Page 1

Project

Item No.

Quantity

BLCT-62-62E

BLCT-62-62E

Full Size Double Electric

Boilerless Combination-Oven/Steamer

with Touchscreen Control

Shown on optional casters

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Side heat shield

Casters

Wire oven rack

Right hinge door

Backflow preventer

Extra year warranty

OPTIONS AND ACCESSORIES

(AT NO CHARGE)

Optional rack with 2.56” (65mm) spacing

Standard rack with 3.35” (85mm) spacing holds ten full size sheet pans

or twenty 12” x 20” x 2-1/2” deep North American hotel pans

Optional rack with 2.56” (65mm) spacing holds twelve full size sheet

pans or twenty-four 12” x 20” x 2” deep Gastronorm pans

Refer to operator manual specification chart for listed model names.

CONSTRUCTION

304 stainless steel exterior and interior

Dual pane tempered viewing window with hinged inner glass for easy cleaning

2” (50mm) fixed drain in the bottom center of cavity

Door mounted drip tray reduces the risk of wet, slippery floors

Automatic door stops in positions 110° and 180° for ease of loading and

unloading and improved safety.

Left hinge door is field convertible to the right side (with the purchase of con-

version kit)

Two step safety door latch. The first step stops the fan.

OPERATION

Injection steam system - water is injected onto the heating elements, the

resulting steam is distributed in the oven chamber by the fan wheel.

Easy to use touchscreen control

Multiple cooking modes include hot air, CombiSmart, CombiOptima, retherm,

steaming, low-temperature steaming, forced steaming, proofing, preheating

Stores up to 500 recipes with up to 15 steps each

Manual or automatic cooling

Automatic humidity pulsing

External core temperature probe

Rack timing allows for setting individual timers for each rack

Reversible 9 speed fan for optimum baking and roasting results

USB port for data and recipe transfer

HACCP recording and documentation

Automated CombiWash, closed circuit cleaning system features very low water

and detergent consumption and no contact with chemicals. No proprietary

chemicals required, see owner’s manual for detergent guidelines.

STANDARD FEATURES

External core temperature probe with multiple measuring points. User-friendly

location reduces strain on the probe

11-1/4” (285 mm) tall stand

Bright halogen lights for superior visibility

Built in hand shower

Removeable cleaning chemical bottle shelf

3 wire shelves per section

Start-up inspection service by factory authorized service agent

One year parts and labor oven warranty*

* For all international markets, contact your local distributor.

BLODGETT OVEN COMPANY

www.blodgett.com • 44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

Page 2

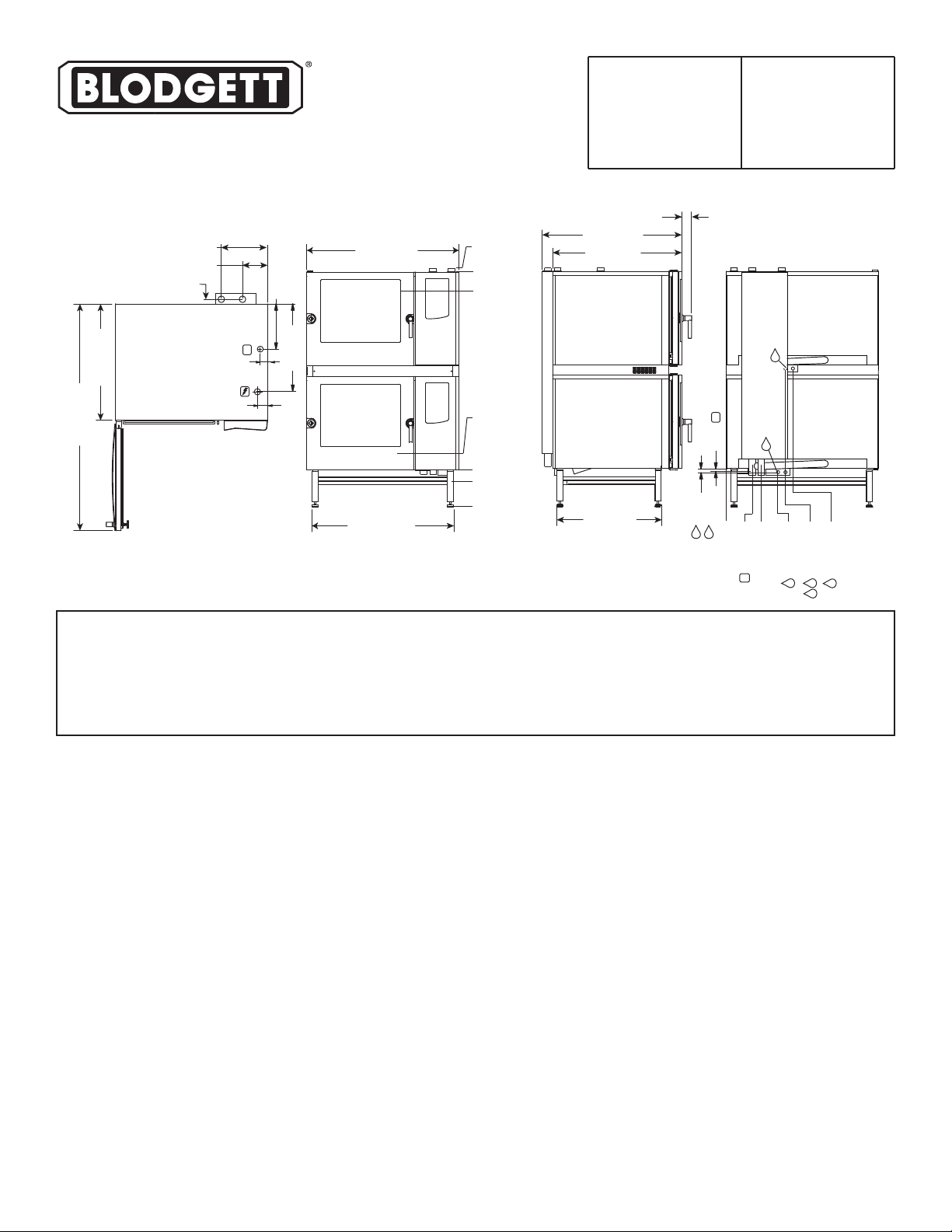

14.06 (357)

17.25 (438)

7.52 (191)

10.43 (265)

20.25 (514)

BLCT-62-62E

APPROVAL/STAMP

DIMENSIONS ARE IN INCHES (MM)

13.85 (352)

7.52 (192)

1.3 (33)

2.2 (57)

33.78 (858)

3.1 (78)

65.71 (1669)

Electrical connection

located on bottom of oven

TOP VIEW

SHORT FORM SPECIFICATIONS: Provide Blodgett Combi model BLCT-62-62E combination-oven/steamer. The BLCT-62-62E has a rack with 3.35” (85mm) spacing that holds ten full

size sheet pans or twenty 12” x 20” x 2-1/2” deep North American hotel pans. The optional rack with 2.5” (65mm) spacing holds twelve full size sheet pans or twenty-four 12” x 20” x 2”

deep Gastronorm pans. Unit shall have 304 stainless steel exterior and interior. Oven door shall have dual pane tempered viewing window with hinged inner glass for easy cleaning.

Unit shall have the ability to cook with pressureless steam, hot air, or combination of steam and hot air. Unit shall have steam injection system. Multiple modes include hot air, combi

with CombiOptima, retherming, steaming, low-temperature steaming, forced steaming, proofing, cooling, and preheating. Unit shall have bright halogen lights for superior visibility.

Touchscreen control stores 500 recipes with 15 stages each, in addition to pre-programmed recipes. External core temperature probe, rack timing allows for setting individual timers for

each rack, HACCP quality control, USB connectivity, automatic service diagnosis. The reversible 9 speed fan provides optimum baking and roasting results. Automated CombiWash,

closed circuit cleaning system features very low water and detergent consumption and no contact with chemicals. Semi automatic deliming system. One-year parts and labor warranty.

Provide start-up inspection service by a factory authorized service agent. Provide options and accessories as indicated.

13.9 (354)

V

26.9 (684)

44.17 (1122)

41.26 (1048)

FRONT VIEW

69.76 (1772)

68.78 (1747)

62.87 (1597)

Max pan

height

15.47 (393)

Min pan

height

11.22 (285)

7.87 (200)

0 (0)

2.83 (72)

40.51 (1029)

37.44 (951)

30.51 (775)

SIDE VIEW

1.50

(38)

U

1.30

(33)

F

BACK VIEW

U

D

F

0 (0)

D

F

F

U

U

DIMENSIONS:

Floor space: 44.17” x 37.44” (1122 x 951mm)

Unit height: 69.76” (1772mm)

OVEN CLEARANCES:

From combustible and non-combustible construction

Right 4” (102mm)

Left 0” (0mm)

Back 2” (50mm)

Blodgett recommends and 12” (305mm) be

maintained on the control side for servicing.

WATER SUPPLY & DRAIN:

Good quality water feed is the responsibility of the owner. Water quality must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm pH: 7.0 - 8.5

Silica: <13 ppm Chlorides: <25 ppm Chlorine: <0.2 ppm

Chloramine: <0.2 ppm

The best defense against poor water quality is a water treatment system designed to meet your

water quality conditions. Blodgett offers optional systems from Optipure.

Pressure: 40(min)-50(max) PSI

Connections: 2” drain connection - max. drain temperature 140°F (60°C)

3/4” garden hose cold water

MINIMUM ENTRY CLEARANCE:

Uncrated 33.78” (858mm)

Appliance is to be installed with backflow protection in accordance with federal, state or local

codes.

Crated 38” (965mm)

SHIPPING INFORMATION (per section):

POWER SUPPLY (per section):

Voltage KW Phase Amperage

208 VAC 21 3 59

240 VAC 21 3 51

480 VAC 21 3 26

Other voltages available, contact factory

www.blodgett.com • 44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

Approx. weight: 945 lbs. (429 kg)

NOTE: The company reserves the right to make substitutions of components without

prior notice

BLODGETT OVEN COMPANY

P/N 61245 Rev F (9/15)

Loading...

Loading...