Page 1

BLCT-6E-H, BLCT-10E-H,

BLCT-61E-H, BLCT-62E-H,

BLCT-101E-H & BLCT-102E-H

COMBI OVEN WITH HOODINI VENTLESS HOOD

INSTALLATION - OPERATION - MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802)864-0183

PN 61734 Rev K (11/17)

© 2017 - G.S. Blodgett Corporation

Page 2

Your Service Agency’s Address:

Model

Serial number

Oven installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alteration,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

WARNING: This unit is not for

use with the Blodgett Flavor

Smoke Smoker

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this oven. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

INSTALLATION

Utility Connections - Standards and Codes ................................. 2

The Blodgett Combi-Oven/Steamer ........................................ 3

Description of the Combi-Oven/Steamer ................................... 4

Oven Location and Leveling ............................................... 5

Oven Assembly to Stand for Floor Models .................................. 6

Plumbing Connections .................................................... 7

Electrical Connection ..................................................... 8

Final Check Lists ......................................................... 9

OPERATION

Safety Information ....................................................... 10

BCT Touchscreen Control Description ..................................... 11

Main Menu ............................................................. 12

Hot Air Mode ........................................................... 13

Steam Mode ............................................................ 15

Retherm Mode .......................................................... 16

CombiSmart Mode ...................................................... 17

Using the Core Probe ................................................... 18

SmartChef Automatic Cooking ........................................... 20

Using Rack Timing ...................................................... 22

Using Advanced Rack Timing ............................................ 23

PreHeat, Cool Down and Proong ........................................ 26

Cook to Perfection ...................................................... 28

Programmed Cooking ................................................... 29

Adding a New Recipe Program ........................................... 30

Favorites ............................................................... 31

USB ................................................................... 32

Timed Start ............................................................. 34

HACCP Library ......................................................... 35

MAINTENANCE

Cleaning & Preventative Maintenance..................................... 36

Page 4

Installation

Utility Connections - Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED

HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED

PERSONNEL MAY RESULT IN DAMAGE TO THE OVEN

AND/OR INJURY TO THE OPERATOR.

Qualied installation personnel are individuals, a rm,

a corporation, or a company which either in person or

through a representative are engaged in, and responsible

for:

• the installation of electrical wiring from the electric

meter, main control box or service outlet to the electric appliance.

Qualied installation personnel must be experienced in

such work, familiar with all precautions required, and have

complied with all requirements of state or local authorities

having jurisdiction.

EPA 202 Test Method

BLCT-6E-H - Using EPA test method 202, emissions of

grease laden vapors were measured at 1.12 mg/m³ for

bone-in, skin-on, quartered roasting chickens, and 0.16

mg/m³ for bacon. Both results being less than the established 5 mg/m³ standard.

BLCT-10E-H - Using EPA test method 202, emissions of

grease laden vapors were measured at 2.62 mg/m³ for

bone-in, skin-on, quartered roasting chickens, and 0.49

mg/m³ for bacon. Both results being less than the established 5 mg/m³ standard.

BLCT-61E-H, BLCT-62E-H, BLCT-101E-H & BLCT-102EH - Using EPA test method 202, emissions of grease

laden vapors were measured at 0.35 mg/m3 for raw,

bone-in, skin-on, halved roasting chickens, and 0.40 mg/

m3 for raw bacon on the BLCT62E-H model. Based on

these data, theoretical values were established by U.L.

for models: BLCT61E-H, BLCT101E-H, and BLCT102EH. All models’ results are less than the established 5 mg/

m3 standard.”

U.S. and Canadian installations

Installation must conform with local codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70-Latest Edition and/or Canadian National

Electric Code C22.1 as applicable.

Appliance is to be installed with backow prevention in

accordance with applicable federal, province and local

codes.

Australia and general export installations

Instllation must conform with Local and National instal-

lation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your Blodgett oven,

please contact your local distributor. If you do not have a

local distributor, please call the Blodgett Oven Company

at 0011-802-658-6600.

2

Page 5

Installation

The Blodgett Combi-Oven/Steamer

The Blodgett Combi-Oven/Steamer offers a completely

new method of cooking. With the Oven/Steamer you have

the choice of two cooking processes: Steam and Hot Air,

either...

• Separately

• Combined, or

• In Sequence

And for easy operation you can choose from three modes:

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanche preserve braise

poach

In the Hot Air mode you can:

roast bake grill

gratinate broil

In the Combination Steam and Hot Air mode you can:

defrost roast rethermalize

reheat bake forced steam

We suggest utilizing combi mode and switching to

hot air mode with the vent open for the nal 1-3 minutes depending on the product.

There are four additional specialized modes to help you:

Retherm - for perfect reheating

Proong - Proof and bake all in the same oven

Preheat - in this mode the oven will preheat to 575ºF

(300ºC) for 15 minutes. The oven will then automatically

lower to 480ºF (249ºC) to protect the advanced electronic components.

Cool Down - allows the oven cavity to cool down rapidly

with the door opened

You can also use two or three functions in se-

quence during one cooking process. We call this:

• combi-steaming

• combi-roasting

• combi-baking

The combination of circulating hot air and steam in the

space saving, high performance Combi-Oven/Steamer

leads to improvements in the following areas:

• increased productivity in the kitchen

• a reduction in capital expenditures for multiple equipment replacement

• a wider range of menu choices

• a simplied cleaning process

The work process is simplied since products are prepared on or in steam table pans and trays. Food can be

cooked, stored, and transported with the same pans.

Small amounts of product can be processed efciently;

pre-cooked and convenience foods can be reheated within minutes. Many frozen foods can be processed with-

out pre-thawing. This exibility in preparation reduces the

need for kettles and steam tables since there is no need

for large amounts of food to be kept warm for long periods

of time.

Today the improvement of food quality is more important

than ever. Vegetables are cooked in the Blodgett CombiOven/Steamer without water at the optimal temperature

of just under 212ºF (100ºC), maintaining valuable vitamins, minerals, nutrients and trace elements. Cooking

meat in the Combi results in less shrinkage and a rmer,

juicier product. The Blodgett Combi-Oven/Steamer is being used more and more for baking. Steam and Hot Air

modes make it a general purpose baking appliance.

3

Page 6

Installation

Description of the Combi-Oven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett Combi-Oven/Steamers are quality produced using high-grade stainless steel with rst class workman-

ship.

The multiple speed fan, which is guarded against acci-

dental nger contact, is driven by a quiet and powerful

motor. The condenser draws out excess steam from the

appliance. Condensation and waste water, which result

during steaming and cleaning, are continuously drained.

The use of high quality insulation impedes excessive heat

radiation and saves energy.

The BLCT-6E-H, BLCT-10E-H, BLCT-61E-H, BLCT-62EH and BLCT-101E-H make it possible to enjoy all of the

advantages of a high quality steamer at the ick of a

switch. Fresh steam enters the oven cavity without pressure and is circulated at high speed. This process en-

ables quick and gentle cooking and ensures high quality

food while providing convenient working methods.

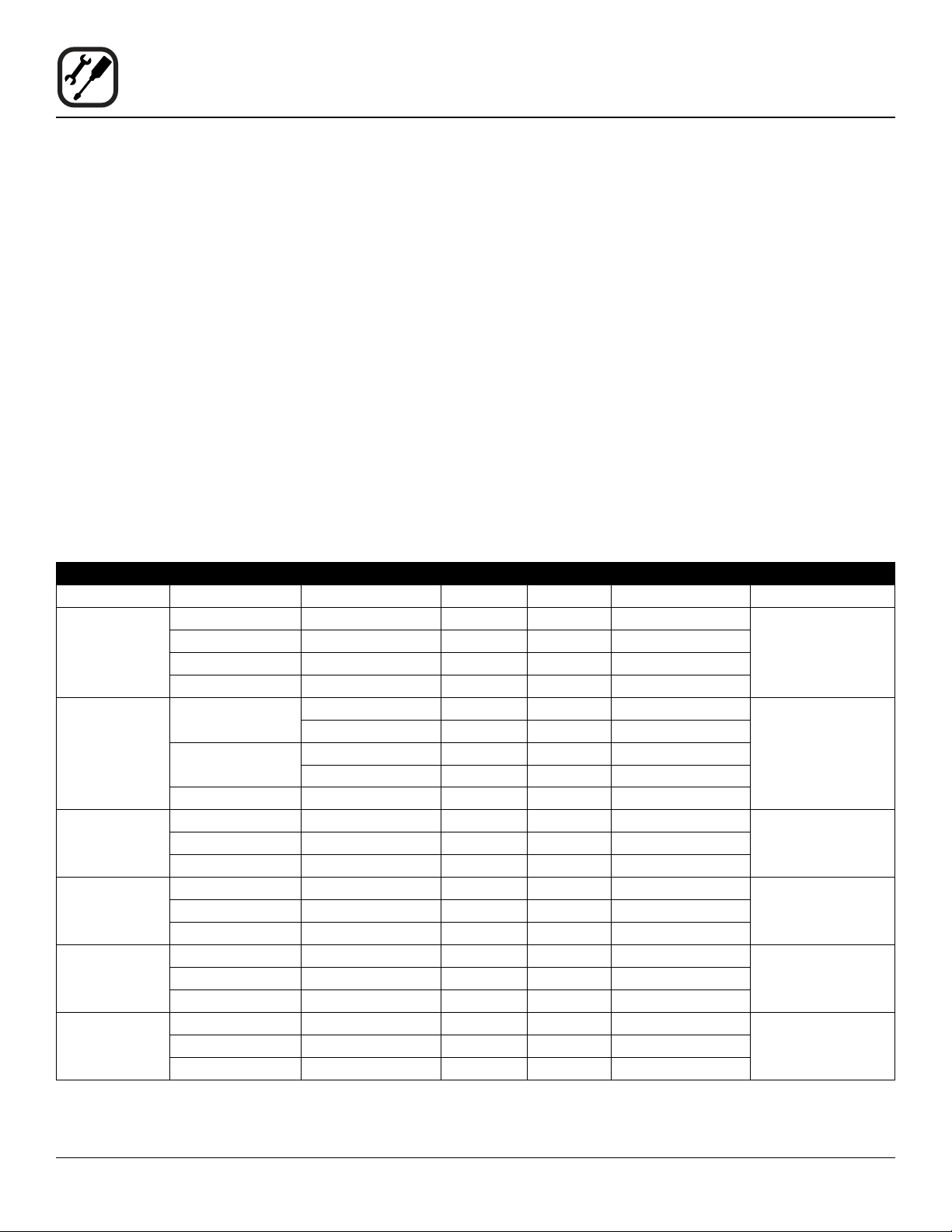

ELECTRICAL RATINGS

Model Voltage kW Hz Phase Max Load (amps) Hood

208 6.9 50/60 1 35

BLCT-6E-H

BLCT-10E-H

BLCT-61E-H

BLCT-62E-H

BLCT-101E-H

BLCT-102E-H

240 9.2 50/60 1 39

208 6.9 50/60 3 20

240 9.2 50/60 3 24

208/230/240

400/415

440/480 10.4/12.4 50/60 3AC 18

208 9 60 3 25

240 9 60 3 22

480 9 60 3 11

208 21 60 3 59

240 21 60 3 51

480 21 60 3 26

208 18 60 3 50

240 18 60 3 44

480 18 60 3 22

208 27 60 3 75

240 27 60 3 65

480 27 60 3 33

10.4/12.7/13.8 50/60 3AC 34

10.4/12.7/13.8 50/60 3NAC 34

12.7/13.8 50/60 3NAC 20

12.7/13.8 50/60 3AC 20

OVEN/STEAMER OPERATION

The practical oven door, with a viewing window, has a

wide swing radius and handle which can be operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simple to use

control. With graphical symbols and recipe storage the

ovens are easy for even inexperienced kitchen staff to

operate.

Cleaning is kept to a minimum thanks to the automatic

Combi Wash system.

115V, 50/60 Hz,

1 phase, 15 amp

115V, 50/60 Hz,

1 phase, 15 amp

115V, 50/60 Hz,

1 phase, 15 amp

115V, 50/60 Hz,

1 phase, 15 amp

115V, 50/60 Hz,

1 phase, 15 amp

115V, 50/60 Hz,

1 phase, 15 amp

4

Page 7

Installation

Oven Location and Leveling

The well planned and proper placement of your oven will

result in long term operator convenience and satisfactory

performance.

Certain minimum clearances must be maintained between the oven and any combustible or non-combustible

construction.

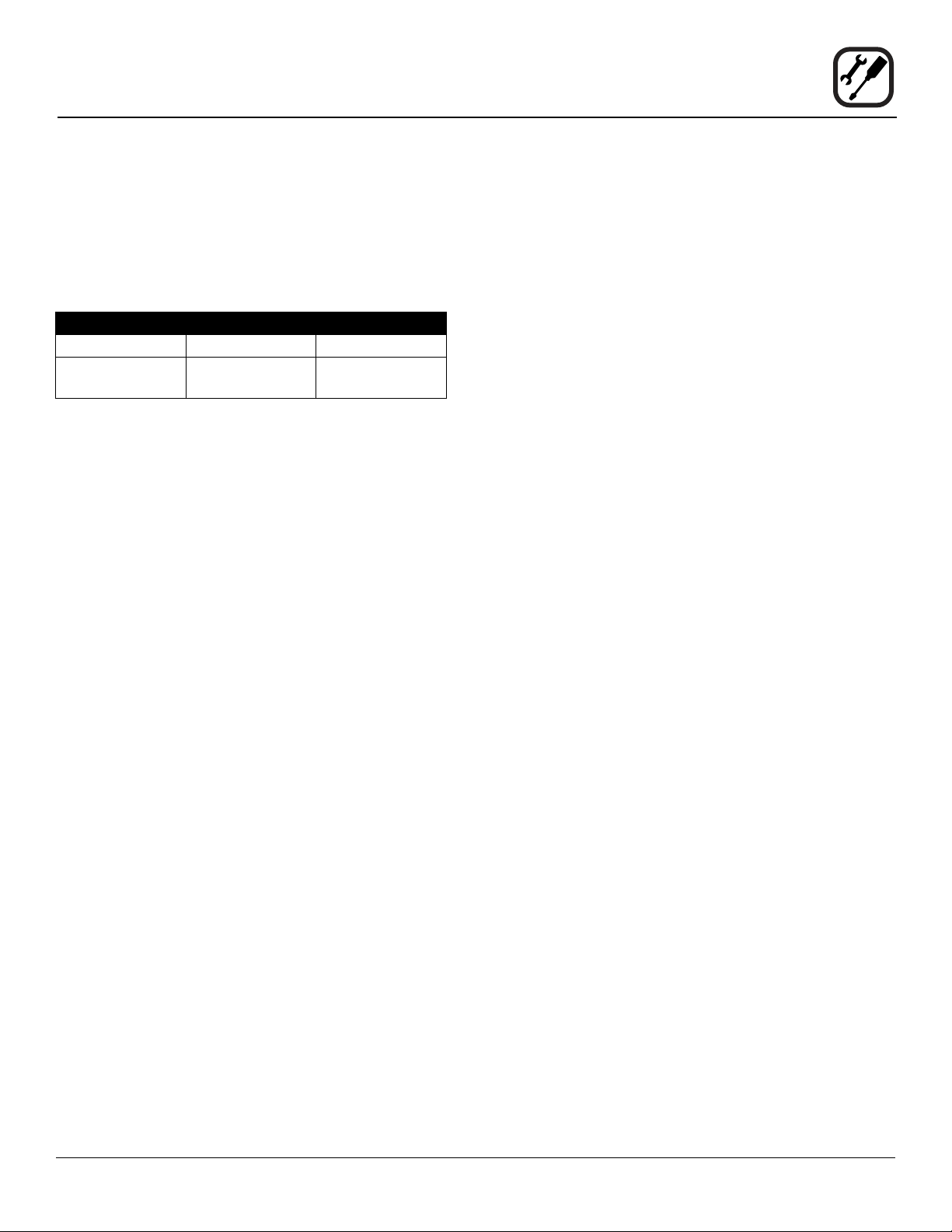

MINIMUM REQUIRED CLEARANCES

Sides Back Top

2.75”

(70mm)

In addition, the following clearances are recommended

for servicing.

• Oven body sides - 12” (30cm)

• Oven body back - 12” (30cm)

• Oven body top - 12” (30cm)

2.75”

(70mm)

0”

(0mm)

Strong sources of heat such as hotplates, tilting frying

pans, deep fat fryers, etc. should not be placed near the

oven, especially near its right side. An optional side heat

shield is available.

To ensure that the oven functions correctly when installed,

it should be placed upright and level (horizontally). This is

measured at the front and side edge of the roof. The oven

can be levelled using the adjusting screws on the stand or

on the legs of table models.

5

Page 8

Installation

Oven Assembly to Stand for Floor Models

BLCT-61E-H, BLCT-62E-H, BLCT-101E-H

& BLCT-102E-H

Your Blodgett COMBI oven has been shipped with black

plastic caps on the corners of its base. In order to mount

your oven to its stand, please do the following:

1. Remove the stand from the packaging. Install the

casters or feet into the base of the stand. If inserting

casters ensure that the locking casters are at the front

of the stand, see gure. Place the stand upright in an

area readily available.

2. Remove all packaging from the oven, so that the oven

can be picked up.

3. Remove the black plastic caps on each corner by

removing the two screws holding them on. Do NOT

discard these screws; they will be used to mount the

oven to the stand.

Note difference in rail

placement

4. Position the oven over the stand and align the corner

brackets on the stand with the holes on the oven.

5. Use the screws from the plastics caps to mount the

oven to the stand.

6. The oven has now been properly fastened to the

stand.

Front of stand

Figure 1

6

Page 9

Installation

Plumbing Connections

WATER CONNECTION

• Must meet the requirements applying to water supplied to household appliances.

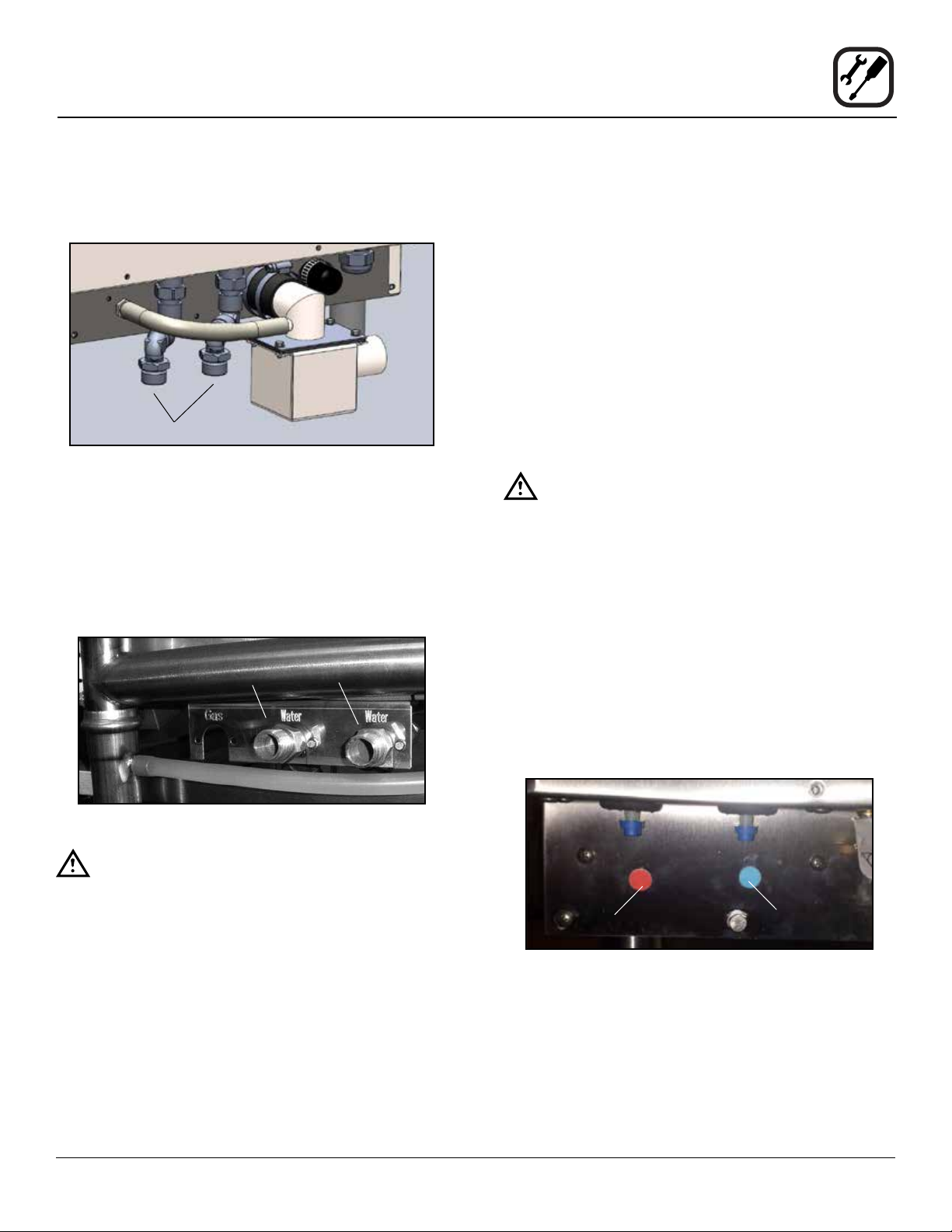

Water & drain connections for Mini Hoodini

Figure 2

BLCT-61, 62, 101 & 102 models

• 1 connection for raw water for the quench jet.

• 1 connection for steam generation and the Combi

Wash jet in the oven chamber. Must meet the re-

quirements applying to water supplied to household

appliances.

DRAIN CONNECTION

Blodgett ovens are equipped with a drain system that removes surplus water from the oven chamber. This may

be condensed water from the products, or it may occur

when the oven chamber is cooled down with cold water,

or when the oven chamber is cleaned.

NOTE: The drain piping must consist of temperature

resistant material, greater than 160°F, and be

of adequate diameter not to cause ow restriction. Improper materials may deform and cause

restrictions, thus affecting performance.

External Trap

The oven is provided with an external drain trap. It is

crucial that this part is installed on the oven. If not,

the oven will not function as intended.

WARNING!!

Connection must be carried out by an authorised plumber, to an open or closed drain.

The drain must never end directly beneath the

oven.

The drain must be of stainless steel or an equally temperature-resistant material, have a diameter of at least

1.5” (38 mm) and a fall of at least 3° or 5%.

Quench

Figure 3

WARNING!!

The water connections must be carried out

by an authorized plumber in accordance with

existing local codes.

Clogged up water lters and dirt in the solenoid valves are not covered by the warranty.

Cold water connection only.

To facilitate cleaning and servicing, the oven should be

connected with an approved exible 3/4” hose. Permanent installations should be tted with a stop-tap and a

non-return valve.

Before connecting the oven to water, ush the tubes

thoroughly. Connect the oven.

Steam

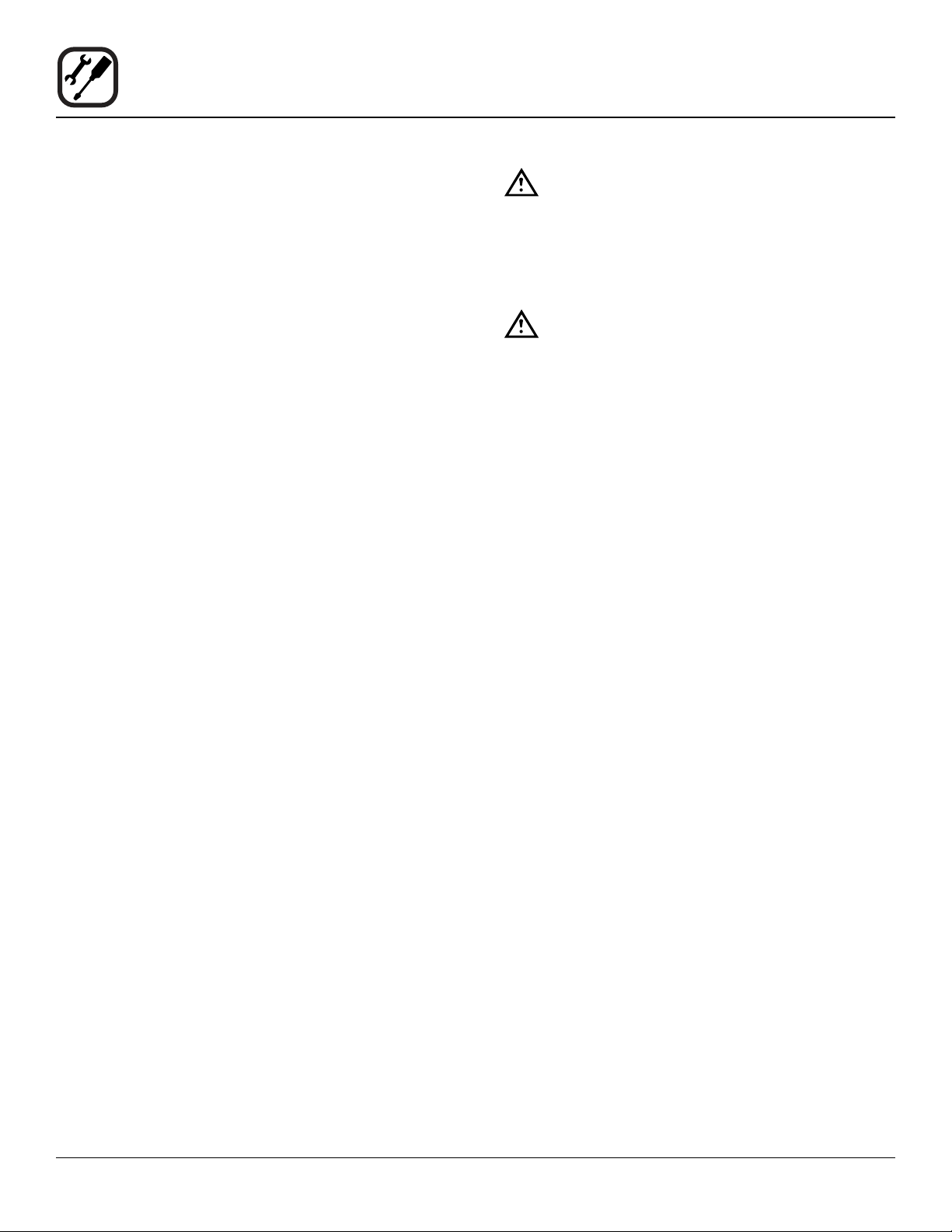

CLEANING CHEMICAL

7. Connect the supplied detergent tubes (red and blue)

to the underside of the oven near the rear. Connect

the blue hose to the tting with the blue sticker and

the red hose to the tting with the red sticker.

Red Tube

Connection

Red Sticker

Blue Tube

Connection

Blue Sticker

Figure 4

8. Insert the blue and red hoses into the proper bottles.

Red is for detergent, blue is for rinse aid.

NOTE: If the tube is cut to length, remove the stain-

less steel weight from the end of the tube

and reinsert.

7

Page 10

Installation

Electrical Connection

ELECTRICAL CONNECTION

NOTE: Electrical connections must be performed by a

qualied installer only.

Before making any electrical connections to these appli-

ances, check that the power supply is adequate for the

voltage, amperage, and phase requirements stated on

the rating name plate mounted on the appliance.

1. The rating plate is located on the right side of the

oven.

An approved plug outlet or a safety cutout must be located close to the oven so that the oven can be disconnected

during installation and repair. The safety cutout must be

able to cut off all poles with a total distance of break of at

least 3 mm.

All appliances must be installed in accordance with Local

or National Electrical codes.

The wiring diagram is located in the motor compartment.

NOTE: Disconnect the power supply to the appliance

before servicing.

WARNING!!

Improper installation may invalidate your warranty.

A strain relief for the power supply cord is provided. The

installer must supply a cord that meets all Local and National installation standards.

WARNING!!

If the supply cord is damaged, it must be replaced by a special cord or assembly available

from the manufacturer or its service agent.

8

Page 11

WARNING!!

Final check list must be performed by a quali-

ed installer only.

Installation

Final Check Lists

OVEN INTERIOR

1. Check interior light

2. Clean the oven

OVEN EXTERIOR

1. Check that the oven has not been damaged in transit

(dents, scratches, etc.)

2. Check/adjust the height and check that the oven is

placed level (horizontally)

3. Check/adjust oven door

CONNECTIONS

1. Check for correct water connection

2. Turn on water supply

3. Check for leaks

4. Turn off water supply

5. Check and clean dirt lter

6. Turn on water supply again

7. Check hand shower

8. Check for correct electrical connection

9. Check connection to drip tray

CONTROL

1. Check and adjust, if necessary, each of the preset

values

2. Heat up the oven at 480°F (249°C) for approximately

5 minutes.

10. Check for correct mounting of drip tray

11. Check for correct fall of hose from drip tray, and check

for leaks

12. Check for correct exhaust and drain connection

13. Clean the oven

14. Apply steel oil

9

Page 12

Operation

Safety Information

The information contained in this section is provided for

the use of qualied operating personnel. Qualied operating personnel are those who have carefully read the information contained in this manual, are familiar with the

functions of the oven and/or have had previous experience with the operation of the equipment described. Adherence to the procedures recommended herein will assure the achievement of optimum performance and long,

trouble-free service.

Please take the time to read the following safety and operating instructions. They are the key to the successful

operation of your Blodgett oven.

What to do in the event of a power failure:

• Turn all switches to off.

• DO NOT attempt to operate the oven until the power

is restored.

NOTE: In the event of a shut-down of any kind, allow a

ve (5) minute shut off period before attempting

to restart the oven.

General safety tips:

• DO NOT remove the control panel cover unless the

oven is unplugged.

OVERVIEW OF SAFETY FEATURES

This oven has a number of safety features which ensure

proper operation. The oven will automatically run the following process when the power button is activated.

1. Oven is turned on by pressing the Power Key.

2. The controller veries, via a pressure sensor, that the

water is connected and owing.

3. The blower in the hood section turns on.

4. The oven veries, via a pressure switch, that the

blower is running.

5. Once the pressure switch veries the blower is running, the heating element for the catalyst turns on.

6. The temperature probe veries the catalyst is hot.

7. Once all of the above steps have been completed by

the control, the oven is ready for cooking. This process takes approximately 5 minutes.

WARNING!!

This unit is not for use with the Blodgett Flavor Smoke Smoker or any smoker device.

It is possible to overwhelm the catalytic system with extremely greasy products. For instance, we do not recommend cooking a full load of raw hamburgers as it may be

excessive for the true intention of this product.

10

Page 13

Operation

BCT Touchscreen Control Description

The ovens include the versatile Blodgett Combi Touchscreen control. The control features:

• Multiple cooking modes include Hot Air, Com-

biSmart, Retherm, Steam, Proong, Cool Down, and

PreHeat.

• Easy to use touch panel display

• Stores up to 1000 recipe programs with multiple

cooking stages. Recipes can be grouped into

categories (beef, chicken, cookies, etc.) for easy retrieval. Includes a favorites category for the recipes

you use the most.

• Internal core temperature probe with 3 measuring

points.

• Low temperature roast & hold and Delta-T cooking

• Reversible 9 speed fan for optimum baking and

roasting results

• The Rack Timer function enables you to set timers

for each individual rack.

• Advanced Rack Timer allows you to create groups

of recipes with similar characteristics (cook temperature, humidity level, etc.) then manage multiple recipes of the same group simultaneously on separate

oven racks.

BASIC OPERATIONS

• To select an item, touch the button on the screen

• To scroll through a list, drag your nger up or down.

The item centered on the “wheel” will be selected.

• To return to the previous display, push the left arrow

key ◄ in the upper left corner of the screen.

• To change the cook function while the oven is oper-

ating, push the down arrow key ▼ in the upper right

corner of the screen.

• To save the current settings and move on to the next

step, push the right arrow key ► in the upper right

corner of the screen.

• USB port for data, software and recipe transfer

• HACCP quality control enables you to control and

document production. Includes production time,

production duration, preparation temperature, and

core temperature.

• Programmable time delay start

• Automatic service diagnosis

11

Page 14

Operation

Main Menu

MAIN MENU DESCRIPTION

1. KEY ICON - Press this key, then enter the code to

change type of user. Choices include user, super user

or technician. The super user code is 87 64 12.

2. GEAR ICON - Press to access the service and super

user menus.

3. RECIPES - Press to cook using programmed recipes

or to create a new recipe.

4. FAVORITES - Press to access the favorites category.

This category can be used to store the recipes you

use the most. The favorites category can store both

factory programmed and your own recipes.

5. MANUAL - Press to cook manually using Steam, Hot

Air, CombiSmart, CombiOptima, or Retherm modes.

Also press to access CombiWash.

6. ADVANCED - Press to access Preheat, Cool Down,

Advanced Rack Timer and Proong modes. Also provides access to USB, HAACP and timed cook start.

1

3

4

5

6

Figure 5

2

12

Page 15

Operation

Hot Air Mode

Entering the Hot Air Mode

1. From the MAIN MENU, press the MANUAL key.

2. Select the HOT AIR mode.

Setting the Cook Time and Temperature

1. In the TEMPERATURE list, drag your nger up or

down to select the desired cook temperature.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

NOTE: To return to the scroll wheel, swipe the up-

per portion of keypad icon box from left to

right. The control defaults to the last entry

method used.

2. In the HOUR & MINUTES lists, drag your nger up or

down to set the desired cook time.

To switch to keypad entry - Swipe you nger from

right to left across the upper portion of TIMER scroll

dial. Select the keypad icon from the center of the box

to bring up the keypad. Enter the desired cook time

in hours and minutes. Press OK at the bottom of the

screen to set the timer.

3. When the cook time expires, the oven automatically

shuts off. Press the CONT. key if you want the oven

to continue operating after the set time has elapsed.

For instant steam injection:

1. Press and hold the STEAM key to distribute humidity

throughout the oven cabinet. The steam stops when

the steam key is released.

Setting the Fan Speed

The BCT has 9 fan speeds to choose from. You can set

the fan speed before or during the cook cycle.

1. To set the fan speed, press the FAN SPEED key in

the lower right corner of the screen.

2. Drag your nger up or down to set the fan speed in

increments of 10% (From 20-100%).

3. Press OK to save the fan speed.

Vent Position

In manual hot air cook mode, the vent positon is automatically adjusted for optimal performance with the Hoodini

system. In recipe cook modes, the vent may be opened

or closed as dened by the recipe steps Press the VENT

key at the bottom of the screen to open or close the vent.

Blodgett recommends setting the vent to open for bread,

pastry, roasting meat or grilling.

At the End of the Cook Cycle

1. When the cook time expires, an alarm sounds and

the display reads “Recipe Done!.

Press EXIT to end the cook cycle.

Press RESTART to continue the cook cycle.

4. The oven starts automatically three seconds after the

cook time and temperature have been selected.

Steam Injection

The BCT control enables steam injection during hot air

cooking. Steam injection may be set either before or during the cook cycle.

For timed steam injection:

1. Touch the Steam button to set the steam timer.

2. Drag your nger up or down the steam timer dial to

set the steam time from 0 to 99 seconds.

3. Click OK to set the steam interval and return to the

main Hot Air display.

13

Page 16

Operation

Hot Air Mode

Keypad Entry

Fan Speed

Vent Position

Steam Injection Timer

Steam

Injection

Setting the Fan Speed

Figure 6

14

Page 17

Operation

Steam Mode

Steaming is the ideal cooking mode for foods that can be

cooked in water.

Tips for Using the Steam Mode

• Prior to steaming, cool the oven to 175°F (80°C). To

lower the temperature quickly, use the Cool Down

mode and open the door.

• We recommend that you start the steaming process

8 minutes before loading the oven.

Entering the Steam Mode

1. From the MAIN MENU, press the MANUAL key.

2. Select the STEAM mode.

Setting the Cook Time and Temperature

1. In the TEMPERATURE list, drag your nger up or

down to select the desired cook temperature. Refer

to table below for steaming temperature recommendations.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

NOTE: To return to the scroll wheel, swipe the up-

per portion of keypad icon box from left to

right. The control defaults to the last entry

method used.

2. In the HOUR & MINUTES lists, drag your nger up or

down to set the desired cook time.

shuts off. Press the CONT. key if you want the oven

to continue operating after the set time has elapsed.

4. The oven starts automatically three seconds after the

cook time and temperature have been selected.

Setting the Fan Speed

The BCT has 9 fan speeds to choose from. You can set

the fan before or during the cook cycle.

1. To set the fan speed, press the FAN SPEED key in

the lower right corner of the screen.

2. Drag your nger up or down to set the fan speed in

increments of 10% (From 20-100%).

3. Press OK to save the fan speed.

Vent Position

The vent position is set automatically in the steam mode.

At the End of the Cook Cycle

1. When the cook time expires, an alarm sounds and

the display reads Recipe Done!.

Press EXIT to end the cook cycle.

Press RESTART to continue the cook cycle.

To switch to keypad entry - Swipe you nger from

right to left across the upper portion of TIMER scroll

dial. Select the keypad icon from the center of the box

to bring up the keypad. Enter the desired cook time

in hours and minutes. Press OK at the bottom of the

screen to set the timer.

3. When the cook time expires, the oven automatically

FUNCTION STEAM TEMPERATURE PRODUCTS

Low Temperature

Steaming

Traditional Steaming 208-212°F (98-100°C) Meat, pasta, potatoes, rice and root vegetables.

Forced Steaming 248°F (120°C) Vegetables that require further processing and for faster pro-

149-194°F (65-90°C) Fish and small vegetables. Steam small vegetables at 80°C for

5-10 minutes to keep their color and crispness.

cessing of hard root and frozen vegetables, pasta and rice. Exercise caution when you use this function.

15

Figure 7

Page 18

Operation

Retherm Mode

Retherm allows you to gently reheat previously prepared

products. During operation a carefully calculated amount

of humidity is added. This process helps maintain the ap-

pearance and avor of the product.

Tips for Successful Retherming

• For faster retherming, leave the product uncovered

during the reheating process.

• To reach the perfect end temperature, use the core

temperature probe. Refer to page 18 for information on using the core probe.

• For retherm of sous-vide or similar products, follow

the supplier’s recommendations.

Entering the Retherm Mode

1. From the MAIN MENU, press the MANUAL key.

2. Select the RETHERM mode.

Setting the Retherm Time and Temperature

1. In the TEMPERATURE list, drag your nger up or

down to select the desired cook temperature.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

NOTE: To return to the scroll wheel, swipe the up-

per portion of keypad icon box from left to

right. The control defaults to the last entry

method used.

2. In the HOUR & MINUTES lists, drag your nger up or

down to set the desired cook time.

4. The oven starts automatically three seconds after the

cook time and temperature have been selected.

Setting the Fan Speed

The BCT has 9 fan speeds to choose from. You can set

the fan before or during the cook cycle.

1. To set the fan speed, press the FAN SPEED key in

the lower right corner of the screen.

2. Drag your nger up or down to set the fan speed in

increments of 10% (From 20-100%).

3. Press OK to save the fan speed.

Vent Position

The vent position is set automatically in the retherm mode.

At the End of the Cook Cycle

1. When the cook time expires, an alarm sounds and

the display reads “Recipe Done!.

Press EXIT to end the cook cycle.

Press RESTART to continue the cook cycle.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TIMER scroll

dial. Select the keypad icon from the center of the box

to bring up the keypad. Enter the desired cook time

in hours and minutes. Press OK at the bottom of the

screen to set the timer.

3. When the cook time expires, the oven automatically

shuts off. Press the CONT. key if you want the oven

to continue operating after the set time has elapsed.

PRODUCTS RETHERM TEMPERATURE TIME

Rice, meat, and vegetables on a plate 284°F (140°C) 8-12 minutes

Whole roasts, stews, and sauces 248-384°F (120-140°C) 40-60 minutes

Pasta, rice, and similar 248°F (120°C) 20-30 minutes

16

Figure 8

Page 19

Operation

CombiSmart Mode

The CombiSmart mode allows you to set an oven temperature and select a preset humidity level. The oven

produces a consistent level of humidity. There is no compensation for the moisture naturally found in the product.

Entering the CombiSmart Mode

1. From the MAIN MENU, press the MANUAL key.

2. Select the COMBI SMART mode.

Setting the Cook Time, Temperature and Humidity

NOTE: To ensure that the oven has reached the correct

humidity level, preheat the oven for 5 minutes at

the preferred humidity level.

1. In the TEMPERATURE list, drag your nger up or

down to select the desired cook temperature.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

NOTE: To return to the scroll wheel, swipe the up-

per portion of keypad icon box from left to

right. The control defaults to the last entry

method used.

2. In the STEAM list, drag your nger up or down to select the desired level of humidity. CombiSmart provides 10 different humidity levels. Refer to table below for humidity level recommendations.

in hours and minutes. Press OK at the bottom of the

screen to set the timer.

4. When the cook time expires, the oven automatically

shuts off. Press the CONT. key if you want the oven

to continue operating after the set time has elapsed.

5. The oven starts automatically three seconds after the

cook time, temperature and humidity have been selected.

Setting the Fan Speed

The BCT has 9 fan speeds to choose from. You can set

the fan before or during the cook cycle.

1. To set the fan speed, press the FAN SPEED key in

the lower right corner of the screen.

2. Drag your nger up or down to set the fan speed in

increments of 10% (From 20-100%).

3. Press OK to save the fan speed.

Vent Position

The vent position is set automatically in the CombiSmart

mode.

At the End of the Cook Cycle

1. When the cook time expires, an alarm sounds and

the display reads Recipe Done!.

Press EXIT to end the cook cycle.

Press RESTART to continue the cook cycle.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of STEAM scroll

dial. Select the keypad icon from the center of the box

to bring up the keypad. Enter the desired humitidy

level. Press OK at the bottom of the screen to set the

humidity.

NOTE: Humidity level must be entered in multiples

of 10 (10, 20, 30, etc).

3. In the HOUR & MINUTES lists, drag your nger up or

down to set the desired cook time.

To switch to keypad entry - Swipe you nger from

right to left across the upper portion of TIMER scroll

dial. Select the keypad icon from the center of the box

to bring up the keypad. Enter the desired cook time

PRODUCTS HUMIDITY LEVEL TEMPERATURE

Dry air grilling 0 392-482°F (200-250°C)

Gravy production during braising of meat 70-80 293-329°F (145-165°C)

Poaching sh, poultry, and crispy vegetables 90-100 158-248°F (70-120°C)

Steaming potatoes, rice, pasta, meat, and more. 100 212°F (100°C) or steaming mode

17

Figure 9

Page 20

Operation

Using the Core Probe

All Blodgett BLCT-6E-H ovens come standard with one

core temperature probe.

The core temperature sensor offers three cooking

modes.

• Normal

• Delta-T

• Cook & Hold

CORE PROBE MODES

Follow this procedure for all three core probe cooking modes.

NOTE: The core probe must be set up prior to activating

a cook cycle.

1. Select the desired cooking mode. Refer to instructions on setting the cooking mode.

2. Set the desired fan speed if applicable. Refer to instructions on setting the fan speed.

3. Set the vent position if applicable. Refer to instructions on setting the vent position.

4. Insert the core probe into the center of the product.

Then plug the probe into the oven at the connector

located in the upper corner of the right side panel.

NOTE: Meat probes on mini combi models are

internal and do not need to be plugged into

the oven.

5. Press the ▼ key at the top of the timer list to display

the probe selection list.

6. Drag your nger up or down the Temp list to select the

desired core probe temperature.

7. Drag your nger up or down the Status list to select

the desired mode.

8. The oven starts automatically three seconds after the

core probe temperature and mode have been selected.

Press to toggle between

timer and core probe

selection list

Retherm screens shown

Figure 10

18

Page 21

Operation

Using the Core Probe

NORMAL CORE PROBE COOKING

In the normal mode, the core probe will notify you when

the product has reached the desired pull temperature.

The cook temperature is constant in the normal mode.

1. Follow steps 1-8 on page 18 to start a normal core

probe cook cycle.

2. The oven sounds an alarm, and turns off when the

specied core temperature has been reached.

Unplug the core probe and remove the product.

DELTA T

When you use Delta-T, the oven maintains a constant

difference in temperature between the core temperature

and the oven temperature. The temperature of the oven

rises slowly as the core temperature rises. Delta-T provides gentle cooking resulting in a tender, juicy product.

Cooking with Delta-T reduces shrinkage by up to 20%

compared to traditional modes of cooking.

1. Follow steps 1-8 on page 18 to start a Delta T cook

cycle.

2. The oven sounds an alarm, and turns off when the

specied core temperature has been reached.

3. Remove the core probe and the product.

COOK & HOLD

Cook & Hold is an extension of Delta-T cooking. The oven

temperature adjusts relative to the actual core temperature of the product. When the desired core temperature is

reached, the oven adjusts the cavity to maintain the core

temperature, acting as a warming mode. Cook & hold is

suitable for roasting over night when the staff is off duty.

1. Follow steps 1-8 on page 18 to start a Cook & Hold

cycle.

2. When the product has reached the desired core temperature the display will read HOLD??? and the oven

will adjust the cavity temperature to maintain the core

probe temperature.

3. Remove the core probe and the product when ready

to serve.

Tips for Using Cook & Hold

• Recommended holding temperature is 140-150°F

(60-65°C). At higher temperatures a gradual dehydration of proteins takes place, the weight of the

meat is reduced and the meat becomes less juicy.

• With a hold temperature of 140-150°F (60-65°C), the

meat can be taken out immediately before carving.

• After being held for 5-6 hours shrinkage increases.

Tips for Delta-T Cooking

• For best results start with an oven temperature of

85-100°F (30-40°C).

• HOT AIR mode is recommended for very fatty and

small roasts. STEAM mode is recommended for

large hams with bones. RETHERM mode is recommended for poultry and other lean pieces of meat.

Recommended Core Temperatures

• Rare 125-135°F (52-57°C)

• Medium 140-145°F (59-62°C)

• Well Done 160-185°F (72-85°C)

19

Page 22

Operation

SmartChef Automatic Cooking

The SmartChef function provides a number of preset

cooking functions for a variety of products.

Entering the SmartChef Mode

1. From the MAIN MENU, press the MANUAL key.

2. Select the SMART CHEF mode.

Using the SmartChef Mode

1. Press the name of the type of product you are going

to cook.

3. The control displays COOKING ADJUSTMENT SLIDERS. Make any adjustments you wish to achieve the

desired results.

a. Grilling - Slide the button to the left for rare meat

and to the right for well-done meat.

Slide the button to the left for a lighter result and

to the right for a darker result.

b. Steaming - Slide the button to the left for rare

meat and to the right for well-done meat.

Slide the button to the left for steaming at low

temperature

Slide the button to the right for forced steaming.

c. Braising - Slide the button to the left for rare

meat and to the right for well-done meat.

Slide the button to the left for a slow result and to

the right for a fast result.

Touch the Tender box if you want the oven to

keep the core temperature for 2 hours.

d. Browning - Slide the button to the left for shorter

cooking time and to the right for longer cooking

time.

Figure 11

2. The control displays the cooking modes programmed

for your product. Press the mode you want to use.

See table for list of available cooking modes.

Figure 12

Slide the button to the left for a lighter result and

to the right for a darker result.

e. Breaded - Slide the button to the left for rare

meat and to the right for well-done meat.

Slide the button to the left for thick breaded products and to the right for thin breaded products.

4. Press the START key when you have adjusted the

results. The oven begins the preheating process and

sounds an alarm, when the oven is ready.

20

Page 23

Figure 13

Operation

SmartChef Automatic Cooking

BEEF PORK POULTRY LAMB VENISON FISH BREAD

Grilling

Roasting

Steaming

Breaded

Browning

AVAILABLE

Braising

ADJUSTMENTS

Grilling

Roasting

Steaming

Breaded

Browning

Braising

Crispy Skin

Grilling

Roasting

Steaming

Breaded

Browning -

Small Pieces

Braising

Dark Poultry

Grilling

Roasting

Steaming

Breaded

Browning

Braising

Grilling

Roasting

Steaming

Breaded

Browning

Braising

Grilling

Roasting

Steaming

Breaded

Baking

Baking Small

Size

Baking with

Steam

Puff Pastry

21

Page 24

Operation

Using Rack Timing

The rack timing function enables you to set one or more

timers for each individual rack. This way you can cook

different products on the same rack or on different racks

as long as they can use the same cooking mode. The

rack timer can be used in Hot Air, Combi, CombiOptima,

Retherm and Steam modes.

TO COOK USING RACK TIMING

1. From the MAIN MENU, press the MANUAL key.

2. Select the desired cooking mode. Set the cook temperature and humidity level if applicable.

3. Press the RACK TIMER key.

4. In the RACK SETUP list, drag your nger up or down

to select the number of racks you want to associate

with the timer. You can choose between 1-10 racks.

5. In the TIMERS PER RACK list, drag your nger up or

down to select the number of timers you want to associate with the rack(s).

6. Push the arrow button in the upper right corner to

continue.

Figure 14

7. Push the ACTIVATE TIMER key for the rack timer you

wish to start.

8. In the HOUR & MINUTES lists, drag your nger up or

down to set the desired cook time.

9. Push the RIGHT ARROW key ► in the upper right

corner to start the timer.

Blue buttons display the active timer settings and the

remaining time. The timer counts down to zero.

Yellow buttons display the active timer settings of

the timers that have reached the nal minute of the

countdown.

Green buttons and an alarm indicate that a rack timer

has nished its countdown. The display counts up the

time that has elapsed since the timer timed out.

10. Push the GREEN KEY to silence the alarm.

11. Push FINISH to end the timer.

Figure 15

22

Page 25

The Advanced Rack Timer allows you to create groups

of recipes with similar characteristics (cook temperature,

humidity level, etc.). The advance rack timer cook screen

lets you manage multiple recipes of the same group simultaneously on separate racks of the oven.

Entering rack timer menus

1. From the MAIN MENU, press ADVANCED.

2. Select RACK TIMER.

SETTING UP GROUPS & RECIPES

Creating a Recipe Group

NOTE: Up to 18 recipes can be assigned to a single

group. In order for recipes to be grouped to-

gether they must have the same cook mode, and

similar temperature settings.

1. To create a recipe group select the + key at the bottom of the screen. This will bring you to the SETUP

GROUP screen.

2. Select NAME BAR to edit the group name. Use the

keypad to enter a group name. Press the right arrow

► key in the upper right hand corner of the screen to

save and return to the SETUP GROUP screen.

3. Select the camera icon in the IMAGE BAR to associate a picture with the group. Press OK to save the

selection and return to the SETUP GROUP screen.

Operation

Using Advanced Rack Timing

Name Bar

Image Bar

Create Recipe

Figure 16

Editing a Group

1. In RACK TIMER MENU screen, press and hold the

group’s icon. A box will appear allowing you to edit or

delete the group.

4. Under RECIPES you can select existing recipes to

add to the group. Once a recipe has been selected a

green check mark will appear to the right indicating it

is part of the group. To remove a recipe, select it again

and the check mark will be removed. To add a new

recipe, see Creating a Recipe.

NOTE: The rst selected recipe will dene the set-

tings for the group. Recipes that have set-

tings incompatible with the group’s settings

will be grayed out.

5. When all desired recipes have been selected, press

the right arrow ► key in the top right corner to save

the group and return to the RACK TIMER MENU.

23

Page 26

Operation

Using Advanced Rack Timing

Creating a Recipe

1. Select the + key from the bottom of the SETUP

GROUP screen.

2. Select the NAME BAR to edit the group name. Use

the keypad to enter a recipe name. Press the right

arrow ► key in the upper right hand corner of the

screen to save and return to the SETUP RECIPE

screen.

3. Select the COLOR BAR to associate a color with the

recipe. Press OK to save the selection and return to

the SETUP RECIPE screen.

4. Select the camera icon in the IMAGE BAR to associate a picture with the recip. Press OK to save the

selection and return to the SETUP RECIPE screen.

Select the SETTINGS BAR below the image bar to edit

the temperature, cook mode, fan speed, vent state, and

cook time of the recipe. Press the right arrow ► key in the

upper right hand corner of the screen to save the recipe

settings and return to the SETUP RECIPE screen.

Editing a Recipe

In SETUP GROUP screen, press and hold the recipes’

icon. A box will appear allowing you to edit or delete the

recipe.

Selecting a Group

1. From the RACK TIMER MENU screen, select the

number of racks you’d like to use and the group with

recipes you wish to use. Then select the right arrow

► key in the upper right hand corner to enter the

RACK TIMER COOK screen.

2. To select a new group, return to the RACK TIMER

MENU screen from the RACK TIMER COOK screen

by selecting the left arrow◄ key in the top left of the

screen.

Name

Bar

Color

Bar

Image

Bar

Settings

Bar

Figure 17

24

Page 27

Operation

Using Advanced Rack Timing

COOKING WITH RACK TIMER

NOTE: The top portion of the RACK TIMER COOK

screen contains the recipes in your group. If

there are more than 6 recipes in your group

you can browse the other recipes by swiping

the screen from right to left in this portion of the

screen. To return to the previous 6 recipes sim-

ply swipe in the reverse direction. The highlighted circle below the recipes indicates what page

(of up to 3) you are currently on.

Assigning a Recipe – Click

1. Select the blue timer box associated with the rack

number you’d like to place a recipe on, it will become

highlighted.

2. Select the recipe icon from the top of the screen associated with the recipe you’d like to place on the selected rack, it will become highlighted.

3. Reselect the highlighted timer box to assign the recipe to the rack.

Assigning a Recipe – Drag and Drop

1. Press and hold the desired recipes’ icon for approximately 2 seconds.

Remove Recipes – Drag and drop

1. Press and hold the recipe bar on a rack until a trash

can appears to the right.

2. Drag the recipe to the trash can.

Figure 18

2. Drag recipe to desired rack location.

Starting a recipe

1. Once a recipe has been added to a rack the unit will

begin preheating to the required temperature. Preheating is indicated by a red thermometer icon to the

right side of the screen. Once preheated the icon will

change to an orange “load” icon.

2. The recipe timer will automatically start when the

oven has preheated and the product has been loaded

into the oven (door opened/closed).

25

Page 28

Operation

PreHeat, Cool Down and Proong

The Advanced Menu gives you access to the PreHeat,

CoolDown and Proong functions.

PREHEAT

Use PreHeat to preheat the oven prior to cooking.

1. From the MAIN MENU, press the ADVANCED key.

2. Select the PREHEAT mode.

3. The PreHeat temperature list is displayed. Drag your

nger up or down to set the desired temperature.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

NOTE: To return to the scroll wheel, swipe the up-

per portion of keypad icon box from left to

right. The control defaults to the last entry

method used.

4. The oven begins preheating automatically three seconds after the temperature has been selected.

COOL DOWN

Use this function to quickly cool the oven cavity. For the

best results, set the cool down temperature 68°F (20°C)

lower than the desired cooking temperature.

1. From the MAIN MENU, press the ADVANCED key.

2. Select the COOL DOWN mode.

3. The Cool Down temperature list is displayed. Drag

your nger up or down to set the desired cool down

temperature.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

4. The oven begins cooling down automatically three

seconds after the temperature has been selected.

26

Figure 19

Page 29

PROOFING

NOTE: Prebaked products do not need proong.

1. From the MAIN MENU, press the Advanced key.

2. Select the PROOFING mode.

3. The PROOFING TEMPERATURE list and timer are

displayed. Drag your nger up or down to set the desired proong temperature.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TEMPERATURE scroll dial. Select the keypad icon from the

center of the box to bring up the keypad. Enter the

desired temperature. Press OK at the bottom of the

screen to set the temperature.

4. In the HOUR & MINUTES lists, drag your nger up or

down to set the proong time.

To switch to keypad entry - Swipe your nger from

right to left across the upper portion of TIMER scroll

dial. Select the keypad icon from the center of the box

to bring up the keypad. Enter the desired cook time

in hours and minutes. Press OK at the bottom of the

screen to set the timer.

5. When the cook time expires, the oven automatically

shuts off. Press the CONT. key if you want the oven

to continue operating after the set time has elapsed.

6. The oven starts automatically three seconds after the

cook time, temperature and humidity have been selected.

Operation

PreHeat, Cool Down and Proong

Figure 20

Setting the Fan Speed

The BCT has 9 fan speeds to choose from. You can set

the fan before or during the cook cycle.

1. To set the fan speed, press the FAN SPEED key in

the lower right corner of the screen.

2. Drag your nger up or down to set the fan speed in

increments of 10% (From 20-100%).

3. Press OK to save the fan speed.

At the End of the Proof Cycle

1. When the proof time expires, an alarm sounds and

the display reads “Recipe Done!.

Press EXIT to end the proof cycle.

Press RESTART to continue the proof cycle.

27

Page 30

Operation

Cook to Perfection

The cook to perfection function helps recipes compen-

sate for temperature uctuations. These can occur when

transitioning between recipes with different temperatures,

opening the door, or adding frozen products. The system

makes real time adjustments to cook time ensuring quality cooking.

CTP threshold (%)

CTP threshold accounts for when the cavity temperature

is below the recipe set temperature. Time will be added

to the recipe as long as the cavity temperature remains

below the CTP threshold percent of temperature.

EXAMPLE: The oven preheats to a recipe’s set temperature of 350°F and a frozen product is loaded. The temperature of the frozen product and opening the door causes

the cavity temperature to drop to 230°F. The CTP will begin extending the total recipe time as long as the cavity

temperature remains below the programmed threshold

value, at 80% this equates to 285°F. This compensates

for the time it takes the oven to recover to the 350°F

called for in the recipe.

CTP tolerance (°)

The CTP tolerance value is a temperature range. If the

oven’s measured temperature is outside the range of desire temperature, the unit will adjust cook times. Unlike

the threshold value, the tolerance compensates when the

oven is too high above set point as well as below set point

by adding or subtracting time as needed.

EXAMPLE: Using the same example of 350°F, a 15° tolerance means that time will be added to the recipe as

long as the cavity is lower than 335°F and subtract if cavity achieves temperatures above 365°F. This may be the

case if you go from a recipe with a higher set temperature

to a lower temperature without allowing the oven to cool.

To set up Cook To Perfection (CTP)

1. From the MAIN MENU select the GEAR ICON.

2. Select SUPER USER from the SETTINGS MENU.

3. Select SETTINGS from the SUPER USER MENU.

4. Select COOK TO PERFECTION and set to YES to

enable.

5. Select CTP THRESHOLD. Enter the percentage of

set temperature you would like CTP to use for a temperature threshold.

6. Select CTP TOLERANCE. Enter the temperature you

would like CTP to use for a temperature tolerance.

Figure 21

28

Page 31

Operation

Programmed Cooking

Programmed cooking is simple in the Blodgett BCT Combi. Choose from one of a wide variety of pre-programmed

recipes or create your own.

Use an Existing Program Recipe

1. From the MAIN MENU, press the RECIPES key. The

CATEGORIES menu is displayed.

2. Press the desired product category.

3. Press the desired product. The programming details

for the selected product are listed. If you want to adjust the recipe, press the gear wheel icon in the top

right corner of the screen. Follow the steps described

in Adding New Recipe Program (page 30).

4. Press START to initiate the cook cycle.

At the End of the Cook Cycle

1. When the cook time expires, an alarm sounds and

the display reads “Recipe Done!.

Press EXIT to end the cook cycle.

Press RESTART to continue the cook cycle.

Category Screen Product Screen

Figure 22

29

Page 32

Operation

Adding a New Recipe Program

1. From the MAIN MENU, press the RECIPES key. The

CATEGORIES menu is displayed.

2. To add a new recipe, press the + in the upper right

corner of the screen.

3. The CHOOSE CATEGORY screen is displayed. Drag

your nger up or down to select the desired product

category. Press the right arrow key ► to save and

advance to the next screen.

4. To name the new recipe, press right arrow key ► in

the TITLE/DESCRIPTION BOX. Use the keyboard to

enter a name and a description of the new recipe.

Press the right arrow key ► to save and advance to

the next screen.

5. Touch the FAVORITE key if you want to add the recipe to your list of favorites.

6. Press the ADD STEP key to add the rst step of the

cooking process.

7. In the SELECT STEP TYPE list drag your nger up or

down to select the desired cooking mode. Press the

right arrow key ► to save and advance to the next

screen.

8. Choose the desired cook settings for the step. Press

the right arrow key ► to save your settings.

9. Add as many steps as needed.

More Functions

• If you want to change the recipe category, press the

MORE FUNCTION key at the bottom of the screen.

Then press CHANGE CATEGORY. You can then

choose a different category.

• To make a copy of the recipe, press the MORE

FUNCTION key at the bottom of the screen. Then

press DUPLICATE RECIPE. The Copying Recipe

message appears. You can then edit the copy.

• To delete the recipe, , press the MORE FUNCTION

key at the bottom of the screen. Then press DELETE RECIPE. Press Yes to delete the recipe.

Choose Category Name Recipe

Figure 23

30

Select Cooking Mode

Page 33

Using Favorites

1. From the MAIN MENU, press the FAVORITES key.

2. Press the desired recipe. The recipes are listed in alphabetical order. All the steps of the recipe, and the

total cooking time are displayed.

3. Touch the START key, to start the oven. The oven

starts the preheating process, and displays “load the

oven”, when the oven is ready.

Adding a Recipe to Favorites

1. From the MAIN MENU, press the RECIPES key.

2. Select the category for the recipe you wish to add to

the favorites list.

3. Press the name of the recipe you wish to add to the

favorites list.

4. Press the gear wheel icon in the upper right corner of

the screen.

Operation

Favorites

5. Press the FAVORITE key so that it changes to YES.

6. Press the right arrow ► key in the upper right corner

to save your recipe to the favorites list.

Figure 24

31

Page 34

USB

Operation

The Blodgett BLCT-6E-H and BLCT-10E-H come standard with a USB port located on the control compartment.

The USB will enable upload and download of product

recipes as well as HACCP data.

TO ACCESS USB MENU

1. Insert the USB card into the slot on the control compartment.

2. From the MAIN MENU, press the ADVANCED key.

3. Press the USB key. The control displays the following

options:

• Import Recipes - from USB to Oven

• Export Recipes - from Oven to USB

RECIPES

To Import Recipes from the USB to the Oven

1. Press Import Recipes.

2. All recipe les currently on the USB drive will be dis-

played. Select the desired recipe le.

3. Select either All Recipes or the appropriate product

category. Select the recipes you wish to upload to the

oven.

To Export Recipes from the Oven to the USB

1. Press Export Recipes.

2. Select either All Recipes or the appropriate product

category. Select the recipes you wish to upload to the

oven.

If All Recipes is selected, you may choose any or all

of the recipes on the USB drive.

If a category is selected, you may choose any or all of

the recipes in that category.

3. Press the USB icon in the upper right corner of the

screen.

4. The Enter Filename screen is displayed. Use the key-

board to name the le. Press the Done key at the bottom of the keyboard to save the lename.

5. Press the right arrow key ► in the top right corner.

The upload begins automatically.

6. The green success box is displayed. Press Finish.

7. The control returns to the USB screen.

If All Recipes is selected, you may choose any or all

of the recipes on the USB drive.

If a category is selected, you may choose any or all of

the recipes in that category.

4. Press the USB icon in the upper right corner of the

screen.

5. If you are overwriting a le currently on the oven, a

screen is displayed requesting you acknowledge the

overwrite.

6. Next the uploading screen appears. When the upload

is complete, a green success screen is displayed.

Press Finish.

7. The control returns to the USB screen.

32

Page 35

Operation

USB

RACK TIMER

To Import and Export Groups and Recipe Files in Advance Rack Timer

NOTE: Importing - you will be given the option to select

the desired recipe le on the USB drive. Once a

recipe set has been selected you will be given

the option to overwrite the existing recipe le

with those on the USB or append them to the

current recipe library.

Exporting – you will be prompted to name the

recipe library being exported.

1. From the MAIN MENU, press ADVANCED.

2. Select RACK TIMER.

3. In the RACK TIMER MENU screen select the BACKUP key from the bottom left hand corner of the screen.

4. Insert the USB drive you wish to copy the les to or

from into the port located at the front of the unit.

5. Select whether you would like to import or export the

recipes.

NOTE: Importing will overwrite any existing groups

and recipes.

6. Follow onscreen prompts to complete import or ex-

port of recipe les.

7. A notication will appear when le transfer is com-

plete. Select “Finish” to exit the pop-up screen.

USB Main Screen

USB Recipe Screen

Figure 25

33

USB Advanced Rack Timing Screens

Page 36

Operation

Timed Start

Timed Start makes it possible to start the oven using any

programmed recipe before staff arrives. This way, the

oven will be hot when you come in in the morning.

1. From the MAIN MENU, press the ADVANCED key.

2. Press the TIMED START key. The control displays

the current timed start.

3. Press the TIMED START box.

4. Drag your nger up or down to select the desired

timed start. Choose from:

• Non-Active - no timed start

• Single Timer - use for a single occurence timed

start

• Weekly Timer - use to set a timed start for each

day of the week.

Programming a Single Timed Start

1. Select Single Timer and press OK.

2. Enter the desired start time. Press OK.

3. The control displays the category list. Select the appropriate product category.

4. Select the desired product recipe.

5. The display shows Single Timer with the recipe name

in the top box and the start time in the second box.

You may edit either start time or recipe by touching

either box.

6. Push the left arrow key ◄ to return to the advanced

menu.

Programming a Weekly Timed Start

1. Select Weekly Timer and press OK.

2. Enter the desired start time. Press OK.

3. The control displays the category list. Select the appropriate product category.

4. Select the desired product recipe.

5. The display shows Week Timer with the recipe name

in the top box, followed by seven boxes, one for each

day of the week with the start time.

You may edit the start time for each day individually

by touching the box for that day.

6. Push the left arrow key ◄ to return to the advanced

menu.

SelectingTimer Mode

Setting a Single Timer

Figure 26

34

Setting a Week Timer

Page 37

Operation

HACCP Library

The ovens comes standard with HACCP data recording.

HACCP enables you to control and document production.

Data recorded includes production time. production duration, preparation temperature and core temperature.

The HACCP library can hold approximately 1000 log les.

You will be notied when the memory is full so that you

can empty the memory with the USB. If nothing is done,

the computer will automatically start to overwrite the old-

est les.

To Activate HACCP Data Recording

NOTE: HACCP data is stored under product recipe

names. Therefore, HACCP is not available for

manual cooking.

HACCP must be activated to record data.

1. From the MAIN MENU, press the GEAR key.

2. Press the SUPER USER key.

3. Press the SETTINGS key.

4. Press the HACCP LOGGING key.

5. Drag your nger up or down to select YES. Press OK

to enable HACCP recording.

To Backup HACCP Data

1. From the HACCP menu, press the key labelled Archive on USB.

2. The display reads SAVING HACCP.

3. When the data is saved to the USB the control returns

to the HACCP screen.

NOTE: The HACCP data on the USB can be lo-

cated in the folder with the serial number.

To Delete HACCP Data from the Oven

1. From the HACCP menu, press the key labelled Delete HACCP Data from Oven.

2. The screen will ask you to conrm that you want to

delete all HACCP les. Press the key next to Accept

to delete the les. Press the key next to Regret to

cancel.

3. The control returns to the HACCP screen.

To View HACCP Data

1. From the MAIN MENU, press the ADVANCED key.

2. Press the HACCP key.

3. From the HACCP menu, press the key labelled either

Show HACCP from Oven or Show HACCP from USB.

4. A list of HACCP log les is displayed. The les are

logged by year, month, date and product name. Use

the UP and DOWN ARROW keys to scroll through the

list until the desired HACCP le is highlighted.

5. Press the OK key in the upper right of the control to

display the HACCP chart.

6. Press the RETURN key at the top left of the screen to

return to the HACCP screen.

35

Page 38

Maintenance

Cleaning & Preventative Maintenance

DAILY CLEANING

Daily cleaning of your Combi oven is essential for sanita-

tion, and to ensure against operational difculties.

Cleaning the Exterior

1. The exterior of the appliance may be cleaned and

kept in good condition with a light oil. Saturate a cloth

and wipe the appliance when it is cold; wipe dry with

a clean cloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet. Cleaning

with a water jet can impregnate chlorides into

the stainless steel, causing the onset of corrosion.

Cleaning the Interior

NOTE: DO NOT use corrosive cleaners not intended for

oven cleaning on your Combi oven.

Blodgett recommends the following products for cleaning

and rinsing of your Blodgett Combi oven. If you choose

to use products other than what Blodgett recommends,

please have your suppler send us the MSDS sheet on the

proposed alternate so we can ensure it meets our standards. Non approved products can cause harm to your

unit and can potentially void your warranty.

1. Open the oven door.

2. Use the attached spray hose, located beneath the

control, to clean the front drip tray. Water will run to

the drain in the oven cavity.

RECOMMENDED OVEN CLEANERS

VENDOR PRODUCT NAME

1st AYD Corporation Kombi-Klean Oven, Grill &

Fryer Cleaner

Alco Chemical 350 Ultra Cycle

Daley International Oven & Grill Cleaner

Ecolab Keystone Oven Cleaner

Oven Cleaner Power

Grease Cutter Plus

Specialty Oven Cleaner

Ecotemp Ultra Kleene

Proforce Oven Grill & Fryer

Cleaner

Johnson Diversey Suma Grill D9

Kay Chemical Empire Inside/Outside

Degreaser

Parkside Pro Products Vestec 550

PDQ Manufacturing Comi-Clean

Performance Food

Group

U.S. Chemical Heavy Duty Oven & Grill

First Mark All Temp Dish

Machine Detergent

Cleaner

RECOMMENDED RINSE AIDS

VENDOR PRODUCT NAME

Alco Chemical 320 Rapid Rinse

Ecolab Keystone Liquid Rinse Additive

Oven Rinse Power

Esteem Dry-All

Eco Temp Ultra Dry

Specialty Oven Rinse RTU

Specialty Oven Rinse

Johnson Diversey Suma Maro A8.8

Suma Nova L6

Parkside Pro

Products

PDQ Manufacturing Combi-Rinse

Performance Food

Group

U.S. Chemical Heavy Duty Rinse Agent

Vestec 510

First Mark Kleer Kwick Plus

Quick Dry Rinse Aid

36

Page 39

Maintenance

Cleaning & Preventative Maintenance

Run the CombiWash automatic cleaning cycle as follows:

1. Check the level of detergent and rinse aid in the containers. The red tube is for detergent and the blue

tube is for rinse aid.

Check that the oven temperature is below 80°C. If the

oven is too hot, use the CoolDown function (see page

page 26).

2. On the MAIN MENU press the MANUAL key.

3. Press the COMBI WASH key.

4. Touch the desired cleaning mode. You can choose

between the following cleaning cycles.

• Flush: Use this before starting the other cleaning programs.

• Light: Use this after steaming and roasting at

low temperatures.

• Medium: Use this after steaming and roasting at

medium temperatures.

• Heavy: Use this after roasting at temperatures

higher than 180°C.

WEEKLY CLEANING

In addition to the daily cleaning it is necessary to clean

the air intakes on a weekly basis. Air intakes provide necessary cooling air to the internal components. They are

generally located on the rear and sides of the equipment.

It is also important to clean the control lter and behind

the fan guard on a weekly basis. This is necessary for

proper functioning of the oven. Scale will build up on the

fan and heat source leading to a less efcient oven.

1. Remove the front grill section and clean the fan

guards once a week on BLCT-61E-H, BLCT-62E-H,

BLCT-101E-H & BLCT-102E-H, models

Cleaning Control Filter

1. Lift and remove lter in housing at rear of unit.

• Intensive: Use this after roasting very greasy

products.

5. Press Start to initiate CombiWash.

Note: If the cleaning cycle is interrupted before it has

been completed, for example because of a

power outage, the oven automatically performs a

safety ush to remove any detergent remnants.

WARNING!!

Dual Power Supply - before servicing, moving

or cleaning disconnect unit from both power

supplies.

Figure 27

2. Wash lter to remove any accumulated grease and/

or particulate.

3. Dry lter and reinsert with labeling facing the front of

the unit.

37

Page 40

Maintenance

Cleaning & Preventative Maintenance

Cleaning Behind the Fan Guard

1. Using a athead screw driver adjust each retaining

clip so the slots are on the bottom of their respective

cutouts.

2. Lift up from the bottom of the fan guard and pull the

top forward to move the fan guard above the retaining bar and over the placement pins on the bottom of

the liner.

3. Thoroughly spray cleaner onto the fan and heat

source. Place the oven in the steam mode for approximately 10 minutes.

4. After ten minutes, rinse the cleaner off. Place the

fan guard back over the retaining bar and placement

pins. Adjust each retaining clip so the slots are at the

top of each cutout. If there is resistance ensure the

bafe is properly seated over the retaining bar and

placement pins.

Door Gasket

It is imperative that the door gasket is properly maintained.

Wiping any grease from the gasket will lengthen its life.

Condenser Intake Fans

To ensure proper operation, it is necessary to check the

three fans in the front of the hood section. These fans

simply blow cool air over a condenser box to convert

any vapor from the oven cavity to water. The air quality

in your kitchen will determine how often these fans must

be cleaned. Keep in mind, these fans are using the ambient air, not cooking cavity air. The cleaning of these fans

should be performed by an experienced technician. This

should be performed at least every 6 months. As stated

above, the frequency is based on your ambient air quality.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are the

proper initial installation of the equipment and a

program for cleaning the appliance routinely. The Oven/

Steamer requires no lubrication. Contact the factory, the

factory representative or a local Blodgett Combi service

company to perform maintenance and repairs should they

be required.

38

Loading...

Loading...