Page 1

Project

Item No.

Quantity

Model CB36D-6-6K (two 6 gallon direct steam kettles on a 36” cabinet

base)

KETTLES

Water resistant, 304 stainless steel construction

316 stainless steel interior cooking surface for corrosion resistance

2/3 jacketed, hemispherical design on bottom for superior heat circulation

Tilt mechanism permits kettle to tilt forward past 90° to empty

Tubular stainless steel legs containing steam control valve and conden-

sate return pipes

Reversible operating handle with heat proof knob

CABINET BASE

Steam supply manifold with safety relief valve

Condensate return manifold with steam traps for each kettle

Hot and cold water faucet with control valves

5" (152 mm) deep sink with drain

Two splash guards

#4 finish stainless steel

Removable side panels

Hinged doors with magnetic latches

6" (152 mm) stainless steel legs

Adjustable bullet feet on the front

Flanged adjustable feet on the rear for securing to the floor

STANDARD FEATURES

Startup inspection service by factory autorized service agent

One year parts and labor warranty*

* For all international markets, contact your local distributor

BLODGETT

www.blodgett.com

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Etched kettle markings

Gallon markings

Litre markeing

Correctional package

Pressure reducing valve

One piece stainless steel lift off cover

Lift-out perforated stainless steel basket

Graduated measuring strip

Ball float trap

Pour lip strainer

One year extended warranty

CB36D-6-6K

Two Direct Steam Kettles

on a 36” Cabinet Base

CB36D-6-6K CABINET BASE WITH KETTLES

Page 2

BLODGETT

www.blodgett.com

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

CB36D-6-6K

SHORT FORM SPECIFICATIONS

Provide Blodgett model CB36D-6-6K (6 pan) two 6 gallon direct steam kettles on a cabinet base.

The kettles shall have a double wall interior to form a steam jacket around the lower 2/3 of the kettle. The bottom of the kettle shall be of hemispherical design for superior heat circula-

tion. Steam control valve mounted in leg. The tubular stainless steel mounting legs shall have the steam supply and condensate return pipes completely concealed within the leg memebers. The sealed stainless steel tilt mechanism bearings shall permit the kettle to tilt forward 90° for complete emptying. A removeable operating handle with heat proof knob shall be

mounted on the left or right. Unit shall have a single support leg with nylon insert. Construction shall be all welded satin finish 304 stainless steel with a 316 stainless steel liner.

The cabinet base shall be #4 finish stainless steel with removable side panels, hinged doors with magnetic latches and 6" (152 mm) stainless steel legs with adjustable bullet feet on the

front and flanged adjustable feet on the rear for securing to the floor. Unit shall have steam supply manifold with safety relief valve and condensate return manifold with steam traps for

each kettle. Unit shall have a hot and cold water faucet with control valves, 5" (152 mm) deep sink with drain and two splash guards.

Kettles shall be ASME code stamped and National Board registered. Provide options and accessories as indicated.

SHIPPING INFORMATION:

Approx. Weight:

CB36D-6-6k 350 lbs. (159 kg)

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

NOTE: The company reserves the right to make substitutions of components without prior notice.

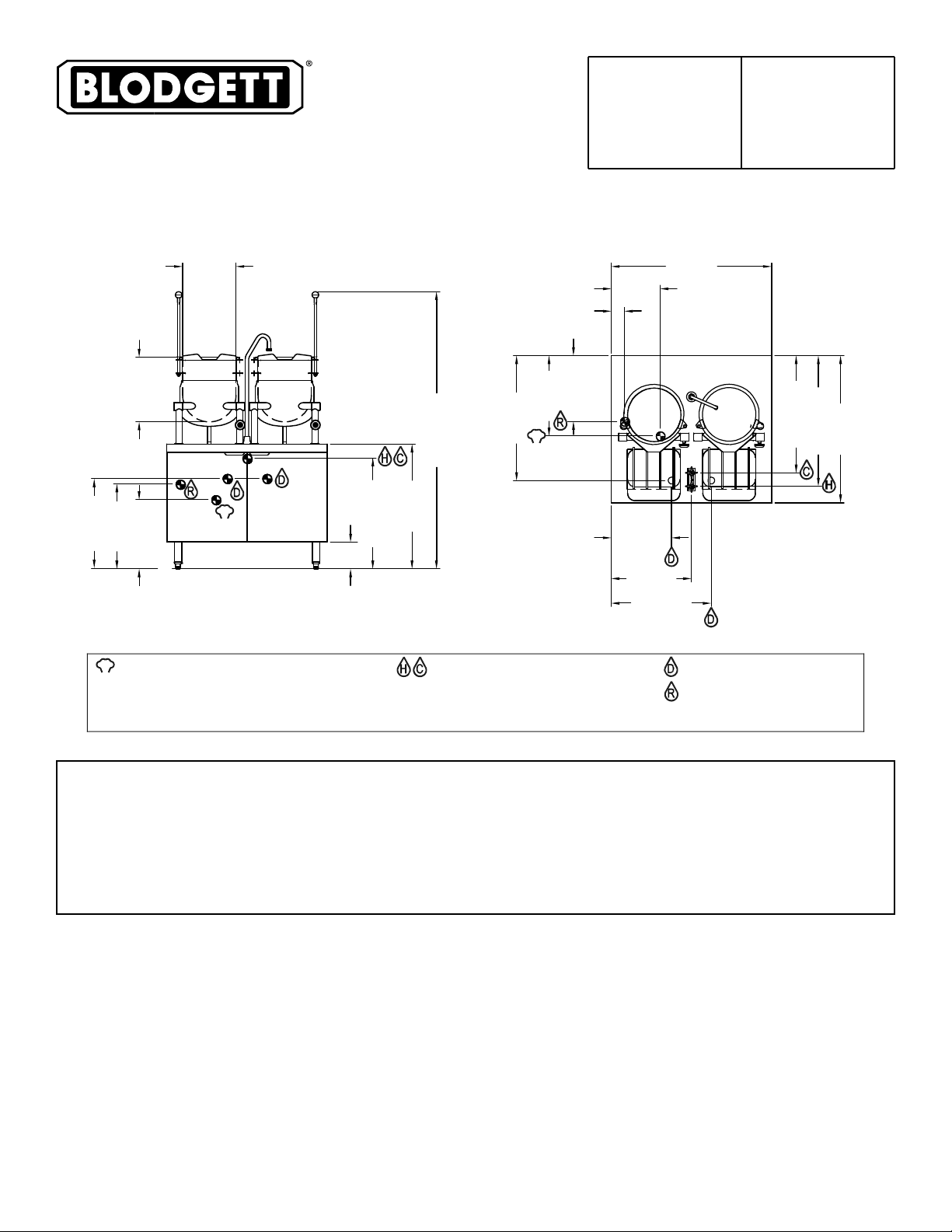

NOTE: SPLASH GUARD NOT SHOWN ON FRONT VIEWDIMENSIONS ARE IN INCHES [MM]

S

STEAM SUPPLY: 3/4” IPS for incoming steam at 5-45

PSI (34-310 kPa). Pressure reducing valve is required if

incoming pressure exceeds 50 PSI (345 kPa).

HOT AND COLD WATER: 3/8” O.D. tubing for

water to kettle fill faucet.

SINK DRAIN: 1-1/8” O.D. tubing

CONDENSATE RETURN: ½”IPS

20.25 [514]

S

19 [483]

15.5 [394] 14.5 [368]

6 [152]

24.75 [629]

28 [711]

62.13 [1578]

Ø12 [305]

S

13.62 [346]

18 [457]

22.5 [572]

3 [76]

11 [279]

36 [914]

28 [711]

18 [457]

14.75 [375]

26.25 [667]

29.25 [743]

33 [838]

APPROVAL/STAMP

P/N S00089 Rev A (6/05)

DIRECT STEAM REQUIREMENTS:

Direct steam at a minimum of 5 psi (34 kPa) and a maximum of 45 psi (310 kPa) 1/4 BHP

required per kettle.

Loading...

Loading...