Page 1

BCX-14G, BCX-14E, BX-14G, BX-14E,

CNVX-14G AND CNVX-14E

INSTALLATION - OPERATION - MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802)864-0183

PN 39678 Rev AC (9/15)

© 2015 - G.S. Blodgett Corporation

Page 2

Your Service Agency’s Address:

Model

Serial number

Oven installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the instllation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. This information may

be obtained by contacting your

local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this oven. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

INSTALLATION

The Blodgett Combi-Oven/Steamer ........................................ 4

Description of the Combi-Oven/Steamer ................................... 5

Owner’s Responsibilities .................................................. 2

Utility Connections - Standards and Codes ................................. 4

Oven Location and Ventilation ............................................. 5

Leg Attachment .......................................................... 6

Caster Attachment ....................................................... 7

Stacking ................................................................ 8

Deliming System Connection and Priming (BCX-14 units only) ............... 9

Plumbing Connections ................................................... 10

Electrical Connections ................................................... 11

Gas Connection......................................................... 12

Gas Hose Restraint ..................................................... 14

Adjustments ............................................................ 15

Final Check Lists ........................................................ 16

OPERATION

Safety Information for Gas Units .......................................... 17

Power Switches ......................................................... 18

Standard Controls for Models BCX-14 and BX-14 .......................... 19

MenuSelect™ Control for Models BCX-14 and BX-14 ...................... 21

Standard Controls for Models CNVX-14 ................................... 27

MenuSelect™ Control for Model CNVX-14 ................................ 29

SmartTouch Touchscreen Control for Model BX-14 & CNVX-14.............. 34

MAINTENANCE

Spray Bottle Operating Procedure...................................................................... 48

Cleaning and Preventive Maintenance ............................................................... 49

Daily Cleaning .............................................................................................. 49

Preventive Maintenance .............................................................................. 49

BX-14 Boilerless Oven Weekly Cleaning ..................................................... 50

Flushing the Boiler - BCX Models Only .............................................................. 51

Deliming.............................................................................................................. 52

BCX Combi Ovens ....................................................................................... 52

BX-14 Boilerless Oven ................................................................................. 55

Deliming Interval Setting - BCX Only ........................................................... 56

Page 4

Installation

The Blodgett Combi-Oven/Steamer

The Blodgett Combi-Oven/Steamer offers a completely

new method of cooking. With the Oven/Steamer you have

the choice of two cooking processes: Steam and Hot Air,

either...

• Separately

• Combined, or

• In Sequence

And for easy operation you can choose from three modes:

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanche preserve braise

poach

In the Hot Air mode you can:

roast bake grill

gratinate broil

In the Combination Steam and Hot Air mode you can:

defrost roast rethermalize

reheat bake forced steam

NOTE: CNVX models only operate in hot air mode.

You can also use two or three functions in sequence

during one cooking process. We call this:

• combi-steaming

• combi-roasting

• combi-baking

The combination of circulating hot air and steam in the

space saving, high performance Combi-Oven/Steamer

leads to improvements in the following areas:

• increased productivity in the kitchen

• a reduction in capital expenditures for multiple equipment replacement

• a wider range of menu choices

• a simplied cleaning process

The work process is simplied since products are prepared on or in steam table pans and trays. Food can be

cooked, stored, and transported with the same pans.

Small amounts of product can be processed efciently;

pre-cooked and convenience foods can be reheated within minutes. Many frozen foods can be processed with-

out pre-thawing. This exibility in preparation reduces the

need for kettles and steam tables since there is no need

for large amounts of food to be kept warm for long periods

of time.

Today the improvement of food quality is more important

than ever. Vegetables are cooked in the Blodgett CombiOven/Steamer without water at the optimal temperature

of just under 100ºC (21ºF), maintaining valuable vitamins, minerals, nutrients and trace elements. Cooking

meat in the Combi results in less shrinkage and a rmer,

juicier product. The Blodgett Combi-Oven/Steamer is being used more and more for baking. Steam and Hot Air

modes make it a general purpose baking appliance.

4

Page 5

Installation

Description of the Combi-Oven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett Combi-Oven/Steamers are quality produced using high-grade stainless steel with rst class workman-

ship.

The multiple speed fan, which is guarded against acci-

dental nger contact, is driven by a quiet and powerful

motor. The condenser draws out excess steam from the

appliance. Condensation and waste water, which result

during steaming and cleaning, are continuously drained.

The use of high quality insulation impedes excessive heat

radiation and saves energy.

The Oven/Steamer has optional adjustable legs which

adapt easily to slightly uneven surfaces and optional oor

stands which are designed for use with all of the table

models.

The high performance fresh steam generator with its control system makes it possible to enjoy all of the advantag-

es of a high quality steamer at the ick of a switch. Fresh

steam enters the oven cavity without pressure and is cir-

culated at high speed. This process enables quick and

gentle cooking and ensures high quality food while pro-

viding convenient working methods. The steam generator

is completely automatic and protected from running dry.

OVEN/STEAMER OPERATION

The practical oven door, with a viewing window, has a

wide swing radius and handle which can be operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simple arrangement of the controls. Graphic symbols make the appliance easy for even inexperienced kitchen staff to operate. The Steam On Demand feature allows the operator

to add steam at any time while operating in either the Hot

Air or Combi modes. This feature is excellent for baking

as well as roasting operations. A fourth function, the Cool

Down mode, allows the oven cavity to cool down rapidly

with the door opened.

Cleaning is kept to a minimum. The interior is sprayed

with a self-acting cleaning solution which interacts with

steam to easily remove crusts and stains. The oven is

designed for easy care and is welded water tight so that

the internal cooking cavity may be rinsed with a hose after

the steam cleaning process.

5

Page 6

Installation

Owner’s Responsibilities

INSTALLATION RESPONSIBILITIES PRIOR TO SERVICE STARTUP INSPECTION

You are entitled to a free start-up inspection service by

our factory ASAP. Before a factory representative arrives

to perform a startup procedure, the owner must already

have satised the following requirements.

1. Oven(s) are uncrated, stacked (if applies) and put in

place.

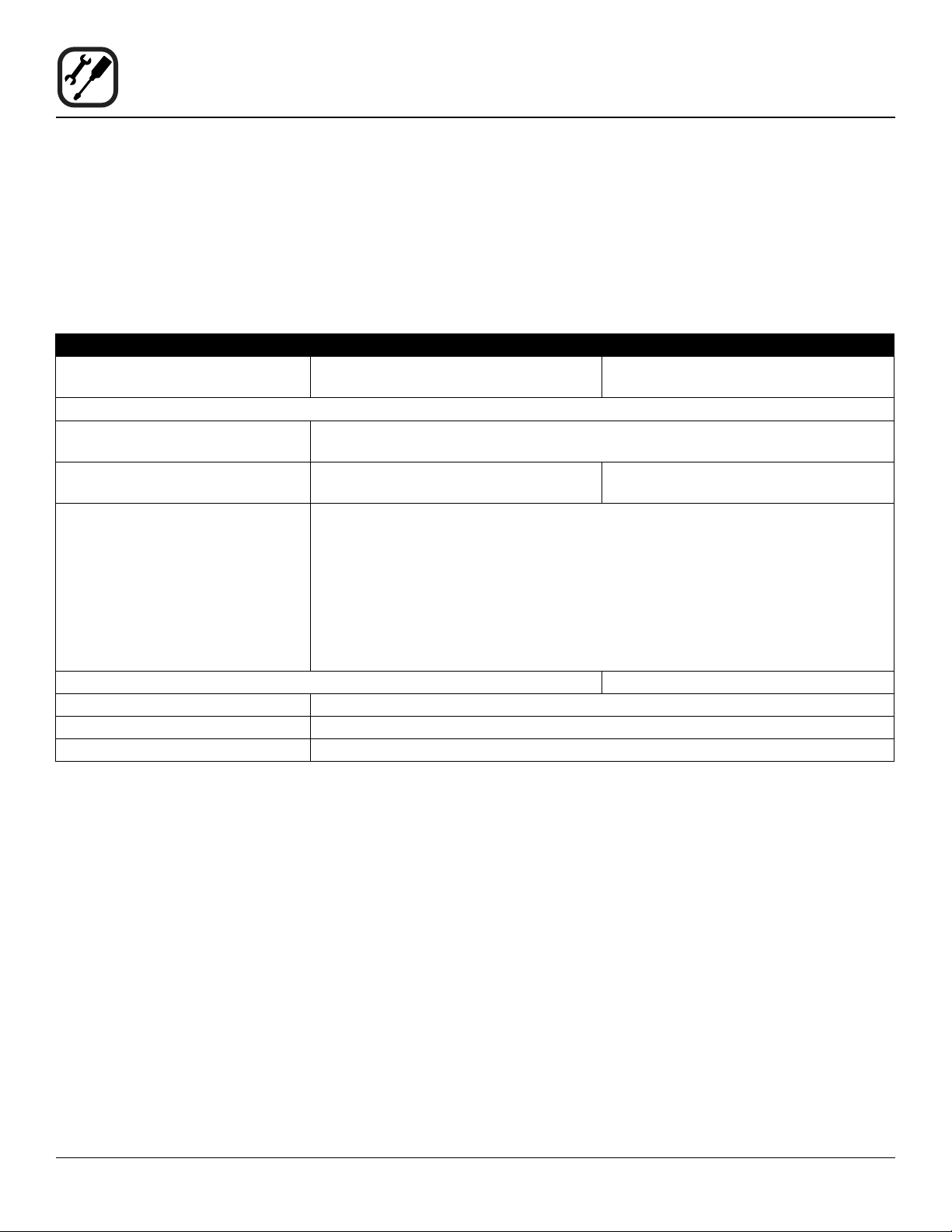

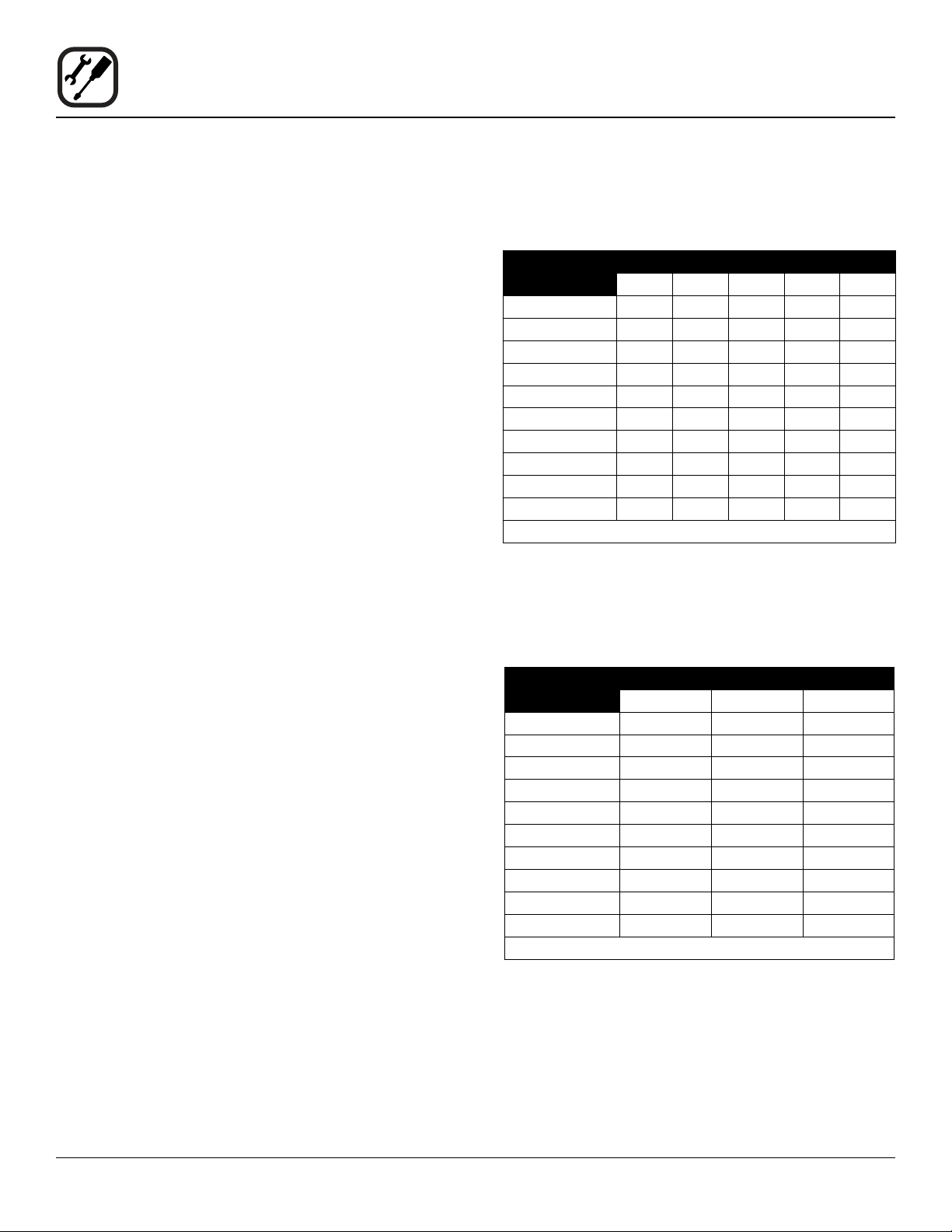

PLUMBING SPECIFICATIONS

BCX-14G/AA, BCX-14E/AA

BX-14G/AA, and BX-14E/AA

WATER

Water pressure 40 PSI minimum

50 PSI maximum

Water connection 3/4” garden hose - Hot and Cold water 3/4” garden hose for spray hose - Cold

Minimum requirements TDS: 40-125 ppm

Hardness: 35-100 ppm

Chlorides: <25 ppm

Silica: <13 ppm

Chlorine: <0.2 ppm

Chloramine: <0.2 ppm

pH: 7.0-8.5

DRAINAGE

Drain type Atmospheric Vented Drain

Drain connection 2.00” (50.8mm) Copper

Maximum water drain temperature 140ºF (60ºC)

NOTE: Please refer to Leg Attachment and Stacking.

Maximum shelf loading - 60 lbs (27.3 Kg)

CNVX-14G/AA

CNVX-14E/AA

water only

2

Page 7

Installation

Owner’s Responsibilities

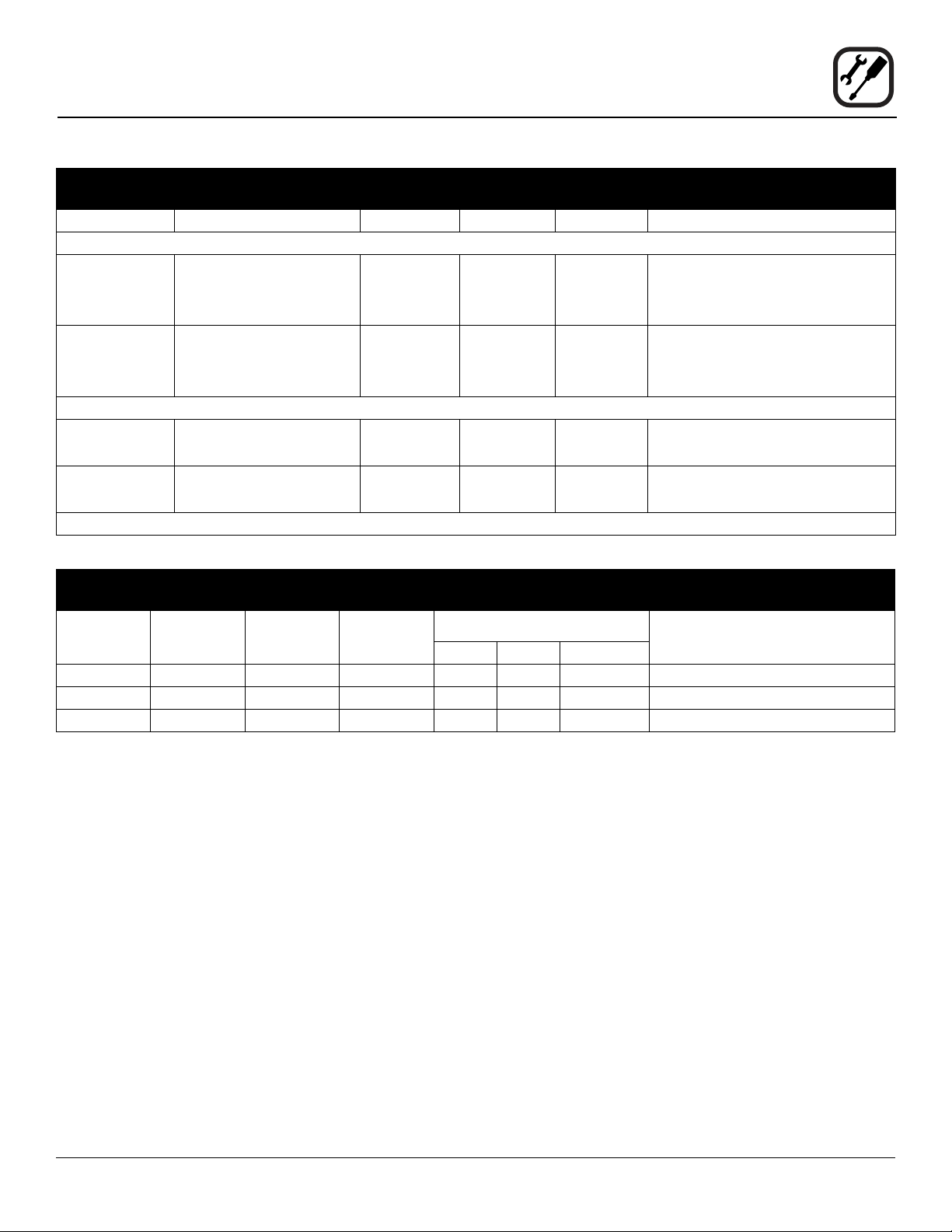

ELECTRICAL RATINGS - GAS OVENS

BCX-14G/AA, BX-14G/AA AND CNVX-14G/AA

TYPE OF GAS GAS INPUT VOLTAGE PHASE AMPS MOTOR

BCX-14G/AA

Natural Steam - 50,000 BTU/Hr

Hot Air - 65,000 BTU/Hr

Total - 115,000 BTU/Hr

Propane Steam - 48,000 BTU/Hr

Hot Air - 65,000 BTU/Hr

Total - 113,000 BTU/Hr

BX-14G/AA and CNVX-14G/AA

Natural Hot Air - 65,000 BTU/Hr 115

Propane Hot Air - 65,000 BTU/Hr 115

3/4” NPT connector for all U.S. and Canadian installations

115

208-240

115

208-240

208-240

208-240

1

1

1

1

1

1

1

1

12

6

12

6

12

6

12

6

3/4 HP 208-240VAC, 3 phase,

50/60 Hz

3/4 HP 208-240VAC, 3 phase,

50/60 Hz

3/4 HP 208-240VAC, 3 phase,

50/60 Hz

3/4 HP 208-240VAC, 3 phase,

50/60 Hz

RATINGS - ELECTRIC APPLIANCES

BCX-14E/AA, BX-14E/AA AND CNVX-14E/AA

VOLTAGE

208 60 19 3 53 53 50 3/4 HP 208-240VAC, 50/60 Hz

240 60 19 3 46 46 43 3/4 HP 208-240VAC, 50/60 Hz

480 60 19 3 23 23 21 3/4 HP 208-240VAC, 50/60 Hz

HZ

KW

PHASE

MAX LOAD (AMPS

L1 L2 L2

MOTOR

3

Page 8

Installation

Utility Connections - Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED

HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED

PERSONNEL MAY RESULT IN DAMAGE TO THE OVEN

AND/OR INJURY TO THE OPERATOR.

Qualied installation personnel are individuals, a rm,

a corporation, or a company which either in person or

through a representative are engaged in, and are responsible for:

• The installation or replacement of gas piping. The

connection, installation, repair or servicing of equipment.

• The installation of electrical wiring from the electric

meter, main control box or service outlet to the electric appliance.

Qualied installation personnel must be experienced in

such work, be familiar with all precautions required and

have complied with all requirements of state or local au-

thorities having jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

NFPA54/ANSI Z223.1-Latest Edition, the Natural Gas Installation Code CAN/CGA-B149.1 or the Propane Installation Code, CAN/CGA-B149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA 70-Latest Edition and/or Canadian Electrical Code CSA C22.1

as applicable.

This equipment is to be installed in compliance with the

Basic Plumbing Code of the Building Ofcials and Code

Administrators International Inc. (BOCA) and the Food

Service Sanitation Manual of the Food and Drug Administration (FDA).

Appliance is to be installed with backow prevention in

accordance with applicable federal, province and local

codes.

General Export Installations

Installation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your appliance,

please contact your local distributor. If you do not have a

local distributor, please call Blodgett Combi at 0011-802658-6600.

4

Page 9

Installation

Oven Location and Ventilation

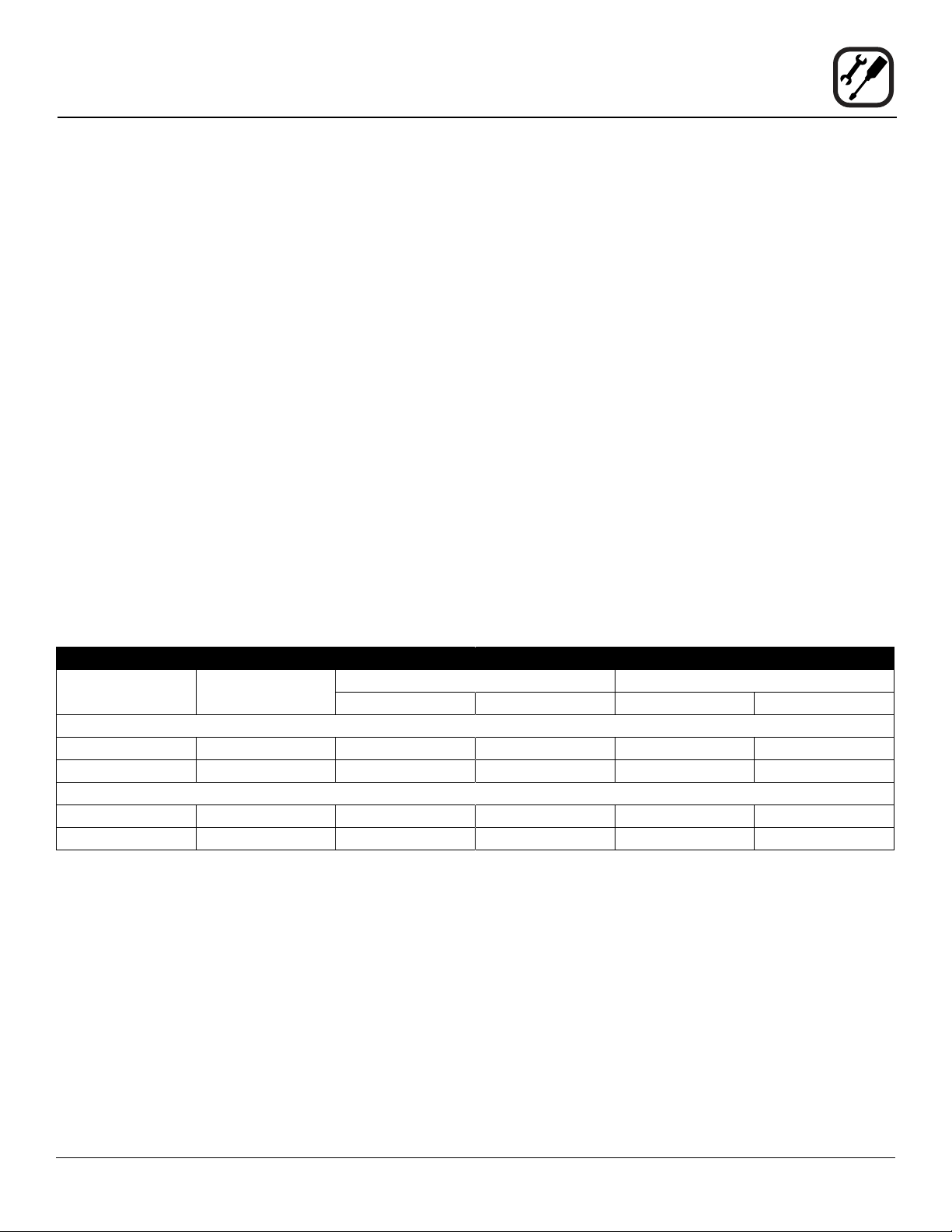

OVEN LOCATION

The well planned and proper placement of your oven will

result in long term operator convenience and satisfactory

performance.

Certain minimum clearances must be maintained between the oven and any combustible or non-combustible

construction. See the table below.

In addition, the following clearances are recommended

for servicing.

• Oven body sides - 12” (30cm)

• Oven body back - 12” (30cm)

NOTE: On gas models, routine servicing can usually

be accomplished within the limited movement

provided by the gas hose restraint. If the oven

needs to be moved further from the wall, the

gas must rst be turned off and disconnected

from the oven before removing the restraint.

Reconnect the restraint after the oven has been

returned to its normal position.

Left Side Heat Shield

Heat sources should not be near the air vents located on

the left hand side of the gas appliance.

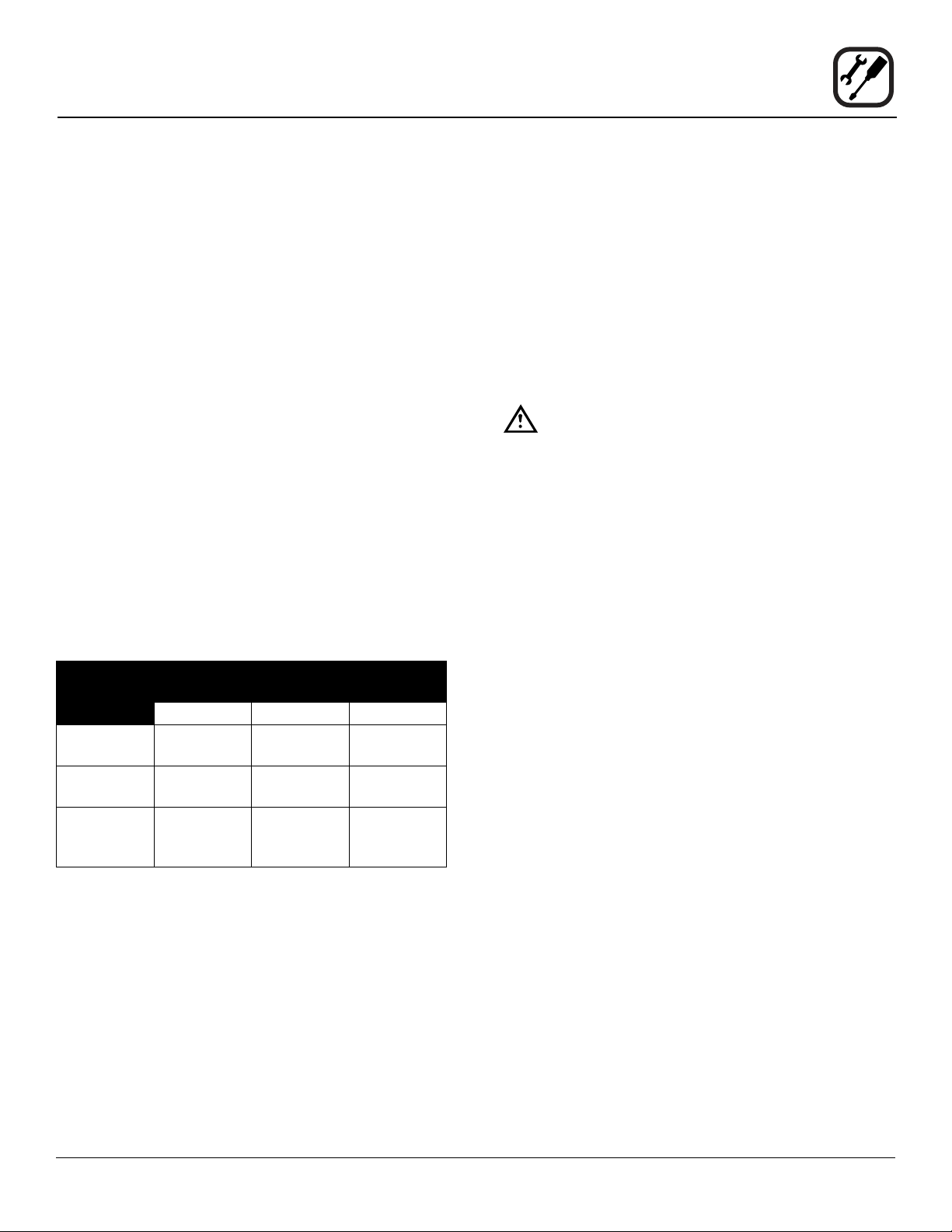

OVEN

MODEL

BCX-14G

CNVX-14G

BX-14G 1”

BCX-14E

BX-14E

CNVX-14E

Right Side Left Side Back

(25.4mm)

(25.4mm)

(50.8mm)

MINIMUM REQUIRED

CLEARANCES

1”

2”

6”

(152.4mm)

0”

(0mm)

2”

(50.8mm)

6”

(152.4mm)

6”

(152.4mm)

3”

(76.2mm)

VENTILATION

The necessity for a properly designed and installed ventilation system cannot be over emphasized. The ventilation

system will allow the unit to function properly while removing unwanted vapors and products of combustion from

the operating area.

The appliance must be vented with a properly designed

mechanically driven exhaust hood. The hood should be

sized to completely cover the equipment plus an overhang of at least 6” (15 cm) on all sides not adjacent to a

wall. The capacity of the hood should be sized appropri-

ately and provisions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be hazardous to the health of the operator; and will

result in operational problems, unsatisfactory

baking, and possible damage to the equipment. Damage sustained as a direct result of

improper ventilation will not be covered by the

Manufacturer’s warranty.

When installed in the Commonwealth of Massachusetts,

this appliance must be interlocked with the hood exhaust

system so that the appliance may be operated only when

the hood exhaust system is running.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the absence of

local codes, refer to the National ventilation code titled,

“Standard for the Installation of Equipment for the Removal of Smoke and Grease Laden Vapors from Commercial

Cooking Equipment”, NFPA-96- Latest Edition.

General Export Installations

Installation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your unit, please

contact your local distributor. If you do not have a local

distributor, please call Blodgett Combi at 0011-802-658-

6600.

5

Page 10

Installation

Leg Attachment

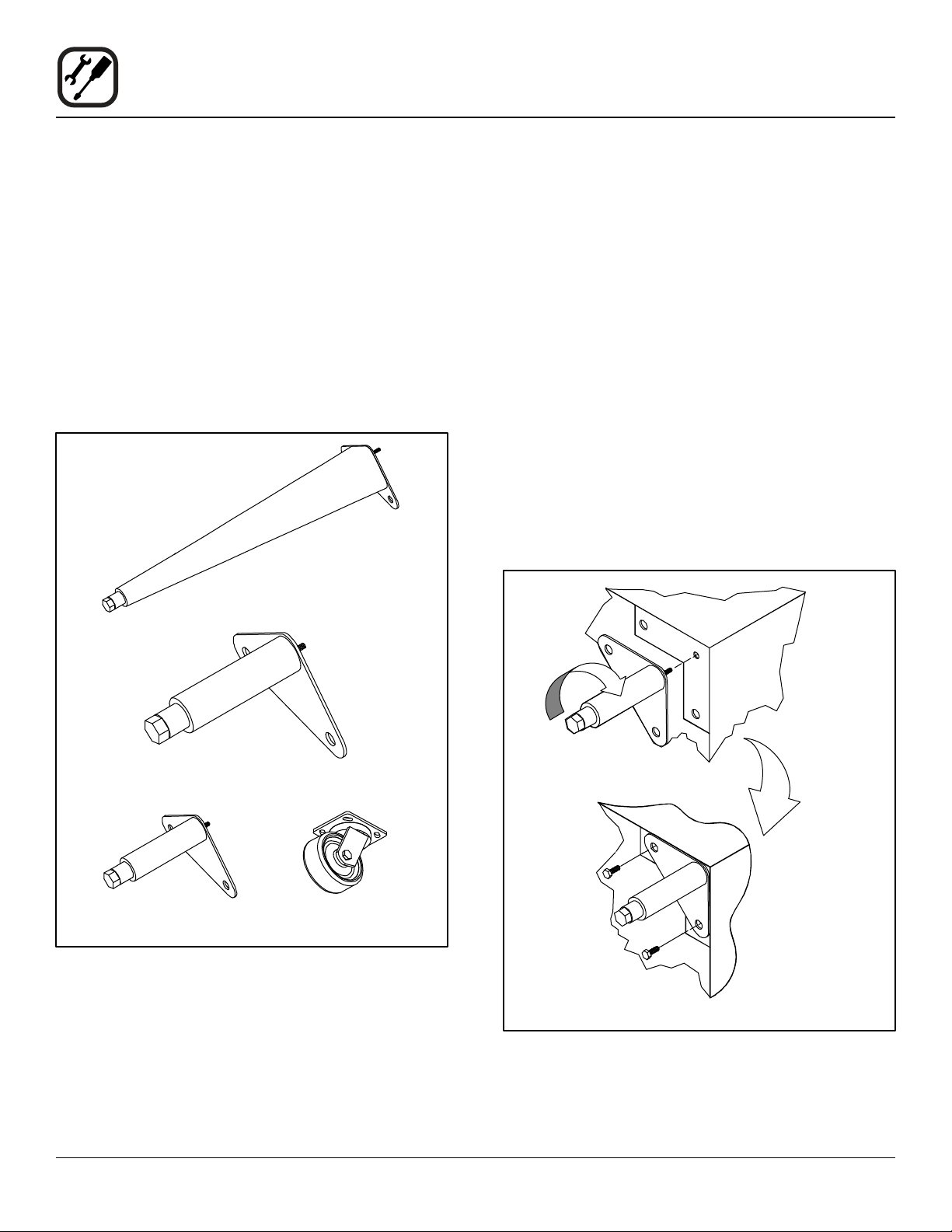

LEG OPTIONS

Legs are available in 4” (101mm), 6” (152mm) or 25”

(635mm) lengths or low prole casters.

• The 4” (101mm) legs may be used when mounting

on a counter.

• The 6” (152.4mm) legs are used on the lower section of a double stacked appliance.

• The 25” (635mm) legs are used for a single appli-

ance located on the oor.

NOTE: For safety reasons, casters must not be used

with the 25” (635mm) legs.

25” (635mm) Adjustable Leg

ATTACHMENT

1. Align the threaded stud on one of the front legs to the

bolt hole located in the bottom corner of the

appliance. Turn the leg clockwise and tighten to the

nearest full turn.

2. Align the leg plate holes with the bolt holes. Secure

with the two 1/2” bolts provided.

3. Repeat the above steps with the other front leg. If low

prole casters are used, install them with the locking

casters in the front of the oven. The rear casters do

not lock. Ensure that the locks are set on the front

casters.

4. Tip the oven up on the newly installed front legs. If

casters are used, check that the locks are set on

the front casters. Repeat the above steps for the

rear legs.

5. Level the oven by screwing the adjustable feet in or

out as necessary.

6” (152,4mm) Adjustable Leg

4” (101mm) Leg Low Prole Casters

Figure 1

Figure 2

6

Page 11

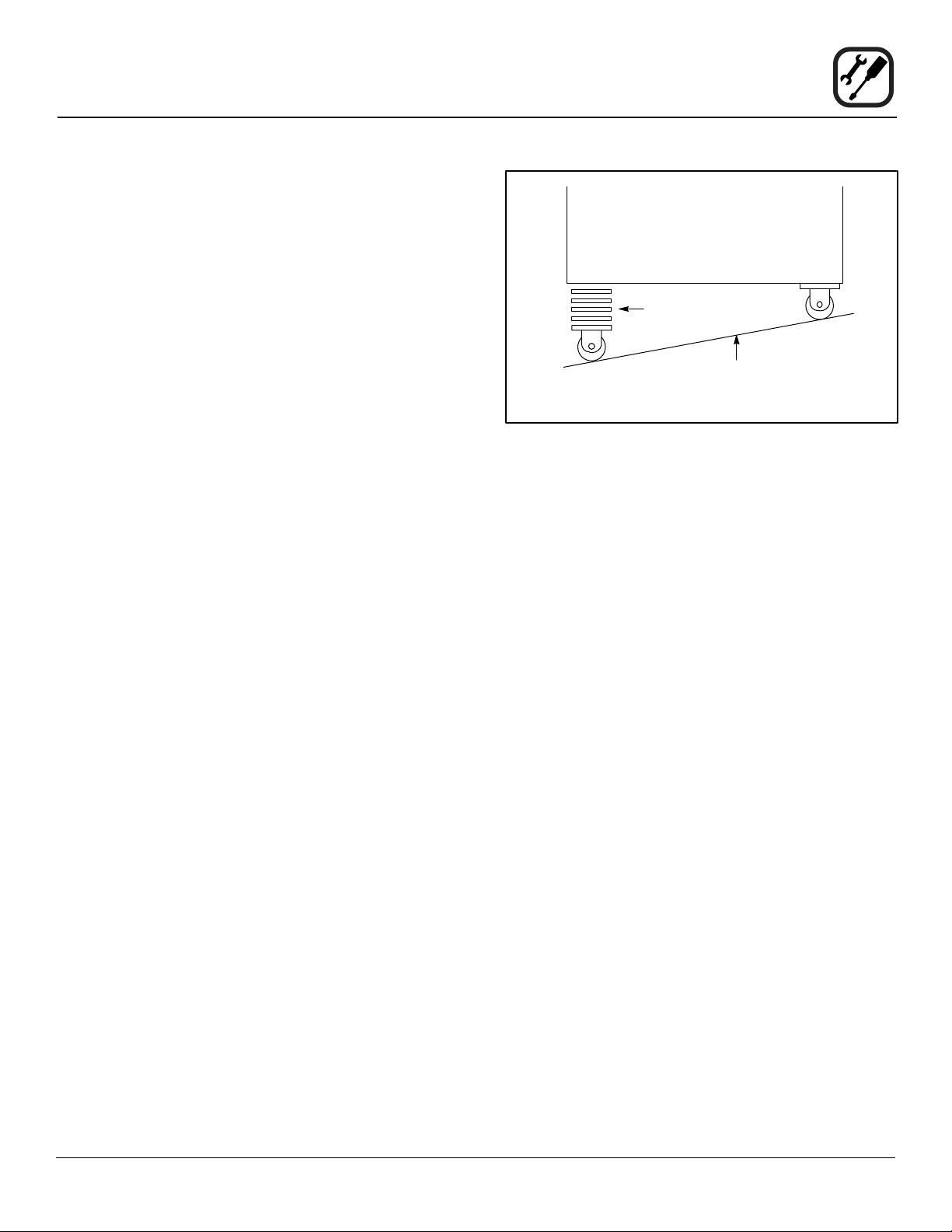

1. Place a level on the oor where the casters are to

rest.

2. Place shims under the low side until it is level.

3. Mount the shims between the casters and the oven

as follows:

Installation

Caster Attachment

a. Align the shims and caster holes with the bolt

holes.

b. Secure with the 1/2” bolts provided.

NOTE: Install them with the locking casters in the

front of the oven. The rear casters do not

lock. Ensure that the locks are set on the

front casters.

4. Tip the oven up on the newly installed casters.

Add shims as necessary

Floor

Exaggerated for clarity

Figure 3

7

Page 12

Installation

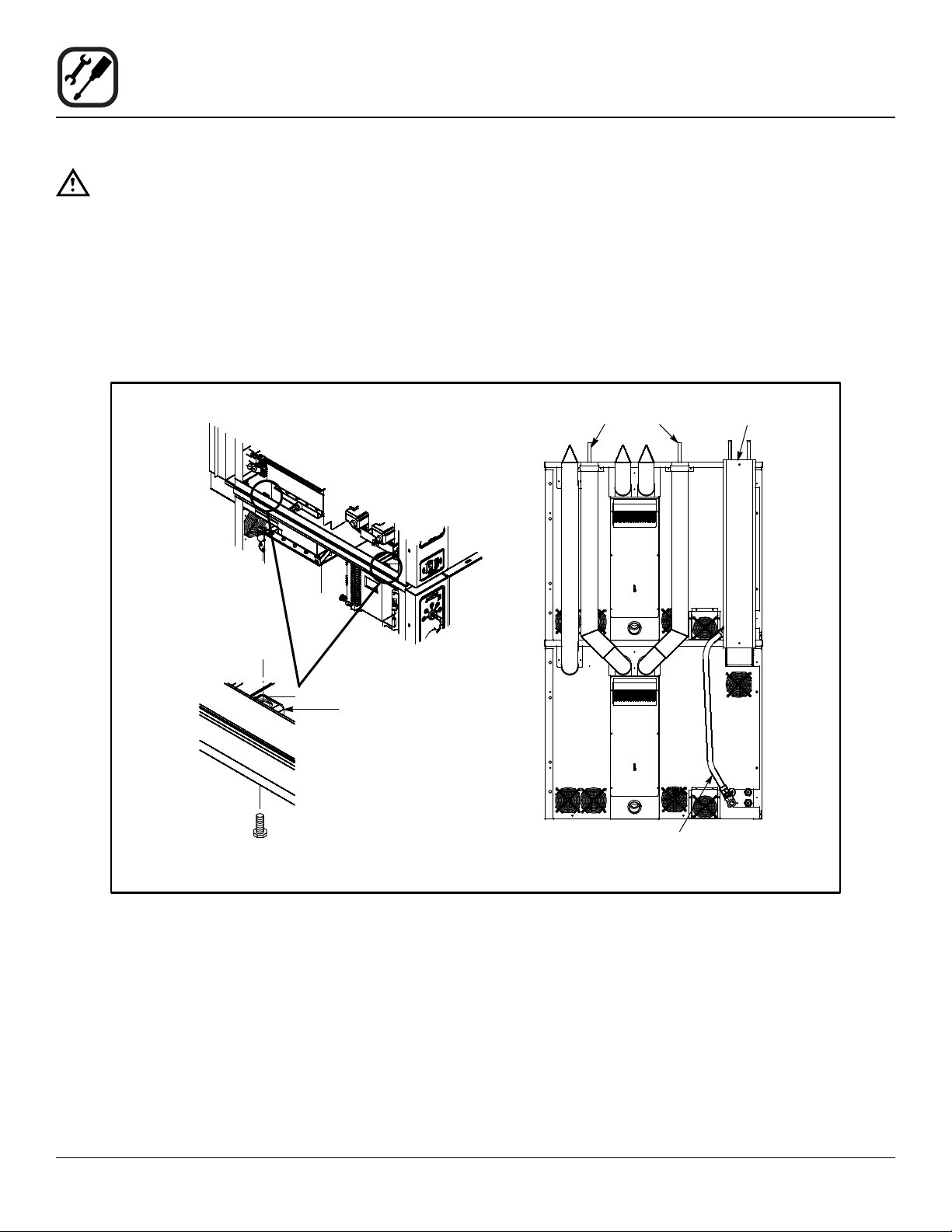

Stacking

WARNING!!

Stacking should be performed by qualied

installation personnel only. The ovens are

heavy. Take care to use proper tools and techniques when lifting and stacking units.

1. Attach the legs or casters to the bottom oven.

2. Place the top oven on the bottom oven. Be sure all

four sides are ush.

3. Remove left side oven panels.

4. Bolt the two ovens together from underneath into the

two threaded nut retainers.

5. GAS APPLIANCES ONLY: Attach the ue vents and

gas manifold as shown.

Steam Generator

Hot Air Flue

Flue (BCX-14 only)

Left Side of Ovens

with Side Panels

Removed

Bolt

Threaded Nut Retainer

Gas Manifold

Rear View BCX-14G

Figure 4

8

Page 13

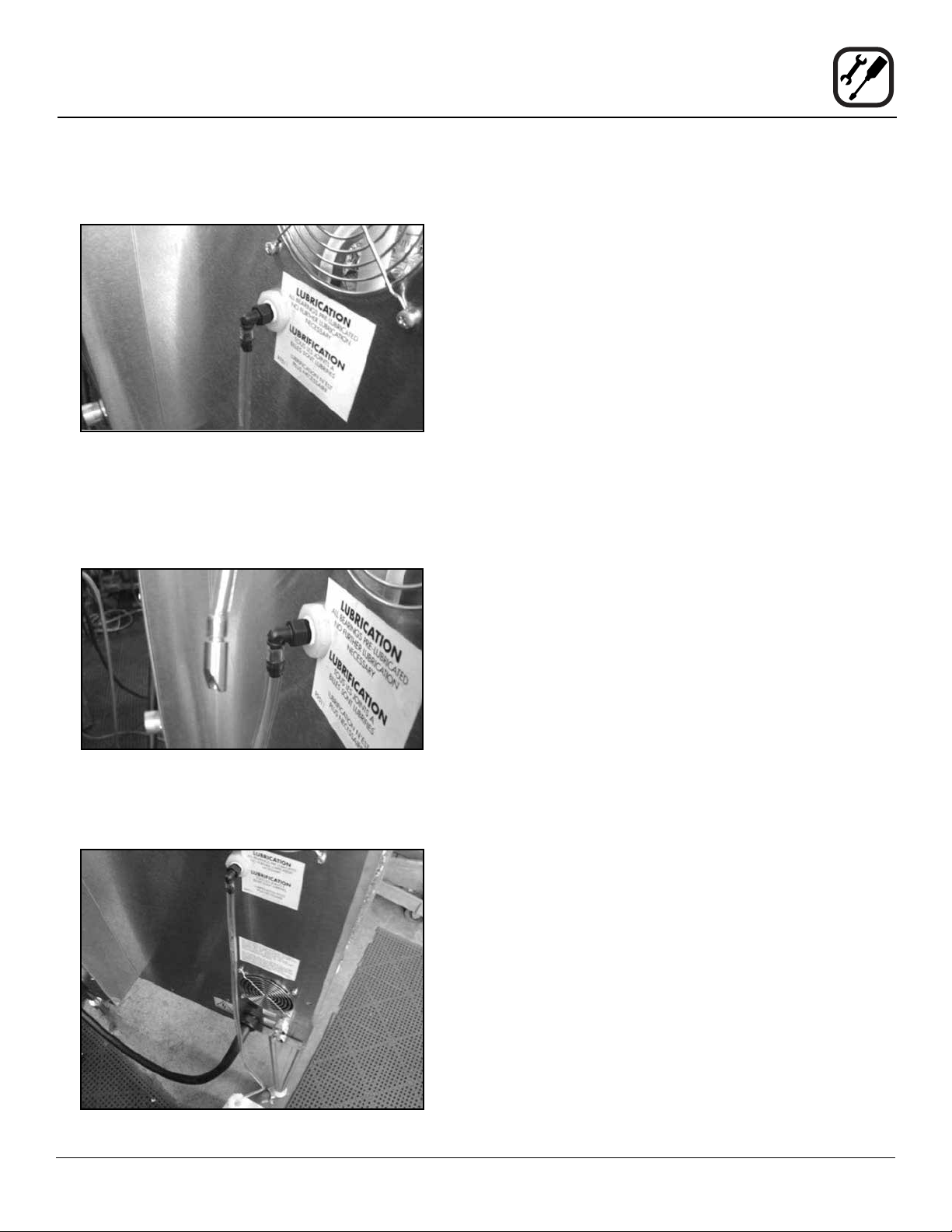

Deliming System Connection and Priming (BCX-14 units only)

DELIMING SYSTEM CONNECTION

1. Push deliming tube onto barbed tting on oven back.

Figure 5

2. Cut deliming tube to length using the bottom of the

deliming uid reservoir in its mounted position as a

guide. Install the jug weight on the deliming uid res-

ervoir end of the deliming tube.

Installation

NOTE: If needed use supplied hose retainers and self

drilling screws to route the deliming tube away

from hot exhaust ports.

PRIME THE DELIMING PUMP

To prime the delime pump, use the following procedure for

your oven control.

Standard Control

1. Rotate the mode switch to COOL DOWN.

2. Press and hold both the Timer knob and the Steam on

Demand knob simultaneously. This will turn the pump

on.

3. Watch for deliming solution to ow through the tube.

Release the two knobs once the delime solution has

reached the barbed tting on the back of the oven.

4. Once the pump is primed, you may turn the mode

switch to any position.

Figure 6

3. Insert the end of the deliming tube with the jug weight

into the deliming solution reservoir.

MenuSelect™ Control

1. Press the Maintenance key.

2. Scroll to select MANAGER PROGRAM. Push the

knob.

NOTE: If the manager password is engaged, it will

need to be entered to proceed.

3. Scroll to PRIME DELIME PUMP and push the knob.

4. The display reads, PUSH KNOB TO PRIME. Hold the

knob to activate the pump.

5. Watch for deliming solution to ow through the tube.

Release the knob once the delime solution has

reached the barbed tting on the back of the oven.

6. Once primed, press the ESC key three times to exit.

Figure 7

9

Page 14

Installation

Plumbing Connections

WATER CONNECTION

NOTE: Hot water maximizes steam production but is not

required. Cold water may be supplied to both

inlets if hot water is not available.

Connect the appliance to quality water via a pressure

hose with 3/4” GHT (19mm) couplings. See below for

connections. A shut off valve is to be provided adjacent

to the oven.

WARNING!!

Operating the appliance without the water regulator installed will invalidate your warranty.

This product must be installed by a licensed Plumber or

Gas Fitter when installed within the Commonwealth of

Massachusetts.

DRAIN CONNECTION

The drain should be run to an open oor drain avoiding

exible hose that could sag and allow trapped water to

accumulate. The customer must supply the piping from

the oven to the drain.

Specic water/drain connection for City of Los Angeles

1. Each drain line from the appliance shall be routed

without dips or sags to terminate above the ood level

rim of an approved indirect waste receptor.

2. The appliance shall be installed in accordance with

the manufacturer’s printed instructions and the LAPC

and LAMC, 1999 editions.

3. A backow protection device may be required by lo-

cal codes. If so, install on the potable water system

directly ahead of the appliance. The backow protection device shall be any of the following: an approved

pressure type vacuum breaker installed at least 12”

above the highest point of use, a double check valve

backow preventer or a reduced pressure principal

backow preventer.

BCX-14G and BX-14G

CNVX-14G

BCX-14E and BX-14E

CNVX-14E

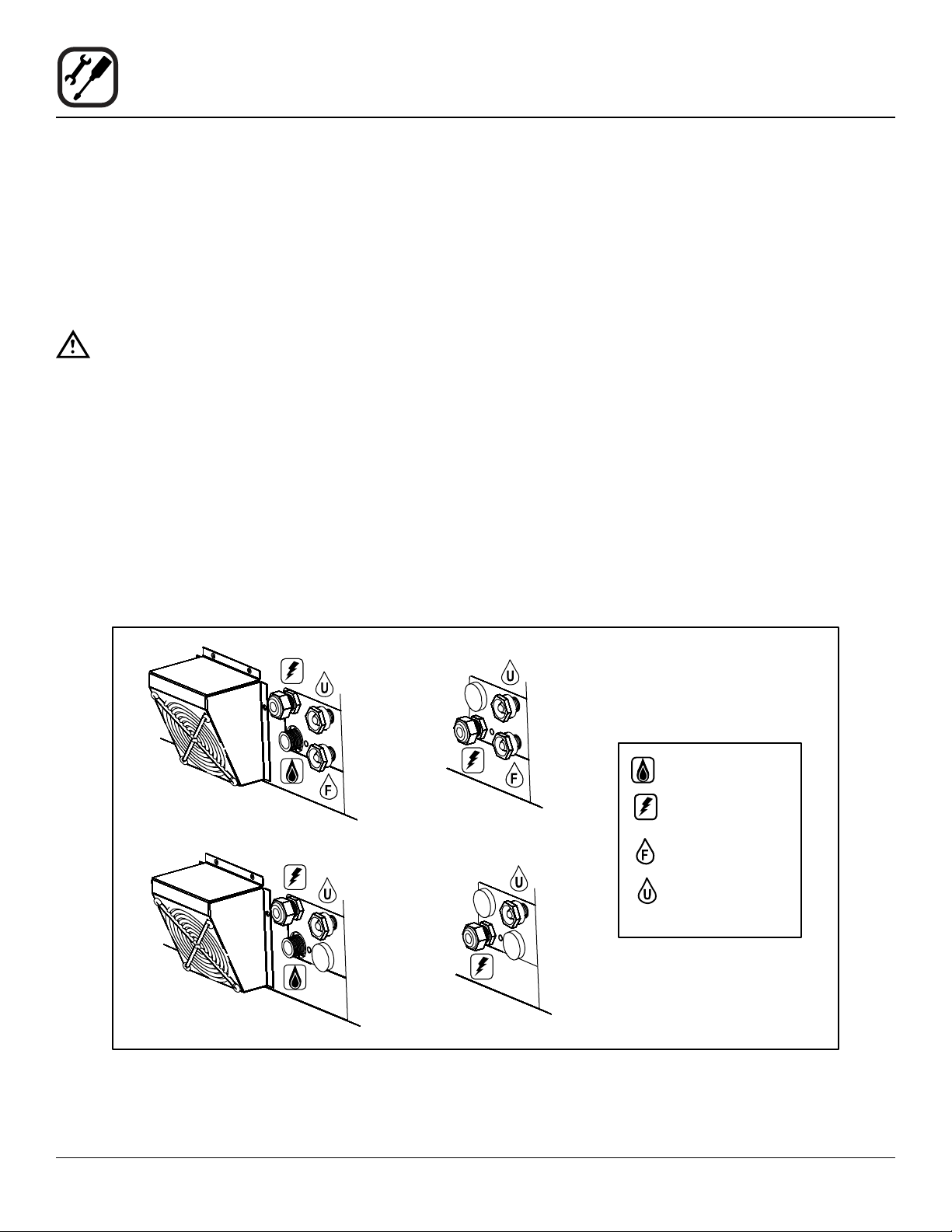

Figure 8

10

Gas connection

Electrical connection

Filtered/boiler

connection

Unltered/condensate

and spray hose

connection

Page 15

Installation

Electrical Connections

ELECTRICAL CONNECTION

All Models

NOTE: Electrical connections must be performed by a

qualied installer only.

Before making any electrical connections to these appli-

ances, check that the power supply is adequate for the

voltage, amperage, and phase requirements stated on

the rating name plate mounted on the appliance.

The circuit breaker that is used to provide power to this

appliance must have a minimum of .076” (3mm) contact

spacing. The circuit breaker must meet all Local and National installation standards.

All appliances must be installed in accordance with Local

or National Electrical codes.

A wiring schematic is located on the inside of the removeable side panel.

NOTE: Disconnect the power supply to the appliance

before servicing.

WARNING!!

Improper installation may invalidate your warranty.

Electric Models

A strain relief for the power supply cord is provided. The

installer must supply a cord that meets all Local and National installation standards.

Gas Models

U.S. and Canadian Installations

A power cord (115V units only) is supplied with a plug attached. Plug the power cord into the desired receptacle.

This oven model uses a variable frequency inverter drive.

Appliances that use variable frequency inverter drives

produce high frequency noise and require lters and

shielded motor cabling. This causes higher leakage current toward Earth Ground. Especially, at the moment of

switching ON this can cause an inadvertent trip of the appliance’s ground fault interrupter (GFCI). Some GFCIs

are more sensitive than others. Blodgett has qualied

the Pass and Seymour brand, part number 2095, 20 A,

125 VAC, 60 Hz, specication grade GFCI duplex receptacle as being immune to the variable frequency inverter

drive’s noise. Blodgett recommends using this specic

GFCI for this model oven.

WARNING!!

If the supply cord is damaged, it must be replaced by a special cord or assembly available

from the manufacturer or its service agent.

11

Page 16

Installation

Gas Connection

GAS PIPING

A properly sized gas supply system is essential for maximum oven performance. Piping should be sized to provide a supply of gas sufcient to meet the maximum demand of all appliances on the line without loss of pressure

at the equipment.

Example:

NOTE: BTU values in the following example are for

natural gas.

You purchase a BCX-14G to add to your existing cook

line.

1. Add the BTU rating of your current appliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total 230,000 BTU

BCX-14G 115,000 BTU

New Total 345,000 BTU

3. Measure the distance from the gas meter to the cook

line. This is the pipe length. Let’s say the pipe length

is 40’ (12.2 m) and the pipe size is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 375,000 BTU. Since

the total required gas pressure, 345,000 BTU is less than

375,000 BTU, the current gas piping will not have to be

increased.

NOTE: The BTU capacities given in the tables are for

straight pipe lengths only. Any elbows or other

ttings will decrease pipe capacities. Contact

your local gas supplier if you have any questions.

Maximum Capacity of Iron Pipe in Cubic Feet of

Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

PIPE

LENGTH (FT)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted L.P. Gas at 11” W.C.

(Pressure drop of 0.5 Inch W.C.)

PIPE

LENGTH (FT)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

From the National Fuel Gas Code Part 10 Table 10-15

NOMINAL SIZE, INCHES

3/4” 1” 1-1/4” 1-1/2” 2”

OUTSIDE DIAMETER, INCHES

3/4” 1” 1-1/2”

12

Page 17

PRESSURE REGULATION AND TESTING

The gas pressure to the appliance must be rated for each

appliance while the burners are on. A sufcient gas pressure must be present at the inlet to satisfy these conditions. Refer to the table below for correct gas pressure.

Each appliance has been adjusted at the factory to oper-

ate with the type of gas specied on the rating plate.

Each oven is supplied with a regulator to maintain the

proper gas pressure. The regulator is essential to the

proper operation of the oven and should not be removed.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE UNIT CONNECTS TO THE GAS SUPPLY

UNLESS THE INLET PRESSURE IS GREATER THAN

14” W.C. (1/2 PSI) (37mbar).

The oven and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.45kPa).

The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during any pressure testing of the gas piping system at test

pressures equal or less than 1/2 psig (3.45kPa).

Installation

Gas Connections

Prior to connecting the appliance, gas lines should be

thoroughly purged of all metal lings, shavings, pipe

dope, and other debris. After connection, the appliance

must be checked for correct gas pressure.

U.S. and Canadian Installations

Installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

NFPA54/ANSI Z223.1-Latest Edition, the Natural Gas Installation Code CAN/CGA-B149.1 or the Propane Installation Code, CAN/CGA-B149.2 as applicable.

General Export Installations

Installation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your appliance,

please contact your local distributor. If you do not have a

local distributor, please call Blodgett Combi at 0011-802658-6600.

GAS PRESSURE

Gas Type Inlet Pressure Orice Size at Sea Level Manifold Pressure

Hot Air Steam Hot Air Steam

BCX-14G

Natural 7-14” W.C. .0531” dia .042” dia 3.5” W.C. 3.5” W.C.

Propane 12-14” W.C. .032” dia .026” dia 10” W.C. 10” W.C.

BX-14G and CNVX-14G

Natural 7-14” W.C. .0531” dia — 3.5” W.C. —

Propane 12-14” W.C. .032” dia — 10” W.C. —

13

Page 18

Installation

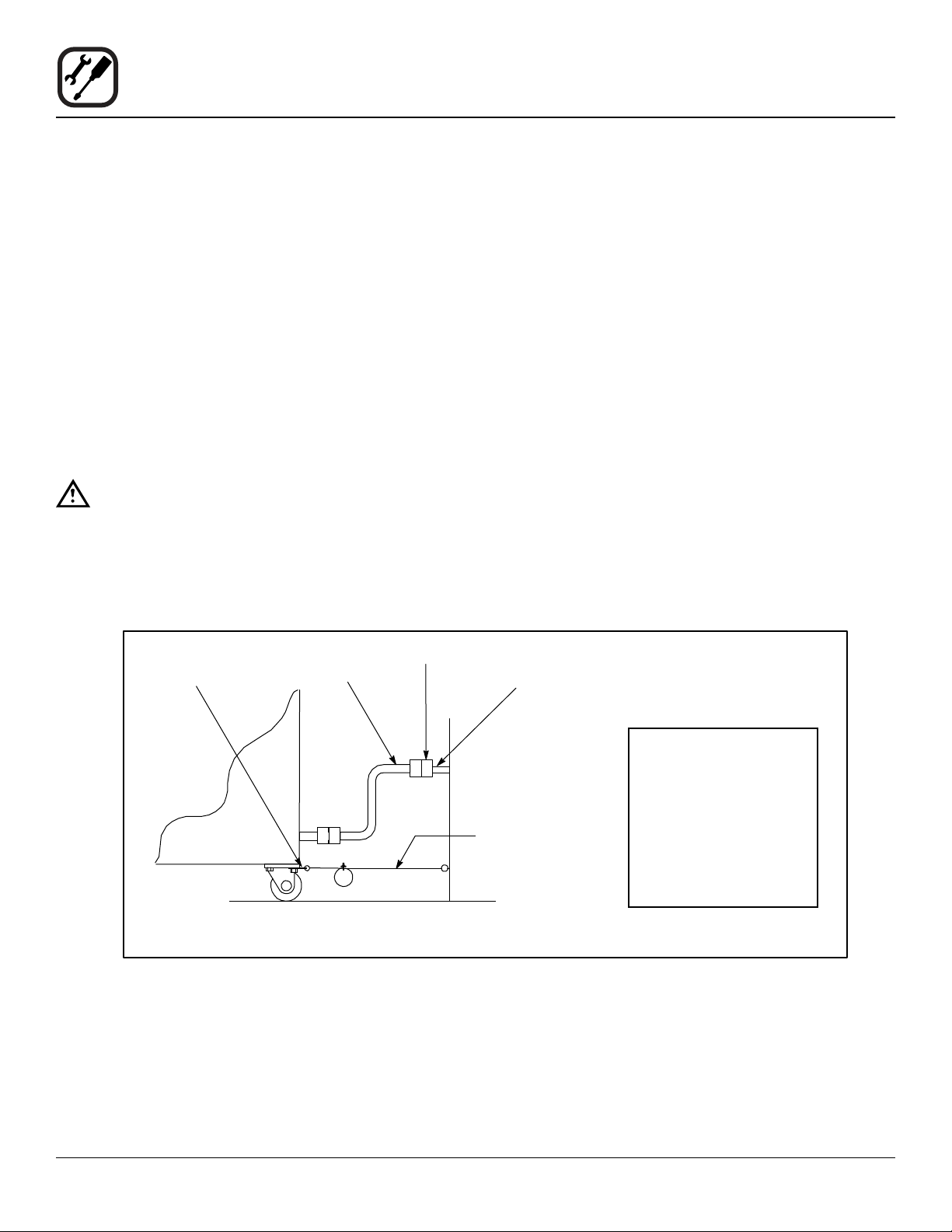

Gas Hose Restraint

If the appliance is mounted on casters, a commercial exible connector with a minimum of 3/4” (1.9 cm) inside di-

ameter must be used along with a quick connect device.

A restraint must be used to limit the movement of the appliance so that no strain is placed upon the exible connector. The restraint should be fastened to the base frame

of the oven as close to the exible connector as possible.

It should be short enough to prevent any strain on the

connector. With the restraint fully stretched the connector

should be easy to install and quick connect.

The restraint (ie: heavy gauge cable) should be attached

without damaging the building. DO NOT use the gas piping or electrical conduit for the attachment of the permanent end of the restraint! Use anchor bolts in concrete or

cement block. On wooden walls, drive hi test wood lag

screws into the studs of the wall.

WARNING!!

If the restraint is disconnected for any reason

it must be reconnected when the appliance is

returned to its original position.

U.S. and Canadian installations

The connector must comply with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or

Connectors For Moveable Gas Appliances CAN/CGA-

6.16 and a quick disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas

Fuel, ANSI Z21.41 or Quick Disconnect For Use With Gas

Fuel CAN 1-6.9. Adequate means must be provided to

limit the movement of the appliance without depending

on the connection and the quick disconnect device or its

associated piping.

A drip leg must be used at each appliance. Refer to

NFPA54/ANSI Z223.1 - Latest Edition (National Fuel Gas

Code) for proper drip leg installation.

General export installations

Installation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your appliance,

please contact your local distributor. If you do not have a

local distributor, please call Blodgett Combi at 0011-802658-6600.

Attachment Plate

(secure with leg mount bolt)

Quick Connect

Gas Hose

Restraint

Installation of Gas Hose and Restraint

(Single Section Shown)

Figure 9

Gas Supply Line

IMPORTANT: Cable restraint

should be fastened as close

as possible to the exible

connector and short enough

to prevent any strain on the

exible connector.

At maximum stretch of short-

ened restraint, the exible

connector should be easy to

install and quick to connect.

14

Page 19

Installation

Adjustments

Before applying power to the appliance for the rst time,

check for the following conditions:

• All electrical safety provisions have been adhered

to and the electrical connections are correct.

• Water is connected, turned on and all of the connections are water tight.

• The pan holders are inserted into the oven cavity.

• Cardboard has been removed from oven cavity.

• Gas has been turned on, if gas unit.

DOOR ADJUSTMENT

The door catch may be adjusted in and out using the following procedure:

1. Flip the rubber boot on the catch towards you.

2. Loosen the locknut to make adjustment.

3. Rotate the catch clockwise or counter clockwise to

get proper adjustment.

4. Retighten locknut, assuring the catch is vertical.

5. Flip the rubber boot back into position.

The hinges can also be adjusted as follows:

1. Loosen the two 1/4-20 bolts on the top of the hinge

plate and the two bolts on the bottom hinge plate.

2. Apply pressure to the door on the corners to get the

proper seal. While pushing, tighten the bolts in place.

Figure 10

15

Page 20

Installation

Final Check Lists

WARNING!!

Final check list must be performed by a quali-

ed installer only.

Combi Mode - BCX-14 and BX-14 only

Turn to COMBI mode, set thermostat to 350ºF (177ºC)

and verify:

• Heat demand lamp is on.

ELECTRICAL CONTROL COMPARTMENT

• Voltage to appliance matches rating plate

PLUMBING FINAL CHECK

• Incoming water pressure within appliance specication.

• Atmospheric vented drain in place.

• Water feed lines intact without leaks.

• Ensure proper clearance as detailed.

• Delime system has been primed. BCX-14 only.

OVEN OPERATIONAL TESTS

NOTE: Checks to be made by customer or authorized

service agent.

Cool Down Mode

• Check that the fan runs with the door open.

Steam Mode - BCX-14 and BX-14 only

Turn on STEAM mode and set thermostat to steam. Verify

the following:

• Heat demand lamp is on.

• Heat demand lamp shuts off at approximately 212ºF

(100ºC).

• Set timer for 1 minute by rotating the knob. Be sure

the buzzer sounds when the time expires.

• Run light (power light) turns on.

• Unit produces steam, window fogs, door seal does

not leak.

• Oven is heating.

• Heat demand lamp shuts off at 350ºF (177ºC) and

oven maintains 350ºF (177ºC).

• Fan shuts off with door open.

Hot Air Mode - All models

Turn to HOT AIR mode and set thermostat to 400ºF

(204ºC) and verify:

• Heat demand lamp is on.

• Oven is heating.

• Heat demand lamp shuts off at 400ºF (204ºC) and

oven maintains 400ºF (204ºC).

• Fan shuts off with door open.

Steam On Demand Mode - BCX-14 and BX-14 only

Turn the oven to Hot Air mode. Set Steam On Demand for

1 minute. Press the Steam On Demand knob and verify:

• Steam demand lamp is on.

• Steam demand lamp shuts off after approximately 1

minute.

Lights

• Press switch to ensure lights come on.

Cavity Vent

• Press switch to ensure that the vent opens and

closes.

Fan Speed

• Press switch to ensure all fan speeds work.

16

Page 21

Operation

Safety Information for Gas Units

The information contained in this section is provided for

the use of qualied operating personnel. Qualied operating personnel are those who have carefully read the information contained in this manual, are familiar with the

functions of the oven and/or have had previous experience with the operation of the equipment described. Adherence to the procedures recommended herein will assure the achievement of optimum performance and long,

trouble-free service.

Please take the time to read the following safety and operating instructions. They are the key to the successful

operation of your Blodgett oven.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

• What to do if you smell gas:

• DO NOT try to light any appliance.

• DO NOT touch any electrical switches.

• Use an exterior phone to call your gas supplier immediately.

What to do in the event of a power failure:

• Turn all switches to off.

• DO NOT attempt to operate the appliance until the

power is restored.

NOTE: In the event of a shut-down of any kind, allow a

ve (5) minute shut off period before attempting

to restart the oven.

General safety tips:

• DO NOT use tools to turn off the gas control. If the

gas cannot be turned off manually do not try to re-

pair it. Call a qualied service technician.

• If the oven needs to be moved for any reason,

the gas must be turned off and disconnected from

the appliance before removing the restraint cable.

Reconnect the restraint after the oven has been

returned to its original location.

• DO NOT remove the control panel cover unless the

oven is unplugged.

• If you cannot reach your gas supplier, call the re

department.

17

Page 22

Operation

Power Switches

CONTROLS IDENTIFICATION

1. HEAT CONTROL SWITCH

Gas Ovens - Used to turn gas on or off.

Electric Ovens - Used to turn power to the elements on or off.

2. CIRCUIT BREAKER - Used to turn power to the unit on or off. This switch should always stay ON.

See View A

Circuit

Breaker

Heat Shutoff

View A

Figure 11

18

Page 23

Operation

Standard Controls for Models BCX-14 and BX-14

CONTROLS IDENTIFICATION

1. MODE SELECTOR SWITCH - turns power to the

oven on or off. Allows selection of Steam, Hot Air,

Combi or Cool Down Modes.

2. DISPLAY - displays time and temperature information.

3. TEMPERATURE DIAL - used to set desired cooking

temperature.

4. HEAT LAMP - lights when the oven is calling for heat

5. TIMER LED - lights when the cook time is displayed

6. PROBE ACTUAL LED - lights when the actual probe

temperature is displayed

7. PROBE SETPOINT LED - lights when the core setpoint temperature is displayed

8. TIMER/PROBE KNOB - use to select and set either

cook time or probe temperature

9. STEAM ON DEMAND DISPLAY - displays the steam

on demand time

10. STEAM ON DEMAND LAMP - lights when steam on

demand is activated.

11. STEAM ON DEMAND KNOB - use to set duration for

steam on demand

12. LIGHTS KEY - press to turn the oven lights on and off

13. FAN SPEED KEY - used to select fan speed.

14. CAVITY VENT KEY - used to open or close vent to

release steam from cavity. The vent is open when the

LED is lit.

15. DELIME LAMP (BCX-14 ovens only) - Flashes when

steam generator deliming is needed. Remains steady

when deliming process is active.

16. FILL LAMP - illuminated until the steam generator is

lled with water.

NOTE: Model BX-14 ovens do not have a ll lamp.

17. PROBE CONNECTION - used to connect the core

temperature probe to the control.

Figure 12

19

Page 24

Operation

Standard Controls for Models BCX-14 and BX-14

TIMER COOKING

1. Press the TIMER/PROBE KNOB (8) to select the timer mode. The TIMER LED lights.

2. Turn the MODE SELECTOR Switch (1) to the desired

function.

3. Set the TEMPERATURE DIAL (3) to the desired cook

temperature.

For Steam mode, set the temperature no higher than

212ºF (100ºC).

For poaching, turn the temperature dial to the POACH

position, 180ºF (82ºC).

The optimum temperature for Combi mode is 300350ºF (149-177ºC).

4. When the oven has reached the cook temperature,

load the product.

5. Rotate knob to enter the desired cook time in the

display. You can clear the display by rotating counter

clockwise. The timer begins on its own.

6. The temperature, time and mode can be altered at

any time during the cooking process.

7. When the timer reaches 00:00, the buzzer sounds.

Press or rotate the TIMER/PROBE KNOB (8) counter

clockwise to silence the buzzer. Remove the product.

PROBE COOKING

1. Press the TIMER/PROBE knob (8) to select the

probe setpoint mode. The PROBE SETPOINT LED

(7) lights.

COOL DOWN

NOTE: The unit can be cooled down rapidly for steam-

ing, cleaning, etc.

1. To cool down the oven cavity, open the door and select Cool Down on the MODE SELECTOR Switch (1).

STEAM ON DEMAND

How to set the Steam On Demand feature:

While in the Hot Air or Combi mode, the unit can be set

to steam for a timed period. At the end of the timed cycle

the unit reverts back to the original setting. Steam On Demand can be used at any time during the cook cycle.

NOTE: Steam On Demand is not available in steam

mode.

1. Turn the STEAM ON DEMAND KNOB (11) to set the

desired length of time. The time is displayed in the

STEAM ON DEMAND DISPLAY (9).

2. Press the STEAM ON DEMAND KNOB (11). The

STEAM ON DEMAND LAMP (10) lights.

Uses for Steam On Demand:

Most of the ideas came from our creative customers. Experiment with this feature on your own and let us know of

any new uses.

• Add a minute or two at the beginning when baking

bread for a shiny crust.

• Kick start large loads such as 20 or more chickens.

By starting large loads with 5 to 8 minutes of steam

you help the oven recover and cut the cooking time

by more than 10%.

2. Rotate the knob to enter the desired nal cook temperature in the display.

3. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

4. Connect the core probe to the PROBE CONNECTION (17) at the bottom of the control.

5. The display gives the actual core probe temperature

by pressing the TIMER/PROBE knob (8) again.

6. When the product reaches the nal cook temperature

the buzzer sounds.

• Bake bagels without boiling. By starting raw bagels

with 1 to 2 minutes of steam you can achieve a

beautiful crust.

• Cream caramel is great at 230ºF to 250ºF in the

Combi mode using 2 minutes of on demand steam.

• When cooking chicken wings, try setting the oven

in the Combi mode at 375ºF and use 3 minutes of

Steam On Demand. This method will stop the tips

from burning. Total cooking time is approximately 12

minutes.

• Pork ribs tend to pull off the bone better when using

5 to 8 minutes of Steam On Demand. Try ribs in the

Combi mode at 350ºF.

20

Page 25

Operation

MenuSelect™ Control for Models BCX-14 and BX-14

CONTROL DESCRIPTION

1. START/STOP KEY - press to start, cancel or pause

the bake

2. COOL DOWN KEY - initiates oven cool down cycle

3. BAKE MORE KEY - press at the end of a bake cycle

to add additional bake time in one minute increments.

4. DISPLAY - displays time or temperature and other

information related to oven function and/or programming.

5. DIAL - used to enter set points, time, and programmable settings. Also used to select the programmed

product.

6. TEMP KEY - used to set or change the bake temperature

7. TIME KEY - used to set or change the bake time.

8. COMBI KEY - press to enter combi mode

9. STEAM KEY - press to enter steam mode

10. HOT AIR KEY - press to enter hot air mode

11. RETHERM KEY - press to enter retherm mode, this

mode uses steam to reheat frozen or precooked product. Retherm has a temperature limit of 250-300ºF.

12. STEAM ON DEMAND KEY - used to initiate steam

injection cycle

13. PROBE KEY - press to use core probe cooking

14. FAN KEY - press to select the fan speed

15. LIGHT KEY - press to turn the lights on and off.

16. VENT KEY - press to manually open and close the

oven vent

17. PROGRAM KEY - press to enter product programming and save programmed settings.

18. ESCAPE KEY - press to back up one step during programming

19. MAINTENANCE KEY - press to enter manager programming and save programmed settings

Figure 13

20. ALPHA/NUMERIC KEYPAD - used to program recipes.

21. POWER KEY - used to place control in and out of

standby mode.

21

Page 26

Operation

MenuSelect™ Control for Models BCX-14 and BX-14

22. CORE PROBE CONNECTION - plug core temperature probe in here when using probe cooking

23. USB Port and COVER - Use to transfer recipes and

data to/from the control

24. BUZZER - The buzzer is turned on/off through the

oven control.

OVEN STARTUP

1. Be sure the gas shutoff switch and/or circuit breaker

switch below the control panel are in the on position.

The display ashes OFF PRESS POWER KEY TO

START.

NOTE: If the real time clock and auto wake up func-

tions are enabled the display reads PRESS

POWER KEY TO START AUTO START.

2. Press the POWER KEY (21). The display reads

PREHEAT and the oven heats to the last manual set

temperature in the hot air mode. The display ashes

READY / IDLE and the alarm beeps 5 times when the

oven is at temperature and ready to bake.

MANUAL COOKING

1. Turn the DIAL (5) until the display reads MANUAL.

2. Press the TIME KEY (7). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake time.

Press the center of the dial to set the bake time.

NOTE: Time is set in one minute increments using

the dial. To set time in less than one minute

increments use the alpha/numeric keypad.

3. Press the TEMP KEY (6). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake temperature. Press the center of the dial to set the bake

temperature. The oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5

degree increments use the alpha/numeric

keypad.

4. Press the desired mode key, combi, steam, hot air or

retherm.

If Combi or Retherm are selected, rotate the dial, or

use the alpha/numeric keypad to enter the desired

percentage of steam.

NOTE: Retherm has a temperature limit of 250-

300ºF.

5. When the display ashes READY / IDLE, open the

doors. Load the product.

6. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROGRAMMED COOKING

1. Turn the DIAL (1) until the name of the product is

highlighted. Press the center of the dial to select. The

oven preheats to the programmed temperature in the

correct cooking mode. The display ashes READY /

IDLE and the alarm beeps 5 times when the oven is

at temperature and ready to bake.

2. Open the doors. Load the product.

3. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROBE COOKING

1. Press the PROBE key (13) to select the probe mode.

The display reads CORE PROBE COOK & HOLD.

Turn the dial to select either YES or NO. Press the

center of the dial to select.

If YES is selected, Cook & Hold has been enabled.

In the Cook & Hold mode, the oven cavity lowers to

the product pull temperature as the product cooks.

If NO is selected, Cook & Hold has not been enabled

the cavity maintains the cook temperature.

2. Turn the DIAL to enter the desired product pull temperature in the display. Press the center of the dial to

save the pull temperature.

3. Press the TEMP KEY (6). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake temperature. Press the center of the dial to set the bake

temperature. The oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5

degree increments use the alpha/numeric

keypad.

22

Page 27

Operation

MenuSelect™ Control for Models BCX-14 and BX-14

4. Press the desired mode key, combi, steam, hot air or

retherm.

If Combi or Retherm are selected, rotate the dial, or

use the alpha/numeric keypad to enter the desired

percentage of steam.

NOTE: Retherm has a temperature limit of 250-

300ºF.

5. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

6. Connect the core probe to the PROBE CONNECTION (22) at the bottom of the control.

NOTE: Do not connected the probe before the cook

mode has been selected.

7. The display gives the actual core probe temperature

as well as the oven set temperature.

8. When the product reaches the pull temperature the

buzzer sounds.

9. Press the START/STOP KEY (1) to silence the buzzer.

3. The Steam on Demand LED ashes until the steam

time has expired.

Venting Moisture from the Oven Cavity

1. Press the VENT KEY (16). This manually opens the

vent until the key is pressed again to close it.

Pause a Bake Cycle

1. To pause a cook cycle, press the START/STOP KEY

(1). The LED on the start/stop key ashes. The bake

cycle will pause until the key is pressed again.

Cancel a Cook Cycle

1. To cancel the cook cycle, press and hold the START/

STOP KEY (1).

At the End of Any COOK Cycle

1. An alarm sounds, the display reads DONE.

2. If more bake time is desired, press the BAKE MORE

KEY (3). This will add an additional one minute of

time for each press of the key.

3. When you are satised with the bake, press the

START/STOP KEY (1) to silence the alarm. Open the

door to remove the product.

If using Cook & Hold - The cavity temperature continues to drop to the product pull temperature and the

display counts up, telling the operator long the product has been held. Disconnect the core probe and

remove the product when ready.

If not using Cook & Hold - The cavity remains at

the cook temperature. The display does not count up.

Disconnect the core probe and remove the product

when the buzzer sounds.

DURING ANY COOK CYCLE

Steam On Demand

While in the Hot Air, Combi or retherm modes, the unit can

be set to steam for a timed period of up to 20 minutes.

At the end of the timed cycle the unit reverts back to the

original setting. Steam On Demand can be used at any

time during the cook cycle.

1. Press the STEAM ON DEMAND KEY (12).

2. Rotate the dial, or use the alpha/numeric keypad to

enter the desired steam on demand time. Press the

center of the dial to initiate Steam on Demand cycle.

NOTE: Steam on Demand time is set in one minute

increments using the dial. To set time in less

than one minute increments use the alpha/

numeric keypad.

Oven Shutdown

1. Press the COOL DOWN KEY (2). The display reads

AUTO COOL DOWN ACTUAL TEMP. To speed up

the cool down process, open the doors and press the

VENT KEY (16) to open the vent.

2. When the oven has cooled down, the display reads

OFF PRESS POWER KEY TO START.

NOTE: The lights shut off and the vent closes auto-

matically at the end of the cool down cycle.

23

Page 28

Operation

MenuSelect™ Control for Models BCX-14 and BX-14

PRODUCT PROGRAMMING

Entering the Program Mode

1. Press the PROGRAM KEY (17). If the control is password protected, the display reads ENTER CODE.

Use the alpha/numeric keypad to enter the manager

passcode 3124, then press the center of the dial to

enter the program mode.

Naming a Product Recipe

NOTE: Use the following procedure to name a new

product or edit the name of an existing product.

1. For a new recipe, turn the dial to the rst open product. Press the center of the dial to select.

To edit an existing name, rotate the dial to the name

to be changed. Press the center of the dial to select.

2. Use the dial to scroll down to Edit Name. Press the

center of the dial to enter the edit name menu.

3. Turn the dial or use the alpha/numeric keypad to se-

lect the rst character. Press the center of the dial to

advance to the next character. Repeat for all remaining characters.

NOTE: Product names may be up to 10 characters

long and can contain spaces. Use the #1

key to insert spaces in a recipe name.

NOTE: To select letters using the keypad, press the

appropriate key once if you need the rst

letter on the key, twice for the second and

three times for the third. For example to enter the letter L press the #5 key three times.

4. Press the PROG KEY (17). With SAVE highlighted,

press the dial to save the product name.

Programming a Product Recipe

NOTE: The control can hold 99 recipes. Each recipe

may have up to 6 cooking stages.

1. Turn the dial to highlight the name of the product to

be programmed. Press the center of the dial to select

the product.

2. The display reads PRODUCT NAME: STAGE 1.

Press the center of the dial to select the stage.

4. Rotate the dial to select the desired cooking mode.

Choose from combi, steam, hot air or retherm. Press

the center of the dial to set the cook mode.

If Combi or Retherm are selected, rotate the dial, or

use the alpha/numeric keypad to enter the desired

percentage of steam.

5. Rotate the dial, or use the alpha/numeric keypad to

enter the desired cook temperature. Press the center

of the dial to set the bake temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5

degree increments use the alpha/numeric

keypad.

NOTE: Retherm has a temperature limit of 250-

300ºF.

6. Rotate the dial to select the desired fan sprrd.

7. Rotate the dial to select the fan rotation cycle. Choose

between manual or auto.

NOTE: This is the length of time the fan will rotate

in one direction before reversing.

If manual is selected, rotate the dial or use the alpha/

numeric keypad to enter the desired fan cycle. Press

the dial to set the fan cycle.

If auto is selected, the program will use the default

fan cycle setting. The default is set through the Manager Programming.

8. Rotate the dial to set the vent position. Choose between OPEN or CLOSE. Press the center of the dial

to set the vent position.

9. Use the dial to scroll down to PRODUCT NAME:

STAGE 2. Press the center of the dial to select stage

2.

10. Repeat steps 2-9 for all remaining stages.

11. When all stages have been programmed, press the

PROGRAM KEY (17). To save the programming, use

the dial to scroll to YES. Press the center of the dial.

The control exits the program mode.

3. Rotate the dial, or use the alpha/numeric keypad to

enter the desired bake time. Press the center of the

dial to set the bake time.

NOTE: Time is set in one minute increments using

the dial. To set time in less than one minute

increments use the alpha/numeric keypad.

24

Page 29

Operation

MenuSelect™ Control for Models BCX-14 and BX-14

USING THE USB PORT

1. With the power on, remove the cover of the USB port

(23) and insert the USB drive.

2. Press the MAINTENANCE KEY (19).

3. Turn the dial to highlight MANAGER PROGRAM.

Press the center of the dial to select.

4. Turn the dial to highlight either COPY RECIPE FROM

USB or COPY RECIPE TO USB, then press the center of the dial to select.

5. When the transfer is complete, press any key to return to the menu.

6. Turn the dial to highlight EXIT. Press the center of

the dial to select. The display returns to the previous

menu.

7. Turn the dial to highlight EXIT. Press the center of the

dial to select.

MANAGER PROGRAMMING

Entering the Manager Program Mode

1. Press the MAINTENANCE KEY (19). If the control

is password protected, the display reads ENTER

CODE. Use the alpha/numeric keypad to enter the

manager passcode 3124, then press the center of the

dial to enter the program mode.

2. Turn the dial to highlight OVEN SETUP. Press the

center of the dial to select the product.

Programming Auto Start

NOTE: The Auto Start function enables the oven to turn

on at a programmed time of day and preheat to

a programmed temperature.

1. Turn the dial to highlight AUTO START. Press the

center of the dial to select.

2. Turn the dial to select either ON or OFF. Press the

center of the dial to select.

If ON is selected, the display reads AUTO START 24

HOUR TIME 00:00. Turn the dial to enter the time you

would like the oven to begin preheating. Press the

center of the dial to select.

The display reads AUTO START TEMP XXX. Turn

the dial to enter the desired preheat temperature.

Press the center of the dial to select.

PROGRAMMING OVEN SETUP

These menus allow the manager to set up basic oven

functions

1. Turn the dial to highlight OVEN SETUP. Press the

center of the dial to select.

2. Turn the dial to highlight MANAGER PROGRAM.

Press the center of the dial to select.

3. Turn the dial to highlight the oven function you with to

change. Press the center of the dial to select. Choose

from the following functions:

Recipe Password - Select YES or NO to enable

password protection on recipe programming. If YES

is selected the passcode 3124 must be entered to

change recipe programming.

Temp Unit - Select either degrees F or C.

Cool Down Temp - Select the set temperature for

the oven to achieve in Cool Down mode

Temp Disp Rate - Set the rate, in seconds, at which

the display switches between actual and setpoint

temperature

Input Rsp Time - Set the length of time allowed to input each variable when programming recipes before

control automatically exits out

Setback Time - When not used for a period of time,

the oven temperature will automatically reduce to

conserve energy. This variable sets the length of time

the oven remains at the idle temperature before being lowered.

Ready Beep - Select either ON or OFF. This is the audible alarm that sounds when the oven has reached

the set temperature.

Cook Done Beep - Select either ON or OFF. This is

the audible alarm that sounds when the product cook

time has expired.

Cook Cool Fan - Select either YES or NO. This function allows the control to display OPEN OVEN DOOR

when you are attempting to lower the set temperature

of the oven.

Restore Manual SE - Select either YES or NO. This

variable enables the oven to remember the last settings used for manual cooking.

NOTE: The following apply to BCX models only.

Boiler Set Temp Preheat - Select the temperature in

the boiler when it is in stand by

Boiler Set Temp Cook - Select the temperature in

the boiler when steam is being produced

25

Page 30

Operation

MenuSelect™ Control for Models BCX-14 and BX-14

Delime Fill Time - Set the length of time the boiler

continues to ll with deliming solution beyond the

standard water level in order to ensure all of the scale

present in the boiler is removed.

Delime Interval - Set the length of time between deliming intervals

Delime Time - Set the time during the day when the

display alerts the user to delime

Flush Interval - Set the length of time between boiler

ushes

Flush Time - Set the time during the day when the

display alerts the user to ush the boiler

4. After editing a function, press the center of the dial

to save.

5. When all desired functions have been edited, turn the

dial to highlight EXIT. Press the center of the dial to

exit the manager programming mode.

26

Page 31

Operation

Standard Controls for Models CNVX-14

CONTROLS IDENTIFICATION

1. MODE SELECTOR SWITCH - turns power to the

oven on or off. Allows selection of Hot or Cool Down

Modes.

2. TEMPERATURE DIAL - used to set desired cooking

temperature.

3. DISPLAY - displays time and temperature information.

4. HEAT LAMP - lights when the oven is calling for heat

5. PROBE ACTUAL LED - lights when the actual probe

temperature is displayed

6. PROBE SETPOINT LED - lights when the core setpoint temperature is displayed

7. TIMER/PROBE KNOB - use to select and set either

cook time or probe temperature

8. LIGHTS KEY - press to turn the oven lights on and off

9. FAN SPEED KEY - used to select fan speed.

10. CAVITY VENT KEY - used to open or close vent to

release steam from cavity.

11. PROBE CONNECTION - used to connect the core

temperature probe to the control.

Figure 14

27

Page 32

Operation

Standard Controls for Models CNVX-14

TIMER COOKING

1. Press the TIMER/PROBE KNOB (7) to select the timer mode. The TIMER LED lights.

2. Turn the MODE SELECTOR Switch (1) to the desired

function.

3. Set the TEMPERATURE DIAL (2) to the desired cook

temperature.

4. When the oven has reached the cook temperature,

load the product.

5. Rotate knob to enter the desired cook time in the

display. You can clear the display by rotating counter

clockwise. The timer begins on its own.

6. The temperature and time can be altered at any time

during the cooking process.

7. When the timer reaches 00:00, the buzzer sounds.

Press or rotate the TIMER/PROBE KNOB (2) counter

clockwise to silence the buzzer. Remove the product.

PROBE COOKING

1. Press the TIMER/PROBE knob (7) to select the

probe setpoint mode. The PROBE SETPOINT LED

(6) lights.

2. Rotate the knob to enter the desired nal cook temperature in the display.

3. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

4. Connect the core probe to the PROBE CONNECTION (11) at the bottom of the control.

5. The display gives the actual core probe temperature

by pressing the TIMER/PROBE knob (7) again.

6. When the product reaches the nal cook temperature

the buzzer sounds.

COOL DOWN

NOTE: The unit can be cooled down rapidly for clean-

ing, etc.

1. To cool down the oven cavity, open the door and select Cool Down on the MODE SELECTOR Switch (1).

28

Page 33

COOKIES

FRENCH FRY

ROAST CHIX

Operation

MenuSelect™ Control for Model CNVX-14

CONTROLS IDENTIFICATION

1. START/STOP KEY - press to start, cancel or pause

the bake

2. COOL DOWN KEY - initiates oven cool down cycle

3. BAKE MORE KEY - press at the end of a bake cycle

to add additional bake time in one minute increments.

4. DISPLAY - displays time or temperature and other

information related to oven function and/or programming.

5. DIAL - used to enter set points, time, and programmable settings. Also used to select the programmed

product.

6. TEMP KEY - used to set or change the bake temperature

7. TIME KEY - used to set or change the bake time.

8. FAN KEY - press to select fan speed.

9. LIGHT KEY - press to turn the oven interior lights on

or off

10. VENT KEY - press to manually open and close the

oven vent

11. PROGRAM KEY - press to enter product programming and save programmed settings

12. ESCAPE KEY - press to back up one step during programming

13. MAINTENANCE KEY - press to enter manager programming and save programmed settings

14. ALPHA/NUMERIC KEYPAD - used to program recipes.

15. POWER KEY - used to place control in and out of

standby mode.

16. PROBE KEY - press to use core probe cooking

17. PROBE CONNECTION - used to connect the core

temperature probe to the control.

18. USB Port and COVER - Use to transfer recipes and

data to/from the control

Figure 15

19. BUZZER - The buzzer is turned on/off through the

oven control.

29

Page 34

Operation

MenuSelect™ Control for Model CNVX-14

OPERATION

OVEN STARTUP

1. Be sure the gas shutoff switch and/or circuit breaker

switch below the control panel are in the on position.

The display ashes OFF PRESS POWER KEY TO

START.

NOTE: If the real time clock and auto wake up func-

tions are enabled the display reads PRESS

POWER KEY TO START AUTO START.

2. Press the POWER KEY (15). The display reads

PREHEAT and the oven heats to the last manual set

temperature in the hot air mode. The display ashes

READY / IDLE and the alarm beeps 5 times when the

oven is at temperature and ready to bake.

MANUAL COOKING

1. Turn the DIAL (5) until the display reads MANUAL.

2. Press the TIME KEY (7). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake time.

Press the center of the dial to set the bake time.

NOTE: Time is set in one minute increments using

the dial. To set time in less than one minute

increments use the alpha/numeric keypad.

3. Press the TEMP KEY (6). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake temperature. Press the center of the dial to set the bake

temperature. The oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5

degree increments use the alpha/numeric

keypad.

4. When the display ashes READY / IDLE, open the

doors. Load the product.

5. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROGRAMMED COOKING

1. Turn the DIAL (5) until the name of the product is

highlighted. Press the center of the dial to select. The

oven preheats to the programmed temperature in the

correct cooking mode. The display ashes READY /

IDLE and the alarm beeps 5 times when the oven is

at temperature and ready to bake.

2. Open the doors. Load the product.

3. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROBE COOKING

1. Press the PROBE key (16) to select the probe mode.

The display reads CORE PROBE COOK & HOLD.

Turn the dial to select either YES or NO. Press the

center of the dial to select.

If YES is selected, Cook & Hold has been enabled.

In the Cook & Hold mode, the oven cavity lowers to

the product pull temperature as the product cooks.

If NO is selected, Cook & Hold has not been enabled

the cavity maintains the cook temperature.

2. Turn the DIAL to enter the desired product pull temperature in the display. Press the center of the dial to

save the pull temperature.

3. Press the TEMP KEY (6). Rotate the dial, or use the

alpha/numeric keypad to enter the desired bake temperature. Press the center of the dial to set the bake

temperature. The oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5

degree increments use the alpha/numeric

keypad.

4. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

5. Connect the core probe to the PROBE CONNECTION (17) at the bottom of the control.

NOTE: Do not connected the probe before the cook

mode has been selected.

6. The display gives the actual core probe temperature

as well as the oven set temperature.

30

Page 35

Operation

MenuSelect™ Control for Model CNVX-14

7. When the product reaches the pull temperature the

buzzer sounds.

8. Press the START/STOP KEY (1) to silence the buzzer.

If using Cook & Hold - The cavity temperature continues to drop to the product pull temperature and the

display counts up, telling the operator long the product has been held. Disconnect the core probe and

remove the product when ready.

If not using Cook & Hold - The cavity remains at

the cook temperature. The display does not count up.

Disconnect the core probe and remove the product

when the buzzer sounds.

DURING ANY COOK CYCLE

Venting Moisture from the Oven Cavity

1. Press the VENT KEY (10). This manually opens the

vent until the key is pressed again to close it.

Pause a Bake Cycle

1. To pause a cook cycle, press the START/STOP KEY

(1). The LED on the start/stop key ashes. The bake

cycle will pause until the key is pressed again.

Cancel a Cook Cycle

1. To cancel the cook cycle, press and hold the START/

STOP KEY (1).

At the End of Any COOK Cycle

1. An alarm sounds, the display reads DONE.

2. If more bake time is desired, press the BAKE MORE

KEY (3). This will add an additional one minute of

time for each press of the key.

PRODUCT PROGRAMMING

Entering the Program Mode

1. Press the PROGRAM KEY (11). If the control is password protected, the display reads ENTER CODE.

Use the alpha/numeric keypad to enter the manager

passcode 3124, then press the center of the dial to

enter the program mode.

Naming a Product Recipe

NOTE: Use the following procedure to name a new

product or edit the name of an existing product.

1. For a new recipe, turn the dial to the rst open product. Press the center of the dial to select.

To edit an existing name, rotate the dial to the name

to be changed. Press the center of the dial to select.

2. Use the dial to scroll down to Edit Name. Press the

center of the dial to enter the edit name menu.

3. Turn the dial or use the alpha/numeric keypad to se-

lect the rst character. Press the center of the dial to

advance to the next character. Repeat for all remaining characters.

NOTE: Product names may be up to 10 characters

long and can contain spaces. Use the #1

key to insert spaces in a recipe name.

NOTE: To select letters using the keypad, press the

appropriate key once if you need the rst

letter on the key, twice for the second and

three times for the third. For example to enter the letter L press the #5 key three times.

4. Press the PROG KEY (11). With SAVE highlighted,

press the dial to save the product name.

3. When you are satised with the bake, press the

START/STOP KEY (1) to silence the alarm. Open the

door to remove the product.

OVEN SHUTDOWN

1. Press the COOL DOWN KEY (2). The display reads

AUTO COOL DOWN ACTUAL TEMP. To speed up

the cool down process, open the doors and press the

VENT KEY (10) to open the vent.

2. When the oven has cooled down, the display reads

OFF PRESS POWER KEY TO START.

NOTE: The lights shut off and the vent closes auto-

matically at the end of the cool down cycle.

31

Page 36

Operation

MenuSelect™ Control for Model CNVX-14

PROGRAMMING A PRODUCT RECIPE

NOTE: The control can hold 99 recipes. Each recipe

may have up to 6 cooking stages.

1. Turn the dial to highlight the name of the product to

be programmed. Press the center of the dial to select

the product.

2. The display reads PRODUCT NAME: STAGE 1.

Press the center of the dial to select the stage.

3. Rotate the dial, or use the alpha/numeric keypad to

enter the desired bake time. Press the center of the

dial to set the bake time.

NOTE: Time is set in one minute increments using

the dial. To set time in less than one minute

increments use the alpha/numeric keypad.

4. Rotate the dial, or use the alpha/numeric keypad to

enter the desired cook temperature. Press the center

of the dial to set the bake temperature.

NOTE: Temperature is set in 5 degree increments

using the dial. To set time in less than 5

degree increments use the alpha/numeric

keypad.

NOTE: Retherm has a temperature limit of 250-

300ºF.

5. Rotate the dial to select the desired fan speed.

Choose from gentle, low, high or turbo. Press the

center of the dial to set the fan speed.

6. Rotate the dial to select the fan rotation cycle. Choose

between manual or auto.

NOTE: This is the length of time the fan will rotate

in one direction before reversing.

If manual is selected, rotate the dial or use the alpha/

numeric keypad to enter the desired fan cycle. Press

the dial to set the fan cycle.

If auto is selected, the program will use the default

fan cycle setting. The default is set through the Manager Programming.

7. Rotate the dial to set the vent position. Choose between OPEN or CLOSE. Press the center of the dial

to set the vent position.

8. Use the dial to scroll down to PRODUCT NAME:

STAGE 2. Press the center of the dial to select stage

2.

9. Repeat steps 2-9 for all remaining stages.

10. When all stages have been programmed, press the

PROGRAM KEY (11). To save the programming, use

the dial to scroll to YES. Press the center of the dial.

The control exits the program mode.

USING THE USB PORT

1. With the power on, remove the cover of the USB port

(18) and insert the USB drive.

2. Press the MAINTENANCE KEY (13).

3. Turn the dial to highlight MANAGER PROGRAM.

Press the center of the dial to select.

4. Turn the dial to highlight either COPY RECIPE FROM

USB or COPY RECIPE TO USB, then press the center of the dial to select.

5. When the transfer is complete, press any key to return to the menu.

6. Turn the dial to highlight EXIT. Press the center of

the dial to select. The display returns to the previous

menu.

7. Turn the dial to highlight EXIT. Press the center of the

dial to select.