Page 1

SG2136E AND SG2136G

CONVEYOR OVENS

INSTALLATION -- OPERATION -- MAINTENANCE

SG2136E ET SG2136G

FOURS À BANDE TRANSPORTEUSE

MANUEL D’INSTALLATION -- FONCTIONNEMENT -- ENTRETIEN

PENDING

BLODGETT OVEN COMPANY

www.blodgett.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN M10499 Rev B (12/01)

E 2001 --- G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNIN G:IMPROPER INSTALLATION,ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENAN C E CAN CAUSE PROPERTY DAMAGE, INJURY OR DEA TH .READ THE

INSTALLA TION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTI SSEMEN T: UNE INST A LL ATION, UN AJUSTEMENT, UNE AL TÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGESÀ LA PROPRIÉTE,DES BLESSURES OU LA MORT. LISEZATTENTI V EMENT LES DIRECTIVES D’INST A L L ATION, D’OPÉRATION ET D’ENTRETIENAV A N T

DE FAIRE L’INSTALLATION OU L’ENTRETIEN DE CET ÉQUIPEMENT.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONS À RESPECTER AU CAS OÙ L’UTILISATEUR PERÇOIT UNE

ODEUR DE GAZ DOIVENT ÊTRE AFFICHÉES DANS UN ENDROIT BIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructions et procédures permettra d’obtenir de bonsrésultats de cuisson et une longue durée de service sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l’avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. Specifica-

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d’illustration font l’objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 3

THE REPUTATION YOU CAN COUNT ON

UNE RÉPUTATION SUR LAQUELLE VOUS POUVEZ COMPTER

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We’ve set the industry’s quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, full-size, half-size, countertop and deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Cela fait maintenant dessus un siècle et demi que Blodgett se spécialisedans

la fabrication de fours. Nous avons établi les normes de qualité qui s’appliquent dans l’industrie à tous les types de fours utilisés dans les services alimentaires, quel qu’e n soit la taille, l’exploitation ou le budget. En fait, ni n’offre

plus de modèles, de tailles et d’applications de fours que Blodgett. À gaz et

électriques. De tailles différentes, sur plan de travail et superposables. Qu’il

s’agisse de fours à convection, des modèles Cook’n Hold et Combi-Oven, ou

de la gamme de fours à pizzas de la plus haute qualité offerte sur le marché.

Pour de plus amples informations sur la gamme complète de fours Blodgett,

veuillez contacter votre représentant Blodgett.

Page 4

Your Service Agency’s Address:

Adressedevotreagencedeservice:

Model/Modèl:

Serial Number/Numéro de série:

Your oven was installed by/

Installateur de votre four:

Your oven’s installation was checked by/

Contrôleur de l’installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

Oven Specifications 2...................

Oven Description and Components 3.....

Oven Description and Components 4.....

Installation

Delivery and Inspection 5...............

Oven Location and Ventilation 6..........

Oven Assembly 8......................

Oven Supports 8......................

Stacking the Ovens (if applicable) 9.....

Conveyor Belt Direction 10..............

Conveyor Belt Support 11...............

Conveyor Belt 12......................

Conveyor Belt Tensioner 14.............

Crumb Pans 14........................

Optional Remote Computer Control 15...

Optional Vent Cover/Chimney 16.........

Utility Connections ---

Standards and Codes 17.................

Gas Connection 18......................

Electrical Connection 21.................

Operation

Safety Information 22....................

Standard Manual Control 23..............

Programmable Menu Control 25..........

Oven Adjustments for Cooking 27.........

Maintenance

Cleaning 29............................

Troubleshooting Guide 31................

Introduction

Caractéristiques du Four 34..............

Description et Composantes du Four 35...

Description et Composantes du Four 36...

Installation

Livraison et Inspection 37................

Emplacement et Ventilation du Four 38.....

Montage du Four 40.....................

Supports du Four 40...................

Empilage des Fours (le cas échéant) 41..

Sens de la Courroie du Convoyeur 42....

Support de la Courroie du Convoyeur 43.

Courroie du Convoyeur 44..............

Tensionneur de la Courroie de

Convoyeur 46.........................

Ramasse-Miettes 46....................

Contrôle à Distance par Ordinateur

(en option) 47.........................

Cheminée/Couvert d’É vent (en option) 48.

Branchement des Sources d’Alimentation ---

Normes et Codes 49.....................

Branchement du Gaz 50.................

Branchement à l’Alimentation Électrique 53.

Fonctionnement

Informations sur la Sécurité 55............

Le Contrôle Manuel Standard 56..........

Contrôle Programmable du Menu 58......

Ajustements du Four Pour la Cuisson 61...

Entretien

Nettoyage 63...........................

GuidedeDépannage 65.................

Page 6

Introduction

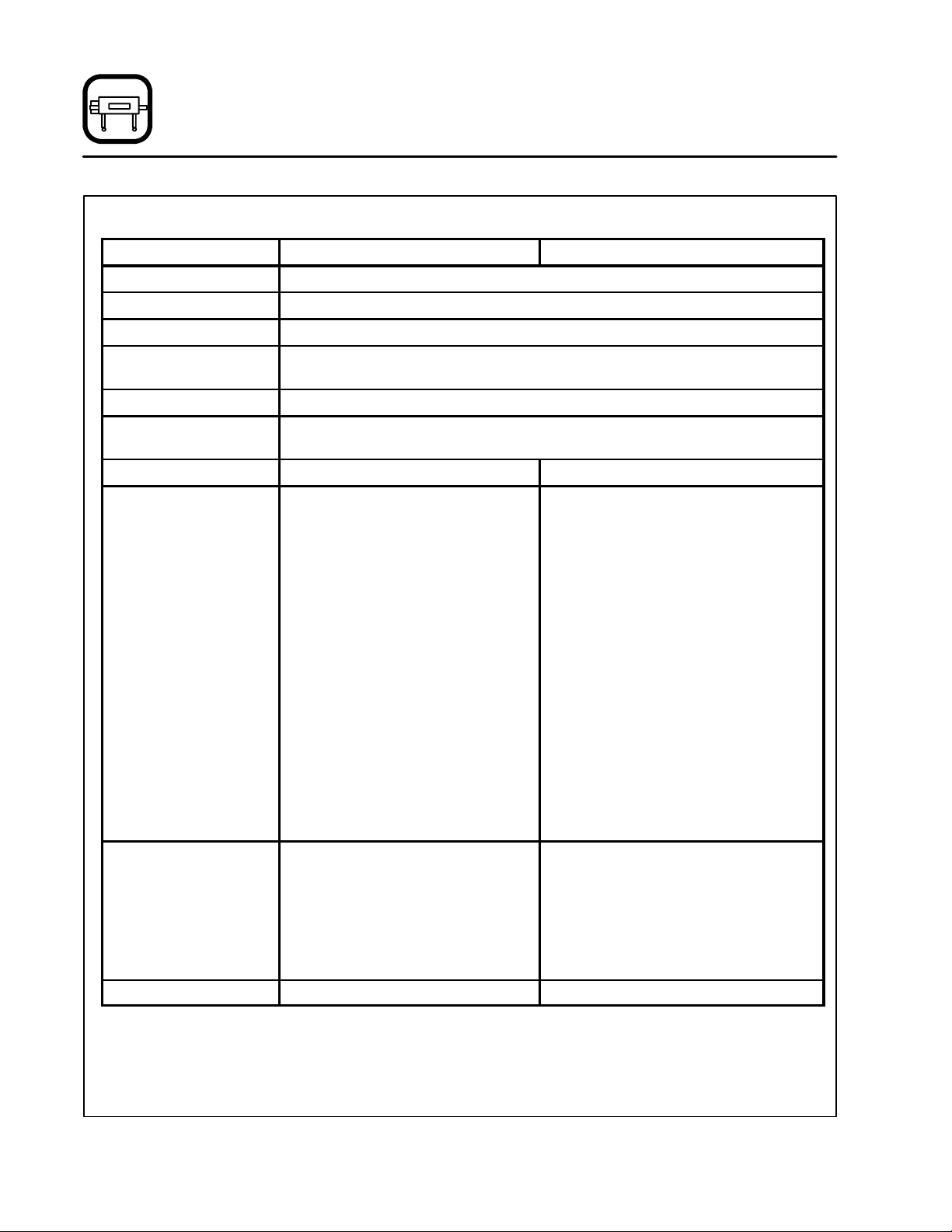

Oven Specifications

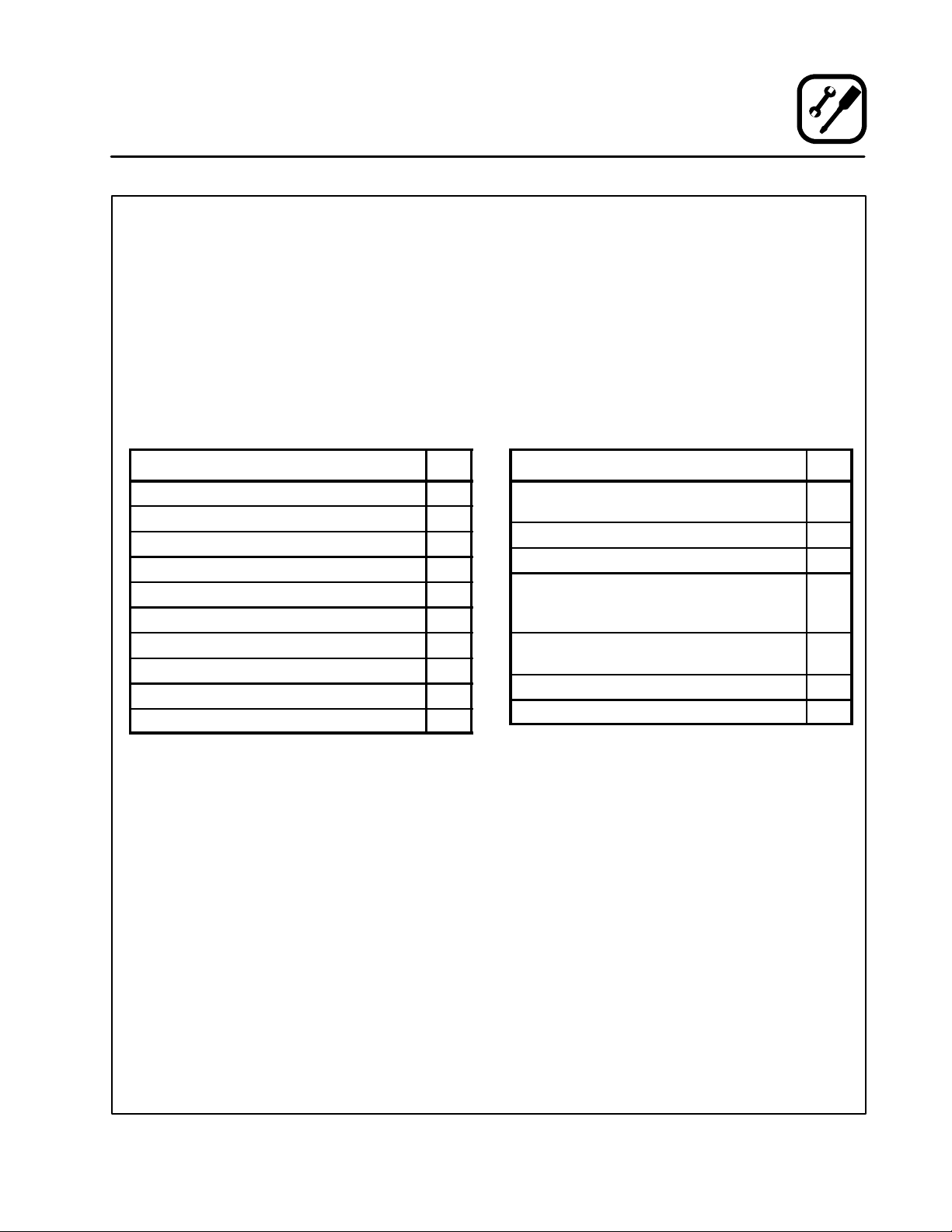

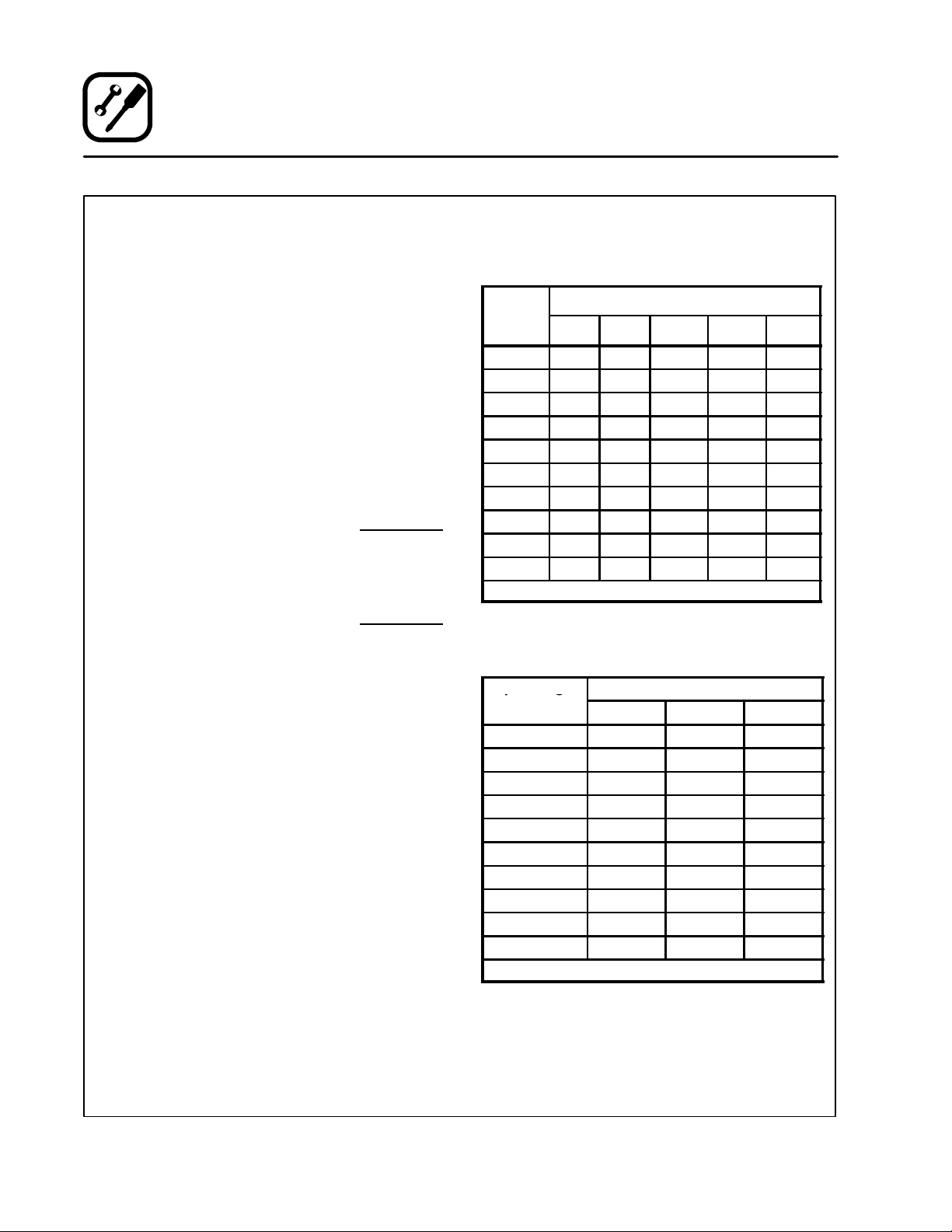

SPECIFICATIONS SG2136G/AA SG2136E/AA

Belt Width 21” (53 cm)

Cooking Zone Length 36” (91 cm)

Baking Area 5.25 sq. ft. (49 m2)

Dimensions

(single unit)

Product Clearance 3.25” (8.3 cm)

Operating

Temperature Range

Maximum Input 60,000 BTU/Hr. (17.6 kW) (63 MJ) 15 kW

Power Supply U.S. and Canadian

208-240V, 1Φ, 60 Hz, 5 amp,

2 wire plus ground

Australia and General Export

208-240V, 1Φ, 50Hz, 5 amp, 2 wire

plus ground

64” x 43.75” x 20” (162.5 cm x 1111 cm x 50.8 cm)

200-600_F (93-315_C)

U.S. and Canadian

208VAC, 1Φ, 60Hz, 76 amp, 2 wire plus

ground

240VAC, 1Φ, 60Hz, 66 amp, 2 wire plus

ground

208VAC, 3Φ, 60Hz, 44 amp, 3 wire plus

ground

240VAC, 3Φ, 60Hz, 38 amp, 3 wire plus

ground

Australia and General Export

220VAC, 1Φ, 50 or 60Hz, 73 amp, 2 wire

plus ground

220/380VAC, 3Φ, 50 or 60Hz, 24 amp,

4 wire plus ground

240/415VAC, 3Φ, 50 or 60Hz, 23 amp,

4 wire plus ground

Gas Supply Natural Gas:

4.5” W.C. (1.1 kPa) minimum

10.5” W.C. (2.61 kPa) maximum

Propane:

11.0” W.C. (2.74 kPa) minimum

13.0” W.C. (3.2 kPa) maximum

Gas Connection 3/4” (1.9 cm) NPT None

2

None

Page 7

Introduction

Oven Description and Components

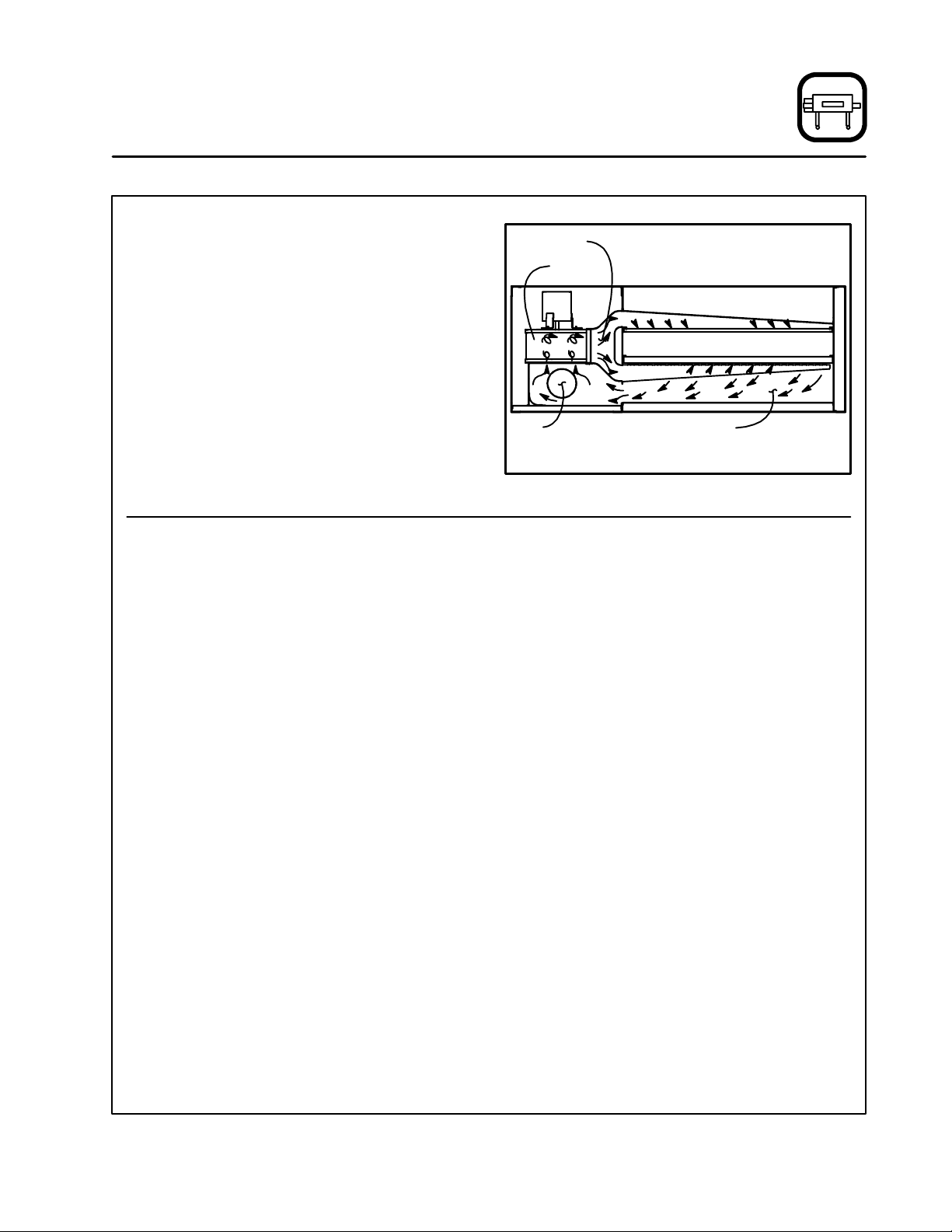

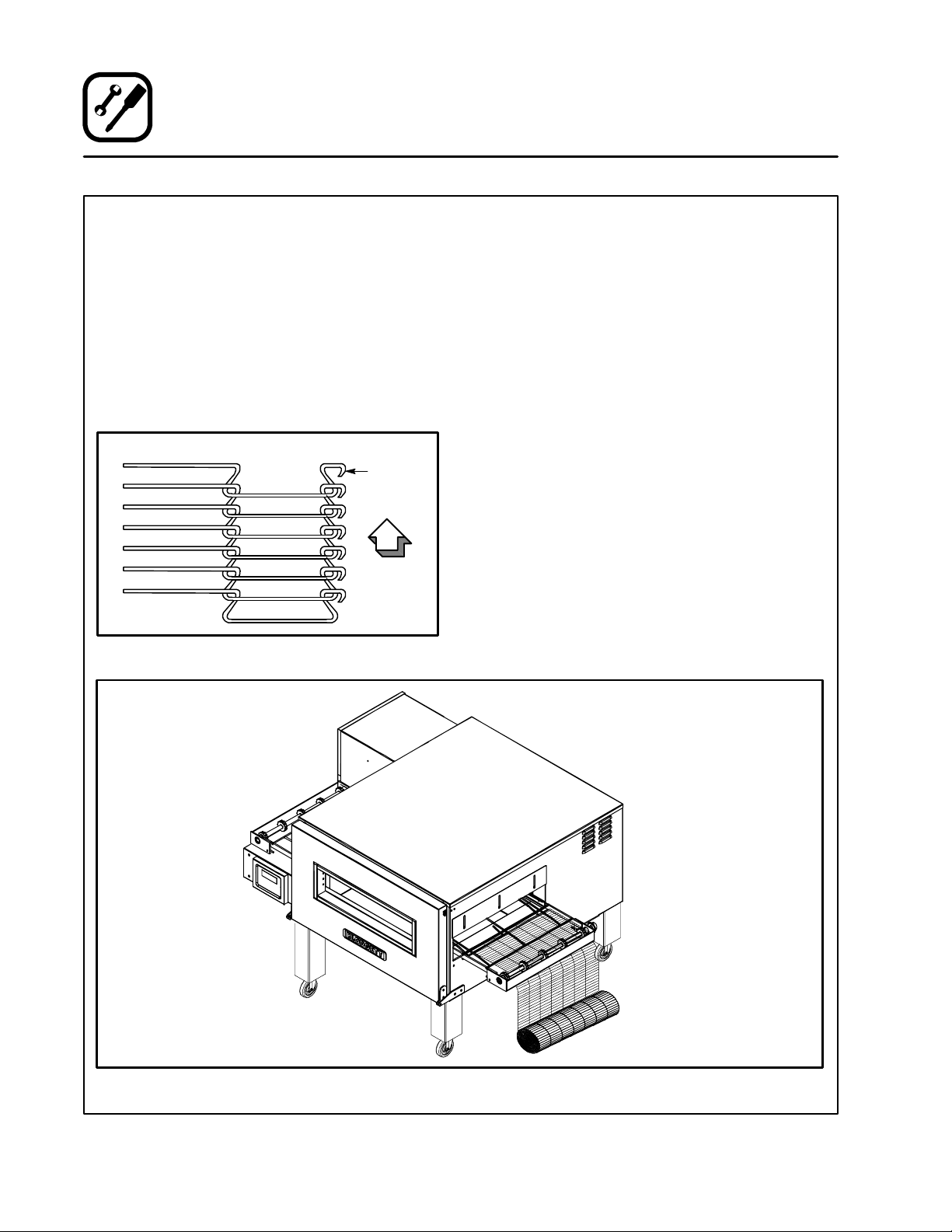

Cooking in a conveyor oven differs from cooking

in a conventionaldeck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber.The moving air continually strips away the layer of cool air surrounding the product, quickly allowing the heat to penetrate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgett conveyor ovens represent the latest advancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recirculated within the cooking chamber before being

vented from the oven: resulting in substantial reductions in energy consumption, a cooler kitchen

environment and enhanced oven performance.

Conveyor Belt --- stainless steel chain link (conveyor) belt that carries product through the oven.

Conveyor Belt Master Links --- all o w easy remov al of the conveyor belt for maintenance and cleaning. Identified by locating double spaces between

regular links on belt.

Conveyor Belt Support Assembly (drive & idle

sides) --- locatedonbothendsofovendeck.Drive

side support drives conveyor belt.

Conveyor Belt Tensioners --- maintain tension on

theendoftheconveyorbelt.

Control Box --- contains control components,

electrical wiring, cooling fans, drive motor and

drive belt.

Drive Motor --- provides power to move the conveyor belt. Located inside the control box.

Drive Belt --- transfers power from the drive motor

to the conveyor drive shaft. Located inside the

control box.

Heated Air

Blower

Fan

Air Plate

Conveyor

Nozzle

Heat

Source

Air Flow Pattern for Blodgett SG2136

Return Air

Figure 1

Baking Chamber --- products pass through the

baking chamber on the conveyor belt for cooking.

Nozzles --- distribute heated air to bottom of the

baking chamber. Located inside the oven, under

theconveyorbelt.

Crumb Pan --- catches crumbs from products on

the conveyor. Located under conveyorbelt at both

ends of the baking chamber.

Pull Down Door --- open for auxiliary product insertion.

Air Flow Plates (2, drive and idle sides) --- d is tribute heated air to the top of baking chamber.Located inside of oven at the top of baking chamber.

Emergency Shut Down Switch --- o n r em ote c on trol ovens, allows user to turn oven and conveyor

offinanemergency.Do not use for general shut

down;damage to blowersand oven body could

occur.

3

Page 8

Introduction

Oven Description and Components

Remote

Mounting Bracket

Remote

Housing

Drive Side

Conveyor

Belt Support

Control Box

Remote Ov en

Control

Air Slides

(2)

Integral

Oven Control

Belt

Tensioner (2)

Idle Side

Conveyor Belt

Support

Pull Down Door

Conveyor

Belt

Access Panel

Product

Stop

Crumb Pan

Nozzles

Air Flow

Plates

Crumb

Pan

False Front for

Pull Down Door Option

False Front

Figure 2

4

Page 9

Installation

Delivery and Inspection

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external dam age. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Ca rriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

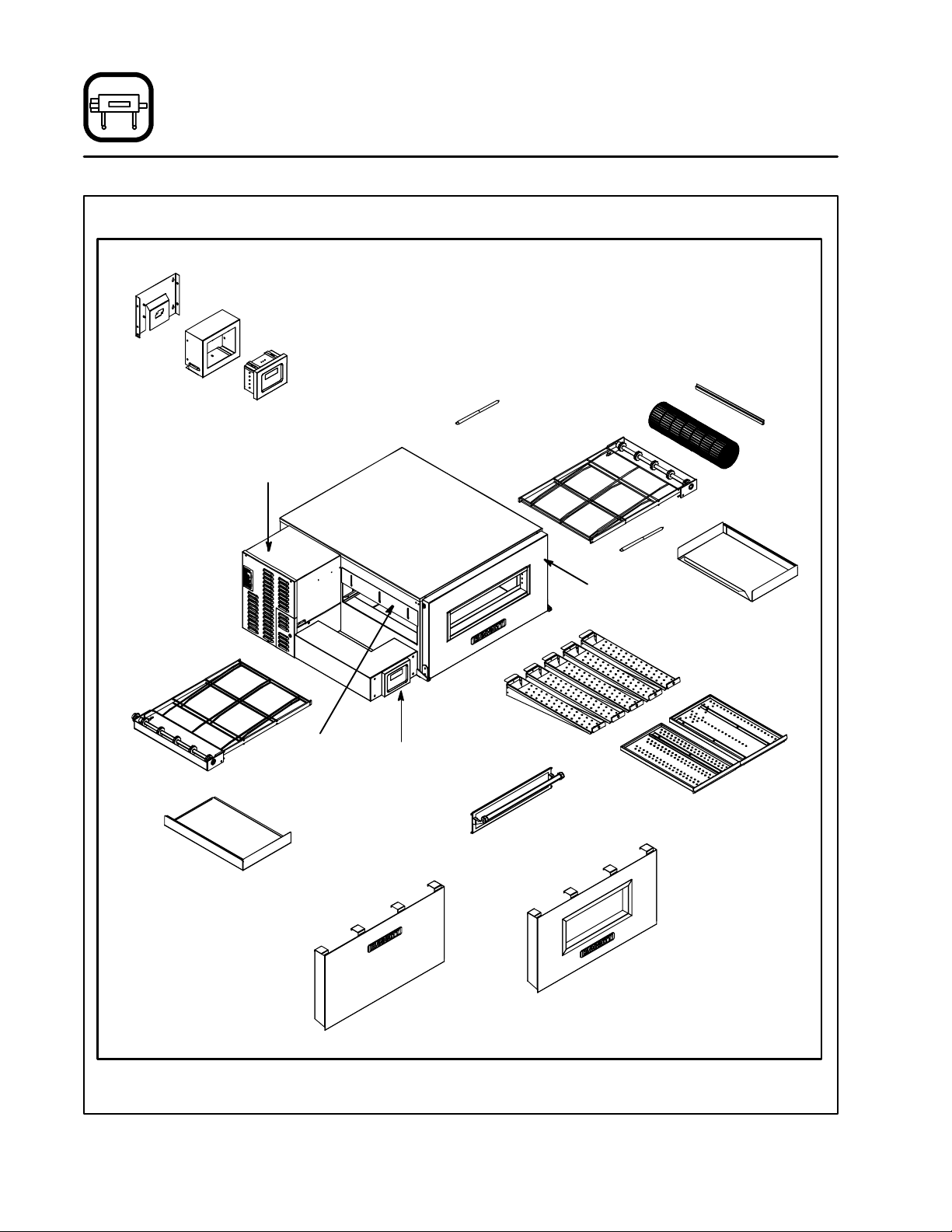

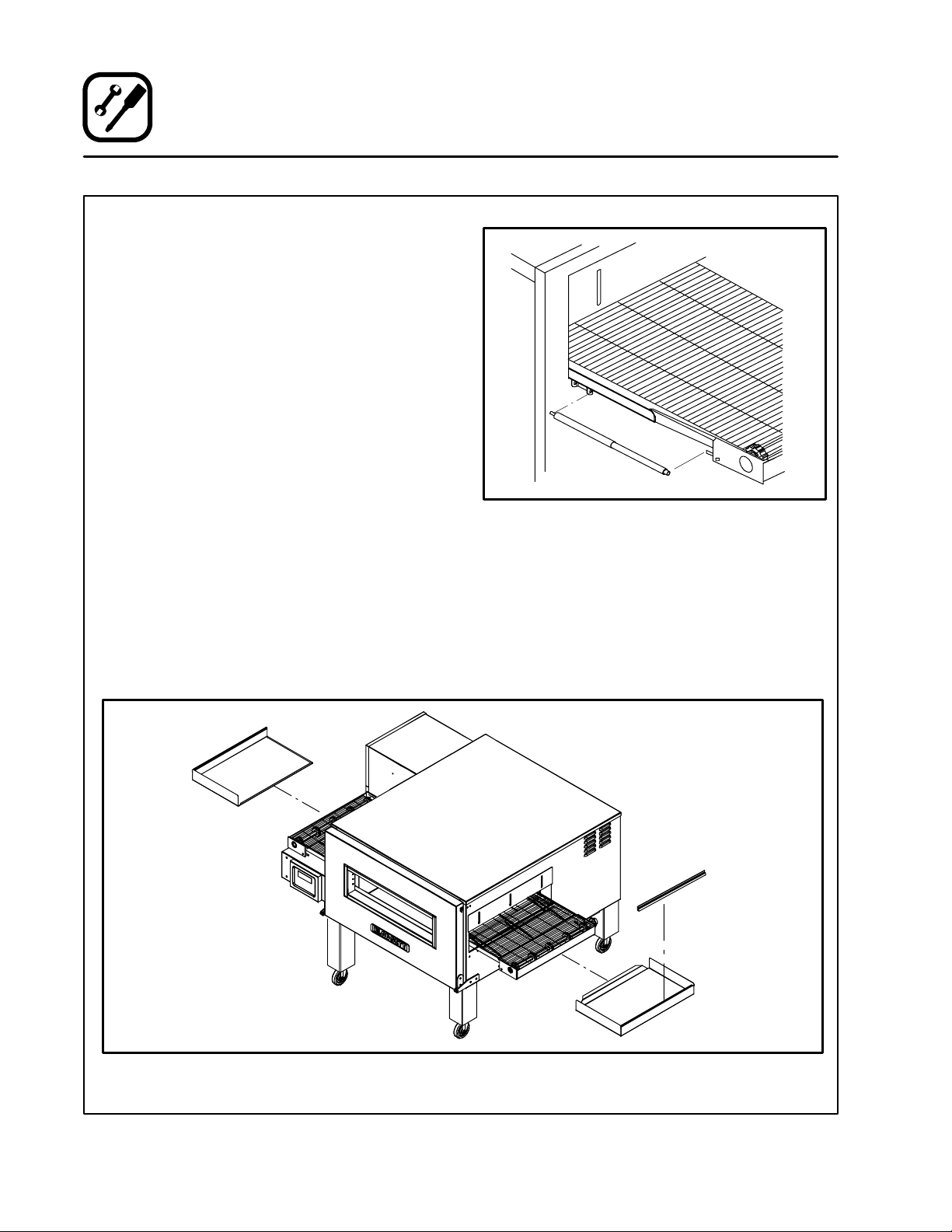

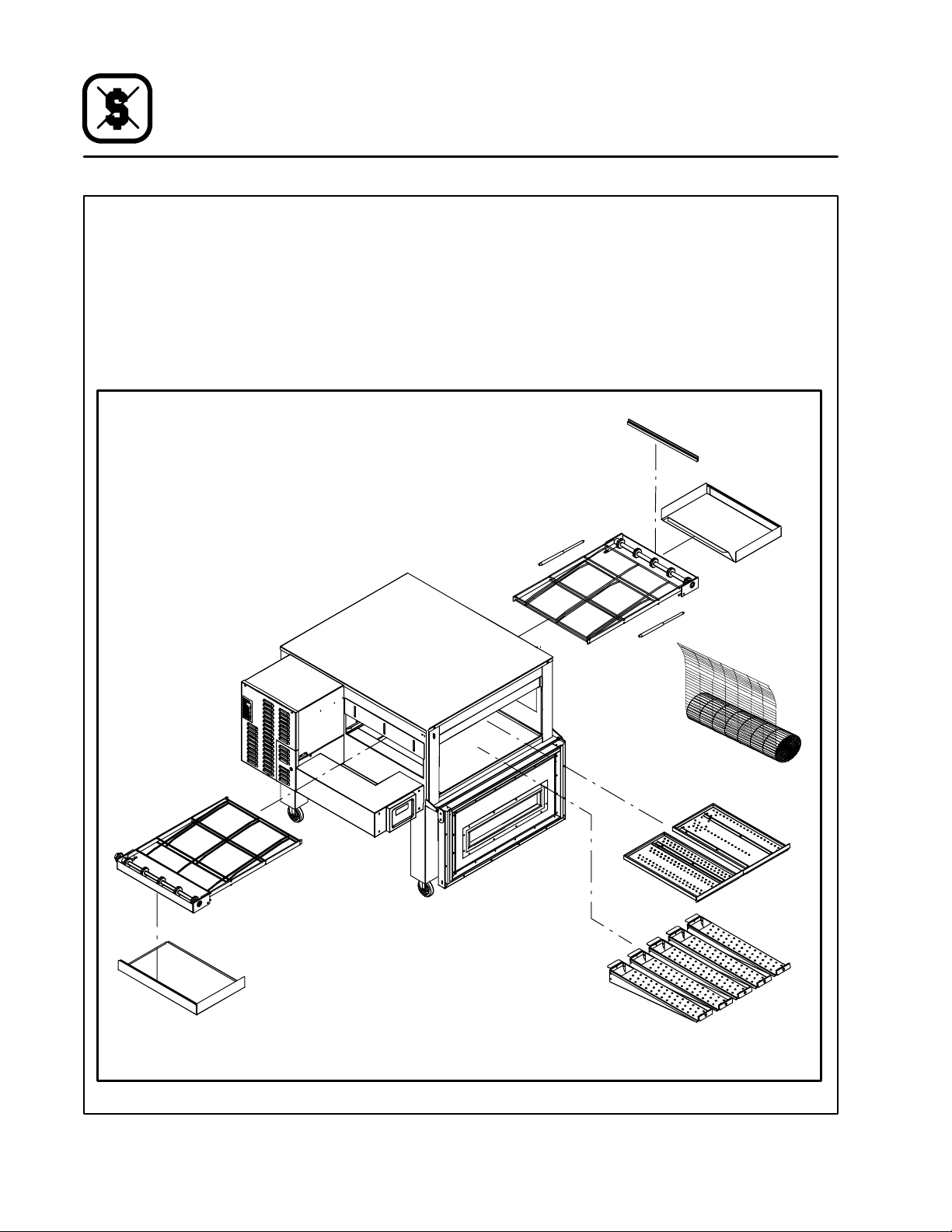

Part Description

Main oven body 1

Left conveyor belt support assembly 1**

Rightconveyorbeltsupportassembly 1**

Air plates 2**

Belt tensioners 2

Rolledwireconveyorbelt 1**

Crumb pans 2

Nozzles 5**

Access panel assembly 1

Product stop 1

Qty.

The Blodgett Oven Company cannot a ssume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a cl aim is necessary.

The oven can now be moved to the installation

site. Check the followinglist with Figure 2 on page

4 to be sure all items were received.

Part Description Qty.

Packet containing: conveyor belt inner

and outer master links

Extra piece of wire conveyor belt 1*

Owner’s manual 1*

Optional stacking kit:

1 for double stacked units

2 for triple stacked units

Optional remote control

(display and operator interface)

Optional remote control cables 1*

Optional false front 1

NOTE: * Item not shown.

**May be shipped installed

1*

1,2*

1

5

Page 10

Installation

Oven Location and V entilation

LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

The following clearances must be maintained between the oven and any combustible or non-combustible construction.

D

Oven body left side/control box --- 6” (15.2 cm)

D

Oven body back --- 0” (0 cm)

The following clearances must be available for servicing.

D

Oven body left side --- 38” (97 cm)

D

Oven body back --- 28” (71 cm)

NOTE: On gas models, routine servicingcan usu-

ally be accomplished within the limited

movement provided by the gas hose restraint. If the oven needs to be moved further from the wall, the gas must first be

turned off and disconnected from the oven

before removing the restraint. Reconnect

the restraint after the oven has been returned to its regular position.

It is essential that an adequate air supply to the

oven be maintained to provide a sufficient flow of

combustion and ventilation air.

D

Place the oven in an area that is free of drafts.

D

Keep the oven area free and clear of all combustiblessuch as paper, cardboard, and flammable

liquids and solvents.

D

Do not place the oven on a curb base or seal to

a wall. This will restrict the flow of air and prevent

proper ventilation to the blower motors. This

condition must be corrected to prevent permanent damage to the oven.

VENTILATION

A mechanically driven ventilation system is required for the removal of excess heat and cooking

vapors. For gas models, a ventilation system is

also required for the removal of the products of

gas combustion. The necessity for a properly designed and installed ventilation system cannot be

over emphasized.

The following are general recommendations and

guidelines for good ventilation. Your specific application may require the services of a ventilation

engineer or consultant

The ventilation hood must work well with the building heating, ventilation and air conditioning (HVAC)

system. The hood exhaust and the supply air flows

should be sized appropriately. Supply air must be

provided by either the hood system or the building

HVAC system in order to prevent an excessive

negative pressure in the oven area. Supply air

should replace approximately 80% of the air flow

exhausted by the hood. The table below can be

used as a guideline, but the correct air flow values

depend on the efficiency of the hood design, the

amount of air flow around the oven, and the current air flow in and out of the kitchen or oven area

(for existing facilities).

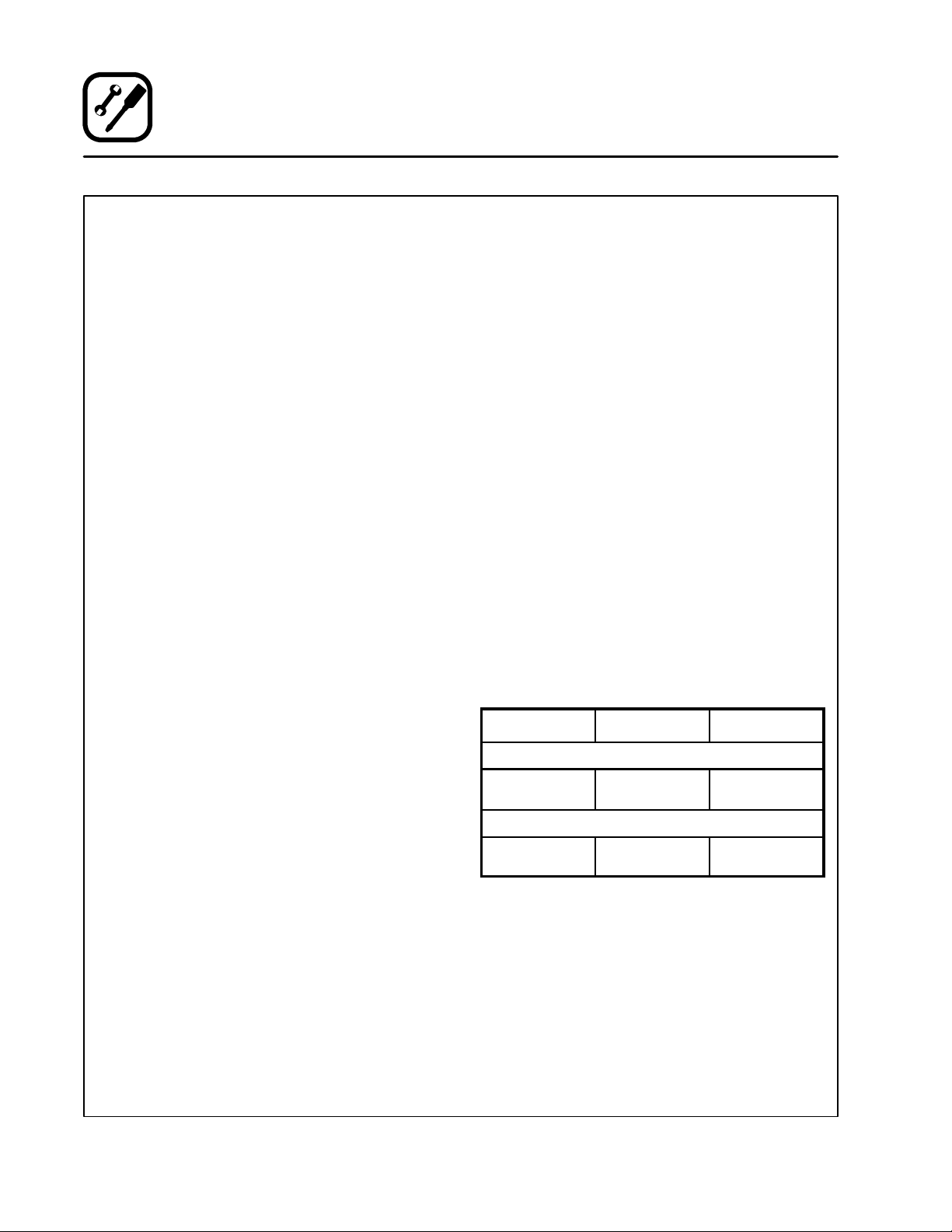

SINGLE

DOUBLE TRIPLE

Exhaust Volume -- CFM (M3/min)

400-500

(14-17)

800-1000

(23-28)

1200-1500

(34-43)

Supply Requirements -- CFM (M3/min)

320-400

(12-14)

640-800

(18-23)

960-1200

(27-34)

Ideally supply air would be provided through the

building HVAC system or, secondly, through the

hoodwith an in-line tempering unit. Air supplieddirectly from outside the building to the kitchen or

oven area, non-tempered, could be used as supplyair but the design would have to accommodate

potential operational and environmental drawbacks.

6

Page 11

Installation

Oven Location and V entilation

NOTE: In NO case should supply air blow at or

near the cooking chamber openings as

that would adversely affect the cooking

consistency and the reliability of the oven.

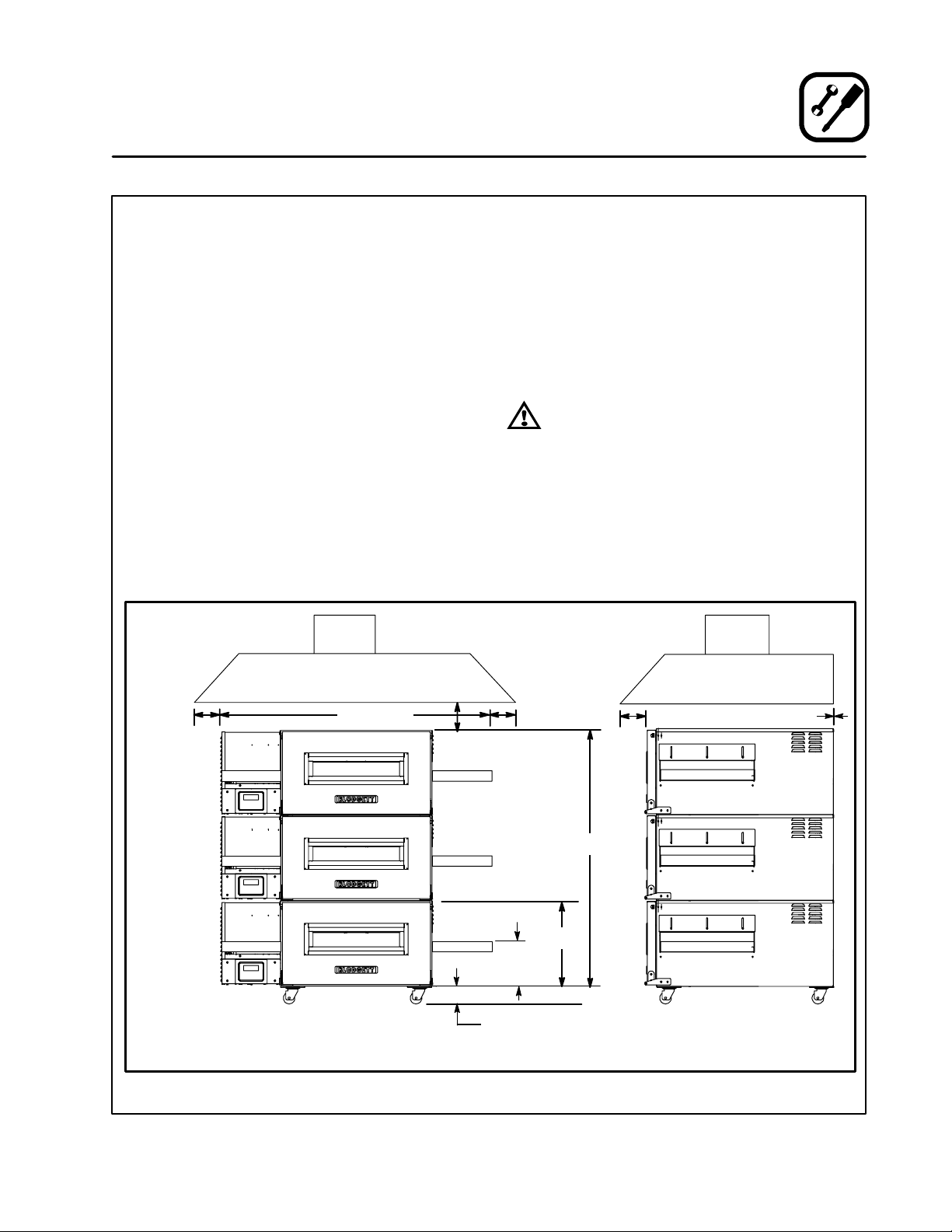

The hood should be sized to completely cover the

equipment plus an overhang of at least 6” (15cm)

on all sides not adjacent to a wall. It may be allowable in some jurisdictions to cover just the baking

chamber, 36” (91.4cm) plus a 6” (15cm) overhang. The distance from the floor to the lower

edge of the hood should not exceed 7’ (2.1m). See

Figure 3.

U.S. and Canadian installations

Refer to your local ventilation codes. Requirements may vary by city, county, province or state.

In the absence of local codes, refer to the National

ventilation code titled, “Standard for the Installation

of Equipment for the Removal of Smoke and

Grease Laden Vapors from Commercial Cooking

Equipment”, NFPA-96-Latest Edition.

3” (7.6 cm)

Minimum

6” (15.2 cm)

Minimum

64” (162.5 cm)

Australia and General Export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your Blodgett oven, please contact

your local distributor. I f you do not have a local distributor, please call the Blodgett Oven Company at

0011-802-860-3700.

WARNING:

Failure to properly vent the oven can be

hazardous to the health of the operator

and may result in operational problems,

unsatisfactory baking and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will not be covered by

the Manufacturer’s warranty.

6” (15 .2cm)

Minimum

0” (0cm) if wall or 6” (15.2cm)

60”

(152.4 cm)

20”

(50.8 cm)

9”

(22.7 cm)

Triple Stack --- 6.5” (17 cm)

Double Stack --- 17.5” (44.5 cm)

Single Stack --- 23.5” (59.7 cm)

Figure 3

7

Page 12

Installation

Oven Assembly

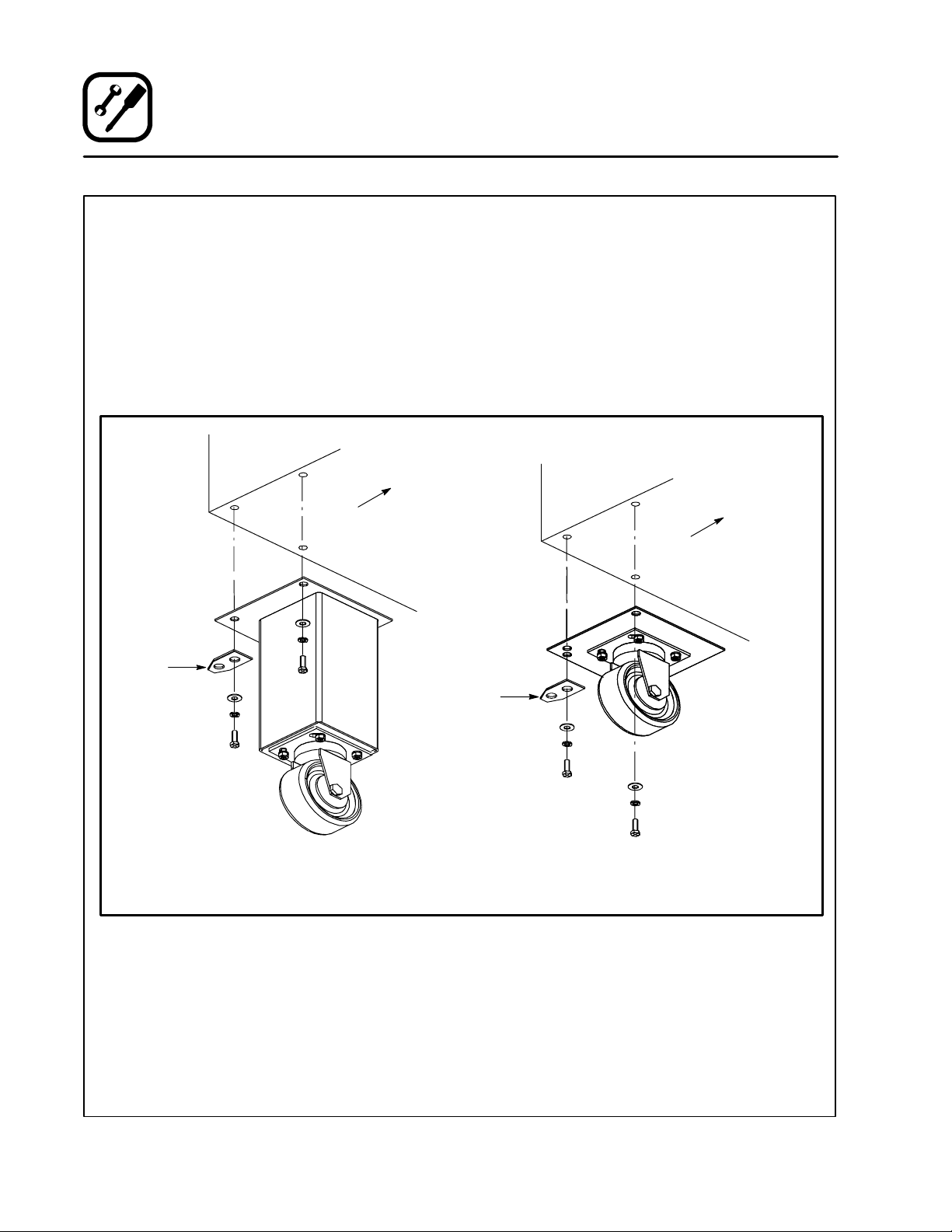

OVEN SUPPORTS

1. Bolt the leg/caster assemblies to the oven with

3/8-16 hex head bolts, lockwashers and

washers.

On gas models attach the restraint bracket to

the left rear leg as shown in Figure 4.

NOTE: Install the locking casters on the front

of the oven. The front of the oven contains the front access door.

Front of

Oven

Strain Relief

Bracket

2. Have several persons carefully lift the oven off

thepalletandsetitontothecasters.

3. Engage the brakes on the front casters.

Front of

Oven

Strain Relief

Bracket

Single and Double Stacked Units

Left rear leg and strain relief bracket shown

Trip le Sta cked Units

Figure 4

8

Page 13

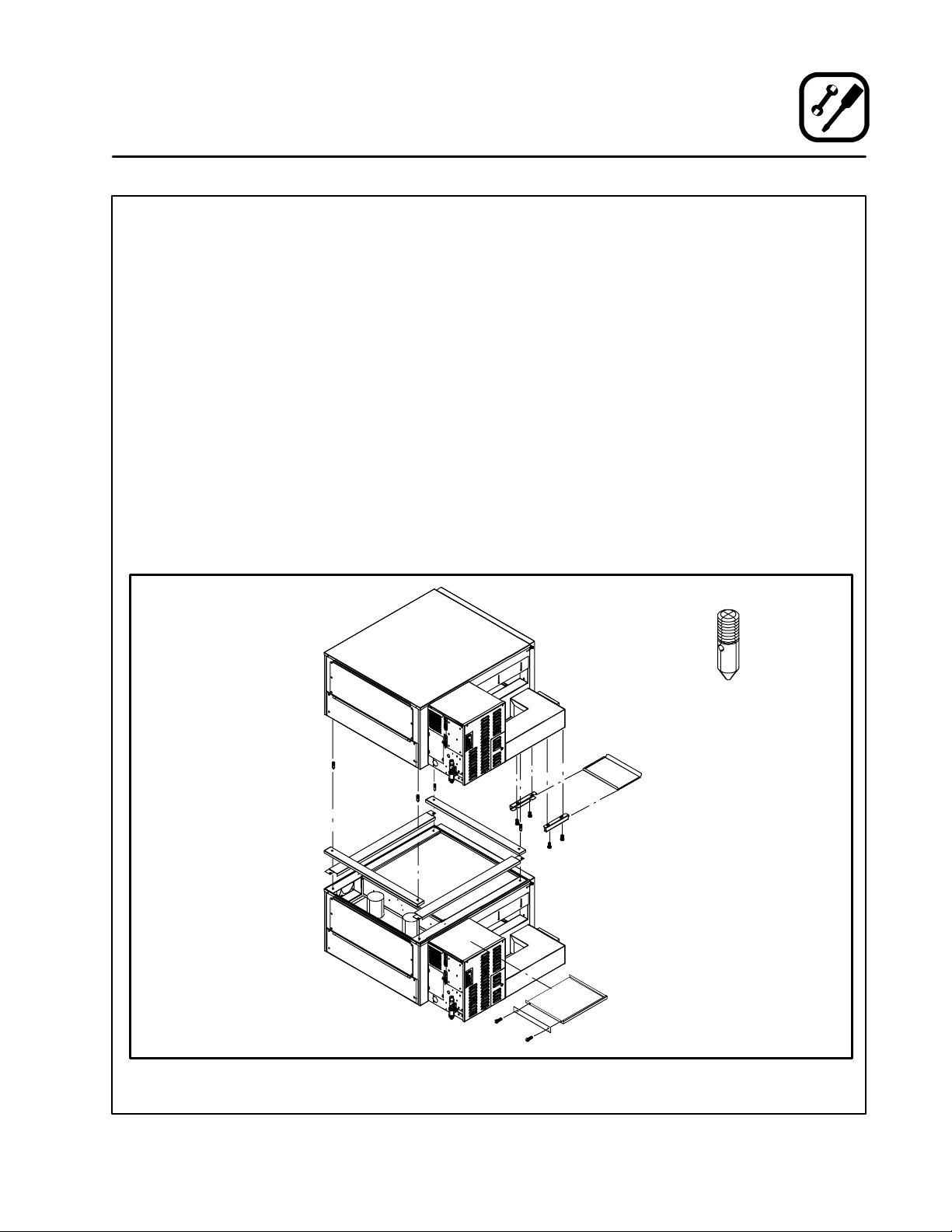

STACKING THE OVENS (if applicable)

1. Install the supports on the bottom unit as de scribed.

2. Have several persons carefully lift the oven off

thepalletandsetitontothecasters.

3. Engage the brakes on the front casters.

4. Rest the top oven on its back. Install the four

oven alignment pins into the nuts on the bottom of the upper oven. The pointed end of the

pin w ill go through the stacking rails and into

the holes on top of the lower oven.

5. Lay the stacking rails on top of the lower oven.

The holes in the rails should line up with the

holes in the oven.

6. For ovens with integral computers, mount

each heat shield bracket to the bottom of the

control tunnel of the top oven with the open

end facing out.

Installation

Oven Assembly

7. Attach the control box stacking spacer as follows:

a.) Place the control box stacking spacer on

top of the control box of the bottom unit.

b.) Loosen the two screws at the top of the

rear of the control box of the lower oven.

c.) Slide the stacking trim over the loosened

screws. Tighten the screws.

d.) A ttach the stacking trim to the side of the

stacking spacer with the screws provided.

8. Have several persons carefully place the upper oven on top of the lower oven. Align the

alignment pins with the holes in the top of the

lower oven.

9. For ovens with integral computers, slide the

front heat shield into the heat shield support.

Oven

Alignment

Pin

Stacking

Rails

Oven

Alignment

Pin

Heat

Shield

Heat Shield Bracket

Stacking Rails

Control Box

Stacking Spacer

Stacking Trim

Figure 5

9

Page 14

Installation

Oven Assembly

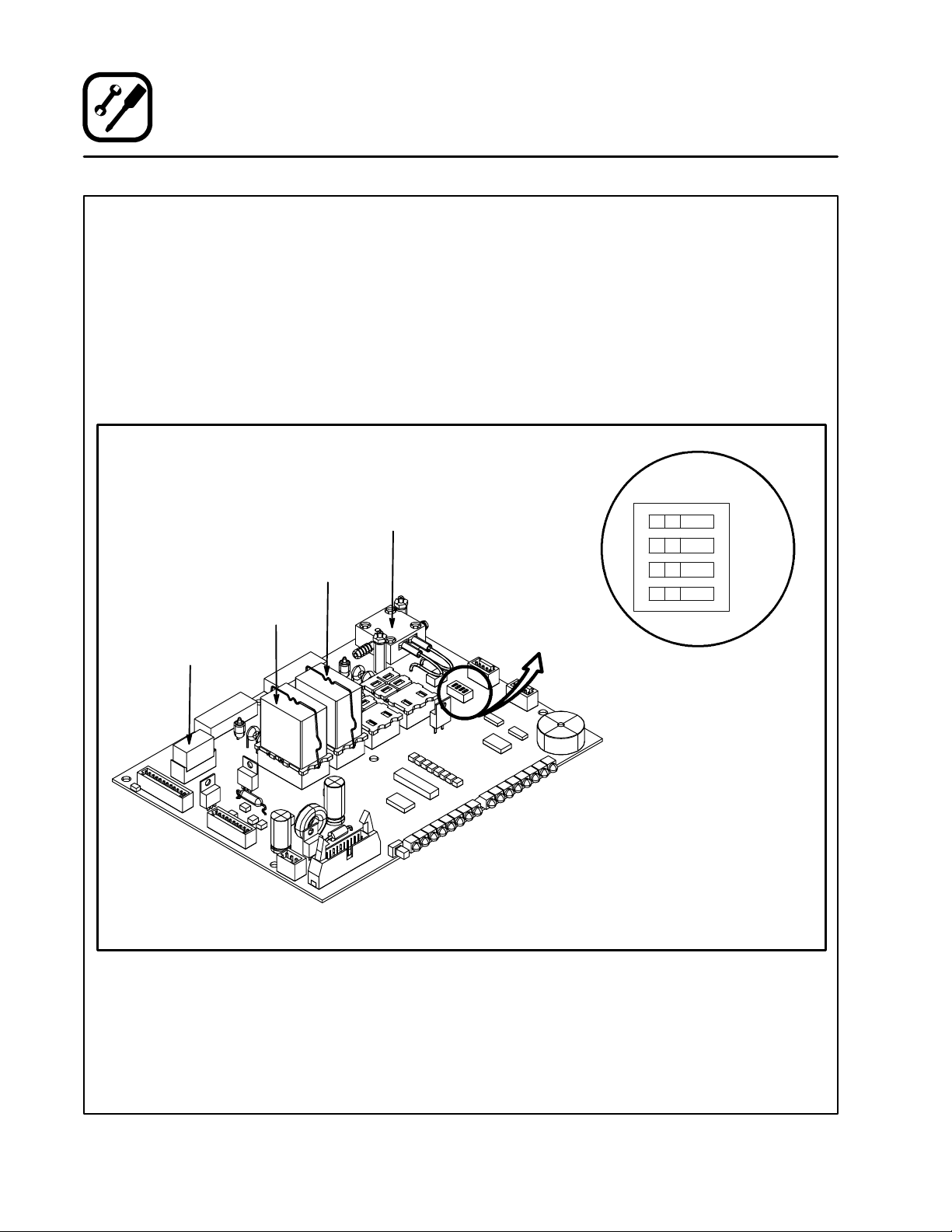

CONVEYOR BELT DIRECTION

Conveyor travel is factory set for either left to right or

right to left belt operation as ordered. If the opposite

direction is required, the polarity of the drive motor

must be reversed as follows and the conveyor belt

must be removed, reversed and reinstalled or the

belt will be damaged. Refer to page 12 for belt installation instructions.

To reverse polarity:

1. WIth the oven cold, DISCONNECT THE POWER CORD TO THE OVEN. Unscrew the electrical box access cover.

2. Flip the dipswitch marked DIR1 on SW4 (switch

4) on the interface board. See Figure 6.

NOTE: The interface board is located on the

upper rear surface of the electrical box.

View A

Heat

Relay

Blower 1

Relay

Circulation Blowers’

Pressure Switch

Blower 2

Relay

Interface Board

SW4

ENB 2

DIR 2

ENB 1

DIR 1

Switch 4

(See View A)

Figure 6

10

Page 15

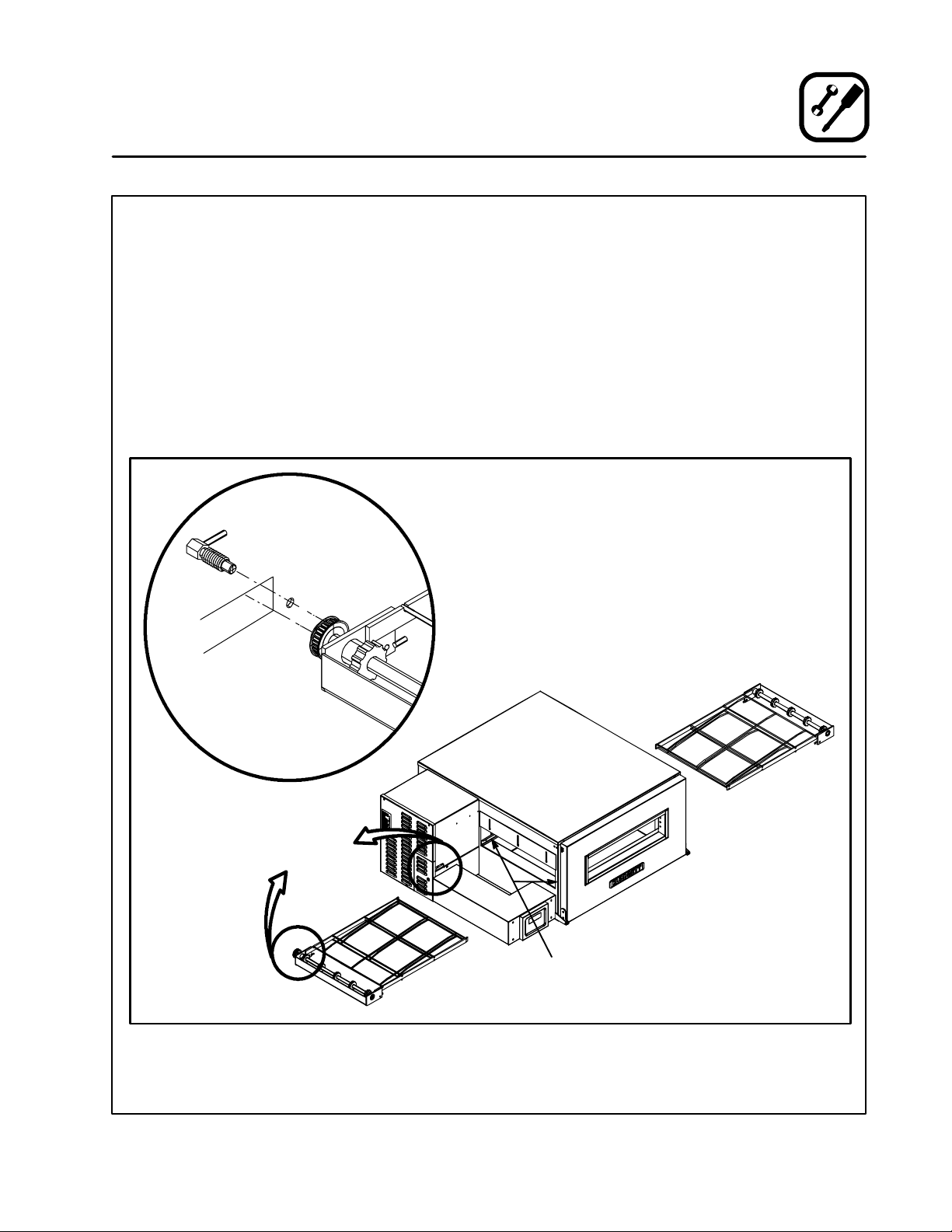

CONVEYOR BELT SUPPORT

NOTE: Conveyor belt support is shipped installed

on some units.

1. Slide the drive side conveyor support rack into

theconveyorsupportguides.

NOTE: The pulley on the conveyor rack must

be inside the electric al box after being

pushed into the oven. See View A.

2. Install the drive belt around the drive motor

pulley and the pulley on the conveyor rack. Pull

the conveyor rack forward to tighten the belt.

View A

Locating

Pin

Installation

Oven Assembly

3. Secure the conveyor using the spring loaded

conveyor locating pin. See View A.

4. Slide the idle side conveyor rack into the conveyor support guides until it touches the drive

side conveyor rack.

NOTE: If the mounting hole cannot be lined up or

the belt is too loose, the drive motor will

need to be repositioned.

Pulley

See View A

Drive Side

Conveyor Rack

Figure 7

Idle Side

Conveyor Rack

Front and Rear

Conveyor Support

Guides

11

Page 16

Installation

Oven Assembly

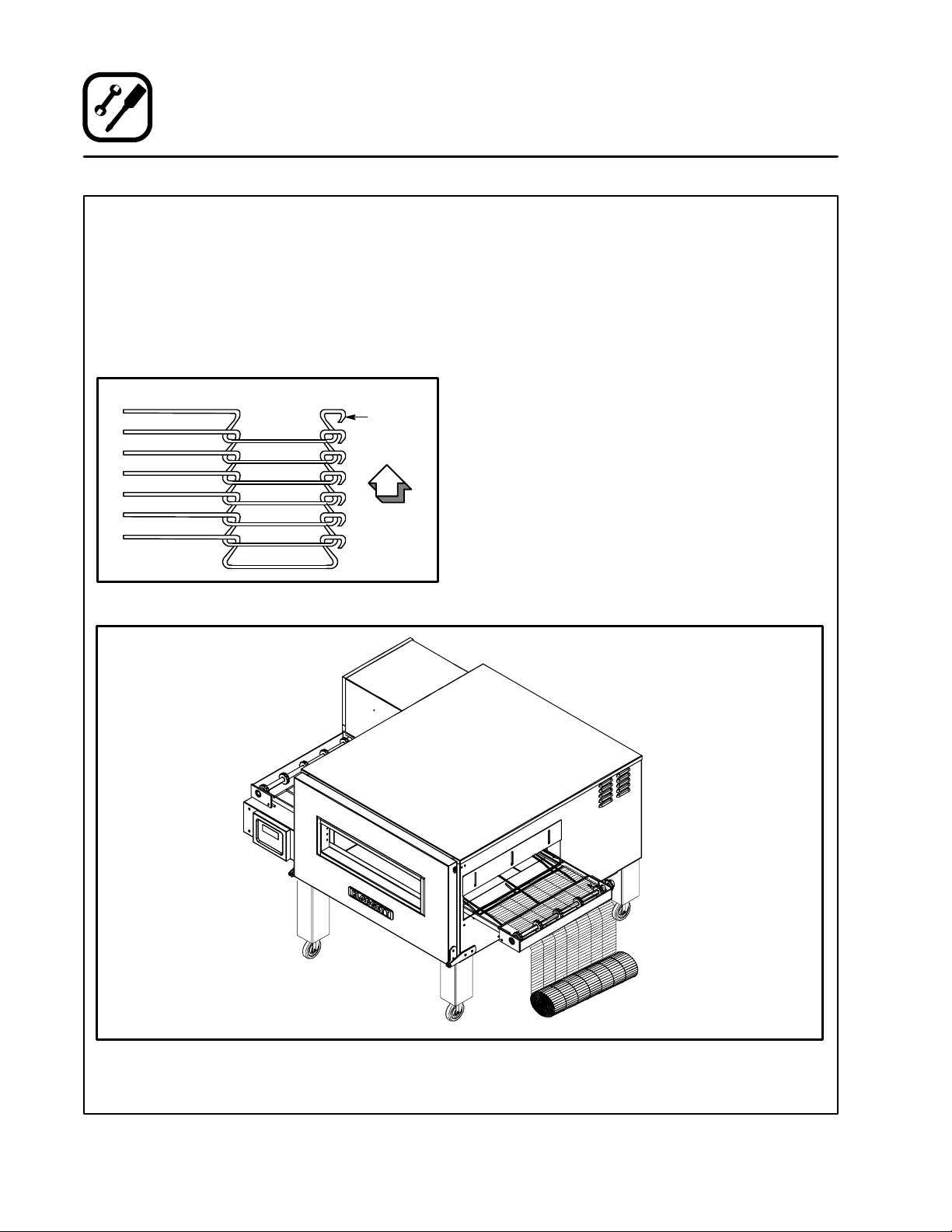

CONVEYOR BELT

NOTE: Conveyor belt is shipped installed on

some units.

NOTE: The following directions are written for left to

right travel. For right to left travel, thread the

belt from the left side of the oven. The two

ends will meet on the right side of the oven.

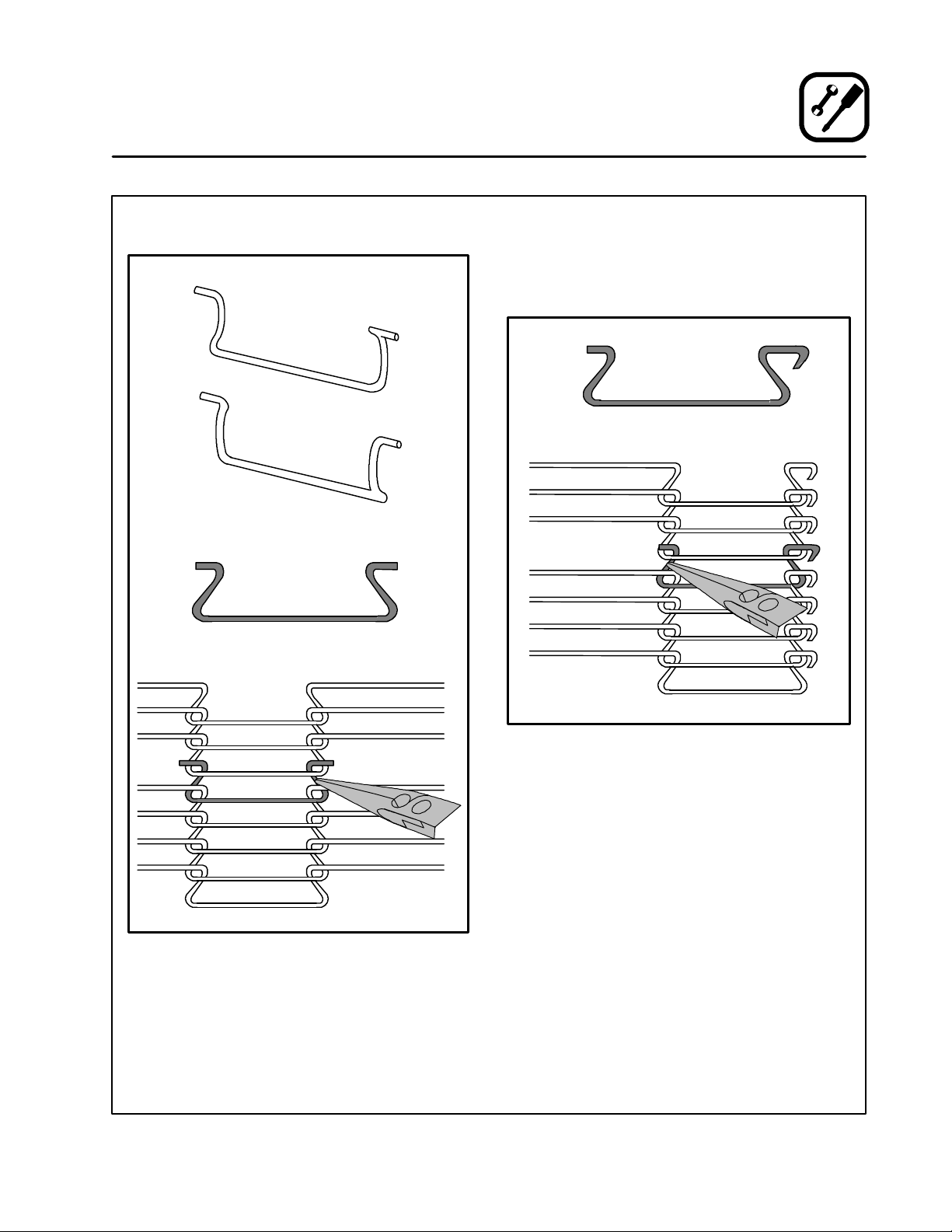

Belt Top

Direction of

Travel

Figure 8

1. Thread the conveyor belt from the right side of

the oven. The conveyor belt has loops on both

ends. The loops must travel backwards on the

conveyor rack to prevent belt damage. See

Figure 9 for proper belt orientation.

Push the belt through the conveyor rack

threading in between the top and bottom

guide rods. Stop when there is approximately

12” (31 cm) of belt hanging out on the left side.

2. Thread the belt around the sprockets on the

left conveyor rack.

3. Take the remainder of the belt, loop it around the

sprockets on the right conveyor rack.

4. Push the remainder of the belt through the

oven cavity on top of the conveyor racks.

5. Each end of the belt should meet approximately

6” (15 cm) past the end of the left conveyorrack.

Figure 9

12

Page 17

Installation

Oven Assembly

6. Install inner ma s t er links. See Figure 10.

Proper

Position

Upside-down

InnerMasterLink

7. Install the outer master links. See Figure 11

NOTE: The extra piece of wire belt can be used to

make additional master links if the original

links are lost or damaged.

Outer Master Link

Figure 10

Figure 11

13

Page 18

Installation

Oven Assembly

CONVEYOR BELT TENSIONER

NOTE: Each tensioner installs between the idle

end of the conveyor (the side opposite the

drive) and the bracket under each conveyor support angle.

1. The belt tensioner contains a spring to adjust

the length. Compress the spring to shorten

the length of the belt tensioner.

2. Insert the pin on the end of the tensioner into

the hole in the bracket under each conveyor

support angle.

3. Expand the tensioner to engage the pin located on the conveyor rack.

CRUMB PANS

1. Slidethedrivesidecrumbpanundertheconveyor rack from the front. The notch in the

crumb pan must line up with the drive shaft.

2. When the notch is lined up with the drive shaft,

push the crumb pan into the cooking chamber.

Hook the end of the crumb pan over the end of

theconveyorrack.

Belt

Tensioner

Figure 12

3. Slide the idle side crumb pan under the end of

theconveyorrack.

4. Slide the product stop over the end of the idle

side crumb pan.

Drive Side

Crumb Pan

Product

Stop

Idle Side

Crumb Pan

Figure 13

14

Page 19

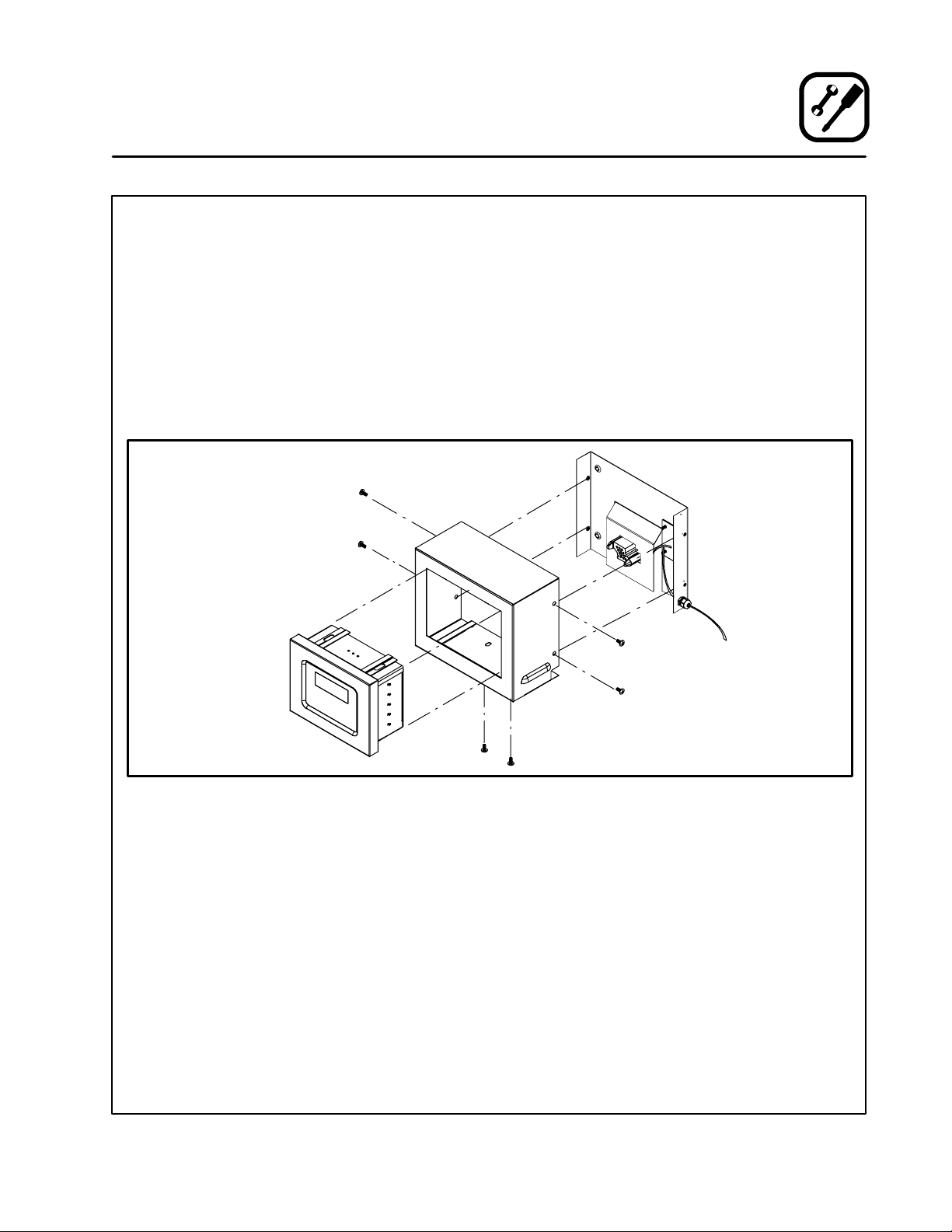

OPTIONAL REMOTE COMPUTER CONTROL

1. Remove the four side screws. Disassemble the

mounting bracket assembly from the housing.

2. Use the mounting bracket as a template to

mark the location for installing mounting bolts

into the wall.

NOTE: The mounting bolts are not supplied.

Up to 1/4” diameter bolts can be used.

Thebolttypeshouldbedeterminedby

the wall construction.

Remote

Housing

Installation

Oven Assembly

3. Attach the mounting bracket to the wall.

4. Slide the remote housing over the mounting

bracket. The holes on the sides of the housing

must line up with the holes on the sides of the

bracket. The control cable will line up with the

large slot in the mounting bracket.

5. Secure the housing to the mounting bracket

with the screws removed in step 1.

6. Be sure the operator control is well seated into

the housing and bracket.

Remote Mounting

Bracket Assembly

Operator

Control

Figure 14

15

Page 20

Installation

Oven Assembly

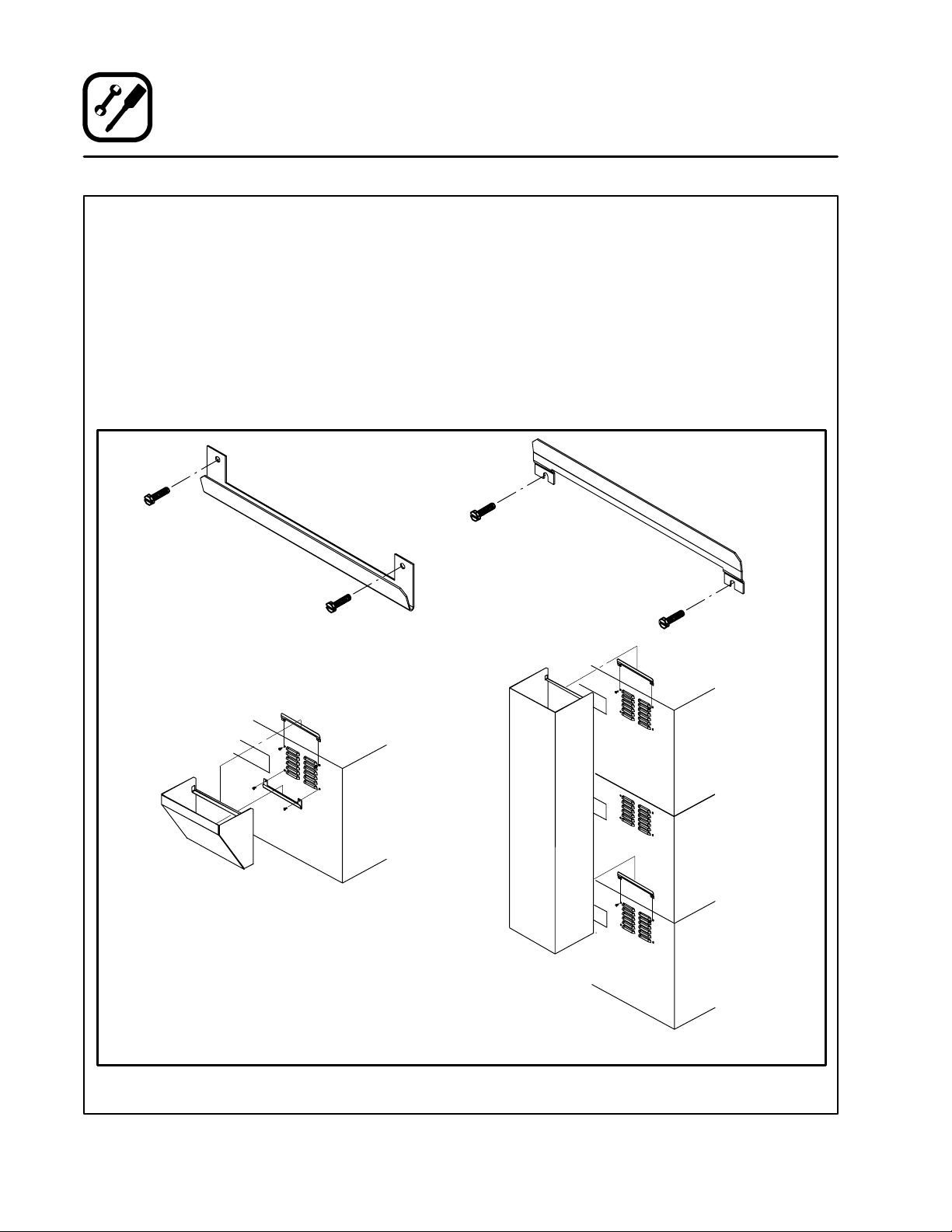

OPTIONAL VENT COVER/CHIMNEY

Single Ovens

1. Fasten a vent cover hanger to the holes at the

bottom of the louvers on the idle end of the

oven.

2. Fasten a chimney hanger to the holes at the

top of t he louvers on the idle end of the oven.

3. Slide the vent cover down onto the hangers.

The closed end must be down.

Vent Cover

Hanger

Stacked Ovens

1. Fasten a chimney hanger to the holes at the

top of the louvers on the idle end of t he top and

bottom ovens.

2. Slide the chimney down onto the hangers.

The closed end must be down.

Chimney

Hanger

Vent

Cover

Chimney

Hanger

Vent

Cover

Hanger

SG2136 Single

Figure 15

Chimney

SG2136 Triple

Chimney

Hanger

16

Page 21

Installation

Utility Connections --- Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATIONAND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D

the installation or replacement of gas piping

and the connection, installation, repair or servicing of equipment.

D

the installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experienced in such w ork, familiar with all precautions

required, and have complied with all requirements

of state or local authorities having jurisdiction.

U.S. and Canadian installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

All ovens, when installed, must be electrically

grounded in accordance with localcodes, or in the

absence of localcodes, with the National Electrical

Code, ANSI/NFPA 70 ---Latest Edition and/or Canadian National Electric Code C22.2 as applicable.

Australia and General Export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your Blodgett oven, please contact

your local distributor. I f you do not have a local distributor, please call the Blodgett Oven Company at

0011-802-860-3700.

17

PENDING

Page 22

Installation

L

t

h

p

g

Gas Connection

GAS PIPING

A properly sized gas supply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a SG2136G conveyor oven to add

to your existing cook line.

1. Add the BTU rating of your current appliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total 230,000 BTU

SG2136G 60,000 BTU

New Total 290,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let’s say

the pipe length is 40’ (12.2 m) and the pipe

size is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 320, 000

BTU. Since the total required gas pressure,

290,000 BTU is less than 320,000 BTU, the

current gas piping will not have to be increased.

NOTE: The BTU capacities given in the tables are

for straight pipe lengths only. Any elbows

or other fittings will decrease pipe capacities. Contact your local gas supplier if you

have any questions.

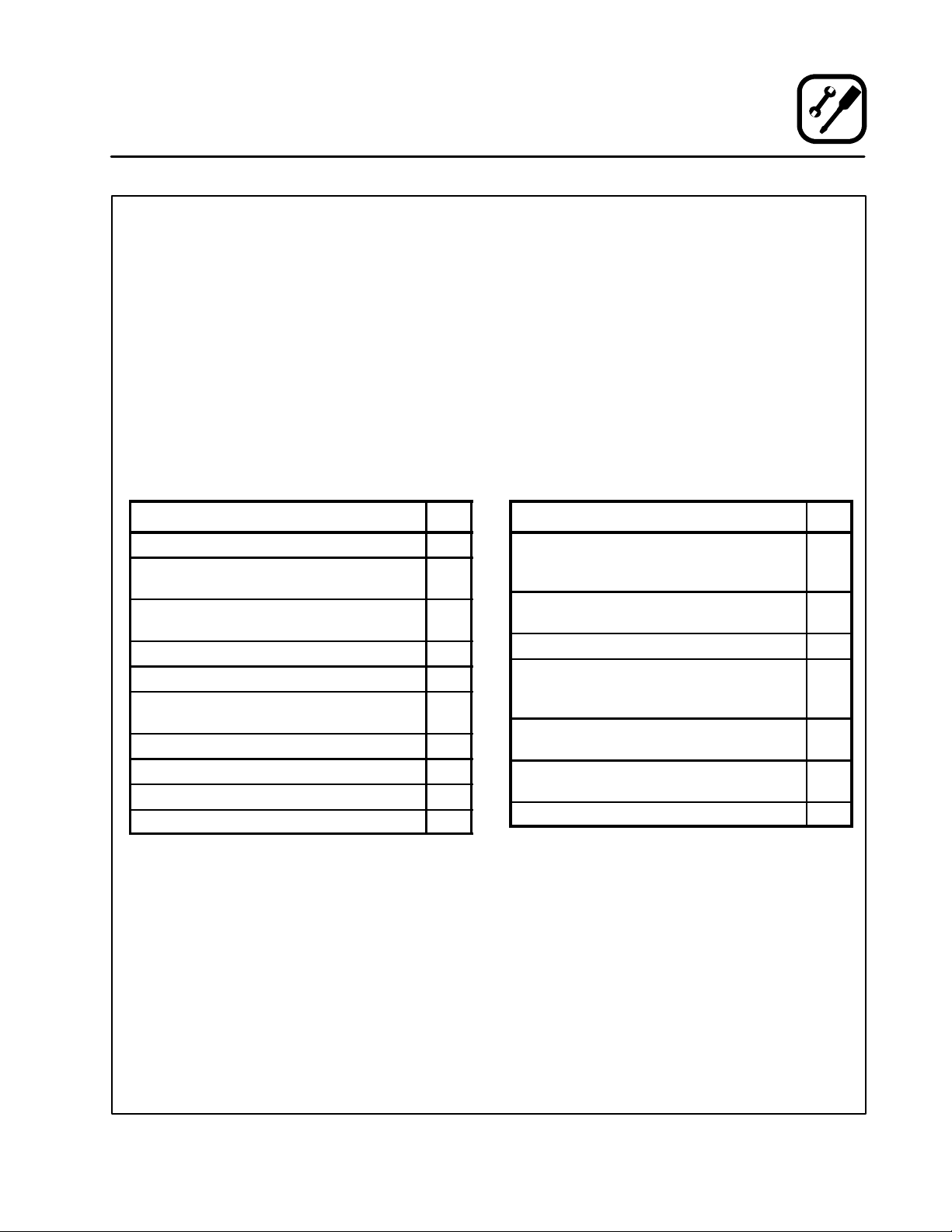

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

eng

(ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted P.P. Gas at 11” W.C.

Pipe Length

From the National Fuel Gas Code Part 10 Table 10-15

3/4” 1” 1-1/4” 1-1/2” 2”

From the National Fuel Gas Code Part 10 Table 10-2

(Pressure drop of 0.5 Inch W.C.)

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

Nominal Size, Inches

Outside Diameter, Inches

3/4” 1” 1-1/2”

18

Page 23

Installation

Gas Connection

PRESSURE REGULATION AND TESTING

SG2136 series ovens are rated at 60,000 BTU/Hr

(17.6 kW) (63 MJ). Each oven has been adjusted

at the factory to operate with the type of gas specified on the rating plate attached to the left side of

the control panel.

Each oven is supplied with a regulator to maintain

thepropergaspressure.The regulator is essen-

tial to the proper operation of the oven and

shouldnot be removed. It is preset to provide the

oven with 3.5” W.C. (0.87 kPa) for natural gas and

10.0” W.C. (2.50 kPa) for Propane while the flame

is on. The regulator is part of the gas valve located

in front of the solenoid valves.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE OVEN CONNECTS TO THE GAS

SUPPLY UNLESS THE SUPPLY EXCEEDS THE

MAXIMUM.

NOTE: The maximum gas supply pressure to the

oven is 10.5” W.C. (2.61 kPa) for natural gas

and 13” W.C. (3.2 kPa) for Popane gas. The

minimum gas supply pressure to the oven is

4.5” W.C. (1.1 kPa) for natural gas and 11.0”

W .C. (2.74 kPa) for Propane gas.

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of t hat system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Gas Connection 3.325” (84.5 mm)

Gas Connection 2.75” (69.9 mm)

Figure 16

19

Page 24

Installation

Gas Connection

GAS HOSE RESTRAINT

If the oven is mounted on casters, a commercial

flexible connector with a minimum of 3/4” (1.9 cm)

inside diameter must be used along with a quick

connect device.

The gas hose restraint (heavy gauge cable),

supplied with the oven, must be used to limit the

movement of the unit so that no strain is placed

upon the flexible connector. Locate the restraint as

follows:

D

The restraint bracket should be fastened to the

left rear oven support. See page 8 for installation of the restraint bracket.

D

The restraint should be short enough to prevent

any strain on the connector.See Figure 17 View

A for length adjustment detail.

D

With the restraint fully stretched the connector

should be easy to install and quick connect.

The permanent end of the restraint should be attached without damaging the building. DO NOT

attach the restraint to the gas piping or electrical

conduit! Use anchor bolts in concrete or cement

block. On wooden walls, drive hi test wood lag

screws into the studs of the wall.

U.S. and Canadian installations

The connector must comply with the Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas Appliances CAN/CGA-6.16 and a quick disconnect

device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI

Z21.41 or Quick Disconnect For Use With Gas Fuel

CAN 1-6.9. Adequate means must be provided to

limit the movement of the appliance without depending on the connection and the quick disconnect device or its associated piping.

A drip leg must be used at each appliance. Refer

to NFPA54/ANSI Z223.1 - Latest Edition (National

Fuel Gas Code) for proper drip leg installation.

Australia and General Export installations

The restraint and quick connect must conform

with Local and National installation standards. Local installation codes and/or requirements may

vary. I f you have any questions regarding the proper installation and/or operation of your Blodgett

oven, please contact your local distributor. If you

do not have a local distributor, please call the

Blodgett Oven Company at 0011-802-860-3700.

WARNING!!

If the restraint is disconnected for any

reason it must be reconnected when the

oven is returned to its original position.

View A

Tighten after

adjusting length of

cable

Figure 17

Socket

Plug

Quick Connect

Gas Supply Line

Socket

Gas

Hose

(See View A)

20

Page 25

Installation

Electrical Connection

Before making any electrical connections to this

unit, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating plate.

A wiring diagram accompanies this manual and is

also attached to the rear of the oven.

SG2136G

U.S. and Canadian installations

SG2136G ovens require a 5 amp, 60HZ, 1Φ,

208-240 VAC, 3 wire service consisting of L1, L2

and ground. Use 75_C wire and size to National

Electric or local codes.

Single phase units MUST NOT be connected to the

high leg of a three phase system. The high leg refers

to a potential of 240 volts between one phase and

neutral. The remaining two legs have a potential of

120 volts between each phase and neutral.

General export installations

SG2136G ovens require a 5 amp, 50/60HZ (see

rating plate), 1Φ, 208-240VAC, 3 wire service con-

sisting of L1, neutral (or L2) and ground. Use 75_C

wire and size to National Electric or local codes.

SG2136E

U.S. and Canadian installations

SG2136E ovens are available in either 1Φ or 3Φ

options. Single phase models require a 90 amp,

60 HZ, 208-240 VAC (see rating plate) 3 wire service consisting of L1, L2 and ground. Three phase

units require a 60 amp, 60 HZ, 208-240 VAC (see

rating plate) 4 wire service consisting of L1, L2, L3,

and ground. Use 75_C wire and size to National

Electric or local codes.

Australia and General Export installations

SG2136E ovens are available in either 1Φ or 3Φ

options. Single phase units require a 90 amp,

50/60 HZ (see rating plate), 208-240 VAC (see rating plate) 3 wire service consisting of L1, L2 and

ground. Three phase units require a 30 amp,

50/60 HZ (see rating plate), 208-240 VAC (see rating plate) 4 wire service consisting of L1, L2, L3

and ground. Use 75_C wire and size to National

Electric or local codes.

WARNING!!

Incorrect wiring will result in extensive

damage to electrical components and

possible fire in the control panel.

THE BLODGETT OVEN COMPANY CANNOT ASSUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPER INSTALLATION.

SG2136E 1Φ

L1

L2

SG2136E Delta Power 3Φ

U.S. and Canadian Installations (or similar)

L1

L2

L3

208-240

208 or 240

(typical)

OvenSupply

OvenSupply

Figure 18

21

SG2136G 1Φ

L1

L2

SG2136E Wye Power 3Φ

Australia and General Export Installations

L1

L2

L3

N

380/400/415

380/400/415

380/400/415

208-240

220/230/240

OvenSupply

OvenSupply

Page 26

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOF THE EQUIPMENT DESCRIBED. ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL HELP ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the k ey to the

successful operation of your Blodgett conveyor

oven.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D

DO NOT try to light any appliance.

D

DO NOT touch any electrical switches.

D

Use an exterior phone to call your gas supplier

immediately.

D

If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D

The control system will automatically go into

standby mode. When the power is restored

press the ON/OFF k ey to restart the oven.

D

DO NOT attempt to operate the oven until the

power is restored.

D

Product in the cooking chamber should be removed. If there is product in the cooking chamber it will continue to cook at a slower rate for a

few minutes.

NOTE: In the event of a shut-down of any kind, al-

low a five (5) minute shut off period before

attempting to restart the oven.

What to do for emergency shut down:

D

The unit is equipped with an emergency shut

down switch located on the front of the oven.

Should you need to stop the belt, fans, or heat

push the emergency switch. DO NOT use the

emergency s witch on remote controlled ovens

as a general on/off switch or damage to the

blowers may occur.

General safety tips:

D

DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D

If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

from the unit before removing the restraint

cable. Reconnect the restraint after the oven

has been returned to its original location.

D

DO NOT remove the electrical box cover or

open the lower control tray unless the oven is

unplugged.

D

This oven is not a hot food storage or holding

device. It is not intended to be operated normally at less than 200_F(93_C).

Automatic Momentary Shut Down (SG2136G

ovens only)

Per agency requirement, the ignition control must

verify proper safety functions every 24 hours of

continous operation. If the oven is operated for 24

hours continuously, it will shut off for 10 seconds

including all blowers, then restart again. If any button is pressed during the off period, the oven will

not automatically restart.

22

Page 27

Operation

Standard Manual Control

MANUAL CONTROL DESCRIPTION

1. DIGITAL DISPLAY --- two line display gives the

time, temperature and other control related information.

2. OV E N O N / O FF ( O N / S TA ND BY ) --- c o n t r o l s

power to the oven.

3. TEMPERATURE KEY --- press to change the

cook temperature.

1

2

4. ARROW KEYS --- press to change the set time

and temperature in the display.

5. TIME KEY --- press to change the cook time.

6. ENTER/RESET KEY --- press to save new

cook time or temperature. Also press to silencethe alarm in case of a fault. The alarm will

sound every ten seconds until the fault clears.

3 4 5

Figure 19

23

6

Page 28

Operation

Standard Manual Control

OPERATION

_

NOTE: The following example is in

_

will read

To turn the oven on:

1. Press the OVEN ON/OFF key (2). The control

defaults to the last time and temperature settings used.

The display reads:

NOTE: HEAT appears in the top line of the dis-

2. The fans begin to run. The conveyor belt begins to travel at the set cook time. The heat

rises to the setpoint temperature.

3. When the oven reaches the set temperature,

READY and SET TEMP flash alternately in the

top line of the display and an audible alarm

sounds.

To change the cook temperature:

1. Press the TEMPERATURE key (3).

The display reads:

2. Press the ARROW keys (4) to scroll to the desired cook temperature.

C if programmed in celsius.

SET TEMP XXXF HEAT

COOK TIME XX:XX

play whenever the control calls for heat.

SET POINT TEMP

F. T h e di s p l a y

XXXF

3. Press the ENTER key (6) to set the new cook

temperature.

To ch a ng e t he c o ok ti me :

1. Press the TIME key (5).

The display reads:

2. Press the ARROW keys (4) to scroll to the desired cook time.

3. Press the ENTER key (6) to set the new cook

time.

To display the actual oven temperature:

1. Press both ARROW keys (4) .

The display reads:

2. Press the down arrow key to return the display

to the setpoint time and temperature.

To turn the oven off:

1. Press the OVEN ON/OFF key (2). The oven is

equipped with a cool-down feature for motor

shaft and bearing protection. This enables the

blower motor(s) to run regardless of the controller status. The blower(s) continue to run

until the oven cools to a safe temperature.

SET COOK TIME

XX:XX

TEMP XXXF

D OW N --- E X I T

24

Page 29

Operation

Programmable Menu Control

MENU CONTROL DESCRIPTION

1. DIGITAL DISPLAY --- two line display gives the

time, temperature and other control related information.

2. OV E N O N / O FF ( O N / S TA ND BY ) --- c o n t r o l s

power to the oven.

3. ARROW KEYS --- press to changethe time and

temperature in the display. Also press to scroll

through menus during programming.

1

2

4. MENU KEYS --- programmable product keys.

Up to four different time and temperature settings can be saved.

5. ENTER/RESET KEY --- press to save settings

while programming. A lso press to silence the

alarm in case of a fault. The alarm will sound

every ten seconds until the fault clears.

3

5

4

Figure 20

25

Page 30

Operation

Programmable Menu Control

MENU PROGRAMMING

_

NOTE: The following example is in

_

will read

To enter programming mo de:

1. With the oven off, press and hold the UP ARROW key (3) and the ENTER/RESET key (5)

simultaneously for approximately three seconds.

The display reads:

2. Press and hold the UP ARROW k ey (3) until

the bottom line of the display reads 111 (the

store access code).

3. Press the ENTER/RESET key (5) to enter the

programming mode.

To pro g ra m t he m e nu key s :

1. The display reads:

2. Press the MENU key (4) to be programmed.

NOTE: For this example we will program

3. The display reads:

Use the ARROW keys (3) to scroll to the desired cook temperature.

Press the ENTER key (5) to store the new cook

temperature.

4. The display reads:

Use the ARROW keys (3) to scroll to the desired cook time.

Press the ENTER key (5) to store the new cook

time.

5. The display flashes:

C if programmed in celsius.

ACCESS CODE

SELECT MENU KEY

MENU1,2,3,OR4

menu key 1.

MENU-1 SELECT TEMP

XXXF PRESS ENTER

MENU-1 COOK TIME

XX:XX PRESS ENTER

PROGRAM DONE

F. T h e di s p l a y

000

MENU-1

To exit the programming mode:

1. Press and hold the UP ARROW key (3) and

the ENTER/RESET key (5) simultaneously for

approximately three seconds.

NOTE: If no key is pressed for 60 seconds, the con-

trol automatically exits the program mode.

OPERATION

1. Press the OVEN ON/OFF key (2). The control

defaults to the last time and temperature settings used.

The display reads:

NOTE: HEAT appears in the top line of the dis-

play whenever the control calls for heat.

2. Press the desired MENU key (4).

3. The fans begin to run. The conveyor belt begins to travel at the set cook time. The heat

rises to the setpoint temperature.

4. When the oven reaches the set temperature,

READY and SET TEMP flash alternately in the

top line of the display and an audible alarm

sounds. The conveyor belt begins to travel at

the set cook time. The heat rises to the setpoint temperature.

NOTE: To change the cook time and temperature

press any of the other menu keys.

To display the actual oven temperature:

1. Press both ARROW keys (4) .

The display reads:

2. Press the down arrow key to return the display

to the setpoint time and temperature.

To turn the oven off:

1. Press the OVEN ON/OFF key (2). The oven is

equipped with a cool-down feature for motor

shaft and bearing protection. This enables the

blower motor(s) to run regardless of the controller status. The blower(s) continue to run

until the oven cools to a safe temperature.

M-X TEMP XXXF HEAT

COOK TIME XX:XX

XXXF

D OW N --- E X I T

26

Page 31

Operation

Oven Adjustments for Cooking

The combination of belt time, oven temperature,

and air flow are important for achieving quality results from your Blodgett conveyor oven. Use the

following guidelines to adjust the belt time and

oven temperature of your unit. For questions regarding further oven adjustments, please contact

your local Blodgett Sales Representative for assistance.

CONVEYOR SPEED AND OVEN TEMPERATURE

Conveyor belt speed (cook time) and oven temperature are the two variables used w h en fine tuning your oven for a specific product. To determine

the optimum bake time and temperature, make

small changes for each trial and keep one variable

constant. For example, if the oven temperature is

460_F (238_C) and the belt speed is 7 minutes,

but the pizza is not browned enough, increase t he

temperature to 475_F (246_C) and keep the belt

speed the same. However, if the center of the pizza

is not completelycooked, keep the oven temperature the same, and increase the bake time to 7

minutes and 30 seconds. I n general, raise the

bake temperature to increase browning, and

lengthen the belt time to increase doneness.

FINISHED PRODUCT TEMPERATURES

Internal temperatures of the cooked products

should be measured immediately after the product exits the cooking chamber to ensure a safe

food temperature. Internal pizza temperatures

should be over 165_F(74_C). Minimum tempera-

ture guidelines vary depending on the food items.

AIR FLOW ADJUSTMENTS

Slide the product clearance adjustment plates to

the lowest possible setting for your menu items.

Lowering the clearance plates will reduce the

amount of hot air escaping from the chamber

openings.

Most often, the ideal oven settings can be dialed

in without making any changes to the airplate. The

oven configuration should not be modified unless

the oven time and temperature adjustments have

proven unsuccessful.

Air flow adjustments may be necessary to fine

tune the oven for your particular product. The air

plate, located at the top of the baking chamber,

containsholesthat can be covered using Block-off

Plates. The plates can easily be adjusted to regulate the air flow for your particular needs. Use the

following guidelines to adjust the Block-off Plates.

SeeFigure21.

1. Ensure the oven is OFF and completel y cooled.

2. Open the front access door.

3. Slide the air plates out from the interior of the

oven.

4. Remove the screws, washers and lockwash-

ersholdingtheBlock-offPlatetotheairplate.

5. Adjust the plates.

6. Replace the screws, washers and lockwash-

ers to tightly secure the Block-off Plates in their

new locations. Make a sketch of the final airplate setup for future reference.

NOTE: One or two block-off plates may be left

off entirely if appropriate to obtain the

desired results.

7. Replace the air plates, and close the front ac-

cess door.

The following examples illustrate air flow regulation.

NOTE: The first half of the oven chamber greatly af-

fects the initial baking of the product, while

the last half largely affects the browning.

D

A good bake time and t emperature have been

established, but more top browning is desired.

Slide one of the Block-off Plates to uncover a

row of holes toward the exit end of the oven.

D

The bottom of the pizza is golden brown, but the

top is too dark. Close rows at the exit end of the

oven to reduce final browning.

D

The center of the pizza is still doughy and the

toppings are not fully cooked. Open up rows at

the chamber entrance and close rows at the

chamber exit.

27

Page 32

Operation

Oven Adjustments for Cooking

Air Slides

Block-Off

Plate

Air Flow Plate

Figure 21

28

Air Flow Plates

Page 33

WARNING!!

Always disconnect the power supply be-

fore cleaning or servicing the oven.

WARNING!!

If the oven needs to be moved, the g as

must be turned off and disconnected from

the unit before removing the restraint. Reconnect the restraint after the oven has

been returned to its original location.

Follow this recommended cleaning schedule for

proper oven performance.

Daily:

1. Clean the conveyor belt using a wire brush. Allow any foreign material to drop into the crumb

pans.

2. Empty and clean the crumb pans. Use a hot water and detergent mix. Rinse with clean water.

3. Make sure cooling fans are operating. Exhaust air should be blowing out from:

D

the louvers on the right side toward the rear

D

and the perforated holes on the bottom of

the tunnel on integral control units.

Every Three Months:

1. Brush and clean the guards of the cooling

fans, the control box intake louvers and rear

ventilation holes.

Every Six Months:

1. Unplug the oven. On gas models, disconnect

the gas connections.

2. Remove the crumb pans, and product stop

from the ends of the conveyor. See page 14.

3. Remove the conveyor belt as follows:

a.) Use needle-nose pliers to remove the

conveyor belt master links. See page 13.

b.) R emove the belt tensioners from the exit

end of the oven.

c.) Slide the belt out from one end. Be sure t o

roll the belt as shown in Figure 22. Otherwisethebeltwillbeupsidedownwhenrethreading.

Maintenance

Cleaning

4. Removetheidlesideconveyorsupport.

5. Remove the drive side conveyor support as

follows:

a.) Remove t he conveyor locating pin that se-

cures the conveyor assembly to the conveyor bracket. The pin is located under

the drive belt, behind the electrical box access door.

b.) Push the conveyor assembly in to loosen

thedrivebelt.Removethedrivebeltfrom

the conveyor pulley. If unable to push the

assembly, loosen motor mounts.

6. Lower the access panel. Remove the air

plates and nozzles.

7. Clean the oven components as follows:

a.) Soak the conveyor belt in a hot water de-

tergent mix in a 3 compartment sink or

large container. Keep the belt rolled when

cleaning. Rinse thoroughly and allow to

drip dry before installing.

b.) Clean the conveyor supports, crumb

pans,productstop,nozzles,andair

plates with a hot water, detergent mix.

Rinse with clean water . For difficult cleaning, use a heavy-duty degreaser or oven

cleaner that is safe for aluminum.

c.) Clean the oven interior with an all purpose

cleaneroranovencleanerthatissafefor

aluminum.

8. Move the oven and clean under it. Be careful

not to damage oven’s gas hose or electrical

cords when moving.

9. Reassemble the oven.

Every 12 Months:

A factory authorized service person should:

1. Open and clean the inside of the controlpanel.

2. Check and tighten all electrical connections.

3. Check DC gear motor brushes for wear.

4. Check conveyor drive chain for cleanliness

and proper lubrication.

If maintenance is required contact your local service company, a factory representative or the

Blodgett Oven company.

29

Page 34

Cleaning

Maintenance

Figure 22

30

Page 35

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Operator control display is blank and there is no power to the oven.

S

Power outlet is not live (new installations).

S

Oven not plugged in.

S

Emergency stop button is pushed in (remote

control oven only).

S

Fuse(s) are blown.

S

24 VDC power supply’s internal breaker tripped.

S

24 VDC power supply defective.

SYMPTOM: Conveyor belt will not run or stops. Display reads M O T O R F A U LT --- C A L L S E R V I C E .

S

Belt hooked on something in oven.

S

Belt overloaded.

S

Defectiveconveyordrivemotor.

S

Defectiveconveyordrivemotorcontroller.

S

Have a qualified person ensure that the power

outlet is live.

S

Check that the power cord is connected.

S

Pull the button out to disengage the emergency

stop.

S

Unpug the oven power cord. Check the 5A fuses

behind the electrical box access door. Call service if blown.

S

Unplug the oven power cord for 15 minutes.

Check the fuses then reconnect.

S

*

S

Turn oven OFF. Unhook and resolve problem.

S

Remove product until the belt starts to move and

call service.

S

*

S

*

SYMPTOM: Operator control display is blank and the oven is on.

S

Connection at the rear of the operator control

has come loose. The oven should continue to

run and respond to any faults, but the operator

control will not function.

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

PLEASE!!

Write down EXACTLY any error message displayed on the operator control display. Report all

error messages.

S

Shut off manual gas valve. Once the oven has

cooled down unplug the oven and call service.

(SG2136G).

S

Press the emergency stop button and call service (SG2136E). (remote control oven only)

31

Page 36

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Burner will not fire (SG2136G) or elements will not heat (SG2136E).

S

Control turned off.

S

Temperature set point not above the ambient

temperature.

S

Convection blower motor(s) not running.

Display: BLOWE R FA ULT --- CA LL SER V ICE

S

Fuse(s) are blown.

S

Emergency stop button is pushed in (remote

control oven only).

For SG2136G ovens only

S

Manual gas valve closed.

S

Combustion blower motor not running.

Display: COMBUSTION BLWR FAIL --- CALL

SERVICE

S

Combustion blower pressure switch defective or

not set properly.

Display: COMB PS FA ULT --- CALL SERVICE

S

Burner did not ignite properly or flame ceased.

Display: IGNITION ALARM --- PRESS RESET

or NO FLAME SENSE - -- RESET OR CALL SERVICE

S

Press ON/OFF key.

S

Set to the desired temperature. See page 24 of

the Operation section for instructions.

S

*

S

Unplug the oven power cord and check the fuses

(SG2136E). Call service if necessary.

S

Pull the button out to disengage the emergency

stop.

S

Open valve.

S

*

S

*

S

Press the reset button on the electrical box

control tray, located to the left of the LED

indicator lights. Call service if necessary.

SYMPTOM: Oven will not reach desired temperature.

S

Manifold gas pressure to too low (SG2136G).

S

Gas pressure to oven is too low (SG2136G).

S

Convection blower motor(s) not running.

S

Fuse(s) are blown.

S

Emergency stop button is pushed in (remote

control oven only).

S

Defective heating element relay (SG2136E).

S

Heating element(s) burned out (SG2136E).

S

Temperature hi-limit switch tripped (open) or out

of adjustment or defective.

Display: HI LIMIT TRIP --- RESET EGO

S

Internal problem with control.

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

S

*

S

Contact local gas representative.

S

*

S

Unplug the oven power cord and check the fuses

(SG2136E). Call service if necessary.

S

Pull the button out to disengage the emergency

stop.

S

*

S

*

S

Press red EGO reset button on rear of electrical

box. Call service if necessary.

S

*

32

Page 37

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Burner operates sporadically (SG2136G).

S

Air pressure switch out of adjustment. Alarm

sounds and display indicates one of two blower

failures.

S

Manifold gas pressure is too low.

S

Gas supply pressure to oven not correct.

SYMPTOM: Control displays: BLOWER ZONE HOT --- CHECK HOOD/LOUVERS.

S

Ventilation hood air flow has slowed or stopped.

S

Louvers are dirty or clogged, restricting cooling

air flow.

S

DefectiveblowercompartmentRTDprobe.

SYMPTOM: Control displays: BLOWER ZONE OVERTEMP --- CALL SERVICE.

S

Note display readout during problem. Call service.

S

*

S

Contact local gas representative.

S

Check hood function.

S

Check for airflow out of the louvers on the right

side of the oven toward the rear. If none, call service. If minimal clean louvers, see page 29.

S

*

S

Ventilation hood air flow has slowed or stopped.

S

Blower compartment cooling fan has stopped or

louvers are dirty or clogged, restricting cooling

air flow.

S

DefectiveblowercompartmentRTDprobe.

SYMPTOM: Control displays: FA U LT --- C H E C K PROBE .

S

Loose probe leads at control.

S

Indicated probe is open or shorted or defective.

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot assume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

Check hood function.

S

Check for airflow out of the louvers on the right

side of the oven toward the rear. If none, call service. If minimal clean louvers, see page 29.

S

*

S

*

S

Note display readout during problem. Call service.

33

Page 38

Introduction

Caractéristiques du Four

CARACTÉRISTIQUES SG2136G/AA SG2136E/AA

Largeur de la courroie 53 cm (21po)

Longueur de la zone de

cuisson

Aire de cuisson 49 m2(2,25pi)

Aire de dégagement

pour les aliments

Dimensions (une unité) 162.5 cm x 1111 cm x 50.8 cm (64 x 43.75 x 20 po)

Température maximale

de fonctionnement

Entrée maximale

dechaleur

Source d’alimentatio n É. U. et Canada

17.6 kW (60,000 BTU/Hr.) (63 MJ) 15 kW

208-240Vc.a., 1Φ, 60 Hz, 5 A,

2 câbles plus prise à la terre

Exportation et l’Australie

208-240Vc.a., 1Φ, 50Hz, 5 A,

2 câbles plus prise à la terre

91 cm (36 po)

2

8.3 cm (3.25 po)

93-315_C (200-600_F)

É. U. et Canada

208Vc.a., 1Φ, 60Hz, 76 A, 2 câbles plus

prise à la terre

240Vc.a., 1Φ, 60Hz, 66 A, 2 câbles plus

prise à la terre

208Vc.a., 3Φ, 60Hz, 44 A, 3 câbles plus

prise à la terre

240Vc.a., 3Φ, 60Hz, 38 A, 3 câbles plus

prise à la terre

Exportation et l’Australie

220Vc.a., 1Φ, 50 or 60Hz, 73 A,

2 câbles plus prise à la terre

220/380Vc.a., 3Φ, 50 or 60Hz, 24 A,

4 câbles plus prise à la terre

240/415Vc.a., 3Φ, 50 or 60Hz, 23 A,

4 câbles plus prise à la terre

Source d’alimentatio n

au gaz

Connexion

d’alimentation en gaz

Gaz naturel :

4,5 po W.C. (1,1 kPa) minimum

10,5 po W.C. (2,61 kPa) maximum

Propane :

11 po W.C. (2,74 kPa) minimum

13,0 po W.C. (3,23 kPa) maximum

3/4 po (NPT) Aucun

34

Aucun

Page 39

Introduction

Description et Composantes du Four

Lacuissondansunfouràconvoyeurdiffèrede

celle d’un four conventionnel à pont ou pour cuisinière, puisque l’air chauffé recircule constamment

sur les aliments grâce à un ventilateur logé dans

un compartiment. Les jets d’air enlèvent constamment la couche d’air froid qui entoure le produit et

permettent ainsi une pénétration rapide de la chaleur. Il en résulte un aliment de grande qualité, cuit

à une température plus basse et dans un temps

plus court.

Le four à convoyeur Blodgett est le résultat des

plus récentes percées au niveau de l’efficacité énergétique, de la fiabilité et de la facilité d’utilisation.

La chaleur normalement perdue est recirculée à

l’intérieur de la chambre de cuisson, ce qui réduit

de façon notable la consommation d’énergie,

garde la cuisine plus fraîche et accroît la performance du four.

Courroie du convoyeur : Ceinture en chaînons

d’acier inoxydable (convoyeur) qui convoie l’aliment à travers le four.

Chaînons de raccord de la courroie du convoyeur : Facilitent le retrait de la courroie du con-

voyeur pour un entretien et un nettoyage plus minutieux.Ceschaînonssontsituésauxespaces

doubles entre les chaînons réguliers de la courroie.

Support de la courroie du convoyeur (côté de

l’entraînement et côté libre) : Se trouve aux deux

extrémités de la sole du four. Le support côté entraînement assure l’entraînement de la courroie

du convoyeur.

Tensionneurs de la courroie de convoyeur :Ils

maintiennent la tension de la courroie du convoyeur .

Boîtedecommandes: Contient les organes de

commande, le câblage électrique, les ventilateurs

de refroidissement, le moteur d’entraînement et la

courroie d’entraînement.

Moteur d’entraînement : Assure la puissance de

déplacement nécessaire pour la courroie du

convoyeur. Se trouve dans la boîte de commandes.

Courroie d’entraînement : Transfère la puissance

du moteur à l’arbre d’entraînement du convoyeur .

Se trouve dans la boîte de commandes.

Air chauffé

Ventilateur

Buses

Source de

chaleur

Circulation de l’air dans les fours à convoyeur SG2136

Plaque de circulation d’air

Convoyeur

Air recirculé

Figure 1

Chambredecuisson: Les produits sont

convoyés sur le convoyeur le long de la chambre

de cuisson pour en assurer la cuisson.

Buses : Situées à l’intérieur du four, sous la courroie du convoyeur, elles distribuent l’air chauffé à

partir du fond de la chambre de cuisson.

Ramasse-miettes : Situés sous la courroie du

convoyeur aux deux extrémités de la chambre de

cuisson, ils attrapent les miettes des aliments laisséessurleconvoyeur.

Porterabattante : S’ouvre pour permettre d’insérer des produits auxiliaires.

Plaques de circulation d’air (2, côté entraînement et côté libre) : Distribuent l’air chaud vers le

haut de la chambre de cuisson. Elles se trouvent

dans le four, au haut de la chambre de cuisson.

Commutateur d’urgence : Dans le cas de fours

à commande à distance, permet à l’utilisateur de

mettre le four et le convoyeur hors tension en cas

d’urgence. Nepasl’utiliserpouréteindrenor-

malement le four ; les souffleuses et le corps

principal du four pourraient se trouver endommagés.

35

Page 40

Introduction

Description et Composantes du Four

Support de

montage éloigné

Boîtier

éloigné

Support de la

courroie du

convoyeur côté

entraînement

Boîte de

commandes

de réglage

Contrôle de

l’opérateur

Volets

(2)

Contrôle intégral

de four

Tensionneur

de courroie (2)

Support de la

courroie du

convoyeur

côté libre

Porte rabattante

Convoyeur à

courroie métallique

Panneau d’accès

Buses

Barre d’arrêt

des aliments

ramasse-

miettes

Plaque de

circulation d’air

ramasse-

miettes

Fausse façade

Figure 2

36

Option de fausse façade

pour porte rabattante

Page 41

Installation

Livraison et Inspection

Tous les fours Blodgett sont expédiés dans des

conteneurs pour éviter les bris. À la livraison de

votre nouveau four :

D

Inspectez le conteneur d’expédition pour vous

assurer qu’il n’est pas endommagé à l’extérieur.Toutemarqueévidentededommagedevraitêtrenotéesurleformulairederéceptionqui

doit être signé par le conducteur.

D

Retirez le four du conteneur et vérifiez s’il n’est

pas endommagé à l’intérieur . Les transporteurs

acceptent les réclamations concernant des dommages cachés s’ils sont avisés dans les quinze

jours suivant la livraison et si le conteneur d’expédition est conservé pour fins d’inspection.

Description des pièces

Corps principal du four 1

Support de la courroie du convoyeur

gauche

Support de la courroie du convoyeur

droite

Plaque de circulation d’air 2**

Tensionneurs de courroie 2

Courroie de convoyeur en métal

(roulée)

Ramasse-miettes 2

Buse 5**

Access panel assembly 1

Barre d’arrêt des aliments 1

Qté

1**

1**

1**

L’entreprise Blodgett Oven ne peut être tenue

responsable de la perte ou des dommages

causés lors du transport. Le transporteur a acceptéla pleine et entière responsabilité de la livraison du produit en bon ordre lorsqu’il a accepté son expédition. Nous sommes toutefois

disposés à vous assister si vous devez remplir

un formulaire de réclamation.

Le four peut maintenant être déplacé vers le site

d’installation. Vérifiez la liste qui suit en vous rapportant à la Figure 2 de la page 4 pour vous assurer d’avoir reçu tous les éléments.

Description des pièces Qté

Paquet contenant : les chaînons de raccord intérieurs et extérieurs de la courroie de convoyeur

Pièce supplémentaire de convoyeur à

courroie métallique

Manuel de l’utilisateur 1*

Trousse d’empilage optionnelle :

1 pour les unités à empilage double

2 pour les unités à empilage triple

Commande à distance optionnelle (affichage et interface opérateur)

Câbles de la commande à distance optionnelle

Fausse façade optionnelle 1

REMARQUE:* Article non montré.

**Peut être expédié monté

1*

1*

1,2*

1

1*

37

Page 42

Installation

Emplacement et Ventilation du Four

EMPLACEMENT

Un emplacement et une installation bien planifiés

du four permettront une utilisation commode et

une performance satisfaisante à long terme.

Maintenez les aires de dégagement suivantes

entre le four et toute construction combustible et

incombustible.

D

Côté gauche du corps principal du four / boîte

decommandes---15.2cm(6po)

D

Arrière du corps principal du four --- 0 cm (0 po)

Maintenez les aires de dégagements suivantes

pour l’entretien

D

Côté gauche du corps principaldu four --- 97 cm

(38 po)

D

Arrière du corps principal du four -- - 71 cm (28 po)

REMARQUE:L’entretien des modèles alimentés au

gaz peut généralement se faire à l’intérieur des limites offertes par l’encastrement des tuyaux. Si le four doit

être déplacé plus loin du mur, fermez

et débranchez d’abord l’alimentation

en gaz du four avant de retirer la

bride. Rebranchez la bride après

avoir replacé le four dans sa position

normale.

Il est essentiel de maintenir une alimentation d’air

suffisante dans le four pour assurer une combustion de même qu’une ventilation adéquates.

D

Placez le four à l’abri des courants d’air.

D

Ne laissez aucun combustible, tel que du papier, du carton, des liquides inflammables ou des

solvants, à proximité du four.

D

Ne pas placer le four sur un muret ni le sceller

contre un mur. Ceci restreindrait le flux d’air au

four et empêcherait la bonne ventilation des

moteurs de soufflantes. Il faut corriger un tel

agencement pour empêcher que le four ne se

trouve endommagé de façon permanente.

VENTILATION

Un système de ventilation mécanique est requis

pour évacuer la chaleur excessive et les vapeurs

de cuisson. Les modèles au gaz requièrent égale-

ment un système de ventilation pour évacuer les

vapeurs issues de la combustion du gaz. On n’insistera jamais a ssez sur l’importance d’un

système de ventilation bien conçu et bien installé.

Les informations qui suivent constituent des recommandations et des directives générales pour

assurer une bonne ventilation. Votre installation

particulière peut exiger les services d’un ingénieur

ou d’un conseiller en ventilation.

La hotte de ventilation doit fonctionner en accord

avec le système de chauffage, de ventilation et de

climatisation (CVCA) de l’édifice. La conduite d’échappement de la hotte et celle de l’alimentation

en air doivent avoir la t aille appropriée. L’alimentation en air doit être fournie soit par le système de

la hotte, soit par le système CVCA de l’édifice, afin

de prévenir toute pression négative dans la région

du four. L’alimentation en air devrait remplacer

approximativement 80% du flux d’air qui s’échappe par la hotte. Vous pouvez utiliser le tableau ci-dessous comme repère, mais les valeurs

correctes du flux d’air dépendent de la conception