Page 1

GB

Service Manual

For Electric BCP Oven

“Programmable Control”

Page 2

Table of Contents

Installation and connection Page

-Data plate & Drain connection 3

-Water connection & Electrical connection/survey of supply lines 4

Start menu 5

Main menu 6

Set-up menu 7

-Select language 8

-Setting sound 9

-Setting clock 10

-Oven set-up 11

Service menu 12

-Select USB key service 13

Restore backup 14

Select backup menu 15

Restore From Backup Menu 16

USB key service menu 17

-Energy counters 18

-Reading counters 19

Error log 20

Error statistics 3-21 21

Service counters 22

-Lime-scale diagnosis 23

-Software updating menu 24

-ClimaOptima calibration 29

-Door sensor calibration 30-31

-Technical service 32

Test function 33-39

Oven number 40

Display oven set-up 41

Edit oven set-up 42-47

Logo 49-50

Language update 51

Enter Code 52

Access Codes 52

Error Codes 53-55

- 2 -

Page 3

Installation and Connections

Data Plate

When communicating with BLODGETT, we kindly ask

you inform us of the serial number of the oven that is

stated on the approval plate. The approval plate is

located on the right-hand corner post of the oven

cabinet, as shown below.

The BLODGETT Technical Support, whose experience

and expert knowledge are at your disposal, can be

contacted at tel. # 800-331-5842 and fax # 802-652-2814.

Drain connection

From the factory, the BLODGETT ovens are equipped with

a drain system that removes surplus water from the oven

chamber. This water may be condensed water from the

products, or it may occur when the oven chamber is cooled

down with cold water, or when the oven chamber is cleaned.

Connection must be carried out by an

authorised plumber, to an open or to a

closed drain.

It is recommended that a water outlet

is available/established in the floor of

the room where the oven is located.

The drain must never end directly beneath

the oven.

The drain must be of copper or an equally temperature

-resistant material, have a diameter of at least 2” (50mm)

and a fall of at least 3° or 5%.

- 3 -

Page 4

Water connections

BLODGETT ovens have one or two water connections. Two is most common.

To facilitate cleaning and service, the oven should be connected with an approved flexible ¾”

hose and the permanent installations should be fitted with a stop-tap and a non-return valve.

Before connecting the oven to water, flush the tubes thoroughly. Connect the oven.

Hardness of the water: 80-100 PPM

pH level 7.0-8.0

Total Dissolvable Solids: 100 PPM

Chloride: max. 0 PPM

Sulfate: max. 40 PPM/Gal

Conductivity: min. 75 microsiemens

Water pressure: min. 36 PSI (2.5 bar) dynamic pressure (when CombiClean activated.

When CombiWash not activated: min. 22 PSI (1.5 bar), max. 87 PSI (6

bar).

Water temperature: max. 70°F (20°C)

If the water temperature exceeds 70°F (20°C), problems with regard to

ClimaOptima calibration and cooling of the oven may occur.

The water connection must be carried out by an authorised plumber in accordance

with existing rules and regulations

To ensure that the water quality is in conformity with the above requirements, the

installation of a water filter in front of the water connection to the oven is

recommended.

1) 1 connection for raw water for the condensation jet (cold water). Located at the back.

2) The installation of a particle filter (0.25mm) is also recommended.

3) 1 connection for the steam generator and the jet in the oven chamber. Must meet the

requirements applying to water supplied to household appliances; however, hot water with a

temperature not exceeding 125°F (50°C) can be used. Located at the front.

Electrical connections

When you connect the oven, you should:

Comply with federal, state and local rules and regulations.

The electrical connection must be carried out by an authorised electrician in accordance with

existing rules and regulations.

An approved plug outlet or a safety cut-out must be located close to the oven so that

the oven can be disconnected during installation and repair. The safety cut-out must be able

to cut off all poles with a total distance of break of at least 3 mm. Each of the two units in a

stacked arrangement (CombiPlus) must have its own plug outlet or safety cut-out.

The warranty does not cover incorrect connection.

- 4 -

Page 5

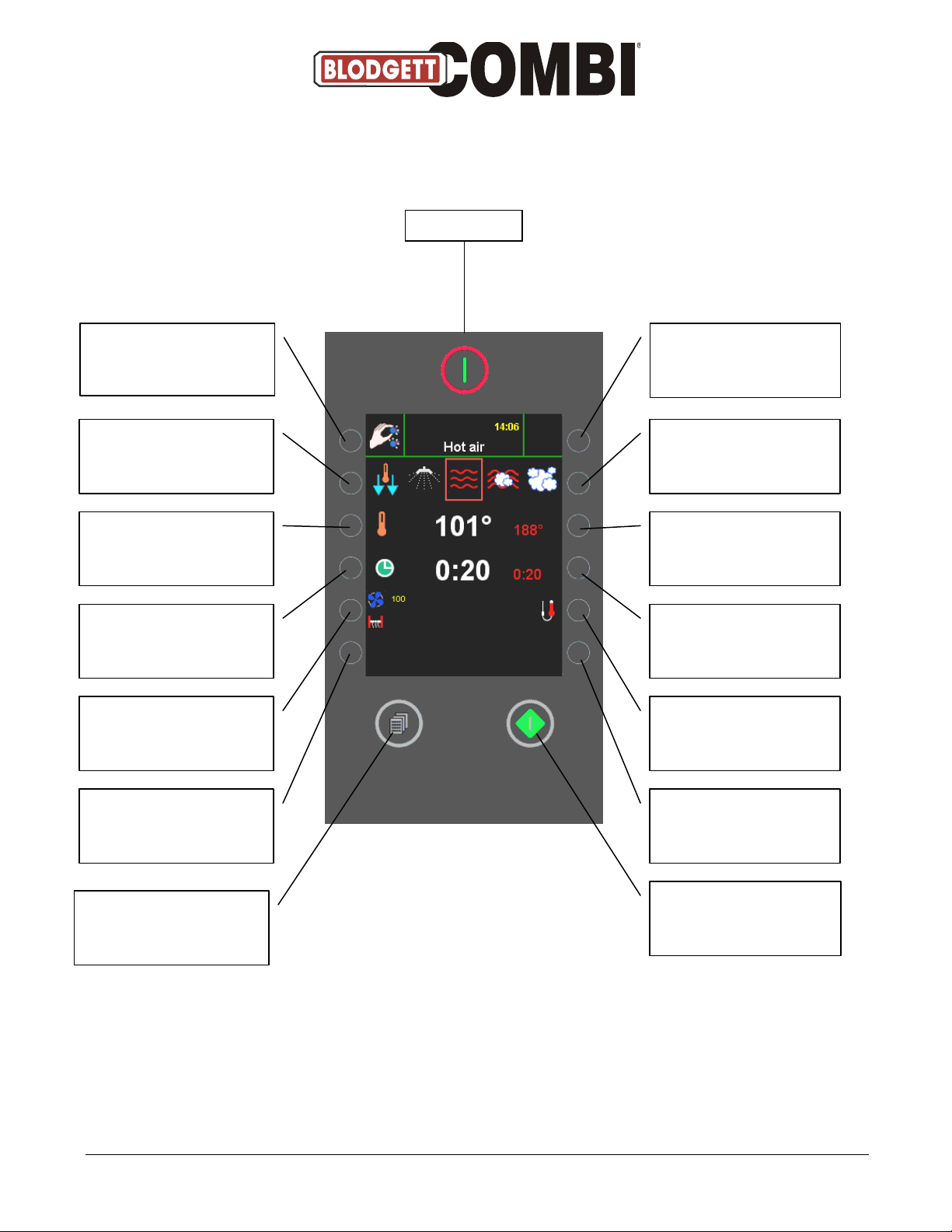

Access to main menu (see

p. 15)

Chooses next function to

the left (see user’s

manual)

Temperature down

Time down (for operation

without time setting, press

key until "-:--" appears)

Access to fan and exhaust

functions (see user’s

manual)

Not active

Not active in HOT AIR

Chooses next function to

the right (see user’s

manual)

Temperature up

Time up

Access to core

temperature mode

(see user’s manual)

Not active in HOT AIR

Access to preset programs

Start/Stop

Power switch

Start Menu

For further information on the modes shown on this page, see user’s manuals

- 5 -

Page 6

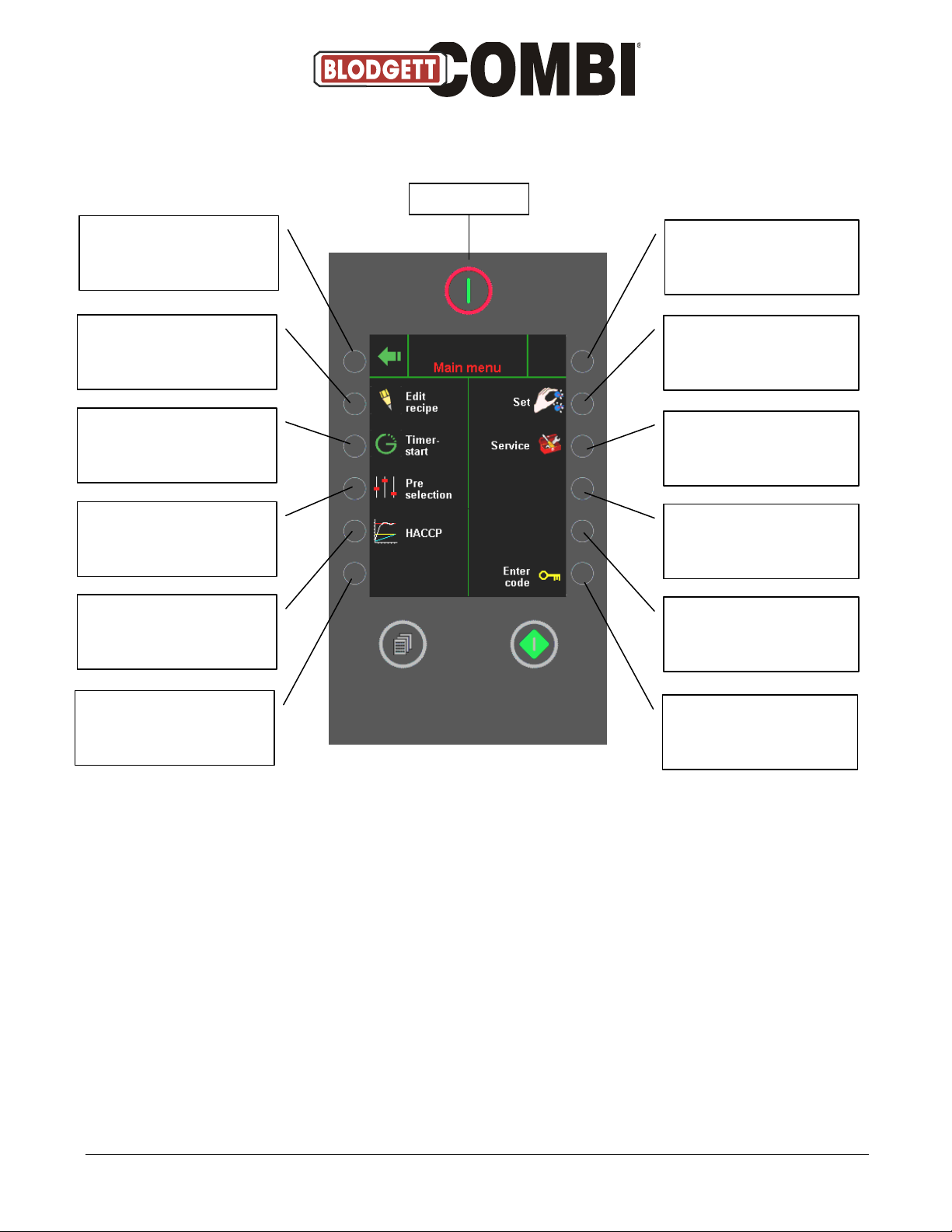

Return to start screen

See user’s manual

See user’s manual

See user’s manual

See user’s manual

Not active

Not active

Access to oven set-up

menu (see p. 16)

Access to service menu

(see p. 23)

Not active

Not active

Access to type in code (see

p. 61)

Power switch

Main Menu

Please note that prior to delivery, the oven’s computer has been thoroughly tested and

correctly set up and we therefore recommend that all users, with or without a code, navigate

in the engineering with the utmost care. Incorrect handling may result in inappropriate

changes to the computer set-up.

Changing the computer set-up requires extended knowledge as to the design and structure of

the oven. If in doubt, please contact your oven supplier.

- 6 -

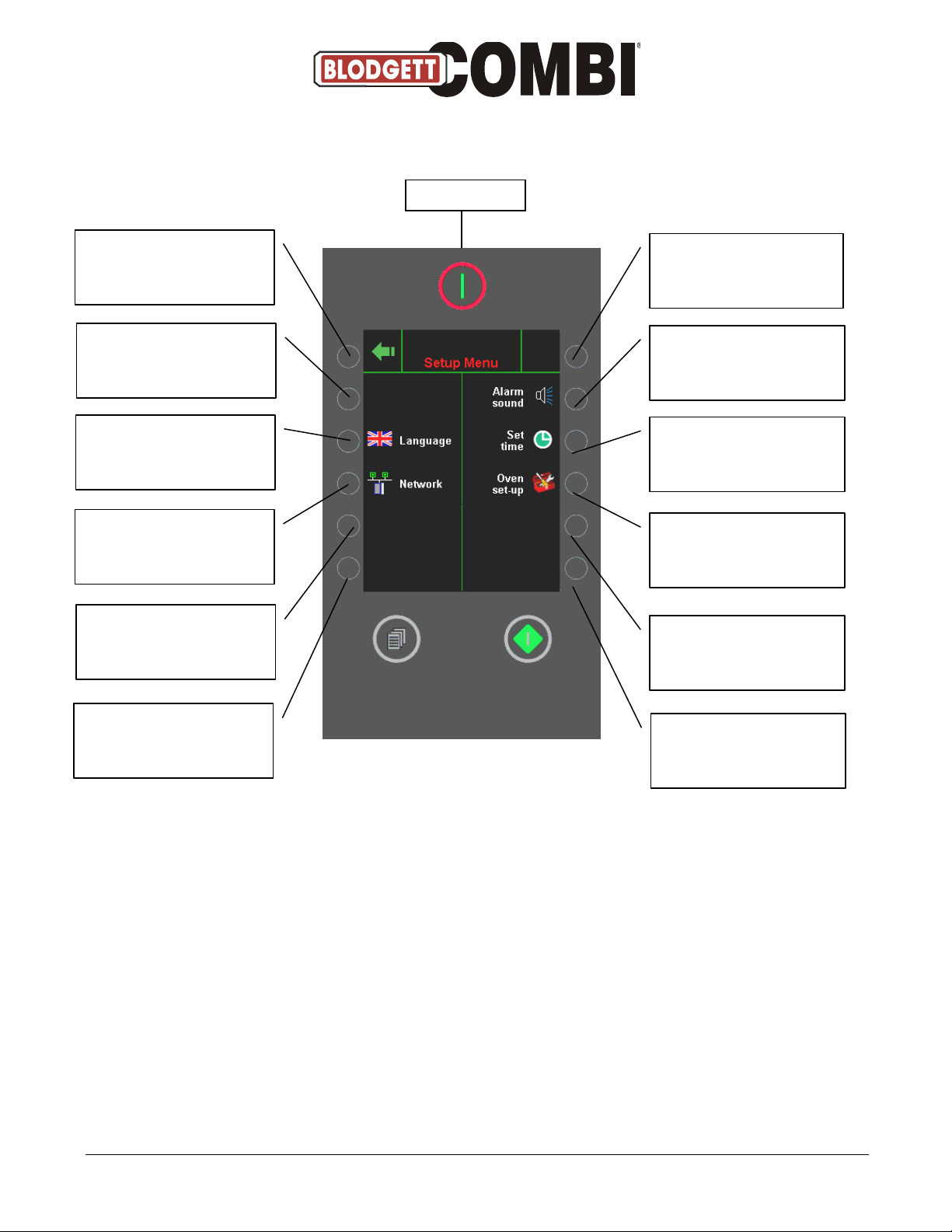

Page 7

Not active

Access to SETTING CLOCK

(see p. 21)

Access to OVEN SET-UP

(see p. 22)

Not active

Return to main menu

Access to SETTING

CONTRAST in display (see

p. 23)

Access to SELECTING

LANGUAGE (see p. 17)

Access to NETWORK (see p.

18-19)

Not active

Not active

Access to SETTING ALARM

(see p. 20)

Not active

Power switch

Set-up Menu

Access to various settings. Avoid changing the settings inappropriately (contact your oven

supplier for further information).

- 7 -

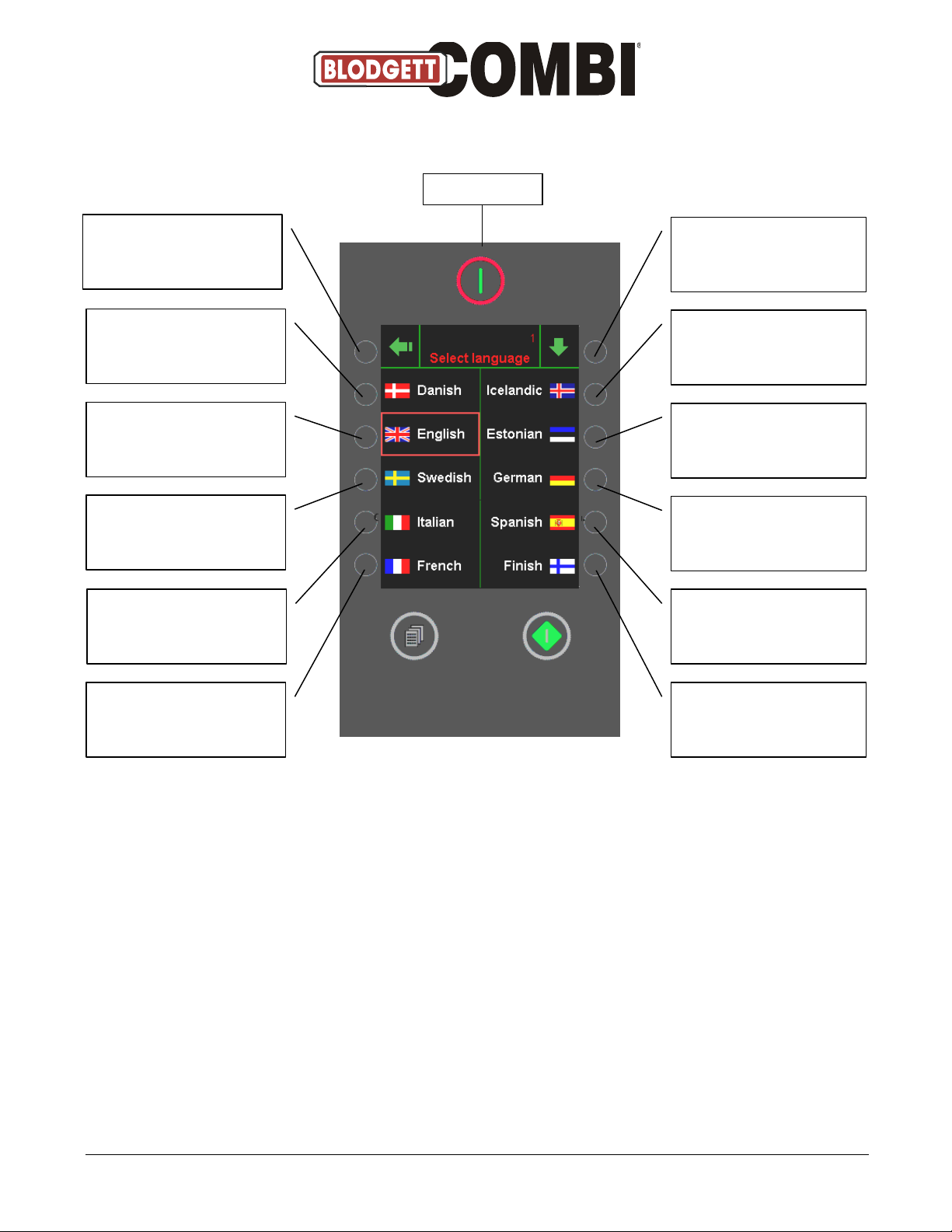

Page 8

Return to SET-UP MENU

Selecting Danish

Selecting English

Selecting Swedish

Selecting Italian

Selecting French

Access to more languages

Selecting Icelandic

Selecting Estonian

Selecting German

Selecting Spanish

Selecting Finnish

Power switch

Select Language

Showing the languages available. The red square indicates which language has been

selected.

- 8 -

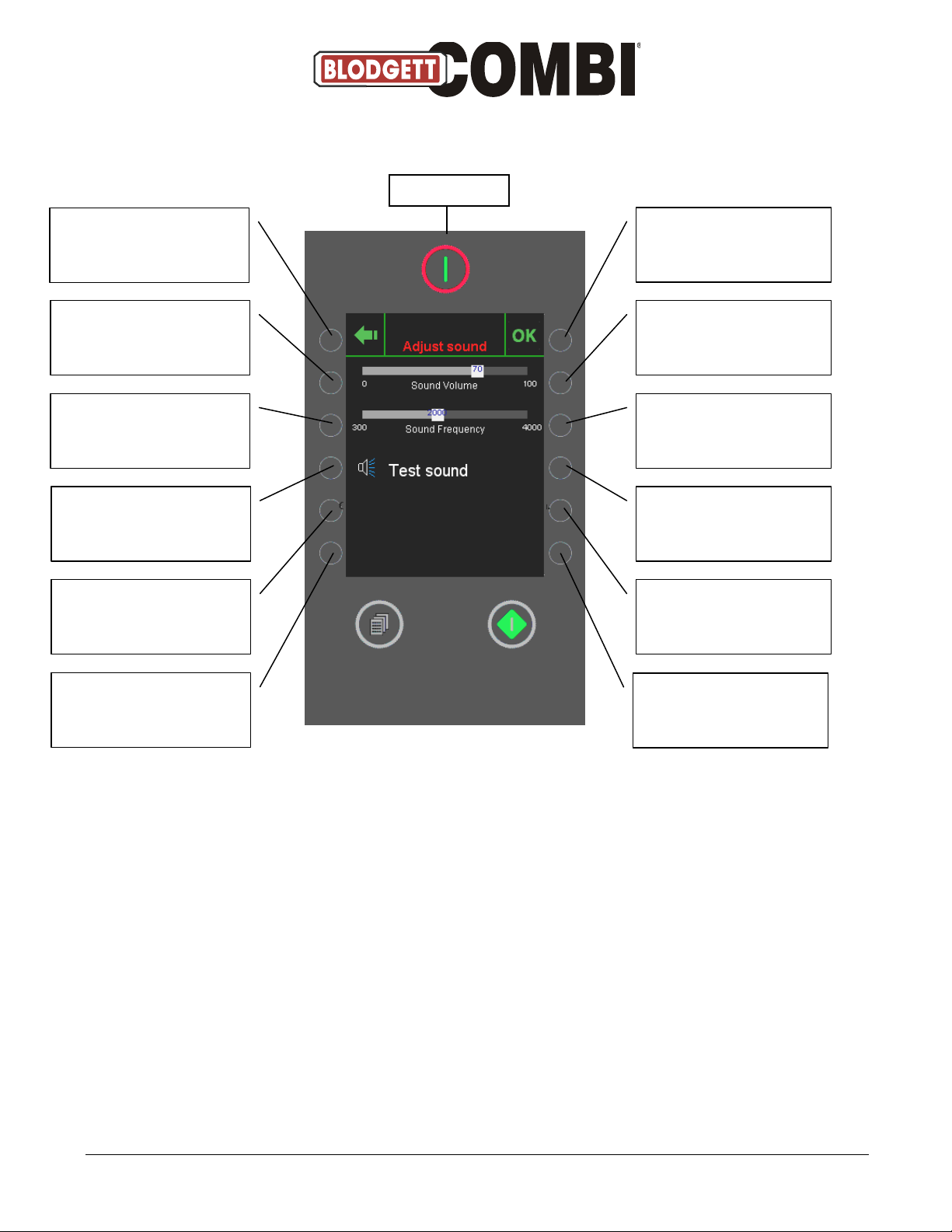

Page 9

Return to SET-UP MENU

Volume down

Sound frequency down

Testing sound

Not active

Not active

Confirmation of setting and

return to SET-UP MENU

Volume up

Sound frequency up

Not active

Not active

Not active

Power switch

Setting Sound

- 9 -

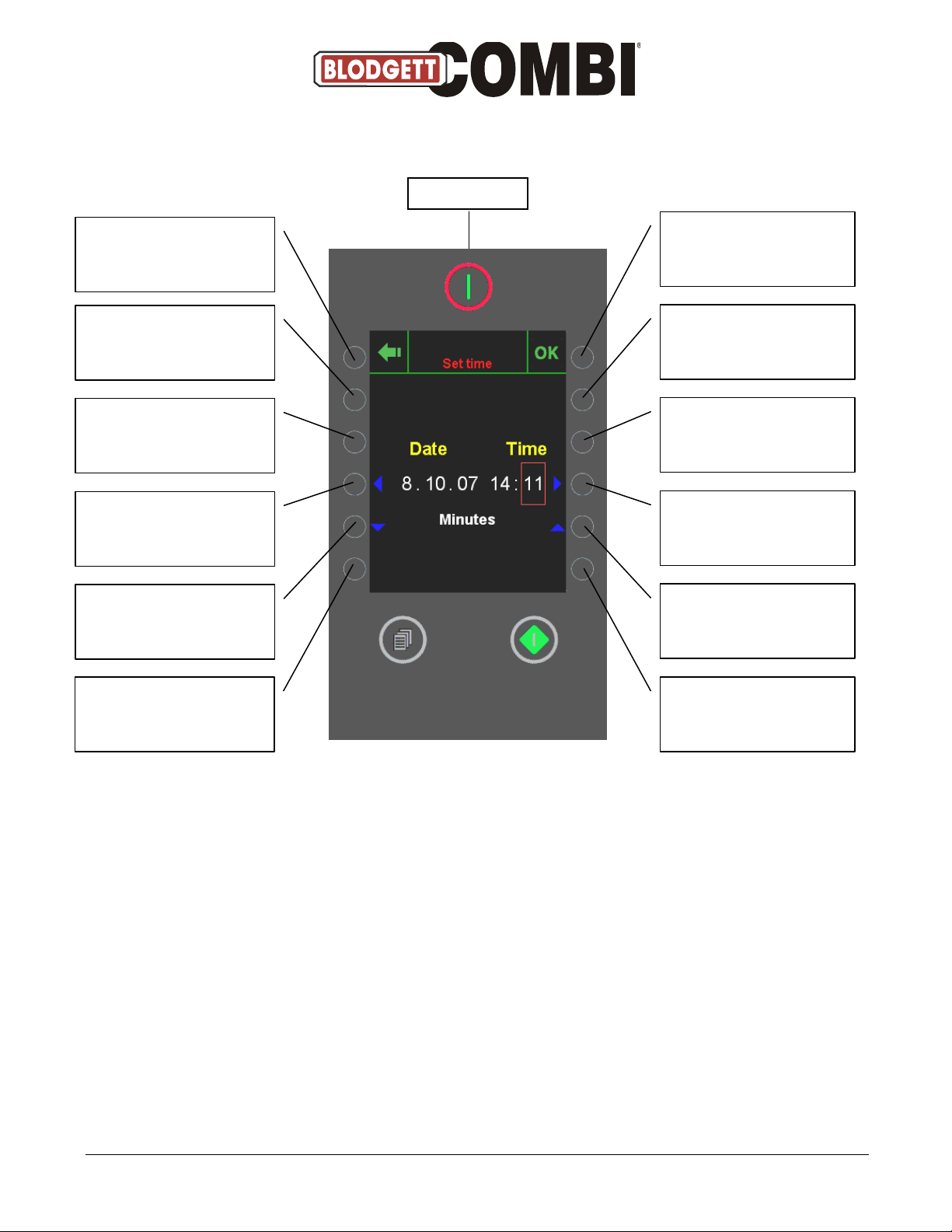

Page 10

Return to SET-UP MENU

Not active

Not active

Move cursor to the left

Day/month/year/hours/

minutes down

Not active

Power switch

Confirmation of setting and

return to SET-UP MENU

Not active

Not active

Move cursor to the right

Day/month/year/hours/

minutes up

Not active

Setting Clock

- 10 -

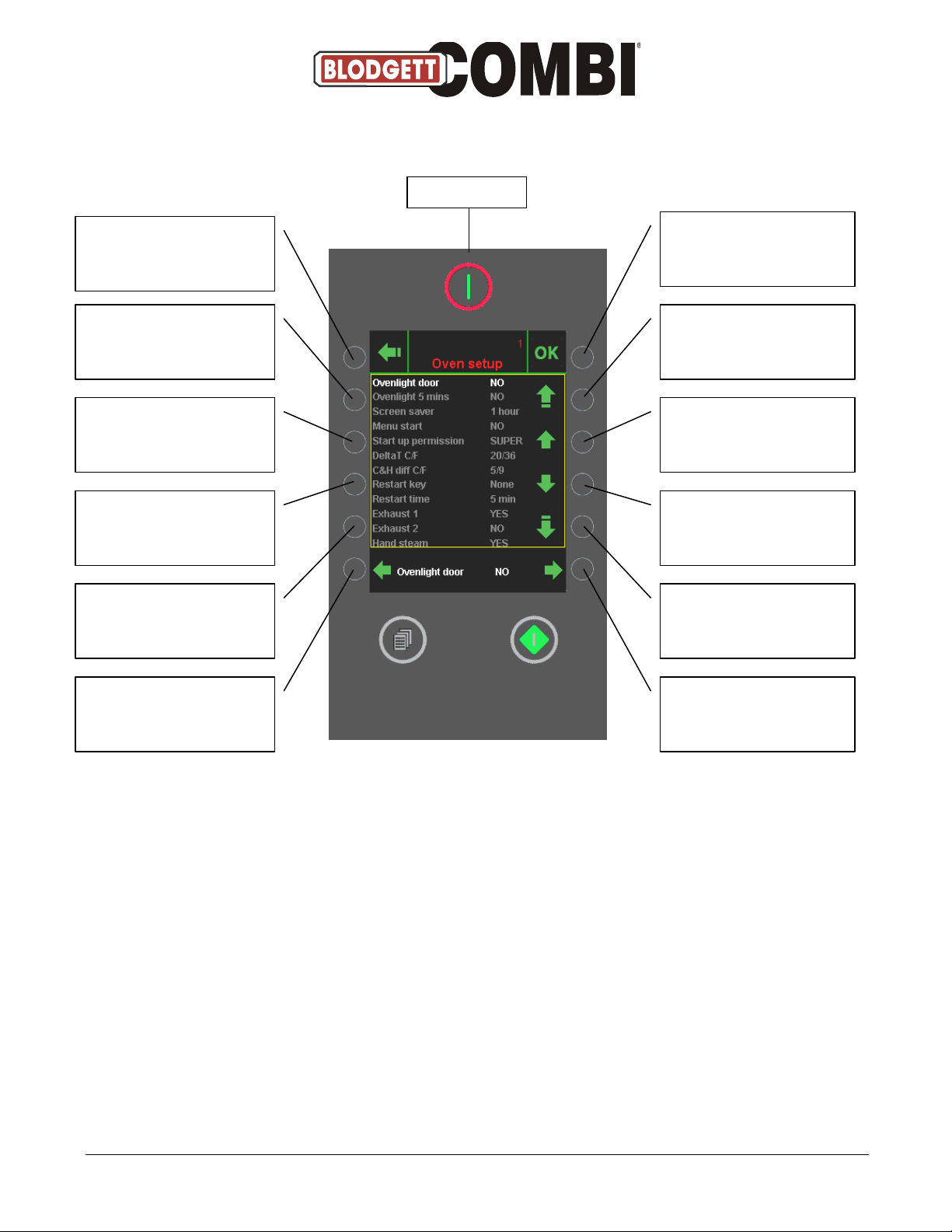

Page 11

Return to SET-UP MENU

Not active

Not active

Not active

Not active

Changing status

Confirm setting, oven

starts automatically

Moving one menu up

Moving one line up

Moving one line down

Moving one menu down

Changing status

Power switch

Oven Set-up

With a code for the computer, the service engineer has the option of many settings. Changing

the set-up requires extended knowledge of the BLODGETT ovens. Unnecessary or incorrect

changes to the settings may change the computer set-up inappropriately.

See Appendix 3, pp. 66 – 67 for a survey of the oven set-up.

- 11 -

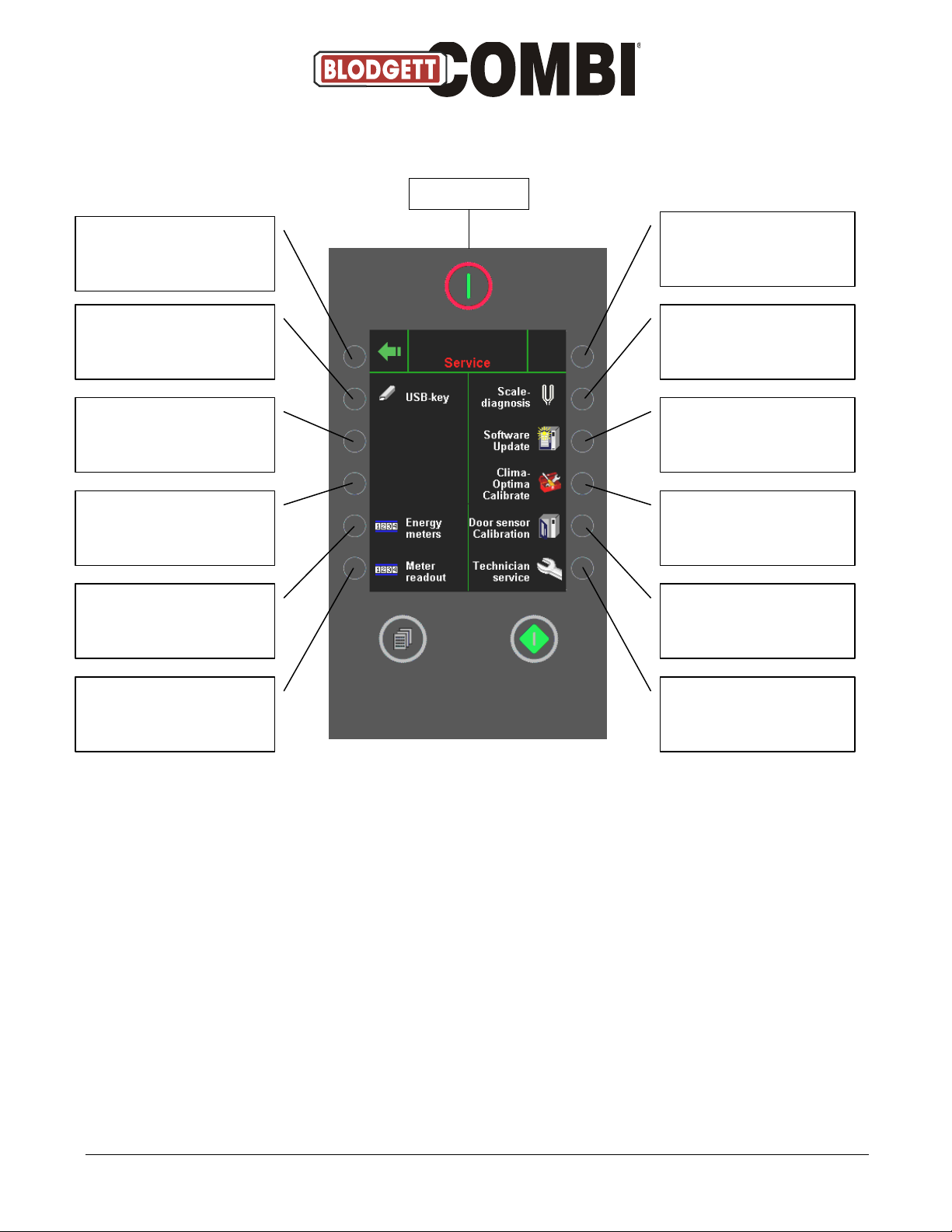

Page 12

Return to MAIN MENU

Access to USB key (see p.

24-28)

Not active

Not active

Energy counter (see p. 29)

Reading counter (see p.

30-33)

Not active

Lime-scale diagnosis (see

p. 34-35)

Software update(see p.

36-39)

ClimaOptima calibration

(see p. 40)

Door-sensor calibration

(see p. 41-42)

Access to TECHNICAL

SERVICE (see p. 43)

Power switch

Service Menu

Access to various service functions.

USB key is only active if a USB key is inserted. If the controller does not find a USB key, the

text “USB key” will be grey.

- 12 -

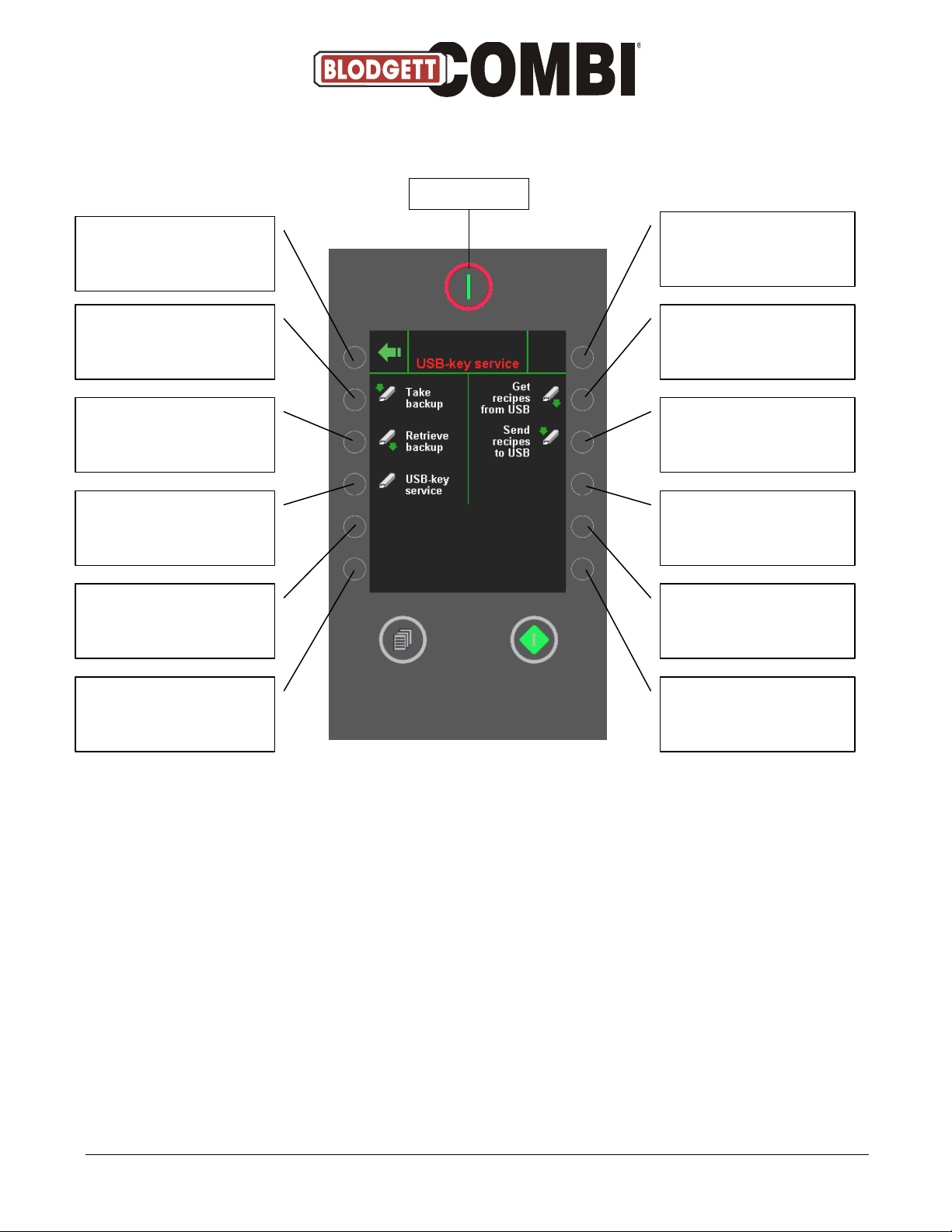

Page 13

Return to SERVICE MENU

Take backup

Access to restore from

backup (see p. 27)

Access to USB key service

(see p. 28)

Not active

Not active

Not active

Retrieve recipes from USB

(see user’s manual)

Send recipes to USB (see

user’s manual)

Not active

Not active

Not active

Power switch

Select USB Key Service

In this menu, you can take a backup and restore data from the backup of the oven set-up and

of the programs.

- 13 -

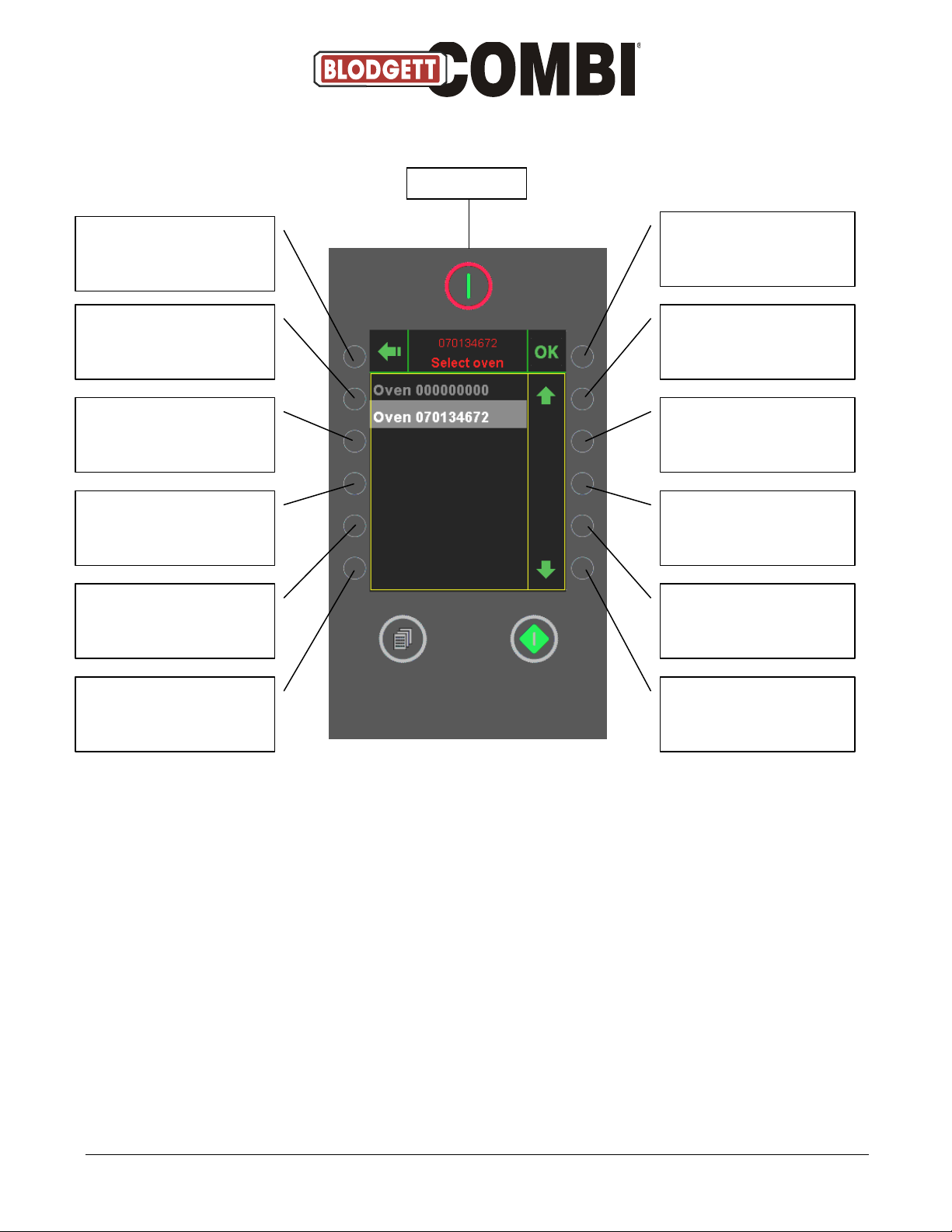

Page 14

Return to SERVICE MENU

Not active

Not active

Not active

Not active

Ej aktiv

Select Oven backup and

proceed to SELECT

BACKUP MENU (see p. 26)

One line up

Not active

Not active

Not active

One line down

Power switch

Restore Backup

In this menu, you select the oven backup to restore from.

This oven XXXXXXXXX(A/B) (ex. this oven 010755667): Shows the number of the oven in

question.

- 14 -

Page 15

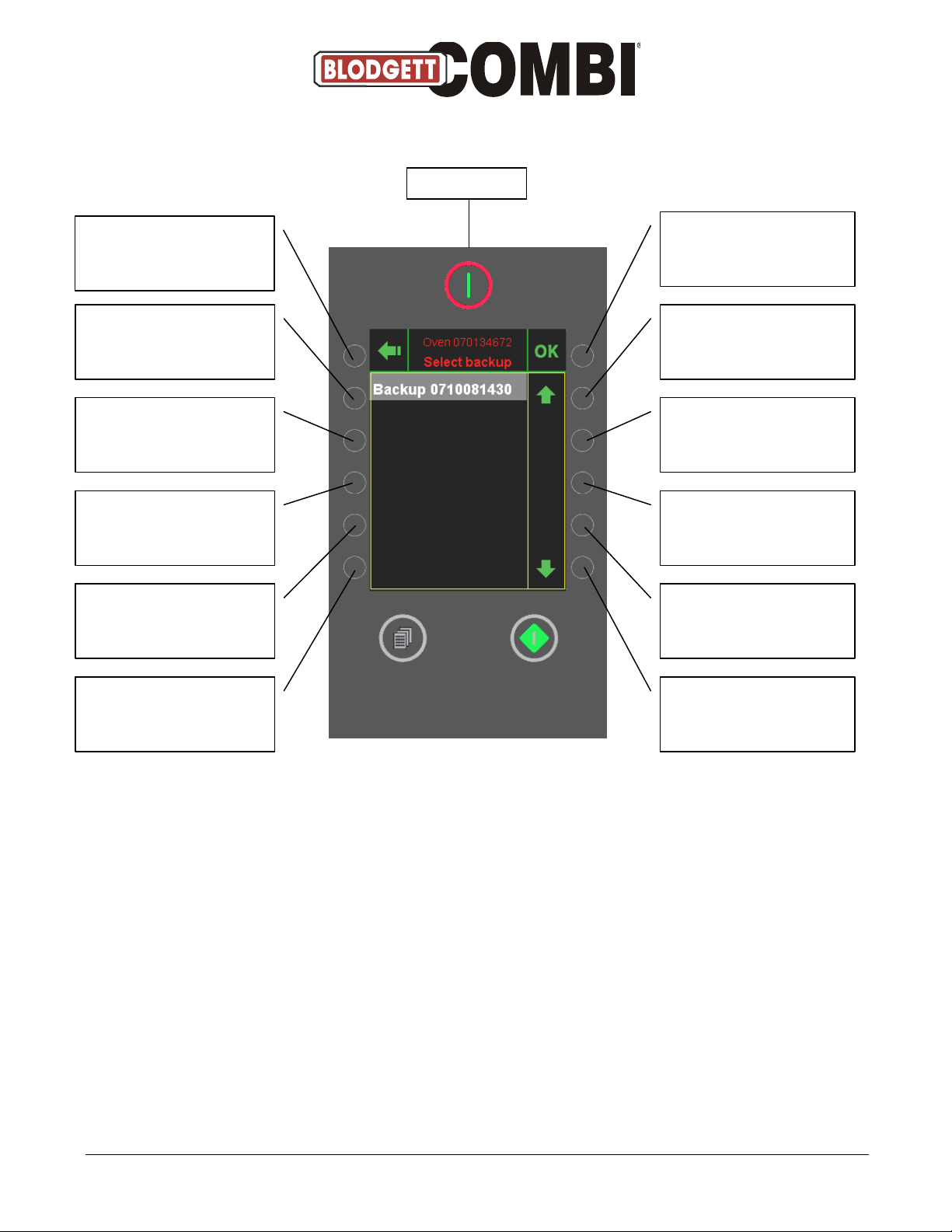

Select Backup Menu

Return to OVEN MENU

Not active

Not active

Not active

Not active

Not active

Select backup and proceed

to RESTORE FROM

BACKUP (see p. 27)

One line up

Not active

Not active

Not active

One line down

Power switch

In this menu, you select the backup to restore from.

Format: Backup ÅÅMMDDTTMM.

- 15 -

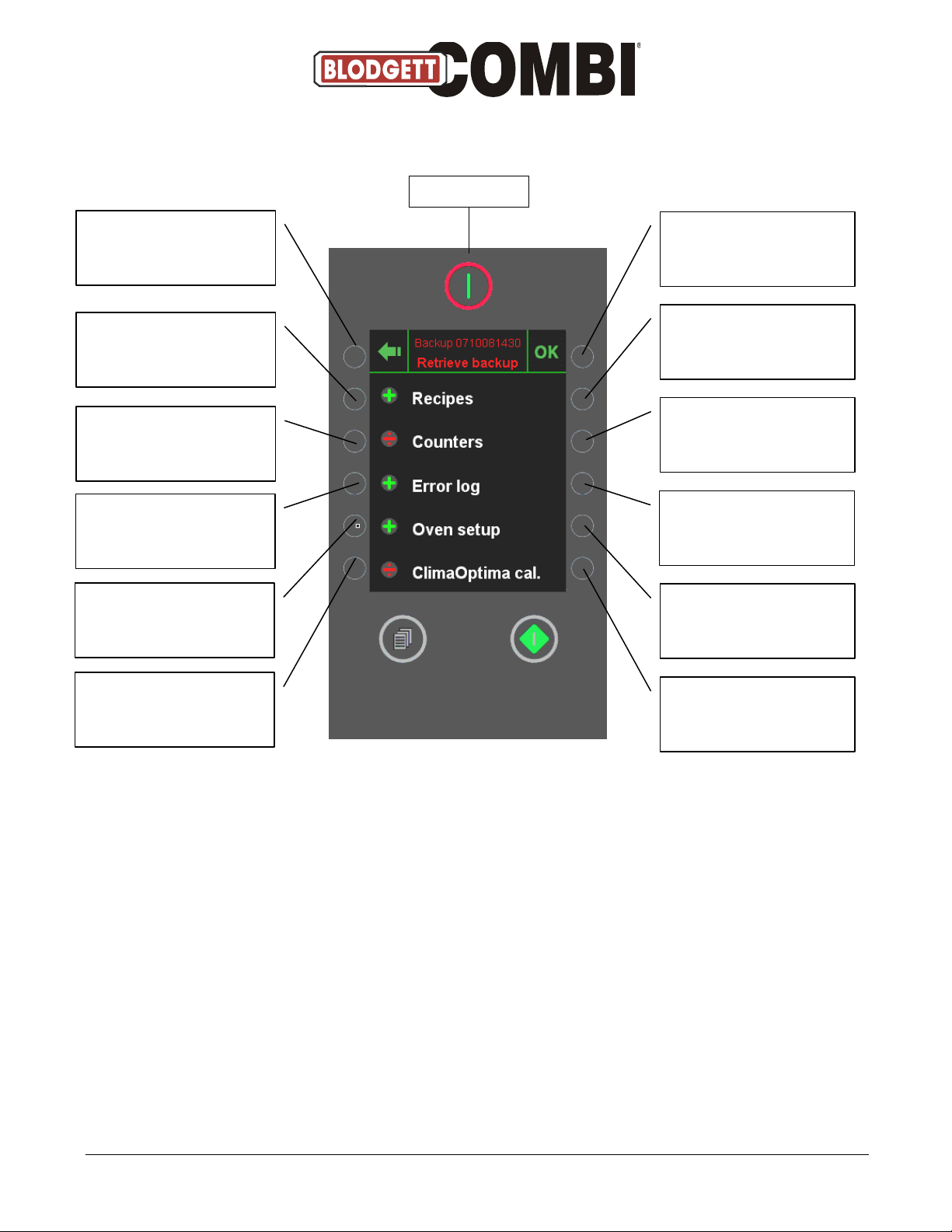

Page 16

Start restoring features

selected and restart when

completed.

Not active

Not active

Not active

Not active

Not active

Power switch

Return to SELECT BACKUP

MENU

Select recipes when

restoring from backup

Select counters when

restoring from backup

Select error log when

restoring from backup

Not active

Select set-up when

restoring from backup

Select ClimaOptima

calibration when restoring

from backup

Restore from Backup Menu

In this menu, you select the features to be restored from the backup.

- 16 -

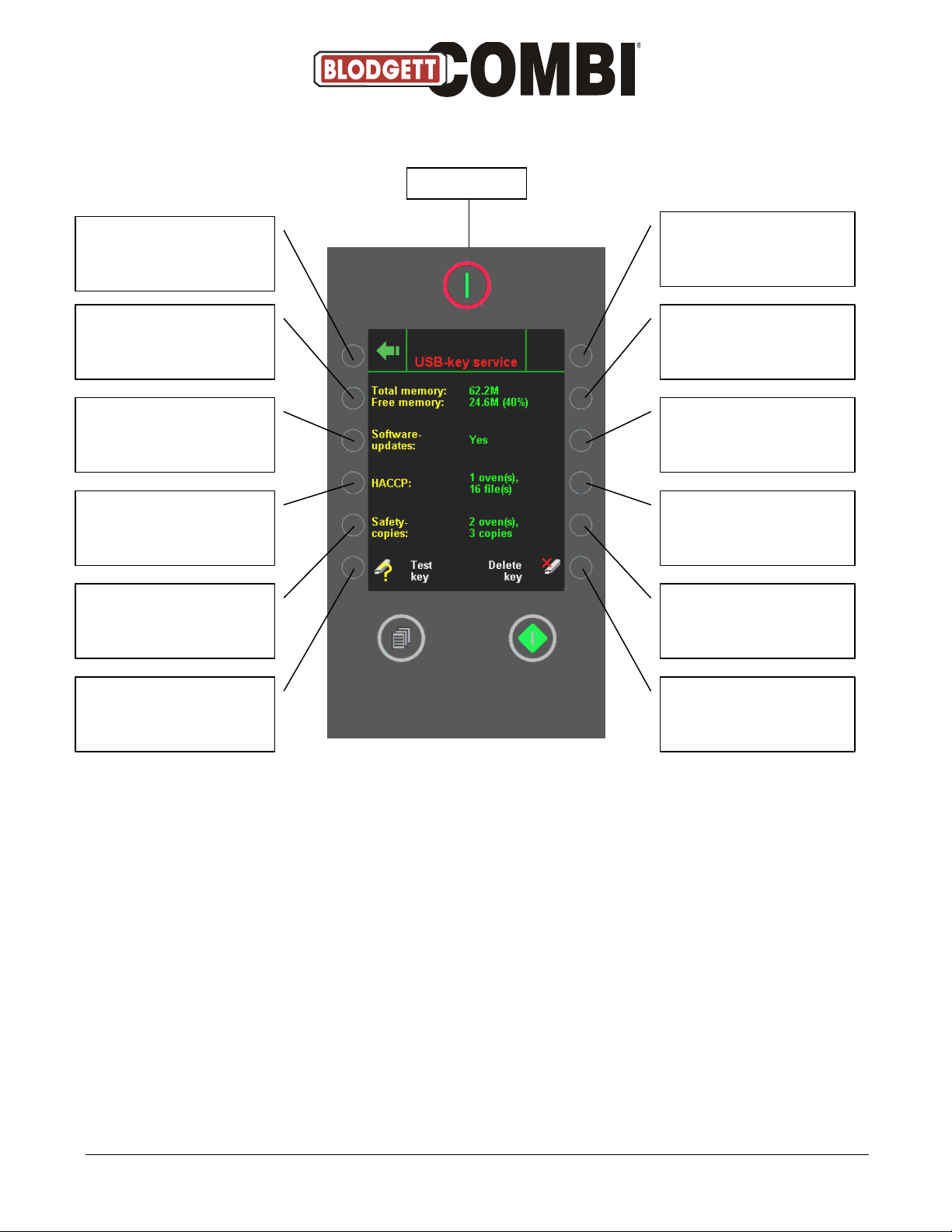

Page 17

Return to SERVICE MENU

Not active

Not active

Not active

Not active

Select Test key

Not active

Not active

Not active

Not active

Not active

Select Delete key

Power switch

USB Key Service Menu

This menu is a survey of the contents of the USB memory key.

With this menu, it is possible to test the USB memory key.

NOTE that when pressing Delete key, the entire contents of the key are deleted.

- 17 -

Page 18

Return to SERVICE MENU

Not active

INFO: Shows oven’s total

power consumption since

last resetting (counter

total)

Not active

INFO: Shows time of last

resetting of counter total

Not active

Not active

Not active

INFO: Shows oven’s total

power consumption since

last resetting (trip counter)

Not active

INFO: Shows time of last

resetting of trip counter.

Resetting of trip counter

Power switch

Energy Counters

Shows consumption of electricity – in total and since last resetting (trip).

- 18 -

Page 19

Reading Counters

Return to SERVICE MENU

Access to error log

(see p. 31)

Access to error statistics

(see p. 32)

Access to service counters

(see p. 33)

Not activ

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Reading of various counters (units, consumption, errors).

- 19 -

Page 20

Return to READING

COUNTERS

Not active

Not active

Not active

Ej aktiv

Ej aktiv

Move to next page

Not active

Not active

Not active

Not active

Not active

Power switch

Error Log

This menu shows the last 30 errors that have occurred, the most recent one at the top.

- 20 -

Page 21

Return to READ COUNTERS

Not active

Not active

Not active

Not active

INFO: Shows time of last

resetting

Next page

Not active

Not active

Not active

Not active

Resetting of error statistics

Power switch

Error Statistics 3-20

This menu shows the number of times the various errors have occurred, and the time of the

most recent error.

- 21 -

Page 22

Service Counters

Return to READ COUNTERS

Not active

Not active

Not active

Not active

INFO: Shows time of last

resetting

Not active

Not active

Not active

Not active

Not active

Resetting of all counters

Power switch

ACT: Shows how many times the unit in question has been active.

TIME: Shows for how long the unit in question has been active.

- 22 -

Page 23

Lime-scale Diagnosis

Return to SERVICE MENU

Not active

Not active

INFO: This bar shows the

level of lime-scale from 0 to

100%.

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Start descaling of steam

generator

Not active

Power switch

Do not interrupt the descaling process.

- 23 -

Page 24

Software Updating Menu

Return to SERVICE MENU

INFO: Shows current

software and IO board

version and oven serial no

Select BLODGETT server for

updating

(see p. 37)

Select USB key for

updating

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Software updating via BLODGETT server, requires Internet access.

- 24 -

Page 25

Return to SOFTWARE

UPDATING MENU

INFO: Software installed in

oven

Not active

INFO: Software accessible

via FTP server

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Select Update

Only visible if more recent

version is available

Not active

Not active

Power switch

BLODGETT Server, Software Updating Menu

In this menu, you update the controller with the latest version of the software via the Internet.

This process usually takes 10 – 20 minutes; the oven must not be turned off during this time.

The oven restarts automatically and is ready for use when the main menu reappears.

- 25 -

Page 26

Return to SOFTWARE

UPDATING MENU

INFO: Software installed in

oven

Not active

INFO: Software accessible

via USB key

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Select Update

Only visible if more recent

version is available

Not active

Not active

Power switch

USB Key (1), Software Updating Menu

In this menu, you update the controller with the latest version of the software via a USB key.

This process usually takes 10 – 20 minutes; the oven must not be turned off during this time.

The oven restarts automatically and is ready for use when the main menu reappears.

- 26 -

Page 27

Not active

INFO: Shows current

software version in oven

(Not active)

Not active

Not active

Not active

Not active

Not active

INFO: Shows software

version to which controller

is being updated

(not active)

Not active

Not active

Press OK to start updating

process

Not active

Power switch

USB Key (2), Software Updating Menu

This function is possible if the controller is updated with software version 1.64 or higher.

1. Oven must be off.

2. Insert USB key in oven.

3. Turn oven on.

4. This menu appears.

- 27 -

Page 28

Step Time Temp. Oven Exhaust

1 Cal. Abt 15 min, 70 Dry Open

2 Cal. Abt. 2 min. 70 Dry Open

3 Cal. Abt. 2 min. 70 Dry Closed

4 Cal. Abt. 8 min 250 Dry Open

5 Cal. Abt. 3 min. 250 Dry Closed

6 Cal. Abt. 5 min. 190 Wet Closed

7 Cooling Abt. 30 sec 105 Open

8 Cal. Abt. 5 min. 130 Wet Closed

9 Cooling Abt. 8 min. 45 Open

10 Cal Abt. 4 min. 70 Wet Closed

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Calibration should be carried out when

CPU board is replaced

Differential pressure sensor is replaced

Fan wheel is removed and mounted again

or replaced.

Filter housing is replaced

The oven should be as dry as possible before calibration is carried out.

The oven temperature must not be higher than 100°F (40°C) when calibration is started.

NOTE: If calibration is started by mistake, turn off the oven (no other keys are active).

NOTE: Do not interrupt the calibration process.

ClimaOptima Calibration

- 28 -

Page 29

Return to SERVICE MENU

Not active

Start calibration of door

sensor

Not active

INFO: During the calibration process, the controller

finds the set point automatically on the basis of the

measurements taken with

door closed and door open.

INFO: The measurement

taken with door closed

should be between 10 and

100. The difference between door closed and door

open should be at least 10.

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Door Sensor Calibration

With this menu, you calibrate the door sensor. On the following page, the calibration process is

explained step by step.

The measurement is an internal value for the distance between the magnet and the sensor.

When the door is door open, the voltage is approx. 2.5 V.

When the door is closed, the voltage moves towards 5 or 0 V depending on the direction of the

magnet.

- 29 -

Page 30

Press ”Start

calibration” to

start calibration

process

Close door

firmly and

press key

again

Open door

in first step

and press

key again

Press ”OK”

to confirm

calibration

How to Calibrate Door Sensor

It is not possible to adjust the door sensor physically, only by means of software.

- 30 -

Page 31

Return to SERVICE MENU

Select Test functions

(see pp. 44-50)

Not active

Select Oven number

(see p. 51)

Not active

Not active

Not active

Select show oven setup

(see p. 52)

Select Edit oven setup

(see pp. 53-59)

Select New boot logo

(see pp. 56-57)

Select Language update

(See p. 58)

Not active

Power switch

Technical Service

In this menu, you access TEST FUNCTIONS and SHOW/EDIT OVEN SET-UP and enter a new

boot logo.

- 31 -

Page 32

Return to TECHNICAL

SERVICE

Access to Test function,

oven (see p. 43)

Access to Test function, fan

(see p. 44)

Access to Test function,

steam generator (see p.

45)

Access to Test function,

CombiWash (see p. 46)

Access to miscellaneous

test functions (see p. 47)

Not active

Access to Main alarm

(survey of thermoswitches) (see p. 48)

Not active

Not active

Not active

Not active

Power switch

Test Functions

- 32 -

Page 33

Return to TEST FUNCTIONS

Activate main contactor

Activate heat

Activate cooling fan

Activate oven chamber jet

Activate interior lighting

Not active

Activate exhaust motor

Activate condensation jet

Not active

Not active

Not active

Power switch

Test Functions, Oven

Heat can only be activated when main contactor and fan motor are on.

Door 1 and Door 2 show status of doors.

Oven shows current temperature in oven chamber.

Drain shows current temperature in drain.

Exhaust shows status of exhaust motor.

- 33 -

Page 34

Return to TEST FUNCTIONS

Activate low fan speed,

motor running left

Activate high fan speed,

motor running left

Activate stop

Not active

Motor speed down.

Not active

Activate low fan speed,

motor running right

Activate high fan speed,

motor running right

Activate main contactor

(otherwise motor unable to

run)

Not active

Motor speed up

Power switch

RPM 1 is used for all oven models.

Test Functions, Fan

- 34 -

Page 35

Return to TEST FUNCTIONS

Cannot be activated until

water level in steam

generator is high and main

contactor is active.

Not active

Not active

Not active

Level DOWN

Confirm level setting

Activate filling jet

Activate drain pump

Not active

INFO: Current temperature

in steam generator

INFO: Water level in steam

generator (high or low)

Level UP

Power switch

How to set the water level:

1. Empty steam generator and read sensor input.

2. Fill steam generator until water level is high, and read sensor input.

3. Set level to a value between high and low sensor input.

4. Conclude by pressing OK.

Test Functions, Steam Generator

- 35 -

Page 36

Return to TEST FUNCTIONS

Activate pump for

detergent

Activate pump for rinse aid

Activate solenoid valve for

water

Not active

Not active

Not active

INFO: Status for water

pressure sensor (2 bar

pressure sensitive switch)

Not active

Not active

Not active

Not active

Power switch

Test Functions, CombiWash

- 36 -

Page 37

Return to TEST FUNCTIONS

Activate external vent. 1

Terminal 4

Activate external vent. 2

Terminal 5

Activate restart lamp

INFO: Restart status

INFO: Voltage at pressure

sensor for ClimaOptima

Not active

Not active

INFO: Temperature

core temperature probe 1

Not active

Not active

INFO: Temperature

Core temp. probe 2

Not active

Not active

INFO: Temperature at IO

board and CPU

Not active

Power switch

Test Functions, Misc.

Core 1: Shows current temperature of core temperature probe 1 (3 measuring points).

Core 2: Shows current temperature of core temperature probe 2 (3 measuring points).

When the external ventilation is activated, the oven control leaves the outlet active during

program performance and 10 minutes after the program has ended.

Note that as external vent. 1 and 2 are merely control voltage, they should be connected

through an external relay (max.: 24V).

Press sens shows voltage from pressure sensor (between 0 and 5 volts).

IO temp shows temperature of IO board.

CPU temp shows temperature of CPU board.

- 37 -

Page 38

Return to TEST FUNCTIONS

Activate main contactor

INFO: Shows status of

thermo-switch circuit

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Test Functions, Main Alarm

- 38 -

Page 39

Return to TECHNICAL

SERVICE

Key in 0/A

Key in 1

Key in 2

Key in 3

Key in 4/CE

Press OK to save oven

number, and return to

TECHNICAL SERVICE

Key in 5/B

Key in 6

Key in 7

Key in 8

Key in 9

Power switch

Oven Number

In this menu, you enter the serial number of the oven.

The serial number consists of 9 figures. The serial number of the CombiPlus models

includes the letters A or B (A = upper oven – B = lower oven).

The serial number is printed on the approval plate.

The serial number is used in the HACCP mode and in the menus Oven back-up and Restore

from backup.

The serial number can only be deleted if it holds 9 figures. Press 4/CE.

- 39 -

Page 40

Return to TECHNICAL

SERVICE

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Display Oven Set-up

This menu shows the features incorporated in this particular oven. Changes not possible.

- 40 -

Page 41

Return to TECHNICAL

SERVICE

Not active

Not active

Not active

Not active

Not active

Not active

Select VC2 for the

Model BCP-xxx

Not active

Not active

Not active

Not active

Power switch

Oven Set-up 1: Select Generation

We recommend that you write down the settings of DISPLAY OVEN SET-UP before making any

changes to the set-up.

- 41 -

Page 42

Return to OVEN SET-UP:

SELECT GENERATION

Not active

Not active

Not active

Not active

Not active

Press OK to confirm

Select ”KPE”

For Model BCP-xxx

Not active

Not active

Power switch

Oven Set-up 2: Select Oven Model

We recommend that you write down the settings of DISPLAY OVEN SET-UP before making any

changes to the set-up.

- 42 -

Page 43

Return to OVEN SET-UP:

SELECT OVEN MODEL

Select oven size 1.06

for model BCP-61

Not active

Select oven size 1.10

for BCP-101

Not active

Not active

Press OK to confirm

Not active

Select oven size 2.10

for Model BCP-102

Not active

Not active

Not active

Power switch

Oven Set-up 3: Select Oven Size

We recommend that you write down the settings of DISPLAY OVEN SET-UP before making

any changes to the set-up.

- 43 -

Page 44

Return to OVEN SET-UP:

SELECT OVEN SIZE

Not active

Not active

Not active

Not active

Not active

Press OK

Next menu

Is this a Pass-Through

oven? YES / NO

Does oven have a restart

button? NONE / DISPLAY /

EXTERN / BOTH (PassTrough ovens only)

Restart time 1-10 min.

Does oven have core

temp. probe 1? YES / NO

Does oven have core

temp. probe 2? YES / NO

Power switch

Oven Set-up 4

- 44 -

Page 45

Return to OVEN SET-UP

Not active

Not active

Not active

Not active

Not active

Press OK

Next menu

Is oven set-up to be BKI

UK* / EUROSP** / CC

Menu***

When oven starts, you are

logged on as USER /

SUPERUSER

Is oven to start in recipes?

YES / NO

Does oven have

CombiNet? YES / NO

Does oven have HACCP?

YES / NO

Power switch

Oven Set-up 5

*Special oven set-up for BKI UK.

**Special oven set-up for EUROSPICE in Sweden.

*** For ovens that start up in the recipes menu (not in the start menu). CombiClean /

CombiWash is then found with each recipe.

- 45 -

Page 46

Return to OVEN SET-UP

Not active

Not active

Not active

Not active

Not active

Press OK

Next menu

Does customer want more

speeds than high and low?

Set hardness of water.

0-8 dH / 8-18 dH / 18→dH

Should the level of

detergent be monitored?

YES / NO

Should clock show 12 or

24 hours?

Temperature scale: Celsius

or Fahrenheit?

Power switch

Oven Set-up 6

- 46 -

Page 47

Oven Set-up 7

Return to OVEN SET-UP

Not active

Not active

Not active

Not active

Not active

Press OK

Oven restarts

Not active

Not active

Not active

Not active

Not active

Power switch

This is the final set-up of the oven. Changes not possible.

- 47 -

Page 48

Power switch

Return to SERVICE ENGINEER

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Not active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Select boot logo if

available, otherwise not

active

Logo

In this menu, you select new boot logo / logo screen saver.

You can have your own logo affixed to the oven. Please contact BLODGETT A/S

- 48 -

Page 49

Return to TECHNICAL

SERVICE

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Power switch

Logo

Oven restarts automatically after downloading of new logo.

The new boot logo will be active after restart and the logo screen saver appears when oven

has been idle for a while.

- 49 -

Page 50

Language Update

Return to TECHNICAL

SERVICE

Not active

Not active

Not active

Not active

Not active

Select font for the

language in question

One line up

Not active

Not active

Not active

One line down

Power switch

In this menu, you update language files from the USB key.

- 50 -

Page 51

Return to MAIN MENU

Press for 0

Press for 1

Press for 2

Press for 3

Press for 4

Confirmation of setting and

return to MAIN MENU

Press for 5

Press for 6

Press for 7

Press for 8

Press for 9

Power switch

Enter Code

Access Codes:

MANAGER’S LEVEL: 87 64 12

SERVICE LEVEL: 57 60 21

- 51 -

Page 52

Error code 3:

Generator too hot (Generator thermo-switch has tripped. Reconnect by pressing button

under operation panel)

Error code 4:

Oven too hot (oven thermo-switch has tripped. Reconnect by pressing button under

operation panel)

Error code 5:

Fan too hot (Thermo-switch in motor has tripped. Wait for 10 min. and try again.)

Error code 6:

Drain too hot (Drain temperature has been too hot (above 165F (75C) for more than 5

min. Check that jet in drain is working. Check for dirt in solenoid valve, jet or dirt filter.

Check if by mistake hot water has been connected. Check if sensor is defective or jet is

sprinkling in the wrong direction.)

Error code 7:

Oven sensor defective (Temperature sensor in oven not working properly. Check wire

connections or replace sensor)

Error code 8:

Core temp. probe not connected (A program using core temp. probe has been selected

but probe has not been connected)

Error code 9:

Generator sensor defective (Temperature sensor in generator not working. Recipes

prescribing use of steam generator cannot be used. Check wire or replace sensor.)

Error code 10:

Drain sensor defective (Sensor in drain not working. Oven can still be used. Check wire

connections or replace sensor.)

Error code 11:

Water shortage (Steam generator was not filled within two minutes. Check that the water

has been turned on. Check if solenoid valve or dirt filter is blocked. Check water pressure

(should be at least 2 bar))

Error code 12:

SSR too hot. Thermo-switch for solid-state relay has tripped. Wait for 10 – 20 minutes and

try again. Check that the cooler opening is not blocked.)

Error code 13:

Generator too hot (Temperature in steam generator higher than 266F (130°C). If error

recurs, descale generator)

Error code 14:

Fan too slow

Error code 16:

IO board too hot

Error code 19:

Internal defect (Oven server process does not respond. Oven server process fails. Restart

oven)

Error code 20:

Internal defect (Failure in communication between computer and IO board)

Error code 21:

Invalid program (Program uses a function which the oven does not support)

Error code 22:

Program interrupted (Power cut-out during program performance. Cut-out has lasted so

long that program cannot be restarted)

Error code 23:

CombiWash (Oven is so hot that CombiWash cannot start. Cool oven and start again.

Error code 24:

Draining defect (Steam generator could not be emptied during flushing. Level sensor

reports high water level when generator is emptied)

Error code 25:

ClimaOptima (ClimaOptima not calibrated. Enter service menu and calibrate)

Error code 26:

ClimaOptima (ClimaOptima sensor defective. Pressure sensor does not give out correct

signal.)

Error code 27:

ClimaOptima (Calibration could not be performed. Start cal when oven is cold and dry)

Error code 28:

Alarm defective (An invalid combination of the main alarms has been detected. The main

alarms are not shown correctly.)

Error code 29:

Door sensor defective (Door sensor does not work. Note: Oven does not stop when door

is opened. Oven can still be used.)

Error code 34:

Water pressure too low (Check that water is turned on)

Error code 36:

Detergent insufficient (Detergent or rinse aid has run out)

Error code 38:

Detergent in oven (CombiClean interrupted while detergent in oven chamber. Run

CombiWash step 0 before using oven. Food products and oven may be damaged if oven is

used before soap is removed.

Error code 39

Memory insufficient (Memory insufficient for this operation)

Error code 40:

IO board hot (Internal temperature of IO board has been too high. Clean filter at the

bottom of the panel. This is a warning: If temperature rises further, oven stops showing

error code 16.

Error code 41:

Main alarm (Steam generator thermo-switch has tripped during out-of-service time. Main

contactor disconnected.)

Error code 42:

SW defect (An SW defect has been detected during operation. Steam generator activated

by mistake.)

Error Codes

- 52 -

Page 53

Oven Set-up (Set-up Menu)

No.

Parameter

Factory Setting

Description

1

Oven light door

NO, YES

Oven light off when door is open

2

Oven light 5 mins

NO, YES

Oven light off after 5 min., otherwise oven light on

continuously.

3

Screen saver

Off, 5sec, 15sec,

1min, 5min,15min,

1hour

Show screen saver after selected time of inactivity.

4

Menu start

NO, YES

Oven starts by showing selection of programs instead of

manual functions.

5

Start up

permission

User, SUPER

Choose if oven should start in the user or superuser mode.

6

DeltaT C/F

10/18 -20/36 70/126

Select difference between core temperature and oven

temperature during Delta-T.

7

C&H diff C/F

3/5.4, 5/9, 10/18

Cook & Hold: Choose at which difference between actual

and set-point core temperature the oven temperature

should be reduced.

8

Restart key

None, Display,

Extern,Both

Pass-Through. Restart last step. From which side of the

oven should the restart be operated?

9

Restart time

1-5-10 min

Pass-Through. Select for how long the oven has to restart

(minutes).

10

Exhaust 1

YES, NO

External ventilation, speed 1 on-off.

11

Exhaust 2

NO, YES

External ventilation, speed 2 on-off (not yet implemented).

12

Hand steam

YES, NO

Select possibility of manual steam while oven is running.

13

Steam int 1

6 - 12 - 30 sec

Injection interval, Combi 1.

14

Steam int 2

3 - 5 - 17 sec

Injection interval, Combi 2.

15

Steam int 3

1 - 8 sec

Injection interval, Combi 3.

16

Reheat Steam int

4 - 8 - 18 sec

Injection interval, Reheating.

17

Proving Steam

input

12 - 20 - 32 sec

Injection interval, Proving.

18

Proving Steam

pulse

0.6 - 1.0 - 2.0 sec

Duration of injection pulse, Proving.

19

Temp. Unit

Cels. Fahr.

Temperature unit, Celsius or Fahrenheit.

20

Oven type

BPE, CPE, KPE

Oven type.

21

Oven size

1.06-2.14

Oven size.

22

Mechanical

vc1, vc2

Oven generation (VC II after Oct. 07).

23

PassThrough

NO. YES

Oven with two doors.

24

Two fans

NO, YES

Is oven equipped with two fans (1.20 and new 1.16)?

25

Custom mode

None, Menu,

Customer-specific function. CombiWash selectable in

Recipes menu; notice about emptying of fat tray; special

recipe icons.

- 53 -

Page 54

No.

Parameter

Factory Setting

Description

26

Recipes

20/4, 200/10

Max. number of recipes and steps.

27

Fan freq. Inv

NO, YES

Is fan with frequency inverter?

28

Fan freq. volt.

5, 10

Control voltage for frequency inverter, 5 or 10V. Only 10V

is used.

29

dT/C&H

NO, YES

Should Delta-T and Cook & Hold be selectable?

30

Core temp 1

NO, YES

Should core temperature 1 be selectable?

31

Core temp 2

NO, YES

Should core temperature 2 be selectable.

32

Pre heat max C/F

250/482, 300/572

Max. preheat temperature 300°C/572°F (250°C or 300°C).

33

CombiNet

NO, YES

CombiNet is access to recipe editing through web and

offline through USB key.

34

ClimaOptima

NO, YES

Is oven equipped with ClimaOptima (automatic humidity

control)?

35

CombiClean /

CombiWash

No, Yes, Wash

Is oven equipped with CombiClean or CombiWash (auto

cleaning system)?

36

CC Level

NO, YES

Monitoring of content of detergent container during

CombiWash.

37

Energy Count

NO, YES

Energy counters (kWh)

38

Drain cooling

NO, YES

Drain cooling with water nozzle (condensation).

39

HACCP logging

NO, YES

Logging of recipe runs.

40

Update server

None, Local,

Laptop PC

Select source for SW update through web.

41

Demo mode

NO, YES

Setting for use at exhibitions (no heat and with temperature

simulation).

42

Oven temp offset

C/F

-10/-18 - 0/0 -10/18

Adjustment of oven temperature sensor.

43

Core 1 temp

offset C/F

-10/-18 - 0/0 10/18

Adjustment of core temperature sensor 1.

44

Core 2 temp

offset C/F

-10/-18 - 0/0 -10/18

Adjustment of core temperature sensor 2.

45

Enable FAN

alarm

NO, YES

Activate fan alarm (Err 14, 15).

46

Restart after PF

Never, 10min,

30min, 60min

Restart after power failure. Select duration of interruption

until oven restarts automatically.

47

Descale

NO, YES

Descale program for steam generator (KPE).

48

Lime saturation

factor

30, 60, 90hrs

Scale diagnosis, monitoring of scale in generator. Select

hardness of water.

49

Multistep Fan

speed

NO, YES

Multistep fan speed, 20-100%, 1 step = 10%

Oven Set-up (Set-up Menu) Continued

1-3 OPEFRATOR LEVEL

1-19 MANAGER’S LEVEL

1-49 SERVICE LEVEL

- 54 -

Page 55

Notes:

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

- 55 -

Loading...

Loading...