Page 1

Installation, Operation &

Maintenance Manual

Refrigerated Base – Self-Contained

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

919-552-9161 • 800-348-2558 • 919-552-9798 (fax) • 800-238-8444 (after hours)

Printed in USA 12/02

MODELS

20036SB 20084SB

20048SB 20096SB

20060SB 20108SB

20072SB 20120SB

Page 2

2

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

INTRODUCTION

GENERAL INFORMATION

This technical manual provides information for the installation,

operation, maintenance, and inspection of this unit

manufactured by Middleby. A complete parts breakdown

is also provided.

TECHNICAL SUPPORT

For any questions regarding the installation, operation or

maintenance of the unit, contact the factory at the following

address:

Technical Service Department

Middleby

1100 Honeycutt Road

Fuquay-Varina, NC 27526

SCOPE OF THE MANUAL

This manual provides sufficient information for maintenance

of the equipment.

EQUIPMENT DESCRIPTION

The unit consists of the following parts:

• Storage compartment - The insulated food storage

compartment is clear storage area. The cooling coil

(evaporator) is contained in this area.

• Drawers - Product is stored by means of food pans set in

drawers. The drawer face is made of an insulated panel.

The drawer face (panel) is fully “gasketed”

to provide a tight seal against the cabinet.

• Condensing Unit Compartment - This area contains

the condensing unit(s) along with the necessary controls

and other components.

• Evaporator Coil - The evaporator coil is located in the

storage compartment and is responsible for distributing

the cold air associated with the refrigeration system.

• Cabinet - The cabinet is the enclosure in which all

of the above mentioned items are housed.

EQUIPMENT SUPPLIED

The unit is shipped from the factory assembled. The

complete assembly is palletized and crated to minimize

the possibility of damage in shipping and storage.

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Electrical and Mechanical . . . . . . . . . . . . . . . . . . . . . . . . .24

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

NOTICE!

MIDDLEBY RESERVES THE RIGHT

TO CHANGE SPECIFICATIONS AND PRODUCT DESIGN

WITHOUT NOTICE. SUCH REVISIONS DO NOT ENTITLE

THE BUYER TO CORRESPONDING CHANGES,

IMPROVEMENTS, ADDITIONS OR REPLACEMENTS

FOR PREVIOUSLY PURCHASED EQUIPMENT.

Page 3

Self-Contained, Refrigerated Bases

SAFETY

3

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

DANGER

EXPLOSION HAZARD

If gas odor is detected, shut down equipment at the main

shutoff valve. Immediately call the emergency phone

number of your gas supplier.

SPECIFICATIONS

SAFETY NOTICES

DANGER

This symbol warns of immediate hazards which WILL

result in severe injury or death.

WARNING

FIRE HAZARD

For your safety, do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any

other appliance.

Keep area around appliances free and clear of

combustibles.

WARNING

Asphyxiation can result from improper ventilation. Do

not obstruct the flow of combustion and ventilation air to

/and from your cooking equipment.

WARNING

This symbol refers to a potential hazard or unsafe

practice which COULD result in injury or death.

CAUTION

This symbol refers to a potential hazard or unsafe

practice which COULD result in injury, product or

property damage.

NOTICE! This symbol refers to information that requires

special attention or must be fully understood, even

though not dangerous.

SAFETY PRECAUTIONS

NOTICE! Post the emergency telephone number of your

gas supplier and instructions to follow if gas odor is

detected.

NOTICE! Be sure this manual and important papers are

given to the proper authority to retain for future

reference.

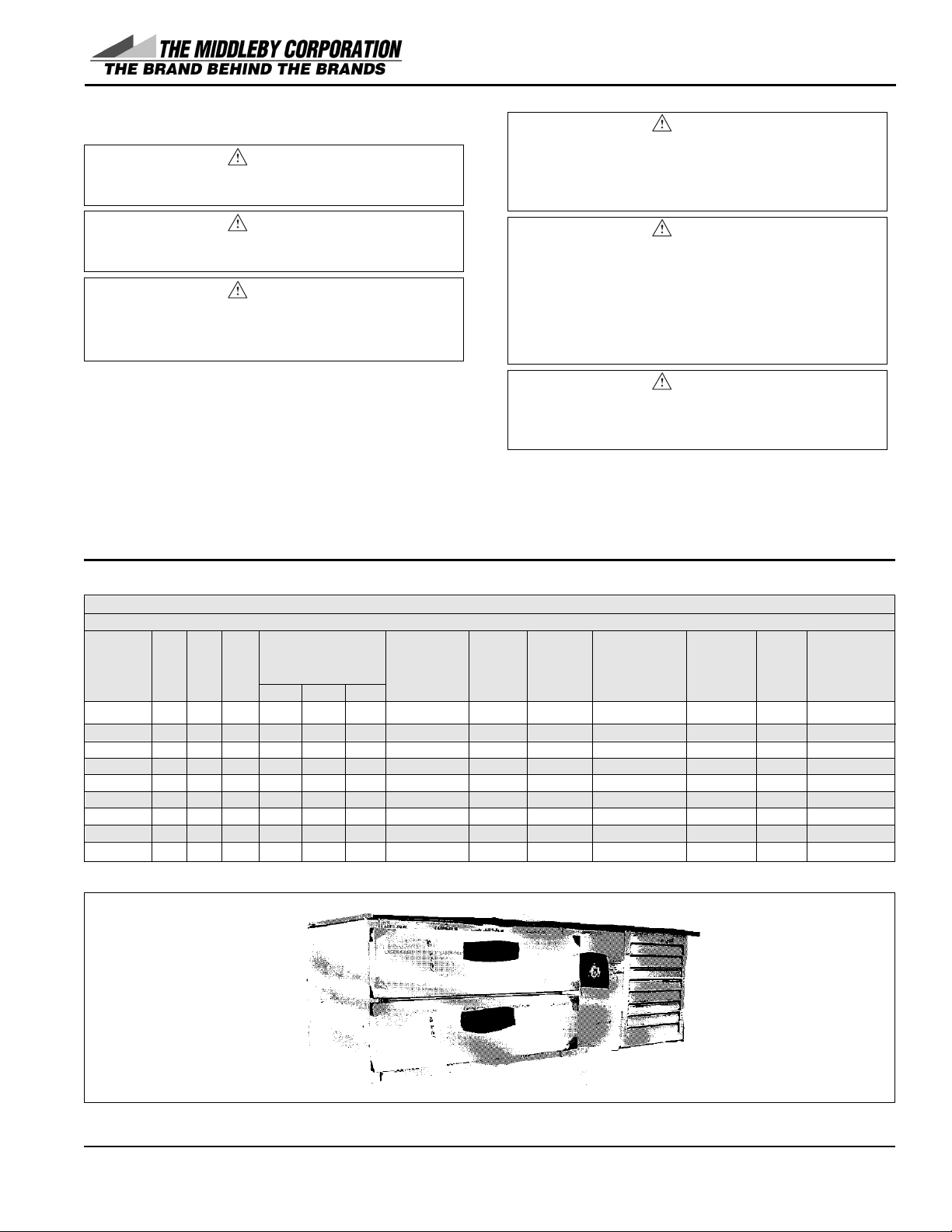

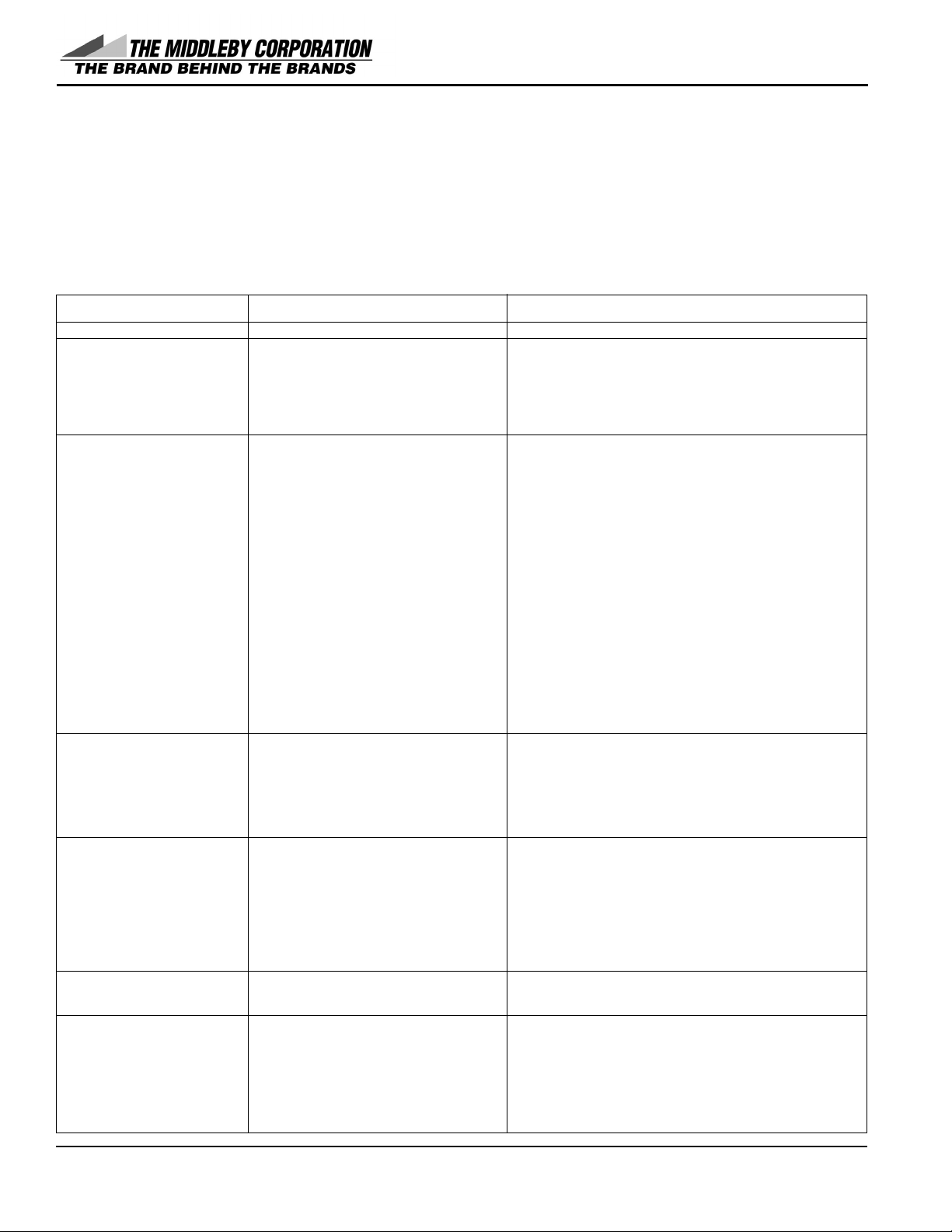

Model W D H* Drawers No. of Ref. Elec. Compressor Evap. Amps Shipping

Number Pans Volume V/Ph/Hz HP BTU Weight

12"x20"x4" (cu.ft.) (lbs.)

18" 26" 31"

20036SB

20048SB

20060SB

20072SB

20084SB

20096SB

20108SB

20120SB

36"

48"

60"

72"

84"

96"

108"

120"

2

-

-

-

-

2

-

4

-

2

-

4

4

6

4

-

2

4

-

-

-

2

4

4

8

8

10

12

12

5.9

8.6

12

15.5

19.3

22.5

24

29.2

1/4

1/4

1/4

1/3

1/3

1/2

1/2

1/2

6

6

6

7

7

7

7

7

310

410

530

650

740

840

960

1050

1100

1100

1100

1600

1600

1600

1600

1600

115/1/60

115/1/60

115/1/60

115/1/60

115/1/60

115/1/60

115/1/60

115/1/60

32"

32"

32"

32"

32"

32"

32"

32"

26"

26"

26"

26"

26"

26"

26"

26"

*Includes 6" legs or casters

Figure 1.1 - General Arrangement Picture

Table 1.1 - Leading Particulars

Page 4

4

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

OPERATION

INTRODUCTION

This model is a heavy-duty piece of equipment designed for

continuous use. It incorporates automatic controls to regulate

the cycling of the refrigeration system.

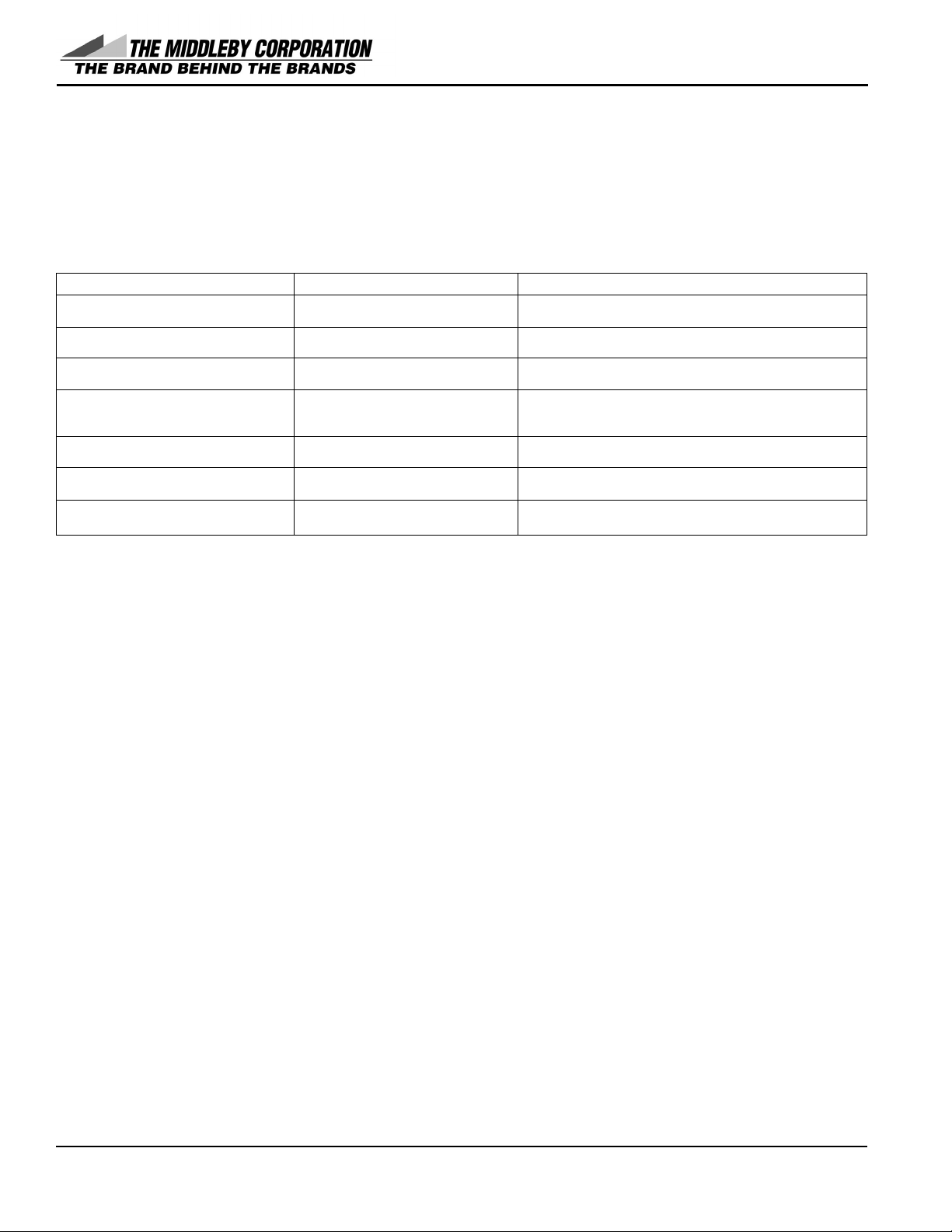

CONTROLS AND INDICATORS

Table 2.1 - Controls and Indicators

NAME TYPE FUNCTION

Low Pressure Switch Contact Points Cycles the refrigerator system (automatic)

Suction Valve Manual Plunger Valve Isolate suction at the compressor

Discharge Valve Manual Plunger Valve Isolate discharge line at receiver

Power Control Switch (On/Off) Contact Points Terminates all of the electrical into and past

the supply cord

Thermostat Contact Points Cycles the refrigerator system (automatic)

Defrost Timer

1

Contact Points Controls scheduled evaporator coil defrosting

Solenoid Valve Automatic Plunger Shuts off refrigerant flow

1

Freezers

Page 5

OPERATION

5

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

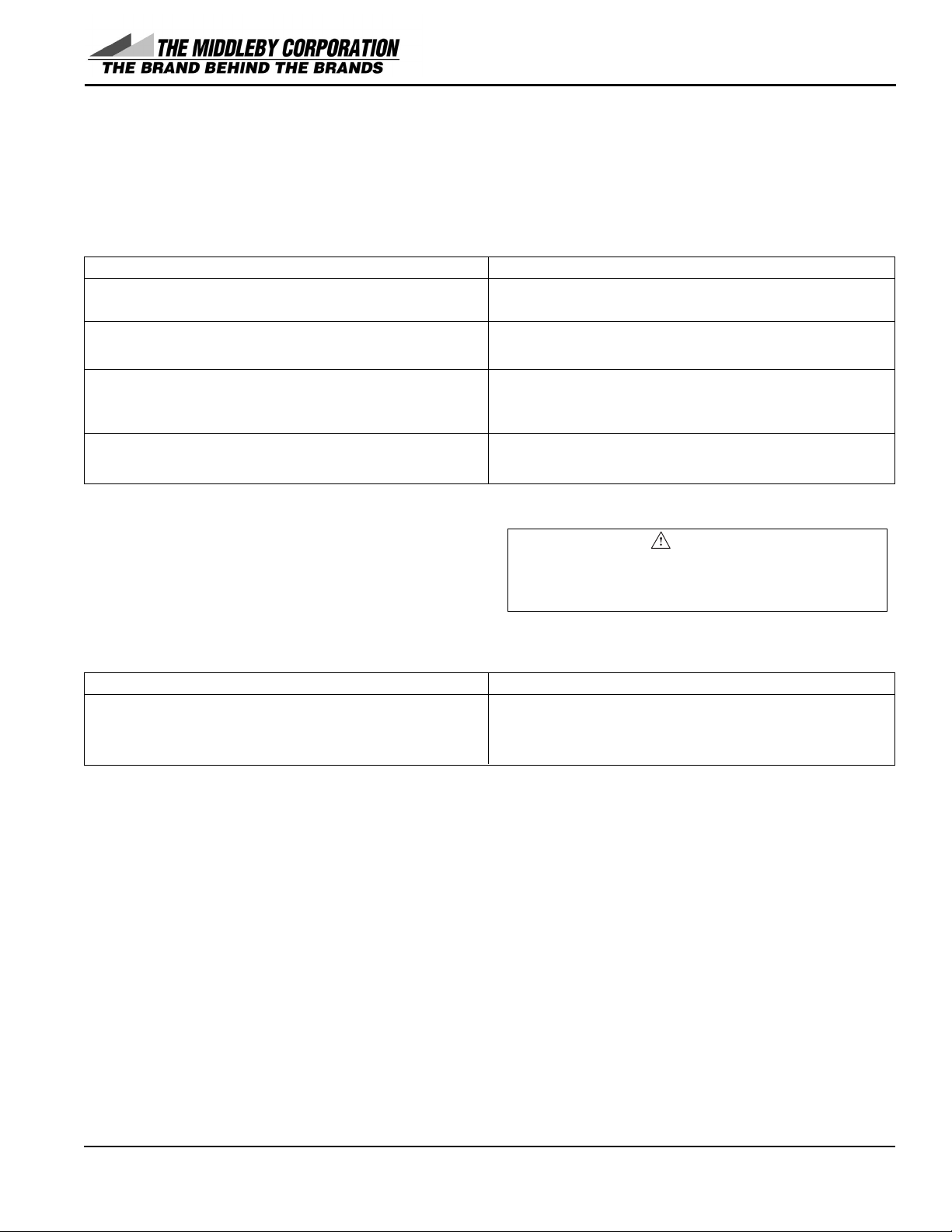

START-UP PROCEDURE

The refrigeration system is completely factory assembled,

pre-charged and ready for operation. To energize the system

it is only necessary to find the power supply cord and

connect it to a proper electrical source. Once the supply cord

SHUT-DOWN PROCEDURE

To shut down, disconnect the electrical supply cord and open

or remove the drawer(s) allowing the interior cabinet

temperature to equalize with the room temperature. A mild

detergent diluted in warm water should be used to wash

down the interior and exterior surfaces of the cabinet.

Table 2.2 - Start-up Procedure (Refrigerated Storage)

Operation Results

1. Activate system by inserting electrical service cord into

electrical supply source and flip power control switch.

2. Locate liquid refrigerant indication glass mounted on

the receiver.

3. Wait 15 minutes.

4. Wait 3 hours.

Compressor should immediately come on line along with the

condenser fan and the evaporator fan.

Once the system has been operating for two minutes, the

glass should appear clear and full of liquid refrigerant.

The temperature in the storage area should begin to

approach the “green zone” on the thermometer indicating

adequate operation.

Once the operating temperature has been reached, stocking

of the containment area can begin.

has been connected to a power source, the unit can be

started by flipping the power control switch to the “ON”

position.

WARNING

Prior to any cleaning of the system involving placing

hands in areas with moving parts, the system should

be deactivated by disconnecting the power supply cord.

Table 2.3 - Shut Down Procedures

Operation Results

1. De-energize the system by flipping the power control

switch to the “OFF” position and disconnecting the

electrical supply cord.

Once the system is de-energized, the condenser fan and the

evaporator fan will cease operation.

Page 6

6

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

OPERATION

PREPARATION FOR AN EXTENDED PERIOD

OF INACTIVITY

This unit is designed for continued use at automatically

cycled intervals. However, in the event of an extended shut

down, both the mechanical refrigeration system and the food

storage compartment system must be serviced.

Table 2.4 - Shut Down Procedures for an Extended Period

Operation Results

1. Fully close discharge valve at the receiver.

2. Fully close suction valve at the compressor.

3. Disconnect power supply.

4. Clean and wipe dry the food storage compartment.

Compressor will pump liquid refrigerant from system

to receiver.

This will isolate the refrigerant between the two valves.

De-energizes the system.

This will reduce the odor buildup during shut down.

Page 7

FUNCTIONAL DESCRIPTION

7

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

SYSTEM DESCRIPTION

This unit is a self contained, automatically controlled,

continuous duty, perishable food storage system. It is

designed with the intent and purpose of storing food items.

The operating temperature is automatically monitored by

controls that are factory set to maintain a predetermined

adequate condition.

The equipment is installed in two basic compartment

assemblies. They are:

• Condensing Unit Compartment - This area contains the

condensing unit along with the necessary controls.

• Storage Compartment - This insulated food storage area

is clear storage area.

SYSTEM OPERATION

The design of the refrigerated cabinet focuses primarily on

the safe storage of food products requiring refrigeration. In

engineering, considerable attention was placed on its

functionality and its serviceability.

The refrigeration system is a closed loop system. Barring a

leak in the system, the addition of refrigerant is not required.

However, a periodic check of its level is recommended to

insure that the system operates at the optimum level at which

it was designed.

The condensing unit is found within the regular equipment

compartment. Also in this compartment is the electrical

control panel that contains the power switch and a terminal

box. On all models that feature forced air evaporators, a

heated condensation evaporator pan or a heated condensing

unit base is provided. The evaporator pan is also located in

the equipment compartment.

Special care in the initial loading of the storage compartment

should be taken. It is suggested that the loading be

scheduled in three equal portions allowing three hours

between each loading.

The chilled food compartment is designed for the storage of

perishable food items that require a temperature range of 37

to 40 degrees Fahrenheit. It is a general rule that adequate

spacing is allowed between stored items to allow for proper

air circulation.

SCHEDULED MAINTENANCE

INTRODUCTION

To ensure the longest and most trouble free operation of the

unit, a thorough maintenance schedule is required to be

adhered to periodically. The maintenance system should

be designed to maximize the efficient use of maintenance

personnel, reduce down time, and provide the orderly

acquisition of spare parts support.

The Middleby refrigeration cabinet will generally be in

operation in a facility where scheduled maintenance is

performed according to Maintenance Index Plans. Your unit

is no exception to required maintenance. This section of the

manual is intended as an alternative to any standard

maintenance program that may pre-exist. The preventive

maintenance schedule is based upon similar maintenance

requirements for commercial refrigeration equipment.

PREVENTIVE MAINTENANCE ACTION INDEX

If you do not have a Maintenance Index Plan, one is included

for you in Table 4.1.

PREPARATION FOR MAINTENANCE

Since many areas affected by the maintenance schedule are

electrically supplied, it is recommended that the system be

de-energized prior to making the inspections.

MAINTENANCE

Weekly Inspection

1. The unit should first be de-energized by switching the

toggle switch to the “OFF” position. The switch is

found on the control panel in the condensing unit

compartment.

NOTE: It is necessary to first remove the front air grill. This

is done by lifting it straight up then pulling the bottom out and

down.

2. Using a vacuum or small hand broom, brush the

condenser in a vertical motion to remove any dust or

debris that may have accumulated.

Page 8

8

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

SCHEDULED MAINTENANCE

Monthly Inspection

1. Check the evaporator drain line at both the inlet and

outlet ends to make certain that there are no

obstructions. It is not recommended to use any

chemicals in clearing a clogged drain. The preferred

method of unstopping an obstructed drain is to use

compressed air. Approximately 60 lbs. should be

sufficient. Simply remove the drain line at the

evaporator coil and attach an air-line to it.

2. With the unit in a cooling cycle, use a flashlight and

locate the refrigerant sight glass. If the compressor

has been running for three minutes there should be no

visible bubbles.

3. If bubbles are present:

a. Determine if there is a leak by using a halide or

electronic leak detector.

b. Repair leak(s).

6. To inspect the evaporator motor, first turn the unit off.

Then, remove the drain line from the evaporator pan.

Loosen the four screws that hold the shroud. Lower

the shroud and disconnect the polarized electrical

connection. With the shroud out of the cabinet,

proceed to inspect the motor mounting bolts and the

fan for cracks or excessive play.

7. Using a mild detergent and water, wipe the vinyl

gasket. Make certain to also clean under the gasket to

remove any mildew or residue.

8. Using a mild, non-abrasive detergent and warm water,

wipe the cabinet exterior. When cleaning always follow

the grain of the stainless steel to prevent scratching or

marring of the finish surface.

Annual Maintenance

1. Slide condensing unit out of the compartment and

check all refrigerant lines for leaks or fatigue. Make

certain that no exposed copper tubing is in contact with

any other metal surface. If there is contact, install an

insulating material between the tow metal components.

2. With the condensing unit out and the breaker at the

main panel “OFF”, inspect the system’s wiring. Look

for a tight fit of all connections and make certain the

that the wire restraining devices are tight. Inspect all

wires and cords, paying particular attention to nicks or

age cracks in the insulation.

3. Visually inspect the outer panel and components of the

cabinet. Check screws and bolts to make certain that

they are tight. Also, make sure that the bolts that

secure the base frame to the deck are tight.

Three Year Frequency

1. Replace the drawer gaskets. To accomplish this, it is

first necessary to remove all products from the

refrigerated compartment to avoid spoilage. Open the

drawers and remove the old gasket. The gaskets snap

in and out of a channel on the back side of the door.

Clean the track thoroughly. Replace the old gasket

with the new one by snapping it into place.

2. Inspect all motors and shafts for both noise and wear.

If they show age, replace them.

3. With the main power off, remove the condensing unit

from its compartment and inspect all wiring. Also,

remove the cover from the controls and check them to

make certain that they are operational and do not show

signs of wear.

4. Inspect the operation of the drawer slide assembly.

Make certain that the moving parts do not show any

signs of wear. Make sure that all screws are tight.

WARNING

The system should be de-energized when checking

for leaks.

i. If a leak is found on a flared fitting, it can often be

repaired by simply tightening the brass flare nut 1/4

of a turn. If tightening does not repair the leak, it

may be necessary to reflare the tubing.

ii. If a leak is found on a brazed joint, it will be

necessary to pump down the system’s refrigerant

charge to remedy the problem.

iii. To pump the refrigerant into the receiver, you must

first connect service gauges to the system at the

suction valve on the compressor and the liquid valve

on the receiver. Purge the gauges before opening

the system’s valves to avoid contamination. Run the

receiver (liquid or high pressure) valve all the way in

to stop the refrigerant from exiting the receiver.

Start the unit and allow it to run until the suction or

low-pressure gauge reads 5 lbs. When it reaches

5 lbs., de-energize the system.

iv. Once pumped down, the necessary repairs can be

made.

4 Using a mild non-abrasive detergent and soft cloth,

wipe the interior lining beginning with the top and

working down. Also, wipe the gasket and where it sits

on the cabinet exterior.

5. Remove the front air grill and unbolt and condensing

unit. Once unbolted, slide it out. The unit is capable of

being completely removed due to the extra tubing

coiled up behind the unit. With the unit de-energized,

check the condenser fan motor and make certain that it

is no loose. Inspect the fan for cracks and make sure

that it is tight on the motor.

Page 9

SCHEDULED MAINTENANCE

9

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

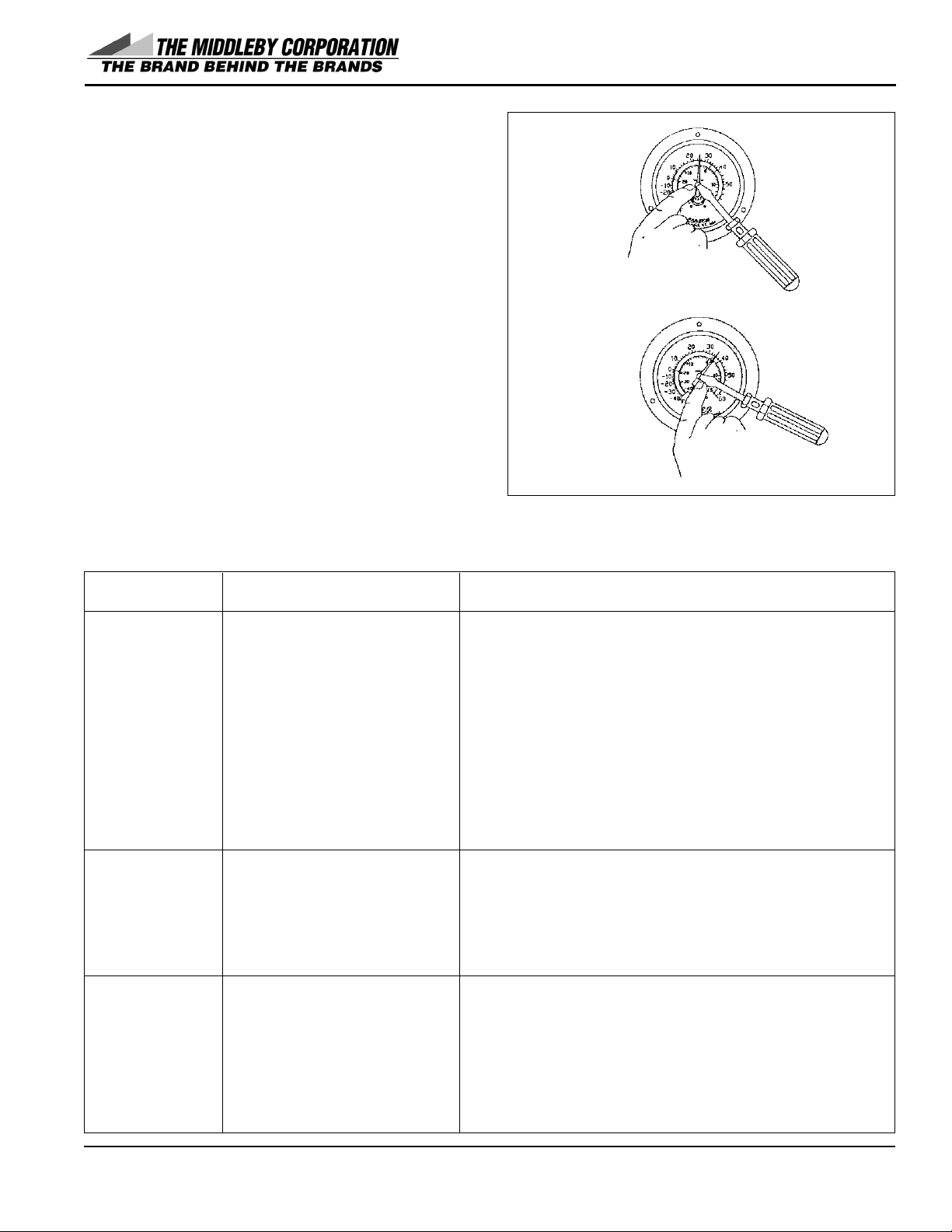

5. To recalibrate the thermometer, remove it from the

cabinet. Using a small, flat screwdriver, remove the

lens. Prepare an ice water bath and immerse the

thermometer bulb at least two inches into the ice bath.

WIthin 30 seconds the indicator dial should read 32

degrees Fahrenheit. If it does not, it needs to be

recalibrated. Do this by placing your index finger on

the opposite side of the needle that needs to move.

Then, using a flat screwdriver, turn the screw at the

center of the dial 1/4 of a turn in the direction you want

to move the dial. Repeat the procedure until the

needle is on 32 degrees. See Figure 4.1.

Figure 4.1 - Thermometer Calibration

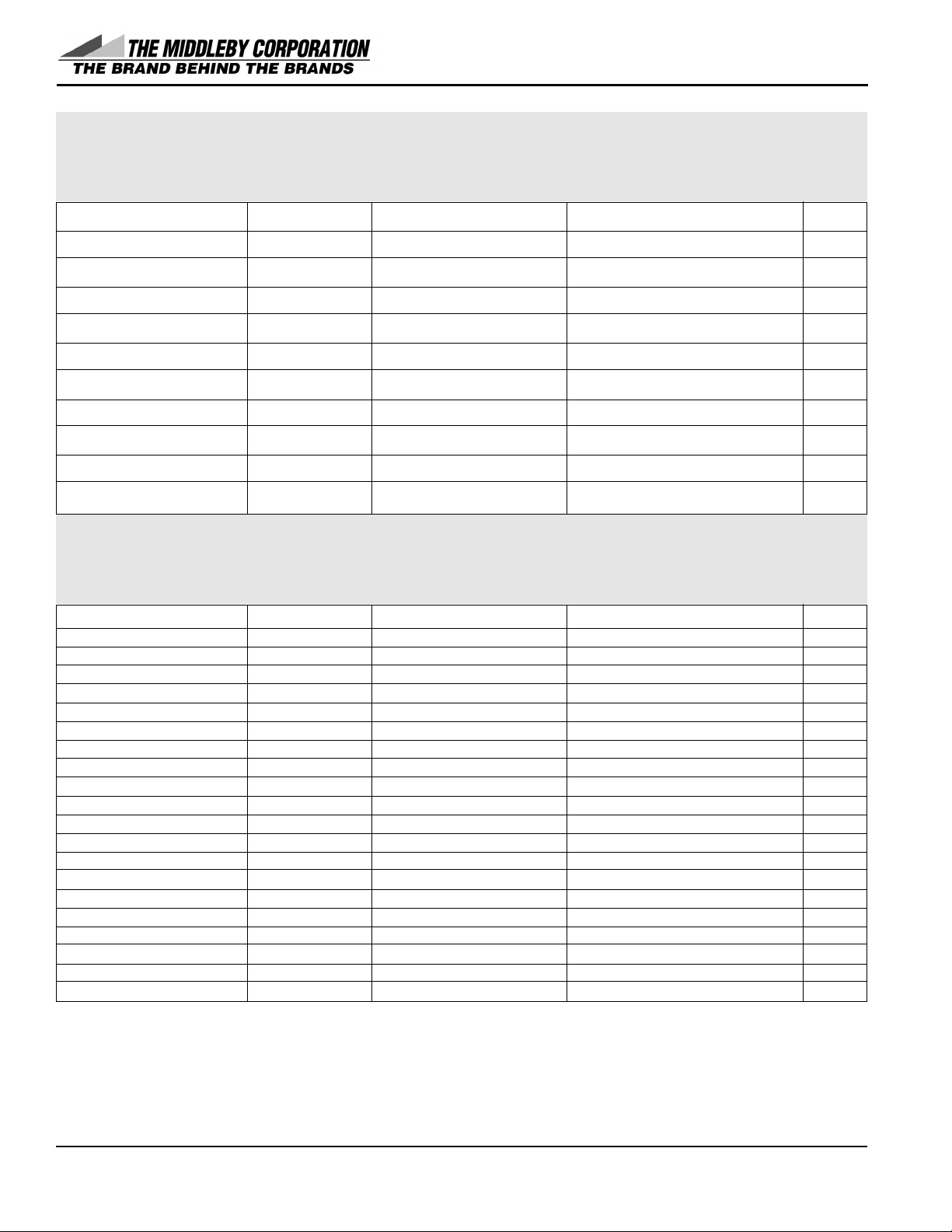

Table 4.1 - Preventative Maintenance Action Index

1.

2.

3.

4.

Weekly

Monthly

Annually

Three-year Frequency

a. Inspect condenser coil to make certain that air flow is not

hampered and that it is clear of dust and debris.

a. Inspect and clear drain line.

b. Check the liquid refrigerant sight glass to make certain that

the system is completely charged.

c. Clean the interior of the cabinet with a mild soap and warm

water solution. Be certain to dry thoroughly.

d. Check both the condenser fan motor and the evaporator

fan motor to make certain that they are operational and that

the fans are tight and secure.

e. Clean door gaskets and breaker strips with a damp cloth.

f. Clean exterior of cabinet with mild soap and warm water.

Dry thoroughly.

a. Slide condensing unit from the refrigeration compartment

and check all joints and fittings for any signs of leaks or

fatigue.

b. Inspect electrical connections to confirm that there is good

contact and that wires are neither weakened nor frayed.

c. Check the integrity of the cabinet.

a. Replace door gaskets.

b. Inspect motor shafts for noise or wear.

c. Inspect electrical controls and wiring.

d. Inspect drawer slides.

e. Recalibrate thermometer.

Lower Temperature

Higher Temperature

Page 10

10

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

TROUBLESHOOTING

INTRODUCTION

This chapter provides a systematic check of components in

determining a possible cause of failure in the event of various

symptoms.

It is necessary that the individual performing the

troubleshooting tasks be familiar with the function of the

equipment as described in the Functional Description section.

The following tables list the most common symptoms that

may be experienced and the recommended corrective action.

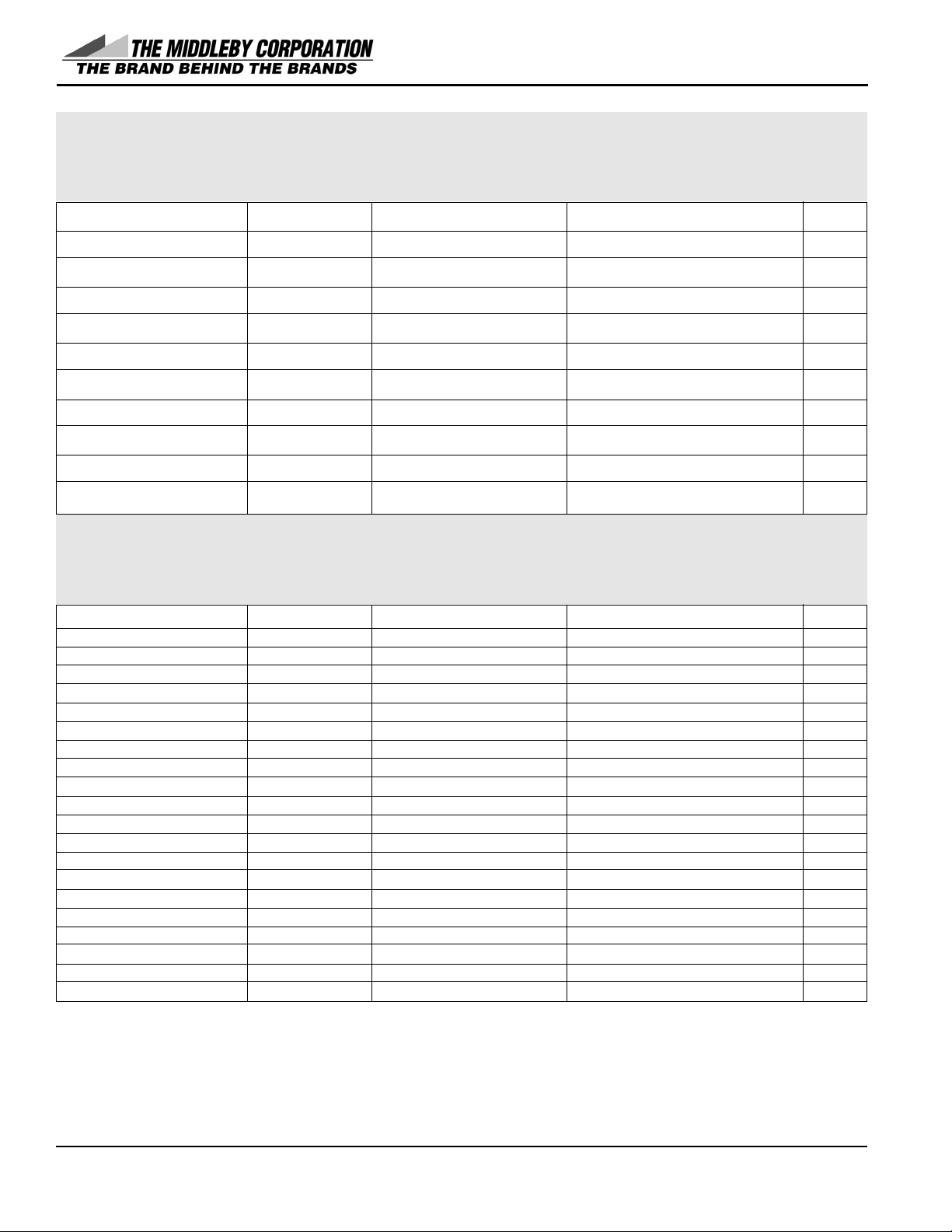

Table 5.1 - Mechanical and Electrical Troubleshooting Guide

SYMPTOM POSSIBLE FAILURE REMEDY

Unit does not operate

Unit runs continuously

Low head pressure

High head pressure

Short cycling

Unit does not cool

1. Control failure

2. Incorrect voltage

3. Failed compressor

1. Low on refrigerant

2. Control failure

3. Bad connection at TXV

4. Restricted air flow or dirty

5. Bad condenser fan motor

6. TXV stuck open

7. Compressor failure

8. Ineffective door seal

9. Restricted circulation in

storage compartment

1. Defective compressor

2. Low refrigerant

3. Ambient temperature too low

1. Blocked or dirty condenser

2. Ambient temperature too high

3. System contains air

4. Refrigerant overcharge

1. Maladjusted control

1. Blown fuse/circuit breaker

2. Bad connection at supply cord

3. Ill fitting gasket

1. Adjust or replace control

2. Correct

3. Replace

1. Leak check system and recharge

2. Adjust or replace control

3. Check and secure sensor bulb to suction line

4. Rectify air flow problem and clean condenser

5. Check and replace if necessary

6. Replace

7. Replace

8. Adjust door strike and hinges

9. Redistribute food for even air flow

1. Replace

2. Leak check system and recharge

3. Raise room temperature

1. Clean and remove any obstructions

2. Lower room temperatures

3. Evacuate, change filter dryer, recharge

4. Reduce amount of refrigeration in system

1. Adjust control

1. Replace fuse/reset circuit breaker

2. Check supply cord at outlet

3. Tighten strike on door latch

Page 11

CORRECTIVE MAINTENANCE

11

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

INTRODUCTION

This chapter focuses on the instruction needed in the

removal and replacement of certain components. It also

addresses the repair of components not listed under the

scheduled maintenance index covered in the Scheduled

Maintenance section.

The level of skills required to perform the service or repair will

vary. Some may require specific training while others may be

performed by any type of mechanic. It is up to the individual

and his/her supervisor to determine the breadth of knowledge

required to perform the necessary service or to make the

necessary repairs.

It is also important to know that any procedure requiring the

handling of refrigerant requires proper certification.

The service or repair items are limited to those parts listed in

Table 7-3.

REPAIR PROCEDURES

7. Using wrenches, remove the suction and discharge

valve stem cover caps on each side of the compressor.

Also, remove the cap nut on the suction and discharge

side as well.

8. Disconnect the high-side line at the compressor. This

is done by heating the brazed connection using an

acetylene and oxygen torch set.

NOTE: Do not apply a flame to a line containing refrigerant.

9. To remove the low-pressure control capillary tube and

service fitting, loosen the 1/4" brass flare nut on the

suction valve.

10. The final step in removing the compressor is to

disconnect it from its mounting. To free the

compressor, remove the wire clips on each of the four

feet.

11. To install the compressor, place it in position on the

base and reinstall the four wire clips.

12. Reattach the suction and discharge valve blocks to the

appropriate sides of the compressor.

13. Reattach the low-pressure control capillary tube and

service fittings to the suction side of the compressor.

14. Reattach the suction line to the compressor.

15. In reconnecting the high-pressure line, it is necessary

to first prepare the line’s end. Using a fine sandpaper

or emery cloth, clean the residue off of the end. Also,

clean the connection on the compressor. Apply flux to

both ends and braze the connections into place.

16. Remove the valve stem cap from the suction valve

block on the side of the compressor. Run the valve

stem all of the way out and then in one turn clockwise.

17. Place the refrigeration service manifold gauge hoses

on the suction and high-side valves. Attach a bottle of

refrigerant to the charging hose and charge the system

with 150 psi of vapor. Using an electronic leak

detector, check the new connections for leaks. Should

a leak appear, evacuate the charge and repair the leak.

Repeat the leak check process again.

18. If the system checks out with no leaks, recover the test

charge using a vacuum recovery pump.

19. With the system pressure at zero, connect the vacuum

pump and evacuate the system. The pump should run

for one hour. The vacuum pump should pull the

system down to 30 inches of vacuum.

20. Reattach the electrical terminal box and secure all

wiring.

WARNING

Prior to performing any work on the refrigeration system,

it is required that the unit be de-energized.

Replacement of Compressor Motor

1. Evacuate the refrigerant from the system using a

refrigeration vacuum pump.

NOTE: Federal laws require the proper handling and

disposal of refrigerant. It is unlawful to release any

refrigerant into the atmosphere.

2. Disconnect the electrical power to the unit. This is

done by turning off the circuit in the main supply panel.

It should be noted on the panel that the refrigerator is

being serviced and that the breaker must remain off.

3. To reach the condensing unit, the front ventilation grill

on the front of the cabinet must be removed. This is

done by pulling the grill up vertically about one inch,

out over the retainer angles and then down.

4. With the grill removed, use a 3/8" wrench or socket

and ratchet to unscrew the mounting bolt that secures

the condensing unit to the cabinet base.

5. Once the mounting bolt is removed, carefully slide the

whole condensing unit forward - lifting it over the anglemounting clip at the front of the base. Due to extra

copper coil refrigeration lines, the unit can be

completely removed from the compartment and placed

on the deck.

6. Find the electrical terminal box on the side of the

compressor and remove the front cover. Disconnect

the wires from the compressor. Remove the screws

that attach the terminal box to the compressor. At this

point, the compressor will be electrically detached.

Page 12

12

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

CORRECTIVE MAINTENANCE

21. Check the refrigeration tag on the unit for the number

of ounces of refrigerant to place into the system for

start-up. Monitor the pressure on both the suction and

discharge sides of the manifold gauges. As the

temperature in the storage area begins to fall, check

the refrigerant flow through the sight glass. The unit is

fully charged when there are no bubbles in the sight

glass. If after five minutes of operation, bubbles are

still present, it may be necessary to add more

refrigerant (add refrigerant in small amount to keep

from overcharging).

WARNING

Overcharging a refrigeration system can be dangerous.

If the system overcharge is sufficient enough to immerse the

major parts of a hermetic compressor in liquid refrigerant, a

situation has been created that when followed by unusual but

possible circumstances, can lead to compressor housing

seam separation or rupture.

The sequence of circumstances that can lead to compressor

housing seam separation or rupture occurs in the following

manner:

1. The system overcharge immerses the compressor

motor, piston, connecting rods, cylinders, etc. in liquid

refrigerant, thereby effectively forming a hydraulic block

preventing the compressor from starting. This

condition is known as locked rotor.

2. Electrical current continues to flow through the

compressor motor windings that become, in effect,

electric resistance heaters. The heat produced begins

to vaporize the excessive liquid overcharge, causing a

rapid increase in system pressure.

3. If the system compressor protective devices fail for any

reason prior to or during this locked rotor heating cycle

or cycles, liquid refrigerant may be vaporized

sufficiently fast enough to raise the pressure within the

system to extremes far greater that the housing or weld

seam is designed to handle.

4. In some instances where the amount of refrigerant

overcharge is critical in proportion to the system

internal volume, the pressure reached can cause a

compressor housing seam separation or rupture that

can be hazardous.

The remedy to eliminate this exceedingly rare, but potential

hazard is to use correct refrigerant charge amounts and

techniques.

Middleby urges that all individuals responsible for training,

teaching, or advising installation mechanics and service

personnel emphasize proper charging techniques. In

addition, Middleby advises strict adherence to refrigerant

charge amounts specifically recommended by the

manufacturer of the refrigeration, air conditioning, or heat

pump system.

Replacement of Low Pressure Control

1. Disconnect the unit from electrical service.

2. Remove control cover and disconnect electrical

terminals.

3. Disconnect capillary tube.

4. Remove mounting fasteners on control base and install

new control by reversing the procedure.

5. To adjust the control, hook up the service gauges to

the suction and discharge valves and crack them to

allow the gauges to read.

6. Using a standard screwdriver, coarse adjust the control

by turning the adjustment screws on top of the control.

Preset the cut-in and cutout and 68 lbs. and 38 lbs.

respectively for a refrigerator and 25 lbs. and 10 lbs.

respectively for a freezer.

7. Start the system. Allow it to run for five minutes.

Monitor the low side pressure. Fine adjustments will

be required to achieve the prescribed cycling

pressures.

NOTE: Running the suction valve in or out as required to

effectively change the pressures can speed up the control

adjustment process.

Replacement of Thermal Expansion Valve (TXV)

1. Close liquid valve and run compressor until it pumps

refrigerant into the receiver (low side service gauge will

read 1 lbs.). Close the suction line valve.

2. Disconnect the sensor bulb on the suction line.

3. Disconnect the liquid line (1/4") and suction line (3/8")

then remove the TXV.

4. Install new TXV, reconnect lines, and re-fasten the

sensor bulb.

NOTE: It is not recommended to adjust the valve super heat

as this comes pre-set from the factory.

Replacement of Filter Dryer

1. Close liquid line valve and run compressor until the low

side refrigeration gauge indicates zero lbs., then close

suction.

2. Remove filter dryer from system and replace with new

dryer.

3. Purge system and add refrigerant if needed.

Replacement of Condenser Fan Motor

1. Disconnect all electrical power to the unit.

2. Remove the condensing unit from the condensing unit

compartment.

Page 13

CORRECTIVE MAINTENANCE

13

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

3. Remove the protective wire shroud from around the

motor.

4. Disconnect the fan motor leads from the terminal box

on the compressor.

5. Remove the mounting screws at the motor base.

6. Using an allen wrench, remove the aluminum fan.

7. To install the new motor, reverse the process.

Replacement of the Condensing Fan

1. Disconnect all electrical power to the unit.

2. Remove the condensing unit from the condensing unit

compartment.

3. Remove the protective wire shroud from around the

motor.

4. Using an allen wrench, loosen the set screw on the

blade hub and slide the blade from the shaft.

5. Reverse the procedure to reassemble.

Replacement of the Anti-Condensate Heater

NOTE: The anti-condensate heater is located behind the

front edge of the vinyl breakers in the door opening.

1. Disconnect all electrical power to the cabinet.

2. Remove vinyl breakers by exerting pressure at the

front edge toward the center of the door.

3. Disconnect anti-condensate heater wiring connection.

4. Remove heater from recessed rail.

5. Replace new heater in rail and reconnect electrical.

Replacement of Drawer Gasket

1. Remove the gasket by pulling it out of the snap-in

track.

2. Clean the gasket track and the immediate area.

3. Snap new gasket into retainer.

Replacement of Power Switch

1. Shut off all electrical power going to the unit.

2. Remove the front air grill.

3. Using a flat blade screwdriver, remove the cover plate

with the switch attached.

4. Remove the wires connected to the switch.

5. Unscrew the lock washer and remove the switch.

6. Reverse the process when installing the new switch.

Replacement of the Drain Line

NOTE: To replace the vinyl drain line, it is necessary that

there be access to the rear of the cabinet.

1. On the cabinet exterior, remove the rear tubing cover

using a 1/4" nut driver.

2. On the interior of the cabinet, remove the drain line

cover.

3. From the inside of the cabinet, pull the drain from the

evaporator shroud fitting.

4. From the drain exit location, pull the drain through the

penetration of the cabinet.

5. At the bottom of the condensing unit compartment, cut

the drain line retaining strap. The drain line should

now be free.

6. To install the new drain line, reverse the process.

CHARGING THE REFRIGERATION SYSTEM

1. Connect service gauges to the suction and discharge

service valves then open valves one full turn.

2. If the system is pressurized slightly, open both manifold

gauge valves and purge the service line gauges.

3. With manifold gauge valves closed, start refrigeration

system.

4. Attach a drum of refrigerant to the suction service side

of the manifold gauges and add refrigerant until the

liquid sight glass is clear of bubbles.

RECALIBRATING THE THERMOMETER

1. To recalibrate the thermometer, remove it from the

cabinet. Using a small, flat screwdriver, remove the

lens. Prepare an ice water bath and immerse the

thermometer bulb at least two inches into the ice bath.

Within 30 seconds the indicator dial should read 32

degrees Fahrenheit. If it does not, it needs to be

recalibrated. Do this by placing your index finger on

the opposite side of the needle that needs to move.

Then, using a flat screwdriver, turn the screw at the

center of the dial 1/4 of a turn in the direction you want

to move the dial. Repeat the procedure until the

needle is on 32 degrees. See Figure 4.1.

Page 14

14

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

PARTS LIST

INTRODUCTION

This section of the manual contains lists of replaceable parts.

Each of the tables contains a list of removable parts

associated with an assembly of the cabinet or refrigeration

system. No parts identification has been provided for details

of permanently assembled items or those that are not

suitable for field repair.

Table 7.1 is a parts list of special tools required for routine

service.

Table 7.1 - Parts List - Special Tools List

Part Number Description Quantity

R1412 Refrigerant service gauges with hoses 1

VA70264 Service valve wrench 1

50992 Refrigerant 30 lbs.

Page 15

PARTS LIST

15

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

Drawer Cartridge 18" DSB18C Middleby 1

Gasket GSB60MV 6449 Jeans 2

Recessed Pulls HXHL08 P73-2000 Component Hardware 2

Drawer Rollers HXDW02 7319000201 Kason 8

Heater Wire L1HR64 64" Refrigeration Hdwe. 1

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 4

Parts List - Cabinet

20036SB

Item Middleby# Mfg# Vendor Qty

Table 7.2 - Parts List

Evaporator Coil Assy. RWE430 BBM11A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT220 AEA9422ZXAEC Tecumseh 1

Compressor RUT221 AEA590AT-946-A2 Tecumseh 1

Condenser RWCD17 50837 Tecumseh 1

Condenser Fan Blade RWFB20 51561 Tecumseh 1

Condenser Fan Motor RWCM05 810M006B45 Tecumseh 1

Receiver RWRT04 51080 Tecumseh 1

Start Capacitor RWCP42 858S165A47 Tecumseh 1

Run Capacitor - - - Relay RWRLY09 820RR12B79 Tecumseh 1

Overload RWOVL05 8300MRTE59 Tecumseh 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20036SB

Item Middleby# Mfg# Vendor Qty

Page 16

16

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

PARTS LIST

Drawer Cartridge 26" DSB26C Middleby 1

Gasket GSB62MV 6449 Jeans 2

Recessed Pulls HXHL08 P73-2000 Component Hardware 2

Drawer Rollers HXDW02 7319000201 Kason 8

Heater Wire L1HR82 82" Refrigeration Hdwe. 1

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 4

Parts List - Cabinet

20048SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE430 BBM11A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT220 AEA9422ZXAEC Tecumseh 1

Compressor RUT221 AEA590AT-946-A2 Tecumseh 1

Condenser RWCD17 50837 Tecumseh 1

Condenser Fan Blade RWFB20 51561 Tecumseh 1

Condenser Fan Motor RWCM05 810M006B45 Tecumseh 1

Receiver RWRT04 51080 Tecumseh 1

Start Capacitor RWCP42 858S165A47 Tecumseh 1

Run Capacitor - - - Relay RWRLY09 820RR12B79 Tecumseh 1

Overload RWOVL05 8300MRTE59 Tecumseh 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Parts List - Refrigeration

20048SB

Item Middleby# Mfg# Vendor Qty

Page 17

PARTS LIST

17

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

Drawer Cartridge 31" DSB31C Middleby 1

Gasket GSB64MV 6449 Jeans 2

Recessed Pulls HXHL08 P73-2000 Component Hardware 2

Drawer Rollers HXDW02 7319000201 Kason 8

Heater Wire L1HR90 90" Refrigeration Hdwe. 1

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 4

Parts List - Cabinet

20060SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE430 BBM11A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT220 AEA9422ZXAEC Tecumseh 1

Compressor RUT221 AEA590AT-946-A2 Tecumseh 1

Condenser RWCD17 50837 Tecumseh 1

Condenser Fan Blade RWFB20 51561 Tecumseh 1

Condenser Fan Motor RWCM05 810M006B45 Tecumseh 1

Receiver RWRT04 51080 Tecumseh 1

Start Capacitor RWCP42 858S165A47 Tecumseh 1

Run Capacitor - - - Relay RWRLY09 820RR12B79 Tecumseh 1

Overload RWOVL05 8300MRTE59 Tecumseh 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20060SB

Item Middleby# Mfg# Vendor Qty

Page 18

18

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

PARTS LIST

Drawer Cartridge 26" DSB26C Middleby 2

Gasket GSB62MV 6449 Jeans 4

Recessed Pulls HXHL08 P73-2000 Component Hardware 4

Drawer Rollers HXDW02 7319000201 Kason 16

Heater Wire L1HR82 82" Refrigeration Hdwe. 2

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 4

Parts List - Cabinet

20072SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE450 BBM16A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT390 AKA9429ZXAEC Tecumseh 1

Compressor RUT391 AK174AT-0388-A9-8-952 Tecumseh 1

Condenser RWCD14 50840-1 Tecumseh 1

Condenser Fan Blade RWFB05 51551 Tecumseh 1

Condenser Fan Motor RWCM06 810M009B48 Tecumseh 1

Receiver RWRT03 81080-1 Tecumseh 1

Start Capacitor RWCP47 85PS165A53 Tecumseh 1

Run Capacitor - - - Relay RWRLY07 82498-1 Tecumseh 1

Overload RWOVL38 8300CRAN21 Tecumseh 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20072SB

Item Middleby# Mfg# Vendor Qty

Page 19

PARTS LIST

19

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

Drawer Cartridge 31" DSB31C Middleby 2

Gasket GSB64MV 6449 Jeans 4

Recessed Pulls HXHL08 P73-2000 Component Hardware 4

Drawer Rollers HXDW02 7319000201 Kason 16

Heater Wire L1HR90 90" Refrigeration Hdwe. 2

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 6

Parts List - Cabinet

20084SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE450 BBM16A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT390 AKA9429ZXAEC Tecumseh 1

Compressor RUT391 AK174AT-0388-A9-8-952 Tecumseh 1

Condenser RWCD14 50840-1 Tecumseh 1

Condenser Fan Blade RWFB05 51551 Tecumseh 1

Condenser Fan Motor RWCM06 810M009B48 Tecumseh 1

Receiver RWRT03 81080-1 Tecumseh 1

Start Capacitor RWCP47 85PS165A53 Tecumseh 1

Run Capacitor - - - Relay RWRLY07 82498-1 Tecumseh 1

Overload RWOVL38 8300CRAN21 Tecumseh 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20084SB

Item Middleby# Mfg# Vendor Qty

Page 20

20

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

PARTS LIST

Drawer Cartridge 18" DSB18C Middleby 2

Drawer Cartridge 26" DSB26C Middleby 2

Gasket GSB64MV 6449 Jeans 4

Gasket GSB62MV 6449 Jeans 4

Recessed Pulls HXHL08 P73-2000 Component Hardware 6

Drawer Rollers HXDW02 7319000201 Kason 24

Heater Wire L1HR90 64" Refrigeration Hdwe. 1

Heater Wire L1HR82 82" Refrigeration Hdwe. 2

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 6

Parts List - Cabinet

20096SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE450 BBM16A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT520 FJCF-A050-IAA-201 Copeland 1

Compressor RUT511 RS43C1E-IAA-100 Copeland 1

Condenser RWCD37 066-0303-00 Copeland 1

Condenser Fan Blade RWFB08 083-0130-00 Copeland 1

Condenser Fan Motor RWCM27 050-0259-12 Copeland 1

Receiver RWRT12 577-0346-02 Copeland 1

Start Capacitor RWCP03 014-0008-57 Copeland 1

Run Capacitor - - - Relay RWRLY02 040-0102-00 Copeland 1

Overload RWOVL02 071-0329-15 Copeland 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20096SB

Item Middleby# Mfg# Vendor Qty

Page 21

PARTS LIST

21

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

Drawer Cartridge 26" DSB26C Middleby 3

Gasket GSB62MV 6449 Jeans 6

Recessed Pulls HXHL08 P73-2000 Component Hardware 6

Drawer Rollers HXDW01 7319000201 Kason 24

Heater Wire L1HR82 82" Refrigeration Hdwe. 3

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 6

Parts List - Cabinet

20108SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE450 BBM16A Heatcraft 1

Evaporator Motor RWEV03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT520 FJCF-A050-IAA-201 Copeland 1

Compressor RUT511 RS43C1E-IAA-100 Copeland 1

Condenser RWCD37 066-0303-00 Copeland 1

Condenser Fan Blade RWFB08 083-0130-00 Copeland 1

Condenser Fan Motor RWCM27 050-0259-12 Copeland 1

Receiver RWRT12 577-0346-02 Copeland 1

Start Capacitor RWCP03 014-0008-57 Copeland 1

Run Capacitor - - - Relay RWRLY02 040-0102-00 Copeland 1

Overload RWOVL02 071-0329-15 Copeland 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20108SB

Item Middleby# Mfg# Vendor Qty

Page 22

22

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

PARTS LIST

Drawer Cartridge 18" DSB18C Middleby 2

Drawer Cartridge 26" DSB26C Middleby 2

Gasket GSB60MV 6449 Jeans 4

Gasket GSB62MV 6449 Jeans 4

Recessed Pulls HXHL08 P73-2000 Component Hardware 8

Drawer Rollers HXDW01 7319000201 Kason 32

Heater Wire L1HR64 64" Refrigeration Hdwe. 2

Heater Wire L1HR82 82" Refrigeration Hdwe. 2

Leg nut CNNP01MS 3/4" large hex nut Best Bolt 6

Parts List - Cabinet

20120SB

Item Middleby# Mfg# Vendor Qty

Evaporator Coil Assy. RWE450 BBM16A Heatcraft 1

Evaporator Motor RWEM03 25300701 Heatcraft 1

Evaporator Fan RWE5101B 5101B Heatcraft 1

Expansion Valve RWEV39 EFS1/4C Sporlan 1

Thermostat RWTT08 A319ABC-24-01 Johnson Controls 1

Condensing Unit RUT520 FJCF-A050-IAA-201 Copeland 1

Compressor RUT511 RS43C1E-IAA-100 Copeland 1

Condenser RWCD37 066-0303-00 Copeland 1

Condenser Fan Blade RWFB08 083-0130-00 Copeland 1

Condenser Fan Motor RWCM24 050-0259-12 Copeland 1

Receiver RWRT12 577-0346-02 Copeland 1

Start Capacitor RWCP03 014-0008-57 Copeland 1

Run Capacitor - - - Relay RWRLY02 040-0102-00 Copeland 1

Overload RWOVL02 071-0329-15 Copeland 1

Filter Dryer RWFD02 C-052-S Sporlan 1

Sight Glass RWSG01 SG-114 Watsco 1

Pressure Control RWPL02 010-1483 Ranco 1

Power Control Switch LWTS01 - Middleby 1

Power Cord MT-004 115V - 1

Wire Harness LH041 - - 1

Parts List - Refrigeration

20120SB

Item Middleby# Mfg# Vendor Qty

Page 23

INSTALLATION

23

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

UNPACKING

Note: Before unpacking the unit, note any crate markings

and check for damage to crating. Notify the carrier if there

should appear to be damage to the unit.

The unit is shipped directly from the manufacturing factory

securely fastened to a single pallet then protected by an

external wrapping.

1. After inspection, carefully remove all external

wrappings and other protective coverings.

2. Review the installation section of the manual

completely prior to installing the unit.

3. Discard crating materials.

INSTALLATION

1. Before moving the unit to the installation sight, doublecheck passageways to ensure that the unit will move

through without modification.

Note: In certain instances, it may be necessary to remove

the drawers. This will allow the unit to fit through tighter

spaces.

2. Position the unit to allow for sufficient ventilation.

Typically, approximately 3" clearance from walls

and other equipment is sufficient.

3. Level the cabinet from front to back and side to side.

This is important so that the cabinet will not be pulled

out of square.

4. Evaporator coil drain lines are factory installed and are

either plumbed into a condensate evaporator pan

or the condensate evaporative base of the condensing

unit to eliminate the need for exterior plumbing. Make

certain that the drain outlet is located such that the

condensate falls into the pan or base. On units with

remotely located refrigeration, the condensate

evaporator pan is optional.

5. Check the door gasket to make certain that it is sealing

properly to the cabinet.

6. Before applying electrical power to the unit, you should

first check the electrical characteristics of the

condensing unit to ensure that they agree with those of

the electrical supply source.

CAUTION

Low or excessive voltage can severely damage the

electrical system.

Note: Adjusting any valves or controls on the system is not

necessary and may void your warranty. All valves and

controls have been set by the factory.

i

When a condensing unit is supplied

Page 24

24

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

ELECTRICAL AND MECHANICAL

INTRODUCTION

This section of the manual contains drawings and schematics

of the electrical and mechanical piping systems.

ELECTRICAL ABBREVIATIONS

AND TERMINOLOGY

• RLA - Rated Load Amperage

Rated load amps is a measure of the current drawn

by a compressor when operated at compressor

manufacturer rating conditions at nominal voltage.

This value is listed at U.L. and C.S.A. as "RLA". It is

in agreement with the N.E.C. definition that the RLA

be the current draw when the compressor is

delivering rated output.

• LRA - Locked Rotor Amperage

The locked rotor amps of a compressor is the

current value recorded three seconds after rated

voltage is applied under locked rotor conditions from

a 75 degree Fahrenheit motor soakout temperature

(The voltage drop is to be predetermined and

adjusted accordingly prior to testing). This value

appears on the compressor serial plate and on all

compressor statistics sheets.

It may be well to note that the practice in the past

was to show an additional column marked, "LRA

U.L. Test Report". This is no longer needed since

the U.L. investigation work, regarding component

rating, will be guided by the compressor

manufacturer's published value.

• MCG - Maximum Continuous Current

Maximum continuous current is a limiting ampere

value that must not be greater than 156% of the

RLA of the compressor as marked on the nameplate

of the particular unit into which that compressor is

applied.

Table 9.1 - Operating Pressures

REFRIGERANT: R-12

Cabinet Ambient Suction Pressure Head Pressure

-5 degrees F (Fre.) 90 degrees F 0-10 lbs. 120-150 lbs.

37 degrees F (Ref.) 90 degrees F 18-35 lbs. 120-150 lbs.

REFRIGERANT: R-22

Cabinet Ambient Suction Pressure Head Pressure

-5 degrees F (Fre.) 90 degrees F 10-15 lbs. 200-250 lbs.

37 degrees F (Ref.) 90 degrees F 37-67 lbs. 200-250 lbs.

REFRIGERANT: 134A

Cabinet Ambient Suction Pressure Head Pressure

-5 degrees F (Fre.) 90 degrees F -5-10 lbs. 120-150 lbs.

37 degrees F (Ref.) 90 degrees F 16-37 lbs. 120-150 lbs.

REFRIGERANT: 404A

Cabinet Ambient Suction Pressure Head Pressure

-5 degrees F (Fre.) 90 degrees F 15-20 lbs. 250-300 lbs.

37 degrees F (Ref.) 90 degrees F 68-84 lbs. 250-300 lbs.

Page 25

ELECTRICAL AND MECHANICAL

25

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

Figure 9.1 - Electrical Schematic

Page 26

26

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

ELECTRICAL AND MECHANICAL

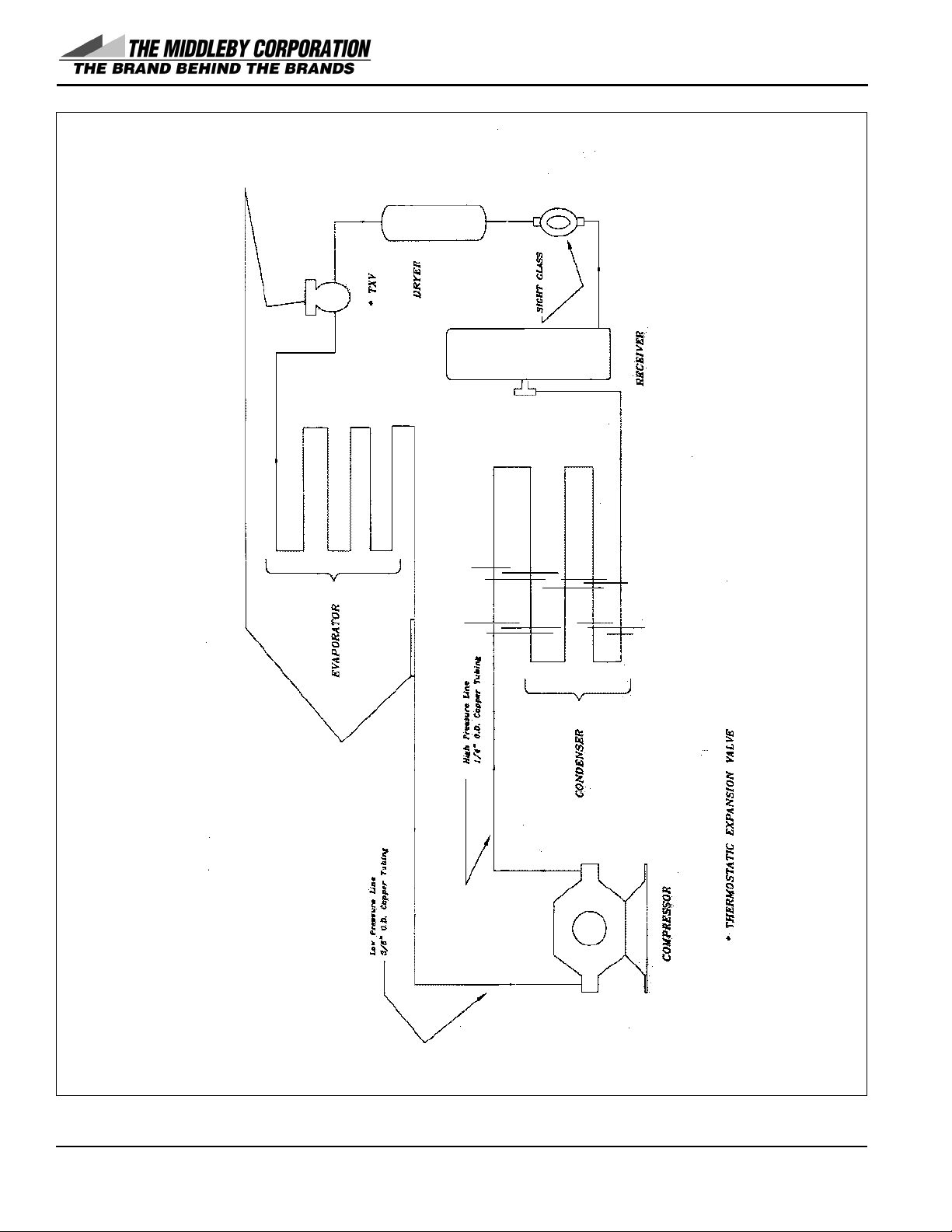

Figure 9.2 - Refrigeration Piping Schematic

Page 27

LIMITED WARRANTY

27

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

INTRODUCTION

Middleby warrants their cabinets and units to consumers only

against defects in material or workmanship under normal use

and service for a period of one year from the date of

shipment. Middleby will repair or replace at their option, any

part, assembly, or portion thereof, which, by their

examination, is deemed to be defective. Middleby will pay

the labor costs for the repair up to twelve (12) months from

the date of shipment.

TERMS

Exclusions

• Middleby’s obligations under this warranty shall not

extend to any malfunction or other problem caused by

unreasonable use, such as, but not limited to, improper

setting of controls, improper installation, improper voltage

supply, loose electrical connections or blown fuses, and

damage not attributable to a defect in workmanship.

This warranty will not apply to any cabinet or component

part that has been subject to any accident, abuse,

misuse, damage caused by fire or floor or any other act

of God, and to any product serviced by an unauthorized

service person or company.

• Middleby will not accept responsibility for the labor costs

related to service and repair of remote condensing units

or other field installations.

• It remains the responsibility of the qualified refrigeration

installation company to provide any accessories required

for a specific climate or application. Middleby does not

imply nor warrant the use of this equipment in adverse

conditions or beyond its intended use.

To Secure Warranty Service

1. To claim a defect under this warranty, direct your claim

to whomever you purchased the product. Be prepared

to provide the model number, serial number, and a

description of the problem.

2. If the above procedure fails to satisfy your claim, you

may write directly to the Middleby, 1100 Old

Honeycutt Road, Fuquay-Varina, NC 27526. Again,

please provide the model number, serial number, and a

description of the problem.

Note: There is no other express warranty on Middleby units

except as stated herein. Any implied warrants of fitness and

merchantability are limited in duration to the duration of this

warranty. The liabilities of Middleby are limited solely and

exclusively to replacement as stated herein and do not

include any liability for any incidental, consequential, or other

damages of any kind whatsoever, whether any claim is based

upon theories of contract negligence or tort. Some states do

not allow limitations on how long an implied warranty lasts, or

the exclusion of limitations of incidental or consequential

damages. So, the above limitations and exclusions may not

apply to you. This warranty gives you specific legal rights

and you may also have other rights that vary from state to

state.

Page 28

28

Printed in USA 12/02

Refrigerated Base-Self-Contained © 2002

NOTES

Loading...

Loading...