 on the control board. The controller then regulates the gearmotor speed to maintain

the desired cooking time / belt travel speed. The

gearmotor output is coupled by a chain with a tensioning arm and idler sprockets to drive the two

driverollersprockets.

Drive Sprocket

(not visible)

Gear Motor

Upper Drive Sprocket

Drive Chain

FIGURE 2

Lower Drive Sprocket

Chain Tensioner Sprocket

Chain Tension Spring

6 --- 2

Page 49

BLODGETT CONVEYOR GRILL

DRIVE TRAIN TROUBLESHOOTING GUIDE

The gearmotor control circuitry has proven to be

very reliable. Any problems relating to speed control have proven to be mechanical in nature; e.g.

belt slippage, loose gears on shafts, etc. If a speed

control (cooking time) problem is suspected, test

Mark the belt by placing a small wet ball of paper

towel at the infeed and time the mark’s travel from

infeed to outfeed. The time should agree with the

cook time setting. If not, remove the rear covers

and refer to the troubleshooting guide below.

by setting a desired cook time in the controller.

POSSIBLE CAUSE(S)

SYMPTOM: Unit always runs at high speed

D

Speed sensor faulty or not positioned correctly.

D

Check wires from the speed sensor to J-7.

Gap between sensor and disc rotor must not exceed .032”.

SYMPTOM: Timed belt speed does not match cook time setting.

D

Belts slipping in drive rollers.

D

Increase belt tension by evenly adjusting the

screw blocks on the infeed end of the platens.

D

Clean belts and drive rollers and platen surfaces.

D

Check that the tension blocks are providing

proper belt tension.

D

Check for loose or slipping drive sprocket on

motor output shaft and on drive rollers.

SUGGESTED REMEDY

SYMPTOM:Driverollerorchainjumpy,timingvaries.

D

Excessive drive roller binding can cause the

chain to jump the sprocket.

D

Gears not properly aligned.

TABLE 1

D

Remove the belts and chain from the drive roller

sprockets and see if the drive roller shafts turn

freely.

D

Check alignment of gears and chain. If gears are

not properly aligned, loosen the setscrews on

each of the drive roller gears and run the unit with

the gears loose. The chain will pull them into

alignment after which the setscrews can be re-

tightened.

6 --- 3

Page 50

MISCELLANEOUS COMPONENTS

DRIVE MOTOR REMOV AL AND REPLACEMENT

NOTE: If necessary, go into MENU or PSWD mode

to make sure the platens are moved down

into a normal cooking height, not the

CLEAN position.

1. Disconnect the unit from the supply power

source before beginning work.

2. Remove the drive chain by raising the chain

tension arm to create slack in the chain and

take it off the idler sprocket and other gears.

3. Remove the s peed sensor from its bracket.

4. Disconnect the drive motor power supply

cable at the terminal strip on the controller

power supply panel.

6. Loosen/remove the four bolts securing the

drive motor to the unit, and remove the drive

motor. You will need to angle it down and out

the back.

FIGURE 3

5. Loosen the two screws holding the upper thermostat mounting plate to the center plate of

the sliding carriage. Move the plate with the

thermostat, wiring, and sensor bulb out of the

way. Be careful not to pull any of t he wires off

or stress the sensor bulb.

FIGURE 4

FIGURE 5

6 --- 4

Page 51

BLODGETT CONVEYOR GRILL

FIGURE 6

7. Remove and save the drive sprocket and key

on the drive motor output shaft.

8. Remove the speed sensor disk from the motor

tail shaft. Remove the sheetmetal bracket. Reinstall the bracket and sensor disk on the new

drive motor.

9. Reverse the procedure t o reinstall the drive

motor, adding the following steps:

A.) Replace any wire ties removed in the ex-

change, bundling the wires just as they

were.

B.) Make sure the upper platen thermostat

mounting plate has been re-secured and

that the wiring and thermostat sensor bulb

are safely routed. Make sure that the sensor

bulb is riding with the moving plate and that

no motion is transmitted to the bulb as the

upper platen moves up or down. If any motion is transmitted to this bulb, the repeated

flexing will cause it to become brittle and

break. Make sure the sensor bulb cannot

contact any live electrical connections or it

will cause a short to ground.

C.) Replace and re-adjust the speed sensor

and speed sensor disk to have a gap not

exceeding .032” (1/32)”.

D.) The drive sprocket on the motor output

shaft should be flush with the end of the

motor shaft and in a lignment with the roller

sprockets that will be driven by the chain.

6 --- 5

Page 52

MISCELLANEOUS COMPONENTS

DRIVE MOTOR COMPONENTS WIRING DIAGRAM

FIGURE 7

6 --- 6

Page 53

BLODGETT CONVEYOR GRILL

SPEED SENSOR REMOVAL AND REPLACEMENT

1. Loosen the setscrew securing the speed sensor disk to the drive motor tail shaft. Remove

the speed sensor disk.

2. Disconnect the sensor wiring by slitting the

black shrink tube insulation and cutting the

splice connections to the cable wires. Cut any

wire ties holding t he sensor wires to the unit.

3. Remove the sensor from its bracket by removing the upper nut and slipping it from the hole

in the bracket.

4. Strip the new sensor leads and slip the re placement heat shrinkable sleeving onto the

wires before reconnecting them. Solder the

leads to the cable ends exactly as removed. In sulate carefully by heat-setting the shrinkable

sleeving.

5. Reverse the removal procedure to install the new

sensor and replace any wire ties previously removed to ensure that wiring does not come to

harm from moving parts during operation.

6. Center the sensor disk into place above the

sensor and tighten the setscrew. Turn the positioning nuts on the sensor to set the gap between it and the edge of the rotor to 1/32” or

less. Tighten the sensor into place.

The gap between the sensor disk and

the sensor should not exceed .032”

FIGURE 8

6 --- 7

Page 54

MISCELLANEOUS COMPONENTS

DRIVE ROLLER AND BEARING BLOCK REMOVAL AND REPLACEMENT

The drive rollers are secured to shafts supported

by spherical bearings mounted in plastic pillow

blocks which slide into the outfeed ends of the platen frames.

1. Place the unit in the clean position and remove

the wiper boxes and belts.

2. Open the power disconnect for the unit and remove the rear cover(s). Remove the drive chain.

3. Loosen the 1/4-20 set screws securing the

driverollertotheflatofthedriveshaft(there

may be one on both ends or only one on end

towards front).

Set Screw

(not visible)

FIGURE 9

4. Removethe3/4”holepluginthefrontframe

member that covers the end of the drive shaft.

Use a round rod as a drift pin to push the drive

shaft out of the roller taking care not to damage

the end of the drive shaft. Do not lose the

spring w ashers.

5. If the drive roller bearings or seals need re placement, remove the 1/4-20 bolts securing

the plastic drive roller bearing blocks to the

frame and slide them out.

6. Press grease seals and spherical bearings out

if replacement is necessary. Lubricate bearings with high temperature food service grade

(USP or NSF) grease.

NOTE: Newer models have plastic bearings

without grease fittings.

7. Position the drive roller between the frame

members.

8. Spread the rear frame member slightly by

wedging a small screwdriver between it and

the drive roller.

FIGURE 11

9. Leaving the first screwdriver wedged between the

drive roller and the rear frame member, use a second small screwdriver to push the spring washer

into place between the drive roller and the frame

member . When it is located correctly you will be

able to push the drive shaft through the rear cover ,

drive roller bearing block, and frame member and

capture the spring washer on the shaft before

pushing it through the drive roller . Failure to

install the spring washers can result in the

chain jumping off of the drive sprockets.

Spring washer shown

before pushing into

place between roller

Bearing Block

and frame.

Drive Roller

FIGURE 10

FIGURE 12

6 --- 8

Page 55

BLODGETT CONVEYOR GRILL

10. With the drive shaft just extending past the other end of the drive roller, pull the drive roller up

as far as possible to a llow the second spring

washer to be put in place over the end of the

shaft. Push the drive roller down into position

while pushing forward on the drive shaft to

keep the spring washer in place. When the

drive roller and shaft are correctly located the

shaft should push through the hole in the front

frame member and into the seals and bearing

in the bearing block.

Second

Drive Shaft

FIGURE 14

Drive Shaft

Spring Washer

FIGURE 13

11. It may be necessary to use a second drive shaft

to align the bearing in the bearing block to allo w

the drive shaft to be pushed through it.

Drive Shaft with Sprocket

12. Tighten the drive roller set screws to the flats of

the shafts.

13. Align roller drive sprockets with the drive motor

sprocket so the chain will track in vertical alignment. Run the unit, check chain tracking and

move sprockets accordingly if misaligned or

the chain chatters.

Drive Roller

Set Screw

Spring Washer

FIGURE 15

6 --- 9

Page 56

IDLE ROLLER TENSION BLOCKS

MISCELLANEOUS COMPONENTS

Belt tensioning is provided by springs located behind the nylon idle roller tension blocks. The idle

roller tension block/spring assembly is secured to

the frame by two sheetmetal screws located on the

bottomsideoftheinfeedendofeachoftheframe

members. A bolt goes through the idle roller block,

a compression spring, into a 3/8”-16 threaded stop

angle and has a 3/8-16 locknut on the end. The tension is removed from the belts by turning the bolt

in to compress the spring as far as possible.During

normal operation, the bolt is turned out until the

beltstakeallthetensionofthespringsandthere

is about a 1/4” gap between the bolt head and the

idle roller tension block.

3/8-16

Lock Nut

Tensi o n

Spring

Idle Roller

Tensi o n Blo c k

5. Grab the end of the spring in a vise and compress it by pushing on the bolt and block until

the end of the bolt sticks out past the spring.

6. Thread the stop angle onto the threads (the

open end of the angle faces away from the

back side of the idle roller block) so that 3/4”

of the bolt extends past the stop angle.

End view of idle roller

Approximately 1/8” gap

between bolt head and

idle roller tension block

during normal operation

FIGURE 17

Nut Mounting

Bracket

3/8-16 x 5-3/4” Bolt

FIGURE 16

To r e p l a ce the tensio n b l o c k

1. Remove the two sheetmetal screws from the

frame members.

2. Hold the stop angle in a vise and turn the locknut until the spring comes free of the 3/8”-16

bolt.

3. Hold the stop angle in the vise while turningthe

bolt head. The spring is pre -loaded by 2” so

push the bearing block down to compress the

spring w hile loosening the last few threads of

the bolt from the stop angle.

4. To install a new spring, put the bolt into the idle

roller block and slide the spring over the bolt.

7. Tighten the locknut onto the end of the bolt

whileholdingthebolthead.

8. The assembly can now be put into the frame

member and secured with the two sheetmetal

screws.

Sheetmetal

Screws

FIGURE 18

6 --- 1 0

Page 57

BLODGETT CONVEYOR GRILL

WIPERS

1. The upper wiper assembly snaps onto four

screw heads on the outfeed end of the upper

platen frame.

FIGURE 19

2. The lower wiper assembly hangs from two

brackets with keyhole slots that engage two

screws under the lower platen frame members. Viton wiper blades are fitted into channels in each of these assemblies. These

blades w ill need to be replaced periodically.

FIGURE 21

FIGURE 20

FIGURE 22

6 --- 1 1

Page 58

CHAPTER 7

MAINTENANCE

Page 59

BLODGETT CONVEYOR GRILL

SERVICE CHECKS

Service personnel should check the following on

each visit:

D

Fill out entry in “Service Log” and fax copy to

Blodgett Technical Support at 802-860-3784.

D

Grease drive roller fittings with food service

grade grease when applicable.

D

Check the amp draws for all legsof each platen

against values shown in the table in the PLATEN section of this manual. Replace platens as

necessary.

D