Page 1

BCMĆ61, BCMĆ101, BCMĆ102 and BCMĆ202

INSTALLATION - OPERATION - MAINTENANCE

BCMĆ61, BCMĆ101, BCMĆ102 et BCMĆ202

MANUEL D'INSTALLATION - FONCTIONNEMENT - ENTRETIEN

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331Ć5842, (802) 860Ć3700 Fax: (802)864Ć0183

PN60740 Rev B (2/11)

E 2010 - G.S. Blodgett Corporation

Page 2

A PERSONAL WORD FROM BLODGETT COMBI

QUELQUES MOTS DE BLODGETT COMBI

Congratulations on your purchase of a BLODGETT Combi appliance. We

firmly believe that your choice has been a wise one, and trust you will reĆ

ceive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policy to which we've always adĆ

hered: For Better Cooking!"

Once you've had a chance to use your Combi, please tell us, your dealer

and colleagues about any creative and interesting applications you have

discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems

be encountered (...we're here to help!) and above all Enjoy Cooking the

BLODGETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Toutes nos félicitations sur votre achat d'appareil de Blodgett Combi.

Nous croyons fermement que votre choix est un choix raisonnable et

nous sommes certains que vous obtiendrez de nombreuses années

d'excellent service de votre nouveau four multiĆusages.

Vous allez découvrir que la cuisson dans les appareils Combi économise

le temps, le travail et le degré de nettoyage de l'appareil aussi bien que

de la cuisine.

Avec les appareil de Combi, la qualité, le goût, la consistence et l'apparĆ

ence des aliments sont améliorés, s'accordant, de ce fait, avec notre

politique "Pour une meilleure cuisson !"

Une fois que vous aurez eu la chance d'utiliser notre Combi, informez

nous, votre concessionnaire et vos collègues, de toutes les applications

nouvelles et intéressantes que vous avez découvertes ; échangez vos

idées avec d'autres utilisateurs. N'hésitez pas à nous prévenir, ou votre

concessionnaire, de tout problème mécanique ou technique que vous

pourriez rencontrer (... nous sommes ici pour vous aider) et parĆdessus

tout RégalezĆvous à cuisiner à la façon BLODGETT Combi!

Pour obtenir de plus amples informations sur l'art culinaire, veuillez conĆ

sulter notre livre de cuisine séparé.

Page 3

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTISSEMENT: UNE INSTALLATION, UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGES À LA PROPRIÉTE, DES BLESSURES OU LA MORT. LISEZ ATTENTIVEĆ

MENT LES DIRECTIVES D'INSTALLATION, D'OPÉRATION ET D'ENTRETIEN AVANT

DE FAIRE L'INSTALLATION OU L'ENTRETIEN DE CET ÉQUIPEMENT.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l'essence ni d'autres vapeurs ou liquides inflamĆ

mables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instrucĆ

tions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructions et procéĆ

dures permettra d'obtenir de bons résultats de cuisson et une longue durée de serĆ

vice sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l'avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. SpecificaĆ

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d'illustration font l'objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 4

Your Service Agency's Address:

Adresse de votre agence de service:

Model/Modèl:

Serial Number/Numéro de série:

Your appliance was installed by/

Installateur de votre four:

Your oven's installation was checked by/

Contrôleur de l'installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

The Blodgett CombiĆOven/Steamer 2. . . . .

Description of the CombiĆOven/Steamer 3.

Installation

Agency Approvals 4. . . . . . . . . . . . . . . . . . . .

Utility Specifications 5. . . . . . . . . . . . . . . . . . .

Unpacking the Oven 6. . . . . . . . . . . . . . . . . .

Oven Location and Leveling 7. . . . . . . . . . . .

Plumbing Connections 8. . . . . . . . . . . . . . . .

Electrical Connection and Ventilation 9. . . .

Final Check Lists 10. . . . . . . . . . . . . . . . . . . . .

Operation

Manual Control Description 11. . . . . . . . . . . .

Manual Cooking 12. . . . . . . . . . . . . . . . . . . . . .

Manual Cooking 12. . . . . . . . . . . . . . . . . . . .

Core Probe Cooking 12. . . . . . . . . . . . . . . . .

Programmed Cooking 13. . . . . . . . . . . . . . . . .

Programming the Control 13. . . . . . . . . . . .

Cooking with a Program 13. . . . . . . . . . . . .

Cooking Tips 14. . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Cleaning & Preventative Maintenance 15. . .

Introduction

The Blodgett CombiĆOven/Steamer 18. . . . .

Description du fourĆétuveur Combi 19. . . . . .

Installation

Certifications 20. . . . . . . . . . . . . . . . . . . . . . . . .

Caractéristiques techniques relatives

aux services publics 21. . . . . . . . . . . . . . . . . .

Déballage du four 22. . . . . . . . . . . . . . . . . . . .

Choix de l'emplacement et nivellement

du four 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Robinetterie 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Raccordement à l'électricité et Ventilation 25

Liste de vérification finale 26. . . . . . . . . . . . . .

Fonctionnement

Description de la commande manuelle 27. .

Cuisson manuelle 28. . . . . . . . . . . . . . . . . . . .

Cuisson manuelle 28. . . . . . . . . . . . . . . . . . .

Cuisson à la sonde 29. . . . . . . . . . . . . . . . . .

Cuisson programmée 30. . . . . . . . . . . . . . . . .

Programmation de la commande 30. . . . . .

Cuisson selon un programme 31. . . . . . . .

Trucs et suggestions en matière

de cuisson 32. . . . . . . . . . . . . . . . . . . . . . . . . . .

Entretien

Nettoyage et entretien préventif 33. . . . . . . .

Page 6

Introduction

The Blodgett CombiĆOven/Steamer

The Blodgett CombiĆOven/Steamer offers a comĆ

pletely new method of cooking. With the Oven/

Steamer you have the choice of two cooking proĆ

cesses: Steam and Hot Air, either...

D Separately

D Combined, or

D In Sequence

And for easy operation you can choose from three

primary cooking modes:

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanch preserve braise

poach

In the Hot Air mode you can:

roast bake

grill gratinate

broil

In the two Combi modes you can:

defrost roast rethermalize

reheat bake forced steaming

There are four additional specialized modes to

help you make the most of your time:

Retherm - for perfect reheating

Proofing - Proof and bake all in the same oven

Preheat - in this mode the oven will preheat to

575_F (300_C) for 15 minutes. The oven will then

automatically lower to 480_F (249_C) to protect

the advanced electronic components.

Cool Down - allows the oven cavity to cool down

rapidly with the door opened

You āācan also āāuse āātwo āāor āthree functions in seĆ

quence during one cooking process. We call this:

D combiĆsteaming

D combiĆroasting

D combiĆbaking

The combination of circulating hot air and steam

in the space saving, high performance CombiĆ

Oven/Steamer leads to improvements in the folĆ

lowing areas:

D increased productivity in the kitchen

D a reduction in capital expenditures for multiple

equipment replacement

D a wider range of menu choices

D a simplified cleaning process

The work process is simplified since products are

prepared on or in steam table āpans āand trays.

Food can be cooked, stored, and transported with

āthe āsame āāpans. āSmall āamounts of product can be

processed efficiently; preĆcooked and conveĆ

nience foods can be reheated within minutes.

āMany frozen foods can be processed without preĆ

thawing. This flexibility in preparation reduces the

need for kettles and steam tables since there is no

need for large amounts of food to be kept warm for

long periods of time.

Today the improvement of food quality is more imĆ

portant than ever. Vegetables are cooked in the

Blodgett CombiĆOven/Steamer without water at

the optimal temperature of just under 212_F

(100_C), maintaining valuable vitamins, minerals,

nutrients and trace elements. Cooking meat in the

Combi results in less shrinkage and a firmer, juicier

product. The Blodgett CombiĆOven/Steamer is

being used more and more for baking. Steam and

Hot āAir āmodes āmake āit āa āgeneral āpurpose baking

appliance.

2

Page 7

Introduction

Description of the CombiĆOven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett CombiĆOven/Steamers are quality proĆ

duced using highĆgrade stainless steel with first

class workmanship.

The multiple speed fan, which is guarded against

accidental finger contact, is driven by a quiet and

powerful motor. The condenser draws out excess

steam from the appliance. Condensation and

waste water, which result during steaming and

cleaning, are continuously drained.

The use of high quality insulation impedes excesĆ

sive heat radiation and saves energy.

The high performance fresh steam generator with

its control system makes it possible to enjoy all of

the advantages of a high quality steamer at the

flick of a switch. Fresh steam enters the oven cavĆ

ity without pressure and is circulated at high

speed. This process enables quick and gentle

cooking and ensures high quality food while proĆ

viding convenient working methods. The steam

generator is completely automatic and protected

from running dry.

OVEN/STEAMER OPERATION

The practical oven door, with a viewing window,

has a wide swing radius and handle which can be

operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simĆ

ple to use control. With graphical symbols and

storage for 10 product recipes the BCM is easy for

even inexperienced kitchen staff to operate.

Cleaning is kept to a minimum thanks to the autoĆ

matic Combi Wash system.

3

Page 8

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONĆ

TAINED HEREIN ARE FOR THE USE OF QUALIĆ

FIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D The installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

D The installation of electrical wiring from the elecĆ

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiĆ

enced in such work, be familiar with all precauĆ

tions required and have complied with all requireĆ

ments of state or local authorities having

jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1-Latest Edition,

the Natural Gas Installation Code CAN/CGAĆ

B149.1 or the Propane Installation Code, CAN/

CGAĆB149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA

70-Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

with the Basic Plumbing Code of the Building OffiĆ

cials and Code Administrators International Inc.

(BOCA) and the Food Service Sanitation Manual of

the Food and Drug Administration (FDA).

Appliance is to be installed with backflow prevenĆ

tion in accordance with applicable federal, provĆ

ince and local codes.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011Ć802Ć860Ć3700.

4

Page 9

Installation

Utility Specifications

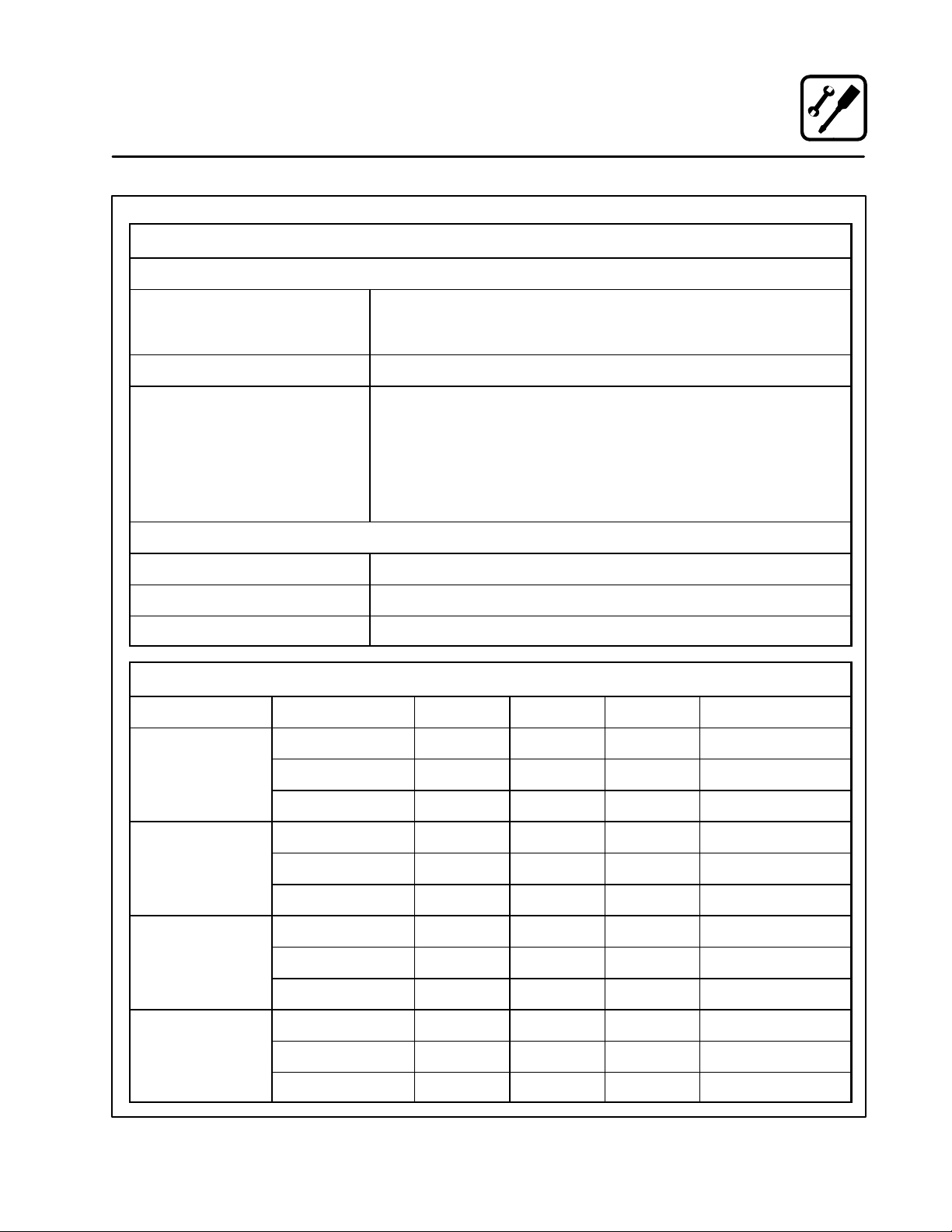

PLUMBING SPECIFICATIONS

WATER

Water Pressure 36.26 PSI (250 kPa, 2.5 bar) during Combi Wash

21.76 PSI (150 kPa, 1.5 bar) when Combi Wash is not active

87 PSI (600 kPa, 6 bar) maximum

Water Connection 3/4" garden hose cold water

Minimum Requirements TDS - less than 100 parts per million

Total Hardness - 80Ć120 parts per million

Chlorides - less than 30 parts per million

pH Factor - 7.0Ć8.0

Chlorine - 0 parts per million

DRAINAGE

Drain Type Atmospheric Vented Drain

Drain Connection 2.00" (50.8mm) Copper

Avg Water Drain Temp. Approximately 140_F (60_C)

ELECTRICAL RATINGS

Model Voltage kW Hz Phase Max Load (amps)

BCMĆ61E

BCMĆ101E

BCMĆ102E

BCMĆ202E

208 9 60 3 26

240 9 60 3 26

480 9 60 3 13

208 18 60 3 52

240 18 60 3 52

480 18 60 3 25

240 27 60 3 80

240 27 60 3 80

480 27 60 3 36

240 60 60 3 175

240 60 60 3 175

480 60 60 3 80

5

Page 10

Installation

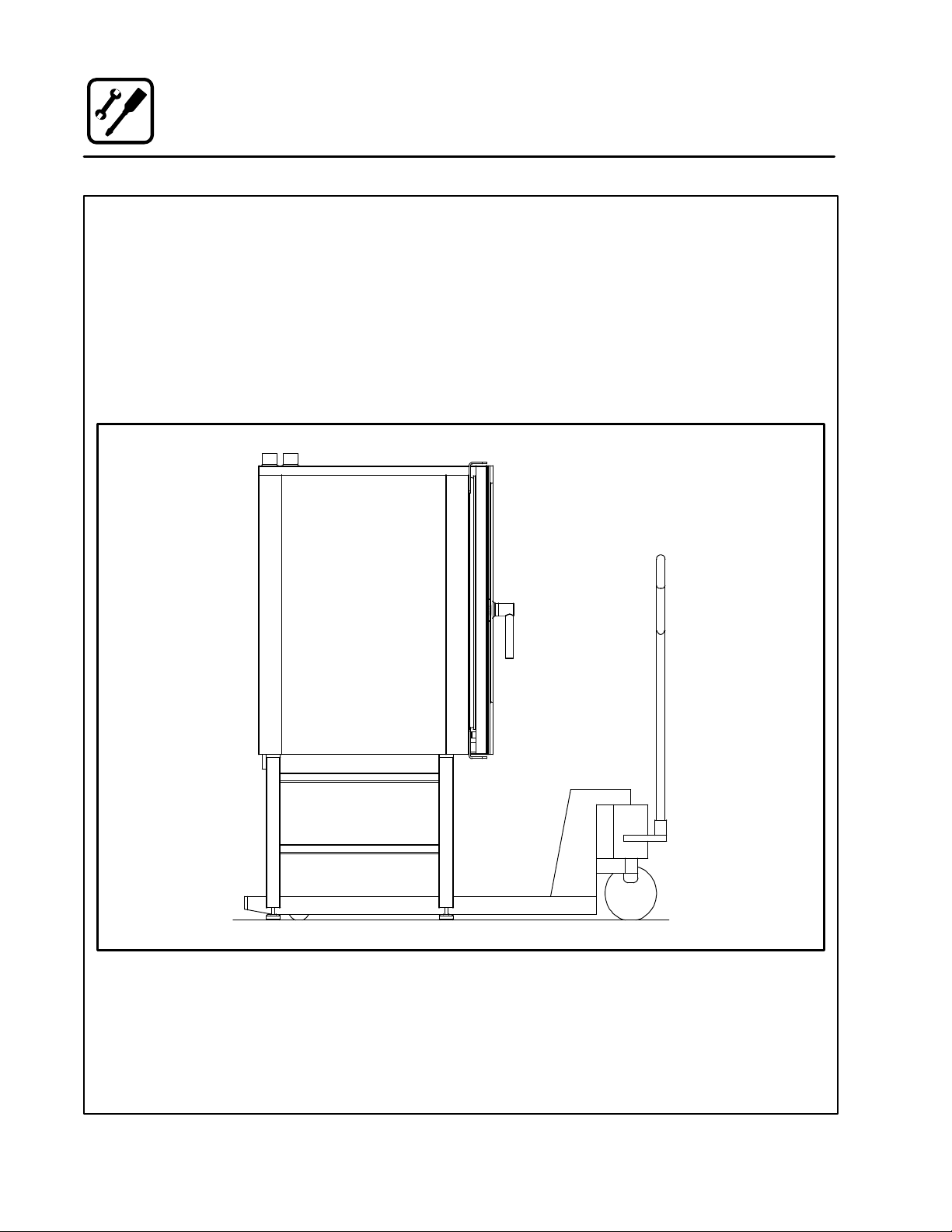

Unpacking the Oven

The oven is best handled while still in its wrapping.

Wherever possible, use a rolling lift.

1. Roll the lift under the lower cross tube of the

stand Place a couple of wooden blocks beĆ

tween the cross tube and the lift.

NOTE: To achieve the best possible balance,

roll the lift from the front of the oven or

from the motor side.

NOTE: If necessary, the oven can also be

lifted off the stand.

2. Remove the original packaging from the oven.

Do not remove the vinyl that covers the stainĆ

less steel surface until the oven has been

installed. Once the vinyl has been removed,

the surfaces are vulnerable to sharp objects

such as tools.

3. Remove all packaging material that secures

the racks in the oven chamber.

Figure 1

6

Page 11

Installation

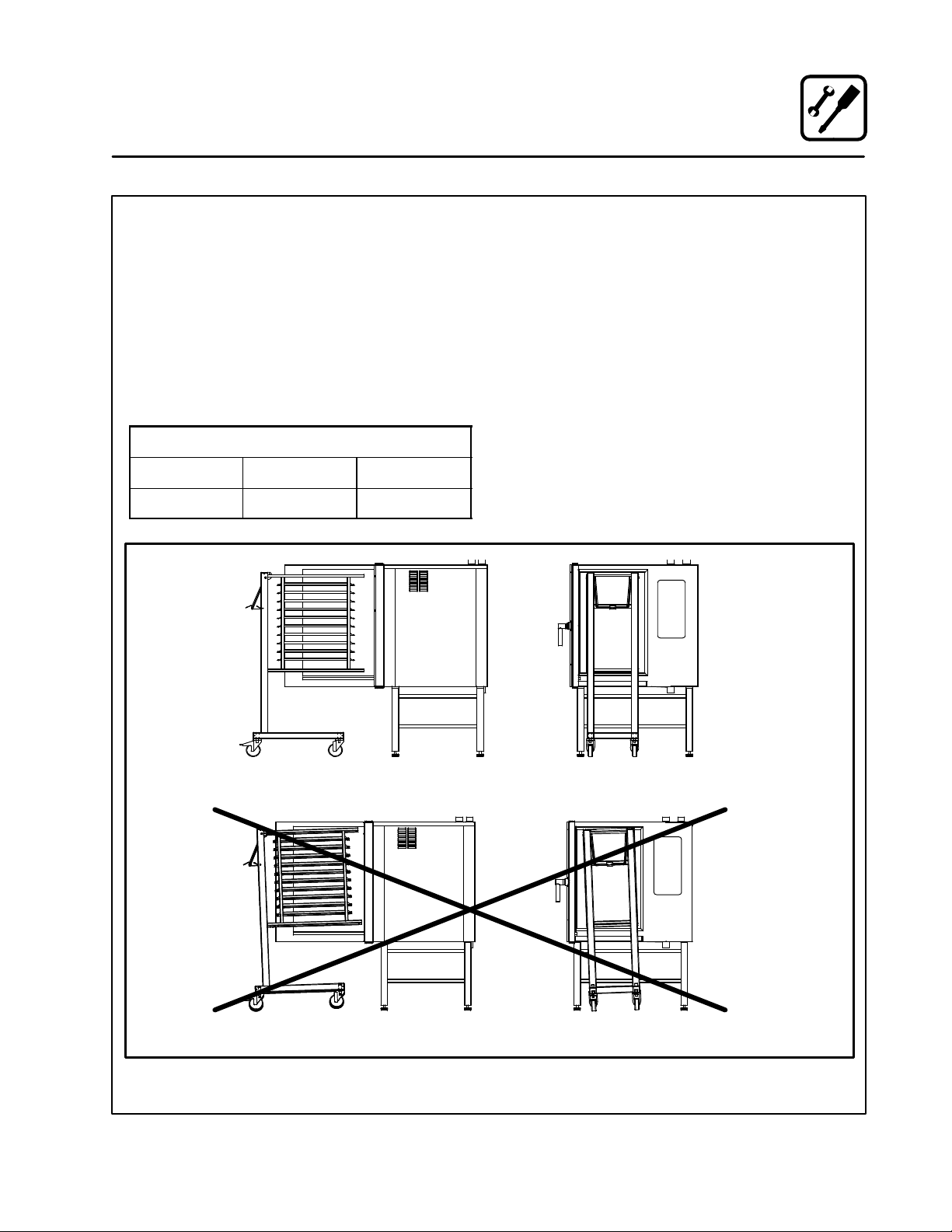

Oven Location and Leveling

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

Certain minimum clearances must be maintained

between the oven and any combustible or nonĆ

combustible construction.

Strong sources of heat such as hotplates, tilting

frying pans, deep fat fryers, etc. should not be

placed near the oven, especially near its right side.

An optional side heat shield is available.

MINIMUM REQUIRED CLEARANCES

Right Side Left Side Back

2.75" (7cm) 2.75" (7cm) 2" (5cm)

In addition, the following clearances are recomĆ

mended for servicing.

D Oven body sides - 12" (30cm)

D Oven body back - 12" (30cm)

To ensure that the oven functions correctly

when installed, it should be placed upright and

level (horizontally). This is measured at the

front and side edge of the roof. The oven can be

levelled using the adjusting screws on the

stand or on the legs of table models. The height

of the oven should also be adjusted to fit the

trolley for rack.

CORRECT INSTALLATION

INCORRECT INSTALLATION

Figure 2

7

Page 12

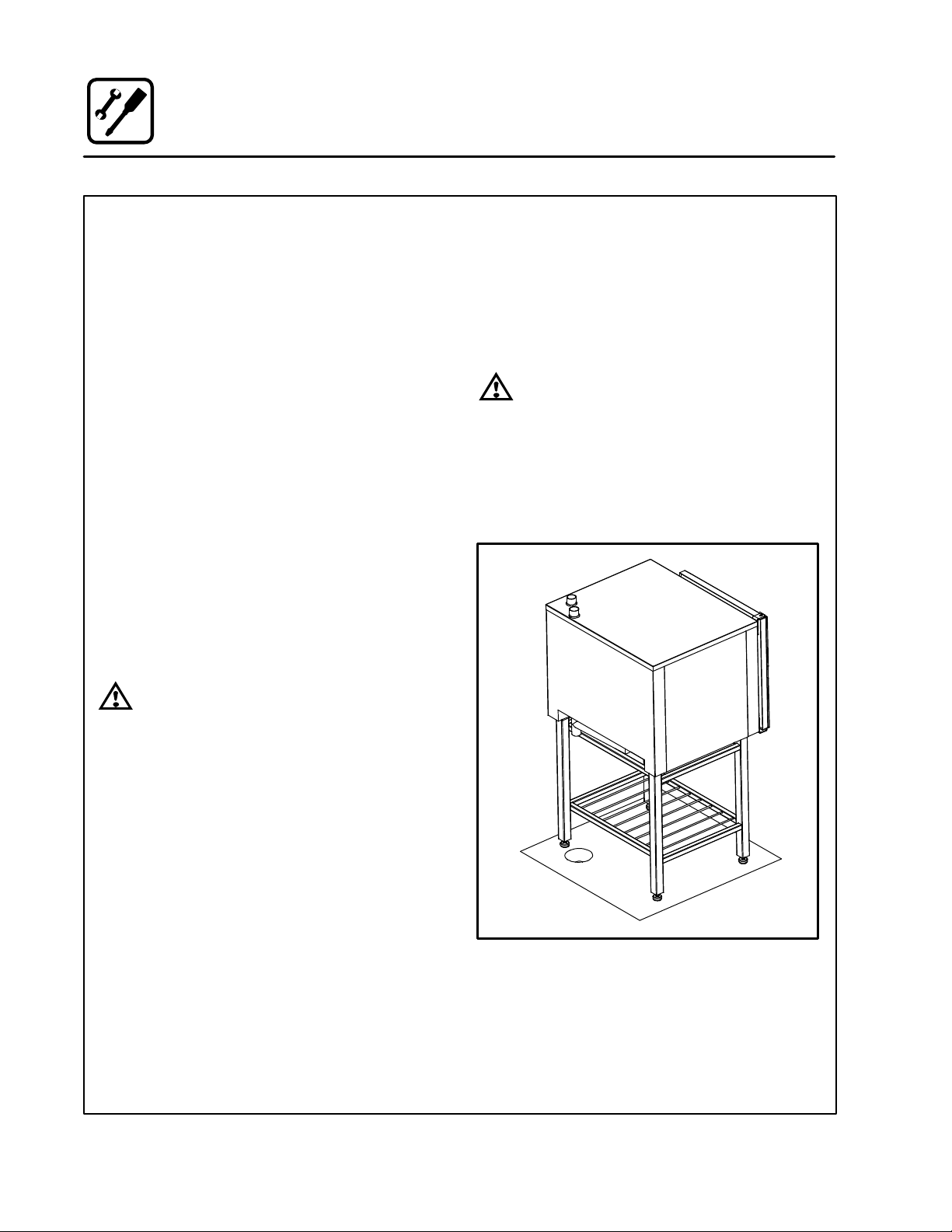

Installation

Plumbing Connections

WATER CONNECTION

Blodgett BCM ovens have one or two water conĆ

nections. In the case of two water connections, the

following applies:

D 1 connection for raw water for the condensation

jet (cold water). The connection is located on

the back.

D 1 connection for the steam generator and the

Combi Wash jet in the oven chamber. Must

meet the requirements applying to water supĆ

plied to household appliances; however, hot

water with a temperature not exceeding 120°F

(49°C) can be used. The connection is located

at the front.

To facilitate cleaning and servicing, the oven

should be connected with an approved flexible

3/4" hose. Permanent installations should be fitted

with a stopĆtap and a nonĆreturn valve.

If the feeder is connected to the water distribution

system with a flexible hose, this hose should be VA

approved.

Before connecting the oven to water, flush the

tubes thoroughly. Connect the oven.

DRAIN CONNECTION

Blodgett ovens are equipped with a drain system

that removes surplus water from the oven chamĆ

ber. This may be condensed water from the prodĆ

ucts, or it may occur when the oven chamber is

cooled down with cold water, or when the oven

chamber is cleaned.

WARNING!!

Connection must be carried out by an auĆ

thorised plumber, to an open or closed

drain. The drain must never end directly

beneath the oven.

The drain must be of stainless steel or an equally

temperatureĆresistant material, have a diameter of

at least 2" (49 mm) and a fall of at least 3° or 5%.

WARNING!!

If the water temperature exceeds 70°F

(21°C), problems with regard to Combi

Optima calibration and cooling of the

oven may occur.

Ovens with a steam generator must not be

connected to a reversed osmosis plant,

as this may cause problems with the readĆ

ing of the water level in the steam generaĆ

tor.

The water connection must be carried out

by an authorised plumber in accordance

with existing local codes.

Clogged up water filters and dirt in the soĆ

lenoid valves are not covered by the warĆ

ranty.

Figure 3

8

Page 13

Installation

Electrical Connection and Ventilation

ELECTRICAL CONNECTION

NOTE: Electrical connections must be performed

by a qualified installer only.

Before making any electrical connections to these

appliances, check that the power supply is adeĆ

quate for the voltage, amperage, and phase reĆ

quirements stated on the rating name plate

mounted on the appliance.

1. The rating plate is located on the right side of

the oven.

An approved plug outlet or a safety cutout must be

located close to the oven so that the oven can be

disconnected during installation and repair. The

safety cutout must be able to cut off all poles with

a total distance of break of at least 3 mm.

All appliances must be installed in accordance

with Local or National Electrical codes.

The wiring diagram is located in the motor

compartment.

NOTE: Disconnect the power supply to the apĆ

pliance before servicing.

WARNING!!

Improper installation may invalidate your

warranty.

VENTILATION

Blodgett BCM ovens are equipped with an open/

direct exhaust system that removes surplus huĆ

midity from the oven chamber. The exhaust sysĆ

tem has an electrically operated damper.

The ventilation motor can be controlled directly

from the oven. This means that the ventilation

starts when a program is started and runs for 10

minutes after the program is completed.

The exhaust tube can be connected to a ventilaĆ

tion system. In that case, a special extraction funĆ

nel is fitted to avoid suction directly from the oven

chamber. This extraction funnel can be ordered

from Blodgett.

If an extraction hood is installed in the ceiling

above the oven, it should project 20" (50 cm) over

the front of the oven.

Figure 4

9

Page 14

Installation

Final Check Lists

WARNING!!

Final check list must be performed by a

qualified installer only.

OVEN EXTERIOR

j Check that the oven has not been damaged

in transit (dents, scratches, etc.)

j Check/adjust the height and check that the

oven is placed level (horizontally)

j Check/adjust oven door

CONNECTIONS

j Check for correct water connection

j Turn on water supply

j Check for leaks

j Turn off water supply

j Check and clean dirt filter

j Turn on water supply again

j Check hand shower

j Check for correct electrical connection

j Check connection to drip tray

j Check for correct mounting of drip tray

j Check for correct fall of hose from drip tray,

and check for leaks

j Check for correct exhaust and drain connecĆ

tion

j Clean the oven

j Apply steel oil

OVEN INTERIOR

j Check that filter housing is mounted correctly

j Check interior light

j Clean the oven

CONTROL

j Check and adjust, if necessary, each of the

preset values

j Heat up the oven at 480° F (249°C) for approxĆ

imately 5 minutes.

10

Page 15

Operation

Manual Control Description

1. MAIN POWER SWITCH - controls power to

the oven

2. TEMPERATURE KEY - press to set the cook

temperature

3. TIME KEY - press to set the cook time

4. PROBE KEY - press to activate core probe

5. PROGRAM KEY - press access and program

product recipes. Control stores up to 10 recĆ

ipe programs with 3 cooking stages each.

6. STAGE KEY - use to enter stage information

during product programming

7. ALARM KEY - press to silence alarms

1

2

3

4

8. HOT AIR KEY - press to select Hot Air mode

9. COMBI KEY - press to select Combi 1, Combi

2 or Retherm mode

10. STEAM KEY - press to select Steam mode

11. VENT KEY - press to open or close the vent

12. FAN KEY - press to change the fan speed.

The fan is reversible with 9 speeds for optiĆ

mum baking and roasting results

13. SELECTION DIAL - turn to enter data into

control

14. START/STOP KEY - press to begin or cancel

a cook cycle

8

9

10

5

6

7

Figure 5

11

12

13

14

11

Page 16

Operation

Manual Cooking

MANUAL COOKING

1. Press the desired mode key on the right side

of the control. The LED next to the key lights

and the mode name is displayed.

To select Reheating, press the COMBI key

once.

To select Combi 1 (30Ć40% humidity), press

the COMBIi key twice.

To select Combi 2 (60Ć80% humidity), press

the COMBI key three times.

2. Press the TEMP key. Turn the dial to enter the

desired cook temperature. Press the TEMP

key again to save the cook temperature.

NOTE: If steam mode is selected, the temperĆ

ature is automatically set to 212_F

(100_C).

3. Press the TIME key. Turn the dial to enter the

desired cook time. Press the TIME key again

to save the cook time.

For continuous cooking, turn the dial until the

display reads --:--. Continuous manual

cooking allows the oven to run continuously at

the set temperature in the set cooking mode.

NOTE: Time is displayed in hours:minutes.

4. Press the FAN key. Turn the dial to enter the

desired fan speed. Press the FAN key again to

save the fan speed.

NOTE: The fan cannot be set below 50% at

temperatures above 390_F (200_ C)

5. The vent position can be set when cooking in

Hot Air mode only.

Press the VENT key to open the vent. The LED

next to the key lights. Press the VENT key

again to close the vent. The LED next to the

key goes out when the vent is closed.

6. Press the START/STOP key to begin the cook

cycle.

7. If you are cooking in Hot Air mode, it is posĆ

sible to inject moisture at any time during the

cook cycle. Press and hold the STEAM mode

key. Steam is injected until the key is released.

8. At the end of the cook cycle, an alarm sounds

and the display flashes. Push the START/

STOP key or open the door to silence the

alarm.

NOTE: The alarm will not sound during a conĆ

tinuous manual cook.

CORE PROBE COOKING

1. Follow the instructions for Manual Cooking to

set the mode, cook temperature, fan speed

and vent position.

2. Press the CORE PROBE key. Turn the dial to

enter the desired product core temperature.

Press the CORE PROBE key again to save the

core temperature.

NOTE: When the CORE PROBE key is seĆ

lected the cook time automatically

changes to --:--.

3. Insert the probe into the product.

The core temperature probe has several meaĆ

suring points on its tip. The computer calcuĆ

lates an average temperature thus ensuring

that the core temperature is 100% correct.

The probe should be inserted vertically in the

thickest part of the product.

When preparing products of different sizes,

insert the sensor in the smallest product and

then move it to a larger product when the core

temperature alarm sounds.

4. Load the product and close the door. Plus the

core probe into the oven.

5. Press the START/STOP key to begin the cook

cycle.

6. When the product has reached the core temĆ

perature the alarm sounds. Push the START/

STOP key or open the door to silence the

alarm.

12

Page 17

Operation

Programmed Cooking

PROGRAMMING THE CONTROL

The Blodgett manual control stores up to 10 recipe

programs with 3 stages per product.

Naming the Program

1. Press the PROGRAM key. Turn the dial until a

free recipe is displayed.

2. Press and hold the PROGRAM key for 5 secĆ

onds. The first letter flashes. Turn the knob unĆ

til the desired letter is displayed. Press the proĆ

gram key to advance to the next digit.

3. Repeat step 2 until the product name is enĆ

tered.

4. Press and hold the PROGRAM key to save the

name.

Program Product Stages

NOTE: Blodgett recommends programming a

preheat with alarm for the first stage. To

program an alarm, press the ALARM key.

1. Press the STAGE key. Stage 1 is displayed.

2. Press the desired mode key on the right side

of the control. The LED next to the key lights

and the mode name is displayed.

To select Reheating, press the COMBI key

once.

To select Combi 1 (30Ć40% humidity), press

the COMBIi key twice.

To select Combi 2 (60Ć80% humidity), press

the COMBI key three times.

3. Press the TEMP key. Turn the dial to enter the

desired cook temperature. Press the TEMP

key again to save the cook temperature.

NOTE: If steam mode is selected, the temperĆ

ature is automatically set to 212_F

(100_C).

4. Press the TIME key. Turn the dial to enter the

desired cook time. Press the TIME key again

to save the cook time.

NOTE: Time is displayed in hours:minutes.

5. Press the FAN key. Turn the dial to enter the

desired fan speed. Press the FAN key again to

save the fan speed.

NOTE: The fan cannot be set below 50% at

temperatures above 390_F (200_ C)

6. The vent position can be set when cooking in

Hot Air mode only.

Press the VENT key to open the vent. The LED

next to the key lights. Press the VENT key

again to close the vent. The LED next to the

key goes out when the vent is closed.

7. Press the STAGE key to advance to stage 2.

Repeat steps 2Ć7 for stages 2 and 3.

NOTE: For recipes shorter than 3 stages, deĆ

lete the current step by pressing STEP

and ALARM simultaneously for 2 secĆ

onds.

8. Press and hold the PROGRAM key to save the

product program.

COOKING WITH A PROGRAM

1. Press the PROGRAM key. Turn the dial to disĆ

play the product recipe name.

2. Press the START/STOP key.

3. If an alarm is used, press the ALARM key to

turn the alarm between steps off.

4. If you are cooking in Hot Air mode, it is posĆ

sible to inject moisture at any time during the

cook cycle. Press and hold the STEAM mode

key. Steam is injected until the key is released.

5. When the program has started, you can

change time, temperature, core temperatureĆ

fan speed and vent position. These changes

will only be active in the current run.

The display shows the total time remaining. To

view the time remaining in the current step,

press the TIME key.

6. At the end of the programmed cook cycle, an

alarm sounds and the display flashes. Push

the START/STOP key or open the door to siĆ

lence the alarm.

13

Page 18

Operation

Cooking Tips

PREHEAT

485Ć575_ F (250Ć300_ C)

Blodgett recommends always preheating the

oven before cooking.

Preheat is used to heat an empty oven. To set the

preheat mode, select the Hot Air key and enter a

temperature above 485°C (250°C). PREHEAT is

displayed. The time can be set to maximum of 15

minutes. The timer will not begin the countdown

until the desired preheat temperature has been

reached.

NOTE: Continuous operation is not available in

preheat.

HOT AIR MODE

85Ć485_F (30Ć250_C)

D The hot air operating mode can be used for

roasting, grilling, baking and gratinating.

D Blodgett recommends that you keep the vent

open when roasting products at very high temĆ

peratures

D It is possible to roast breaded products such as

breaded fish and breaded pork chops. For maxĆ

imum effect, use enameled cast iron pans or siliĆ

coneĆcoated baking sheets.

RETHERM MODE

85Ć355_F (30Ć180_C)

D Retherm is a very gentle process and therefore

very suitable for reheating.

D Use a core temperature probe to reach the perĆ

fect end temperature.

D For the reheating of sousĆvide products, etc.,

follow the product reheating recommendations.

SousĆvide products should not be covered.

STEAM MODE

85Ć250_F (30Ć120_C)

D Blodgett recommends preĆsteaming the oven

for 8 minutes before loading product.

D Steaming at 212°F (100°C is recommended for

all kinds of hard vegetables, rice and pasta.

D Low temperature steaming at 85Ć211°F

(70Ć80°C) is recommended for fish.

D Forced steaming at 250°F (120°C) is an aggresĆ

sive and very rapid process, which should be

used with care.

COMBI MODES

85Ć485_F (30Ć250_C)

D COMBI 1 is recommended for the roasting of all

kinds of meat cuts. The pores of the meat close

quickly, which prevents the juice from leaving

the meat. For long roast times at 175Ć265°F

(80Ć130°C), COMBI STEAMING 1 helps reduce

shrinkage.

D COMBI 2 is recommended for roasts that

should be wellĆdone, and if you want to use the

juice for gravy. At temperatures higher than

335°F (170°C), the crust of the meat becomes

nice and brown.

14

Page 19

Maintenance

Cleaning & Preventative Maintenance

DAILY CLEANING

Daily cleaning of your Combi oven is essential for

sanitation, and to ensure against operational diffiĆ

culties.

Cleaning the Exterior

1. The exterior of the appliance may be cleaned

and kept in good condition with a light oil. SatĆ

urate a cloth and wipe the appliance when it

is cold; wipe dry with a clean cloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet. CleanĆ

ing with a water jet can impregnate chloĆ

rides into the stainless steel, causing the

onset of corrosion.

Cleaning the Interior

NOTE: DO NOT use corrosive cleaners not inĆ

tended for oven cleaning on your Combi

oven.

Blodgett recommends the following products

for cleaning and rinsing of your Blodgett ComĆ

bi oven. If you choose to use products other

than what Blodgett recommends, please have

your suppler send us the MSDS sheet on the

proposed alternate so we can ensure it meets

our standards. Non approved products can

cause harm to your unit and can potentially

void your warranty.

Recommended oven cleaners:

Johnson Diversey Suma Nova LĆ6

Four, 1 gallon (3.78 litre) containers

Product code 57252280

One, 5 gallon (18.9 litre) container

Product code 57252100

Recommended Rinse Aid:

Johnson Diversey Suma Maro A8.8

Four, 1 gallon (3.78 litre) containers

Product code 57270280

One, 5 gallon (18.9 litre) container

Product code 57270100

1. Open the oven door.

2. Use the attached spray hose, located beneath

the control, to clean the front drip tray. Water

will run to the drain in the oven cavity.

Run the CombiWash automatic cleaning cycle

as follows:

1. Check that the oven cleaner and rinse agent

containers are both full.

2. Press the PROGRAM key. Turn the dial until

COMBIWASH is displayed.

3. CombiWash features four different cleaning

cycles. Press the STAGE key to select the deĆ

sired cleaning cycle.

Cycle 1 (44 minutes)

Cycle 2 (1 hour)

Cycle 3 (1 hour, 49 minutes)

Cycle 4 (2 hours, 38 minutes)

NOTE: Use cycle 1 or 2 after steaming and

roasting at low temperatures. Use

cycle 3 or 4 after steaming and roastĆ

ing at high temperatures.

4. Press the Start/Stop key to initiate the clean

cycle.

5. If the cavity temperature is above 175_F

(80_C), the oven will automatically enter cool

down. When the cavity is below 175_F (80_C)

the CombiWash cycle begins.

6. The control counts down the time remaining

in the wash cycle.

7. When the wash cycle is over, the oven autoĆ

matically switches to an energy saving standĆ

by mode.

15

Page 20

Maintenance

Cleaning & Preventative Maintenance

WEEKLY CLEANING

In addition to the daily cleaning, it is necessasry to

clean the control filter and behind the fan guard on

a weekly basis. This is necessary for proper funcĆ

tioning of the oven. Scale will build up on the fan

and heat source leading to a less efficient oven.

Cleaning the Control Filter

The control filter is located below the control

compartment, in front of the spray hose.

1. To remove, pull down on the black knob on the

left of the filter.

2. Clean the filter with soap and water.

3. Reinstall the filter. Press up on the filter until the

back of the knob is inserted into the hole in the

bottom of the oven.

4. Push up on the center of the knob to expand

the back of the knob securing the filter.

Cleaning Behind the Fan Guard

1. Loosen the two screws and on the fan guard

(or baffle).

2. Swing the baffle forward.

3. Thoroughly spray cleaner onto the fan and

heat source. Place the oven in the steam

mode for approximately 10 minutes.

4. After ten minutes, rinse the cleaner off. Return

the fan guard to the closed position. Rotate

the two screws to secure the fan guard.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are

āthe āāāproper āāinitial āāinstallation āāof āāthe equipment and

a program for cleaning the appliance routinely.

The Oven/Steamer requires no lubrication. ConĆ

tact the factory, the factory representative or a loĆ

cal Blodgett Combi service company to perform

maintenance and repairs should they be required.

Deliming

The control keeps track of boiler usage between

descaling. When the oven has reached 95% of the

time the control warns the operator that the oven

needs to be delimed.

Deliming the Oven

1. Be sure the container delivering the deliming

agent to the appliance is full. Be sure to use a

nonĆdiluted deliming agent such as "Lime

Away" by EcoĆLabs or "Lime Out", by US

Chemical.

2. Press the PROGRAM key. Turn the dial until

DELIMING is displayed.

3. Press the START/STOP key.

4. The remainder of the process is automatic.

The control displays the deliming steps as

they occur.

16

Page 21

BCMĆ61, BCMĆ101 et BCMĆ102

Manuel D'Installation - Utilisation - Entretien

17

Page 22

Introduction

The Blodgett CombiĆOven/Steamer

Le fourĆétuveur Combi de Blodgett propose une

toute nouvelle manière de cuire les aliments. Avec

le fourĆétuveur Combi, vous pouvez choisir entre

deux modes de cuisson : à la vapeur et à l'air

chaud, soit...

D séparément

D combiné, ou

D en séquence

En outre, trois modes de fonctionnement faciles

s'offrent à vous :

En mode Steam (vapeur), vous pouvez :

étuver réchauffer reconstituer

bouillir décongeler mijoter

blanchir conserver braiser

pocher

En mode Hot Air (air chaud), vous pouvez :

rôtir cuire du pain et des gâteaux

griller gratiner

In the Combi Optima mode you can:

décongeler rôtir réchauffer

étuver cuire du pain et des gâteaux

Il existe quatre modes spécialisés supplémentairĆ

es pour vous aider à tirer le maximum de votre

temps :

Remise en température : Assure un réchauffage

parfait.

Apprêt : Apprêtez et faites cuire dans le même

four.

Préchauffage : Sous ce mode, le four préchauffe

à 300°C (575°F) durant 15 minutes. Ensuite, il se

refroidit automatiquement jusqu'à 249°C (480°F)

afin de protéger les composants électroniques

perfectionnés.

Refroidissement : Permet à l'enceinte du four de

se refroidir rapidement avec la porte ouverte.

De plus, vous pouvez utiliser deux ou trois foncĆ

tions de manière séquentielle au cours d'une

même cuisson. Nous appelons cette méthode :

D étuvage combiné

D rôtissage combiné

D cuisson de pain combinée

La circulation de l'air chaud combinée avec la vaĆ

peur du fourĆétuveur Combi à haute performance

assurer des améliorations à plusieurs niveaux :

D productivité accrue dans la cuisine

D diminution des dépenses liées au remplaceĆ

ment des appareils de cuisine

D un choix de menus plus vaste

D un nettoyage simplifié

Le travail est simplifié puisque les aliments sont

préparés sur des plateaux ou dans des récipients

de la table à vapeur. Vous pouvez cuire, stocker et

transporter les aliments dans ces mêmes réciĆ

pients. Vous pouvez préparer avec efficacité de

petites quantités d'aliments de même que réĆ

chauffer les plats cuisinés et les aliments prêtsĆàĆ

servir en quelques minutes seulement. Il devient

possible aussi de préparer certains aliments surĆ

gelés sans même les décongeler. Cette souplesse

au niveau de la préparation réduit l'utilisation de

chaudrons et de tables à vapeur puisqu'il n'est

plus nécessaire de conserver au chaud de granĆ

des quantités d'aliments pendant de longues

périodes.

De nos jours, il devient de plus en plus important

d'améliorer la qualité des aliments. Avec le fourĆ

étuveur Combi de Blodgett, la cuisson des léguĆ

mes se fait sans eau et à une température optimaĆ

le légèrement inférieure à 100_C (212_F),

permettant ainsi de conserver les vitamines, les

minéraux, les éléments nutritifs et les oligoĆéléĆ

ments. La viande cuite dans le Combi perd moins

de sa masse et demeure plus ferme et plus juteuĆ

se. Vous utiliserez aussi le fourĆétuveur Combi daĆ

vantage pour les produits de la boulangerie, car

les modes Steam (vapeur) et Hot Air (air chaud) du

fourĆétuveur Combi en font un appareil de cuisson

tout usage.

18

Page 23

Introduction

Description du fourĆétuveur Combi

À PROPOS DU FOURĆÉTUVEUR

Les foursĆétuveurs Combi de Blodgett sont des

appareils haut de gamme fabriqués en acier

inoxydable de première qualité en faisant appel à

des procédés supérieurs.

Le ventilateur à deux vitesses est doté d'un dispoĆ

sitif de protection pour les doigts et alimenté par

un puissant moteur silencieux. Le condenseur asĆ

pire l'excès de vapeur de l'appareil. La condensaĆ

tion et les eaux usées générées par la vapeur et le

nettoyage sont continuellement évacuées.

L'isolant de haute qualité empêche un rayonneĆ

ment thermique excessif et aide à conserver

l'énergie.

Le générateur de vapeur fraîche haute performanĆ

ce comporte un système de commande qui vous

permet de profiter de tous les avantages d'un étuĆ

veur de haute qualité au simple actionnement

d'un bouton. La vapeur fraîche entre dans la cavité

du four sans pression et y circule à haute vitesse.

Cette méthode simple et pratique favorise une

cuisson rapide et en douceur qui vous procure

des aliments de première qualité. Le générateur

de vapeur est complètement automatique et il est

doté d'un dispositif qui l'empêche de fonctionner

à sec.

FONCTIONNEMENT DU FOURĆÉTUVEUR

COMBI

La porte pratique du four est dotée d'un hublot et

possède un grand rayon d'ouverture. La poignée

de la porte est facile à saisir, même avec des mains

mouillées ou grasses..

La commande simple d'utilisation facilite le foncĆ

tionnement. Grâce à ses symboles graphiques et

à son espaceĆmémoire pouvant accueillir jusqu'à

10 recettes de produit, le BCM s'avère facile d'utiĆ

lisation même pour les employés de cuisine sans

expérience.

Le système automatique CombiWash réduit le

nettoyage au minimum.

19

Page 24

Installation

Certifications

LES PRÉSENTES CONSIGNES D'INSTALLATION

SONT DESTINÉES AU PERSONNEL D'INSTALĆ

LATION ET D'ENTRETIEN QUALIFIÉ SEULEĆ

MENT. TOUTE INSTALLATION OU TOUT ENTREĆ

TIEN EFFECTUÉ PAR DES PERSONNES NON

COMPÉTENTES POURRAIENT ENDOMMAGER

LE FOUR OU CAUSER DES BLESSURES.

Le terme personnel d'installation qualifié désigne

une personne, une entreprise, une société ou une

organisation assumant, elleĆmême ou par l'entreĆ

mise d'un représentant, les responsabilités suiĆ

vantes :

D la pose ou le remplacement des tuyaux de gaz.

Le raccordement, la mise en service, la réparaĆ

tion ou l'entretien du matériel.

D La pose du câblage électrique à partir du compĆ

teur, de la boîte de distribution principale ou de

la prise jusqu'à l'appareil.

Le personnel qualifié doit détenir de l'expérience

dans ces domaines, connaître toutes les mesures

de sécurité pertinentes et respecter les normes de

la province ou des autorités locales.

Mises en service américaines et canadiennes

La mise en service doit respecter les normes locaĆ

les ou, en l'absence de tels normes, les règleĆ

ments suivants : National Fuel Gas Code,

NFPA54/ANSI Z223.1 - dernière édition, le Code

d'installation du gaz naturel CAN/CGAĆB149.1 ou

le Code d'installation du propane, CAN/CGAĆ

B149.2, selon le cas.

Référence : National Electrical Code, ANSI/NFPA

70 - dernière édition ou le Code canadien de

l'électricité CSA C22.1, selon le cas.

La mise en service de ce matériel doit respecter

les normes suivantes : Basic Plumbing Code of the

Building Officials and Code Administrators InterĆ

national Inc. (BOCA) et Food Service Sanitation

Manual du Food and Drug Administration (FDA).

L'appariel doit etre installe avec l'empechement

de refoulement selon les codes federale,

provincial et locaux.

Mise en service dans les autres pays

L'installation doit respecter les normes nationales

et locales, qui varient selon le pays. Si vous avez

des questions sur les méthodes d'installation acĆ

ceptables ou sur le fonctionnement de votre appaĆ

reil, veuillez communiquer avec votre détaillant.

S'il n'y a aucun détaillant dans votre région, veuilĆ

lez communiquer avec Blodgett Combi au

0011Ć802Ć860Ć3700.

20

Page 25

Installation

Caractéristiques techniques relatives aux services publics

SPÉCIFICATIONS DE PLOMBERI

EAU

Pression d'eau 250 kPa (2,5 bar, 36,26 lb/po2) durant le nettoyage CombiWash

150 kPa (1,5 bar, 21,76 lb/po2) lorsque le nettoyage CombiĆ

Wash est hors fonction 600 kPa (6 bar, 87 lb/po2) maximum

Raccordement d'eau Flexible d'arrosage d'eau froide, 1,905 cm (3/4 po)

Conditions requises

minimum

DRAINAGE

Type de drain Drain de mise à l'air libre

Raccordement du drain Cuivre 50,8 mm (2,00 po)

Température moyenne

de l'eau au drainage

Total des solides en suspension (TDS) - doit être moins que

100 parties par million

Dureté totale de l'eau - 80Ć120 parties par million

Chlorides - doit être moins que 30 parties par million

Le pH de l'eau - 7.0Ć8.0

Chlorine - 0 parties par million

Environ 71_C (160_F)

CARACTÉRISTIQUES TECHNIQUES ÉLECTRIQUES

Modèle du Four Tension kW Fréquence Phase Charge maximale

(ampères)

BCMĆ61E

208 9 60 3 26

240 9 60 3 26

480 9 60 3 13

BCMĆ101E

BCMĆ102E

BCMĆ202E

208 18 60 3 52

240 18 60 3 52

480 18 60 3 25

240 27 60 3 80

240 27 60 3 80

480 27 60 3 36

240 60 60 3 175

240 60 60 3 175

480 60 60 3 80

21

Page 26

Installation

Déballage du four

Gardez le four dans son emballage pour en facilitĆ

er la manipulation. Chaque fois que c'est posĆ

sible, utilisez un chariot élévateur manuel à levier.

1. Faites rouler le chariot sous la traverse tubulĆ

aire inférieure du bâti sur pieds. Placez deux

blocs de bois entre la traverse tubulaire et le

chariot.

REMARQUE:Pour obtenir le meilleur équilibre

possible, faites rouler le chariot

depuis le devant du four ou son

côté moteur.

REMARQUE:Si nécessaire, on peut aussi lever

le four du bâti sur pieds.

2. Retirez l'emballage d'origine du four. AttenĆ

dez d'avoir mis le four en place avant de retirer

le vinyle recouvrant la surface en acier inoxydĆ

able. Une fois le vinyle retiré, les surfaces deĆ

viennent vulnérables aux objets durs et couĆ

pants comme les outils et les couteaux.

3. Retirez tout le matériau d'emballage qui retiĆ

ent les grilles dans l'enceinte du four.

Figure 6

22

Page 27

Installation

Choix de l'emplacement et nivellement du four

Il est important de bien choisir l'emplacement de voĆ

tre four afin d'en augmenter les performances et

l'utilité.

Vous devez conserver un dégagement minimal enĆ

tre le four et toute construction combustible ou non

combustible.

On doit éviter de poser toute source puissante de

chaleur, comme une plaque de cuisson, une

poêle à frire basculante, une sauteuse ou une friĆ

teuse, près du four, particulièrement son côté

droit. On peut facultativement se procurer un

écran thermique latéral.

DÉGAGEMENT ACCEPTABLE

Côté droit Côté gauche Arrière

2.75" (7cm) 2.75" (7cm) 2" (5cm)

De plus, il est recommandé de respecter les dégaĆ

gements suivants pour l'entretien.

D Parois latérales du four - 30cm (12")

D Paroi arrière du four - 30cm (12")

Pour s'assurer que le four fonctionne convenĆ

ablement une fois mis en place, on doit le poser

érigé et horizontalement de niveau. Cela se

mesure aux rebords avant et latéral du toit. On

peut niveler le four à l'aide des vis de réglage

sur le bâti sur pieds ou sur les pattes de

modèles de table. On doit aussi régler la hauĆ

teur du four afin qu'il accueille convenableĆ

ment le chariot à grilles.

MISE EN PLACE CONVENABLE

MISE EN PLACE INAPPROPRIEE

Figure 7

23

Page 28

Installation

Robinetterie

RACCORDEMENT À L'ALIMENTATION EN EAU

Les fours Blodgett BCM présentent un ou deux

raccords à l'alimentation en eau. Ce qui suit s'apĆ

plique aux cas de deux tels raccords :

D un raccord pour l'eau brute (non traitée) servant

au giclage de condensat (eau froide). Ce racĆ

cord se trouve à l'arrière du four;

D un raccord en prévision du générateur de vaĆ

peur et du jet CombiWash dans l'enceinte du

four. Ce raccord doit absolument se conformer

aux exigences applicables à l'alimentation en

eau aux appareils électroménagers; toutefois,

on peut se servir d'eau chaude à une tempéraĆ

ture ne dépassant pas 49 °C (120 °F). Le racĆ

cord se trouve à l'avant du four.

Pour faciliter le nettoyage, l'entretien et les réparaĆ

tions, on doit relier au four un flexible de 1,905 cm

(3/4 po) approuvé. Les mises en place permaĆ

nentes doivent comprendre un robinet d'arrêt et

un clapet antiĆretour.

Si le distributeur se relie au système d'alimentaĆ

tion d'eau par un flexible, ce dernier doit être apĆ

prouvé VA.

Avant de raccorder le four à l'alimentation en eau,

rincez les tubes à fond. Raccordez le four.

RACCORDEMENT À L'ÉVACUATION D'EAU

Les fours Blodgett sont dotés d'un système d'évaĆ

cuation qui purge l'excédent d'eau de l'enceinte

du four. Il peut s'agir d'eau de condensation proĆ

venant des produits, de l'eau froide pour refroiĆ

dissement de l'enceinte du four, ou de l'eau résiĆ

duelle découlant d'un nettoyage du four.

AVERTISSEMENT!!

Le raccordement à l'évacuation d'eau doit

absolument s'effectuer à un tuyau de viĆ

dange. Ce dernier ne doit jamais se terĆ

miner directement sous le four.

Le tuyau de vidange doit être fait d'acier inoxydĆ

able ou d'un matériau d'une résistance thermique

aussi élevée, présenter un diamètre d'au moins

5,08 cm (2 po) et une pente descendante d'au

moins 3° ou 5 %.

AVERTISSEMENT!!

Si la température de l'eau dépasse 21°C

(70°F), il pourra survenir des problèmes

d'étalonnage Combi Optima et de refroiĆ

dissement du four.

Il faut éviter de relier tout four équipé d'un

générateur de vapeur à un processus de

traitement de l'eau par osmose inverse;

sinon, cela causera des problèmes de

lecture du niveau d'eau dans le généraĆ

teur de vapeur.

Le raccordement à l'alimentation en eau

doit absolument faire l'objet d'exécution

par un(e) plombier(ère) autorisé(e) conĆ

formément aux codes locaux existants.

La garantie ne couvre pas les filtres à eau

bouchés ou l'encrassement dans les

électrovalves.

Figure 8

24

Page 29

Installation

Raccordement à l'électricité et Ventilation

RACCORDEMENT À L'ÉLECTRICITÉ

REMARQUE:Seul un technicien qualifié peut effecĆ

tuer le raccordement à l'électricité.

Avant de procéder au raccordement à l'électricité

des appareils, assurezĆvous que la source d'aliĆ

mentation est conforme aux spécifications de tenĆ

sion, d'intensité et de phase indiquées sur la plaĆ

que signalétique de l'appareil.

1. La plaque signalétique se trouve sur le côté

droit du four.

Une prise électrique ou un interrupteur de sécurité

approuvé(e) doit absolument se trouver près du

four de manière qu'on puisse débrancher le four

aux fins de mise en place ou de réparation. L'interĆ

rupteur de sécurité doit absolument être en meĆ

sure de couper tous les pôles avec une distance

totale de coupure d'au moins 3 mm.

L'installation de tous les appareils doit se conforĆ

mer aux codes d'électricité nationaux et locaux.

Le schéma de câblage se trouve dans le compartiĆ

ment du moteur.

REMARQUE:Débranchez la source d'alimentation

électrique de l'appareil avant de proĆ

céder à l'entretien.

VENTILATION

Les fours Blodgett BCM sont équipés d'un

système d'échappement ouvertĆdirect qui abĆ

sorbe l'excès d'humidité de l'enceinte du four. Ce

système d'échappement contient un amortisseur

à fonctionnement électrique.

On peut commander le moteur de ventilation diĆ

rectement depuis le four. Cela signifie que la venĆ

tilation se met en marche dès la mise à exécution

d'un programme, et tourne durant 10 minutes

après l'achèvement de son exécution.

On peut relier le tube d'échappement à un

système de ventilation. Dans ce cas, on installe un

entonnoir d'extraction spécial pour éviter la sucĆ

cion directe depuis l'enceinte du four. On peut se

procurer cet entonnoir d'extraction auprès de

Blodgett.

Si on met en place une hotte d'extraction au plaĆ

fond auĆdessus du four, elle doit projeter 50,8 cm

(20 po) parĆdessus le devant du four.

ATTENTION !!

Une installation non conforme annule voĆ

tre garantie.

Figure 9

25

Page 30

Installation

Liste de vérification finale

ATTENTION !!

Seul un installateur qualifié peut effectuer

les étapes suivantes de la liste de

vérification.

EXTÉRIEUR DU FOUR

j Vérifiez la présence de dommages du four

causés en transit (bosselures, égratignures,

etc.).

j Vérifiez et, au besoin, rectifiez la hauteur, et véĆ

rifiez également si on a convenablement niveĆ

lé le four (horizontalement).

j Vérifiez et, au besoin, rectifiez l'ajustement de

la porte du four.

RACCORDS

j Confirmez le raccordement convenable à l'aliĆ

mentation en eau.

j Ouvrez l'alimentation en eau.

j Vérifiez la présence de fuites.

j Fermez l'alimentation en eau.

j Vérifiez et nettoyez le filtre à eau de tout enĆ

crassement.

j Ouvrez de nouveau l'alimentation en eau.

j Vérifiez la douche à main.

j Confirmez le raccordement convenable à la

prise électrique.

j Vérifiez le raccordement au plateau à égoutteĆ

ment.

j Confirmez le montage convenable du plateau

à égouttement.

j Confirmez la pente convenable du flexible deĆ

puis le plateau à égouttement et vérifiez la

présence de fuites.

j Confirmez le raccordement convenable du

système d'échappement et du tuyau d'évaĆ

cuation.

j Nettoyez le four.

j Appliquez une huile à acier.

INTÉRIEUR DU FOUR

j Confirmez le montage convenable du boîtier

du filtre.

j Vérifiez la lampe intérieure.

j Nettoyez le four.

COMMANDE

j Vérifiez et, au besoin, rectifiez chaque valeur

préréglée.

j Faites chauffer le four à une température de

249°C (480°F) durant environ cinq minutes.

26

Page 31

Fonctionnement

Description de la commande manuelle

1. INTERRUPTEUR MARCHEĆARRÊT PRINCIĆ

PAL. Commande l'alimentation électrique du

four.

2. TOUCHE TEMPÉRATURE. Appuyez sur cette

touche afin de régler la température de cuisĆ

son.

3. TOUCHE DE TEMPS DE CUISSON (TIME).

Appuyez sur cette touche afin de régler le

temps de cuisson.

4. TOUCHE DE SONDE (PROBE). Appuyez sur

cette touche afin d'actionner la sonde de temĆ

pérature.

5. TOUCHE DE PROGRAMME (PROGRAM).

Appuyez sur cette touche afin d'accéder aux

recettes de produit et de les programmer. La

commande peut stocker un maximum de 10

recettes avec trois stades de cuisson chaĆ

cune.

6. TOUCHE STADE (STAGE). Appuyez sur cette

touche afin de saisir des données sur les

stades de cuisson dans le cadre de la proĆ

grammation de recette de produit.

7. TOUCHE SIGNAL SONORE (ALARM). ApĆ

puyez sur cette touche afin d'actionner l'acĆ

cord silencieux du signal sonore.

8. TOUCHE D'AIR CHAUD (HOT AIR). Appuyez

sur cette touche afin de sélectionner le mode

d'injection d'air chaud.

9. TOUCHE COMBI. Appuyez sur cette touche

afin de sélectionner le mode Combi 1, Combi

2 ou Retherm (Remise en température).

10. TOUCHE VAPEUR. Appuyez sur cette touche

afin de choisir le mode d'injection de vapeur

(cuisson à l'étuvée).

11. TOUCHE ÉVENT. Appuyez sur cette touche

afin d'ouvrir ou de fermer l'évent.

12. TOUCHE SOUFFLANTE. Appuyez sur cette

touche afin de modifier la vitesse de la soufĆ

flante. Vous pouvez choisir parmi neuf viĆ

tesses en vue de résultats de cuisson et de

rôtissage optimaux. Vous pouvez également

inverser le sens de rotation de la soufflante.

13. CADRAN DE SÉLECTION. Tournez ce cadran

pour saisir des données et les transmettre à la

commande.

14. TOUCHE DE MARCHEĆARRÊT (START/

STOP). Appuyez sur cette touche afin d'aĆ

morcer ou d'annuler un cycle de cuisson.

1

8

2

9

3

4

5

6

7

Figure 10

27

10

11

12

13

14

Page 32

Fonctionnement

Cuisson manuelle

CUISSON MANUELLE

1. Appuyez sur la touche du mode désiré du

côté droit de la commande. La DÉL à côté de

la touche s'allume et l'écran affiche le nom du

mode.

Pour sélectionner le réchauffage, appuyez sur

la touche COMBI une seule fois.

Pour sélectionner le mode Combi 1 (30 % à 40

% d'humidité), appuyez sur la touche COMBI

deux fois.

Pour sélectionner le mode Combi 2 (60 % à 80

% d'humidité), appuyez sur la touche COMBI

trois fois.

2. Appuyez sur la touche TEMP. Ensuite, tourĆ

nez le cadran pour saisir la température de

cuisson désirée. Enfin, appuyez de nouveau

sur la touche TEMP afin d'enregistrer la temĆ

pérature de cuisson désirée.

REMARQUE:Si vous sélectionnez le mode vaĆ

peur, la commande règle autoĆ

matiquement la température à

100 °C (212 °F).

3. Appuyez sur la touche TIME. Ensuite, tournez

le cadran pour saisir le temps de cuisson désiĆ

ré. Enfin, appuyez de nouveau sur la touche

TIME afin d'enregistrer le temps de cuisson

désiré.

Pour assurer une cuisson continue, tournez le

cadran jusqu'à ce que l'écran affiche les inĆ

scriptions --:--. La cuisson manuelle conĆ

tinue permet au four de fonctionner conĆ

tinûment à la température établie dans le

mode de cuisson établi.

REMARQUE:L'écran affiche le temps selon le

format heures:minutes.

4. Appuyez sur la touche FAN. Ensuite, tournez

le cadran pour saisir la vitesse de soufflante

désirée. Enfin, appuyez de nouveau sur la

touche FAN afin d'enregistrer la vitesse de

soufflante désirée.

REMARQUE:Il est impossible d'établir une viĆ

tesse de soufflante inférieure à

50 % à des températures dépasĆ

sant 200°C (390°F).

5. On peut régler la position de l'évent seuleĆ

ment dans le cadre de la cuisson en mode air

chaud.

Appuyez sur la touche VENT pour ouvrir l'évĆ

ent. La DÉL à côté de la touche s'allume. ApĆ

puyez de nouveau sur la touche VENT pour

fermer l'évent. La DÉL à côté de la touche s'éĆ

teint avec l'évent en position fermée.

6. Appuyez sur la touche START/STOP pour

amorcer le cycle de cuisson.

7. Dans le cadre de la cuisson en mode air

chaud, il est possible d'injecter de la vapeur

en tout temps durant le cycle de cuisson. ApĆ

puyez sur la touche de mode vapeur (STEAM)

et gardezĆla enfoncée. L'injection de vapeur

se poursuit jusqu'à ce que vous relâchiez la

touche.

8. À la fin du cycle de cuisson, un signal sonore

se fait entendre et l'écran clignote. Appuyez

sur la touche START/STOP ou alors ouvrez la

porte afin d'arrêter le signal sonore.

REMARQUE:Le signal sonore ne se fera pas

entendre au cours d'une cuisson

manuelle continue.

28

Page 33

Fonctionnement

Cuisson manuelle

CUISSON À LA SONDE

1. Suivez les instructions pour la cuisson manĆ

uelle afin d'établir le mode, la température de

cuisson, la vitesse de la soufflante et la posiĆ

tion de l'évent.

2. Appuyez sur la touche CORE PROBE. EnĆ

suite, tournez le cadran pour saisir la tempéraĆ

ture de c

de nouveau sur la touche CORE PROBE afin

d'enregistrer la température de c

désirée.

REMARQUE:Lorsque vous appuyez sur la

touche CORE PROBE, l'affiĆ

chage du temps de cuisson

change automatiquement à

--:--.

3. Insérez la sonde dans la pièce à faire cuire.

La pointe de la sonde à température de c

de pièce présente plusieurs points de meĆ

sure. L'ordinateur du four calcule une tempéĆ

rature moyenne pour ainsi assurer une temĆ

pérature de c

On doit insérer la sonde verticalement dans la

partie la plus épaisse de la pièce à faire cuire.

Lorsque vous préparez des produits de grosĆ

seurs différentes, insérez la sonde dans la

plus petite pièce, et ensuite, lorsque le signal

sonore de température se fait entendre, déĆ

placez la sonde dans une plus grosse pièce.

4. Chargez la pièce dans le four et fermez la

porte. Branchez la sonde dans le four.

5. Appuyez sur la touche START/STOP afin d'aĆ

morcer le cycle de cuisson.

6. Lorsque la température au c Ć

teint la valeur préétablie, le signal sonore se

fait entendre. Appuyez sur la touche START/

STOP ou alors ouvrez la porte du four pour

arrêter le signal sonore.

29

Page 34

Fonctionnement

Cuisson programmée

PROGRAMMATION DE LA COMMANDE

La commande manuelle Blodgett peut stocker

jusqu'à 10 programmes de recette avec trois

stades de cuisson par produit.

Attribution d'un nom au programme.

1. Appuyez sur la touche PROGRAM. Tournez le

cadran jusqu'à ce que l'écran affiche une reĆ

cette gratuite.

2. Enfoncez la touche PROGRAM et gardez-la

enfoncée cinq secondes. La première lettre

clignote. Tournez le bouton jusqu'à ce que l'éĆ

cran affiche la lettre désirée. Appuyez sur la

touche PROGRAM afin d'avancer au caĆ

ractère suivant.

3. Reprenez l'étape 2 plusieurs fois jusqu'à ce

que vous ayez saisi au complet le nom du proĆ

duit.

4. Enfoncez la touche PROGRAM et gardez-la

enfoncée pour enregistrer le nom attribué.

Stades de programme de produit.

REMARQUE:Blodgett recommande de programĆ

mer un préchauffage avec signal soĆ

nore à l'intention du premier stade.

Afin de programmer un signal soĆ

nore, appuyez sur la touche ALARM

1. Appuyez sur la touche STAGE. L'écran afĆ

fiche le premier stade.

2. Appuyez sur la touche du mode désiré du

côté droit de la commande. La DÉL à côté de

la touche s'allume et l'écran affiche le nom du

mode.

Pour sélectionner le réchauffage, appuyez sur

la touche COMBI une seule fois.

Pour sélectionner le mode Combi 1 (30 % à 40

% d'humidité), appuyez sur la touche COMBI

deux fois.

Pour sélectionner le mode Combi 2 (60 % à 80

% d'humidité), appuyez sur la touche COMBI

trois fois.

3. Appuyez sur la touche TEMP. Ensuite, tourĆ

nez le cadran pour saisir la température de

cuisson désirée. Enfin, appuyez de nouveau

sur la touche TEMP afin d'enregistrer la temĆ

pérature de cuisson désirée.

REMARQUE:Si vous sélectionnez le mode vaĆ

peur, la commande règle autoĆ

matiquement la température à

100 °C (212 °F).

4. Appuyez sur la touche TIME. Ensuite, tournez

le cadran pour saisir le temps de cuisson désiĆ

ré. Enfin, appuyez de nouveau sur la touche

TIME afin d'enregistrer le temps de cuisson

désiré.

REMARQUE:L'écran affiche le temps selon le

format heures:minutes.

5. Appuyez sur la touche FAN. Ensuite, tournez

le cadran pour saisir la vitesse de soufflante

désirée. Enfin, appuyez de nouveau sur la

touche FAN afin d'enregistrer la vitesse de

soufflante désirée.

REMARQUE:Il est impossible d'établir une viĆ

tesse de soufflante inférieure à

50% à des températures dépasĆ

sant 200°C (390°F).

6. On peut régler la position de l'évent seuleĆ

ment dans le cadre de la cuisson en mode air

chaud.

Appuyez sur la touche VENT pour ouvrir l'évĆ

ent. La DÉL à côté de la touche s'allume. ApĆ

puyez de nouveau sur la touche VENT pour

fermer l'évent. La DÉL à côté de la touche s'éĆ

teint avec l'évent en position fermée.

7. Appuyez sur la touche STAGE afin d'avancer

au stade 2. Reprenez les étapes 2 à 7 pour les

stades 2 et 3.

REMARQUE:Dans les cas des recettes plus

courtes que trois stades, suppriĆ

mez l'étape actuelle en appuyant

simultanément sur STEP et

ALARM durant deux secondes.

8. Appuyez sur la touche PROGRAM et gardezla enfoncée pour enregistrer le programme de

ce produit.

30

Page 35

Fonctionnement

Cuisson programmée

CUISSON SELON UN PROGRAMME

1. Appuyez sur la touche PROGRAM. Tournez le

cadran jusqu'à ce que l'écran affiche le nom

de la recette du produit.

2. Appuyez sur la touche START/STOP.

3. Si le programme utilise un signal sonore, apĆ

puyez sur la touche ALARM afin de mettre le

signal sonore hors service entre les étapes.

4. Dans le cadre de la cuisson en mode air

chaud, il est possible d'injecter de la vapeur

en tout temps durant le cycle de cuisson. ApĆ

puyez sur la touche de mode vapeur (STEAM)

et gardezĆla enfoncée. L'injection de vapeur

se poursuit jusqu'à ce que vous relâchiez la

touche.

5. Une fois le programme démarré, vous pouvez

modifier le temps et la température de cuisĆ

son, la température de c Ć

tesse de la soufflante et la position de l'évent.

Ces changements auront cours seulement

durant l'exécution actuelle.

L'écran affiche le temps total qui reste. Pour

visualiser le temps restant dans l'étape acĆ

tuelle, appuyez sur la touche TIME.

6. À la fin du cycle de cuisson programmée, le

signal sonore se fait entendre et l'écran cligĆ

note. Appuyez sur la touche START/STOP ou

alors ouvrez la porte afin d'arrêter le signal soĆ

nore.

31

Page 36

Fonctionnement

Trucs et suggestions en matière de cuisson

PRÉCHAUFFAGE

250 à 300 °C (485 à 575 °F)

Blodgett recommande de toujours préchauffer

le four avant la cuisson.

Le préchauffage sert à chauffer un four vide. Pour

placer le four en mode de préchauffage, sélectionĆ

nez la touche Hot Air et saisissez une température

supérieure à 250 °C (480 °F). L'écran affiche PREĆ

HEAT. Vous pouvez établir un délai maximal de 15

minutes. La minuterie n'amorcera pas le compte

à rebours avant que le four ait atteint la tempéraĆ

ture de préchauffage désirée.

REMARQUE:Le fonctionnement continu n'est pas

accessible en mode de préchaufĆ

fage.

MODE D'AIR CHAUD (HOT AIR)

30 à 250 °C (85 à 485 °F)

D Le mode de fonctionnement à air chaud peut

servir au rôtissage, au grillage, à la cuisson au

four et au gratinage.

D Blodgett recommande de garder l'évent ouvert

durant le rôtissage à très haute température.

D Il est possible de rôtir des produits panés, comĆ

me des poissons et des côtelettes de porc.

Pour obtenir l'effet maximal, utilisez des

plaques en fonte émaillée ou enduites de siliĆ

cone.

MODE DE REMISE EN TEMPÉRATURE (REĆ

THERM)

30 à 180 °C (85 à 355 °F)

D La remise en température est un processus très

doux et, ainsi, convient très bien au réchaufĆ

fage.

D Utilisez une sonde de température afin que le

c de la pièce atteigne la température parĆ

faite d'achèvement.

D Pour réchauffer des produits sous vide, etc.,

suivez les recommandations de réchauffage du

produit. On doit éviter de recouvrir les produits

sous vide.

MODE VAPEUR

30 à 120 °C (85 à 250 °F)

D Blodgett recommande de préinjecter de la vaĆ

peur dans le four durant huit minutes avant de

charger le produit dans le four.

D Blodgett recommande l'étuvage à 100 °C (212

°F) pour toutes sortes de légumes durs, riz et

pâtes.

D Blodgett recommande l'étuvage à basse temĆ

pérature (70 à 80 °C [85 à 211 °F]) pour le poisĆ

son.

D L'étuvage forcé à 120 °C (250 °F) est un procesĆ

sus agressif et très rapide, et on doit l'utiliser

avec soin et prudence.

MODES COMBI

30 à 250 °C (85 à 485 °F)

D Blodgett recommande le mode Combi 1 pour le

rôtissage de toutes sortes de coupe de viande.

Les pores de la viande se referment rapideĆ

ment, ce qui empêche les jus de cuisson de

couler de la viande. Dans les cas de longs

temps de rôtissage à des températures de 80 à

130 °C (175 à 265 °F), le mode COMBI STEAMĆ

ING 1 aide à réduire la diminution de volume de

la viande durant la cuisson.

D Blodgett recommande le mode Combi 2 pour

les rôtis bien cuits, et s'il faut utiliser les jus de

cuisson pour en faire un fond ou une sauce. À

des températures supérieures à 170 °C (335

°F), la croute de la viande devient brunie.

32

Page 37

Entretien

Nettoyage et entretien préventif

NETTOYAGE QUOTIDIEN

Le nettoyage quotidien du four est essentiel pour

respecter les conditions sanitaires minimales et

éviter les problèmes de fonctionnement

Nettoyage de l'extérieur

1. Vous pouvez nettoyer l'extérieur de l'appareil et

le maintenir en bon état au moyen d'une huile

légère. Imbibez un chiffon et frottez l'appareil

lorsqu'il est froid, puis essuyez avec un chiffon

propre et sec.

ATTENTION !!

NE PULVÉRISEZ PAS l'extérieur de l'appaĆ

reil avec de l'eau et ne le nettoyez pas au

moyen d'un jet d'eau. Nettoyer à l'aide d'un

jet d'eau peut imprégner les chlorures dans

l'acier inoxydable, entraînant la formation

de corrosion.

Nettoyage de l'intérieur

REMARQUE:N'EMPLOYEZ PAS des nettoyants

corrosifs non prévus pour le nettoyĆ

age des fours sur votre four COMBI.

Blodgett recommande les produits suivants en

vue de nettoyage et de rinçage de votre four

Combi. Si vous choisissez d'utiliser des proĆ

duits différents de ceux que recommande

Blodgett, demandez à votre fournisseur de

nous envoyer la fiche signalétique (santé et séĆ

curité) de chacun de ces produits afin que nous

nous assurions qu'ils répondent à nos normes.

Tout produit non approuvé peut nuire à votre

unité et potentiellement annuler votre garantie.

Produits de nettoyage de four recommandés :

Johnson Diversey Suma Nova LĆ6

Quatre contenants de 3,78 litres (1 gallon)

Code de produit : 57252280

Un contenant de 18,9 litres (5 gallons)

Code de produit : 57252100

Agent de rinçage recommandé :

Johnson Diversey Suma Maro A8.8

Quatre contenants de 3,78 litres (1 gallon)

Code de produit : 57250280

Un contenant de 18,9 litres (5 gallons)

Code de produit : 57250100

1. Ouvrez la porte du four.

2. ServezĆvous du flexible de pulvérisation fourĆ

ni, situé sous la commande, pour nettoyer le

plateau à égouttement avant. L'eau résiduelle

s'écoulera par le tuyau de vidange dans l'enĆ

ceinte du four.

Faites tourner le cycle de nettoyage automatiĆ

que CombiWash comme suit :

1. Confirmez que les contenants d'agent nettoyĆ

ant et d'agent de rinçage du four sont tous

deux pleins.

2. Appuyez sur la touche PROGRAM. Tournez le

cadran jusqu'à ce qu'il affiche COMBIWASH.

3. CombiWash propose quatre différents cycles

de nettoyage. Utilisez les touches flèche

droite et gauche pour sélectionner le cycle de

nettoyage désiré.

Étape 1 (44 minutes)

Étape 2 (1 heure)

Étape 3 (1 heure 49 minutes)

Étape 4 (2 heures 38 minutes)

REMARQUE:Utilisez l'étape 1 ou 2 après avoir

cuit à l'étuvée ou rôti à basse temĆ

pérature. Utilisez l'étape 3 ou 4

après avoir cuit à l'étuvée ou rôti

à haute température.

4. Appuyez sur la touche Start/Stop pour amorĆ

cer le cycle de nettoyage.

5. Si la température de l'enceinte du four déĆ

passe 80 °C (175 °F), le four passera automaĆ

tiquement au mode de refroidissement. Si elle

est inférieure à ce point de démarcation, ou

lorsqu'elle l'atteint, le cycle de nettoyage

CombiWash s'amorce.

6. La commande compte à rebours le temps qui

reste au cycle de nettoyage.

7. Une fois le cycle de nettoyage terminé, le four

passe automatiquement à un mode d'attente

en service économiseur d'énergie.

33

Page 38

Entretien

Nettoyage et entretien préventif

NETTOYAGE HEBDOMADAIRE

En plus du nettoyage quotidien, il est nécessaire

de nettoyer aussi le filtre de commande et derrière

le protecteur de la soufflante sur une base hebdoĆ

madaire pour assurer le fonctionnement convenĆ

able du four. Sinon, il y aura formation et accuĆ

mulation de tartre sur la soufflante et la source de

chaleur, et cela réduira l'efficacité du four.

Nettoyage du filtre de commande

Le filtre de commande se trouve sous le compartiĆ

ment de la commande, en avant du flexible de pulĆ

vérisation.

1. Pour retirer le filtre, tirez vers le bas sur le bouĆ

ton noir sur le côté gauche du filtre.

2. Nettoyez le filtre au savon et à l'eau.

3. Remettez le filtre en place. Appuyez vers le

haut sur le filtre jusqu'à insérer l'arrière du

bouton noir dans le trou du bas du four.

4. Poussez vers le haut sur le centre du bouton

noir pour faire agrandir l'arrière du bouton et

fixer le filtre en place.

Nettoyage à l'arrière du protecteur de la soufĆ

flante

1. Desserrez les deux vis sur le protecteur de la

soufflante (ou la chicane).

2. Faites pivoter la chicane vers l'avant.

3. Vaporisez abondamment l'agent nettoyant

sur la soufflante et la source de chaleur. PlaĆ

cez le four en mode vapeur environ 10 minuĆ

tes.

4. Au bout de 10 minutes, rincez les surfaces de

l'agent nettoyant. Remettez le protecteur de

la soufflante en position fermée. Remettez en

place les deux vis, et serrezĆles pour fixer le

protecteur de la soufflante en place.

ENTRETIEN PRÉVENTIF

The best preventive maintenance measures are