Page 1

BCPĆ61, BCPĆ101 and BCPĆ102

INSTALLATION - OPERATION - MAINTENANCE

BCPĆ61, BCPĆ101 et BCPĆ102

MANUEL D'INSTALLATION - FONCTIONNEMENT - ENTRETIEN

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331Ć5842, (802) 860Ć3700 Fax: (802)864Ć0183

PN 60739 Rev A (6/10)

E 2010 - G.S. Blodgett Corporation

Page 2

A PERSONAL WORD FROM BLODGETT COMBI

QUELQUES MOTS DE BLODGETT COMBI

Congratulations on your purchase of a BLODGETT Combi appliance. We

firmly believe that your choice has been a wise one, and trust you will reĆ

ceive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policy to which we've always adĆ

hered: For Better Cooking!"

Once you've had a chance to use your Combi, please tell us, your dealer

and colleagues about any creative and interesting applications you have

discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems

be encountered (...we're here to help!) and above all Enjoy Cooking the

BLODGETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Toutes nos félicitations sur votre achat d'appareil de Blodgett Combi.

Nous croyons fermement que votre choix est un choix raisonnable et

nous sommes certains que vous obtiendrez de nombreuses années

d'excellent service de votre nouveau four multiĆusages.

Vous allez découvrir que la cuisson dans les appareils Combi économise

le temps, le travail et le degré de nettoyage de l'appareil aussi bien que

de la cuisine.

Avec les appareil de Combi, la qualité, le goût, la consistence et l'apparĆ

ence des aliments sont améliorés, s'accordant, de ce fait, avec notre

politique "Pour une meilleure cuisson !"

Une fois que vous aurez eu la chance d'utiliser notre Combi, informez

nous, votre concessionnaire et vos collègues, de toutes les applications

nouvelles et intéressantes que vous avez découvertes ; échangez vos

idées avec d'autres utilisateurs. N'hésitez pas à nous prévenir, ou votre

concessionnaire, de tout problème mécanique ou technique que vous

pourriez rencontrer (... nous sommes ici pour vous aider) et parĆdessus

tout RégalezĆvous à cuisiner à la façon BLODGETT Combi!

Pour obtenir de plus amples informations sur l'art culinaire, veuillez conĆ

sulter notre livre de cuisine séparé.

Page 3

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTISSEMENT: UNE INSTALLATION, UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGES À LA PROPRIÉTE, DES BLESSURES OU LA MORT. LISEZ ATTENTIVEĆ

MENT LES DIRECTIVES D'INSTALLATION, D'OPÉRATION ET D'ENTRETIEN AVANT

DE FAIRE L'INSTALLATION OU L'ENTRETIEN DE CET ÉQUIPEMENT.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l'essence ni d'autres vapeurs ou liquides inflamĆ

mables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instrucĆ

tions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructions et procéĆ

dures permettra d'obtenir de bons résultats de cuisson et une longue durée de serĆ

vice sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l'avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. SpecificaĆ

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d'illustration font l'objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 4

Your Service Agency's Address:

Adresse de votre agence de service:

Model/Modèl:

Serial Number/Numéro de série:

Your appliance was installed by/

Installateur de votre four:

Your oven's installation was checked by/

Contrôleur de l'installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

The Blodgett Combi-Oven/Steamer 2.....

Description of the Combi-Oven/Steamer 3.

Installation

Agency Approvals 4....................

Utility Specifications 5...................

Unpacking the Oven 6..................

Oven Location and Leveling 7............

Plumbing Connections 8................

Electrical Connection and Ventilation 9....

Final Check Lists 10.....................

Operation

Blodgett Programmable Control

Introduction 11..........................

BCP Cooking Modes 12..................

Welcome Screen 14.....................

Work Menu 15..........................

Manual Cooking 16......................

Core Probe Cooking 21..................

Programmed Cooking 25.................

Programming a Product 27...............

Programming a Product 31...............

Setting a Timed Start 32..................

Setting Preset Time & Temperature 35.....

Oven Setup 36..........................

USB Functions 38.......................

HACCP Library 40.......................

Optional CombiNet 42...................

Maintenance

Cleaning & Preventative Maintenance 44...

Deliming 46.............................

Introduction

Le four-étuveur Combi de Blodgett 48......

Descriptiondufour-étuveurCombi 49......

Installation

Certifications 50.........................

Caractéristiques techniques relatives

aux services publics 51..................

Déballage du four 52....................

Choix de l’emplacement et nivellement

du four 53..............................

Robinetterie 54..........................

Raccordement à l’électricité e

Ventilation 55...........................

Liste de vérification finale 56..............

Fonctionnement

Introduction à la commande

programmable Blodgett 57...............

Modes de cuisson BCP 58...............

Image-écran d’accueil 61.................

Menu Travail (Work) 62...................

Cuisson manuelle 63....................

Cuisson à la sonde de température 69.....

Cuisson programmée 74.................

Programmation d’un produit 76...........

Programmation d’un produit 80...........

Établissement d’un allumage temporisé 81

Établissement d’une durée et d’une

température prédéterminées 84...........

Configuration du four 85.................

Fonctions BSU (USB) 87.................

Bibliothèque ARMPC (HACCP) 90.........

Fonction optionnelle CombiNet 92.........

.

Entretien

Nettoyage et entretien préventif 94........

Détartrage 96...........................

Page 6

Introduction

The Blodgett CombiĆOven/Steamer

The Blodgett CombiĆOven/Steamer offers a comĆ

pletely new method of cooking. With the Oven/

Steamer you have the choice of two cooking proĆ

cesses: Steam and Hot Air, either...

D Separately

D Combined, or

D In Sequence

And for easy operation you can choose from three

primary cooking modes:

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanch preserve braise

poach

In the Hot Air mode you can:

roast bake

grill gratinate

broil

In the two Combi modes you can:

defrost roast rethermalize

reheat bake forced steaming

There are four additional specialized modes to

help you make the most of your time:

Retherm - for perfect reheating

Proofing - Proof and bake all in the same oven

Preheat - in this mode the oven will preheat to

575_F (300_C) for 15 minutes. The oven will then

automatically lower to 480_F (249_C) to protect

the advanced electronic components.

Cool Down - allows the oven cavity to cool down

rapidly with the door opened

You āācan also āāuse āātwo āāor āthree functions in seĆ

quence during one cooking process. We call this:

D combiĆsteaming

D combiĆroasting

D combiĆbaking

The combination of circulating hot air and steam

in the space saving, high performance CombiĆ

Oven/Steamer leads to improvements in the folĆ

lowing areas:

D increased productivity in the kitchen

D a reduction in capital expenditures for multiple

equipment replacement

D a wider range of menu choices

D a simplified cleaning process

The work process is simplified since products are

prepared on or in steam table āpans āand trays.

Food can be cooked, stored, and transported with

āthe āsame āāpans. āSmall āamounts of product can be

processed efficiently; preĆcooked and conveĆ

nience foods can be reheated within minutes.

āMany frozen foods can be processed without preĆ

thawing. This flexibility in preparation reduces the

need for kettles and steam tables since there is no

need for large amounts of food to be kept warm for

long periods of time.

Today the improvement of food quality is more imĆ

portant than ever. Vegetables are cooked in the

Blodgett CombiĆOven/Steamer without water at

the optimal temperature of just under 212_F

(100_C), maintaining valuable vitamins, minerals,

nutrients and trace elements. Cooking meat in the

Combi results in less shrinkage and a firmer, juicier

product. The Blodgett CombiĆOven/Steamer is

being used more and more for baking. Steam and

Hot āAir āmodes āmake āit āa āgeneral āpurpose baking

appliance.

2

Page 7

Introduction

Description of the CombiĆOven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett CombiĆOven/Steamers are quality proĆ

duced using highĆgrade stainless steel with first

class workmanship.

The multiple speed fan, which is guarded against

accidental finger contact, is driven by a quiet and

powerful motor. The condenser draws out excess

steam from the appliance. Condensation and

waste water, which result during steaming and

cleaning, are continuously drained.

The use of high quality insulation impedes excesĆ

sive heat radiation and saves energy.

The high performance fresh steam generator with

its control system makes it possible to enjoy all of

the advantages of a high quality steamer at the

flick of a switch. Fresh steam enters the oven cavĆ

ity without pressure and is circulated at high

speed. This process enables quick and gentle

cooking and ensures high quality food while proĆ

viding convenient working methods. The steam

generator is completely automatic and protected

from running dry.

OVEN/STEAMER OPERATION

The practical oven door, with a viewing window,

has a wide swing radius and handle which can be

operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simĆ

ple to use touchscreen control. With graphical

symbols and storage for 200 product recipes the

BCP is easy for even inexperienced kitchen staff

to operate.

Cleaning is kept to a minimum thanks to the autoĆ

matic Combi Wash system.

3

Page 8

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONĆ

TAINED HEREIN ARE FOR THE USE OF QUALIĆ

FIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D The installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

D The installation of electrical wiring from the elecĆ

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiĆ

enced in such work, be familiar with all precauĆ

tions required and have complied with all requireĆ

ments of state or local authorities having

jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1-Latest Edition,

the Natural Gas Installation Code CAN/CGAĆ

B149.1 or the Propane Installation Code, CAN/

CGAĆB149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA

70-Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

with the Basic Plumbing Code of the Building OffiĆ

cials and Code Administrators International Inc.

(BOCA) and the Food Service Sanitation Manual of

the Food and Drug Administration (FDA).

Appliance is to be installed with backflow prevenĆ

tion in accordance with applicable federal, provĆ

ince and local codes.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011Ć802Ć860Ć3700.

4

Page 9

Installation

Utility Specifications

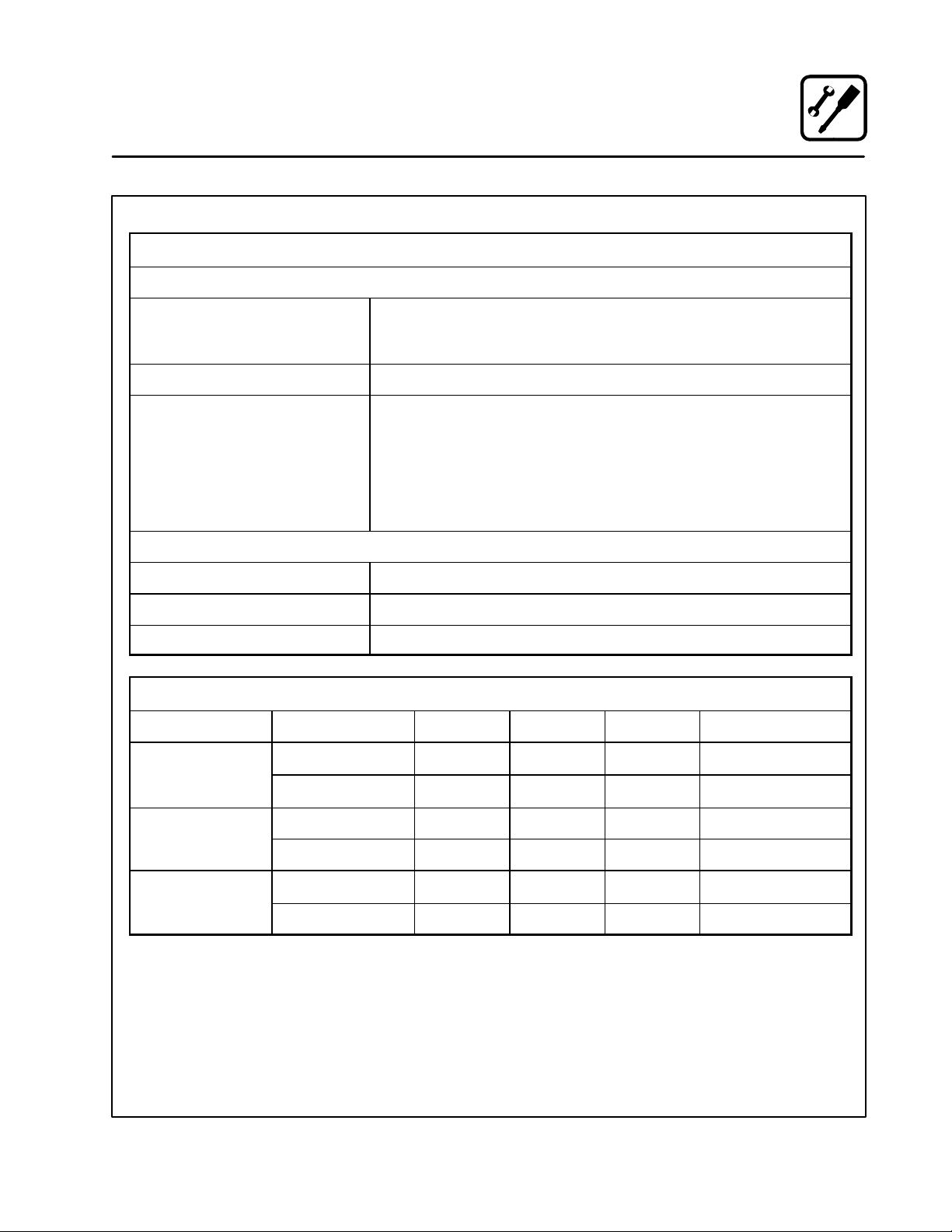

PLUMBING SPECIFICATIONS - BCPĆ61E, BCPĆ101E and BCPĆ102E

WATER

Water Pressure 36.26 PSI (250 kPa, 2.5 bar) during Combi Wash

21.76 PSI (150 kPa, 1.5 bar) when Combi Wash is not active

87 PSI (600 kPa, 6 bar) maximum

Water Connection 3/4" garden hose cold water

Minimum Requirements TDS - less than 100 parts per million

Total Hardness - 80Ć120 parts per million

Chlorides - less than 30 parts per million

pH Factor - 7.0Ć8.0

Chlorine - 0 parts per million

DRAINAGE

Drain Type Atmospheric Vented Drain

Drain Connection 2.00" (50.8mm) Copper

Avg Water Drain Temp. Approximately 140_F (60_C)

ELECTRICAL RATINGS - BCPĆ61E, BCPĆ101E and BCPĆ102E

Model Voltage kW Hz Phase Max Load (amps)

BCPĆ61E 208 9 60 3 25

240 9 60 3 22

BCPĆ101E

BCPĆ102E 208 27 60 3 75

208 18 60 3 50

240 18 60 3 44

240 27 60 3 65

5

Page 10

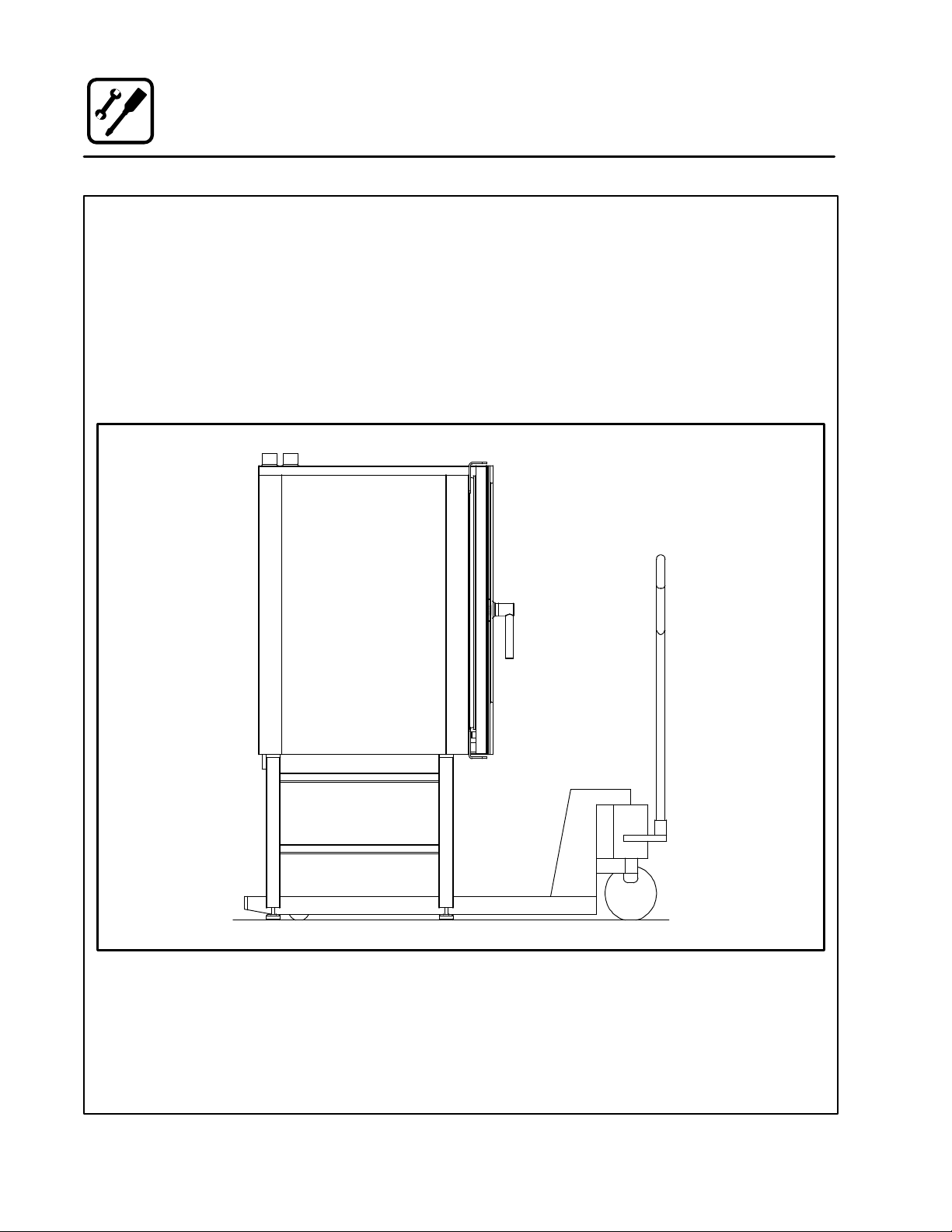

Installation

Unpacking the Oven

The oven is best handled while still in its wrapping.

Wherever possible, use a rolling lift.

1. Roll the lift under the lower cross tube of the

stand Place a couple of wooden blocks beĆ

tween the cross tube and the lift.

NOTE: To achieve the best possible balance,

roll the lift from the front of the oven or

from the motor side.

NOTE: If necessary, the oven can also be

lifted off the stand.

2. Remove the original packaging from the oven.

Do not remove the vinyl that covers the stainĆ

less steel surface until the oven has been

installed. Once the vinyl has been removed,

the surfaces are vulnerable to sharp objects

such as tools.

3. Remove all packaging material that secures

the racks in the oven chamber.

Figure 1

6

Page 11

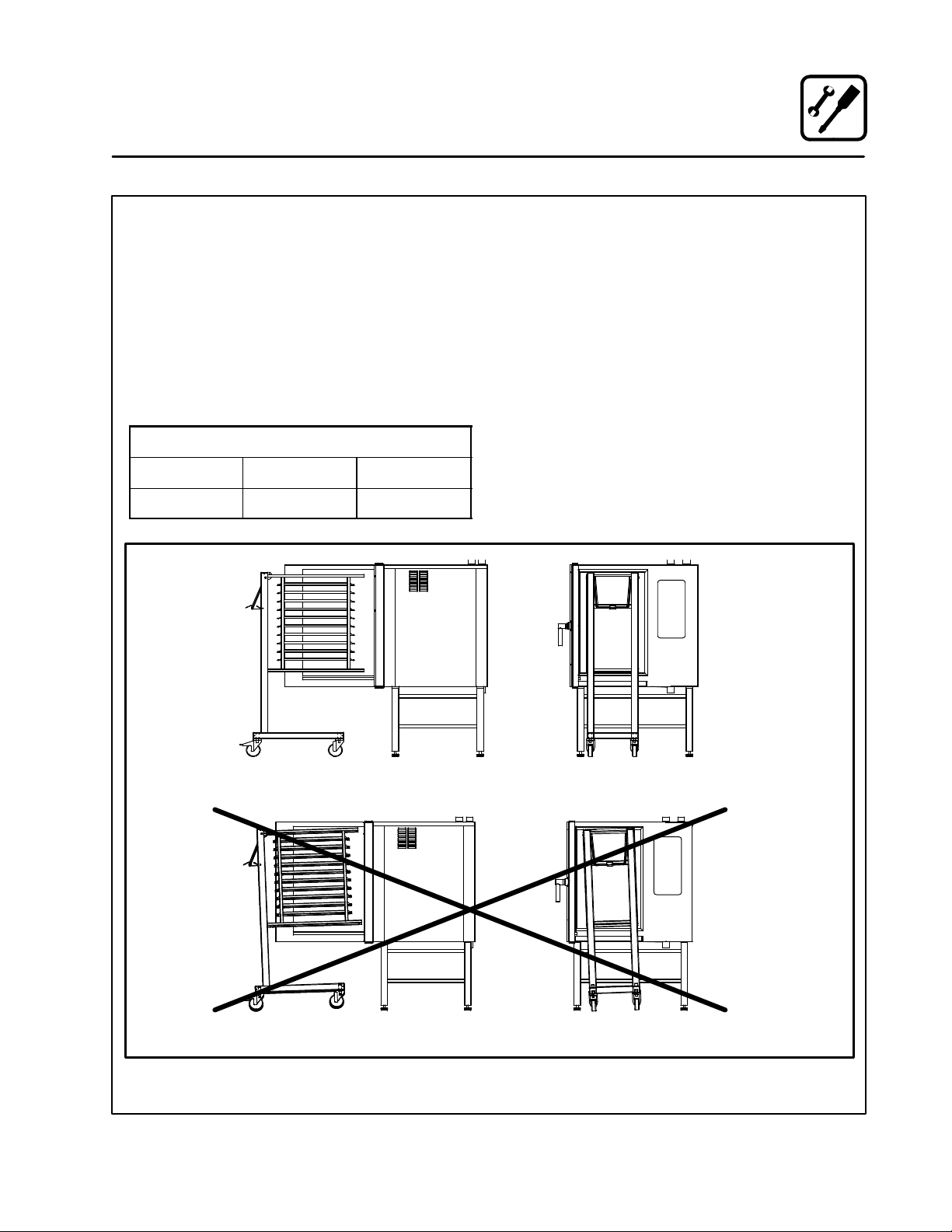

Installation

Oven Location and Leveling

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

Certain minimum clearances must be maintained

between the oven and any combustible or nonĆ

combustible construction.

Strong sources of heat such as hotplates, tilting

frying pans, deep fat fryers, etc. should not be

placed near the oven, especially near its right side.

An optional side heat shield is available.

MINIMUM REQUIRED CLEARANCES

Right Side Left Side Back

2.75" (7cm) 2.75" (7cm) 2" (5cm)

In addition, the following clearances are recomĆ

mended for servicing.

D Oven body sides - 12" (30cm)

D Oven body back - 12" (30cm)

To ensure that the oven functions correctly

when installed, it should be placed upright and

level (horizontally). This is measured at the

front and side edge of the roof. The oven can be

levelled using the adjusting screws on the

stand or on the legs of table models. The height

of the oven should also be adjusted to fit the

trolley for rack.

CORRECT INSTALLATION

INCORRECT INSTALLATION

Figure 2

7

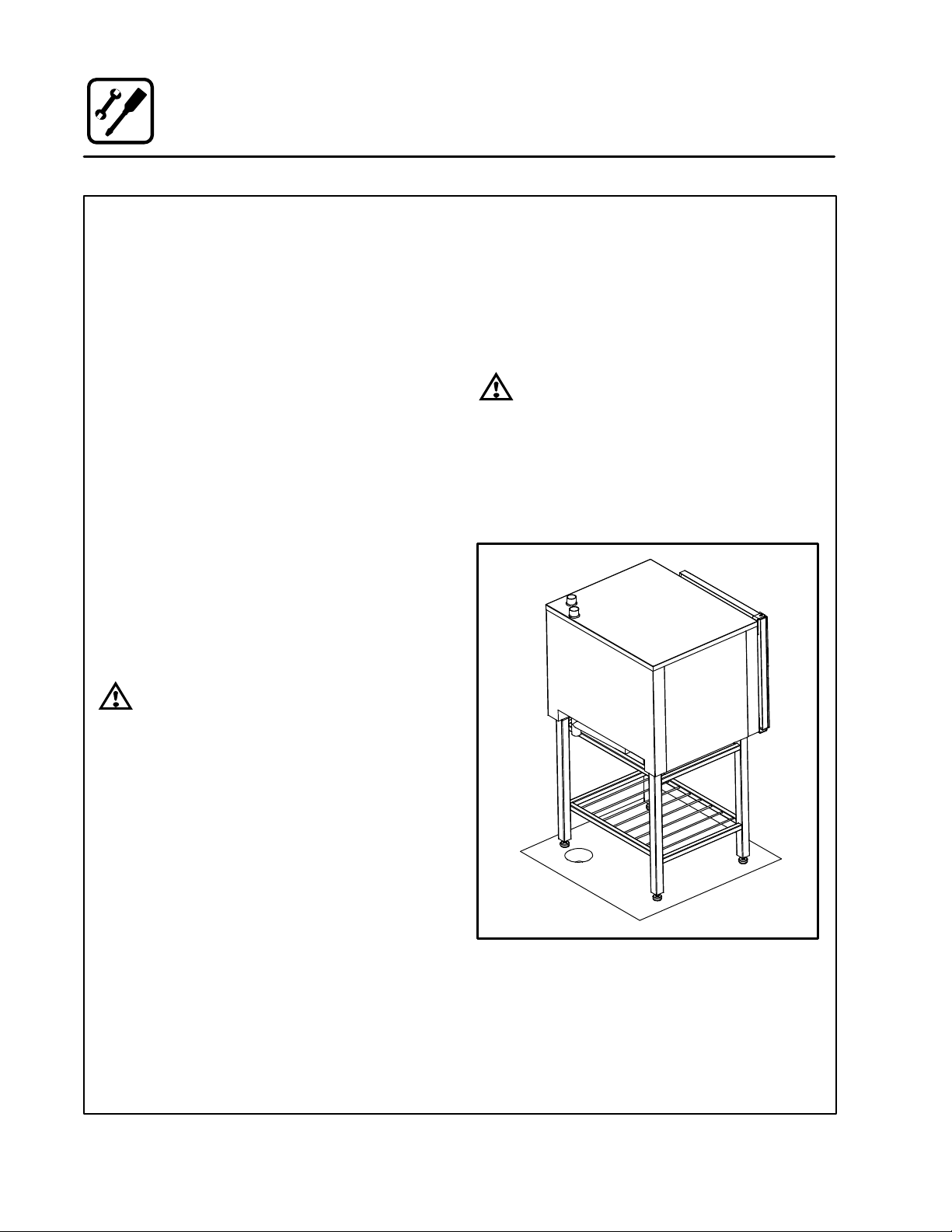

Page 12

Installation

Plumbing Connections

WATER CONNECTION

Blodgett BCP ovens have one or two water conĆ

nections. In the case of two water connections, the

following applies:

D 1 connection for raw water for the condensation

jet (cold water). The connection is located on

the back.

D 1 connection for the steam generator and the

Combi Wash jet in the oven chamber. Must

meet the requirements applying to water supĆ

plied to household appliances; however, hot

water with a temperature not exceeding 120°F

(49°C) can be used. The connection is located

at the front.

To facilitate cleaning and servicing, the oven

should be connected with an approved flexible

3/4" hose. Permanent installations should be fitted

with a stopĆtap and a nonĆreturn valve.

If the feeder is connected to the water distribution

system with a flexible hose, this hose should be VA

approved.

Before connecting the oven to water, flush the

tubes thoroughly. Connect the oven.

DRAIN CONNECTION

Blodgett ovens are equipped with a drain system

that removes surplus water from the oven chamĆ

ber. This may be condensed water from the prodĆ

ucts, or it may occur when the oven chamber is

cooled down with cold water, or when the oven

chamber is cleaned.

WARNING!!

Connection must be carried out by an auĆ

thorised plumber, to an open or closed

drain. The drain must never end directly

beneath the oven.

The drain must be of stainless steel or an equally

temperatureĆresistant material, have a diameter of

at least 2" (49 mm) and a fall of at least 3° or 5%.

WARNING!!

If the water temperature exceeds 70°F

(21°C), problems with regard to Combi

Optima calibration and cooling of the

oven may occur.

Ovens with a steam generator must not be

connected to a reversed osmosis plant,

as this may cause problems with the readĆ

ing of the water level in the steam generaĆ

tor.

The water connection must be carried out

by an authorised plumber in accordance

with existing local codes.

Clogged up water filters and dirt in the soĆ

lenoid valves are not covered by the warĆ

ranty.

Figure 3

8

Page 13

Installation

Electrical Connection and Ventilation

ELECTRICAL CONNECTION

NOTE: Electrical connections must be performed

by a qualified installer only.

Before making any electrical connections to these

appliances, check that the power supply is adeĆ

quate for the voltage, amperage, and phase reĆ

quirements stated on the rating name plate

mounted on the appliance.

1. The rating plate is located on the right side of

the oven.

An approved plug outlet or a safety cutout must be

located close to the oven so that the oven can be

disconnected during installation and repair. The

safety cutout must be able to cut off all poles with

a total distance of break of at least 3 mm.

All appliances must be installed in accordance

with Local or National Electrical codes.

The wiring diagram is located in the motor

compartment.

NOTE: Disconnect the power supply to the apĆ

pliance before servicing.

WARNING!!

Improper installation may invalidate your

warranty.

VENTILATION

Blodgett BCP ovens are equipped with an open/

direct exhaust system that removes surplus huĆ

midity from the oven chamber. The exhaust sysĆ

tem has an electrically operated damper.

The ventilation motor can be controlled directly

from the oven. This means that the ventilation

starts when a program is started and runs for 10

minutes after the program is completed.

The exhaust tube can be connected to a ventilaĆ

tion system. In that case, a special extraction funĆ

nel is fitted to avoid suction directly from the oven

chamber. This extraction funnel can be ordered

from Blodgett.

If an extraction hood is installed in the ceiling

above the oven, it should project 20" (50 cm) over

the front of the oven.

Figure 4

9

Page 14

Installation

Final Check Lists

WARNING!!

Final check list must be performed by a

qualified installer only.

OVEN EXTERIOR

j Check that the oven has not been damaged

in transit (dents, scratches, etc.)

j Check/adjust the height and check that the

oven is placed level (horizontally)

j Check/adjust oven door

CONNECTIONS

j Check for correct water connection

j Turn on water supply

j Check for leaks

j Turn off water supply

j Check and clean dirt filter

j Turn on water supply again

j Check hand shower

j Check for correct electrical connection

j Check connection to drip tray

j Check for correct mounting of drip tray

j Check for correct fall of hose from drip tray,

and check for leaks

j Check for correct exhaust and drain connecĆ

tion

j Clean the oven

j Apply steel oil

OVEN INTERIOR

j Check that filter housing is mounted correctly

j Check interior light

j Clean the oven

CONTROL

j Check and adjust, if necessary, each of the

preset values

j Heat up the oven at 480° F (249°C) for approxĆ

imately 5 minutes.

10

Page 15

Figure 5

Operation

Blodgett Programmable Control Introduction

The BCP ovens include the versatile Blodgett ProĆ

grammable control. The control features:

D Multiple cooking modes include hot air, combi

with CombiOptima, reheating/regenerating,

steaming, lowĆtemperature steaming, forced

steaming, proofing, cooling, and preheating

D CombiOptima automatically measures and

controls the humidity level in the oven, helping

to retain the appearance and juiciness of the

product.

D Easy to use touch panel with crystal clear TFT

display

D Stores up to 200 recipe programs with 10 cookĆ

ing stages each. Recipes can be grouped into

categories (beef, chicken, cookies, etc.) for

easy retrieval.

D External core temperature probe with 3 measurĆ

ing points. Ability to run 2 core probes simultaĆ

neously.

D Low temperature roast & hold and DeltaĆT cookĆ

ing

D Reversible 9 speed fan for optimum baking and

roasting results

D USB port for data, software and recipe transfer

D HACCP quality control enables you to control

and document production. Includes production

time, production duration, preparation temperĆ

ature, and core temperature.

D CombiNet for monitoring and remote controlĆ

ling the oven via computer or internet. FuncĆ

tions include recipe management, HACCP, serĆ

vice diagnosis and software updating

D Programmable time delay start

D Automatic service diagnosis

11

Page 16

Operation

BCP Cooking Modes

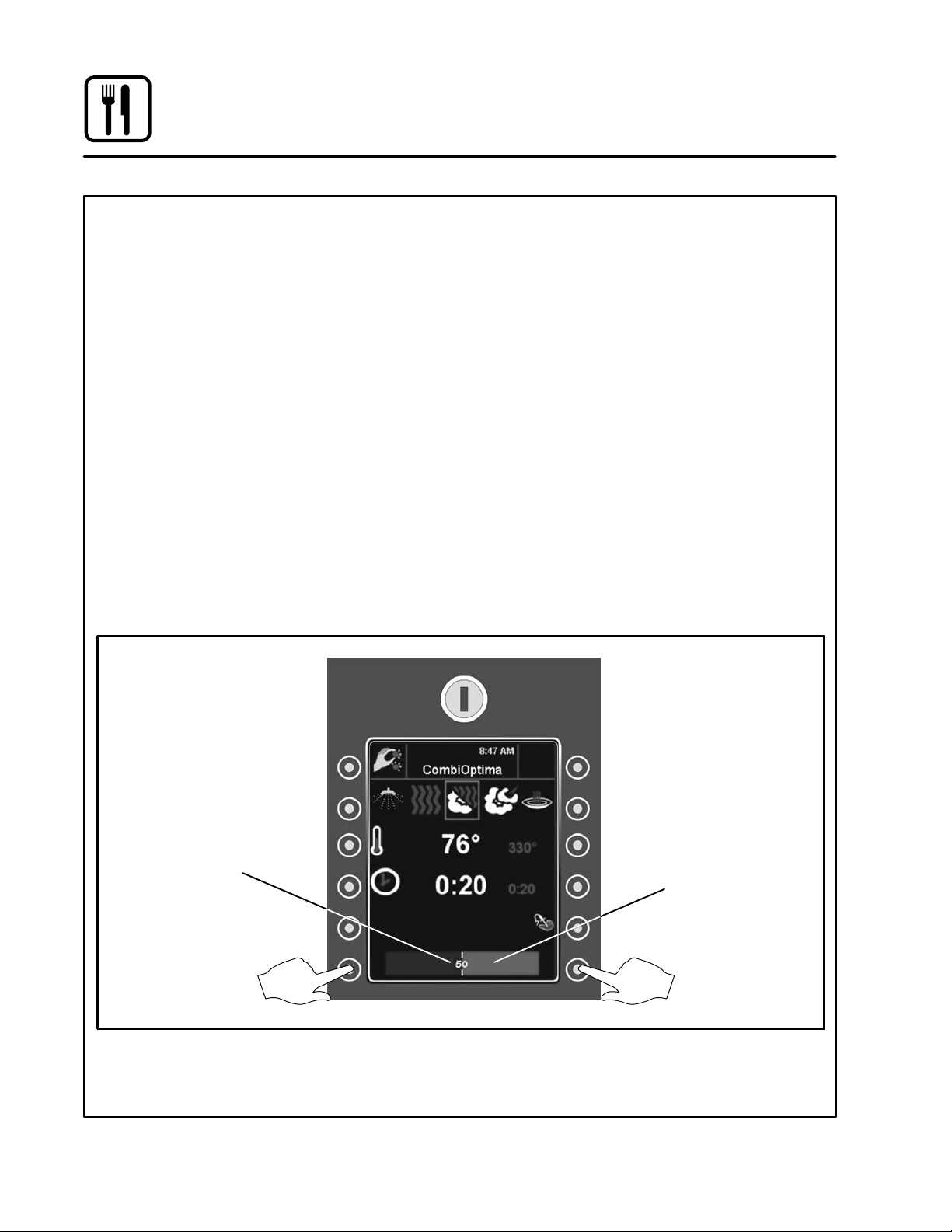

COMBIOPTIMA MODE

CombiOptima offers you the possibility of adding

up to 100% humidity to the oven chamber at temĆ

peratures from 160 to 480°F (70 to 250°C).

When using CombiOptima correctly, you minimise

shrinkage and enhance the appearance and taste

of your product.

Many products contain a large amount of water,

increasing the humidity level during cooking. The

oven automatically regulates the humidity to mainĆ

tain the desired level.

Setting the humidity level

1. Use the bottom keys on the left and right to set

the desired humidity level. The blue and red

bar indicated the actual humidity level in the

oven cavity. The white number in the center

of the bar indicated the desired humidty level.

NOTE: If the bar is all red, the oven containss

0% humidity. If the bar is all blue, the

oven contains 100% humidity.

2. Preheat the oven for 5 minutes with the deĆ

sired humidity content. Depending on the

amount of product in the oven and the desired

humidity level and temperature, the desired

humidity is typically reached after 1 to 5 minĆ

utes.

Tips for setting the humidity level

D To make gravy when braising meat, apply 70 to

80% humidity at 300Ć325°F (145Ć65CC).

D For poaching fish, poultry and crispy vegetaĆ

bles, apply 70 to 95% humidity at 150Ć250°F

(70Ć120°C).

D For short cook times and products, such as

herbĆmarinated cuts of meat and fresh vegetaĆ

bles, use 70% humidity at 375°F (190°C ). DeĆ

spite the short cook time, products such as

cook very gently.

If the oven is not connected to a soft water

plant, CombiOptima cannot function properly.

Humidty level

setpoint

Press this key to

decrease humidity

level

Actual humidty

level bar

Press this key to

increase humidity

level

Figure 6

12

Page 17

Operation

BCP Cooking Modes

STEAM MODE

The steam mode provides 100% humidity in the

cooking chamber. Use the steam mode for the folĆ

lowing applications:

Low Temperature Steaming

Steaming at 150Ć195°F (65Ć90°C) is recomĆ

mended for delicate products such as fish.

Steaming fresh vegetables such as carrots, asparĆ

agus, and beans at 175°F (80°C) for 5 to 10 minĆ

utes produces products that keep their color and

crispness.

Traditional Steaming

Steaming at 208Ć212°F (98Ć100°C) is recomĆ

mended for all kinds of root vegetables, potatoes,

pasta, rice and meat.

Forced Steaming

Steaming at 250°F (120°C) can be used for vegeĆ

tables that need further processing and for faster

preparation of pasta, rice, hard root vegetables

and frozen vegetables. Forced steaming should

be used with care.

Tips for Using the Steam Mode

D We recommend that you start the steaming proĆ

cess 8 minutes before you place the products

in the oven chamber. For food safety reasons,

the oven automatically checks the water in the

steam generator. If the water temperature is beĆ

low 150°F (65°C), the tank is emptied, refilled

and the water is heated.

D To get the oven ready for production quickly and

to ensure a perfect start of the steaming proĆ

cess, we recommend that you cool down the

oven chamber to 175°F (80°C). To lower the

temperature quickly, use the Cool Down mode

and open the door.

If the oven is not connected to a soft water

plant, the Steam mode cannot function properĆ

ly.

RETHERM MODE

Reheating is a very gentle process 70Ć350°F

(20Ć180°C). The program operates with low fan

speed and adds a carefully calculated amount of

humidity which maintains the nice appearance

and taste of the product.

Tips for Using Retherm

D To quicker retherming, products should not be

covered.

D For best results, use a core temperature probe.

D When retherming sousĆvide products, follow

supplier recommendations.

Recommended Times & Temperatures

D 8 to12 minutes at 285°F (140°C) for plated

meals with rice, meat and vegetables.

D 40 to 60 minutes at 250Ć285°F (120Ć140°C) for

whole roasts, stews and sauces.

D 20 to 30 minutes at 250°F (120°C) for pasta and

rice.

PROOFING MODE

The oven is designed to maintain the perfect huĆ

midity for all products that need to be proofed beĆ

fore they are baked.

For your convenience, the Blodgett BCP has a

preset program called Semiautomatic Bread". In

this program the bread is proofed and baked in the

same process.

Recommended Times & Temperatures

D Low temperature and long proofing time of 90°F

(32°C) for 45 minutes for 14Ć28 ounces

(400Ć800g) loaves of bread

D High temperature and short proving time 100°F

(38°C) for 25 minutes for 2Ć7 ounce (60Ć200g)

rolls and baguettes.

PREHEAT MODE

In this mode the oven will preheat to 575_F

(300_C) for 15 minutes. The oven will then autoĆ

matically lower to 480_F (249_C) to protect the adĆ

vanced electronic components. We recommend

preheating the oven 80Ć100_F (27Ć38_C) above

the cook temperature.

13

Page 18

Operation

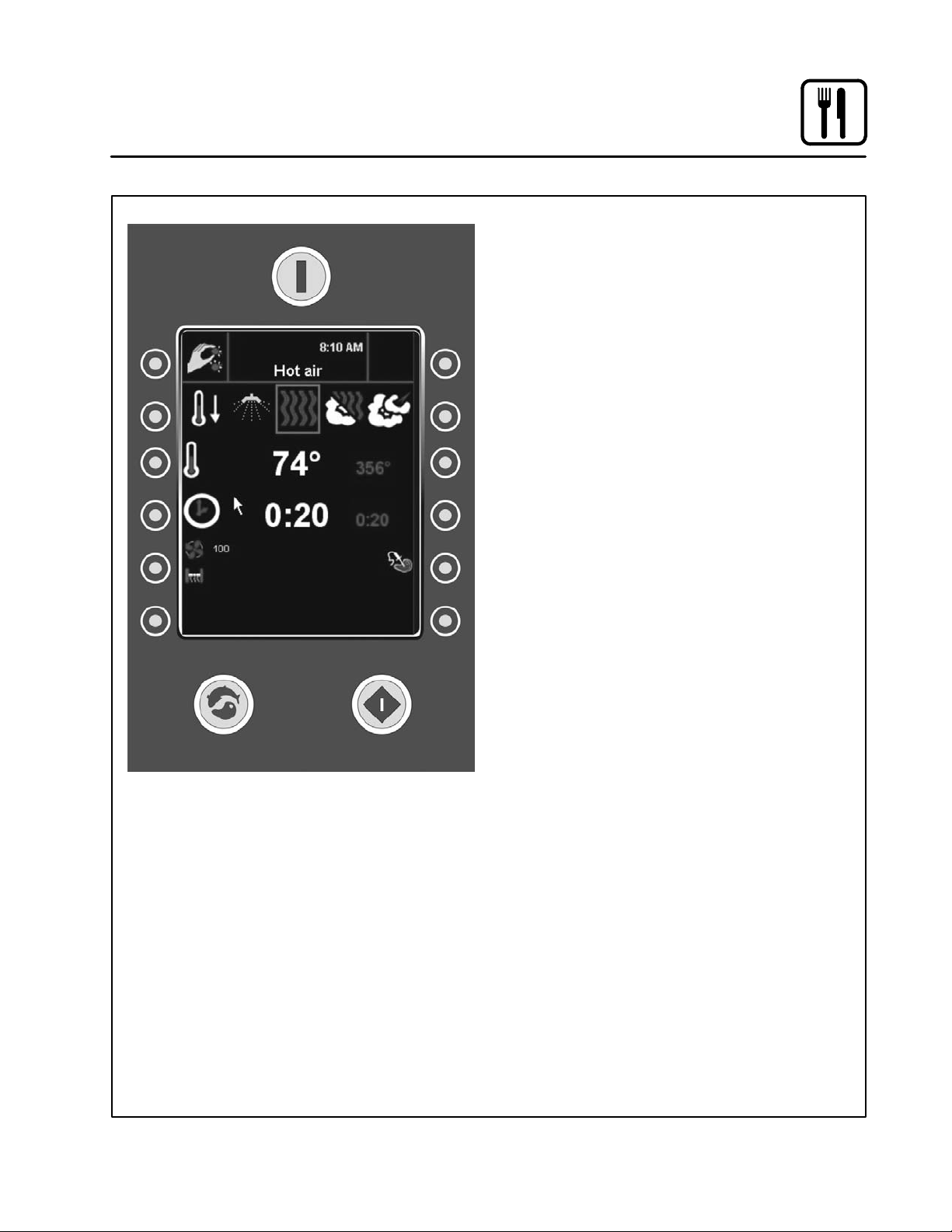

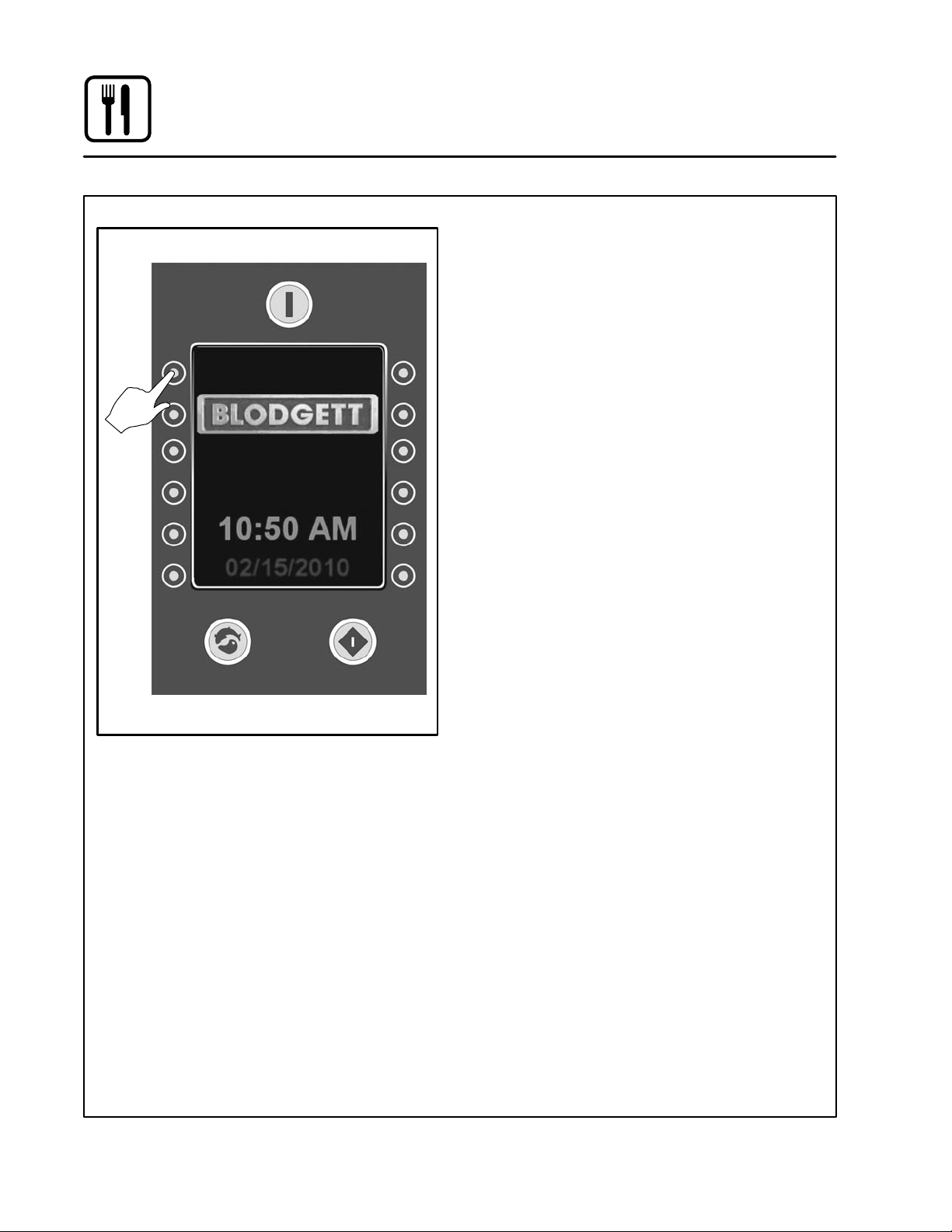

Welcome Screen

Figure 7 shows the welcome screen that will apĆ

pear when you power up your BCP oven.

1. Press the any of the 6 keys on either side of

the control to access the WORK Menu.

Figure 7

14

Page 19

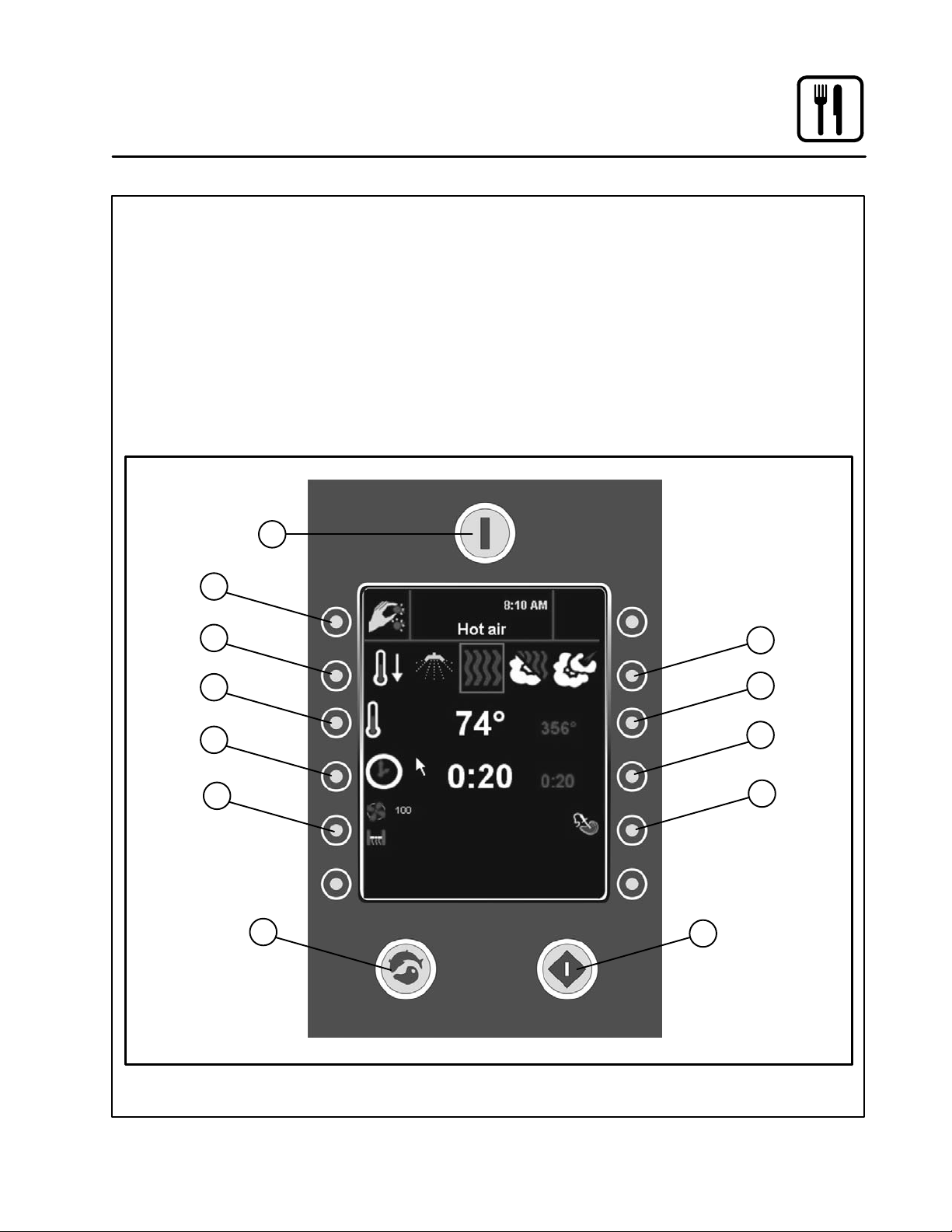

Operation

Work Menu

1. MAIN POWER SWITCH - controls power to

the oven

2. MAIN MENU KEY - press to move to main

menu

3. LEFT MODE SELECTION KEY - press to seĆ

lect mode to the left.

4. LEFT OVEN TEMP KEY - press to decrease

set temperature.

5. LEFT COOK TIME KEY - press to decrease

the set cook time

6. FAN & VENT KEY - press to access fan and

vent submenus

1

2

3

7. PROGRAM KEY - press to access program

menu

8. RIGHT MODE SELECTION KEY - press to seĆ

lect mode to the right.

9. RIGHT OVEN TEMP KEY - press to increase

set temperature.

10. RIGHT COOK TIME KEY - press to increase

the set cook time

11. CORE PROBE KEY - press to access core

probe setting submmenu

12. START/STOP KEY - press to begin or cancel

a cook cycle

8

4

5

6

7

Figure 8

12

9

10

11

15

Page 20

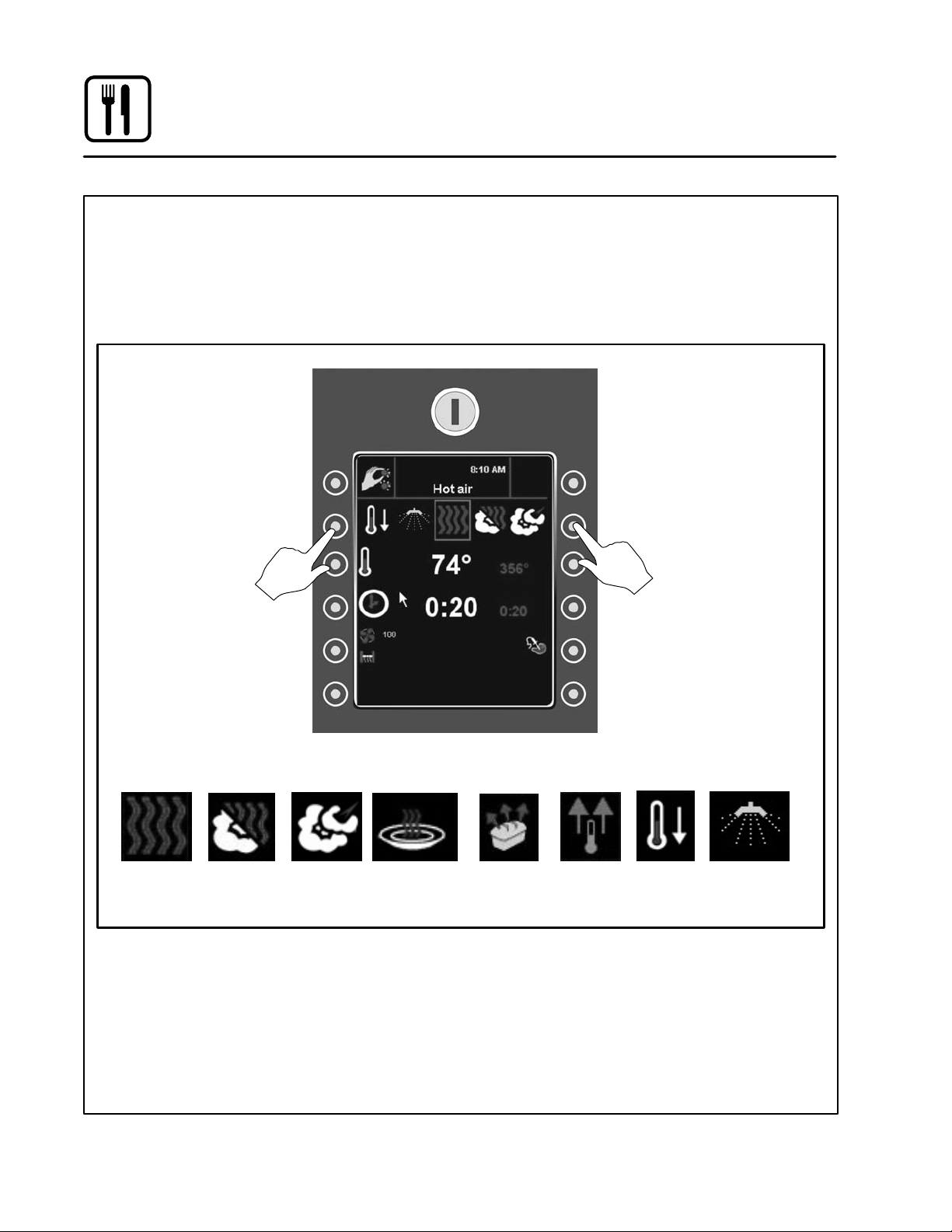

Operation

Manual Cooking

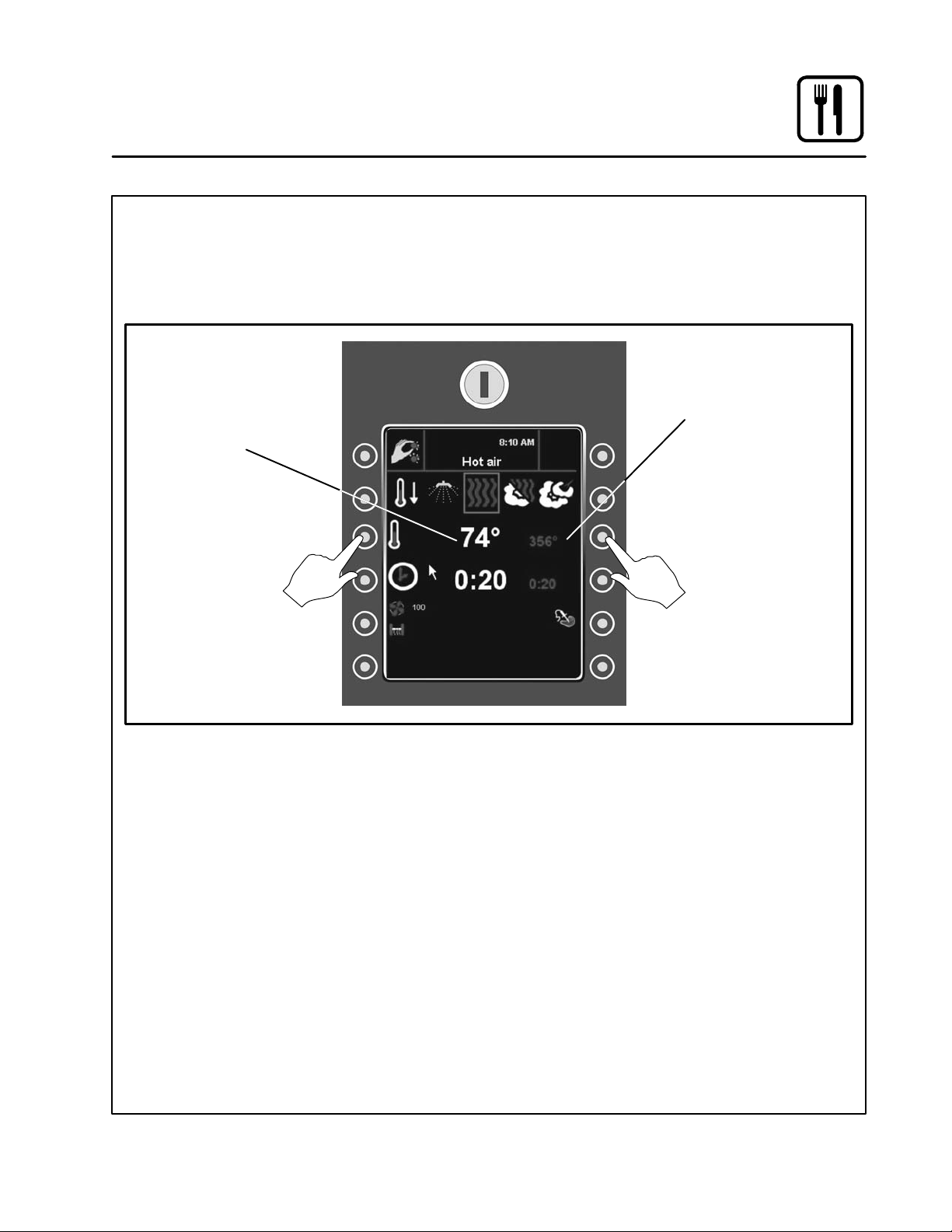

MODE SELECTION

1. Use the keys on the right and left of the mode

selection icons to select the desired mode.

NOTE: The selected icon will apper inside a red

box in the center of the screen.

Press this key to

scroll to the left

Setting Humidty Level in CombiOptima

If CombiOptima is selected you will need to enter

the desired humidity level. Follow the procedure

on page 12 to set the desired humidity level for

CombiOptima mode.

Press this key to

scroll to the right

Hot Air Combi

Optima

Choose from the following oven modes:

Steam Retherm Proofing Preheat Cool

Down

Figure 9

16

Combi

Wash

Page 21

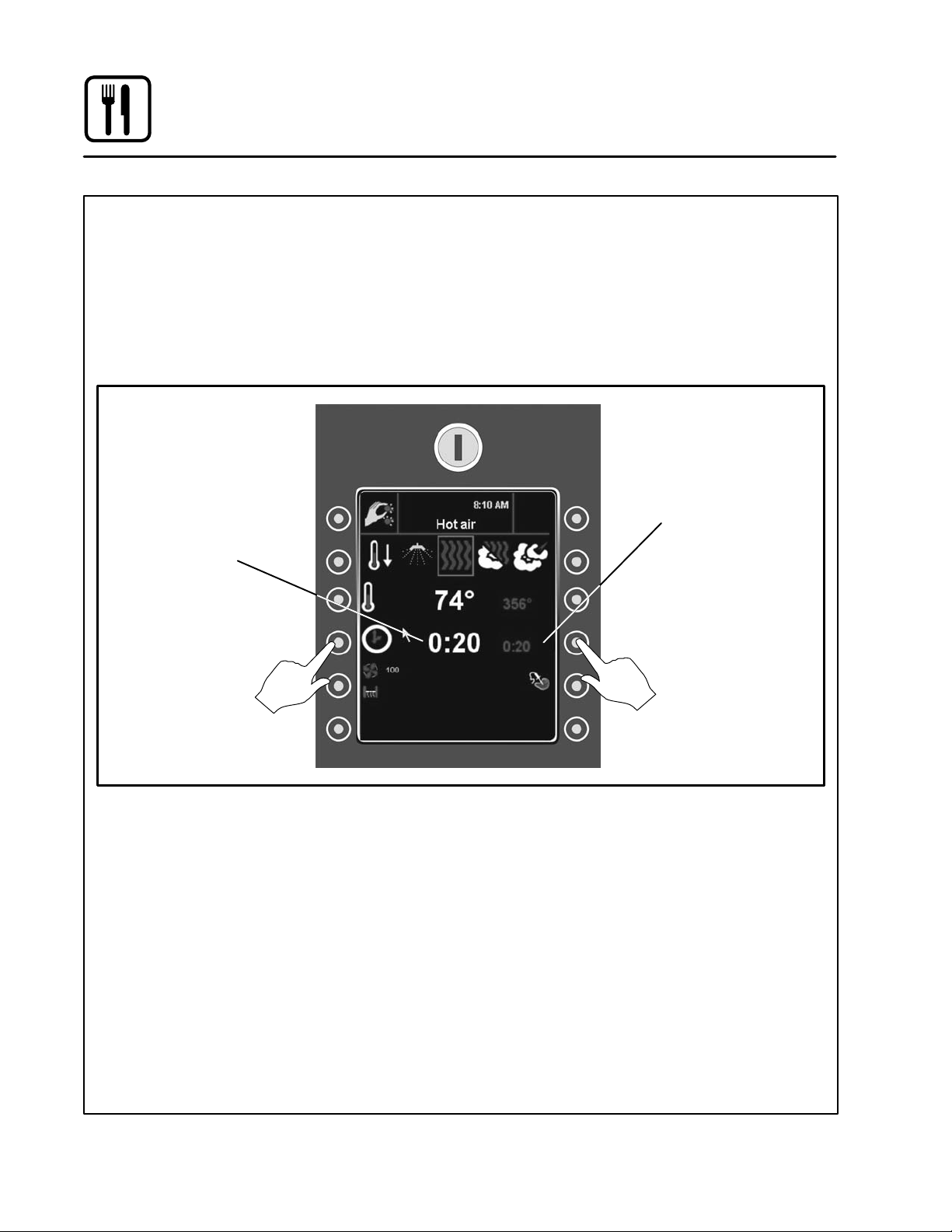

SETTING THE COOK TEMPERATURE

1. Use the 3rd keys down on the right or left to

set the desired cook temperature. The large

white number in the center of the screen disĆ

Operation

Manual Cooking

plays the actual oven temperature. The smallĆ

er red number on the right of the screen disĆ

plays the set temperature.

Actual oven

temperature

Press this key to

decrease set

temperature

Oven set

temperature

Press this key to

increase set

temperature

Figure 10

17

Page 22

Operation

Manual Cooking

SETTING THE COOK TIME

1. Use the 4th keys down on the right or left to

set the desired cook time. For continuous opĆ

eration, press the left key until the display

shown no time.

The smaller red number on the right of the screen

displays the set cook time.

Time

remaining

Once the cook cycle is activated, the large white

number in the center of the screen displays the

time remaining.

Oven set time

Press this key to

decrease set time

Press this key to

increase set time

Figure 11

18

Page 23

Operation

Manual Cooking

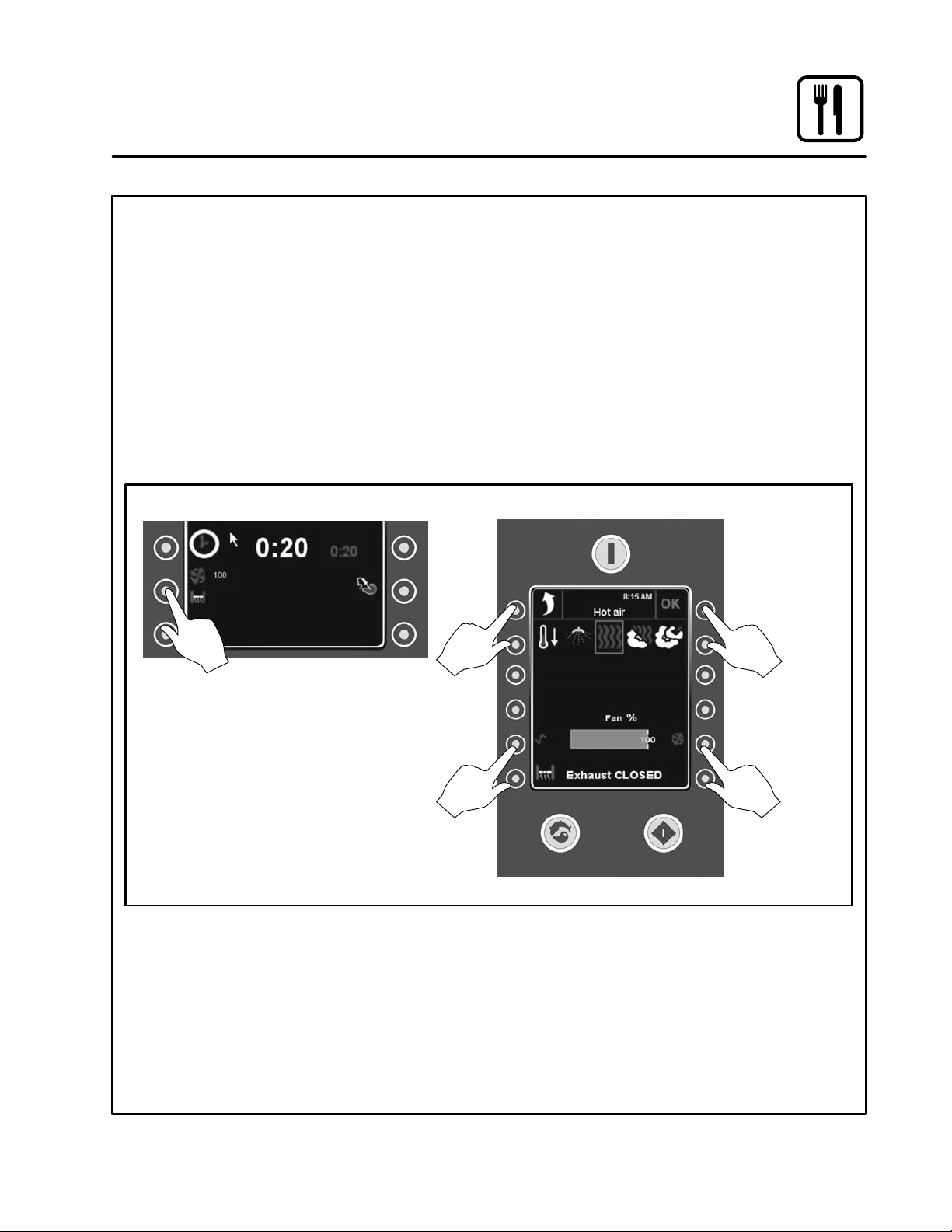

SETTING THE FAN SPEED

The fan function is active in HOT AIR, STEAM

and RETHERM only. In all other modes, the fan

is controlled automatically by the oven.

1. Press the FAN and VENT key to access the

FAN/VENT submenu.

2. Use the 5th keys down on the right or left to

set the desired fan speed.

NOTE: Note that the fan wheel is reversible. It will

run clockwise for a few minutes, then reĆ

verse and run counterclockwise. This

creates an even bake pattern.

Tips for setting fan speed

D A fan speed between 20 and 50% is recomĆ

mended for puff pastry, Danish pastry, cakes

and small products as well as in the DeltaĆT and

Cook & Hold modes.

D You should add 1 to 2 minutes of preparation

time for each 1/2 hour when low fan speed is

used.

D Fan speeds between 50% and 90% are recomĆ

mended for particularly juicy end products that

can accept longer cook times.

D Fan speeds below 50% cannot be used at temĆ

peratures above 390°F (200°C).

FAN/VENT SubmenuWORK Menu

Press this key

to access

FAN/VENT

submenu

Press this key

to cancel and

return to WORK

Menu

Press this key

to increase

fan speed

Press this

key to save

settings

Press this key

to decrease

fan speed

Figure 12

19

Page 24

Operation

Manual Cooking

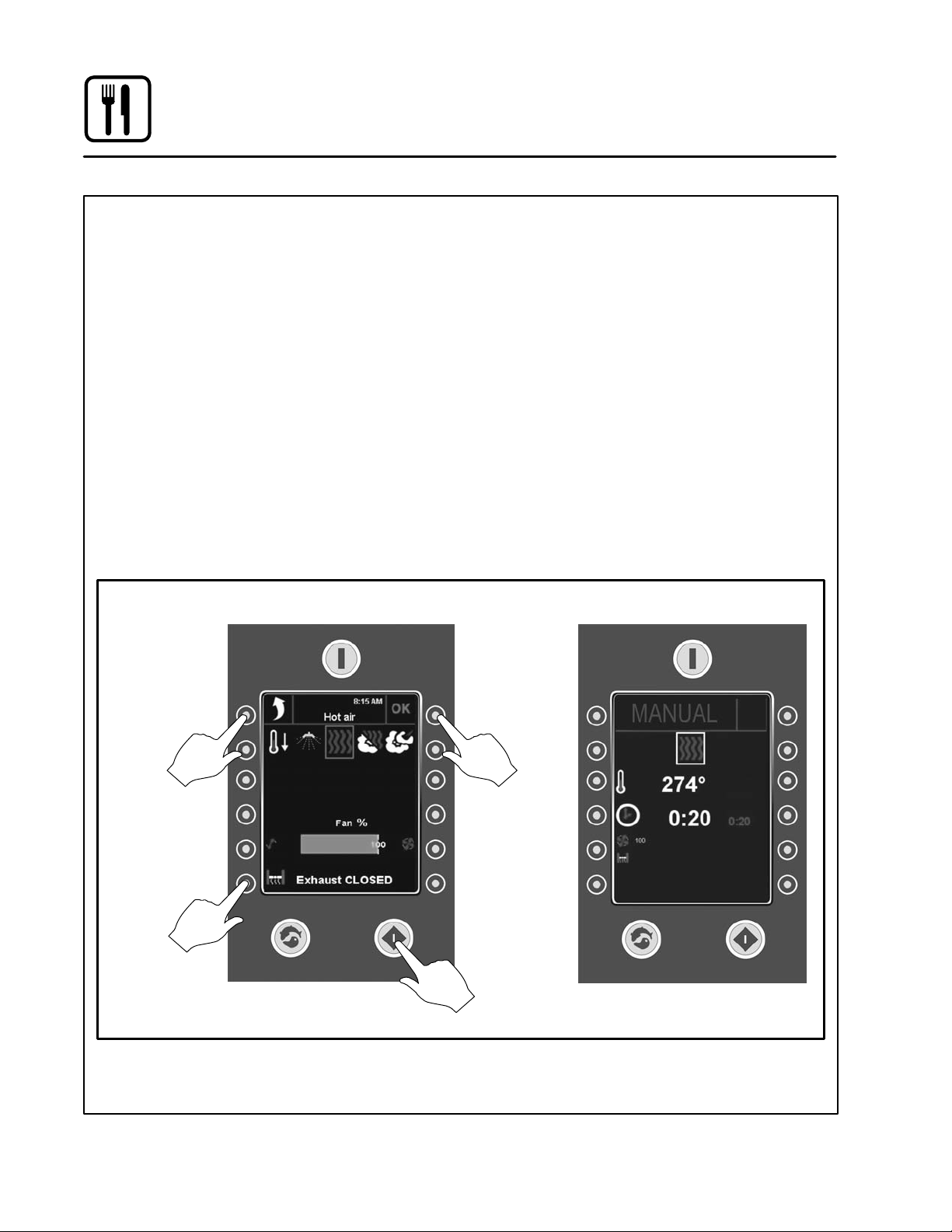

SETTING THE VENT POSITION

It is only possible to set the exhaust function in

the HOT AIR mode. In the other modes, the exĆ

haust function is controlled automatically by the

oven.

1. Press the VENT key to toggle between Vent

Open or Vent Closed.

Tips for setting vent position

D Open exhaust is recommended for bread and

pastry, as well as roasting meat and to achieve

a grill effect.

TO RETURN TO WORK MENU

1. Press the OK key on the top right to save your

settings and return to the WORK Menu. Press

the top right key to return the the WORK Menu

without saving your changes.

FAN/VENT Submenu

TO INITIATE MANUAL COOK CYCLE

1. From the WORK Menu, press the START/

STOP key located on the bottom left side of

the control to initiate the cook cycle.

2. The square around the mode will flash and the

display counts down the cook time. The cook

time, temperature, fan speed and vent posiĆ

tion may be changed during the cook cycle.

In Hot Air mode, press and hold the button on

the bottom right of the screen to inject steam.

Press any key to turn on the oven lights.

3. When there is one minute left, the computer

counts down from 59 seconds.

4. When the time has expired on the final stage,

an alarm sounds and a message appears noĆ

tifying you that the program is complete. Press

the key to the left of ENTER, or open the door,

to silence the alarm.

MANUAL COOK screen

Press this key

to cancel and

return to

WORK Menu

Press this key

to toggle the

vent open or

closed

Press this

key to save

settings

Press START/STOP key

to initiate cook cycle

Figure 13

20

Page 25

All Blodgett BCP ovens come standard with one

core temperature probe. It is possible to run two

core probes at the same time. An additional probe

may be purchased from your Blodgett dealer.

The core temperature sensor offers three cookĆ

ing modes.

D Active

D DeltaĆT

D Cook & Hold

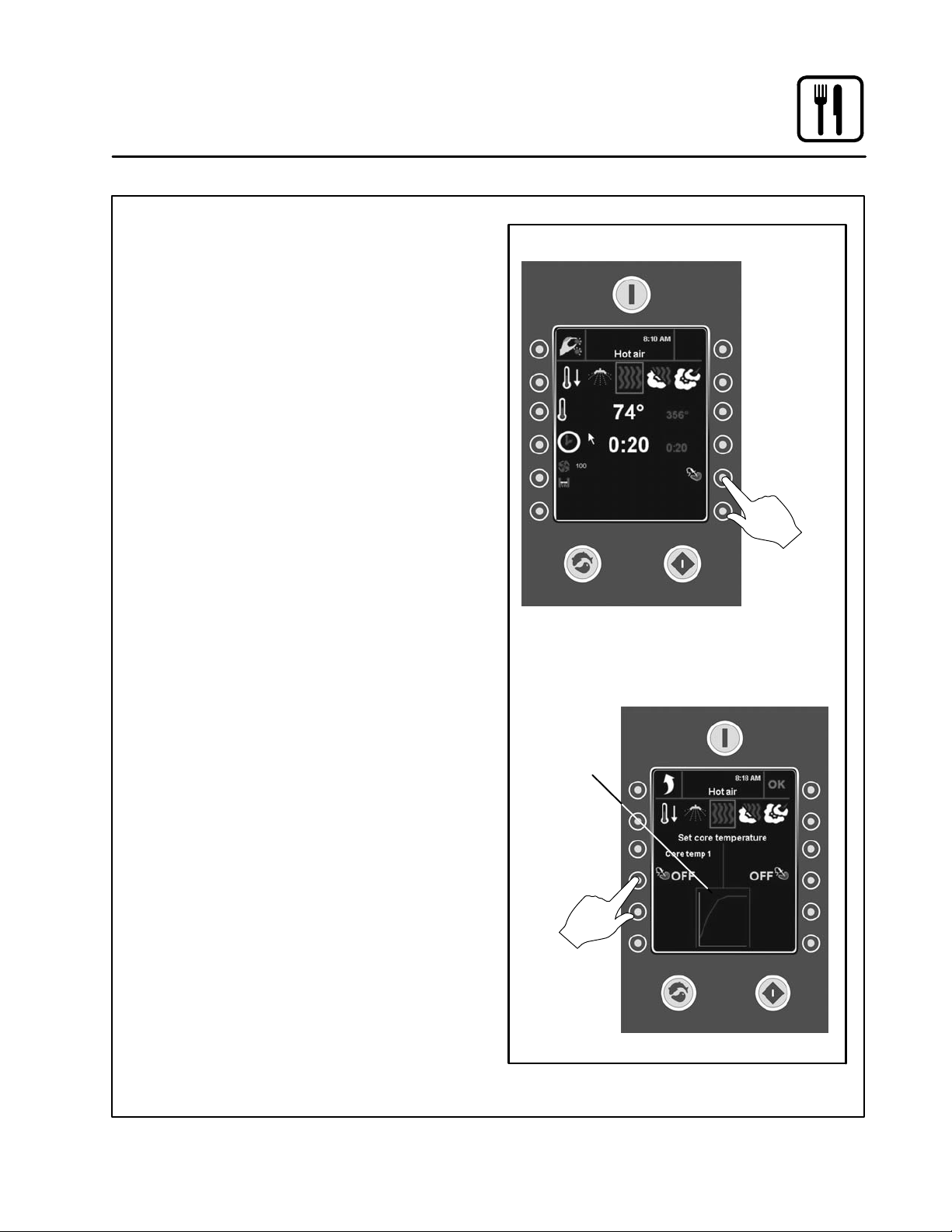

ENTERING CORE PROBE MODES

Follow this procedure for all three core probe

cooking modes.

NOTE: The core probe must be set up prior to acĆ

tivating a cook cycle.

1. Select the desired cooking mode Refer to

page 16 for instructions on setting the cooking

mode.

2. Set the desired fan speed if applicable. Refer

to page 19 for instructions on setting the fan

speed.

3. Set the vent position if applicable. Refer to

page 20 for instructions on setting the vent

position.

4. Insert the core probe into the center of the

product. Then plug the probe into the oven at

the connector located in the upper corner of

the right side panel.

5. Press the CORE PROBE key on the WORK

Menu. The control displays the Core Probe

submenu.

6. Press the key next to the core probe icon. The

control displays the Set Core Probe screen.

The graph on the display illustrates the differĆ

ence between the actual oven temperature

and core temperature. The blue line repreĆ

sents core temperature probe 1. Core probe

2 is green. The red line is the actual oven temĆ

perature.

Operation

Core Probe Cooking

WORK Menu

Press this

key to move

to the Core

Probe

submenu

CORE PROBE Submenu

Core probe

status graph

Press this

key to select

the first core

probe

21

Figure 14

Page 26

Operation

Core Probe Cooking

ACTIVE CORE PROBE COOKING

In the active mode, the core probe will notify you

when the product has reached the desired pull

temperature. The cook temperature is constant in

the active mode.

1. Follow steps 1Ć6 on page 21 to enter the core

probe cooking screens.

2. Use the keys on the left of the display to set

the desired core probe pull temperature. The

core probe set temperature is displayed in

red.

3. Press the OK key to save the save the desired

core probe temperature.

4. Press the START/STOP key to start the core

probe cook cycle.

5. When the product has reached the desired

core temperature an alarm sounds and the

SET CORE PROBE Screen

Press this key

to cancel and

return to WORK

Menu

display reads ENTER. Press the key next to

ENTER, or open the door, to silence the alarm.

6. Unplug the core probe and remove the prodĆ

uct.

COOKING WITH TWO CORE PROBES

When one of the probes reaches the desired core

temperature, an alarm sounds and a ENTER apĆ

pears in the display.

1. Press the key next to ENTER, or open the

door, to silence the alarm.

2. Take out the product and close the door.

3. The oven continues until the second probe

reaches the desired core temperature.

Press this key to

raise probe temp

Press this key to

lower probe temp

Press this key to

save your settings

Press this key to

start the core

probe cook cycle

Figure 15

22

Page 27

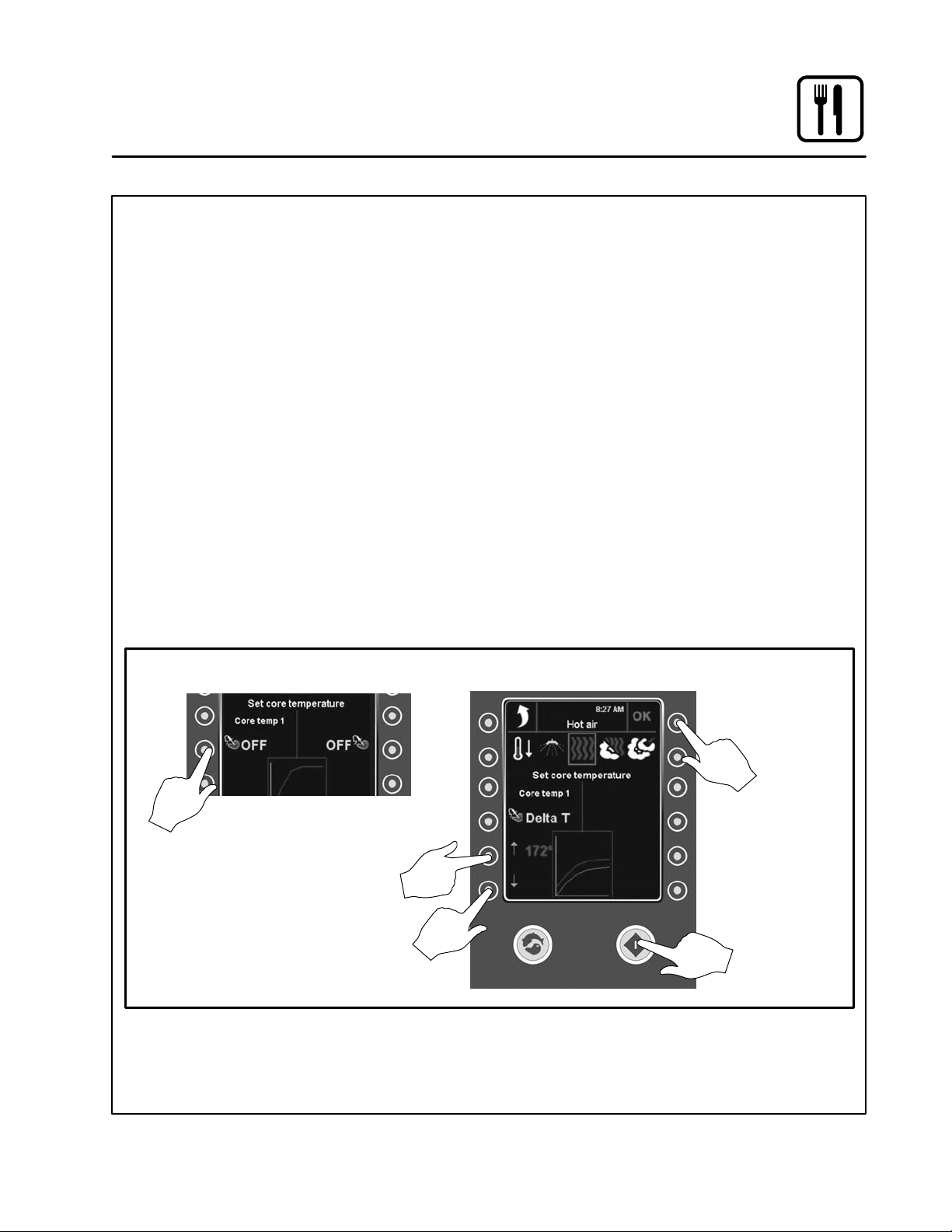

DELTAĆT COOKING

In the DeltaĆT mode the oven temperature adjusts

relative to the actual core temperature of the prodĆ

uct. DeltaĆT provides gentle cooking resulting in a

tender, juicy product. Cooking with DeltaĆT reĆ

duces shrinkage by up to 20% compared to tradiĆ

tional modes of cooking.

1. Follow steps 1Ć6 on page 21 to enter the core

probe cooking screens.

2. Press the CORE PROBE key on the WORK

Menu. The control displays the Core Probe

submenu.

3. Press the Core Probe key twice to access the

DeltaĆT cooking screen.

4. Use the keys on the left of the display to set

the desired core probe pull temperature. The

core probe set temperature is displayed in

red.

5. Press the OK key to save the save the desired

core probe temperature.

6. Press the START/STOP key to start the DeltaĆT

cook cycle.

Operation

Core Probe Cooking

7. When the product has reached the desired

core temperature an alarm sounds and the

display reads ENTER. Press the key next to

ENTER, or open the door, to silence the alarm.

8. Unplug the core probe and remove the prodĆ

uct.

Tips for DeltaĆT Cooking

D For best results start with an oven temperature

of 85Ć100°F (30Ć40°C).

D HOT AIR mode is recommended for very fatty

and small roasts. STEAM mode is recomĆ

mended for large hams with bones. RETHERM

mode is recommended for poultry and other

lean pieces of meat.

Recommended Core Temperatures

D Rare 125Ć135°F (52Ć57°C)

D Medium 140Ć145°F (59Ć62°C)

D Well Done 160Ć185°F (72Ć85°C)

Press this

key twice

to access

the DeltaĆT

screen

SET CORE PROBE Screen

Press this

key to raise

probe temp

Press this key to

lower probe temp

DELTAĆT Cooking Screen

Press this key to

save your settings

Press this key

to start the

DeltaĆT

cook cycle

Figure 16

23

Page 28

Operation

Core Probe Cooking

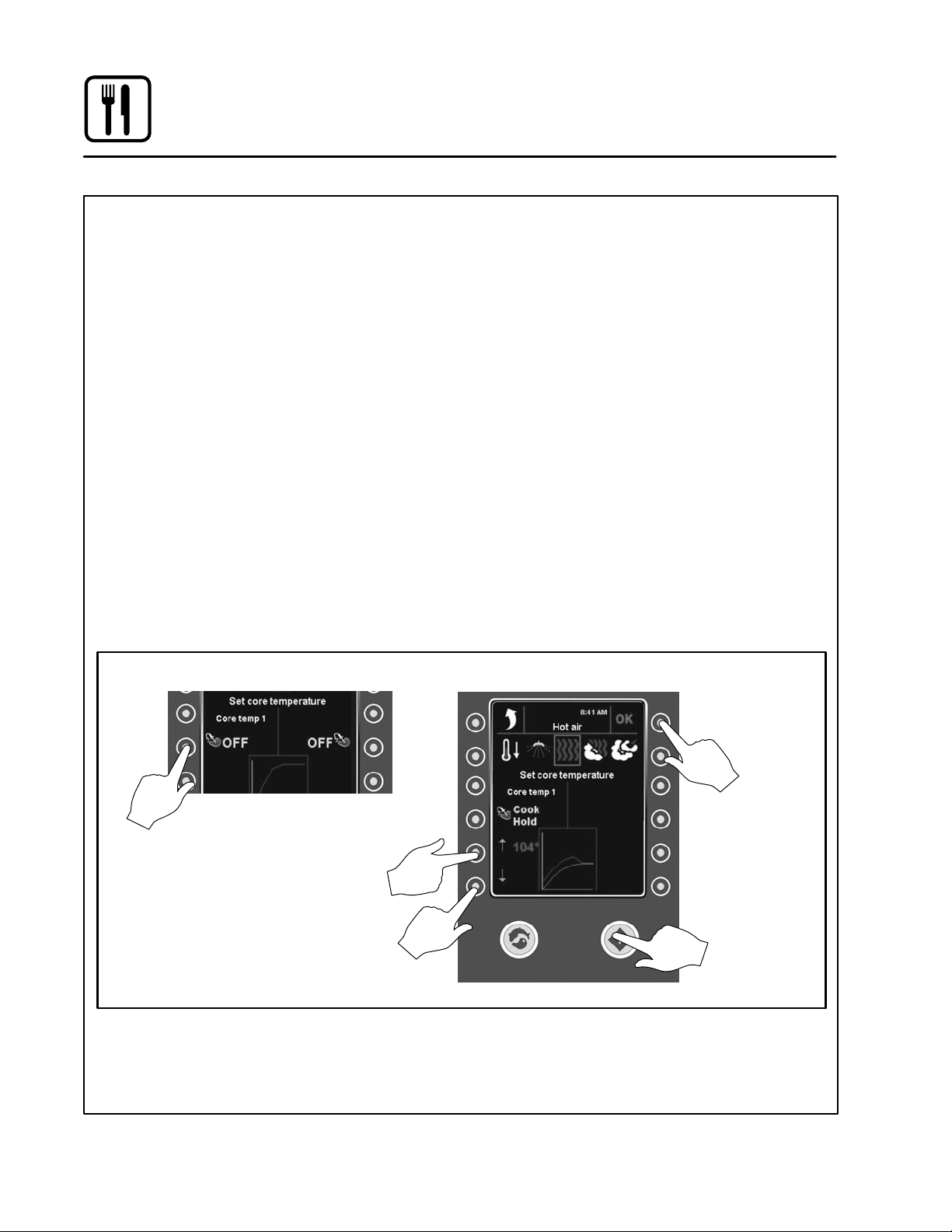

COOK & HOLD

Cook & Hold is an extension of DeltaĆT cooking.

The oven temperature adjusts relative to the actuĆ

al core temperature of the product. When the deĆ

sired core temperature is reached, the oven adĆ

justs the cavity to maintain the core temperature,

acting as a warming mode. Cook & hold is suitable

for roasting over night when the staff is off duty.

1. Follow steps 1Ć6 on page 21 to enter the core

probe cooking screens.

2. Press the CORE PROBE key on the WORK

Menu. The control displays the Core Probe

submenu.

3. Press the Core Probe key three times to acĆ

cess the Cook & Hold cooking screen.

4. Use the keys on the left of the display to set

the desired core probe temperature. The core

probe set temperature is displayed in red.

5. Press the OK key to save the save the desired

core probe temperature.

6. Press the START/STOP key to start the Cook

& Hold cook cycle.

7. When the product has reached the desired

core temperature the display will read

HOLD??? and the oven will adjust the cavity

temperature to maintain the core probe temĆ

perature.

8. Unplug the core probe and remove the prodĆ

uct when ready to serve.

Tips for Using Cook & Hold

D Recommended holding temperature is

140Ć150°F (60Ć65°C). At higher temperatures a

gradual dehydration of proteins takes place, the

weight of the meat is reduced and the meat beĆ

comes less juicy.

D With a hold temperature of 140Ć150°F

(60Ć65°C), the meat can be taken out immediĆ

ately before carving.

D After being held for 5Ć6 hours shrinkage inĆ

creases.

Press this

key three

times to

access

the Cook &

Hold screen

SET CORE PROBE Screen

Press this

key to raise

probe temp

Press this key to

lower probe temp

COOK & HOLD Screen

Press this key

to save your

settings

Press this key

to start

Cook & Hold

Figure 17

24

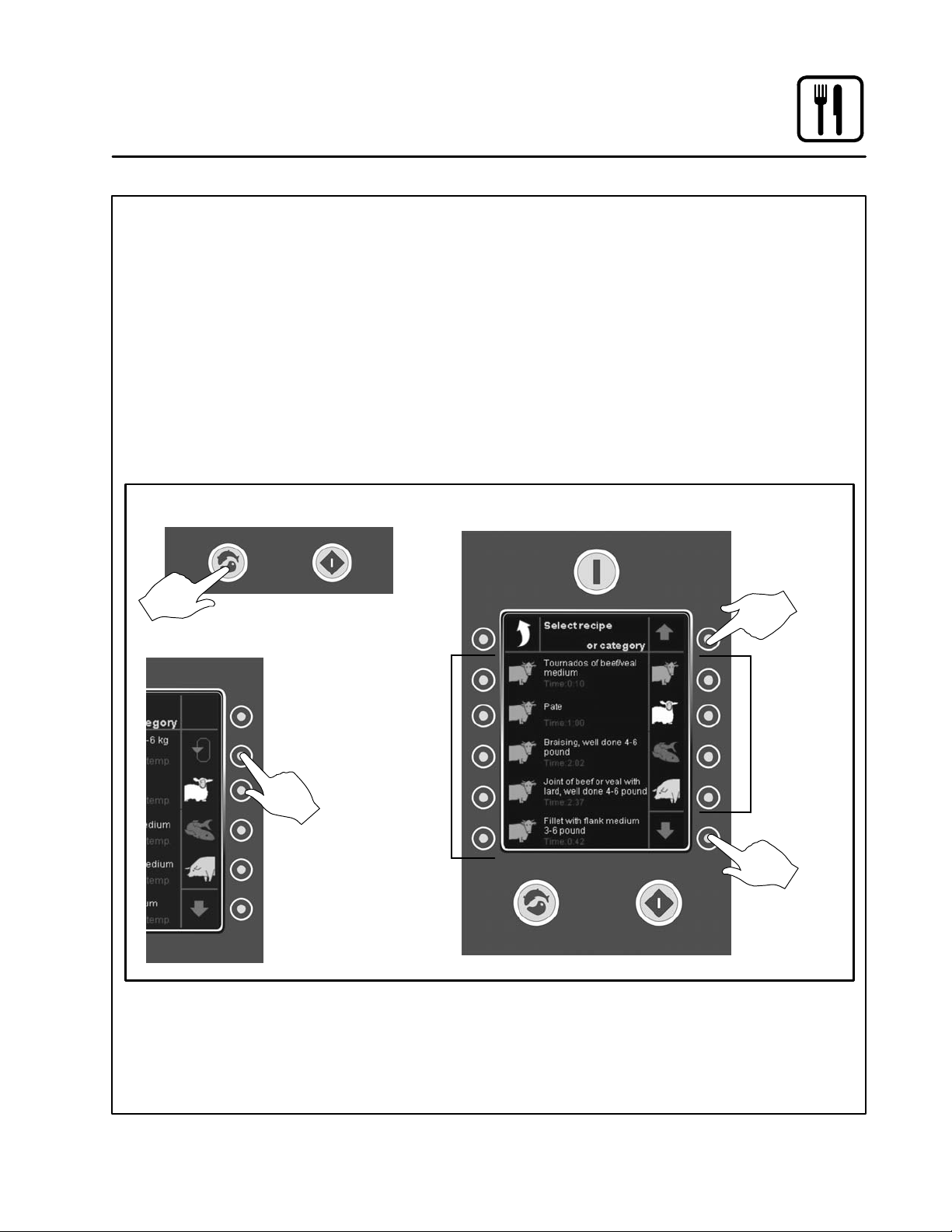

Page 29

Operation

Programmed Cooking

BCP ovens can store 200 product programs with

10 cooking stages each. Products are grouped

into categories (beef, chicken, bread, etc.) for

easy retrieval. Use the following procedure to

cook using a preĆprogrammed product recipe.

1. Press the PROGRAM key located on the botĆ

tom right of the control. The Program submeĆ

nu is displayed.

The right side of the display shows the product

categories. The green arrow at the bottom inĆ

ducates there are more categories than disĆ

played.

The left side of the display shows the recipes

in the current category

Bottom of BCP Control

Press this key to access

the Program submenu

2. If the desired category is not visible, press the

key next to the green arrow to display addiĆ

tional categories.

3. Press the key next to the desired product cateĆ

gory.

4. The product programs in the choosen categoĆ

ry are displayed on the right side of the screen.

If the category has more than 5 products a

scroll key will appear at the top of the category

list. Press this key to scroll through the prodĆ

uct programs in the category.

PROGRAM Submenu

Press this key

to display

additional

categories

Product

Program

keys

Press to scroll

through all product

programs within a

category

Product

Category

keys

Press this key

to display

additional

categories

Figure 18

25

Page 30

Operation

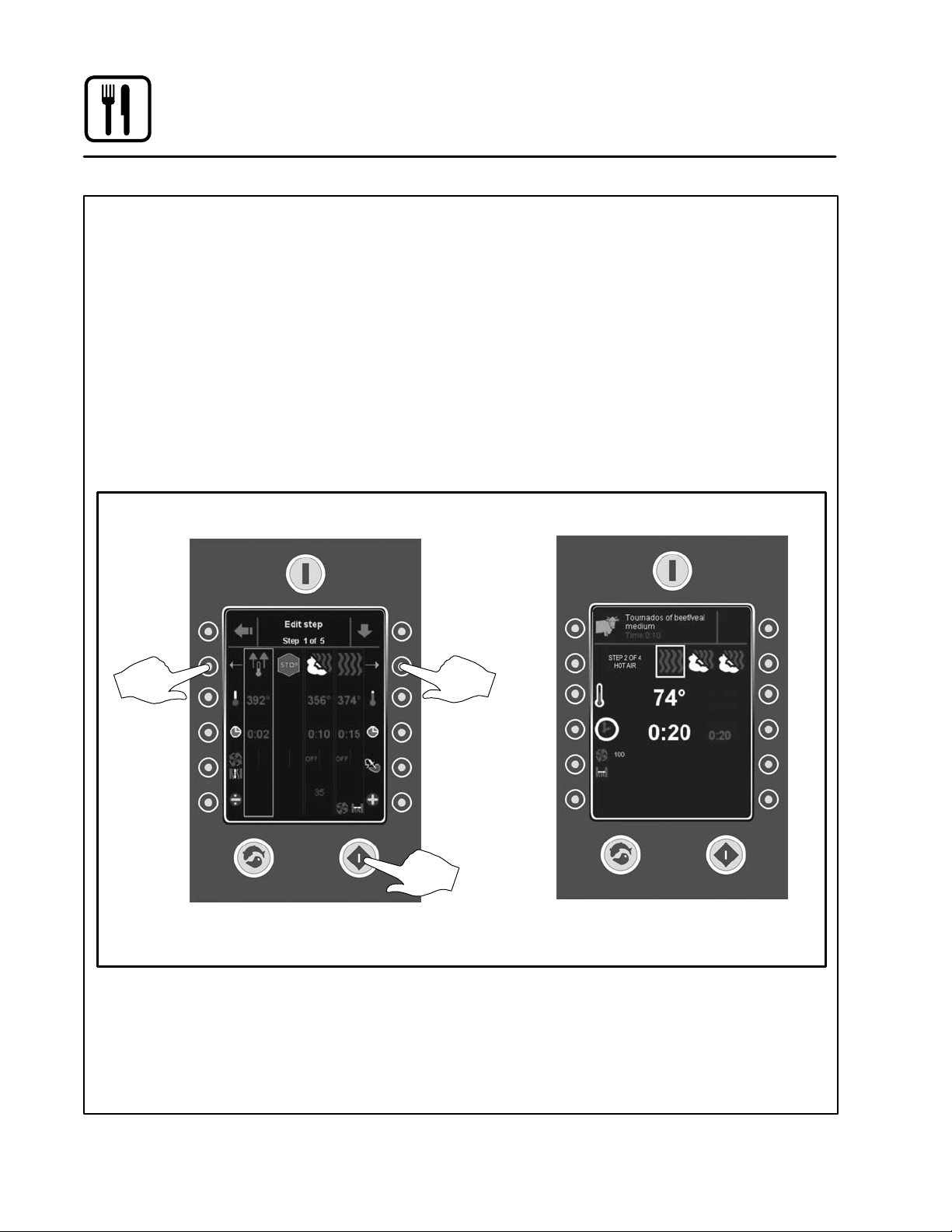

Programmed Cooking

5. Press the key next to the desired product proĆ

gram. The display changes to the Edit Step

screen. This screen gives the operator the

chance to change the cook temperature, time,

fan speed, vent and humidity level (if applicaĆ

ble) for any stage of the program. Changes

made will be for the current bake only. The

program will not be changed for future bakes.

6. Press the START/STOP key to initiate the proĆ

grammed cook cycle. The display shows the

Program Cooking screen.

NOTE: If the first stage of the program is a preĆ

heat, an alarm sounds at the end of the

stage and a message appears notifyĆ

EDIT STEP Screen

ing you that the preheat is complete..

Press the key next to ENTER to silence

the alarm and proceed to stage 2.

7. The square around the mode for the current

stage will flash and the display counts down

the cook time.

8. When there is one minute left in each stage,

the computer counts down from 59 seconds.

9. When the time has expired on the final stage,

an alarm sounds and a message appears noĆ

tifying you that the program is complete. Press

the key to the left of ENTER, or open the door,

to silence the alarm.

10. The control returns to the WORK Menu.

PROGRAM COOKING Screen

Press to

return to

settings

for the

previous

stage

The yellow box indicated the current

stage in edit mode.

Press to

move to

settings for

the next

stage

Press to start

product

program

Figure 19

26

Page 31

Operation

Programming a Product

Use the following procedure to create a new prodĆ

uct program or edit an existing program.

1. Press the MAIN MENU key in the upper left

corner to advance the control to the main

menu.

2. Press the EDIT PROGRAM key on the MAIN

menu.

If, when one of the functions in the main menu

is activated, a screen appears asking for a

WORK Menu

Press

to go to

MAIN

Menu

code, this function is blocked. You need a

code to access. Select enter code, press

876412 and confirm by pressing OK in the upĆ

per right corner.

3. To create a new product recipe, press the

NEW RECIPE key. To edit an existing product

recipe, follow the procedure on page 25 to seĆ

lect the product program to be edited.

MAIN Menu

Press to

edit or

create a

program

Press to

create

a new

program

Figure 20

27

Page 32

Operation

Programming a Product

4. The Edit Program screen is displayed. This is

the main screen for creating and editing prodĆ

uct programs.

Naming or Renaming the Product Program

5. Press the Change Text key on the Edit ProĆ

gram screen. The ENTER TEXT screen is disĆ

played.

NOTE: Skip this step if you are editing an exĆ

isting program and do not need to

change the name.

EDIT PROGRAM Screen

Press to

cancel

6. Use the keys on the right and left of the screen

to enter a new name, or edit an existing prodĆ

uct name. below for details.

Press the green arrow key on the top right at

any time to cancel the edit and return to the

EDIT PROGRAM screen without saving your

changes.

7. Press the OK key to save your changes. The

display return to the EDIT PROGRAM screen.

ENTER TEXT Screen

Press to

save

name

Press to move cursor

to the left

Press to selects next letter to the left

Press to move quickly to the left

Press to select upper or lower

case letter

Press to erase letter to the left Press to write a

Figure 21

28

Press to move

cursor to the right

Press to select next

letter to the right

Press to move

quickly to the right

letter in a red box

Page 33

Operation

Programming a Product

Selecting or Changing the Product Category

8. Press the CHANGE ICON key on the Edit ProĆ

gram screen. The SELECT CATEGORY

screen is displayed.

NOTE: Skip this step if you are editing an exĆ

isting program and do not need to

change the category.

9. Use the keys on the right and left of the screen

to select the desired product category. See

below for details.

EDIT PROGRAM Screen

Press the green arrow key on the top right at

any time to cancel the edit and return to the

EDIT PROGRAM screen without saving your

changes.

10. Press the OK key to save your changes. The

display return to the EDIT PROGRAM screen.

SELECT CATEGORY Screen

Press to

save

category

Press to cancel

Press keys to move yellow

box to the left

Press keys to

move yellow

box to the left

Figure 22

29

Page 34

Operation

Programming a Product

Creating or Changing the Product Program

Cooking Steps

11. Press the CHANGE STEPS key on the Edit

Program screen. The EDIT STEP screen is

displayed.

NOTE: Skip this step if you are editing an exĆ

isting program and do not need to

change the program for any of the

cooking steps.

12. If programming a new product be aware that

the control will provide three steps automatiĆ

cally:

The 1st step is a preheat. Use the keys to the

left and right to set the desired preheat temĆ

perature and time.

The 2nd step is a stop. This step will sound an

alarm when the preheat step is complete alertĆ

ing the operator that the oven is ready to acĆ

cept product.

The 3rd step contains a default cook program

that you can modify as needed.

13. Press one of the top two keys to scroll the yelĆ

low box to the 3rd step.

NOTE: If editing an existing program, use

these keys to select the step to be

edited.

14. Press the green arrow down key to advance

to the EDIT STEP CHANGE FUNCTION

screen.

15. The mode for the selected step appears in a

yellow box on the top row. Press the keys on

the right and left of the bottom row until the deĆ

sired mode appears inside the red box.

16. Use the keys to the side of the middle row to

select either add, delete or change

ADD - Use Add to add a new step. The green

line next to the current step indicates where

the new step will be inserted. Use the keys to

the right and left to move the green line if necĆ

essary.

DELETE - Use Delete to remove the current

highlighted step.

CHANGE - Use Change to modify the mode

of the current highlighed step.

17. You may have up to 10 cooking steps. PreĆ

heat, Stop and Cool Down do not count as

cooking steps. Once all steps have been addĆ

ed, deleted or changed, press the green up

arrow key to return to the EDIT STEP screen.

18. To edit the cooking parameters, scroll the yelĆ

low box to the step to be edited.

19. Use the keys on the side to set the desired

temperature, time, fan speed, vent postion

and humidity (if applicable) for the selected

step. You may also program a core probe

cook. See the directions for core probe cookĆ

ing on pages 21 through 24.

20. When all steps are correct, press the green

side arrow at the top left of the screen to return

to the EDIT PROGRAM screen.

Saving the Product Program

21. Press the SAVE key to save your program to

the oven control.

Exiting Program Mode

22. Press the green side arrow at the top left of the

screen three times to return to the WORK

menu.

30

Page 35

Operation

Programming a Product

EDIT PROGRAM Screen

Yellow box indicates current

stage in edit mode.

EDIT STEP CHANGE FUNCTION Screen

Press to select the desired mode

Press to select Add, Delete or Change

Press to select step to be modified

EDIT STEP Screen

Press to move to

EDIT STEP CHANGE

FUNCTION screen

Press to scroll

the yellow box

to the left

Use these keys to lower

the temperature, time, fan

speed, vent postion and

humidity (if applicable) for

the current step.

Press to scroll

the yellow box

to the right

Use these keys to raise

the temperature, time, fan

speed, vent postion and

humidity (if applicable) for

the current step.

Figure 23

31

Page 36

Operation

Setting a Timed Start

Timer Start makes it possible to start the oven beĆ

fore staff arrives. This way, the oven will be hot

when you come in in the morning.

1. Press the MAIN MENU key in the upper left

corner to advance the control to the main

menu.

2. Press the TIMED START key on the MAIN

menu. The Timer Start screen is displayed.

WORK Menu

Press to go to

MAIN Menu

MAIN Menu

Press for single

instance timed

start

Press for daily

timed start

Press to select

product program

to use

See page 33 for instructions on programming

a single timed start.

3. Choose between START TIME (for a single

instance timed start) or DAILY START (to proĆ

gram a daily timed start). See page 34 for inĆ

structions on programming a daily timed start.

TIMER START Screen

Press to

set a timer start

Press to activate

the timer

Figure 24

32

Page 37

Single Instance Timed Start

1. The control displays the Starting Time screen.

2. Use the side arrow keys to select the parameĆ

ter to set. The current parameter is indicated

by the red box.

3. Use the up and down arrow keys to change

the current parameter.

NOTE: Set only the date, disregarding month

and year.

4. Press the OK key to save your settings and reĆ

turn to the TIMER START screen.

5. Press the RECIPE key to select the Product

Program to run with the timed start. See page

25 for instructions on selecting a product proĆ

gram.

STARTING TIME Screen

Operation

Setting a Timed Start

6. Press the STATUS key to activate the timed

start.

7. When time setting is complete, press OK toĆ

save your settings and return to the Main

Menu.

8. Press the main power switch to turn off the

oven. The oven restarts automatically when

the set date and time is reached. The door

must be closed while TIMER START is acĆ

tive.

NOTE: You may activate the timer and not

turn off the oven until you have finished

for the day.

Press to go to MAIN

Menu without saving

settings

Press to move selection

box to the left

Press to decrease date

or time

Press to go to

accept settings

Press to move selection

box to the right

Press to increase date

or time

Figure 25

33

Page 38

Operation

Setting a Timed Start

Daily Timed Start

1. The control displays the DAILY START screen.

2. If the clock next to a day is red, that day is not

currently active. If the clock is green, a daily

timer is currently active for that day.

To activate all 7 days at once press the DAILY

TIMER key on the right of the screen.

3. Use the keys to on the right side of the screen

to change the start time for each day.

4. Press the OK key to save your settings and reĆ

turn to the TIMER START screen.

5. Press the RECIPE key to select the Product

Program to run with the timed start. See page

25 for instructions on selecting a product proĆ

gram.

DAILY TIMER Screen

6. Press the STATUS key to activate the timed

start.

7. When time setting is complete, press OK toĆ

save your settings and return to the Main

Menu.

8. Press the main power switch to turn off the

oven. The oven restarts automatically when

the set date and time is reached. The door

must be closed while TIMER START is acĆ

tive.

NOTE: You may activate the timer and not

turn off the oven until you have finished

for the day.

Press to return to

MAIN Menu without

saving settings

Press to go to

accept settings

Press to activate all 7

days at once

Press to increase

the time

Press to decrease

the time

Figure 26

34

Page 39

Operation

Setting Preset Time & Temperature

You can make changes to the preset time and temĆ

perature in all modes except CombiWash.

NOTE: Core temperature, fan/exhaust and Combi

Optima (humidity content) cannot be set in

this menu.

1. From the Work menu select the mode to preĆ

set. Enter the desired preset time and temperĆ

ature. See pages 16 through 18 for selecting

mode, time and temperature.

2. When all 3 parameters have been entered.

press the MAIN menu key on the top left.

WORK Menu

Press to

access

MAIN

Menu

3. Press the PRESELECTION key on the left side

of the screen. The Preselection screen is disĆ

played.

4. Verify the mode, time and temperature are

correct.

5. Press the OK key to accept the parameters

and return to the Main menu.

6. Press the Arrow key at the top left of the screen

to return to the Work menu.

7. Repeat this procedure for any additional cookĆ

ing modes.

PRESELECTION Screen

MAIN Menu

Press to

access Preselection screen

Press to

return to

MAIN

Menu

without

saving

settings

Figure 27

35

Press to

accept

preset

parameters

Page 40

Operation

Oven Setup

1. Press the MAIN MENU key in the upper left

corner to advance the control to the main

menu.

2. Press the OVEN SETUP key on the MAIN

menu. The Oven Setup menu is displayed.

SETTING THE LANGUAGE

1. Press the LANGUAGE key on the left of the

screen.

2. Select the key next to the desired language.

Only ten languages are displayed at one time.

To view additional languages press the down

arrow key at the top right of the screen.

3. Once the new language is selected all text on

the screen is automatically translated. There

is no need to accept the change.

SETTING THE OVEN ALARM

1. Press the ALARM SOUND key on the right

side of the control. The display changes to the

Alarm Sound screen.

2. Use the keys on the left and right of the control

to adjust the alarm volume, frequency and

duration.

3. Press the OK key in the top right corner of the

display to save the changes. The control reĆ

turns to the Oven Setup menu.

SETTING THE OVEN TIME

1. Press the SET TIME key on the right side of the

control.

2. Use the side arrow keys to select the parameĆ

ter to set. The current parameter is indicated

by the red box.

3. Use the up and down arrow keys to change

the current parameter.

NOTE: Set only the date, disregarding month

and year.

4. Press the OK key to save your settings and reĆ

turn to the Oven Setup menu.

SETTING THE OVEN SETUP

WARNING!!

Incorrect changes to the set up of the

oven may have a serious effect on its reliĆ

ability in service. Contact your Blodgett

service agent before making any

changes.

1. Press the OVEN SETUP key on the right of the

screen.

2. Select the oven parameter with the the vertical

arrows on the right of the screen. Change the

parameter using the horizontal arrows at the

bottom of the screen.

3. When all parameters are set, press the OK key

at the top right of the screen. The control reĆ

turns to the Oven Setup menu.

36

Page 41

WORK Menu

Press to

return to

MAIN Menu

Operation

Oven Setup

OVEN SETUP Menu

Press to

access

MAIN

Menu

MAIN Menu

Press to set

language

Press to

access

CombiNet

Press to

access OVEN

SETUP screen

Press to

set oven

alarm

Press to

set clock

Press to

access

oven setĆ

up paramĆ

eters

Figure 28

37

Page 42

Operation

USB Functions

The Blodgett BCP comes standard with a USB

port located underneath the control compartment.

The USB will enable upload and download of

product recipes as well as HACCP data.

To Access USB Menu

1. Insert the USB card into the slot below the

control compartment.

2. From the MAIN menu, press the SERVICE key.

The USB Menu is displayed.

MAIN Menu

Press to access

SERVICE screen

To Backup System Data

1. Press the key labelled Take Backup on the left

side of the USB screen.

2. The control briefly displays the files to be

backed up including product recipe proĆ

grams, counters, error logs, oven setup and

Combi Optima data.

3. Data files are automatically named according

to the year, month, date and time they were

saved.

4. When backup is complete, the control returns

to the SERVICE menu.

SERVICE Menu

Press to

access USB

screen

Press to back up

oven data USB

Press to back up

restore a previous

data backup

Press to read files on

USB key and test

connection to computer

USB Screen

Press to copy

recipes from USB

to oven

Press to copy

recipes from oven

to USB

Figure 29

38

Page 43

Operation

USB Functions

To Restore System Data from USB

1. Press the key labelled Retrieve Backup on the

left side of the USB screen.

2. Backup data is stored by oven serial number.

If the same USB key is used for more than one

oven, be sure to select the correct serial numĆ

ber.

3. Select the data file to be restored. Data files

are automatically named according to the

year, month, date and time they were saved.

4. Press the OK button in the upper right corner

of the display to restore the selected data file.

5. Use the MAIN POWER key at the top of the

control to reboot the oven.

Copy Recipes from USB to Oven

1. Press the key labelled Get Recipes from USB

on the right side of the USB screen.

2. Select the recipes to be copied to the oven.

See Figure 30.

NOTE: The control displays the product cateĆ

gories in yellow as folders. Individual

program recipes are displayed in

white.

3. Press the OK button in the upper right corner

of the display to accept the recipes to be copĆ

ied.

4. The RECIPE ACCEPT screen is displayed.

Press ADD to add the selected product proĆ

grams to the oven. Press OVERWRITE to overĆ

write existing programs with the recipes on

the USB.

Copy Recipes from Oven to USB

1. Press the key labelled Send Recipes to USB

on the right side of the USB screen.

2. Select the location on the USB folder to save

the product recipes. You may overwrite an exĆ

isting file or create a new file with a name

matching the serial number of the oven.

3. Press the OK button in the upper right corner

of the display to copy the recipes from the

oven to the USB.

Press to

select or

deselect

individual

recipes

RECIPE UPLOAD Screen UPLOAD ACCEPT Screen

Press to copy

selected

recipes to

oven

Press to

scroll up

Press to

select all

recipes

Press to

deselect

all recipes

Press to

scroll down

Figure 30

Press to

add recipes

Press to

overwrite

existing

recipes

39

Page 44

Operation

HACCP Library

The Blodgett BCP comes standard with HACCP

data recording. HACCP enables you to control

and document production. Data recorded inĆ

cludes production time. production duration,

preparation temperature and core temperature.

The HACCP library can hold approximately 1000

log files. You will be notified when the memory is

full so that you can empty the memory with the

USB. If nothing is done, the computer will autoĆ

matically start to overwrite the oldest files.

To Activate HACCP Data Recording

NOTE: HACCP data is stored under product recĆ

ipe names. Therefore, HACCP is not availĆ

able for manual cooking.

HACCP must be activated to record data.

1. Press the MAIN menu key in the upper left corĆ

ner of the WORK menu to advance the control

to the main menu.

2. Press the HACCP key on the left side of the

control to access the HACCP menu.

3. Be sure that Active appears in the status bar

at the bottom of the control. If the status is inĆ

active, press the key on the left of the status

bar to toggle to Active.

To View HACCP Data

1. From the HACCP menu, press the key laĆ

belled either Show HACCP from Oven or

Show HACCP from USB. See Figure 31.

2. A list of HACCP log files is displayed. The files

are logged by year, month, date and product

name. Use the UP and DOWN ARROW keys

to scroll through the list until the desired

HACCP file is highlighted.

3. Press the OK key in the upper right of the conĆ

trol to display the HACCP chart. See

Figure 31.

4. Press the RETURN key at the top left of the

screen to return to the HACCP screen.

To Backup HACCP Data

1. From the HACCP menu, press the key laĆ

belled Archive on USB. See Figure 31.

2. The displays reads SAVING HACCP.

3. When the data is saved to the USB the control

returns to the HACCP screen.

NOTE: The HACCP data on the USB can be loĆ

cated in the folder with the name of the

oven serial number.

To Delete HACCP Data from the Oven

1. From the HACCP menu, press the key laĆ

belled Delete HACCP Data from Oven. See

Figure 31.

2. The screen will ask you to confirm that you

want to delete all HACCP files. Press the key

next to Accept to delete the files. Press the key

next to Regret to cancel.

3. The control returns to the HACCP screen.

40

Page 45

Operation

HACCP Library

Press to move

to MAIN menu

Press to access

HACCP Menu

WORK Menu

MAIN Menu

HACCP Menu

HACCP DATA Chart

Press to return

to HACCP menu

HACCP DATA CHART COLOR KEY:

Red line Preset temp.

White lIne Current oven temp.

Vertical blue line Door opened

Light green line #1 (left) core probe temp.

Light yellow line #2 (right) core probe temp.

Figure 31

41

Page 46

Operation

Optional CombiNet

The optional CombiNet feature allows you run the

oven remotely from a pc. This is useful for writing

product recipes as well as viewing and downloadĆ

ing HACCP and other oven data with the conveĆ

nience of a large screen and keyboard.

CONNECTING TO A NETWORK OR PC

NOTE: CombiNet requires the installation of Java.

The program can be downloaded from

www.java.com.

1. Remove the control panel cover.

2. Connect the oven to a network or pc via the

ethernet cable. The connection can be found

on the back of the control.

3. Replace the control cover and connect the

other end of the cable to your local network or

directly to a pc.

WORK Menu

4. Press the MAIN MENU key in the upper left

corner to advance the control to the main

menu.

5. Press the OVEN SETUP key on the MAIN

menu. The Oven Setup menu is displayed.

6. Press the NETWORK key on the left of the

screen. The screen displays the IP address of

the oven.

NOTE: If the oven is connected to a pc, use

the IP address displayed. If the oven is

connected to a network you may need

to change the IP address to match the

naming configuration for your network

7. Press the OK key on the top right of the conĆ

trol. The oven will restart itself.

8. From the pc, open an Internet Exporer window

and go to the IP address for the oven.

OVEN SETUP Menu

Press to

access

MAIN Menu

Press to

access

COMBI

NET

MAIN Menu

Press to

access OVEN

SETUP menu

Figure 32

42

Page 47

Operation

Optional CombiNet

REMOTE OVEN CONTROL

1. Select Control Oven from the menu on the left

of the screen.

2. The oven display appears in the window on

the right. You are now controlling the oven reĆ

motely. You may use your mouse to navigate

through the oven menus and use your keyĆ

board to enter data.

HACCP VIA COMBI NET

1. Select HACCP from the menu on the left of the

screen.

2. The HACCP data is displayed on the right side

of the screen.

Select Function

Send recipes

to oven

REMOTE RECIPE MANAGMENT

1. Select Recipes from the menu on the left of

the screen.

2. Press Get from Oven to retrieve product

recipes currently programmed in the oven liĆ

brary.

3. Add new recipes and/or edit and delete

recipes from the library now located on the pc.

See Figure 33.

4. Press Send to Oven to download all recipes

from the pc to the oven control. If necessary,

click the Browse button to select the desired

recipe location. Click the Upload button to

upload the recipes.

Recipe Screen

Click to import

Click to save

recipes on pc

Click to

add recipe

additional

recipes

Click on category

icon to open recipe

Figure 33

43

Click to

copy recipe

Click to

delete recipe

Page 48

Maintenance

Cleaning & Preventative Maintenance

DAILY CLEANING

Daily cleaning of your Combi oven is essential for

sanitation, and to ensure against operational diffiĆ

culties.

Cleaning the Exterior

1. The exterior of the appliance may be cleaned

and kept in good condition with a light oil. SatĆ

urate a cloth and wipe the appliance when it

is cold; wipe dry with a clean cloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet. CleanĆ

ing with a water jet can impregnate chloĆ

rides into the stainless steel, causing the

onset of corrosion.

Cleaning the Interior

NOTE: DO NOT use corrosive cleaners not inĆ

tended for oven cleaning on your Combi

oven.

Blodgett recommends the following products

for cleaning and rinsing of your Blodgett ComĆ

bi oven. If you choose to use products other

than what Blodgett recommends, please have

your suppler send us the MSDS sheet on the

proposed alternate so we can ensure it meets

our standards. Non approved products can

cause harm to your unit and can potentially

void your warranty.

1. Open the oven door.

2. Use the attached spray hose, located beneath

the control, to clean the front drip tray. Water

will run to the drain in the oven cavity.

Run the CombiWash automatic cleaning cycle

as follows:

1. Check that the oven cleaner and rinse agent

containers are both full.

2. From the WORK menu, select the clean cycle.

The CombiWash menu is displayed.

3. CombiWash features four different cleaning

cycles. Use the Left and Right Arrow keys to

select the desired cleaning cycle.

Step 1 (44 minutes)

Step 2 (1 hour)

Step 3 (1 hour, 49 minutes)

Step 4 (2 hours, 38 minutes)

NOTE: Use Steps 1 or 2 after steaming and

roasting at low temperatures. Use

Steps 3 or 4 after steaming and roastĆ

ing at high temperatures.

4. Press the Start/Stop key to initiate the clean

cycle.

COMBIWASH Menu

Recommended oven cleaners:

Johnson Diversey Suma Nova LĆ6

Four, 1 gallon (3.78 litre) containers

Product code 57252280

One, 5 gallon (18.9 litre) container

Product code 57252100

Recommended Rinse Aid:

Johnson Diversey Suma Maro A8.8

Four, 1 gallon (3.78 litre) containers

Product code 57270280

One, 5 gallon (18.9 litre) container

Product code 57270100

44

Press to

select

cleaning

mode

Press to start

CombiWash

Press to

select

cleaning

mode

Figure 34

Page 49

Maintenance

Cleaning & Preventative Maintenance

5. If the cavity temperature is above 175_F

(80_C), the oven will automatically enter cool

down. When the cavity is below 175_F (80_C)

the CombiWash cycle begins.

6. The control counts down the time remaining

in the wash cycle.

7. When the wash cycle is over, the oven autoĆ

matically switches to an energy saving standĆ

by mode.

WEEKLY CLEANING

In addition to the daily cleaning, it is necessasry to

clean the control filter and behind the fan guard on

a weekly basis. This is necessary for proper funcĆ

tioning of the oven. Scale will build up on the fan

and heat source leading to a less efficient oven.

Cleaning the Control Filter

The control filter is located below the control

compartment, in front of the spray hose.

1. To remove, pull down on the black knob on the

left of the filter.

2. Clean the filter with soap and water.

3. Reinstall the filter. Press up on the filter until the

back of the knob is inserted into the hole in the

bottom of the oven.

4. Push up on the center of the knob to expand

the back of the knob securing the filter.

Cleaning Behind the Fan Guard

1. Loosen the two screws and on the fan guard

(or baffle).

2. Swing the baffle forward.

3. Thoroughly spray cleaner onto the fan and

heat source. Place the oven in the steam

mode for approximately 10 minutes.

4. After ten minutes, rinse the cleaner off. Return