Page 1

GB

Service & Installation Manual

For BCM Electric Oven

“Manual Control”

Page 2

Table of Contents

Data Plate 3

Installation and connection

-Water connection 4

-Drain connection 5

-Electrical connection/survey of supply lines 6

Start Menu 7

Oven set-up 8

Set –up Mode U 9-10

Test Mode 11

Test Mode D0-D6 12

Test Mode D7-D15 13

Test Mode D16-D20 14

Test Mode D21-D28 15

User Menu 17

User Menu B1-B7 18

User Menu B8-B13 19

User Menu B14-B21 20

User Menu B22-B24 21

Error Codes 22

-Error Code List 23

-Error Codes Guide

Notes 24

Sequence of operation

-Off / On Mode Operation 1

-Hot Air / CombiOptima Operation 2

-Steam / Reheating Operation 3

-Cooling down / Preheat operation 4

Manual Controller

Water level Sensor

BCM Start up Guide

Diagnostic Mode D-Level

Wire Diagram

-Wire Schematic_Diagram 1-8

-Understanding Wire Schematic 2-8

- 2 -

Page 3

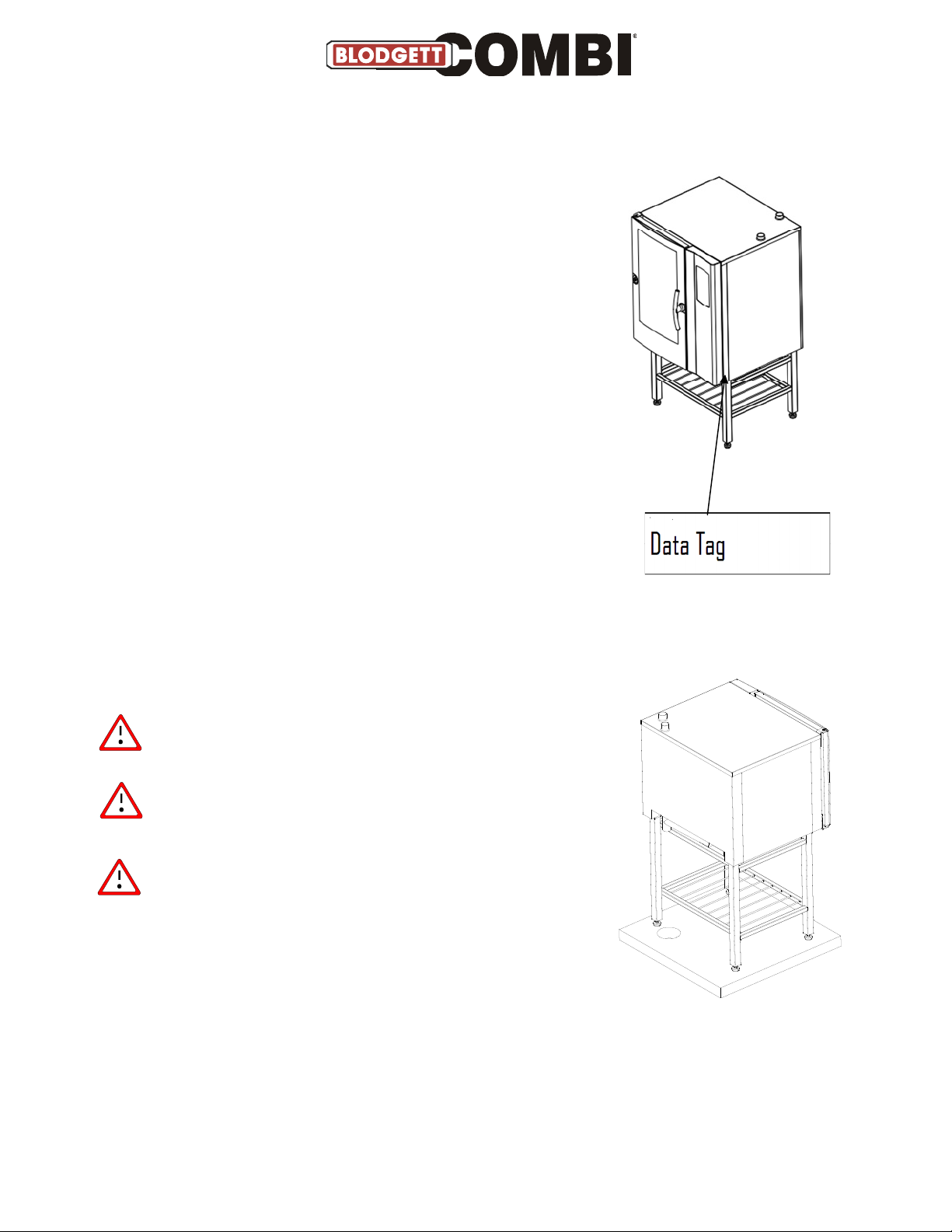

Installation and Connections

Data Plate

When communicating with BLODGETT, we kindly ask

you inform us of the serial number of the oven that is

stated on the approval plate. The approval plate is

located on the right-hand corner post of the oven

cabinet, as shown below.

The BLODGETT Technical Support, whose experience

and expert knowledge are at your disposal, can be

contacted at tel. # 800-331-5842 and fax # 802-652-2814.

Drain connection

From the factory, the BLODGETT ovens are equipped with

a drain system that removes surplus water from the oven

chamber. This water may be condensed water from the

products, or it may occur when the oven chamber is cooled

down with cold water, or when the oven chamber is cleaned.

Connection

authorised plumber, to an open or to a

closed drain.

It is recommended that a water outlet

is available/established in the floor of

the room where the oven is located.

must

be carried out by an

The drain must never end directly beneath

the oven.

The drain must be of

-resistant material, have a diameter of at least 2” (50mm)

and a fall of at least 3° or 5%.

copper

or an equally temperature

Page 4

Water Connections

BLODGETT ovens have one or two water connections. Two is most common.

To facilitate cleaning and service, the oven should be connected with an approved flexible ¾” hose

and the permanent installations should be fitted with a stop-tap and a non-return valve.

Before connecting the oven to water, flush the tubes thoroughly. Connect the oven.

Hardness of the water: 80-100 PPM

pH level 7.0-8.0

Total Dissolvable Solids: 100 PPM

Chloride: max. 0 PPM

Sulfate: max. 40 PPM/Gal

Conductivity: min. 75 microsiemens

Water pressure: min. 36 PSI (2.5 bar) dynamic pressure (when CombiClean activated.

When CombiWash not activated: min. 22 PSI (1.5 bar), max. 87 PSI (6

bar).

Water temperature: max. 70°F (20°C)

If the water temperature exceeds 70°F (20°C), problems with regard to ClimaOptima

calibration and cooling of the oven may occur.

The water connection must be carried out by an authorised plumber in accordance

with existing rules and regulations

To ensure that the water quality is in conformity with the above requirements, the

installation of a water filter in front of the water connection to the oven is

recommended.

1) 1 connection for raw water for the condensation jet (cold water). Located at the back.

2) The installation of a particle filter (0.25mm) is also recommended.

3) 1 connection for the steam generator and the jet in the oven chamber. Must meet the

requirements applying to water supplied to household appliances; however, hot water with a

temperature not exceeding 125°F (50°C) can be used. Located at the front.

Electrical Connections

When you connect the oven, you should:

Comply with federal, state and local rules and regulations.

The electrical connection

existing rules and regulations.

An approved plug outlet or a safety cut-out

oven can be disconnected during installation and repair. The safety cut-out must be able to cut

off all poles with a total distance of break of at least 3 mm. Each of the two units in a stacked

arrangement (Combi-Plus) must have its own plug outlet or safety cut-out.

The warranty does not cover incorrect connection.

must

be carried out by an authorised electrician in accordance with

must be located close to the oven so that the

- 4 -

Page 5

Installation and Connection

Drain connection

From the factory, the BLODGETT ovens are equipped with a drain system that removes surplus water

from the oven chamber. This water may be condensed water from the products, or it may occur

when the oven chamber is cooled down with cold water, or when the oven chamber is cleaned.

Connection

plumber, to an open or to a closed drain.

It is recommended that a water outlet

is available/established in the floor of

the room where the oven is located.

The drain must never end directly beneath

the oven.

The drain must be of

an equally temperature-resistant material, have a

diameter of at least 2” (50 mm) and a fall of at

least 3° or 5%.

must

be carried out by a license

stainless steel, cooper

or

Installation and Connection

Electrical connection/survey of supply lines

The electrical connection

rules and regulations.

The wiring diagram is located in the motor compartment.

The terminal for the electrical connection is located behind the right side plate.

An approved plug outlet or a safety cut-out

oven can be disconnected during installation and repair. The safety cut-out must be able to cut

off all poles with a total distance of break of at least 3 mm. Each of the two units in a stacked

arrangement (CombiPlus) must have its own plug outlet or safety cut-out.

The warranty does not cover incorrect connection.

When you connect the oven, you should:

must

be carried out by an authorised electrician in accordance with existing

must be located close to the oven so that the

• Follow the installation instructions and the information given on the rating plate.

• Comply with federal, state and local rules and regulations.

Page 6

Checking before Use

The oven should be checked before you start using it.

On the outside

•

Check that the oven has not been damaged in transit (dents, scratches, etc.)

•

Check/adjust the height and check that the oven is placed level (horizontally)

•

Check/adjust oven door

• Connections

•

Check for correct water connection

•

Turn on water supply

•

Check for leaks

•

Turn off water supply

•

Check and clean dirt filter

•

Turn on water supply again

•

Check hand shower

•

Check for correct electrical connection

•

Check connection to drip tray

•

Check for correct mounting of drip tray

•

Check for correct fall of hose from drip tray, and check for leaks

•

Check for correct exhaust and drain connection

•

Clean oven

•

Apply steel oil

• Oven chamber

•

Check that filter housing is mounted correctly

•

Check interior light

•

Clean oven

• Operation panel

•

Check and adjust, if necessary, each of the preset values

•

Heat up the oven at 485°F (250°C) for approx. 5 min.

The installation checklist and the instruction checklist (appendices 1 and 2) should be

filled in and returned to BLODGETT 30 days after the installation, at the latest.

Blodgett Fax # 802-652-2814

- 6 -

Page 7

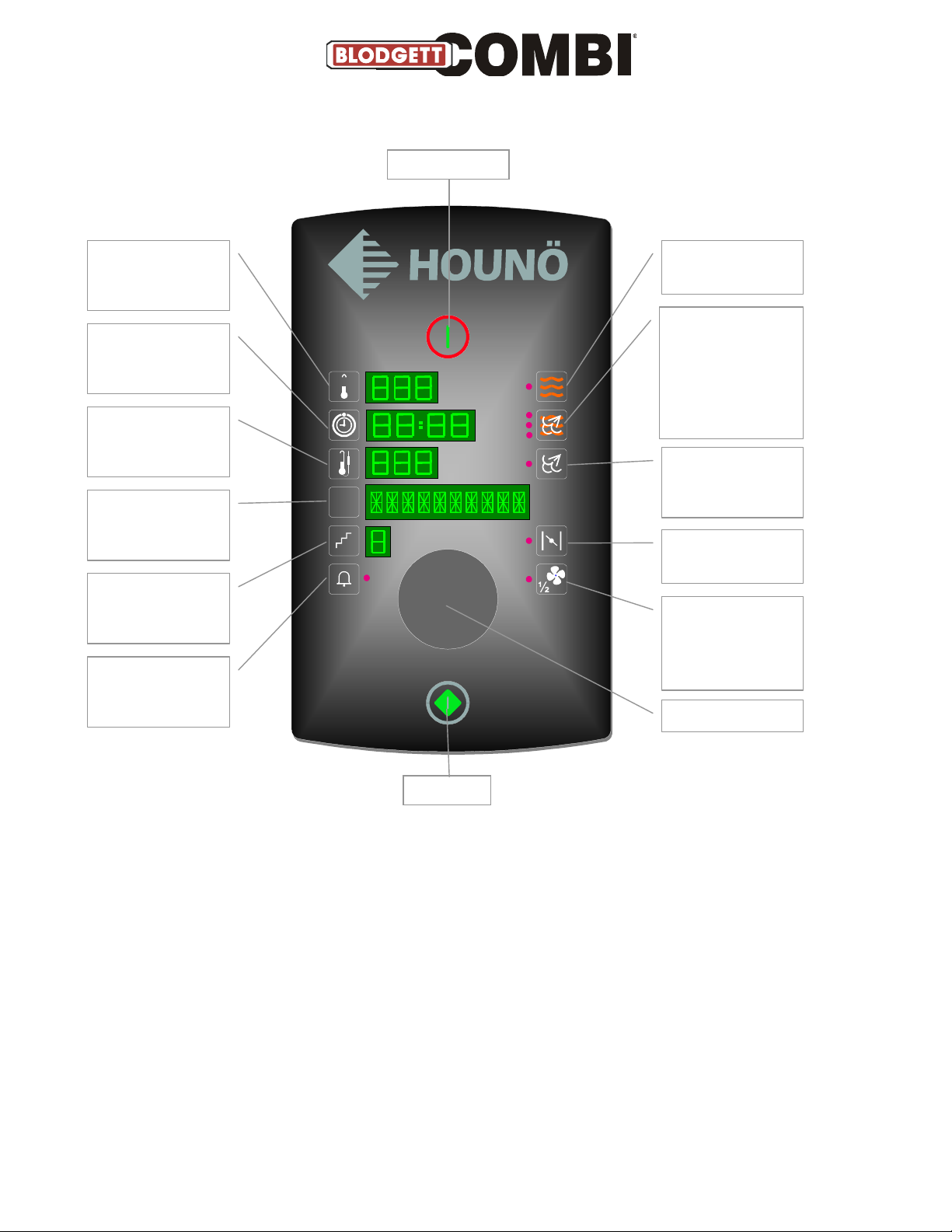

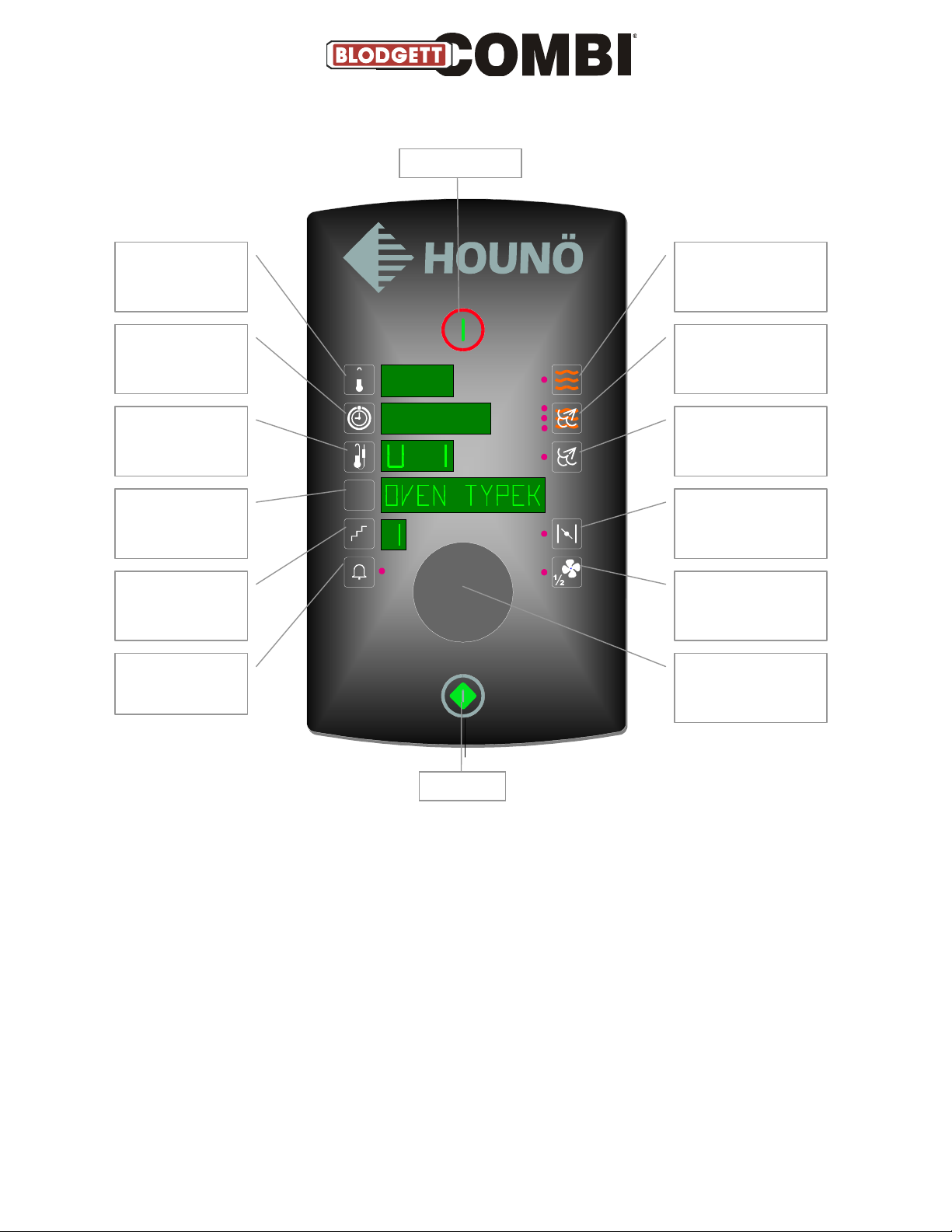

Start Menu

Program key

Step key

Alarm key

Start/Stop

Power Switch

Change oven

temperature with

turn switch

Change time with

turn switch

Core temperature

on C and K models.

Injection time on B

model.

PRG

HOT AIR selected if

control lamp on

COMBI STEAMING

selected if upper or

middle control lamp

is on. REHEATING is

selected if lower

control lamp is on

Steaming on C and

K, preheating on B

.

Exhaust open if

control lamp on

Fan speed can be

set between 20 and

100%. Control lamp

is on when speed

< 100.

Set temperature

(press temperature key, temperature flashes, set temperature with turn

switch, press temperature key again to save).

Set time

(press time key, time flashes, set time with turn switch).

Set core temperature

(press core temperature key, set temperature with turn switch).

Set injection time

(press injection key, time flashes, set injection time with turn switch). B

model only.

Turn switch

Page 8

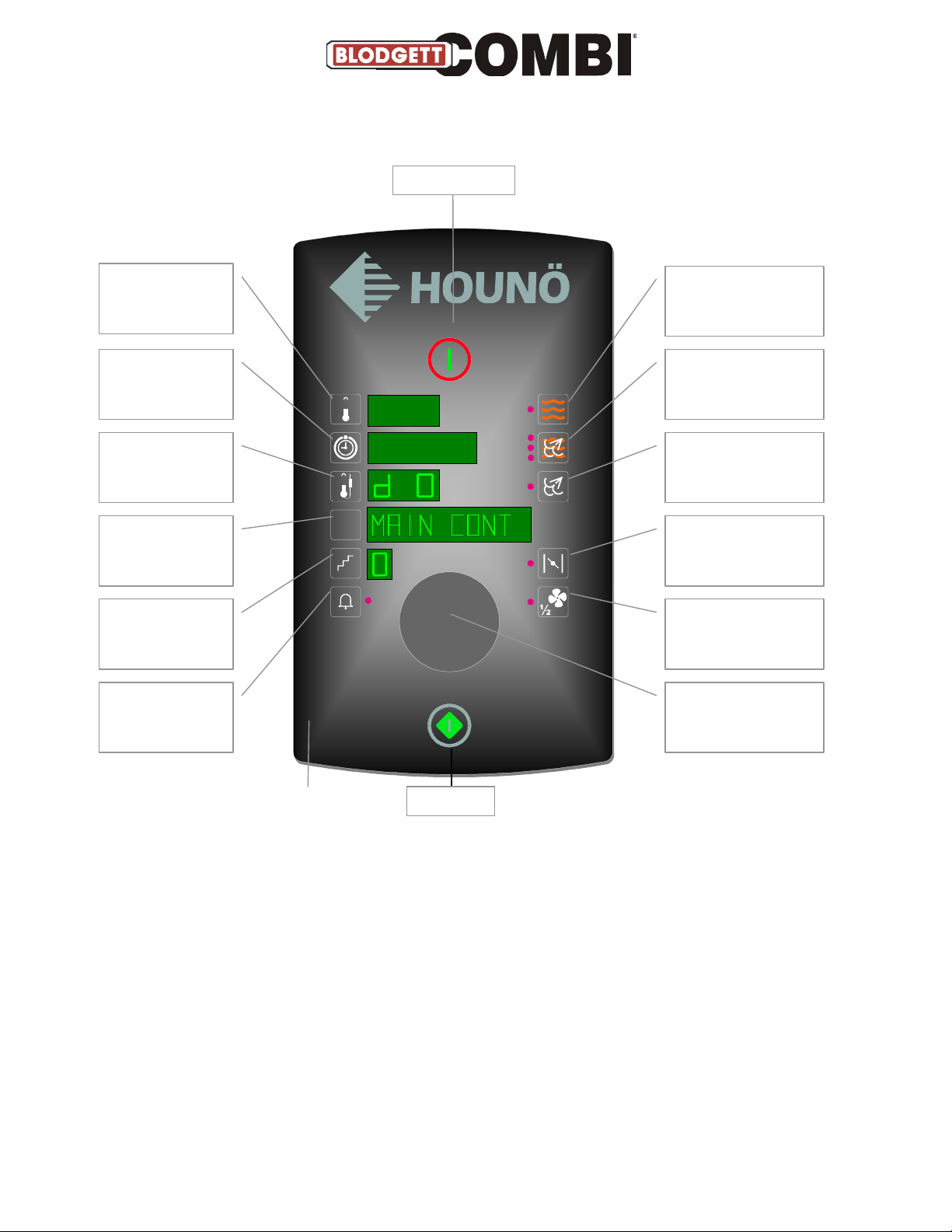

Oven set-up

Power Switch

Display shows

setting

Not active

Display shows "U"

No.

Display shows

description of "U"

function

Display shows

setting

Confirmation of

special settings

PRG

Press HOT AIR and

STEAMING for 2 sec.

Possible to change to

"d" test mode with

combi steam key

Press STEAMING/

PREHEATING and

HOT AIR for 2 sec.

Not active

Not active

Select "U" settings

with turn switch

Not active

To enter set-up mode, press hot-air key and steaming/preheating key for 2 sec.

To leave set-up mode, turn switch to the left. Change between set-up and test mode by

pressing combi-steam key.

The set-up mode is only intended for service engineers who wish to change the set-up of the

computer control of the oven model in question.

The program display shows a description of the "U" function in question.

Page 9

Set-up Mode U

In the set-up function, it is possible to set the oven controller to match the mechanical set-up and

the choice of software.

If the set-up has been changed in U1, U4 or U15, the oven will be reset.

U1 Oven model

You select the oven model (B, C or K) by pressing the step key.

1= K, 2= C, 3= B.

You press the temperature key to select a PassThrough model (two doors).

1= one door (standard) 2= two doors

When you have selected the oven model, confirm by pressing the alarm key if the control lamp

flashes.

After that, the controller initializes.

NOTE: ALL settings and programs are reset.

U2 Oven size

You choose the oven size by pressing the step key: 0-7.0= 1.06, 1= 1.08, 2= 1.10, 3= 1.12, 4=

1.16, 5= 1.20, 6= 2.10, 7= 2.14.

The oven size you have chosen is shown in the field next to the temperature key.

U3 CombiWash

You activate or deactivate CombiClean by pressing the step key.

0=OFF, 1=ON.

U4 Temperature scale

You choose between Celsius and Fahrenheit as scale of temperature by pressing the step key.

0= Celsius 1= Fahrenheit.

You can ”even out” the current temperature by pressing the temperature key.

0=OFF, 1=ON

When you have chosen the temperature scale, confirm by pressing the alarm key if the control lamp

flashes.

After that, the controller initializes.

NOTE: ALL settings and programs are reset.

U5 Not in use

U6 Low-temperature steaming

You activate and deactivate low-temperature steaming by pressing the step key.

0= OFF, steaming only possible at 100°C, 1= ON, steaming only possible between 30°C and 120°C.

NOTE: This function is available on K models only. If chosen on a B or C model, nothing

happens.

U7 Preheating at 300°C

You activate and deactivate preheating by pressing the step key.

0= OFF, 1= ON.

NOTE: Preheating at temperatures above 250°C is only possible for max. 15 minutes.

U8 Setting water level sensor

When you press the temperature key, the water level value starts flashing and can then be set

between 40 and 80 (default 70).

If the conductivity of the water is low, set the water level higher.

U9 Automatic restart

You activate and deactivate automatic restart by pressing the step key.

0= OFF, 1= 10 minutes, 2= 30 minutes, 3= 60 minutes.

This means that if there is a power cut, the program that was interrupted will be reassumed provided

that the power returns within the time set.

- 9 -

Page 10

U10 Programs

You activate the program mode by pressing the step key.

0= OFF, 1= 10 programs with 3 process steps.

NOTE: It is still possible to activate the cleaning program even though the program mode

is not active.

0= OFF.

U11 Core temperature probe

You activate and deactivate the core temperature probe by pressing the step key.

0= OFF, 1= ON.

U12 Drain cooling

You activate and deactivate drain cooling by pressing the step key.

0= OFF, 1= ON.

U13 Timer start

You activate or deactivate timer start by pressing the step key.

0= OFF, 1= ON.

U14 Demo

You activate or deactivate the demo mode by pressing the step key.

0= OFF, 1= ON.

NOTE: If the demo mode is on (1= ON), the oven will run without heating elements and

steam generator being switched on.

When the oven starts, it will let you know whether the demo mode is on.

U15 Initialising

You reset the controller by pressing the alarm key.

- 10 -

Page 11

Power Switch

Display shows

setting

Display shows

setting

Test Mode

For test mode, press

HOT AIR and COMBI

STEAMING for 2 sec.

For test mode, press

COMBI STEAMING and

HOT AIR for 2 sec.

Display shows "d"

No.

Possible to change to

"U" setting by pressing

STEAMING/PREHEATING

Display shows a

description of the

"d" function

PRG

Not active

Display indicates

whether the

function is active

Not active

Activates each

function briefly

Possible to choose a

"d" function with turn

switch

Not active

To enter test mode, press hot-air key and combi-steam key for 2 sec.

To exit test mode, turn switch left. Change between set-up mode and test mode by pressing

steaming/preheating key.

How to operate the selected component: You turn the component on (1) and off (2) by pressing

the step key. Or, you press the alarm key, and the component is active for as long as you press

the key.

The set-up mode is only intended for service engineers who wish to test the various

modes/functions.

Page 12

Test Mode D0-D6

In the test mode, it is possible to activate all electrical components. This is very useful in connection

with fault detection and the testing and adjusting of replacement parts.

D0 Main contactor(s)

This function activates contactor K1.

You activate or deactivate the function by pressing the step key. The function can, however, only be

activated when the fan is on.

To pulse, press the alarm key.

0= OFF, 1= ON.

Status for the main alarms appear in the display as follows:

Digit 1 fan

Digit 2 oven

Digit 3 generator

Digit 4 Solid State Relay

If ER28 appears, the alarm sensor circuit board or wiring harness is defective.

D1 Oven heat

This function activates contactor K2.

You activate or deactivate the function by pressing the step key.

Humidity pulsing is possible by pressing the alarm key.

0= OFF, 1= ON.

D2 Steam generator heat

Available on K models only

This function activates contactor K3.

You activate or deactivate the function by pressing the step key. However, this function can only be

activated when there is water in the steam generator.

To pulse, press the alarm key.

0= OFF, 1= ON.

D3 Fan, right-hand, high/low

This function activates the frequency exchanger.

You can test the speed of the motor by pressing the step key.

0= OFF, 2= ON

By pressing the time key, it is possible to adjust the speed of the motor from 0 to 100%.

The RPM appears in the temperature display.

Note: The main contactor K1 must be active for this function to work, as the frequency

transformer is connected via K1

D4 Fan, left-hand, high/low

This function activates the frequency exchanger.

You can test the speed of the motor by pressing the step key.

0= OFF, 2= ON

By pressing the time key, it is possible to adjust the speed of the motor from 0 to 100%.

The RPM appears in the temperature display.

Note: The main contactor K1 must be active for this function to work, as the frequency

transformer is connected via K1

D6 Solenoid valve

This function activates solenoid valve MV1.

You activate or deactivate the function by pressing the step key

To pulse, press the alarm key.

0= OFF, 1= ON.

- 12 -

Page 13

Test Mode D7-D15

D7 Filling valve

Available on K models only.

This function activates solenoid valve MV2.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key. 0= OFF, 1= ON.

D8 Drain pump

Available on K models only.

This function activates motor M2.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key. 0= OFF, 1= ON.

D9 Drain cooling

This function is not available on B models.

This function activates solenoid valve MV3.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key. 0= OFF, 1= ON.

D10 Damper motor

This function activates motor M3.

In the display next to ”Time”, it is possible to read the status of the damper motor switch.

OFF= damper open, ON= damper closed.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key. 0= OFF, 1= ON.

D11 Exhaust

This function activates the outlet for controlling the external ventilation, terminals 4 and 5.

In the display next to ”Time”, it is possible to read which outlet is active.

OFOF= both outlets are off, ONOF= outlet 4 is active and outlet 5 is off.

OFON= outlet 4 is off and outlet 5 is active. ONON= both outlets are active.

You activate or deactivate the function by pressing the step key.

0= OFOF, 1= OFON, 2= ONOF, 3= ONON.

D12 Cooling fan

This function activates motors M7 and M7A.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key.

0= OFF, 1= ON.

D14 Interior light

This function activates H1.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key.

0= OFF, 1= ON.

D15 Oven temperature

Here it is possible to read the current oven temperature, P1.

In the field next to ”Temperature”, the current temperature is shown. If ERR appears, the sensor

circuit is defective.

In the field next to ”Time”, an adjustment value between 80 and 120 (default 100) is shown.

To adjust the temperature, press the time key until the digit in the display flashes. Then adjust

upwards or downwards until the correct temperature is shown. Finally, press the time key again to

save the setting.

The temperature can be adjusted by +- 50°F (10°C).

- 13 -

Page 14

Test Mode D16-D20

D16 Core temperature

This function is not available on B models.

C and K models can use only one core temperature probe, it is possible, however, to test

core temperature probes 1 and 2.

Here it is possible to read the current temperature of the core temperature sensor, P2 + P2A.

In the field next to ”Temperature”, the current temperature is shown. If ERR appears, the sensor

circuit is defective.

In the field next to ”Time”, an adjustment value between 80 and 120 (default 100) is shown.

To adjust the temperature, press the time key until the digit in the display flashes. Then adjust

upwards or downwards until the correct temperature is shown. Finally, press the time key again to

save the setting.

The temperature can be adjusted by +- 50°F (10°C).

You change between the various measuring points of the core temperature probe by pressing the

step key.

1= Core temp probe 1, point 1, 2= Core temp probe, point 2, 3= Core temp probe 1, point 3.

4= Core temp probe 2, point 1, 5= Core temp probe, point 2, 6= Core temp probe 2, point 3.

D17 Steam generator temperature

Available on K models only.

Here it is possible to read the current steam generator temperature, P3.

In the field next to ”Temperature”, the current temperature is shown. If ERR appears, the sensor

circuit is defective.

In the field next to ”Time”, an adjustment value between 80 and 120 (default 100) is shown.

To adjust the temperature, press the time key until the digit in the display flashes. Then adjust

upwards or downwards until the correct temperature is shown. Finally, press the time key again to

save the setting.

The temperature can be adjusted by +- 50°F (10°C).

D18 Drain temperature

Here it is possible to read the current steam generator temperature, P4.

In the field next to ”Temperature”, the current temperature is shown. If ERR appears, the sensor

circuit is defective.

In the field next to ”Time”, an adjustment value between 80 and 120 (default 100) is shown.

To adjust the temperature, press the time key until the digit in the display flashes. Then adjust

upwards or downwards until the correct temperature is shown. Finally, press the time key again to

save the setting.

The temperature can be adjusted by +- 50°F (10°C) (approx. 2°F (.5°C) per step).

D20 Door sensor

Here it is possible to read the status of and calibrate door sensor 1 = SE1 and 2 = SE1A.

You change between door sensor 1 and 2 by pressing the step key.

After some time, the text “DOOR SENSOR” changes to show the status of the sensor: >CLOSED<,

>OPEN<, >SENS ERROR<. You start the calibration by pressing the exhaust key.

How to calibrate:

1. Press the damper key

2. >CLOSE< flashes

3. Close the door

4. Press the damper key

5. >OPEN< flashes

6. Open door in the first step

7. Press the damper key

8. >CALIB OK< or >CALIB ERR< appears

9. Press the damper key to confirm

In the display next to the temperature key, it is possible to read the current value (0 – 120).

In the display next to the time key, it is possible to read the set point.

- 14 -

Page 15

Test Functions D21-28

D21 Water level

Available on K models only.

Here it is possible to read the status of SE2.

In the display next to ”Time”, the conductivity is shown and it is indicated whether the water level is

high or low

XX|LO= low water level, XX|HI= high water level.

XX = conductivity of the water.

Default setting is approx. 80 with no water and 40.60 with water. The better the conductivity, the

lower the measured value.

D22 Thermo-switch oven

Here it is possible to read the status of Q1 and Q1A.

In the display next to ”Time”, it is shown whether the circuit is connected or disconnected.

OF= disconnected ON= connected.

In the event of defects, it is possible to reset thermo-switches Q1 and Q2 that are located at the

bottom of the oven below the operation panel.

Note: Q2 is only found in ovens with 2 fan motors (1.16 and 1.20). Q1 and Q1A are series

connected which is why there is only one input signal.

D23 Thermo-switch fan

Here it is possible to read the status of S2 and S2A

In the display next to ”Time”, it is shown whether the circuit is connected or disconnected.

OF= disconnected ON= connected.

In the event of defects, wait for 10 – 20 minutes, then try again.

Note: Q2 is only found in ovens with 2 fan motors (1.16 and 1.20). S1 and S1A each have

their own input on the IO board hence 2 x status (On On / OFF OF / On OF / OF On).

D24 Damper switch

Here it is possible to read the status of M3.

In the display next to ”Time”, it is possible to read the status of the damper motor switch.

OF= damper open, ON= damper closed.

D27 Pump for detergent

Only possible on ovens with CombiWash

This function activates pump M5.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key.

0= OFF, 1= ON.

D28 Pump for rinse aid

Only possible on ovens with CombiWash

This function activates pump M6.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key.

0= OFF, 1= ON.

- 15 -

Page 16

Test Mode D29-D47

D29 CombiWash water

Only possible on ovens with CombiWash.

This function activates solenoid valve MV4.

You activate or deactivate the function by pressing the step key.

To pulse, press the alarm key.

0= OFF, 1= ON.

D34 Water pressure sensor

Here it is possible to read the status of P7.

OF|HI= water pressure adequate, ON|LO= water pressure inadequate.

D36 Steam generator thermo-switch

Here it is possible to read the status of Q3

In the display next to ”Time”, it is shown whether the circuit is connected or disconnected.

OF= disconnected ON= connected.

In the event of defects in the oven, it is possible to reset thermo-switch Q3 which is located at the

bottom of the oven below the operation panel.

D37 Motor RPM 1

Here it is possible to read the number of revolutions for fan motor 1.

The number of revolutions is shown in the display next to the temperature key.

D38 Motor RPM 2

Available on 1.16 and 1.20 models only.

Here it is possible to read the number of revolutions for fan motor 2.

The number of revolutions is shown in the display next to the temperature key.

D46 Temperature CPU board

Here it is possible to read the temperature of the CPU board.

In the display next to ”Temperature”, the temperature of the CPU board is shown. Max 140°F

(60°C).

D47 Temperature IO board

Here it is possible to read the temperatures of the IO board.

In the display next to ”Temperature”, the temperature of the IO board is shown. Max 140°F (60°C).

- 16 -

Page 17

Turn switch

Main switch

Start/Stop

User Menu

Display shows

setting

Display shows

setting

Display shows "b"

No.

Display shows

description of "b"

function

Display shows

setting

Press key for 5 sec.

to access user

menu

Not active

Not active

Not active

PRG

Not active

Not active

To enter user menu, press alarm key for 5 sec.

To exit user menu, turn the switch to the left.

The user menu can be operated by the end-customer as well as by the service engineer.

Page 18

User Menu B1-B7

B1 Save pre-settings

In this function, you save the preset time and temperature.

If, for instance, the end user uses HOT AIR at 180°C for 30 minutes, the standard setting can be

changed as follows:

1. Change time and temperature.

2. Enter user menu (keep pressing alarm key for 5 sec.)

3. Select B1 (save pre-settings).

4. Press alarm key to accept.

You can only save the settings when the control lamp next to the alarm key flashes.

B2 Timer start

(Please see user manual)

B3 Sound level low

In this function, you adjust the sound that is heard when a key is activated. The sound level can be

adjusted from 0 to 9 (0 is no sound at all).

You adjust the sound level by pressing the step key.

B4 Sound level high

In this function, you adjust the sound that comes from the alarm. The sound level can be adjusted

from 1 to 9 (1 is very low).

You adjust the sound by pressing the step key.

B5 Sound frequency

In this function, you adjust the sound frequency.

The sound frequency can be adjusted from 1 to 9.

You adjust the sound by pressing the step key.

You test the sound by pressing the alarm key.

B6 Interior light

In this function, you adjust the interior light.

The light can be set at 0 or 5.

0= Light is always on.

5= Light goes out when the oven has been idle for 5 minutes.

You adjust the interior light by pressing the step key.

B7 Current temperature

In this function, you choose whether the oven should display the current temperature or the preset

temperature.

You choose between 0 and 1

0= The preset temperature is shown.

1= The current temperature is shown.

You change the setting with the step key.

- 18 -

Page 19

User Menu B8-B13

B8 Exhaust

In this function, you choose whether the oven should start up the extraction hood.

0= Extraction hood not controlled by oven

1= Extraction hood runs for 10 minutes after oven has stopped.

This applies to an extraction hood mounted on the oven as well as for an external extraction hood.

B9 Time graphics

In this function, you determine whether the oven should be able to show graphically how long time

has passed of a cooking sequence.

You choose between 0 and 1.

0= No graphics

1= Graphics, for instance ”llllll------”, appear

You change the setting with the step key.

B10 Minutes

In this function, you set the minutes of the oven’s clock.

1. Press the key next to the temperature display (digit flashes).

2. Turn the switch to the desired setting of minutes.

3. Press the key next to the temperature display (digit stops flashing)

You can set the minutes from 0 to 59.

The oven’s clock may appear as screen saver.

B11 Hours

In this function, you set the hours of the oven’s clock.

1. Press the key next to the temperature display (digit flashes)

2. Turn the switch to the desired setting of hours.

3. Press the key next to the temperature display (digit stops flashing)

You can set the hours from 0 to 23.

The oven’s clock may appear as screen saver.

B12 Day/weekday

In this function, you set the day of the month and of the week.

1. Press the key next to the temperature display (digit flashes)

2. Turn the switch to the desired day of the month (1-31).

3. Press the key next to the temperature display (digit stops flashing)

4. Press the key next to the time display (digit flashes)

5. Turn the switch to the desired day of the week (1-7).

6. Press the key next the time display (digit stops flashing)

You select automatic updating to summer time.

0= No automatic updating to summer time.

1= Automatic updating to summer time.

If you choose not to have the oven update to summer time automatically, you cannot set the

weekday.

Automatic updating to summer time only functions correctly in Western Europe.

B13 Month

In this function, you set the month.

1. Press the key next to the temperature display (digit flashes).

2. Turn the switch to the desired month.

3. Press the key next to the temperature display (digit stops flashing).

You can set the month from 1 to 12.

- 19 -

Page 20

User Menu B14-B21

B14 year

In this function, you set the year.

1. Press the key next to the temperature display (digit flashes).

2. Turn the switch to the desired setting.

3. Press the key next to the temperature display (digit stops flashing).

You set the year from 6 to 20.

B15 CombiWash

In this function, you activate or deactivate CombiWash.

0= Manual cleaning

1= CombiWash

Press step key to change setting.

B16 Pulsing interval, reheating

In this function, you set the pulsing time in the reheating mode.

1. Press the key next to the temperature display (digit flashes).

2. Turn the switch to the desired time.

3. Press the key next to the temperature display (digit stops flashing)

You set the time from 5 – 50 sec.

B17 Pulsing interval, Combi Steam 1

In this function, you set the pulsing time for Combi Steam 1.

1. Press the key next to the temperature display (digit flashes).

2. Turn the switch to the desired time.

3. Press the key next to the temperature display (digit stops flashing)

You set the time from 2 to 50 sec.

B18 Pulsing interval, Combi Steam 2

In this function, you adjust the pulsing time for Combi Steam 2.

1. Press the key next to the temperature display (digit flashes).

2. Turn the switch to the desired time.

3. Press the key next to the temperature display (digit stops flashing)

You set the time from 1 sec. to the number of seconds specified to be the pulsing time for Combi

Steam 1.

B19 Save all (Backup)

In this function, you save set-up and programs to the IO board for subsequent restoration. This can

be used as backup when set-up and programs are correct.

Press alarm key to save.

B20 Restore all

In this function, you restore set-up and programs you have saved earlier.

B21 Restore original

In this function, you restore the original programs from 0 to 4.

1. Press step key to select program.

2. Press alarm key when program has been found.

- 20 -

Page 21

User Menu B22-B24

B22 Screen saver

In this function, you set the time that should pass until the clock appears in the display. Press step

key to select time.

0= no screen saver

1= 10 sec.

2= 30 sec.

3= 60 sec.

4= 180 sec.

5= 600 sec.

The screen saver appears when the oven has been idle for a particular period of time.

B23 Language

In this function, you change the language of the computer.

Press step key and select 1, 2, 3 or 4. There are also four language variants: A – D (see below).

To change the language, you need to update again (see B24)

B24 Software update

In this function, you update the computer software by means of a special memory key (not a USB

key).

1. Insert memory key.

2. Press alarm key to view software version and language variants.

3. Press step key to select language variant.

4. Press alarm key again to start updating process.

The software version of the oven in question is also shown in the start-up sequence when the oven is

switched on.

1 Danish English English English

2 Swedish German French Estonian

3 English Kroatian Spanish Hungarian

4 Finnish Slovenian Italian Russian

A B C D

Page 22

Display shows error

"Er" No

Display shows

description of error

PRG

Error codes

Main switch

Start/Stop

All keys can be used to acknowledge an error message.

Turn switch

Page 23

by pressing button under oven.)

by pressing button under oven.)

minutes and try again.

Drain too hot

(Drain temperature has been above 75

°

C for more

than 5 min. Check that jet in drain is working.)

working properly.)

probe has been selected but probe has not been connected.)

working.)

be used.)

Check that the water has been turned on.)

130°C. If fault recurs, descale generator)

Error code 14:

FAN SPEED

Fan running too slow

Error code 18:

DATA ERROR

Error in set

-

up data

Error code 19:

WRONG LANG

Wrong language

board.)

Error code 22:

NO RESTART

Restart not possible

(Oven has been without power too long.)

Error code 23:

OVEN WARM

Oven too hot at CombiWash start

-up

the core temperature probe defective.)

Error code 28:

ALARM ERR

Configuration error in main alarms

(3, 4, 5, 12) (warning)

Error code 34:

WATER PRES

Water pressure too low

(Check that water is turned on.)

Error code 40:

IO BRD HOT

Temperature in IO board critical

(Warning after program run.)

Error code 43:

WRONG SW

Wrong software version

(Visual Cooking I oven)

Error code 44:

DAMPER ERR

Failure during initialisation of exhaust at oven start

-up

Error code 3: GENRA HOT

Error code 4: OVEN HOT

Error code 5: FAN HOT

Error code 6: DRAIN > 75

Error code 7: OVEN SENS

Error code 8: PROBE SENS

Error code 9: GENER SENS

Error code 10: DRAIN SENS

Error code 11: WATER SHOR

Error code 12:

Error code 13: GENER > 130

SSR HOT SSR too hot (Solid-state relay too hot.)

Error codes

Generator too hot (Generator thermo switch has tripped. Reconnect

Oven too hot (Oven chamber thermo switch has tripped. Reconnect

Fan too hot (Thermo switch in motor has tripped. Wait for 10

Oven sensor defective (Temperature sensor in oven chamber not

Core temp. probe not connected (A program using core temp.

Generator sensor defective (Temperature sensor in generator not

Drain sensor defective (Sensor in drain not working. Oven can still

Water shortage (Steam generator was not filled within two minutes.

Generator too hot (Temperature in steam generator higher than

Error code 15:

Error code 16: IO BRD HOT IO board too hot (> 60°C)

Error code 20: NO COM IO

Error code 24: DRAIN ERR

Error code 25: PROBE ERR

Error code 29: DOOR SENS Wrong door sensor signal (warning)

CPU HOT CPU board too hot (> 60°C)

Internal defect (Failure in communication between computer and IO

Draining failure (Drain blocked or failure of drain pump. Water level

in generator still high after 10 seconds of draining.)

Core temperature probe defective (1, 2 or 3 of the elements in

Page 24

Notes:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Page 25

BCP & BCM, ERROR CODES & CAUSES

3 - Generator Hot – Generator High Limit Thermostat Open(Opens at 275˚F) (Manual Reset under a

cover at the bottom of the control panel)

4 – Oven Hot - Oven High Limit Thermostat Open (Opens at 662˚F) (Manual Reset under a cover at the

bottom of the control panel)

5 – Fan Hot – Motor Thermal Limit Open (2 Gray Wires) (Opens at 320˚F) Wait 10 minutes and try again.

If 5 appears again, the cooling fans, motor bearings, or thermal switch within the motor failed.

6 – Drain Hot – RTD Probe in Drain (100 Ohm Probe) reads over 167˚F for over 5 minutes.

7 – Oven sensor Defect – RTD Probe in Generator (100 Ohm Probe) Shorted/Open

8 – Core Probe Missing – Control has an active Core (Meat) Probe. Deactivate both Core Probes or

insert Core Probe in the probe port on the control side.

9 – Gen Sensor Defect – RTD Probe in Generator (100 Ohm Probe) Shorted/Open

10 – Drain Sensor Defect - RTD Probe in Drain (100 Ohm Probe) Shorted/Open

11 – Water Shortage – Steam Generator could did fill in 5 minutes.

12 – SSR Hot – one of the two SSR Heat Sink Automatic Reset Snap Disks that are wired in series is Open

(Open at 248˚F)

13 – Generator > 265 – RTD Probe in Generator (100 Ohm Probe)reads over 265˚F.

14 – Fan Slow – Fan Hall Sensor (Brown, Black and Red Wires), Inverter or the Motor has failed or a

wiring issue exists.

16 – IO Board Hot – The IO Board senses a temperature above 140˚F.

19 –Internal Error–The control has sensed a failed process, restart the control.

20 – IO Com Error- Failure of communication between the CPU and IO Board.

21 – Invalid recipe – Indicates a recipe is programmed for a feature the oven does not have.

22 - Program Terminated – Power interrupted while a program was in progress and enough time

elapsed that the program cannot resume.

24 – Empty Error – Steam Generator water level sensor reads water 25 seconds after running the drain

pump to drain the boiler.

25 – CombiOptima not Calibrated – Enter the Service Menu and run the calibration.

26 – CombiOptima Sensor Error – The Pressure sensor gives a reading outside the range of 0.5 - 4.5.

27 – CombiOptima calibr. Fault – Calibration could not be completed, Start calibration when the oven is

cold and dry.

Page 26

BCP & BCM, ERROR CODES & CAUSES

28 – Main Alarm Error –No 24V signal to high limit board

29 – Door Sensor Error – Wrong door sensor signal

34 – Water Pressure Low – Water Pressure Switch (located on the larger solenoid assembly) is closed.

(Opens at 22 PSI)

36 – No Detergent – Time Based detergent monitoring is disabled.

38 – Detergent In Oven – Combi wash interrupted while the detergent was in the oven. Run Combi

Wash in Step 0 to clear detergent prior to inserting product.

39 – Insufficient Memory – The units memory is not sufficient for the current operation.

40-IO Board Hot- The IO Board senses a temperature above 140°F.

41 – Main Alarm -

42 – Error in SW – Software Error. Reboot software to current version.

For Gas Ovens

44-Dammper Error-Failure during initialization of exhaust at oven start-up.

45-24V Error-24V missing or failure of main contactor output.

50-Switch On-Pressure switch on when gas-air control unit running (timeout 20 sec.)

51-Switch Off-Pressure switch not on when gas-air control unit running (timeout 20 sec.)

52-Gas Valve-Gas valve does not open (automatic gas burner control has failed (timeout 20 sec.))

53-No Fan RPM-Gas-air control unit does not revolve when pressure switch is on.

54-Fan Error-Gas-air control unit does not run at correct RPM just before ignition.

55-Gas Fail-Warning: Ignition failed.

56-Gas Error-Flame fails to occur after 3 attempts.

57-Gas Stop-Warning: Gas failure during operation.

Page 27

BLODGETT OVEN COMBI

1

Sequence of Operation for BCP and BCM (electric)

Unit is turned “OFF”

You will have AC voltage at:

• The bottom of the main contactor (T1, T2, T3)

• Fuse F5 in the front

• The transformer (T1) in the front of the oven

• Fuse F1, F2, F3 and F4 in the front

• On the CPU and the IO board (J10 pin 5 and 6)

There are no DC voltage when the unit is turned OFF

Unit is turned “ON”

• The boot logo appear on the screen for about 30 sec. then ready to

operate (only BCP)

• Light will come on after 30 sec.(only BCP) (12 VAC between J9 pin 3 and

terminal 1)

• The exhaust valve will “open” and “close” after 30 sec. (24 VAC between

J2 pin 12 and terminal 1) (Ground J2 pin 15 when closed)

When a mode is started

The IO board verifies the following with DC voltage:

• The door sensor SE1 is closed sending either towards 0 or towards 5

DC voltage to J1 pin 34 depending on the pole of the magnet.

• With door sensor SE1 open the DC voltage is 2,5 on J1 pin 34.

The IO board verifies the following with AC voltage:

• The high limit stat of the motor is closed sending 24 VAC to J1 pin 10

• The high limit stat of the oven is closed sending 24 VAC to J1 pin 9

• The high limit stat of the boiler is closed sending 24 VAC to J1pin 12

• The high limit stat of the SSR closed sending 24 VAC to J1 pin 13

• Main contactor K1 is activated (24 VAC on coil of contactor A1 and A2)

output from IO board is coming from plug J2 pin 2 going through all the

high limit stats and to the coil.

• When the main contactor is activated the terminal L4 on the contactor

provides power to the frequency inverter (terminal L/R) which controls

the motor M1.

• The IO board makes a connection between J2 pin 28 and 27 to terminal

+12V, and Start, this will start the fan.

• The speed of the fan depends of the DC voltage on terminal Com and

Speed of the inverter (IO board J2 pin 33 and 34) 0 – 10 VDC

• The motor reverses direction every 2 minutes by making a connection to

the terminal REV of the inverter (IO board J2 pin 29) +12VDC

Page 28

BLODGETT OVEN COMBI

2

Unit set in “Hot air”

Max temperature 250°C/482°F

• The SSR gets DC voltage on the terminal -/+1 (if boiler model) -/+1 and

2 (if no boiler) DC coming from J2 pin 22 and 23.

• The IO board will get a resistance input from P1 (oven temperature

sensor PT100) on J1 pin 37 and 38 telling the IO board when to switch

off the SSR.

• When the time runs out H2 (buzzer) will be activated.

Unit set in “CombiOptima”

• The SSR gets DC voltage on the terminal -/+1 (if boiler model) -/+1 and

2 (if no boiler) DC coming from J2 pin 22 and 23.

• The IO board will get a resistance input from P1 (oven temperature

sensor PT100) on J1 pin 37 and 38 telling the IO board when to switch

off the SSR.

• The sensor P9 is supplied by 12 VDC from J1 pin 25 and 26.

• The sensor measure pressure between 0 – 3 mbar (0,5 – 4,5 VDC)

• Depending on the temperature/fan speed/pressure the computer

calculates the humidity.

• The higher temperature the lower pressure (voltage)

• The higher humidity the lower pressure (voltage)

• Dry and cold oven gives the highest reading (voltage)

(There are no precise measures/voltages it depends on the oven. That is why it

has to be calibrated.)

Page 29

BLODGETT OVEN COMBI

3

Unit set in “Steam”

Max temperature 100°C/212°F, Forced steam 120°C/348°F

• If P3 (temperature sensor of boiler PT100) register an Ohm value which

is higher than 65°C/149°F it will start filling to HIGH level. If the value is

lower than 65°C/149°F empty and flush the boiler as described below.

• The empty pump M2 gets 208V/230V signal from J11 pin 4 and F6.

• The boiler will now get flushed this is the sequence:

1. Empty boiler 25/35/45 sec. depends on the boiler size

2. Empty boiler 5 sec. and filling 5 sec.

3. Empty boiler 10 sec.

4. Empty boiler 5 sec. and filling 5 sec.

5. Empty boiler 10 sec.

6. Empty boiler 5 sec. and filling 5 sec.

7. Filling 5 sec.

8. Filling to high level

9. Wait 2 sec. check level again

Ready the run the boiler

• The boiler will be filled by MV2 (filling valve) get 24 VAC from J2 pin 10

• The level sensor SE2 is supplied by 12 VDC when the sensor give a

ground signal to J1 pin 33 the IO board will cut off the MV2 valve.

• When the HIGH level is registered, the SSR gets DC voltage on the

terminal -/+2 DC coming from J2 pin 22 and 25 to heat up the water.

• If the level sensor register LOW level (not ground signal on J1 pin 33)

during boiling the MV2 (filling valve) will be activated 3 times for X sec.

• If the IO board does not register HIGH level with in the 3 tries, MV2 will

be activated continuously until HIGH level is reached.

• Temperature in drain P4 J1 pin 47 and 48 above 65°C/149°F, active MV3

24 VAC (J2 pin 11) will cool down until the temperature is below

60°C/140°F.

• When the time runs out H2 (buzzer) will be activated.

Unit set in “Reheating”

Temperature 20°C/68°F to 180°C/356°F

• Standard fan speed 50% (5 VDC on inverter terminal Com and Speed, IO

board J2 pin 33 and 34)

• As standard inject water every 8 sec. for 1/10 of sec. through MV1

(injection valve) 24 VAC (IO board J2 pin 8)

• Temperature in drain P4 J1 pin 47 and 48 above 65°C/149°F, active MV3

24 VAC (J2 pin 11) will cool down until the temperature is below

60°C/140°F.

• When the time runs out H2 (buzzer) will be activated.

*Standard settings can be changed in setup

Page 30

BLODGETT OVEN COMBI

4

Unit set in “Proving” (Only BCP)

• Standard fan speed 50% (5 VDC on inverter terminal Com and Speed, IO

board J2 pin 33 and 34)

• As standard inject water every 20 sec. for 1 sec. through MV1 (injection

valve) 24 VAC (IO board J2 pin 8)

• When the time runs out H2 (buzzer) will be activated.

*Standard settings can be changed in setup

Unit set in “Cooling down” (Only BCP)

The IO board registers if the door sensor is OPEN or CLOSED.

• If the door sensor registers OPEN 2,5 VDC on J1 pin 34, the fan M1 will

be on 100% speed (10 VDC on inverter terminal Com and Speed, IO

board J2 pin 33 and 34) until the temperature selected is reached.

• If the door sensor registers CLOSED either towards 0 VDC or towards 5

VDC on J1 pin 34, the fan M1 will be on 100% speed. If the temperature

is above 150°C/302°F the MV1 (injection valve) will be activated 24 VAC

(IO board J2 pin 8) for 0,1 sec. and then off for 1 sec. the sequence will

continue until the temperature is below 150°C/302°F.

• When the temperature is below 150°C/302°F the MV1 (injection valve)

will be activated for 1 sec. and then off for 1 sec. it will continue to run

this sequence until the temperature is reached.

• When the temperature is reached H2 (Buzzer) will be activated.

Unit set in “Preheating”

Max temperature 300°C/572°F

Max time 15 min.

Standard High speed

• The SSR gets DC voltage on the terminal -/+1 (if boiler model) -/+1 and

2 (if no boiler) DC coming from J2 pin 22 and 23.

• The IO board will get Ohm input from P1 (oven temperature sensor

PT100) on J1 pin 37 and 38 telling the IO board when the temperature is

reached, when it is reached it will stay on that temperature for the time

set.

• When the time runs out H2 (buzzer) will be activated.

Page 31

Front side B, C, K controller

Short

Power

5V

3.3V

24V AC

Testpins

Start IO

Keyboard

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 5

Dias 5

RS232

Encoder

CPU

reset

5V

Programming

connector

flash at

start-up

Com IO light diodes:

Yellow transmit

Green receive

Must flash

Clock: Must

flash (1 sec)

Power:

24V AC

Start IO

COM IO

Not used

Page 32

Back side B, C, K controler

Buzzer

Buzzer

Keyboard

Memory key

connector

Programming

connector

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 6

Dias 6

Power:Power:

1,2 1,2 -- COM IO COM IO

3 3 -- GNDGND

4 4 -- Start IOStart IO

5,6 5,6 -- 24V AC24V AC

Power

1 6

Battery

(3V)

Encoder

RS232

not used

Page 33

BCP / BCM Water Level Switch

Wire Side

pos

Sensor Side

24Vdc

- 1

Delime Pump Black

24Vdc+

2

Delime Pump Red

-------

3

Not used

130 Q1

4 High Limit stat Motor “G”

41 Q4

5 High Limit stat Motor “G”

86 SE2

6 (

Boiler Level sensor Black

)

77 P3

7 100k Ohm Boiler Probe

76 P3

8 100k Ohm Boiler Probe

69 P1

9 100k Ohm Cavity Probe

68 P1

10 100k Ohm Cavity Probe

88 SE3A

11

Not used

87 SE3

12 Speed sensor Motor “sig”

211 SE1

13 Speed sensor Motor 5V

-

90 X90

13

Not used

210 SE1

14 Speed sensor Motor 5V+

89 X30

14

Not used

94P912V+

15 (

Boiler level sensor Brown

92P912V

- 16 (Boiler level sensor Blue

)

Test Points

)

)

Sensor Power

Empty

Full

12 VDC

1.2 VDC

0 VDC

Plug X31:

Page 34

stic mode allows you to navigate through all components to test

Press and hold the Hot Air and Combi keys

t

display 1 to activate that component

Instructions to activate the chemical pump to prime it during the start up process.

Combi

the

ed

next to the

1 will be displayed

press the Stage key

without the oven

simultaneously

the

tage key again to deactivate it

and the chemical pump will activate

Diagno

mode. To activate diagnostic mode,

scroll the dial to the desired componen

stage key will

BCM START UP GUIDE

Diagnostic Mode

d - Level

them

displayed next to the PROG key and then press

, press the s

being in a cooking

for 2 seconds then

Stage key once. The

0 will be displayed.

Step 1. Press and hold the Hot Air and

The Display will now show d 0 next to

Step 2. Scroll the dial till d30 is display

The Display will show DELIME PMP

Step 3. Press the Stage key once,

When pump has been primed,

keys simultaneously for 2 seconds.

Probe key

next to the Probe key.

PROG key.

next to the stage key

once to 0 the pump will deactivate.

.

Press and

hold the Hot

Air & Combi

Keys for 2-3

seconds.

BCM Blodgett Combi Oven

Page 1

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Wiring diagram:

High limit

High limit

Page 1

circuit board

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 2

Dias 2

Oven light

Cooling fan,

empty pump

CombiWash

pump, vent.

Output

Supply

Com. to CPU

Input

Input to IO

board

To high limit

components

Page 44

Wiring diagram:

Page 2

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 3

Dias 3

Main

contactor

Please note main

connection direct

on main contactor

Main fuse for

transformer

fase

Main fuse for

transformer

neutral

Main terminals

neutral, earth

Ring element

Ø400 motor 1

Solid state

relay no. 1

Ring element

Ø470 motor 1

Ring element

Ø400 motor 2

Solid state

relay no. 2

Please note

this is only

for C - CPE

Ring element

Ø470 motor 2

Page 45

Connection

to main

contactor

Solid state

relay no. 1

Wiring diagram:

Page 3

Solid state

relay no. 2

Solid state

relay no. 3

Solid state

relay no. 4

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 4

Dias 4

Please note

this is only

for K - KPE

Ring element

Ø400 motor

M1

Ring element

Ø400 motor M2

Ring element

Ø470 motor

M1

Ring element

Ø470 motor M2

Element

steam boiler

Element

steam boiler

Temp. sensor

steam boiler

High limit steam

boiler 135°C

Top element

steam boiler

Element

steam boiler

Page 46

Connection to

main fuse F5

Connection to

neutral terminal

Fuse for detergent /

rins pump and vent.

Fuse for

interior light

Wiring diagram:

Page 4

Terminals on

main contactor

Transformer

Fuse for IO and

CPU board

Fuse for all

24V output

Frequency

inverter

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 5

Dias 5

Interior light

Plug on IO

board

Buzzer (Sound)

Plug on IO

board for com.

1. Main fan

2. Main fan (only

used on 1.16 and

1.20

Page 47

Wiring diagram:

Page 5

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 6

Dias 6

Plug on Alarm

sens print

Sensor for

water pressure

Switch for

exhaust

Sensor for

ClimaOptima

Restart

switch

Doorsensor

singel door

Level sensor

boiler

Oven temp.

sensor

Core probe

temp. sensor 1

Doorsensor if

Passthrough

Core probe

temp. sensor 2

Temp.

sensor drain

Connection

to temp.

sensor boiler

Page 48

Solenoid valve

SSR

filling boiler

Coil main

contactor

Wiring diagram:

Page 6

Lamp in restart

button

Solenoid valve

CombiWash

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 7

Dias 7

Plug on alarm

sens. print

High limit

boiler

High limit motor

2 only used in

1.16/1.20

High limit

motor 1

High limit

SSR if more

than 2 SSR

High limit

Connection to

fuse F1

Motor for

exhaust

Solenoid valve

drain

Solenoid valve

inject

High limit oven only

when 1.16/1.20

High limit

oven

Connections to solid

stat relay

Connections to

frequency inverter

Page 49

Wiring diagram:

Connection to

terminal 2 (ext. vent)

Page 7

Connection to

Fuse F5

9. maj 2011

9. maj 2011

HOUNÖ A/S

HOUNÖ A/S

Dias 8

Dias 8

Connection to

Fuse F3

Connection to

terminal 1

Rinse pump

Detergent pump

Connection to

Fuse F3

Connection to

neutral terminal

Cooling fan in the

top of tech. room

Connection to

Fuse F5

Empty pump

boiler

Cooling fan in the

back of tech. room

Loading...

Loading...