Page 1

MARK V

CONVECTION OVEN

INSTALLATION - OPERATION - MAINTENANCE

MARK V

FOURS À CONVECTION

MANUEL D'INSTALLATION - FONCTIONNEMENT - ENTRETIEN

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658Ć6600 Fax: (802)864Ć0183

BLODGETT OVEN COMPANY

www.blodgett.com

PN 17561 Rev U (6/11)

E 2011 - G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTISSEMENT: UNE INSTALLATION, UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGES À LA PROPRIÉTE, DES BLESSURES OU LA MORT. LISEZ ATTENTIVEĆ

MENT LES DIRECTIVES D'INSTALLATION, D'OPÉRATION ET D'ENTRETIEN AVANT

DE FAIRE L'INSTALLATION OU L'ENTRETIEN DE CET ÉQUIPEMENT.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l'essence ni d'autres vapeurs ou liquides inflamĆ

mables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instrucĆ

tions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructions et procéĆ

dures permettra d'obtenir de bons résultats de cuisson et une longue durée de serĆ

vice sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l'avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. SpecificaĆ

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d'illustration font l'objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 3

THE REPUTATION YOU CAN COUNT ON

UNE RÉPUTATION SUR LAQUELLE VOUS POUVEZ COMPTER

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We've set the industry's quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, fullĆsize, halfĆsize, countertop and deck, conĆ

vection, Cook'n Hold, CombiĆOvens and the industry's highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Cela fait maintenant dessus un siècle et demi que Blodgett se spécialise dans

la fabrication de fours. Nous avons établi les normes de qualité qui s'appliĆ

quent dans l'industrie à tous les types de fours utilisés dans les services aliĆ

mentaires, quel qu'en soit la taille, l'exploitation ou le budget. En fait, ni n'offre

plus de modèles, de tailles et d'applications de fours que Blodgett. À gaz et

électriques. De tailles différentes, sur plan de travail et superposables. Qu'il

s'agisse de fours à convection, des modèles Cook'n Hold et CombiĆOven, ou

de la gamme de fours à pizzas de la plus haute qualité offerte sur le marché.

Pour de plus amples informations sur la gamme complète de fours Blodgett,

veuillez contacter votre représentant Blodgett.

Page 4

Your Service Agency's Address:

Adresse de votre agence de service:

Model/Modèl:

Serial Number/Numéro de série:

Your oven was installed by/

Installateur de votre four:

Your oven's installation was checked by/

Contrôleur de l'installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

Oven Description and Specifications 2. . . .

Oven Components 3. . . . . . . . . . . . . . . . . . . .

Installation

Delivery and Location 4. . . . . . . . . . . . . . . . .

Oven Assembly 5. . . . . . . . . . . . . . . . . . . . . .

NSF Bolts 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Leg Attachment 6. . . . . . . . . . . . . . . . . . . . .

Caster Assembly 6. . . . . . . . . . . . . . . . . . . .

Double Section Assembly 7. . . . . . . . . . . .

Oven Leveling 7. . . . . . . . . . . . . . . . . . . . . .

Utility Connections - Standards

and Codes 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connection 9. . . . . . . . . . . . . . . . .

Initial Startup 10. . . . . . . . . . . . . . . . . . . . . . . . .

Operation

Safety Information 11. . . . . . . . . . . . . . . . . . . .

Solid State Manual Control 12. . . . . . . . . . . . .

Solid State Manual Control with

Digital Timer 13. . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital Control 14. . . . . . . . . . . . . .

Blodgett IQ2T Vision Control 16. . . . . . . . . .

How Cook and Hold Works 26. . . . . . . . . . . .

General Guidelines for Operating

Personnel 27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suggested Times and Temperatures 28. . . .

Maintenance

Introduction

Description et Spécifications du Four 31. . . .

Éléments du Four 32. . . . . . . . . . . . . . . . . . . . .

Installation

Livraison et Implantation 33. . . . . . . . . . . . . . .

Montage du Four 34. . . . . . . . . . . . . . . . . . . . .

Boulons NSF 34. . . . . . . . . . . . . . . . . . . . . . .

Assemblage des Pieds 35. . . . . . . . . . . . . . .

Montage des Roulettes 35. . . . . . . . . . . . . .

Montage de la Section Double 36. . . . . . . .

Mise à Niveau du Four 36. . . . . . . . . . . . . . .

Branchements de Service - Normes et

Codes 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Raccordement Électrique 38. . . . . . . . . . . . . .

Mise en Marche Initiale 39. . . . . . . . . . . . . . . .

Utilisation

Informations de Sécurité 40. . . . . . . . . . . . . . .

Commandes Standard 41. . . . . . . . . . . . . . . .

Commandes Standard avec le

Temporisateur Numérique 42. . . . . . . . . . . . .

Commandes Numériques à

SemiĆConducteurs 43. . . . . . . . . . . . . . . . . . . .

Blodgett IQ2T Commande Vision 46. . . . . .

Principe de la Fonction de Cuisson

et Maintien 57. . . . . . . . . . . . . . . . . . . . . . . . . . .

Consignes Générales à l'Intention

des Utilasateurs 58. . . . . . . . . . . . . . . . . . . . . .

Durées et Températures Suggérées 59. . . . .

Cleaning and Preventative Maintenance 29.

Troubleshooting Guide 30. . . . . . . . . . . . . . . .

Entretien

Nettoyage et Entretien Préventif 60. . . . . . . .

Guide de Détection des Pannes 61. . . . . . . .

Page 6

Introduction

Oven Description and Specifications

Cooking in a convection oven differs from cooking

in a conventional deck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. The moving air conĆ

tinually strips away the layer of cool air surroundĆ

ing the product, quickly allowing the heat to peneĆ

trate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgett convection ovens represent the latest adĆ

vancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recircuĆ

lated within the cooking chamber before being

vented from the oven: resulting in substantial reĆ

ductions in energy consumption and enhanced

oven performance.

Blodgett Electric Convection Ovens

ELECTRICAL SPECIFICATIONS (per section)

KW Hz Volts Phase

L1 L2 L3 N

U.S. and Canadian installations

11.0 60 208 1 51 - 51 - 6 AWG

11.0 60 208 3 31 29 29 - 8 AWG

11.0 60 220Ć240 1 44 - 44 - 6 AWG

11.0 60 220Ć240 3 26 24 24 - 8 AWG

11.0 60 440 3 15 14 14 - 12 AWG

11.0 60 480 3 14 13 13 - 12 AWG

General Export installations

11.0 50 208 3 18 18 18 4 Size per local code

11.0 50 220Ć240 1 48 - - 48 Size per local code

11.0 50 220/380 3 18 16 16 2 Size per local code

11.0 50 240/415 3 18 14 14 4 Size per local code

11.0 50 230/400 3 18 15 15 3 Size per local code

Amps

Air Flow Pattern for

Figure 1

Electrical Connection

(minimum size)

2

Page 7

Introduction

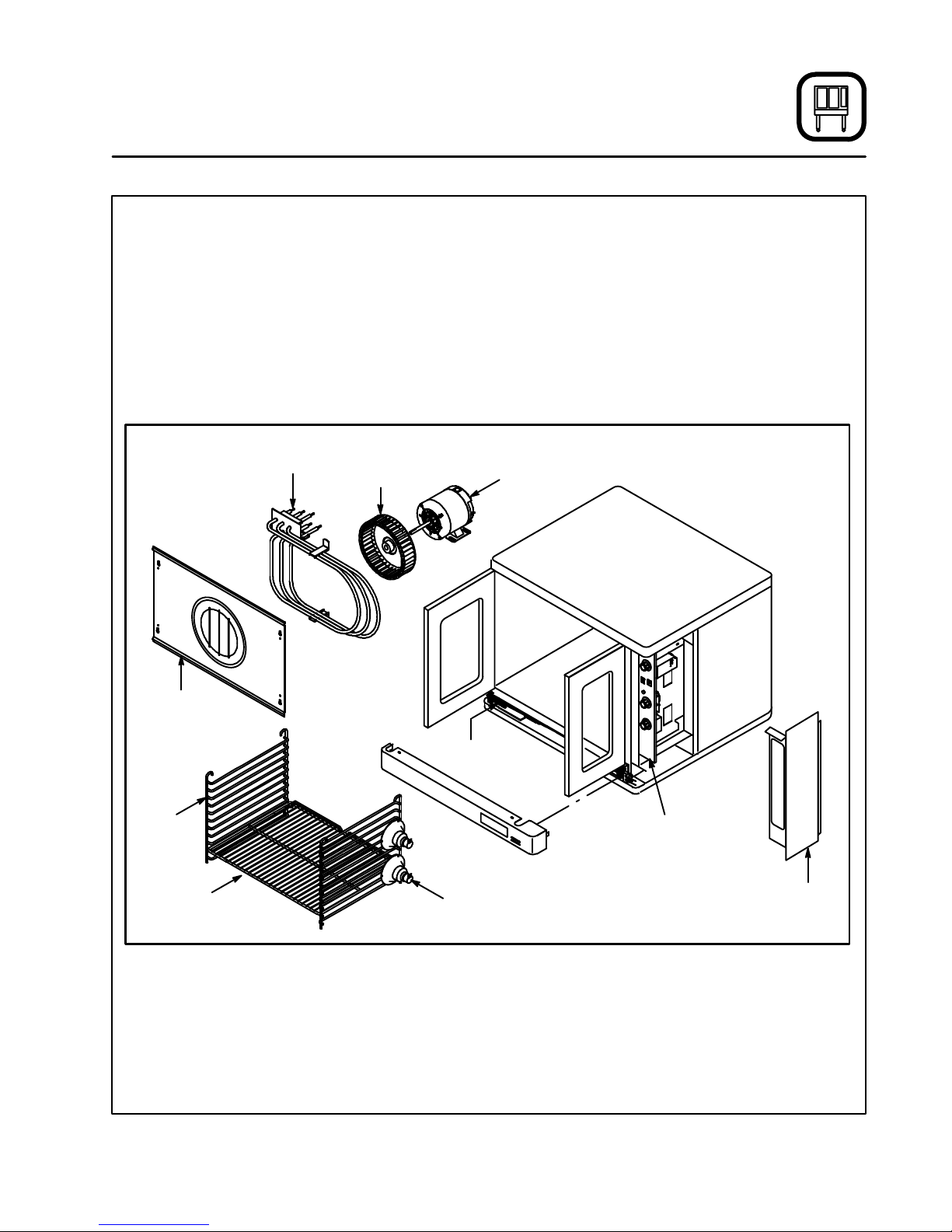

Oven Components

Heating Elements - located on the back wall of

the oven, the elements provide heat to the baking

chamber on electric ovens.

Chain & Turnbuckle - controls operation of the

oven doors.

Control Panel - contains wiring and components

to control the oven operation.

Oven Racks - five racks are provided standard.

Additional racks are available.

Heating

Elements

Blower

Wheel

Rack Supports - hold oven racks.

Baffle - located on the back interior wall of the

oven. Protects the blower wheel.

Blower Wheel - spins to circulate hot air in the

baking chamber.

Convection Motor - provides power to turn the

blower wheel.

Oven Lights - provide lighting inside the baking

compartment.

Convection

Motor

Blower

Wheel Cover

Rack

Support

Oven Rack

Chain &

Turnbuckle

Oven Lights

Figure 2

Control

Panel

Control

Panel Cover

3

Page 8

Installation

Delivery and Location

DELIVERY AND INSPECTION

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D Inspect the shipping container for external damĆ

age. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D Uncrate the oven and check for internal damĆ

age. Carriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inĆ

spection.

The Blodgett Oven Company cannot assume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a claim is necessary.

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

The following clearances must be maintained beĆ

tween the oven and any combustible or nonĆcomĆ

bustible construction.

D Oven body right side - 1" (2.5 cm)

D Oven body left side - 1" (2.5 cm)

D Oven body back - 1" (2.5 cm)

D Oven body bottom - 1/2" (1.2 cm)

The following clearances must be available for serĆ

vicing.

D Oven body sides - 12" (30 cm)

D Oven body back - 12" (30 cm)

It is essential that an adequate air supply to the

oven be maintained to provide a sufficient flow of

combustion and ventilation air.

D Place the oven in an area that is free of drafts.

D Keep the oven area free and clear of all combusĆ

tibles such as paper, cardboard, and flammable

liquids and solvents.

D Do not place the oven on a curb base or seal to

a wall. This will restrict the flow of air and prevent

proper ventilation. Tripping of the blower moĆ

tor's thermal overload device is caused by an

excessive ambient temperature on the right

side of the oven. This condition must be corĆ

rected to prevent permanent damage to the

oven.

Before making any utility connections to this oven,

check the rating plate to be sure the oven specifiĆ

cations are compatible with the electrical services

supplied for the oven.

1. The rating plate is located on the underside of

the upper ledge above the right hand door.

4

Page 9

Installation

Oven Assembly

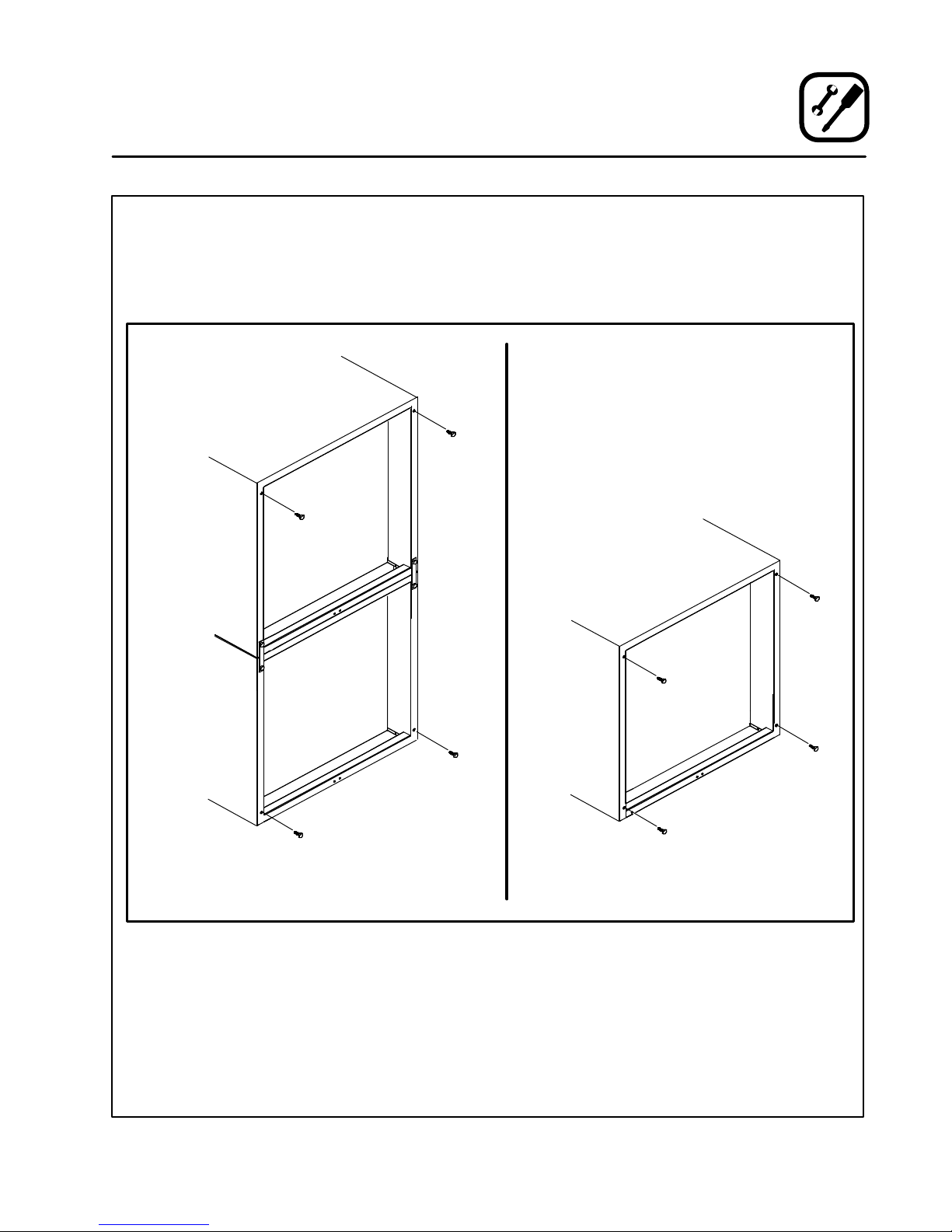

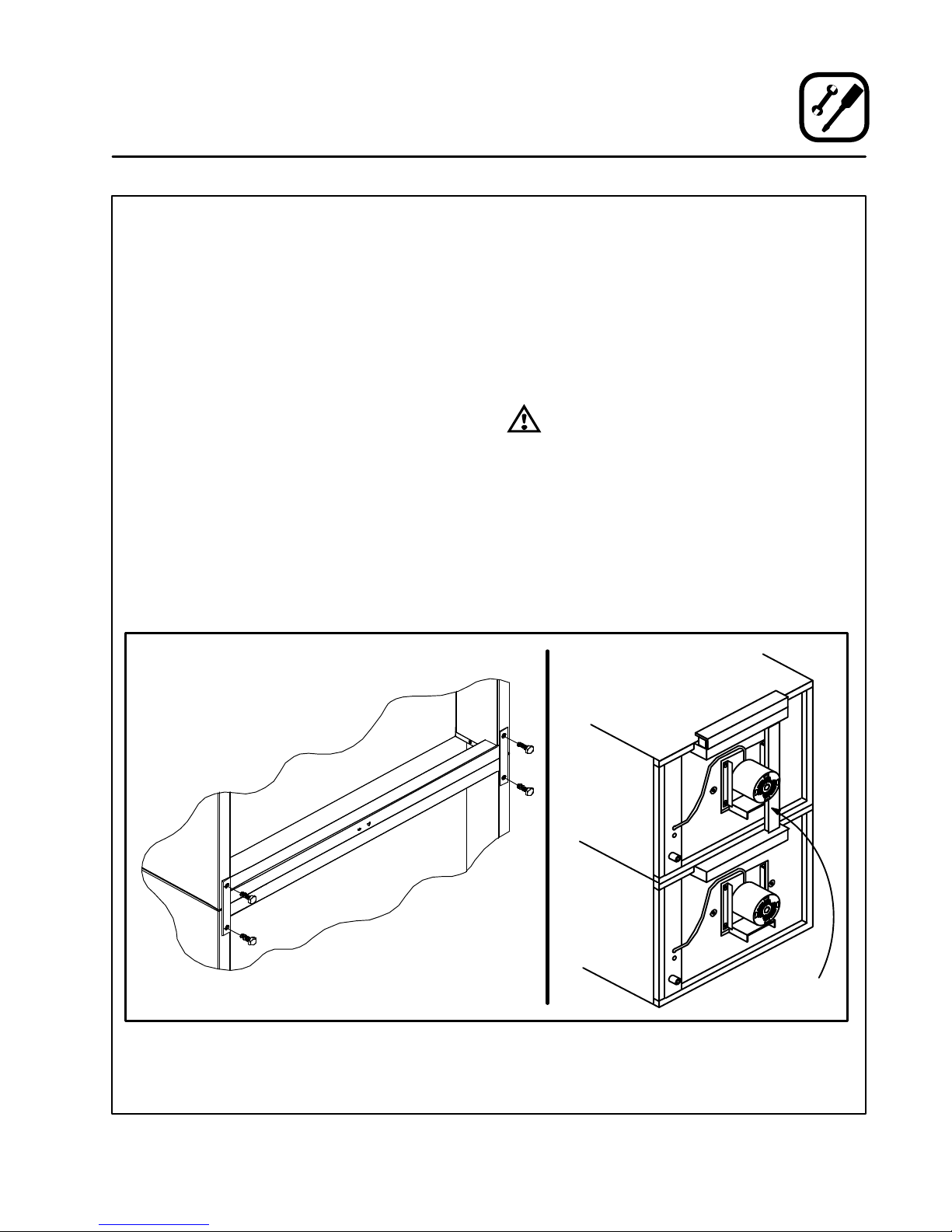

NSF BOLTS

These bolts are required by NSF to block any exĆ

posed hole on the back of an oven. This includes:

D any unit, single or stacked, without a back panel.

D any holes in stacked units not used for mountĆ

ing stacking brackets.

1. Locate the 5/16" bolts that were shipped with

the oven.

2. Install the bolts as shown in Figure 3.

Double Stacked Units Units without back panels

Figure 3

5

Page 10

Installation

Oven Assembly

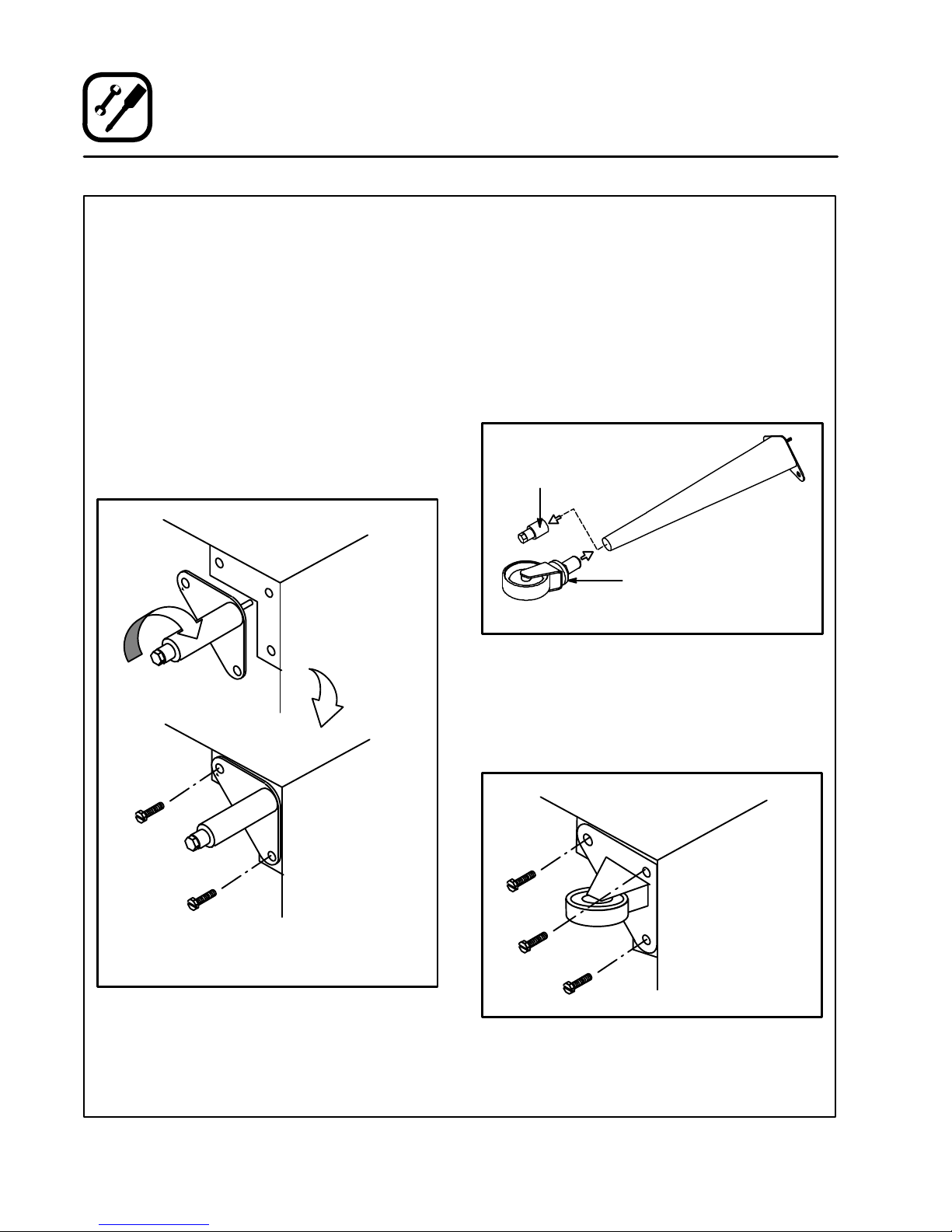

LEG ATTACHMENT

1. Push the oven onto a lift with the bottom of the

oven down.

2. Align the threaded stud in each leg with the

nut located inside each bottom corner of the

oven frame. Turn the legs clockwise and tightĆ

en to the nearest full turn.

3. Align the two leg plate holes in each leg with

those in the oven bottom. Secure each leg usĆ

ing two 1/2" bolts.

NOTE: If using casters see CASTER ASĆ

SEMBLY before proceeding.

4. Level the oven by screwing the adjustable leg

feet in or out as necessary.

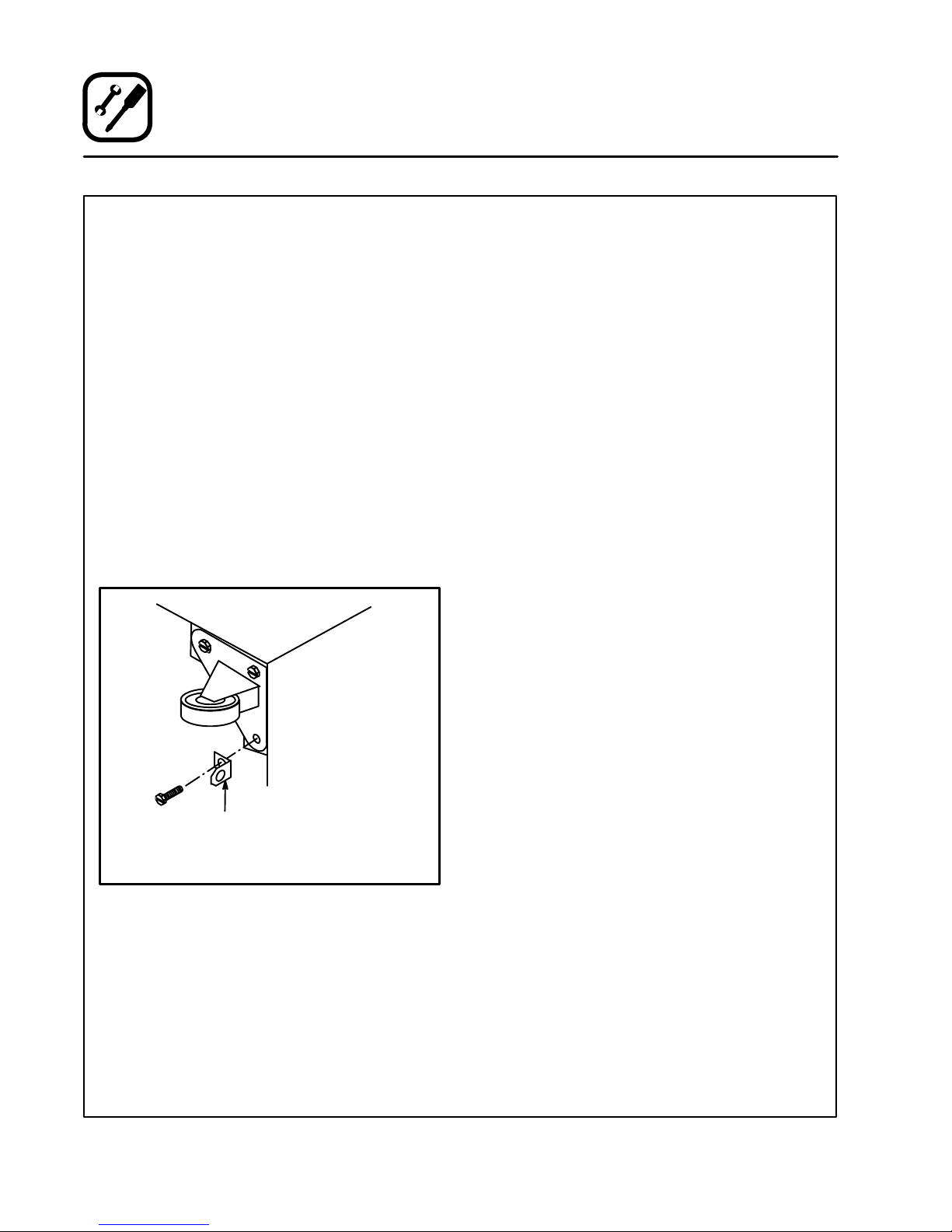

CASTER ASSEMBLY

NOTE: Install the locking casters on the front of

the oven. Install the nonĆlocking casters on

the back of the oven.

Casters for Single and Double Stacked Ovens:

1. Attach the legs as described.

2. Pry the adjustable feet out of the legs

3. Insert one caster into each leg as shown.

Tighten the lock nuts to secure the casters.

Adjustable

Leg Foot

Caster Assembly

25" (64 cm) Legs Shown

Figure 5

6" (15 cm) Legs Shown

Figure 4

Low Profile Casters for Double Stacked Ovens:

1. Align the three holes in each caster assembly

plate with those in the oven bottom. Secure

each caster using three 1/2" bolts.

Figure 6

6

Page 11

Installation

Oven Assembly

DOUBLE SECTION ASSEMBLY

NOTE: Old style ovens refer to units with painted exĆ

posed rear angle. New style ovens refer to

units with rear angle iron enclosed in steel.

The following instructions apply to stacking two

new style ovens.

1. Secure the short legs to the bottom sections

as described.

2. Place the upper section in position on top of

the lower oven.

3. Attach the stacking brackets using the reĆ

maining 5/16" bolts shipped with the ovens.

4. Attach the flue connector.

The following instructions apply to stacking a new

style oven on an old style oven.

1. Secure the short legs to the bottom sections

as described.

2. Place the upper section in position on top of

the lower oven.

3. Attach the stacking brackets using the reĆ

maining 5/16" bolts shipped with the ovens.

4. Drill a clearance hole for a 5/16" bolt in the

angle iron of the old style oven. Use the holes

in the stacking brackets as a pilot.

5. Attach the stacking brackets to the old style

oven with the 5/16" bolts and nuts provided in

the kit.

6. Attach the flue connector.

WARNING!!

When stacking ovens be sure to remove

the single oven flue boxes prior to attachĆ

ing threeĆpiece connector.

OVEN LEVELING

After assembly, the oven should be leveled and

moved to the operating location.

1. The oven can be leveled by adjusting the feet

or casters located on the bottom of each leg.

Flue

Connector

Figure 7

7

Page 12

Installation

Utility Connections - Standards and Codes

THE INSTALLATION INSTRUCTIONS CONĆ

TAINED HEREIN ARE FOR THE USE OF QUALIĆ

FIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D the installation of electrical wiring from the elecĆ

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiĆ

enced in such work, familiar with all precautions

required, and have complied with all requirements

of state or local authorities having jurisdiction.

U.S. and Canadian installations

All ovens, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70-Latest Edition and/or CanaĆ

dian National Electric Code C22.2 as applicable.

The ventilation of this oven should be in accorĆ

dance with local codes. In the absence of local

codes, refer to the National ventilation code titled,

Standard for the Installation of Equipment for the

Removal of Smoke and Grease Laden Vapors from

Commercial Cooking Equipment", NFPAĆ96ĆLatest

Edition.

General export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local disĆ

tributor, please call the Blodgett Oven Company at

0011Ć802Ć860Ć3700.

8

Page 13

Wiring diagrams are located in the control

compartment and on the back of the oven.

The electric motor, indicator lights and related

switches are connected to the oven as follows:

The service line will enter trough the rear of the

oven and connected to the terminal block (see diaĆ

gram).

1. Remove the bottom trim and control panel.

Removal of the body side is not necessary.

2. Remove knockĆout in the rear of the unit and

run the supply power line to terminal block

and connect the wires.

3. Reinstall the control panel and the bottom

trim.

NOTE: To prevent damage there is no power to

the heating elements when the blower is

not operating.

THE BLODGETT OVEN COMPANY CANNOT ASĆ

SUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPER INSTALĆ

LATION.

Installation

Connect wires to

terminal block

Electrical Connection

Run supply line

through the knockĆout

Figure 8

9

Page 14

Installation

Initial Startup

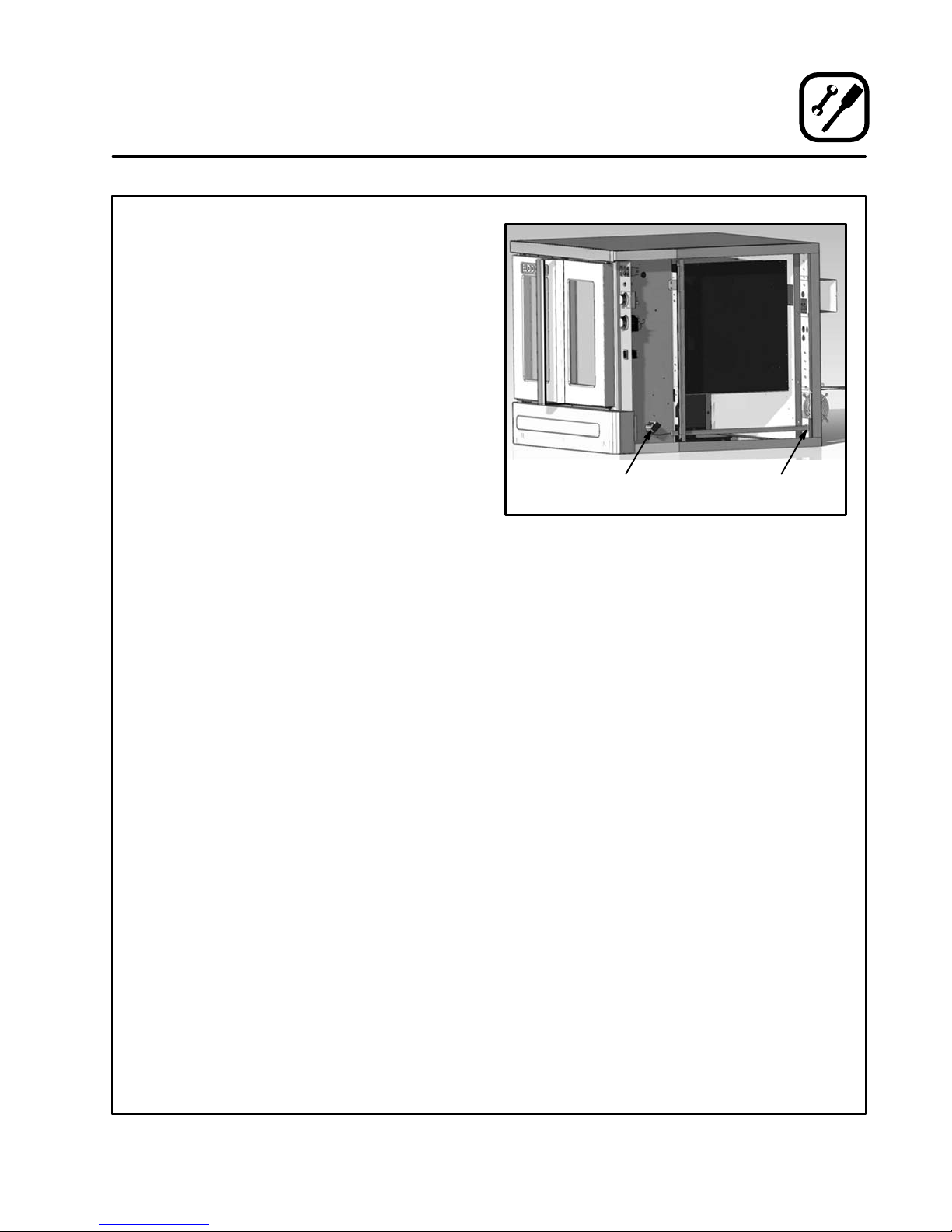

OVEN RESTRAINT

If casters are used in conjunction with a power

supply cord for movable appliances, a fixed reĆ

straint should be provided.

The restraint (ie: heavy gauge cable) should be atĆ

tached without damaging the building. DO NOT

use the gas piping or electrical conduit for the atĆ

tachment of the permanent end of the restraint!

Use anchor bolts in concrete or cement block. On

wooden walls, drive hi test wood lag screws into

the studs of the wall.

If the oven is moved from its regular location, the

restraint must be reconnected when the oven is reĆ

turned.

1. Mount the supplied bracket to the leg bolt just

below the power cord.

2. Attach the clip on restraining cable to the

mounting bracket.

ADJUSTMENTS ASSOCIATED WITH INITIAL

INSTALLATION

Each oven, and its component parts, have been

thoroughly tested and inspected prior to shipĆ

ment. However, it is often necessary to further test

or adjust the oven as part of a normal and proper

installation. These adjustments are the responsiĆ

bility of the installer, or dealer. Since these adjustĆ

ments are not considered defects in material or

workmanship, they are not covered by the Original

Equipment Warranty. They include, but are not

limited to:

D calibration of the thermostat

D adjustment of the doors

D leveling

D tightening of fasteners.

No installation should be considered complete

without proper inspection, and if necessary, adĆ

justment by qualified installation or service perĆ

sonnel.

Back of Oven

Restraint Cable

Bracket

Double stacked unit shown. Use the same procedure for

single units.

Figure 9

10

Page 15

THE INFORMATION CONTAINED IN THIS SECĆ

TION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATĆ

ING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONĆ

TAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPĆ

ERATION OF THE EQUIPMENT DESCRIBED. ADĆ

HERENCE TO THE PROCEDURES RECOMĆ

MENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLEĆFREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett conveyor

oven.

Operation

Safety Information

SAFETY TIPS

For your safety read before operating

General safety tips:

D If the oven needs to be moved for any reason,

the supply cord must be disconnected from the

unit before removing the restraint cable. ReconĆ

nect the restraint after the oven has been reĆ

turned to its original location.

D DO NOT remove the control panel cover unless

the oven is unplugged.

11

Page 16

Operation

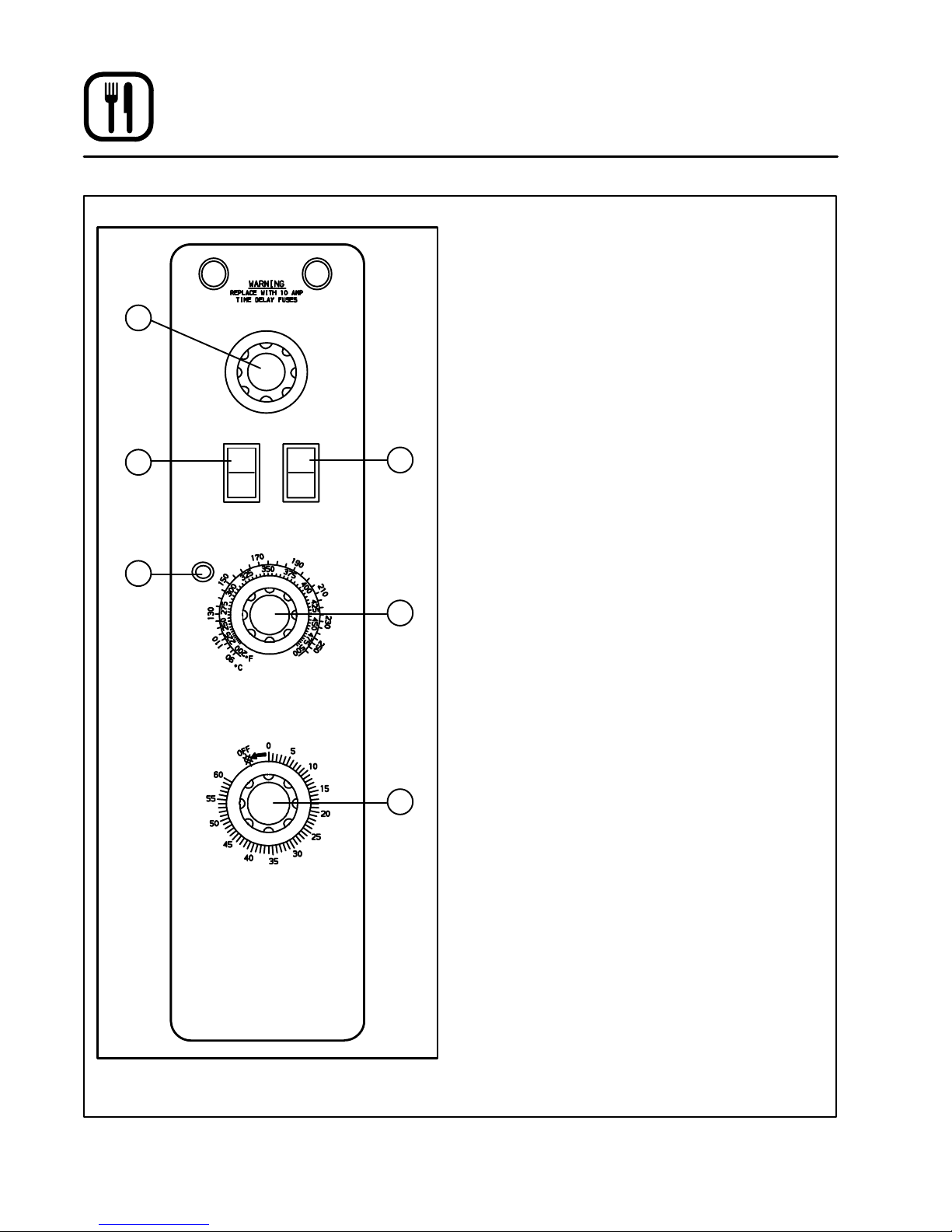

Solid State Manual Control

1

3

4

COOL

DOWN

LIGHT OFF

OVEN READY

OVEN OFF

ON

OFF

LIGHTS

SOLID STATE

THERMOSTAT

COOK

HI

LO

BLOWER

CONTROL DESCRIPTION

1. SELECTOR SWITCH - controls power to the

oven for cook or cool down.

2. BLOWER SWITCH - controls blower speed,

either hi or lo.

3. LIGHTS SWITCH Ć controls interior lights.

4. OVEN READY LIGHT - when lit indicates eleĆ

ments are heating. When the light goes out

the oven has reached operating temperature.

5. SOLID STATE THERMOSTAT Ć allows either 8

preĆset temperatures to be selected in accorĆ

dance with customer requirements, or an infiĆ

2

nite selection of temperatures from 200Ć500_F

(95Ć260_C). (infinite control shown)

6. TIMER - activates an electric buzzer that

sounds when the cook time expires.

OPERATION

1. Turn the SELECTOR Switch (1) to COOK. The

blower and control compartment cooling fan

5

operate and are controlled automatically by

the action of the doors.

2. Set BLOWER Switch (2) to the desired speed.

3. Set the SOLID STATE THERMOSTAT (5) to the

desired setting or temperature.

4. Preheat until the OVEN READY LIGHT (4)

goes out.

5. Load product into the oven. Determine cook

time and set the TIMER (6).

6. When the buzzer sounds, remove the product

6

from the oven. Turn the TIMER knob (6) to OFF

to silence the buzzer.

7. Turn the SELECTOR Switch (1) to OVEN OFF.

TIMER

Figure 10

12

Page 17

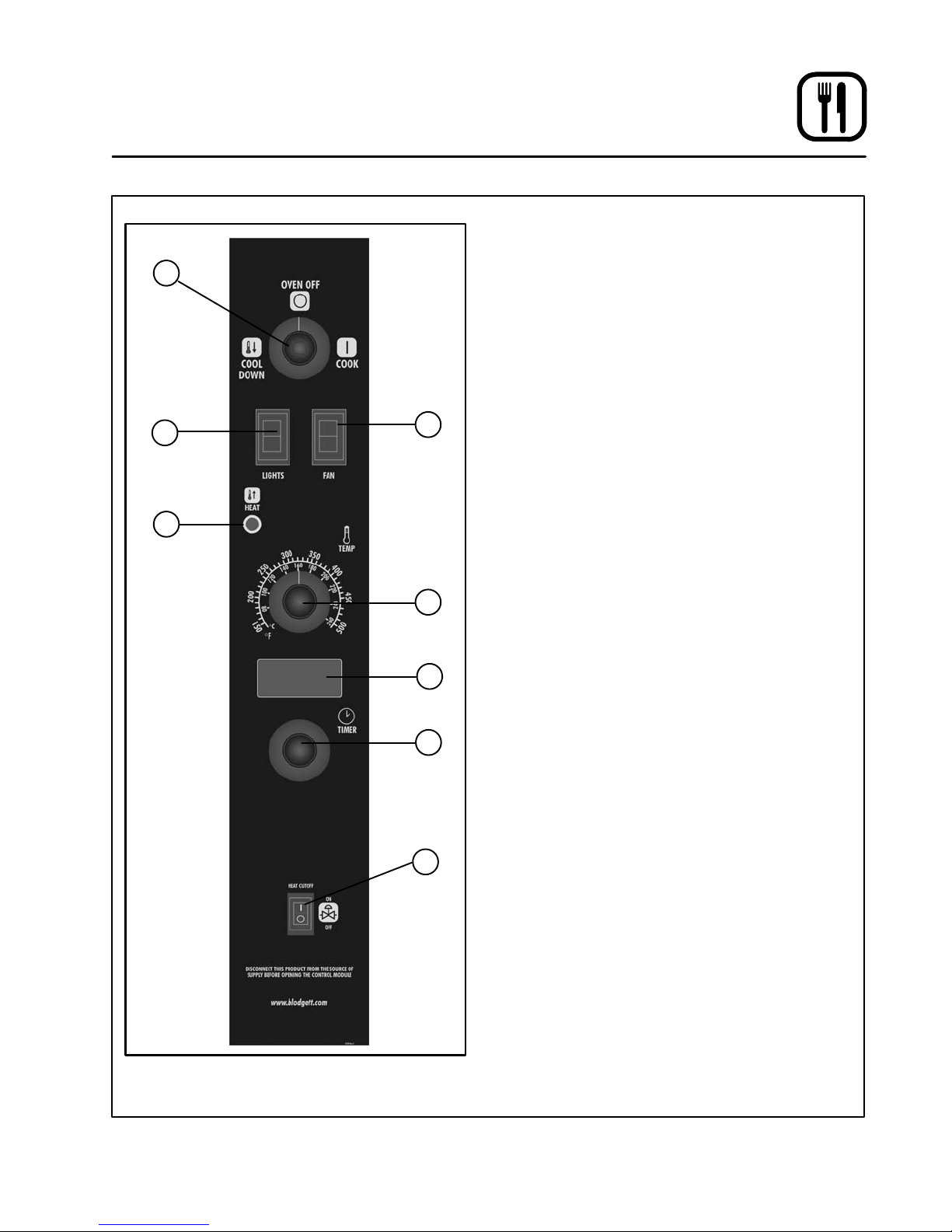

Operation

Solid State Manual Control with Digital Timer

CONTROL DESCRIPTION

1. SELECTOR SWITCH - controls power to the

1

3

4

2

5

6

7

8

oven for cook or cool down.

2. BLOWER SWITCH - controls blower speed, eiĆ

ther hi or lo.

3. LIGHTS SWITCH - controls interior lights.

4. OVEN READY LIGHT - when lit indicates

burner operation. When the light goes out the

oven has reached operating temperature.

5. SOLID STATE THERMOSTAT - allows an infiĆ

nite selection of temperatures from 150Ć500_F

(66Ć260_C).

6. DISPLAY - displays cook time

7. TIMER DIAL - used to enter desired cook

time

8. HEAT CUTOFF - circuit breaker

OPERATION

1. Turn the SELECTOR Switch (1) to COOK. The

blower and control compartment cooling fan

operate and are controlled automatically by

the action of the doors. The display reads

00:00.

2. Set BLOWER Switch (2) to the desired speed.

3. Set the SOLID STATE THERMOSTAT (5) to the

desired temperature.

4. Preheat until the OVEN READY LIGHT (4)

goes out.

5. Load product into the oven. Rotate the dial (7)

to the desired time. The timer will begin to

countdown after approximately 1 second.

6. When the buzzer sounds, remove the product

from the oven. Turn the TIMER dial (7) to siĆ

lence the buzzer.

7. Turn the SELECTOR Switch (1) to OVEN OFF.

Figure 11

13

Page 18

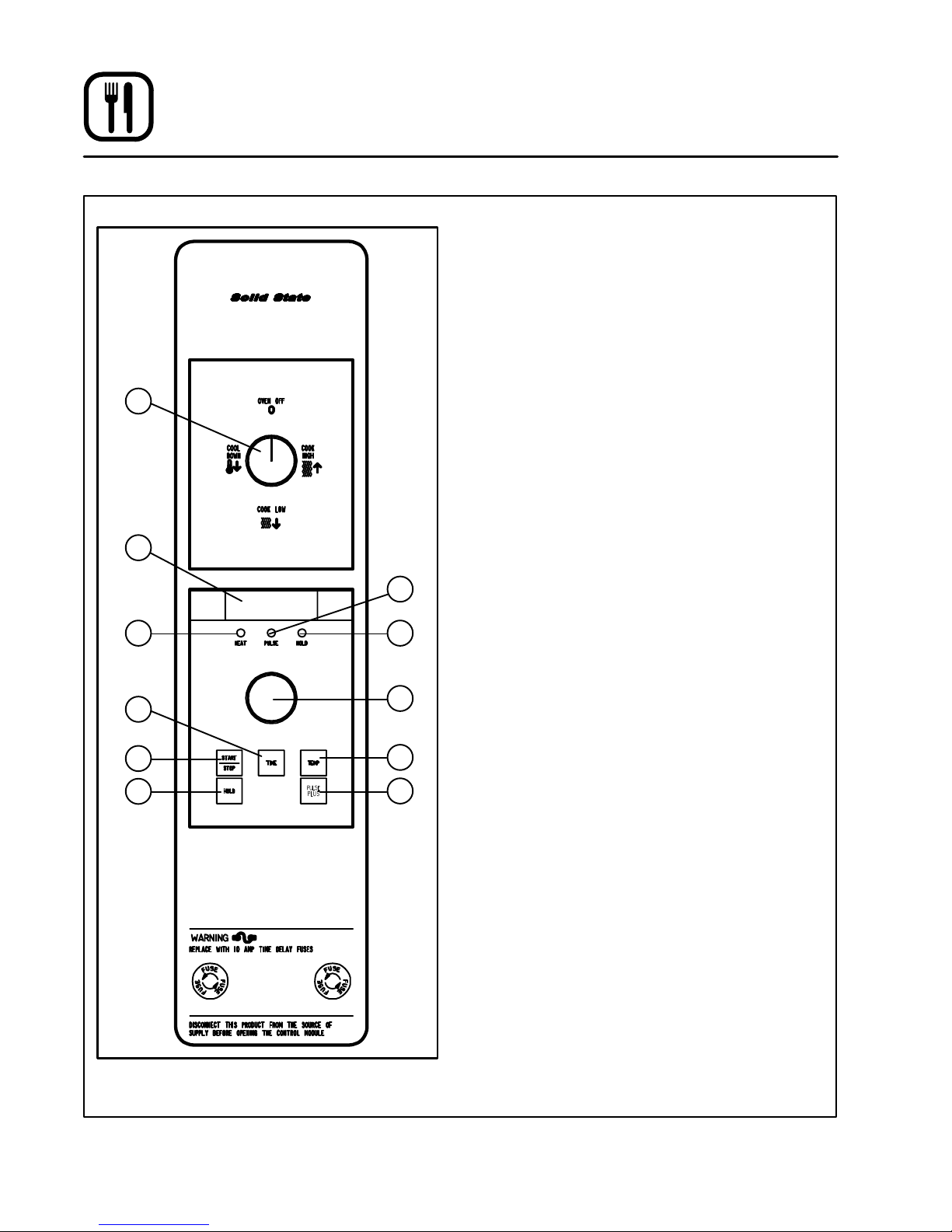

Operation

Solid State Digital Control

1

2

3

CONTROL DESCRIPTION

1. SELECTOR SWITCH - turns power to the

oven on or off. Allows selection of Cook or

Cool Down Modes and fan speed (if applicaĆ

ble).

2. DISPLAY - displays time or temperature and

other information related to oven function.

3. HEAT LAMP - lights when heater is on.

4. PULSE LAMP - lights when Pulsed Fan Mode

is turned on.

5. HOLD LAMP - lights when Hold Mode is

turned on.

6. DIAL - used to enter set points in display

7. START/STOP KEY - starts or stops the timer.

8. TIME KEY - used to show time in the display.

9. TEMP KEY - used to show set temperature in

the display.

NOTE: Actual temperature is shown while the

4

10. HOLD KEY - turns Hold Mode on or off.

5

11. PULSE KEY - turns Pulse Mode on or off.

TEMP key is held down.

8

7

10

Figure 12

6

9

11

PROGRAMMING

To set the cook temperature:

1. Press TEMP (9) key.

2. Rotate dial (6) to enter temperature.

To set the cook time:

1. Press TIME (8) key.

2. Rotate the dial (6) to enter time.

NOTE: Time is entered in hours : minutes or

minutes : seconds.

To set the hold time:

1. Press HOLD key (10) to turn hold mode on.

NOTE: HOLD light is on.

2. Rotate dial (6) to enter the hold temperature.

3. Press START/STOP key (7)

To set the pulse time:

1. Press PULSE KEY (11) to turn pulse mode on.

NOTE: Pulse light is on.

2. Rotate DIAL (6) to enter the pulse time. Pulse

time is a portion of the preĆset cook time.

14

Page 19

Operation

Solid State Digital Control

OPERATION

Cook Only:

1. Turn SELECTOR switch (1) to the desired poĆ

sition.

2. Enter the cook time and temperature.

3. Load product into oven.

NOTE: The display reads LOAD with the oven

is near the set temperature.

4. Press the START/STOP key (7). The timer beĆ

gins to count down.

5. When the cook timer reaches 00:00 the buzzĆ

er sounds and the display reads DONE.

6. Press the START/STOP key (7) to silence the

buzzer.

7. Remove the product.

Cook with Hold:

NOTE: HOLD light is on when hold mode is on

and off when hold mode is off.

1. Turn SELECTOR switch (1) to the desired poĆ

sition.

2. Enter the cook time and temperature.

3. Press the HOLD key (10). Enter the hold temĆ

perature.

4. Load product into oven.

NOTE: The display reads LOAD with the oven

is near the set temperature.

5. Push the START/STOP (7) key. Timer begins

to count down.

6. When the cook timer reaches 00:00 the buzzĆ

er sounds and the display reads DONE. The

buzzer turns off after a few seconds. The disĆ

play reads HOLD until the oven reaches the

hold temperature. Then the timer begins to

count up.

7. Push the START/STOP key (7) to stop timer.

8. Remove the product.

9. Push HOLD (10) key to turn off hold mode.

Cook with Pulse:

NOTE: PULSE light is on when pulse mode is on

and off when pulse mode is off.

1. Turn the SELECTOR SWITCH (1) to the deĆ

sired position.

2. Enter cook time and cook temperature.

3. Press PULSE KEY (11). Enter the pulse time.

NOTE: Pulse time is a portion of the cook time

and does not increase the previously

entered cook time.

4. Load product into oven.

NOTE: The display reads LOAD with the oven

is near the set temperature.

5. Push START/STOP KEY (7). The timer begins

to count down the cook time. The oven will be

in pulse mode for the set pulse time. Once the

set time has expired, the unit will automatically

switch to cook mode and continue counting

down.

6. When the cook timer reaches 00:00 the buzzĆ

er sounds and the display reads DONE.

7. Push the START/STOP KEY (7) to turn the

buzzer off.

8. Remove the product.

15

Page 20

Operation

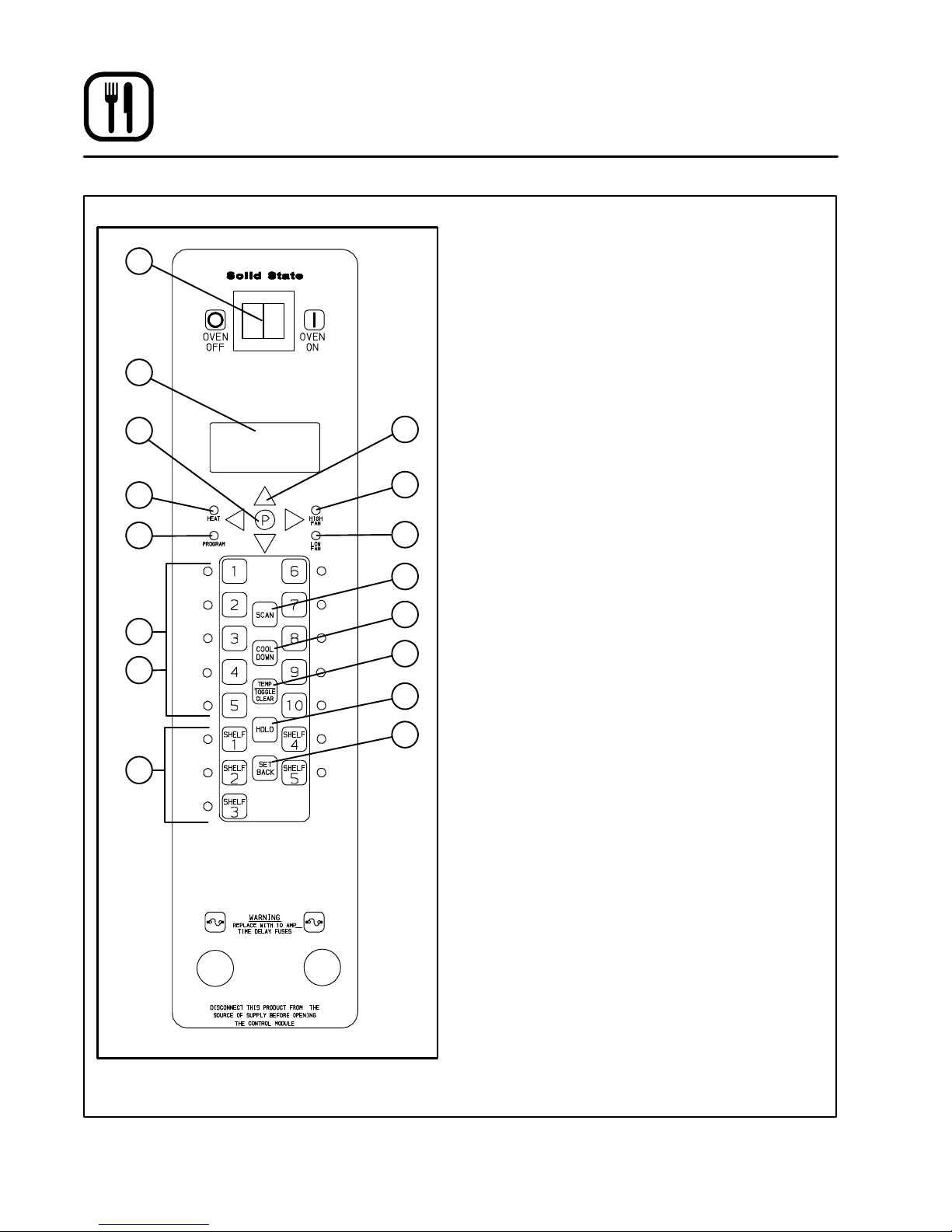

Blodgett IQ2T Vision Control

1

2

3

5

6

14

15

16

10

11

12

13

COMPONENT DESCRIPTION

1. OVEN POWER SWITCH - controls power to

the oven.

2. DISPLAY - displays temperature and other

controller related information.

3. PROGRAM KEY - press to enter the programĆ

ming mode.

4. PROGRAM ARROW KEYS - use to move

through programming menus and options

5. HEAT LED - when lit indicates the control is

4

7

8

9

calling for heat.

6. PROG LED - when lit indicates the controller

is in the programming mode.

7. HIGH FAN LED - when lit indicates the fan is

running at high speed.

8. LOW FAN LED - when lit indicates the fan is

running at low speed.

9. SCAN KEY - Press to view time remaining on

multiple cook cycles and to review recipe proĆ

gramming.

10. COOL DOWN KEY - press to enter the cool

down mode.

11. TEMP/TOGGLE/CLEAR KEY - press during

programming to toggle options.

12. HOLD KEY - press to enter hold mode.

13. SET BACK KEY -

14. PRODUCT KEYS (1Ć10) - assigns a key to a

programmed recipe and begins a proĆ

grammed cooking process. Also used to enĆ

ter numeric values in the programming mode.

15. PRODUCT LEDS - when lit indicate which

product keys are currently in use or proĆ

grammed for the current oven temperature

and fan speed.

16. SHELF KEYS (1Ć5) - assigns a shelf key.

Figure 13

16

Page 21

Operation

Blodgett IQ2T Vision Control

OVEN OPERATION

Oven Startup:

1. Toggle the POWER SWITCH (1) to ON. The

display gives the software revision level. The

oven preheats to the lowest programmed first

stage temperature. The LEDS (15) for all prodĆ

ucts with the same first stage temperature

light.

Single Product Cooking Procedure:

NOTE: If the led next to the desired product key is

lit skip step 1.

1. Press the desired PRODUCT KEY (14). The

oven preheats to the first stage temperature for

the selected product. When the oven reaches

10_ of the preheat temperature an alarm

sounds and the DISPLAY (2) read:

LOAD

2. Load the product into the oven. Press the deĆ

sired PRODUCT KEY (14).

If the shelf timing function is toggled to the

on position for that product key, the DISĆ

PLAY (2) reads:

PICK SHLF

Press a SHELF KEY (16) to assign the product

to that shelf and start the cook cycle. Within

five seconds, the DISPLAY (2) scrolls the prodĆ

uct name and shelf number and counts down

the remaining cook time.

If the shelf timing function is toggled to the

off position for that product, pressing the

product key will start the cook cycle. The DISĆ

PLAY (2) scrolls the product name and counts

down the remaining cook time.

NOTE: If the selected product has a cook time

of greater than 59:59 the DISPLAY (2)

switches to hours:minutes.

NOTE: If the selected product is a single stage

recipe the LEDS for all single stage

products with the same cook temperaĆ

ture and fan speed will light. If the seĆ

lected product is a multiple stage recĆ

ipe no other product LEDS will light.

NOTE: Press and hold the selected product

key for three seconds to cancel the

cook cycle for normal operation. To

cancel the cook cycle when using

shelf timing, press and hold the correĆ

sponding SHELF KEY (16) for 3 secĆ

onds.

3. When the cook time expires an alarm sounds

and the DISPLAY (2) reads:

DONE

Product name

4. Press the selected product key to silence the

alarm. Remove the product. If shelf timing is

used, press the flashing SHELF KEY (16) to siĆ

lence the alarm.

Multiple Batch Cooking Procedure:

This procedure is for single stage recipes with the

same cook temperature and fan speed only.

NOTE: If the led next to the first desired product

key is lit skip step 1.

1. Press the first desired PRODUCT KEY (14).

The LEDS for all recipes with the same cook

temperature and fan speed will light.

The oven preheats to the cook temperature for

the selected product. When the oven reaches

10_ of the preheat temperature an alarm

sounds and the DISPLAY (2) reads:

LOAD

17

Page 22

Operation

Blodgett IQ2T Vision Control

2. Load the product into the oven. Press the deĆ

sired PRODUCT KEY (14).

If the shelf timing function is toggled to the

on position for that product key, the DISĆ

PLAY (2) reads

PICK SHLF

Press a SHELF KEY (16) to assign the product

to that shelf and start the cook cycle. Within

five seconds, the DISPLAY (2) scrolls the prodĆ

uct name and shelf number and counts down

the remaining cook time.

If the shelf timing function is toggled to the

off position for that product, pressing the

product key will start the cook cycle. The DISĆ

PLAY (2) scrolls the product name and counts

down the remaining cook time.

3. Load the second product. Press the desired

PRODUCT KEY (14). the DISPLAY (2) reads

PICK SHLF

Press a SHELF KEY (16) to assign the product

to that shelf and start the cook cycle for prodĆ

uct two.

NOTE: Only products with lighted LEDS may

be selected.

Repeat step 3 for additional products.

4. The DISPLAY (2) scrolls the product name and

counts down the remaining cook time for the

product with the least time remaining.

NOTE: To view the remaining cook time for

the other products press and hold the

SCAN KEY (9). The display cycles

through the remaining cook times for

each product. Only the led for the

product with the cook time displayed

will be lit.

5. When a cook time expires an alarm sounds.

The display reads

DONE

The led for the finished product lights. All other

LEDS are dark.

6. Press the SHELF KEY (16) for the finished

product to silence the alarm. Remove the

product. Close the oven door. The DISPLAY

(2) scrolls the product name and counts down

the remaining cook time for the product with

the least time remaining.

7. When the cook time expires an alarm sounds

and the display reads:

DONE

8. Press the SHELF KEY (16) to silence the

alarm. Remove the product.

Oven Cool Down:

1. Close the oven door. Press the COOL DOWN

KEY (10).

NOTE: Cool down cannot be activated with the

oven door open. Once the cool down cycle

has begun the doors may be opened to

speed the cooling process.

To Review Repipe Programming:

1. Press the SCAN KEY (9). The display read:

RECIPE REVIEW

Select Product

The LEDs (15) for all previously programmed

product keys light. Press the PRODUCT KEY

(14) you wish to review. The display gives the

recipe cook time for stage 1. Use the PROĆ

GRAM ARROW KEYS (4) to scroll through the

recipe programming for the selected product

key.

2. The control will exit recipe review after 30 secĆ

onds if no key is pressed.

18

Page 23

Operation

Blodgett IQ2T Vision Control

PRODUCT KEY PROGRAMMING

To enter the product programming mode

1. Press and hold the PROGRAM KEY (3). The

DISPLAY (2) reads:

Prod Cnt

Programming

Use the PROGRAM ARROW KEYS (4) to highĆ

light Programming. Press the PROGRAM KEY

(3) to select. The display reads:

ENTER CODE

Use the PRODUCT KEYS (14) to enter the proĆ

gramming access code 1724. Press the PROĆ

GRAM KEY (3). The display reads:

RECIPE

Press the PROGRAM KEY (3). All of the prodĆ

uct LEDSs will light and the display reads:

Select Product

To Program

To program the product

4. The display reads:

Shelf Cook

XXX

Definition: Shelf cook enables the operĆ

ator to reference product to one of the

five shelf positions in the oven. At the

end of a shelf cooking cycle the oven

will display the name of the product and

the shelf number that is ready to be

pulled. Shelf cooking is not available

for multiĆstage recipes.

Use non shelf cooking when you do not

need to reference product to one of the

five shelf positions in the oven. Non

shelf cooking may be used for single

stage recipes and MUST be used for

multiĆstage recipes.

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either YES (for shelf cooking) or NO (for

non shelf cooking). Press the PROGRAM KEY

(3).

To select the product to program

2. Press the desired product key. The display

reads:

All

Name

With All highlighted, press the PROGRAM

KEY (3). The display reads:

Product Name

AAA

The first alphabetical listing in the product

name library appears.

3. To change the product name, use the PROĆ

GRAM ARROW KEYS (4) to scroll through the

product name library. When the desired prodĆ

uct name is highlighted, press the PROGRAM

KEY (3) to select.

5. The display reads:

Stage 1 Time

XX:XX

Use the PRODUCT KEYS (14) to enter the deĆ

sired cook time. Press the PROGRAM KEY (3).

6. The display reads:

Stage 1 Temp

XXXF (or C)

Use the PRODUCT KEYS (14) to enter the deĆ

sired cook temperature. Press the PROGRAM

KEY (3).

19

Page 24

Operation

Blodgett IQ2T Vision Control

7. The display reads:

Stage 1 Timing

XXX

Definition: There are 3 options for timĆ

ing mode when shelf cooking: Straight,

Flex and Sensitivity. Straight has no

time adjustment. Flex adjusts the cook

time to compensate for any difference

between the setpoint and actual temĆ

perature. Sensitivity enables a product

key to have a flex adjustment for each

of the five shelves. Sensitivity values are

set in the manager level programming.

NOTE: Sensitivity is only available when usĆ

ing shelf cooking.

Use the PROGRAM ARROW KEYS (4) to seĆ

lect the desired timing mode. Press the PROĆ

GRAM KEY (3).

8. The display reads:

Stage 1 Fan Spd

XX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either HIGH or LOW fan speed. Press the

PROGRAM KEY (3).

9. The display reads:

Stage 1 Fan On

XX:XX

Use the PRODUCT KEYS (14) to enter the deĆ

sired length of the time the fan should be on

in the pulse cycle. Press PROGRAM KEY (3).

The display reads:

Stage 1 Fan OFF

XX:XX

Use the PRODUCT KEYS (14) to enter the deĆ

sired length of the time the fan should be off

in the pulse cycle. Press the PROGRAM KEY

(3).

10. If you are programming a product using shelf

cooking skip to step 11.

If you are programming a product that does

not use shelf cooking the display reads:

Stage 2 Time

XX:XX

Repeat steps 5 through 10 for each remaining

stage. If you are programming a single stage

recipe without shelf cooking enter at time of

00:00 for stage 2.

11. The display reads:

Alarm 1 Time

XX:XX

Stage 1 Fan Cyc

XXX

Definition: There are 3 options for fan

cycle time: Pulse, Heat and Full. Pulse

allows the fan to turn on and off as proĆ

grammed. Heat allows the fan to operĆ

ate with heat only. Full provides continuĆ

ous fan operation when door is closed.

Use the PROGRAM ARROW KEYS (4) to seĆ

lect the fan cycle. If heat or full are selected

skip to step 10. If pulse is selected the display

reads:

Definition: If you would like the alarm to

sound prior to the completion of the

cook cycle you may program it here.

The alarm time counts up from the beĆ

ginning of the cook cycle. For example,

if you want an alarm 9 minutes into the

cook cycle, program the alarm time at

9:00.

Use the PRODUCT KEYS (14) to enter the time

for the first alarm to sound. If 00:00 is entered

for an alarm time, skip to step NO TAG.

Press the PROGRAM KEY (3). If a time other

than 00:00 is entered the display reads:

20

Page 25

Operation

Blodgett IQ2T Vision Control

Alarm 1 Name

XXX

To change the alarm name, use the PROĆ

GRAM ARROW KEYS (4) to scroll through the

alarm name library.

Press the PROGRAM KEY (3). The display

reads:

Alarm 1 Done

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either AUTOMATIC or MANUAL.

Press the PROGRAM KEY (3). The display

reads:

Alarm 1 Tone

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either NONE, SHORT, MEDIUM, LONG,

DOUBLE, or LONG/SHORT.

Press the PROGRAM KEY (3). The display

reads:

Alarm 2 TIme

XXX

Repeat step 11 for alarm 2. If no Alarm 2 is deĆ

sired, enter a time of 0.

Use the PRODUCT KEYS (14) to enter desired

hold temperature. The minimum hold temperĆ

ature is 140F. Press the PROGRAM KEY (3).

14. The display reads:

Hold Done

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either AUTOMATIC or MANUAL. Press the

PROGRAM KEY (3).

15. The display reads:

Hold Fan Speed

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect HIGH or LOW.Press the PROGRAM KEY

(3).

To exit the program mode

16. The display reads:

Exit

All

Use the PROGRAM ARROW KEYS (4) to scroll

down until exit is highlighted. Press the PROĆ

GRAM KEY (3). The display reads:

12. Press the PROGRAM KEY (3). The display

reads:

Hold Time

XX:XX

Use the PRODUCT KEYS (14) to enter desired

hold time. If a hold time of 00:00 is entered skip

to step NO TAG. Press the PROGRAM KEY

(3).

13. The display reads:

Hold Temp

XXXF

Recipe

Exit

To program another product key select recipe.

To exit the progam mode select exit. The disĆ

play reads:

Product Cnt

Programming

Use the PROGRAM ARROW KEYS (4) to scroll

down until exit is highlighed. Press the PROĆ

GRAM KEY (3) to exit the programming mode.

21

Page 26

Operation

Blodgett IQ2T Vision Control

MANAGER LEVEL PROGRAMMING

Entering the manager programming mode

1. Press and hold the PROGRAM KEY (3). The

display reads:

Prod Cnt

Programming

Use the PROGRAM ARROW KEYS (4) to highĆ

light Programming. Press the PROGRAM KEY

(3) to select. The display reads:

ENTER CODE

Use the PRODUCT KEYS (14) to enter the proĆ

gramming access code 6647. Press the PROĆ

GRAM KEY (3). The display reads:

System

ProdName Lib

Programming the MANAGER SYSTEM options

1. With System highlighted, press the PROĆ

GRAM KEY (3) to select. The display reads:

Appliance Type

XXX

3. The display reads:

Tone Volume

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect None, 1, 2, 3 or 4. Press the PROGRAM

KEY (3) to select the desired level for all audiĆ

ble signals.

4. The display reads:

Temperature

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either F or C. Press the PROGRAM KEY (3)

to select the desired temperature units.

5. The display reads:

Hold Time

XXX

Use the PRODUCT KEYS (14) to enter the

length of hold time for the manual hold button.

Press the PROGRAM KEY (3).

If a time of 00:00 is enter skip to step 6.

If a hold time is entered the display reads:

Hold Temp

XXX

Use the PROGRAM ARROW KEYS (4) to highĆ

light electric half, electric full, XCEL, gas half or

gas full. Press the PROGRAM KEY (3) to select

the correct appliance type.

2. The display reads:

Language

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lecteither English or Other. Press the PROĆ

GRAM KEY (3) to select the desired language.

Use the PRODUCT KEYS (14) to enter the hold

temperature for the manual hold button. Press

the PROGRAM KEY (3). The display reads:

Hold Done

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either AUTOMATIC or MANUAL. Press the

PROGRAM KEY (3). The display reads:

Hold Fan Speed

XXX

Use the PROGRAM ARROW KEYS (4) to seĆ

lect HIGH or LOW. Press the PROGRAM KEY

(3).

22

Page 27

Operation

Blodgett IQ2T Vision Control

6. The display reads:

Setback Time

XXX

Definition - Setback time is an energy

savings feature that automatically lowĆ

ers the cavity temperature when the

oven is idle.

Use the PRODUCT KEYS (14) to enter the

length of the time the oven is idle before enterĆ

ing setback mode. Press the PROGRAM KEY

(3).

If a time of 00:00 is enter skip to step 7.

If a setback time is entered the display reads:

Setback Temp

XXX

Use the PRODUCT KEYS (14) to enter the setĆ

back temperature. Press the PROGRAM KEY

(3).

7. The display reads:

Shelf Sense

XXX

Definition - If you are using sensitivity

as a timing mode for single stage stage

recipes this feature must be turned on.

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either Yes or No. Press the PROGRAM

KEY (3).

If no is selected skip to step 8.

If yes is selected the display reads:

Shelf 1 Sens

XXX

Use the PRODUCT KEYS (14) to enter a sensiĆ

tivity level of 1Ć9 for shelf 1. Press the PROĆ

GRAM KEY (3). Repeat for shelves 2Ć5.

8. The display reads:

Preheat Time

XXX

Definition - This function programs

time for the oven to idle after reaching

the preheat temperature allowing heat

to saturate the oven cavity. The preheat

time only applies to the initial preheat

after a cold start. This is strictly a

prompt, the user may begin a bake

cycle even with the preheat prompt disĆ

played.

Use the PRODUCT KEYS (14) to enter a preĆ

heat time. Press the PROGRAM KEY (3).

23

Page 28

Operation

Blodgett IQ2T Vision Control

Programming the PRODUCT NAME

NOTE: Use these instructions to modify an existĆ

ing name, to add a product name or to deĆ

lete a name already in the library.

NOTE: Names may be up to 16 characters long

and can contain letters and numbers.

1. After entering the manager level programĆ

ming (see page 22) the display reads:

System

ProdName Lib

With ProdName Lib highlighted, press the

PROGRAM KEY (3) to select. The display

reads:

Prod Name Lib

2. Use the up and down PROGRAM ARROW

KEYS (4) to scroll through the existing product

names. Or press the PRODUCT KEY (14) that

corresponds with the first letter of the name

you are looking for. Then use the PROGRAM

ARROW KEYS (4) to scroll to the desired

name.

3. Press the SCAN KEY (9) to edit the name.

4. Use the PRODUCT KEYS (14) to edit the prodĆ

uct name. Press the right arrow key to adĆ

vance to the next character.

To clear the product name, press the TEMP/

TOGGLE/CLEAR KEY (11).

NOTE: Use product key 1 for spaces, periĆ

ods, quotation marks and underlines.

5. Once the product name has been entered,

press the PROGRAM KEY (3). The display

reads:

Save Library

ADD

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either ADD, MODIFY or CANCEL. Select

ADD to create a new product name. Select

MODIFY to change an existing product name.

Select CANCEL to exit the edit mode without

saving your changes.

NOTE: To delete an exsisting product name,

find the name in the product library.

Press the TEMP/TOGGLE/CLEAR KEY

(11) to clear the entire product name.

Then select MODIFY to overwrite the

name with a clear screen.

6. Press the PROGRAM KEY (3) to exit the prodĆ

uct name library.

24

Page 29

Operation

Blodgett IQ2T Vision Control

Programming the ALARM NAME

NOTE: Use these instructions to modify an existĆ

ing name, to add an alarm name or to deĆ

lete a name already in the library.

NOTE: Names may be up to 16 characters long

and can contain letters and numbers.

1. After entering the manager level programĆ

ming (see page 22) the display reads:

System

ProdName Lib

Use the PROGRAM ARROW KEYS (4) to highĆ

light Alarm Lib. Press the PROGRAM KEY (3)

to select. The display reads:

Alarm Name Lib

2. Use the up and down PROGRAM ARROW

KEYS (4) to scroll through the existing alarm

names. Or press the PRODUCT KEY (14) that

corresponds with the first letter of the name

you are looking for. Then use the PROGRAM

ARROW KEYS (4) to scroll to the desired

name.

3. Press the SCAN KEY (9) to edit the name.

4. Use the PRODUCT KEYS (14) to edit the alarm

name. Press the right arrow key to advance to

the next character.

To clear the alarm name, press the TEMP/

TOGGLE/CLEAR KEY (11).

NOTE: Use product key 1 for spaces, periĆ

ods, quotation marks and underlines.

5. Once the alarm name has been entered,

press the PROGRAM KEY (3). The display

reads:

Save Library

ADD

Use the PROGRAM ARROW KEYS (4) to seĆ

lect either ADD, MODIFY or CANCEL. Select

ADD to create a new alarm name. Select

MODIFY to change an existing alarm name.

Select CANCEL to exit the edit mode without

saving your changes.

NOTE: To delete an exsisting alarm name,

find the name in the product library.

Press the TEMP/TOGGLE/CLEAR KEY

(11) to clear the entire alarm name.

Then select MODIFY to overwrite the

name with a clear screen.

6. Press the PROGRAM KEY (3) to exit the alarm

name library.

Exiting the manager program mode

1. The display reads:

System

ProdName Lib

Use the PROGRAM ARROW KEYS (4) to scroll

up until Exit is highlighted. Press the PROĆ

GRAM KEY (3). The display reads:

Prod Cnt

Programming

Use the PROGRAM ARROW KEYS (4) to scroll

up until Exit is highlighted. Press the PROĆ

GRAM KEY (3) to exit the programming mode.

25

Page 30

Operation

How Cook and Hold Works

With the optional COOK & HOLD feature, meat is

roasted at lower temperatures for longer periods

of time. This preserves flavor and tenderness and

prevents over drying. There are three phases in

cook and hold roasting.

D Primary Cooking - controlled by the COOK &

HOLD TIMER. The meat is cooked at a low temĆ

perature until approximately 2/3 done.

D Cooking from Stored Heat - when the primaĆ

ry cook time expires, the oven automatically

switches to HOLD. The product continues to

cook from the heat stored in the oven. Meat

must remain in the hold cycle for a minimum of

1Ć1/2 to 2 hours before being served.

D Hold - holds the product for several hours beĆ

fore serving without loss of moisture or tenderĆ

ness.

All meat should be completely thawed by refrigerĆ

ation. Using frozen meat increases the cook time

causing shrinkage.

Product Cook

Prime rib, bone cap off

14Ć18 lbs. (6.4Ć8.1 kg)

Te mp .

200_F

93_C

Hold

Te mp .

140_F

60_C

250_

225_

200_

175_

150_

125_

100_

Temperature (F)

75_

50_

25_

Oven temp.

Meat temp

Quantity Cook Time

(Hrs)

1

3

6

3

3Ć1/4

3Ć1/2

Oven switches from

cook to hold

Stored heat

Product may be

held up to 16 hours

Product may be

removed and

served

345612 789

Time (hours)

Figure 14

Min. Hold

Time (Hrs)

1

1Ć1/2

2

Total Time

(Hrs)

4

4Ć3/4

5Ć1/2

Prime rib, bone cap on

14Ć18 lbs. (6.4Ć8.1 kg)

Top or bottom rounds

20Ć22 lbs. (9.1Ć10.0 kg)

Pork roast or ham

10Ć12 lbs. (4.5Ć5.4 kg)

Turkey

20Ć22 lbs. (9.1Ć10.0 kg)

Leg of Lamb, bone in

8Ć10 lbs. (4.36Ć4.5 kg)

200_F

93_C

200_F

93_C

250_F

121_C

250_F

121_C

225_F

107_C

140_F

60_C

140_F

60_C

170_F

76_C

170_F

76_C

160_F

71_C

26

1

3

6

1

3

6

2

4

6

1

6

2

4

6

3Ć1/2

4

4Ć1/2

3Ć1/2

4

4Ć1/2

4

4Ć1/4

4Ć1/2

3Ć1/4

4

2Ć1/2

2Ć3/4

3

1

1Ć1/2

2

1

1Ć1/2

2

1

1Ć1/2

2

1

1Ć1/2

1

1Ć1/2

2

4Ć1/2

5Ć1/2

6Ć1/2

4Ć1/2

5Ć1/2

6Ć1/2

5

5Ć3/4

6Ć1/2

4Ć3/4

5Ć1/2

3Ć1/2

4Ć1/4

5

Page 31

Operation

General Guidelines for Operating Personnel

COOK TIMES AND TEMPERATURES

Preheating the oven

Always preheat the oven before baking or roastĆ

ing. We recommend preheating 50_F (28_C)

above the cook temperature to offset the drop in

temperature when the doors are opened and cold

product is loaded into the oven. Set the thermostat

to the cook temperature after the product is

loaded.

NOTE: For frozen product, preheat the oven

100_F (56_C) above the cook temperaĆ

ture.

Cook Temperatures

Generally, cook temperatures should be 50_F

(28_C) lower than deck or range oven recipes. If

the edges of the product are done but the center

is raw, or if there is color variation, reduce the therĆ

mostat setting another 15Ć25_F (10Ć15_C). ConĆ

tinue to reduce the cook temperature on succesĆ

sive loads until the desired results are achieved.

NOTE: Cooking at excessive temperatures will

not reduce cook time, it will produce unĆ

satisfactory baking and roasting results.

Cook Time

Check the product in about half the time recomĆ

mended for deck or range oven recipes. Record

times and temperatures which provide best reĆ

sults for future reference.

NOTE: Cook time will vary with the amount of

product loaded, the type of pan and the

temperature.

OPERATING TIPS

Pans and Racks

Product or pan height determines how many

racks are used. The oven holds up to 10 18" x 26"

(45.7 x 66.0 cm) bun pans.

Load the oven from the bottom, centering the pans

on the rack. Never place a pan or aluminum foil on

the bottom of the oven. This obstructs the flow of

air and results in uneven baking and roasting.

Roasting

To reduce shrinkage when roasting, place meat

directly on the racks. Place a sheet pan oneĆhalf

full of water in the bottom rack position. The water

evaporates, increasing humidity in the oven

chamber. The pan catches grease from the meat,

making oven cleaning easier.

Baking

Weigh the product to ensure equal distribution in

each pan. Varying amounts of product will cause

uneven baking results.

Fans

The fan must be operating for the oven to heat.

Use the Pulse Plus feature to allow light or liquid

product to set in the pan and to avoid rippling toĆ

wards the fan. If your oven is not equipped with

this feature use the following procedure.

1. Preheat the oven 25_F (15_C) above the bakĆ

ing temperature.

2. Load the oven with product. Close the doors.

3. Set the thermostat to the baking temperature.

4. Turn the oven off.

5. Allow the product to set for 5-7 minutes with

the fan off. The residual heat in the oven sets

the product.

6. Turn the oven on for the remainder of the bake.

Lights

Turn the oven lights off when not viewing the prodĆ

uct. Leaving the lights on for extended periods of

time shortens the bulb life considerably.

27

Page 32

Operation

Suggested Times and Temperatures

Product Temperature Time # Shelves

Meats

Hamburger Patties (5 per lb)

Steamship Round (80 lb. quartered)

Standing Rib Choice (20 lbs, trimmed, rare)

Banquet Shell Steaks (10 oz. meat)

Swiss Steak after Braising

Baked Stuffed Pork Chop

Boned Veal Roast (15 lbs.)

Lamb Chops (small loin)

Bacon (on racks in 18" x 26" pans)

Poultry

Chicken Breast & Thigh

Chicken Back & Wing

Chicken (21/2 lbs. quartered)

Turkey Rolled (18 lb. rolls)

Fish and Seafood

Halibut Steaks, Cod Fish (frozen 5 oz)

Baked Stuffed Lobster (21/2 lb.)

Lobster Tails (frozen)

400_F (205_C)

275_F (135_C)

235_F (115_C)

450_F (235_C)

275_F (135_C)

375_F (190_C)

300_F (150_C)

400_F (205_C)

400_F (205_C)

350_F (175_C)

350_F (175_C)

350_F (175_C)

310_F (155_C)

350_F (175_C)

400_F (205_C)

425_F (220_C)

8Ć10 mins.

2 hrs 45 mins.

2 hrs 45 mins.

7Ć8 mins.

1 hr.

25Ć30 mins.

3 hrs. 10 mins.

7Ć8 mins.

5Ć7 mins.

40 mins.

35 mins.

30 mins.

3 hrs 45 mins.

20 mins.

10 mins.

9 mins.

10

2

2

5

5

5

2

5

10

5

5

5

3

5

3

5

Cheese

Macaroni & Cheese Casserole

Melted Cheese Sandwiches

Potatoes

Idaho Potatoes (120 ct.)

Oven Roasted Potatoes (sliced or diced)

Baked Goods

Frozen Berry Pies (22 oz)

Fresh Apple Pie (20 oz.)

Pumpkin Pies (32 oz.)

Fruit Crisp

Bread (24 Ć 1 lb. loaves)

Southern Corn Bread

Baking Soda Biscuits

Brown & Serve Rolls

Sheet Cakes (5 lb. mixed batter per pan)

Chocolate Cake

Brownies

NOTE: Actual times and temperatures may vary considerably from those shown above. They are affected

by weight of load, temperature of the product, recipe, type of pan and calibration of thermostat.

Should your recipe vary, write in your proven time and temperature for ready reference.

350_F (175_C)

400_F (205_C)

400_F (205_C)

325_F (165_C)

325_F (150_C)

350_F (175_C)

300_F (150_C)

300_F (150_C)

325_F (155_C)

375_F (190_C)

400_F (205_C)

350_F (175_C)

325_F (160_C)

325_F (160_C)

325_F (150_C)

30 mins.

8 mins.

50 mins.

10 mins.

35 mins.

25Ć30 mins.

30Ć50 mins.

25 mins.

30 mins.

15Ć20 mins.

6 mins.

15 mins.

16Ć18 mins.

20 mins.

15 mins.

5

10

5

5

5 (30 pies)

5 (30 pies)

5 (20 pies)

5

3

5

5

5

5

5

5

28

Page 33

Maintenance

Cleaning and Preventative Maintenance

CLEANING THE OVEN

Painted and stainless steel ovens may be kept

clean and in good condition with a light oil.

1. Saturate a cloth, and wipe the oven when it is

cold.

2. Dry the oven with a clean cloth.

On the stainless front or interiors, deposits of

baked on splatter may be removed with any nonĆ

toxic industrial stainless steel cleaner. Heat tint

and heavy discoloration may be removed with any

nonĆtoxic commercial oven cleaner.

1. Apply cleaners when the oven is cold. Always

rub with the grain of the metal.

The porcelain interior can be cleaned with any

commercial oven cleaner. Be sure caustic cleanĆ

ing compounds DO NOT come in contact with the

blower wheel and the aluminized steel panel diĆ

rectly behind it.

1. Remove the racks, rack supports and blower

wheel from the oven.

2. Soak the parts in a solution of ammonia and

water.

3. Reinstall after cleaning.

NOTE: If the oven is moved the restraint must be

reconnected after the unit is returned to it's

regular position.

PREVENTATIVE MAINTENANCE

The best preventative maintenance measures are,

the proper installation of the equipment and a proĆ

gram for routinely cleaning the ovens.

Annual Maintenance

This oven requires no lubrication, however, the

venting system should be checked annually for

possible deterioration resulting from moisture and

corrosive flue products.

If maintenance or repairs are required, contact

your local Blodgett service company, a factory

representative or the Blodgett Oven company.

WARNING!!

Always disconnect the appliance from the

power supply before servicing or cleanĆ

ing.

29

Page 34

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Heating elements do not come on.

S Oven not plugged in.

S Power switch on the control panel is off.

S Control set below ambient temperature.

S Doors are open.

S Computerized controls - error code on display.

SYMPTOM: Oven does not come to ready.

S The oven has not reached preheat temperature.

S Fan delay feature may be activated, if applicable.

S Internal problem with main temperature control.

SYMPTOM: Convection fan does not run.

S Oven is not plugged in.

S Oven is not set to the cook mode.

S Circuit breaker tripped.

S Fan delay feature may be activated, if applicable.

S Doors are open

SYMPTOM: General baking problems.

S Plug in electrical supply cord.

S Set the control panel to COOK or OVEN ON.

S Set to desired cook temperature.

S Close doors.

S *

S Wait for oven to reach preheat temperature.

S Deactivate fan delay feature.

S *

S Plug in electrical supply cord.

S Set the control panel to COOK or OVEN ON.

S Reset the breaker.

S Deactivate fan delay feature.

S Close doors.

S Computerized controls - incorrect product

programming.

S Thermostat out of calibration.

*Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

All repairs and/or adjustments be done by your local Blodgett service agency and not by the owner/operator. Blodgett cannot asĆ

sume responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S Reprogram control per Operation section.

S *

30

Page 35

La cuisson dans un four à convection diffère de la

q

q

cuisson dans un four de cuisine ordinaire en ce

sens que de l'air chaud circule en permanence auĆ

tour de l'aliment cuit, sous l'effet d'un ventilateur

enfermé dans une enceinte spéciale. Le mouveĆ

ment continu de l'air, en éliminant constamment la

couche d'air froid qui se formerait autrement auĆ

tour de l'aliment, permet la pénétration plus rapide

de la chaleur. Il en résulte un aliment de qualité

comparable à ceux préparés dans un four ordinaiĆ

re, mais cuit à température inférieure et en moins

de temps.

Le four à convection représente ce qu'il y a de plus

perfectionné en termes de rendement énergétiĆ

que, de fiabilité et de facilité d'emploi. Comme la

source thermique se trouve à l'intérieur même de

la chambre de cuisson, d'importantes économies

d'énergie peuvent être réalisées en même temps

que d'excellents résultats de cuisson.

Introduction

Description et Spécifications du Four

Circulation de l'air dans les fours à convection

Figure 1

SPÉCIFICATIONS ÉLECTRIQUES (par section de four)

KW Fréqu Tension Phase

ence

Installation ÉĆU et Canadar

11.0 60 208 1 51 - 51 - 6 AWG

11.0 60 208 3 31 29 29 - 8 AWG

11.0 60 220Ć240 1 44 - 44 - 6 AWG

11.0 60 220Ć240 3 26 24 24 - 8 AWG

11.0 60 440 3 15 14 14 - 12 AWG

11.0 60 480 3 14 13 13 - 12 AWG

Installation à l'export

11.0 50 208 3 18 18 18 4 Calibre suivant code local

11.0 50 220Ć240 1 48 - - 48 Calibre suivant code local

11.0 50 220/380 3 18 16 16 2 Calibre suivant code local

11.0 50 240/415 3 18 14 14 4 Calibre suivant code local

11.0 50 230/400 3 18 15 15 3 Calibre suivant code local

Ampères

L1 L2 L3 N

Connexion électrique

(calibre minimum)

31

Page 36

Introduction

Éléments du Four

Éléments chauffants - situés sur la paroi arrière

du four, les éléments procurent de la chaleur à la

chambre de cuisson des fours électriques.

Chaîne et Tendeur - contrôlent le fonctionneĆ

ment des portes de four.

Panneau de Contrôle - contient les câblages et

les éléments permettant de contrôler le fonctionĆ

nement du four.

Grilles de four - cinq grilles sont fournies en

équipement standard. Des grilles supplémentaiĆ

res sont disponibles.

Éléments

chauffants

Ventilateur

Support de Grille - tient les grilles en place.

Couvercle de Ventilateur - situé sur la paroi intéĆ

rieur au fond du four. Protège le ventilateur.

Ventilateur - tourne pour faire circuler l'air chaud

dans le four.

Moteur à Convection - fournit la force pour faire

tourner le ventilateur.

Éclairage du Four - fournit l'éclairage à l'intéĆ

rieur du four.

Moteur à

Convection

Couvercle de

Ventilateur

Support de

Grille

Grilles de four

Chaîne et

Tendeur

Éclairage du

Four

Figure 2

32

Panneau de

Contrôle

Couvercle du panneau

de commande

Page 37

Installation

Livraison et Implantation

LIVRAISON ET INSPECTION

Tous les fours sont expédiés en conteneurs. A la

réception de votre four Blodgett vous devez:

D Vérifier que les emballages ne sont pas abimés.

Toute défection dans l'emballage doit être noĆ

tée sur l'accusé de reception de la marchandiĆ

se; celuiĆci doit être signé par le chauffeur.

D Sortir le four de son emballage et vérifier son

bon état. Les transporteurs n'acceptent les réĆ

clamations et plaintes que si elles sont faites

dans les quinze jours qui suivent la livraison et

si l'emballage a été conservé afin d'être

inspecté.

La Blodgett Oven Co., n'est pas responsable

des dégâts subis pendant le transport. Le

transporteur est seul responsable de la livraiĆ

son du matériel en bon état lorsque l'expédiĆ

tion a été acceptée. Néanmoins, nous sommes

à votre disposition pour vous aider à composer

votre dossier de réclamation.

IMPLANTATION DU FOUR

L'implantation correcte et bien étudiée du four

sera à l'avantage à long terme de l'opérateur et

permettra d'obtenir un rendement satisfaisant.

Les espaces de dégagement ci-dessous doivent

être prévus entre le four et toute construction comĆ

bustible ou non.

D Côté droit du four - 2.5 cm (1")

D Côté gauche du four - 2.5 cm (1")

D Arrière du four - 2.5 cm (1")

D Dessous du four - 1.2 cm (1/2")

Les espaces de dégagement ciĆdessous doivent

être possible pour permettre l'entretien.

D Côtés du four - 30 cm (12")

D Arrière du four - 30 cm (12")

Il est essentiel qu'une circulation d'air adéquate

au four soit maintenue pour apporter un débit d'air

de combustion et de ventilation suffisant.

D L'emplacement ne doit pas avoir de courants

d'air.

D Maintenez la zone du four libre et dégagée de

tous matériaux combustibles tels que le papier,

le carton, ainsi que les liquides et solvants

inflammables.

D Ne pas mettre le four sur une base courbée ni

le sceller au mur afin d'éviter de limiter le débit

d'air et d'empêcher ainsi une ventilation

appropriée. Le déclenchement du dispositif de

surcharge thermique du moteur à soufflerie est

causé par une température ambiante excessive

du côté droit du four. Cette condition doit être

corrigée afin d'éviter d'endommager le four en

permanence.

Avant de raccorder le four aux prises des services

publics, vérifier la plaque signalétique afin de

s'assurer que les spécifications du four soient

compatibles avec les services électriques fournis

à ce dernier.

1. La plaque signalétique est située sous le

rebord supérieur du four, auĆdessus de la

porte droite.

33

Page 38

Installation

Montage du Four

BOULONS NSF

La NSF exige la pose de boulons dans tous les

trous vides situés à l'arrière du four, notamment

dans les cas suivants :

D tout appareil, seul ou superposé, ne comporĆ

tant aucun panneau arrière

D tout trou d'appareils superposés ne servant pas

à maintenir une ferrure de montage superposé.

1. Repérez les boulons de 5/16 po expédiés

avec le four.

2. Posez les boulons comme l'illustre la Figure 3.

Deux appareils superposés

Appareils sans panneau arrière

Figure 3

34

Page 39

Installation

Montage du Four

ASSEMBLAGE DES PIEDS

1. Pousser le four, couché sur le dos, sur un

élévateur.

2. Alignez le goujon fileté du pied sur le trou de

vis prévu dans le coin avant du fond de caisse.

Vissez le pied, dans le sens des aiguilles

d'une montre, jusqu'au dernier tour complet

possible.

3. Alignez les deux orifices de la plaque du pied

sur les trous prévus au bas du four. Fixez le pied

à l'aide de deux boulons de 12.7 mm (1/2 po).

REMARQUE:Si des roulettes sont utilisées, voir

MONTAGE DES ROULETTES

avant de continuer.

4. Si nécessaire, mettez le four de niveau en visĆ

sant ou en dévissant la vis de niveau des pieds

réglables.

MONTAGE DES ROULETTES

REMARQUE:Installer les roulettes à frein sur le deĆ

vant du four. Installer les roulettes

sans frein à l'arrière.

Roulettes pour four simple ou pour four superĆ

posés :

1. Placer les pieds comme décrit.

2. Desserrer l'écrou de blocage des embouts au

bas de chaque pied réglable. Retirer les embouts.

3. Insérer une roulette dans chaque pied, comĆ

me illustré. Serrer les écrous de blocage pour

fixer les roulettes.

Embouts de

pied ajustables

Ensemble de roulette

Figure 5

Illustré : pieds de 15 cm (6")

Figure 4

Roulettes de bas profile pour deux fours superĆ

posés :

1. Aligner les trois trous dans chaque plaque de

l'ensemble de roulette avec les trous dans le

fond du four. Fixer chaque roulette à l'aide de

trois boulons de 12.7 mm (1/2 po).

Figure 6

35

Page 40

Installation

Montage du Four

MONTAGE DE LA SECTION DOUBLE

REMARQUE:Les vieux modèles de fours sont ceux

qui ont un cadre arrière peinturé. Les

nouveaux modèles de fours sont ceux

avec un cadre arrière enfermé en acier.

Les instructions suivantes sont applicable a

l'assemblage de deux nouveaux modèles de

fours.

1. Fixez les pieds de courte longueur au bas de

la section inférieure comme décrit.

2. Posez la section supérieure parĆdessus la

section inférieure.

3. Fixez les ferrures de montage superposé au

moyen des autres boulons de 5/16 po

expédiés avec les fours.

4. Raccordez le connecteur de carneau.

Les instructions suivantes sont applicables a

l'assemblage d'un nouveau modèle de four (le

four supérieur) avec un vieux modèle de four (le

four inférieur).

1. Fixez les pieds de courte longueur au bas de

la section inférieure comme décrit.

2. Posez la section supérieure parĆdessus la

section inférieure.

3. Fixez les ferrures de montage superposé au

moyen des autres boulons de 5/16 po expéĆ

diés avec les fours.

4. Forez un trou pour un boulon de 5/16" dans le

cadre du vieux modèle du four. Untilisez les

trous dans les agrafes d'empilage.

5. Fixez les agrafes d'empilage au vieux modèle

du four a l'aide de boulons 5/16" et des écrous

qui se trouve dans le trousseau d'assemblage.

6. Raccordez le connecteur de carneau.

AVERTISSEMENT!!

Lors de la superposition de deux fours

simples, il est nécessaire d'enlever les

boîtes de carneau des unités simples avant

l'installation du connecteur à trois pièces.

MISE À NIVEAU DU FOUR

Après assemblage le four doit être mis à niveau et

installé à son emplacement d'utilisation.

1. Le four peut être mis à niveau en ajustant les

vis de mise à niveau ou les roulettes en bas de

chaque pied.

Le Connecteur

Figure 7

36

Page 41

Installation

Branchements de Service - Normes et Codes

LES CONSEILS D'INSTALLATION ET

D'ENTRETIEN CONTENUS DANS CE MANUEL

NE S'ADRESSENT QU'Á UN PERSONNEL

QUALIFIÉ. UN PERSONNEL NON QUALIFIE

PEUT SE BLES SER ET/OU ABÎMER LE FOUR

LORS DE SON INSTALLATION ET/OU SON

ENTRETIEN.

Un personnel d'installation qualifié est représenté

soit par des personnes physiques, soit par un

société, une usine, une corporation qui en

personne ou par l'intermédiaire d'un représentant

s'engage à et est responsable de:

D l'installation du câblage électrique reliant le

compteur d'électricité, l'armoire électrique ou la

prise de courant à l'appareil électrique.

Le personnel d'installation qualifié doit être

expérimenté dans ce type de travail, s'être

familiarisé avec toutes les précautions requises et

respecter tous les réglements promulgués par les

autorités provinciales ou locales compétentes.

Installation aux ÉtatsĆUnis et au Canada

La mise en service doit respecter les normes locaĆ

les ou, en l'absence de tels normes, les règleĆ

ments suivants : National Electrical Code, ANSI/

NFPA 70 - dernière édition ou le Code canadien

de l'électricité CSA C22.1, selon le cas.

La ventilation de ce four devrait être conforme aux

codes locaux. En l'absence de codes locaux, se

reporter au code national de la ventilation intitulé

Normes pour l'installation d'équipements pour

l'enlèvement des fumées et vapeurs grasses proĆ

venant d'équipements commerciaux pour la cuiĆ

sine", NFPAĆ96Ć Édition la plus récente.

Généralités concernant les installations à

l'exportation