Page 1

SC-GH SERIES

BLODGETT OVEN COMPANY

HIGH EFFICIENCY GAS FIRED CONVECTION STEAMER

INSTALLATION – OPERATION – MAINTENANCE

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802) 864-0183

www.blodgett.com

S00061 Rev C (6/10)

1

Page 2

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

WARNING: Improper installation, operation, adjustment, alteration, service

or maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly before

installing, operating or servicing this equipment.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other appliance.

PURCHASER: Instructions to be followed in the event that the operator of this

appliance smells gas must be posted in a prominent location. This information shall be

obtained by consulting the local gas supplier.

Intended for commercial use only. Not for household use.

Do not attempt to operate this unit in the event of power failure.

Adequate clearances must be maintained for safe and proper operation.

The appliance area must be kept free and clear of combustibles.

Do not obstruct the flow of combustion and ventilation air.

Contact the factory, the factory representative or a local service company to perform

maintenance and repairs should the appliance malfunction. Refer to warranty terms.

This manual should be retained for future reference.

2

Page 3

TABLE OF CONTENTS

DESCRIPTION PAGE

1.0 Service Connections ............................................................................................... 4

2.0 Installation ............................................................................................................... 5

3.0 Performance Check ............................................................................................... 11

4.0 Operation Instructions ........................................................................................... 12

5.0 Maintenance .......................................................................................................... 14

6.0 Deliming Procedure ............................................................................................... 19

7.0 Troubleshooting..................................................................................................... 20

3

Page 4

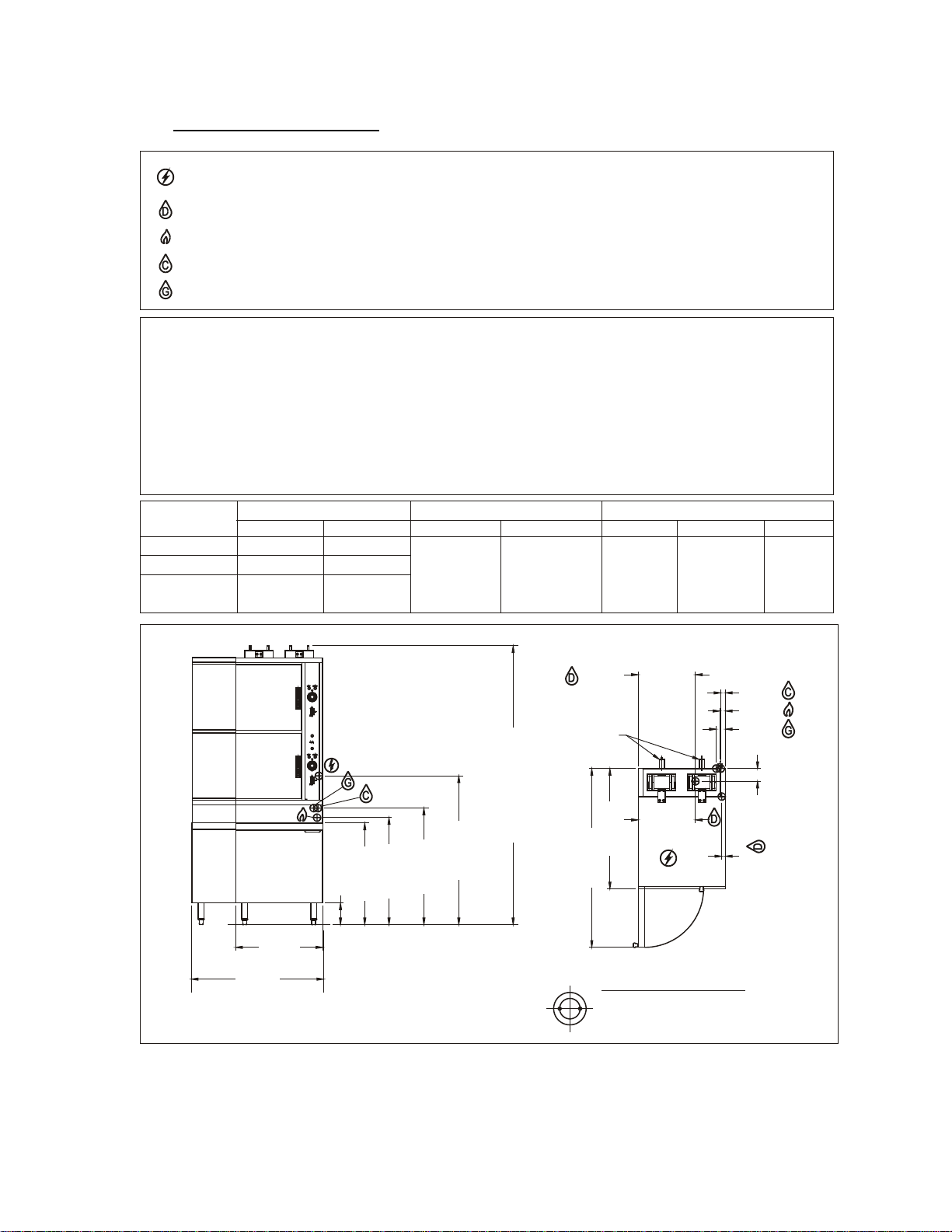

1.0 SERVICE CONNECTIONS

24 [610]

SC-5HE 67 [1704]

SC-7GH 67.00 [1704]

SC-10GH 76.88 [1953]

SC-16GH 70.38 [1788]

6.00 [152]

28.00 [711]

29.50 [749]

32.13 [816]

41.00 [1041]

36 [914]

SC-16GH ONLY

REAR FLANGED FOOT DETAIL

7/16" [11mm] HOLES

ON 2.5 [63] B.C.

2 EQUALLY SPACED

Ø

DIMENSIONS ARE IN INC HES [MM]

Unless otherwise specified, Electrical Connection to be 120 Volts, 60 Hertz single phase with ground. Furnished with 6 foot cord with 3 prong plug.

Maximum 4.0 amps.

DRAIN: 2" IPS piped to open floor drain. No Solid Connection. Maximum 24" length bef or e open air gap opening. (No bends or elbows)

GAS CONNECTION: 3/4" IPS supply line required.

CONDENSING COLD WATER: 3/8" O.D. tubing at 25-50 PSI(170-345 kPa)

GENERATOR WATER: 3/8" O.D. tubing at 25-50 PSI(170-345 kPa)

Less than 1.5 PPM

Less than 13 PPM

Less than 20 PPM

Less than 60 PPM

WATER QUALITY STATEMENT FOR GENERATOR

7.0-8.5pH Factor

Chlorine

Silica

Total alkalinity

Total dissolved solids

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR WATER QUALITY IS NOT COVERED UNDER WARRANTY.

Water which fails to meet these standards should be treated by installation of water conditioner.

local water treatment specialist and have the water analyzed. Your water supply must be within these general guidelines:

Water quality is the major factor affect ing the performance of your appliance. If you are unsure of water quality, consult a

12 - 14 INCH6 - 14 INCH

MODEL

95,000

SC-5GH

BTU/HR. kW/HR.

28

41SC-7GH

140,000

190,000

SC-10GH

56

152 - 352mm 305 - 352mm

PROPANENATURAL LEFT

0

RIGHT BACK

6 INCH

152mm

SC-16GH

0

GAS SUPPLY PRESSURE (W.C.) INSTALLED CLEARANCE

1.5 [38]

2.5 [64]

1.25 [32]

3.50 [89]

SAFETY RELIEF

VALVES

33.13 [841]

49.25 [1251]

18 [457]

SC-16GH

15.75 [400]

1 [25]

USE ON NON-COMBUSTIBLE FLOORS ONLY

4

Page 5

2.0 INSTALLATION

WARNING: Do not connect the appliance to the electrical supply until

after the gas connection has been made.

Installation must conform to local codes, or in absence of local codes, with the National Fuel

Gas Code - ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA

B149.1, as applicable.

1. The appliance and its individual shut off valve must be disconnected from the gas supply

piping system during any pressure testing of that system at pressures in excess of ½ psi

(3.5 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its

individual manual shut off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½ psi (3.5 kPa).

Electrical grounding must be provided in accordance with local codes, or in the absence of

local codes, with the National Electrical Code ANSI/NFPA 70, OR THE Canadian Electrical

Code, CSA C22.2, as applicable.

Ventilation must be provided in accordance with local codes, or in the absence of local

codes, with ANSI/NFPA 96 Standard for Ventilation and Fire Protection of Commercial

Cooking Operations.

WARNING: ELECTRICAL GROUNDING INSTR UCTIONS

This appliance is equipped with a three-prong (grounding) plug for your

protection against shock hazard and should be plugged directly into a

properly grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug. (120V units only).

WIRING DIAGRAM FOR APPLIANCE IS LOCATED ON RIGHT HAND SIDE PANEL OF

THE COOKER CABINET.

5

Page 6

2.0 INSTALLATION (Continued)

2.1 EXHAUST FANS AND CANOPIES:

Canopies are set over ranges, ovens, kettles, etc., for ventilation purposes. It is

recommended that a canopy extend 6" past the appliance and be located 6' 6" from the

floor. Filters should be installed at an angle of 45 degrees or more with the horizontal.

This position prevents dripping of grease and facilitates collecting the run-off grease in

a drip pan, usually installed with the filter. A strong exhaust fan tends to create a

vacuum in the room and may interfere with burner performance or may extinguish pilot

flames. Makeup air openings approximately equal to the fan area will relieve such

vacuum. In case of unsatisfactory performance on any appliance, check with the

exhaust fan in the “OFF” position.

2.2 WALL EXHAUST FAN:

The exhaust fan should be installed at least two feet above the vent opening at the top

of the unit.

2.3 CLEARANCES:

Adequate clearance must be provided in aisle and at the side and back. Adequate

clearances for air openings into the combustion chamber must be provided, as well as

for serviceability for use on noncombustible floors. Minimum clearance from

combustible and noncombustible construction, 0" on left side, 0" on right side and 6"

from back.

WARNING: These procedures must be followed by qualified

personnel or warranty will be voided. An open gap floor drain is

required immediately below the appliance drain.

6

Page 7

2.0 INSTALLATION (Continued)

To Install:

1. Uncrate carefully. Report any freight damage to the freight company immediately.

2. Set the unit in place. Be certain to maintain the minimum clearances from combustibles

and non-combustibles.

3. For an appliance supplied with legs, level the appliance using a spirit level. Should

flanged adjustable feet be provided, anchor to floor using proper anchoring devices.

4. Seal bolts and flanged feet with Silastic or other equivalent compound.

5. Be certain to leave adequate clearances for cleaning, maintenance and service.

WARNING: For an appliance equipped with casters, the installation

shall be made with a connector that complies with the standard for

connectors for moveable gas appliances, ANSI Z21.69-CSA 6.16 and a

quick-disconnect device that complies with the standard for quickdisconnect devices for use with gas fuel, ANSI Z21.41-CSA 6.9;

adequate means must be provided to limit the movement of the

appliance without depending on the connector and the quickdisconnect device or its associated piping to limit the appliance

movement; the location where the restraining means may be attached

to the appliance is on bottom of unit directly below relief valve.

If the unit is also equipped with an optional water fill valve it too must

be installed with a flexible water supply tube, a quick disconnect and

strain relief.

GAS CONNECTION:

CAUTION: The pipe thread compound used when installing pipes must

be a type that is resistant to the action of liquified petroleum or

propane gases.

NOTICE: If this equipment is being installed at over 2,000 feet altitude

and was not so specified on order, contact service department. Failure

to install with proper orifice sizing may void the warranty.

7

Page 8

2.0 INSTALLATION (Continued)

1.0 The Serial and Rating Plate on the unit indicates the type of gas your unit is equipped to

burn. DO NOT connect to any other gas type.

2.0 A ¾” NPT line is provided at rear for the connection. Each compartment is equipped

with an internal pressure regulator set at 3.5" W.C. manifold pressure for natural gas and

10" W.C. for propane gas. Use c” pipe tap on the burner manifold for checking

pressure.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the

volume of gas required for satisfactory performance. A steady supply pressure, between 6"

W.C. and 14" W.C. for natural gas and 12" W.C. and 14" W.C. for propane gas is

recommended. With all units operating simultaneously, the manifold pressure on all units

should not show any appreciable drop. Fluctuations of more that 25% on natural gas and

10% on propane gas will create problems, affecting burner operation. Contact your gas

company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt or other foreign matter before connecting the

line to the unit. Use pipe joint compound suitable for use with Liquid Propane on all

threaded connections.

Test pipe connections thoroughly for gas leaks.

WARNING: Never use an open flame to check for gas leaks. Check

all connections for leaks using soapy water before use.

ELECTRICAL CONNECTION:

120 VAC-60 Hz - Single Phase

Units with this electrical rating are factory supplied with a three-wire cord and three-prong

plug which fits any standard 120V, three-prong grounded receptacle. A separate 15 amp

supply is needed for each unit.

8

Page 9

2.0 INSTALLATION (Continued)

PLUMBING CONNECTIONS:

NOTICE: Plumbing connections must comply with applicable sanitary, safety and

plumbing codes.

Two water lines are provided. Connect water supply lines to the 3/8" copper tubes at the

rear of the ste amer.

One line is for supply of water to the generator and one for cold condensate water to

condense live steam entering the drain line.

DRAIN CONNECTIONS:

Appliance drain is 2 inch pipe size. Provide open air gap type drain.

WARNING: An open gap floor drain is required immediately below the

appliance drain.

COLD WATER CONDENSER:

The steamer is equipped with a cold water condenser, in the rear of the cooking chamber,

which helps to condense the steam prior to discharge into the drain. The steamer freely

vents itself by the negative pressure created by the condensate water drainage. This

negative pressure prevents steam leakage around the door gasket and helps draw the

steam through the cooking compartment. Steam leakage at the door may indicate a

plugged or improperly installed drain.

Temperature of condensate water flowing through the drain is controlled by the thermostatic

cooling valve (TCV) located inside the controls compartment on the right side of the unit.

The valve has been factory set to keep condensate water flowing into the drain at or below

140F. Depending on local plumbing code requirements, this setting may be changed to

obtain a different maximum drainage temperature. Refer to next section Performance

Check for instructions to set the (TCV).

9

Page 10

INSTALLATION (Continued)

WATER CONDITIONING:

It is important that the water supplied to the generator be softened to no more than 2.0

grains of hardness and have a pH of 6 to 7.5. This degree of hardness can be easily

obtained with the use of a properly maintained water softener. The use of a water meter will

determine the water consumption and when the water softener needs regeneration or

recharging. Failure to comply with these water condition standards may void the warranty.

Untreated water contains scale producing minerals which can precipitate onto the surfaces

in the steam generator. Due to the temperatures in the steam generator, the minerals can

bake onto the surfaces and components. This can result in early component failure and

reduced product life. Water level probes become coated with scale. Scale may bridge

across the probe insulator from the metal extension which senses the water level in the

steam generator shell. Once this scale becomes wet, the water level control is unable to

maintain the proper water level in the steam generator.

STRAINERS and FILTERS will NOT remove minerals from the water.

10

Page 11

3.0 PERFORMANCE CHECK

CAUTION: The appliance and its parts are hot. Use care when operating,

cleaning and servicing the appliance.

Once the steamer is installed and all mechanical connections have been made, thoroughly

test the steamer before operation.

1. Check that proper water, drain and electrical and gas connections have been made.

2. Turn main power switch ON.

3. Check that “Ignition” light comes on and cycles “ON” and “OFF”.

4. After approximately 15 minutes, the “READY” light should come on, indicating that the

water temperature is 205º Fahrenheit (97º Celsius). When the “READY” light comes on,

set timer to the “5 minute” position. With door open, observe that no steam is entering

the compartment and that the “COOKING” light is OFF.

5. Close compartment door. The COOKING light should now illuminate and steam should

be heard entering the compartment after about 45 seconds.

6. After five minutes of operation check drain line to ensure that water from the cold water

condenser is flowing through the drain line.

7. Open compartment door and observe that steam supply to chamber is cut off. “READY”

light should again come on as “COOKING” light turns “OFF”.

8. Close compartment door and let cooking cycle finish. When the timer returns to “0"

position, a buzzer will sound signaling the end of the cooking cycle. Buzzer must be

manually turned off by setting the timer to its “OFF” position.

9. With all compartments of the steamer operating in the cooking cycle, check the

temperature of the condensate coming out the drain. If the drain temperature exceeds

local plumbing code requirements, adjust the Thermostatic Cooling Valve (TCV) out for a

lower drain temperature and in for a higher drain temperature. A TCV setting of

approximately 2.75 yields a drain temperature of 140F. A setting of approximately 2.5

or 3 yields temperatures of 125F and 155F, respectively.

11

Page 12

4.0 OPERATION INSTRUCTIONS

CAUTION: If you smell gas during the lighting procedure,

immediately shut off the gas supply until the leak has been

corrected.

LIGHTING

Do not attempt to operate this unit in the event of a power failure.

1. Ensure power, gas and water supply is on.

2. Turn power switch “ON”.

3. Steam generator tanks will begin filling with water.

4. Once proper water level has been reached, the ignition light will come on and should

remain on.

5. Cooker is now ready for use.

Your steamer has been factory set, when “ON” to maintain water temperature during the

READY phase at approximately 205º Fahrenheit (97º Celsius) just below water boiling point.

CAUTION: The appliance and its parts are hot. Use care when

operating, cleaning and servicing the appliance.

CAUTION: Live steam and accumulated hot water in the

compartment may be released when the door is opened.

CAUTION: An obstructed drain can cause personal injury or

property damage.

WARNING: In the event of main burner ignition failure, a 5 minute

purge period must be observed prior to re-establishing ignition

source.

12

Page 13

4.0 OPERATION INSTRUCTIONS (Continued)

WARNING: In the event you smell gas, shut down equipment at

the main shut off valve and contact the local gas company or gas

supplier for service.

WARNING: When this appliance is installed with casters and is

connected to the supply piping by means of a connector for

moveable appliances, a restraint to prevent damage to the

connector or quick disconnect device should have been

installed. If disconnection of the restraint is necessary,

reconnect this restraint after the appliance has been returned to

its originally installed position.

Frequently check that the compartment drain and plumbing is free of all obstructions.

Never place food containers, food or food portion bags in the cooking compartment

in such a way that the compartment dr ain becomes obstructed.

Each compartment is equipped with a removable drain screen. Frequently check

the drain screen for accumulation of food particles. Should food particles

accumulate against, or clog the drain screen, remove it, clean it thoroughly and

then replace it in its original position.

CONTROLS

Ready Pilot Light When lit, indicates steam generator has reached 205º Fahrenheit

(97º Celsius) and is ready for the cooking cycle.

Cooking Pilot Light When lit, indicates that a cooking cycle is in progress.

Timer Set the cooking time (0 to 60 minutes) - steam cooking will begin

when the door is closed. The cooking cycle will be interrupted if the

door is opened during the cooking cycle; resume cooking by closing

the door.

ON The steam generator will automatically fill and begin heating to the

pre-set temperature. Red Pilot will light on the main power switch.

DELIME Closes the drain valve while CLR liquid is being poured into the

steam generator during the Delime procedure. Amber Pilot will light

on the main power switch.

OFF The steam generator will drain. No lights.

13

Page 14

Ignition Light When lit, indicates ignition at the pilot.

NOTE: Each cooking compartment has its own steam generator and controls

and can be operated independently.

SHUTDOWN

STAND BY

1. Set Timer to “OFF” position and leave door slightly open.

COMPLETE SHUTDOWN

1. Set timer to “OFF” and turn power switch “OFF”. Steam generator will drain

automatically.

2. Turn water supply “OFF”.

3. Close manual gas shut off valve.

4. Disconnect power supply

STEAM COOKING

Your steamer efficiently cooks vegetables or other foods for immediate serving. Steam

cooking should be carefully time controlled. Keep holding time of hot food to a minimum to

produce the most appetizing results. Prepare small batches, cook only enough to start

serving, then cook additional amounts to meet demand. Separate frozen foods into smaller

pieces to allow more efficient cooking.

Use a pan cover for pre-cooked frozen dishes that cannot be cooked in the covered

containers in which they are packed if they require more than 15 minutes of cooking time.

When cover is used, approximately one-third additional cooking time is necessary.

Cooking time for frozen foods depends on amount of defrosting required. If time permits,

allow frozen foods to partially thaw overnight in a refrigerator. This will reduce their cooking

time.

14

Page 15

4.0 OPERATION INSTRUCTIONS (Continued)

PREPARATION

Prepare vegetables, fruits, meats, seafood and poultry normally by cleaning, separating,

cutting, removing stems, etc. Cook root vegetables in a perforated pan unless juices are

being saved. Liquids can be collected in a solid 12" x 20" pan placed under a perforated

pan. Perforated pans are used for frankfurters, wieners and similar items when juices do

not need to be preserved. Solid pans are good for cooking puddings, rice and hot breakfast

cereals. Vegetables and fruits are cooked in solid pans in their own juices. Meats and

poultry are cooked in solid pans to preserve their own juices or to retain broth. Canned

foods can be heated in their opened cans (cans placed in 12" x 20" solid pans) or the

contents may be poured into solid pans.

PANS

The steamer compartment is designed to accept combinations of 12 inches x 20 inches

pans (either solid or perforated). Each compartment will accommodate ten 1", five 2 ½",

three 4" or two 6" pans.

15

Page 16

5.0 MAINTENANCE

NOTICE: Contact the factory, the factory representative or local service company

to perform maintenance and repairs.

WARNING: Disconnect the power supply to the appliance before

cleaning or servicing.

CAUTION: The appliance and its parts are hot. Use care when

operating, cleaning and servicing the appliance.

CAUTION: Live steam and accumulated hot water in the compartment

may be released when the door is opened.

DAILY:

CLEANING

At the end of each day, or between cooking cycles if necessary:

1. Turn main power switch OFF.

2. Remove pans and racks from compartment and wash in sink.

3. Wash compartment interior with clean water.

4. Use warm soapy water with a cloth or sponge to clean exposed bead of door gasket,

rinse with warm clear water and wipe with a dry cloth.

Wipe surfaces which touch door gasket with a cloth or sponge and warm soapy water,

rinse with warm clear water and wipe with a dry cloth. Do not apply food oils or

petroleum solvents or lubricants directly to door gasket or surfaces which touch

door gasket.

5. Wipe all solids away from drain opening in compartments to prevent clogging.

Keep cooking compartment drain working freely. After cooking grease producing foods,

operate steam with compartment empty for 30 minutes at end of the day, or pour ½

gallon of warm soapy water down the drain, followed by ½ gallon of warm clear water.

6. Leave door slightly open when steamer is not in use.

16

Page 17

5.0 MAINTENANCE (Continued)

WEEKLY (or more often if necessary):

1. Clean exterior with a damp cloth and polish with a soft dry cloth.

2. Use a non-abrasive cleaner to remove discolorations.

3. Clean around burner air mixer and orifice if lint has accumulated.

It is NOT RECOMMENDED to use cleaning agents that are corrosive.

Use of cleaning agents that contain chloride, acids or salts which are corrosive may cause

pitting and corrosion when used over a period of time; this will reduce the life of the

appliance.

Should pitting or corrosion occur, this is not covered by the warranty.

Follow the recommended cleaning instructions. Use a mild detergent, warm water and rinse

thoroughly.

Never spray water into electric controls.

Following daily and period maintenance procedures will enhance the long-life for your

equipment. Climactic conditions - salt air - may require more thorough and frequent

cleaning otherwise the life of the equipment could be adversely affected.

STAINLESS STEEL

To remove normal dirt, grease or product residue from stainless steel, use ordinary soap

and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a

clean cloth. Never use vinegar or any corrosive cleaner.

To remove grease and food splatter or condensed vapors that have baked on the

equipment, apply cleanser to a damp cloth or sponge and rub cleanser on the metal in the

direction of the polishing lines on the metal. Rubbing cleanser as gently as possible in the

direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB

WITH A CIRCULAR MOTION.

17

Page 18

5.0 MAINTENANCE (Continued)

Soil and burnt deposits which do not respond to the above procedure can usually be

removed by rubbing the surface with SCOTCH-BRITE scouring pads or STAINLESS

scouring pads. DO NOT USE ORDIN ARY STEEL WOO L as any particles left on the

surface will rust and further spoil the appearance of the finish. NEVER USE A WIRE

BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPPER, FILE OR

OTHER STEEL TOOLS. Surfaces which are marred collect dirt more rapidly and become

more difficult to clean. Marring also increases the possibility of corrosive attack. Refinishing

may then be required.

TO REMOVE HEAT TINT:

Darkened areas sometimes appear on the stainless steel surface where the area has been

subjected to excessive heat. These darkened areas are caused by thickening of the

protective surface of the stainless steel and are not harmful. Heat tint can normally be

removed by the foregoing, but tint which does not respond to this procedure calls for a

vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or

a STAINLESS scouring pad in combination with a powdered cleanser. Heat tint action may

be lessened by not applying or by reducing heat to equipment during slack periods.

MONTHLY:

REMOVAL OF SCALE DEPOSITS:

It is recommended that your steamer be delimed once a month, or more often if necessary.

Should your steamer develop a heavy build-up of lime scale deposits, use the CLR

TREATMENT KIT available from your authorized servicer.

Before beginning deliming procedures, ensure that water is not overflowing into the cooking

compartment.

18

Page 19

6.0 DELIMING PROCEDURE

CAUTION: Read and follow instructions on the CLR bottle. Use plastic

or rubber gloves to avoid skin contact. If CLR comes in contact with

skin, rinse with clean water.

1. Completely drain steam generator by setting on/off switch to “OFF”. Set cooking timer to

0.

2. Set on/off switch to DELIME.

3. Unscrew deliming port located in front of generator. Screw in the supplied deliming

funnel. Make sure funnel is in upright position. Pour 200 ounces of solution into

generator slowly to avoid spillage. Remove funnel and screw in delime port cap

securely. Turn on/off switch to “ON”.

4. Operate steamer in READY cycle for ½ hour, then turn on/off switch “OFF” and allow

generator to drain.

5. Flush cycle. Turn on/off switch to “ON”. When ready light comes on, switch to “OFF” to

flush generator. Repeat this step three times to completely flush generator.

6. Clean exterior and interior. Use a mild solution of soap and water. Rinse with clean

water. Dry with a soft cloth. LEAVE COMPARTMENT DOOR OPEN WHEN NOT IN

USE.

The steamer is now ready for use. Turn off for overnight shutdown.

TWICE A YEAR:

At least twice a year, have an authorized service person clean and adjust the unit for

maximum performance.

All units are adjusted at the factory. In case of operation problems at initial installation,

check type of gas supply and manifold pressure and compare it with information on the

rating plate.

WARNING: Adjustments and service work may be performed only by a

qualified technician who is experienced in, and knowledgeable with the

operation of commercial gas cooking equipment. However, to assure

your confidence, contact your authorized service agency for reliable

service, dependable advice or other assistance and for genuine factory

parts.

19

Page 20

7.0 TROUBLESHOOTING

Burners do not come on:

1. Gas supply to unit is “OFF”.

2. Power Switch is not turned “ON”.

3. Steam generator probe not sensing the water level, will not call for ignition.

4. Ignitor not functioning.

5. Gas combination supply valve not “Opening”.

Burners produce carbon deposits:

1. Wrong o rifice size.

2. Wrong gas supply.

3. Incorrect pressure at supply.

Water flows into cooking compartment:

1. Short circuit between operating level probe and body inside steam generator.

2. Excessive scale build-up on operating probe.

3. Water fill solenoid valve is open, plugged or defective

These problems are an indication of severe harmful water conditions which should be

corrected immediately to avoid damage to the components and performance of the steamer.

Call your service agency for assistance.

Door leaks:

1. Check for damage to door gasket.

20

Page 21

7.0 TROUBLESHOOTING (Continued)

Water accumulates in the compartment:

1. Compartment drain clogged.

Water flows into drain during shut down:

1. Condensate valve does not close. Check thermostatic cooling valve body for foreign

particles or damage.

Water not being supplied to steam generator:

1. Water supply is “OFF”.

2. Supply water pressure too low.

3. Defective water fill solenoid valve.

4. Probes shorted or not sensing water, thereby not operating fill solenoid valve.

5. Check that drain solenoid is closed.

21

Loading...

Loading...