HV-50

INSTALLATION - OPERATION - MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 864-0183

PN 52944 Rev K (8/14)

© 2014 - G.S. Blodgett Corporation

Your Service Agency’s Address:

Model

Serial number

Oven installed by

Installation checked by

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the instllation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this oven. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

INSTALLATION

Oven Description ........................................................ 2

Utility Connections - Standards and Codes ................................. 3

Oven Location and Ventilation ............................................. 4

Oven Assembly to Stand .................................................. 5

Stacking ................................................................ 7

Plumbing Connections .................................................... 8

Electrical Connections .................................................... 9

OPERATION

Standard Control ........................................................ 10

MenuSelect™ Control ................................................... 12

SmartTouch Touchscreen Control ......................................... 17

MAINTENANCE

Spray Bottle Operating Procedure ........................................ 31

Cleaning and Preventive Maintenance .................................... 32

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Installation

Oven Description

ABOUT THE HYDROVECTION

Blodgett Hydrovection ovens are quality produced using

high-grade stainless steel with rst class workmanship.

The multiple speed fan, which is guarded against acci-

dental nger contact, is driven by a quiet and powerful

motor. The condenser draws out excess moisture from

the appliance. Condensation and waste water, which result during hydro cooking and cleaning, are continuously

drained.

The use of high quality insulation impedes excessive heat

radiation and saves energy.

The Hydrovection has an 11” high stand for double stack

units and a 29” high stand for single ovens.

PLUMBING SPECIFICATIONS

WATER

Water pressure 30 PSI (207 kPa) minimum

50 PSI (345 kPa) maximum

Water connection 3/4” garden hose - Cold water only

Water pressure regulator setting Preset to 30 PSI (207 kPa)

Minimum requirements TDS: 40-125 ppm

Hardness: 35-100 ppm

Chlorides: <25 ppm

Silica: <13 ppm

Chlorine: 0 ppm

pH: 7.0-8.5

DRAINAGE

Drain type Atmospheric Vented Drain

Drain connection 1” NPT Male

Maximum water drain temperature 140ºF (60ºC)

The practical oven door, with viewing window, have a

wide swing radius and handle which can be operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simple arrangement of the controls. Graphic symbols make the

appliance easy for even inexperienced kitchen staff to

operate. A third function, the Cool Down mode, allows the

oven cavity to cool down rapidly with the door opened.

Cleaning is kept to a minimum. The interior is sprayed

with a self-acting cleaning solution which interacts with

humidity to easily remove crusts and stains. The oven is

designed for easy care and is welded water tight so that

the internal cooking cavity may be rinsed with a hose after

the cleaning process.

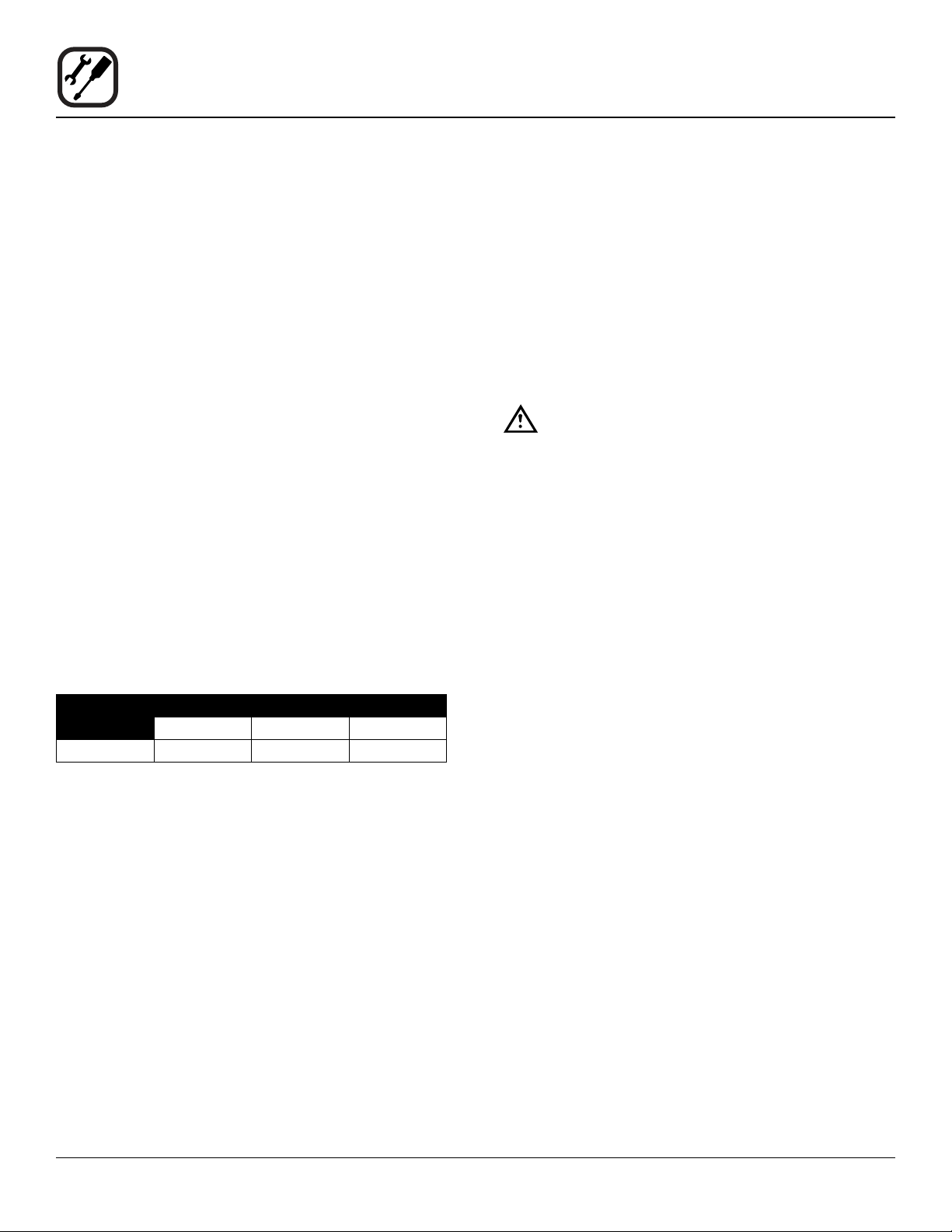

ELECTRICAL RATINGS

VOLTAGE

208 60 13 1 62 — 62 3/4 HP, 208-240V, 3 phase, 2.6 amps

208 60 13 3 38 38 34 3/4 HP, 208-240V, 3 phase, 2.6 amps

240 60 13 1 53 — 53 3/4 HP, 208-240V, 3 phase, 2.6 amps

240 60 13 3 31 31 29 3/4 HP, 208-240V, 3 phase, 2.6 amps

HZ

KW

PHASE

MAX LOAD (AMPS)

L1 L2 L2

2

MOTOR

Installation

Utility Connections - Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED

HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED

PERSONNEL MAY RESULT IN DAMAGE TO THE OVEN

AND/OR INJURY TO THE OPERATOR.

Qualied installation personnel are individuals, a rm,

a corporation, or a company which either in person or

through a representative are engaged in, and responsible

for:

• the installation or replacement of gas piping and the

connection, installation, repair or servicing of equip-

ment.

• the installation of electrical wiring from the electric

meter, main control box or service outlet to the electric appliance.

Qualied installation personnel must be experienced in

such work, familiar with all precautions required, and have

complied with all requirements of state or local authorities

having jurisdiction.

U.S. and Canadian installations

The installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1, as applicable.

Installation must conform with local codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70-Latest Edition and/or Canadian National

Electric Code C22.1 as applicable.

Appliance is to be installed with backow prevention in

accordance with applicable federal, province and local

codes.

Australia and general export installations

Instllation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your Blodgett oven,

please contact your local distributor. If you do not have a

local distributor, please call the Blodgett Oven Company

at 0011-802-658-6600.

3

Installation

Oven Location and Ventilation

OWNER’S RESPONSIBILITIES

Installation responsibilities prior to service startup

inspection

You are entitled to a free start-up inspection service by

our factory ASAP. Before a factory representative arrives

to perform a startup procedure, the owner must already

have satised the following requirements.

1. Oven(s) are uncrated, stacked (if applies) and put in

place.

NOTE: Please refer to Stacking.

Maximum shelf loading - 60 lbs (27.3 Kg)

OVEN LOCATION

The well planned and proper placement of your oven will

result in long term operator convenience and satisfactory

performance.

Certain minimum clearances must be maintained between the oven and any combustible or non-combustible

construction. See the table below.

In addition, the following clearances are recommended

for servicing.

• Oven body sides - 12” (30cm)

• Oven body back - 12” (30cm)

OVEN

MODEL

HV-50E 0” (0mm) 0” (0mm) 0” (0mm)

NOTE: Blodgett recommends 4” clearance from any heat

source on the control panel side of the oven, an

optional heat shield should be considered.

MINIMUM REQUIRED CLEARANCES

Right Side Left Side Back

VENTILATION

The necessity for a properly designed and installed ventilation system cannot be over emphasized. The ventilation

system will allow the unit to function properly while removing unwanted vapors and products of combustion from

the operating area.

The appliance must be vented with a properly designed

mechanically driven exhaust hood. The hood should be

sized to completely cover the equipment plus an overhang of at least 6” (15 cm) on all sides not adjacent to a

wall. The capacity of the hood should be sized appropri-

ately and provisions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be hazardous to the health of the operator; and will

result in operational problems, unsatisfactory

baking, and possible damage to the equipment. Damage sustained as a direct result of

improper ventilation will not be covered by the

Manufacturer’s warranty.

When installed in the Commonwealth of Massachusetts,

this appliance must be interlocked with the hood exhaust

system so that the appliance may be operated only when

the hood exhaust system is running.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the absence of

local codes, refer to the National ventilation code titled,

“Standard for the Installation of Equipment for the Removal of Smoke and Grease Laden Vapors from Commercial

Cooking Equipment”, NFPA-96- Latest Edition.

General Export Installations

Installation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your unit, please

contact your local distributor. If you do not have a local

distributor, please call Blodgett at 0011-802-658-6600.

4

Installation

Oven Assembly to Stand

NOTE: The oven weighs approximately 350 lbs, we rec-

ommend using either a fork truck or genie lift to

raise the oven.

1. Remove the bolts securing the oven shipping brackets to the pallet.

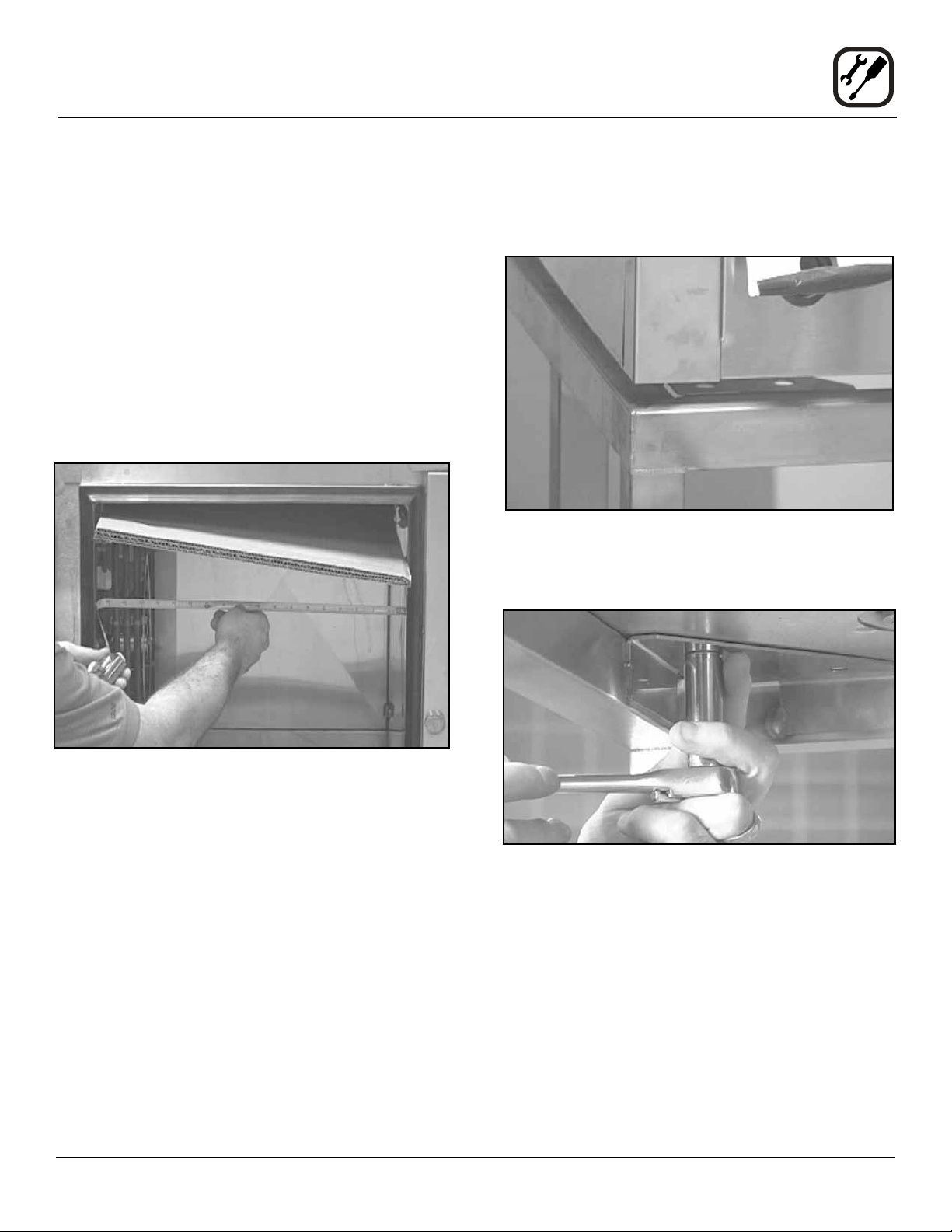

2. Open the oven door. Remove the side racks and baf-

e from inside the oven cavity.

3. Cut a piece of cardboard 18” (457 mm) x 26” (660

mm) and place in the oven cavity above the elements.

This will protect the oven from the forks of the forklift.

4. Adjust the forks on the lift to less than 16” (406 mm)

apart so they will t between the elements and the

right side of the oven cavity.

7. Position the stand below the oven. Be sure the support arms on the stand are on the right side when

facing the front of the oven. Place the oven ush with

the front of the stand and lower into place.

Figure 2

8. Attach the oven to the stand using the bolts removed

in STEP 6.

Figure 1

5. Raise the oven to above the height of the stand.

6. Remove the shipping brackets from the bottom of the

oven. Save the bolts to use in STEP 8.

Figure 3

5

Installation

Oven Assembly to Stand

OVEN LEVELING

1. Place a level on top of the oven. Loosen the set

screws on the side of each caster. Turn the adjustment collar clockwise to raise and counter clockwise

to lower the oven.

2. When the oven is level, tighten the casters by turning

the two set screws on the side of each caster assembly.

Figure 4

6

WARNING!!

Stacking should be performed by qualied

installation personnel only. The ovens are

heavy. Take care to use proper tools and techniques when lifting and stacking units.

Installation

Stacking

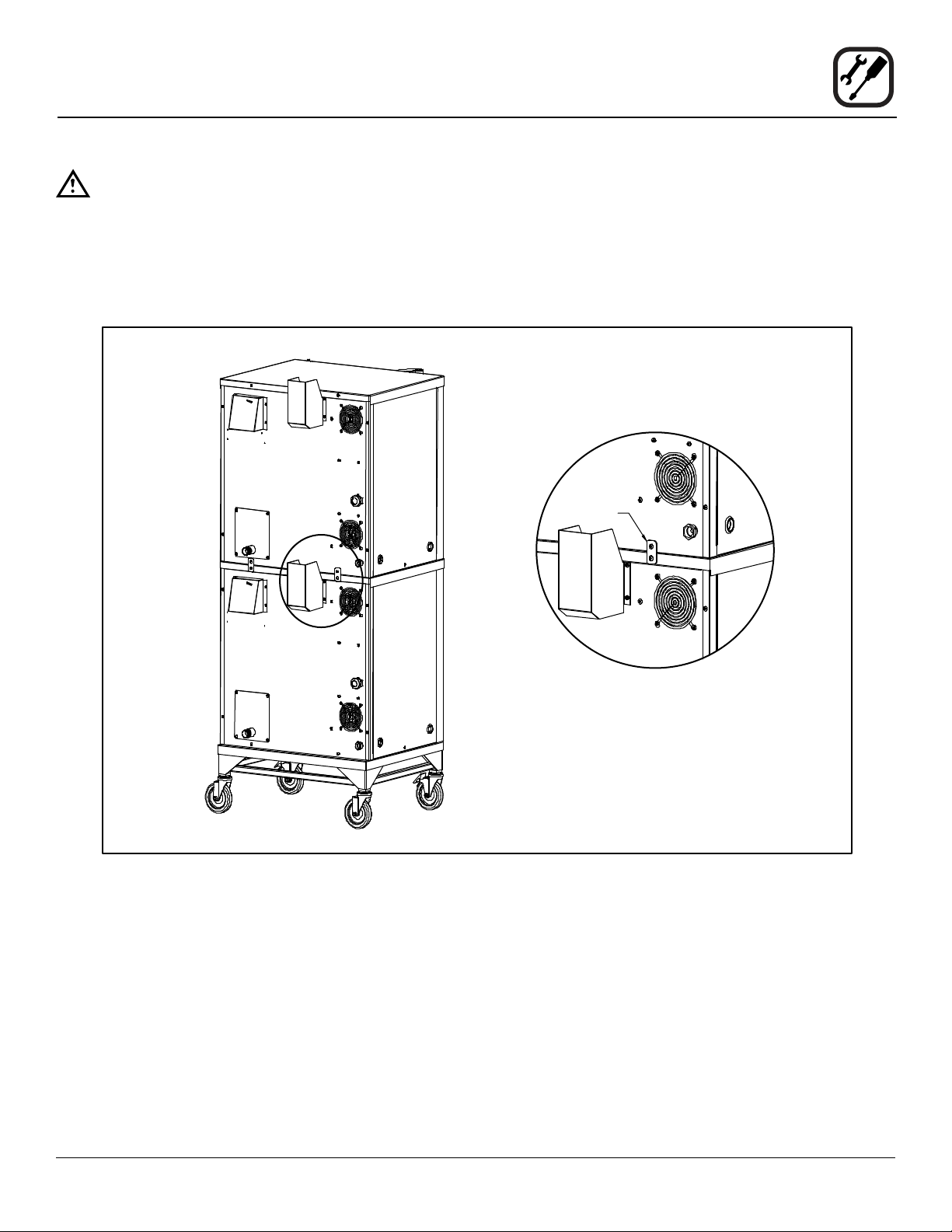

1. Attach the stand to the bottom oven.

2. Place the top oven on the bottom oven. Be sure all

four sides are ush.

3. Bolt the two ovens together on the rack using two

stacking straps.

Strap

SEE VIEW A

VIEW A

Figure 5

7

Installation

Plumbing Connections

WATER CONNECTION

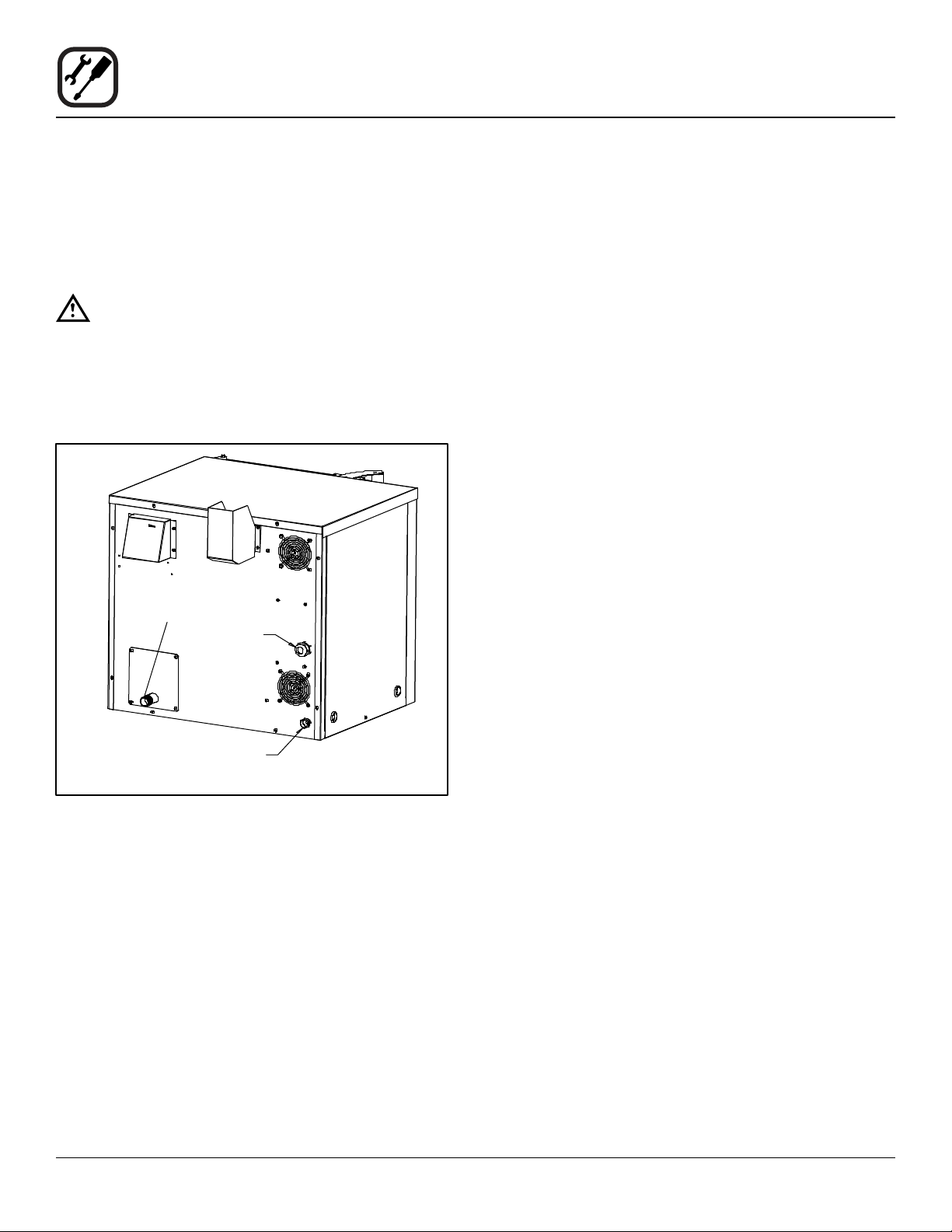

NOTE: Must use COLD WATER ONLY.

Connect the appliance to quality water via a pressure

hose with 3/4” GHT (19mm) couplings. See Figure 6 for

connections. A shut off valve is to be provided adjacent to

the oven.

WARNING!!

Operating the appliance without the water regulator installed will invalidate your warranty.

This product must be installed by a licensed Plumber or

Gas Fitter when installed within the Commonwealth of

Massachusetts.

Drain

Connection

Electrical

Connection

DRAIN CONNECTION

The drain should be run to an open oor drain avoiding

exible hose that could sag and allow trapped water to

accumulate. The drain hose should not be submerged in

water. if the drain is submerged, the oven will not drain

properly. The customer must supply the piping from the

oven to the drain.

Specic water/drain connection for City of Los Angeles

1. Each drain line from the appliance shall be routed

without dips or sags to terminate above the ood level

rim of an approved indirect waste receptor.

2. The appliance shall be installed in accordance with

the manufacturer’s printed instructions and the LAPC

and LAMC, 1999 editions.

3. A backow protection device may be required by local codes. If so, install on the potable water system

directly ahead of the appliance. The backow protection device shall be any of the following: an approved

pressure type vacuum breaker installed at least 12”

above the highest point of use, a double check valve

backow preventer or a reduced pressure principal

backow preventer.

Water Connection - Filtered Water

highly recommended

Figure 6

8

All Models

NOTE: Electrical connections must be performed by a

qualied installer only.

Before making any electrical connections to these appli-

ances, check that the power supply is adequate for the

voltage, amperage, and phase requirements stated on

the rating name plate mounted on the appliance.

The circuit breaker that is used to provide power to this

appliance must have a minimum of .076” (3mm) contact

spacing. The circuit breaker must meet all Local and National installation standards.

All appliances must be installed in accordance with Local

or National Electrical codes.

A wiring schematic is located on the inside of the removeable side panel.

NOTE: Disconnect the power supply to the appliance be-

fore servicing.

Installation

Electrical Connections

WARNING!!

Improper installation may invalidate your warranty.

A strain relief for the power supply cord is provided. The

installer must supply a cord that meets all Local and National installation standards.

WARNING!!

If the supply cord is damaged, it must be replaced by a special cord or assembly available

from the manufacturer or its service agent.

9

Operation

Standard Control

CONTROLS IDENTIFICATION

1. MODE SELECTOR SWITCH - turns power to the

oven on or off. Allows selection of Hydro, Hydro Max,

Hot Air, Combi or Cool Down Modes.

1

3

2

2. DISPLAY - displays time and temperature information.

3. TEMPERATURE DIAL - used to set desired cooking

temperature.

4. HEAT LAMP - lights when the oven is calling for heat

5. TIMER LED - lights when the cook time is displayed

6. PROBE ACTUAL LED - lights when the actual probe

temperature is displayed

4

6

5

7

7. PROBE SETPOINT LED - lights when the core setpoint temperature is displayed

8. TIMER/PROBE KNOB - use to select and set either

cook time or probe temperature

9. LIGHTS KEY - press to turn the oven lights on and off

10. FAN SPEED KEY - used to select fan speed.

11. CAVITY VENT KEY - used to open or close vent to

release steam from cavity.

8

12. PROBE CONNECTION - used to connect the core

temperature probe to the control.

9

12

13. CIRCUIT BREAKER - Used to turn power to the unit

on or off.

10

11

13

Figure 7

10

Operation

Standard Control

TIMER COOKING

1. Press the TIMER/PROBE KNOB (8) to select the timer mode. The TIMER LED lights.

2. Turn the MODE SELECTOR Switch (1) to the desired

function.

3. Set the TEMPERATURE DIAL (3) to the desired cook

temperature.

4. When the oven has reached the cook temperature,

load the product.

5. Rotate knob to enter the desired cook time in the

display. You can clear the display by rotating counter

clockwise. The timer begins on its own.

6. The temperature, time and mode can be altered at

any time during the cooking process.

7. When the timer reaches 00:00, the buzzer sounds.

Press or rotate the TIMER/PROBE KNOB (8) counter

clockwise to silence the buzzer. Remove the product.

PROBE COOKING

1. Press the TIMER/PROBE knob (8) to select the

probe setpoint mode. The PROBE SETPOINT LED

(7) lights.

COOL DOWN

NOTE: The unit can be cooled down rapidly.

1. To cool down the oven cavity, open the door and select Cool Down on the MODE SELECTOR Switch (1).

2. Rotate the knob to enter the desired nal cook temperature in the display.

3. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

4. Connect the core probe to the PROBE CONNECTION (12) at the bottom of the control.

5. The display gives the actual core probe temperature

by pressing the TIMER/PROBE knob (8) again.

6. When the product reaches the nal cook temperature

the buzzer sounds.

11

Operation

MenuSelect™ Control

1

HV-50

CONTROL DESCRIPTION

1. START/STOP KEY - press to start, cancel or pause

2

the bake

2. COOL DOWN KEY - initiates oven cool down cycle

3. BAKE MORE KEY - press at the end of a bake cycle

to add additional bake time in one minute increments.

3

4. DISPLAY - displays time or temperature and other

information related to oven function and/or programming.

4

10

11

13

14

17

19

5. DIAL - used to enter set points, time, and programmable settings. Also used to select the programmed

product.

S

E

O

L

T

E

S

C

S

E

R

P

T

5

6. TEMP KEY - used to set or change the bake temperature

7. TIME KEY - used to set or change the bake time.

6

8

7

8. HYDRO KEY - press to enter hydro mode

9

9. HOT AIR KEY - press to enter hot air mode

10. FAN KEY - press to select the fan speed

12

11. LIGHT KEY - press to turn the lights on and off.

12. VENT KEY - press to manually open and close the

15

oven vent

13. PROGRAM KEY - press to enter product programming and save programmed settings.

16

14. ESCAPE KEY - press to back up one step during programming

15. MAINTENANCE KEY - press to enter manager programming and save programmed settings

18

16. ALPHA/NUMERIC KEYPAD - used to program recipes.

17. POWER KEY - used to place control in and out of

CIRCUIT BREAKER

standby mode.

20

18. PROBE KEY - press to use core probe cooking

19. CORE PROBE CONNECTION - plug core temperature probe in here when using probe cooking

21

20. USB PORT - Used to download programming information from a USB drive

21. CIRCUIT BREAKER - Used to turn power to the unit

on or off.

Figure 8

12

Operation

MenuSelect™ Control

OVEN STARTUP

1. Be sure the shutoff switch and/or circuit breaker

switch below the control panel are in the on position.

The display ashes OFF PRESS POWER KEY TO

START.

NOTE: If the real time clock and auto wake up func-

tions are enabled the display reads PRESS

POWER KEY TO START AUTO START.

2. Press the POWER KEY (17). The display reads

PREHEAT and the oven heats to the last manual set

temperature in the hot air mode. The display ashes

READY / IDLE and the alarm beeps 5 times when the

oven is at temperature and ready to bake.

MANUAL COOKING

1. Turn the DIAL (5) until the display reads MANUAL.

2. Press the TIME KEY (7). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake time.

Press the center of the dial to set the bake time.

NOTE: Time is set in one minute increments using

the dial. To set time in less than one minute

increments use the alpha/numeric keypad.

3. Press the TEMP KEY (6). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake temperature. Press the center of the dial to set the bake

temperature. The oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5 degree increments use the alpha/numeric keypad.

4. Press the desired mode key, Hydro or Hot Air.

If Hydro is selected, rotate the dial, or use the alpha/

numeric keypad to enter the desired percentage of

moisture.

5. When the display ashes READY / IDLE, open the

door. Load the product.

6. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROGRAMMED COOKING

1. Turn the DIAL (1) until the name of the product is

highlighted. Press the center of the dial to select. The

oven preheats to the programmed temperature in the

correct cooking mode. The display ashes READY /

IDLE and the alarm beeps 5 times when the oven is

at temperature and ready to bake.

2. Open the door. Load the product.

3. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROBE COOKING

1. Press the PROBE key (18) to select the probe mode.

The display reads CORE PROBE COOK & HOLD.

Turn the dial to select either YES or NO. Press the

center of the dial to select.

If YES is selected, Cook & Hold has been enabled.

In the Cook & Hold mode, the oven cavity lowers to

the product pull temperature as the product cooks.

If NO is selected, Cook & Hold has not been enabled

the cavity maintains the cook temperature.

2. Turn the DIAL to enter the desired product pull temperature in the display. Press the center of the dial to

save the pull temperature.

3. Press the TEMP KEY (6). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake temperature. Press the center of the dial to set the bake

temperature. The oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5 degree increments use the alpha/numeric keypad.

4. Press the desired mode key, Hydro or Hot Air.

If Hydro is selected, rotate the dial, or use the alpha/

numeric keypad to enter the desired percentage of

moisture.

5. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

13

Operation

MenuSelect™ Control

6. Connect the core probe to the PROBE CONNECTION (19) at the bottom of the control.

NOTE: Do not connect the probe before the cook

mode has been selected.

7. The display gives the actual core probe temperature

as well as the oven set temperature.

8. When the product reaches the pull temperature the

buzzer sounds.

9. Press the START/STOP KEY (1) to silence the buzzer.

If using Cook & Hold - The cavity temperature continues to drop to the product pull temperature and the

display counts up, telling the operator how long the

product has been held. Disconnect the core probe

and remove the product when ready.

If not using Cook & Hold - The cavity remains at

the cook temperature. The display does not count up.

Disconnect the core probe and remove the product

when the buzzer sounds.

DURING ANY COOK CYCLE

Venting Moisture from the Oven Cavity

1. Press the VENT KEY (12). This manually opens the

vent until the key is pressed again to close it.

Pause a Bake Cycle

1. To pause a cook cycle, press the START/STOP KEY

(1). The LED on the start/stop key ashes. The bake

cycle will pause until the key is pressed again.

Cancel a Cook Cycle

1. To cancel the cook cycle, press and hold the START/

STOP KEY (1).

AT THE END OF ANY COOK CYCLE

1. An alarm sounds, the display reads DONE.

2. If more bake time is desired, press the BAKE MORE

KEY (3). This will add an additional one minute of

time for each press of the key.

3. When you are satised with the bake, press the

START/STOP KEY (1) to silence the alarm. Open the

door to remove the product.

OVEN SHUTDOWN

1. Press the COOL DOWN KEY (2). The display reads

AUTO COOL DOWN ACTUAL TEMP. To speed up

the cool down process, open the door and press the

VENT KEY (12) to open the vent.

2. When the oven has cooled down, the display reads

OFF PRESS POWER KEY TO START.

NOTE: The lights shut off and the vent closes auto-

matically at the end of the cool down cycle.

PRODUCT PROGRAMMING

Entering the Program Mode

1. Press the PROGRAM KEY (13). If the control is password protected, the display reads ENTER CODE.

Use the alpha/numeric keypad to enter the manager

passcode 3124, then press the center of the dial to

enter the program mode.

Naming a Product Recipe

NOTE: Use the following procedure to name a new prod-

uct or edit the name of an existing product.

1. For a new recipe, turn the dial to the rst open product. Press the center of the dial to select.

To edit an existing name, rotate the dial to the name

to be changed. Press the center of the dial to select.

2. Use the dial to scroll down to Edit Name. Press the

center of the dial to enter the edit name menu.

3. Turn the dial or use the alpha/numeric keypad to se-

lect the rst character. Press the center of the dial to

advance to the next character. Repeat for all remaining characters.

NOTE: Product names may be up to 10 characters

long and can contain spaces. Use the #1 key

to insert spaces in a recipe name.

NOTE: To select letters using the keypad, press the

appropriate key once if you need the rst letter on the key, twice for the second and three

times for the third. For example to enter the

letter L press the #5 key three times.

4. Press the PROG KEY (13). With SAVE highlighted,

press the dial to save the product name.

14

Operation

MenuSelect™ Control

Programming a Product Recipe

NOTE: The control can hold 99 recipes. Each recipe may

have up to 6 cooking stages.

1. Turn the dial to highlight the name of the product to

be programmed. Press the center of the dial to select

the product.

2. The display reads PRODUCT NAME: STAGE 1.

Press the center of the dial to select the stage.

3. Rotate the dial, or use the alpha/numeric keypad to

enter the desired bake time. Press the center of the

dial to set the bake time.

NOTE: Time is set in one minute increments using

the dial. To set time in less than one minute

increments use the alpha/numeric keypad.

4. Rotate the dial to select the desired cooking mode.

Choose from Hydro or Hot Air. Press the center of the

dial to set the cook mode.

If Hydro is selected, rotate the dial, or use the alpha/

numeric keypad to enter the desired percentage of

moisture.

5. Rotate the dial, or use the alpha/numeric keypad to

enter the desired cook temperature. Press the center

of the dial to set the bake temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5 degree increments use the alpha/numeric keypad.

6. Rotate the dial to select the desired fan speed.

Choose from gentle, low, high or turbo. Press the

center of the dial to set the fan speed.

9. Use the dial to scroll down to PRODUCT NAME:

STAGE 2. Press the center of the dial to select stage

2.

10. Repeat steps 2-9 for all remaining stages.

11. When all stages have been programmed, press the

PROGRAM KEY (13). To save the programming, use

the dial to scroll to YES. Press the center of the dial.

The control exits the program mode.

USING THE USB PORT

1. With the power on, remove the cover of the USB port

(20) and insert the USB drive.

2. Press the MAINTENANCE KEY (15).

3. Turn the dial to highlight MANAGER PROGRAM.

Press the center of the dial to select.

4. Turn the dial to highlight either COPY RECIPE FROM

USB or COPY RECIPE TO USB, then press the center of the dial to select.

5. When the transfer is complete, press any key to return to the menu.

6. Turn the dial to highlight EXIT. Press the center of

the dial to select. The display returns to the previous

menu.

7. Turn the dial to highlight EXIT. Press the center of the

dial to select.

7. Rotate the dial to select the fan rotation cycle. Choose

between manual or auto.

NOTE: This is the length of time the fan will rotate in

one direction before reversing.

If manual is selected, rotate the dial or use the alpha/

numeric keypad to enter the desired fan cycle. Press

the dial to set the fan cycle.

If auto is selected, the program will use the default

fan cycle setting. The default is set through the Manager Programming. See page 18.

8. Rotate the dial to set the vent position. Choose between OPEN or CLOSE. Press the center of the dial

to set the vent position.

15

Operation

MenuSelect™ Control

MANAGER PROGRAMMING

Entering the Manager Program Mode

1. Press the MAINTENANCE KEY (15). If the control

is password protected, the display reads ENTER

CODE. Use the alpha/numeric keypad to enter the

manager passcode 3124, then press the center of the

dial to enter the program mode.

2. Turn the dial to highlight OVEN SETUP. Press the

center of the dial to select the product.

Programming Auto Start

NOTE: The Auto Start function enables the oven to turn

on at a programmed time of day and preheat to a

programmed temperature.

1. Turn the dial to highlight AUTO START. Press the

center of the dial to select.

2. Turn the dial to select either ON or OFF. Press the

center of the dial to select.

If ON is selected, the display reads AUTO START 24

HOUR TIME 00:00. Turn the dial to enter the time you

would like the oven to begin preheating. Press the

center of the dial to select.

The display reads AUTO START TEMP XXX. Turn

the dial to enter the desired preheat temperature.

Press the center of the dial to select.

Programming Oven Setup

These menus allow the manager to set up basic oven

functions

1. Turn the dial to highlight OVEN SETUP. Press the

center of the dial to select.

Input Rsp Time - Set the length of time allowed to input each variable when programming recipes before

control automatically exits out

Setback Time - When not used for a period of time,

the oven temperature will automatically reduce to

conserve energy. This variable sets the length of time

the oven remains at the idle temperature before being lowered.

Ready Beep - Select either ON or OFF. This is the audible alarm that sounds when the oven has reached

the set temperature.

Cook Cool Fan - Select either YES or NO. This function allows the control to display OPEN OVEN DOOR

when you are attempting to lower the set temperature

of the oven.

Restore Manual - Select either YES or NO. This variable enables the oven to remember the last settings

used for manual cooking.

4. After editing a function, press the center of the dial

to save.

5. When all desired functions have been edited, turn the

dial to highlight EXIT. Press the center of the dial to

exit the manager programming mode.

2. Turn the dial to highlight MANAGER PROGRAM.

Press the center of the dial to select.

3. Turn the dial to highlight the oven function you wish to

change. Press the center of the dial to select. Choose

from the following functions:

Recipe Password - Select YES or NO to enable

password protection on recipe programming. If YES

is selected the passcode 3124 must be entered to

change recipe programming.

Temp Unit - Select either degrees F or C.

Cool Down Temp - Select the set temperature for

the oven to achieve in Cool Down mode

Temp Disp Rate - Set the rate, in seconds, at which

the display switches between actual and setpoint

temperature

16

Maintenance

SmartTouch Touchscreen Control

CONTROL DESCRIPTION

1. DISPLAY - displays information related to oven function and/or programming.

2. USB Port and COVER - Use to transfer recipes and

data to/from the control

3. CORE PROBE CONNECTION - plug core temperature probe in here when using probe cooking

4. CIRCUIT BREAKER - Used to turn power to the unit

on or off.

1

2

3

CIRCUIT BREAKER

4

Figure 9

17

Maintenance

SmartTouch Touchscreen Control

MANUAL MODE COOKING

1. Select the POWER button to turn on the oven and

proceed to the manual screen.

2. Set the desired cook settings.

Temperature - Press the temperature text and enter

the desired oven temperature on the keypad provided. Press SAVE & EXIT key to return to this screen.

Cook Time - Press the time text and enter the desired cook time on the keypad provided. Press SAVE

& EXIT to return to this screen.

Core Probe Cooking - To use the core probe cooking feature, press the PROBE COOK icon. Press the

temperature text that appears and enter the desired

product core temperature on the keypad provided.

Press SAVE & EXIT key to return to the manual cook

screen. Insert a product probe in the probe outlet on

the control panel. To use the HOLD option, press the

HOLD key. Once activated, key will be blue. To escape from probe cooking press the time icon.

Cavity Moisture - Press the HOT AIR icon to reduce

the cavity moisture content in 10% increments. At 0%

the oven is in the Hot Air mode. Press the HYDRO

icon to increase the cavity moisture content in 10%

increments. Press % text to set the exact percentage with the keypad. Press the SAVE & EXIT key

to return to the manual cook screen. Press and hold

the HOT AIR icon for 1 second to set humidity to 0%

quickly. Press and hold the HYDRO icon for 1 second

to set the humidity to 100% quickly.

Fan Speed - With the FAN icon highlighted, press the

fan speed text (Gentle, Low, High or Turbo). When

Turbo is displayed, press the text again to reduce the

fans speed to Gentle.

Fan Reversal Interval - To adjust the fan reversal

time, press the FAN REVERSAL icon. Then press

the time text and enter the desired reversal interval

on the keypad provided. Press SAVE & EXIT key to

return to this screen.

Vent Position - At any time the vent can be opened

or closed by toggling the VENT icon. When the icon

is highlighted the vent is open.

Lights - At any time the lights can be turned on or off

by toggling the LIGHT icon.

3. Press START Icon to begin cooking. Press Cancel

key to stop cooking. Press +1 MIN to add 1 minute to

the cook time.

Power Screen Mode Selection Screen

Figure 10

18

Temp

Maintenance

SmartTouch Touchscreen Control

Time

Hot Air Mode

Fan Speed

Lights

Probe Cooking

Hydro Mode

Fan Reversal

Increment

Vent Position

Figure 11

19

Maintenance

SmartTouch Touchscreen Control

MENU MODE COOKING

1. On a manual screen, press the ESC key to exit the

screen.

2. Select the MENU key to cook using the preprogrammed menu items.

4. Select the desired food category for your product.

Figure 12

3. Push the SELECT ITEM PRODUCT ICON in the top

right corner of the screen

Figure 14

5. Within the food category, select the desired product

you wish to cook.

Figure 15

Figure 13

6. Once selected the control returns to the Menu Cooking screen. Press the START KEY to begin the cook

cycle.

20

SHELF COOKING

1. Select the SHELF COOKING key.

Maintenance

SmartTouch Touchscreen Control

3. During the cook cycle, individual shelf cook timers will

count down as the product is cooked. If you wish to

cancel the bake, you can press the STOP ALL key, or

you can stop individual shelves.

To add time, select +1 MIN key for individual shelves

or +1 MIN ALL key to add time to all shelves. Each

time the key is pressed, 1 minute of cook time is added.

Press STOP again to reset to the original values.

CLEAR ALL to clear all products from all shelves. All

Shelves must be cleared to escape the screen.

Once the bake is complete the beeper will sound.

Figure 16

2. Select which shelves you intend to place the selected

food item on. Press selected item icon in the upper

right corner of the screen to add different items that

share the same cook temperature but may have different cook times.

Once preheated, start icons will appear. You can

choose start all or start individual shelves.

Figure 18

Figure 17

21

Maintenance

SmartTouch Touchscreen Control

EDITING A MENU

1. Select the MENU/EDIT icon to edit the recipes in the

menu mode.

3. To edit an existing item, select the item while the EDIT

ITEMS key is highlighted.

To delete an Item, select the item while the DELETE

key is highlighted.

To create a new item, select the NEW ? icon while the

EDIT key is highlighted.

Figure 19

2. Select the EDIT ITEMS icon to edit the menu items.

Figure 20

Figure 21

22

4. Each recipe is made up of steps containing seven

settings - temperature, time, fan, etc. A new step is

needed when you desire a different setting within a

step.

To edit a setting within a particular step, press the

icon for that setting. A keypad will appear for you to

input your value.

To add a step, press the + key icon.

To edit a step, press the arrow keys on the bottom left

hand corner of the screen to highlight the step you

wish to edit. Follow the instructions above to edit the

settings.

To delete a step, use the arrow keys on the bottom

left hand corner of the screen to highlight the step

you wish to delete. Press the red X icon to delete the

highlighted step.

Once you are nished, press the DISK icon to save

the changes.

Maintenance

SmartTouch Touchscreen Control

Figure 22

23

Maintenance

SmartTouch Touchscreen Control

EDITING A CATEGORY

1. Select the MENU/EDIT icon to edit the recipes in the

menu mode.

To delete a category, select the category while the

DELETE key is highlighted.

To create a new category, select the NEW ? icon

while the EDIT key is highlighted.

Figure 23

2. Select the EDIT CATEGORIES icon to select which

items are in each category.

Figure 25

4. Select what you would like to edit.

To edit the name, press the EDIT NAME key. A keyboard will appear, enter the desired name and press

ENTER to return to this menu.

Figure 24

3. To edit an existing category, select the category while

the EDIT key is highlighted.

Figure 26

24

Maintenance

SmartTouch Touchscreen Control

5. To edit the category icon, press the category icon displayed in the category edit screen. The Select Icon

screen is displayed. Select the desired icon. To view

more icon options, press the arrow key.

Once the category icon is selected, the category edit

screen is displayed. Press the DISK icon to save your

changes.

6. To edit items within a category, press the SELECT

ITEMS key on the edit category screen.

Select the items you would like to appear within the

category. When complete, press ESC key to return

to the previous menu. Press the DISK icon to save

your changes.

Figure 27

Figure 28

25

Maintenance

SmartTouch Touchscreen Control

CREATING NEW MENU ITEMS

1. Select the EDIT ITEMS key.

Figure 29

2. Select New?

5. Program the recipe steps - Each recipe is made

up of steps containing seven settings - temperature,

time, fan, etc. A new step is needed when you desire

a different setting within a step.

To edit a setting within a particular step, press the

icon for that setting. A keypad will appear for you to

input your value.

To add a step, press the + key icon.

To edit a step, press the arrow keys on the bottom left

hand corner of the screen to highlight the step you

wish to edit. Follow the instructions above to edit the

settings.

To delete a step, use the arrow keys on the bottom

left hand corner of the screen to highlight the step

you wish to delete. Press the red X icon to delete the

highlighted step.

Once you are nished, press the DISK icon to save

the changes.

6. To le recipe under an existing category, press the

EDIT CATEGORIES key. Select the desired category. Press the SELECT ITEMS key. Highlight the new

item. Press the ESC key. The disk will be displayed,

press to save your changes.

3. Select the food icon to be displayed. Use the arrow keys to page through the available icons. Press

the desired icon to select and return to the previous

screen.

4. Name the item. Press the blank shelf below the icon

to name the recipe. A keyboard will appear. Enter the

desired name. Press ENTER when nished to return

to the previous screen.

26

CREATING NEW CATEGORIES

1. Select the EDIT CATEGORIES key.

Maintenance

SmartTouch Touchscreen Control

4. Press EDIT NAME. A keyboard will appear. Enter the

desired name. Press ENTER when nished to return

to the previous screen.

5. Press SELECT ITEMS. Select items to be led in the

new category. Items will be highlighted as they are

selected. Press ESC key to return to the previous

screen. The disk will be displayed, press to save your

changes.

6. To display the category, it must be added to the default menu as follows:

Press the EDIT MENUS key. Select the DEFAULT

key. Select the CATEGORIES key. Highlight the new

category. Press the ESC key to return to the previous

screen. The disk will be displayed, press to save your

changes.

Figure 30

2. Select New?

3. Select the category icon to be displayed. Use the arrow keys to page through the available icons. Press

the desired icon to select and return to the previous

screen.

27

Maintenance

SmartTouch Touchscreen Control

TRANSFERRING RECIPES USING THE USB

1. Return to the power screen.

To Store Menu Data to a USB

1. Press the STORE MENU DATA to USB key to transfer recipes to the USB.

Figure 31

2. Press the TOOLS key. Enter the code 6647 on the

keypad.

Figure 33

2. The keyboard screen is displayed. Use to enter de-

sired le name. Press the ENTER key when nished.

Figure 32

3. Press the MANAGE MENU DATA key. Insert the USB

drive into the Intelliport.

Figure 34

28

3. The status screen appears to display the download

status. The display returns to the previous screen

when download is complete.

Maintenance

SmartTouch Touchscreen Control

Figure 37

Figure 35

4. Press the ESC key to exit USB screen.

To Retrieve Menu Data from USB

1. Press the GET MENU DATA from USB key to transfer

recipes from the USB.

Figure 36

2. The control displays all menu (.MNU) les on the USB

drive. Select the desired le.

3. The overwrite warning screen appears. Press YES to

continue

Figure 38

4. The status screen appears to display the upload status. The display returns to the previous screen when

upload is complete.

5. Press the ESC key to exit USB screen.

29

Maintenance

SmartTouch Touchscreen Control

COOL DOWN

1. To cool down the unit, press the COOL DOWN icon.

2. The oven will toggle between cooling and open door

in yellow until the oven is cool. Once cool, the oven

will go to standby.

NOTE: If the oven is shut down with the circuit break-

er switch at the bottom of the front panel, the

display will return to the power screen. Select

your option to begin.

Figure 39

Figure 40

30

NOTE: Only use a commercial oven cleaner/degreaser

with the spray bottle. DO NOT use chemicals that

are not intended as oven cleaners. See chemical

manufacturer’s information for intended use.

1. Unscrew the sprayer head and ll the

container to the MAX mark. Screw the head assembly

on rmly to ensure an airtight seal. The liquid

must be clean and free from foreign matter. Do not

overll - space must be left for compressing air.

2. To build up pressure, pump approximately 20 full

strokes when the container is lled with liquid. The

higher the pressure, the ner the spray. If the container is only partially lled, then more pumping is

required to compress the additional air space.

3. To spray, depress the trigger with your thumb.

4. Adjust spray nozzle for a wide spray pattern.

Maintenance

Spray Bottle Operating Procedure

WARNING!!

Protective clothing and eyewear should be

worn while using cleaning agents.

Pressure Pump

Spray Head

Pump

Pressure

Vessel

Spray Trigger

5. After a period of spraying, the pressure will drop. Restore the pressure by operating the air pump.

6. Release pressure after use by inverting the spray

head and depressing the trigger or by slowly unscrewing the spray head assembly which will al-

low air to escape from around the lling aperture.

7. After use, rinse the spray bottle with clean water and check that the hole in the nozzle is perfectly

clean and clear. Warm water (not hot) used with a

household detergent is a useful cleaning agent for

this purpose.

NOTE: Further information can be found in the in-

struction leaet supplied with your spray bottle.

Clean the pump 2 or 3 times per week with warm water

Figure 41

Complete Spray Bottle - P/N R0006

Spray Head Repair Kit - P/N R6332

31

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily Cleaning

Daily cleaning of the appliance is essential for sanitation,

and to ensure against operational difculties. The stainless steel cavity may corrode with improper cleaning of

the oven. Use an oven cleaning detergent in conjunction

with the supplied spray bottle.

For difcult cleaning, allow the spray-on oven cleaner to

work longer before rinsing.

1. Cool the appliance down to 140ºF (60ºC) or, if the

oven has been idle, turn the Hydro mode on

for 3 to 4 minutes in order to warm the cavity

surfaces.

On stainless interiors, deposits of baked on splatter, oil,

grease or light discoloration may be removed with a

good non toxic industrial stainless steel cleaner. Apply cleaners when the oven is cold and always rub with

the grain of the metal. The racks, rack supports and the

blower wheel may be cleaned in the oven or by removing

them from the oven and soaking them in a solution of

ammonia and water.

NOTE: DO NOT use corrosive cleaners not intended for

oven cleaning on your Hydrovection oven.

Recommended cleaners:

• ECOLAB - Greasecutter Plus

2. Fill the spray bottle and pump air into

the container with the pressure pump.

3. Spray the interior of the oven with a cleaning

solution. Be certain to spray cleaner through the fan

guard to cover all surfaces.

NOTE: Never spray water into the appliance when

the temperature is above 212ºF (100ºC).

4. Let the cleaner work the time recommended by

the cleaning solution manufacturer. For difcult,

baked on grease, etc. allow to work over night.

5. Set the timer for 15 to 20 minutes.

6. Run the oven at 225ºF (107ºC) in the Hydro mode

with 100% humidity. This will soften all burned on

residue.

7. Rinse the appliance interior with water

(a hose is supplied, but take care that only the

interior cavity is sprayed with water). Wipe the interior

dry after rinsing.

8. The door should be kept slightly open after cleaning.

This will allow the oven to vent and increase the life

of the door gasket.

• CELLO - EZ Clean

• Diversey-Lever - Advance Oven Cleaner

WARNING!!

Be sure to read and follow the MSDS or

safety instructions on the bottle for your oven

cleaner.

32

Maintenance

Cleaning and Preventive Maintenance

Oven Weekly Cleaning

In addition to the daily cleaning, it is necessasry to clean

behind the fan guard of this oven on a weekly basis. This

is necessary for proper functioning of the oven. Scale will

build up on the fan and heat source leading to a less ef-

cient oven.

1. Turn off the oven. Make sure that the oven is cooled

down to under 140ºF (60ºC).

2. Remove the rack guides.

3. Rotate the screw to unlock the fan guard.

Figure 42

5. Thoroughly spray cleaner onto the fan and heat

source. Close the door to allow the cleaner to work.

6. After ten minutes, rinse the cleaner off. Return the

fan guard to the closed position. Rotate the screw to

secure the fan guard.

Remove and clean the blower wheel every 6 months.

CLEANING THE EXTERIOR

The exterior of the appliance may be cleaned and kept in

good condition with a light oil. Saturate a cloth and wipe

the appliance when it is cold; wipe dry with a clean cloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet. Cleaning

with a water jet can impregnate chlorides into

the stainless steel, causing the onset of corrosion.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are the

proper initial installation of the equipment and a

program for cleaning the appliance routinely. The Hydro-

vection requires no lubrication. Contact the factory, the

factory representative or a local Blodgett service company to perform maintenance and repairs should they be

required.

4. Remove the fan guard.

Figure 43

33

Loading...

Loading...