Page 1

E-SB

Convection Steamer on Electric Boiler Base

E-SB CONVECTION STEAMER

Project

Item No.

Quantity

q Model 6E-SB (6 pan convection steamer on a 24” electric boiler base)

q Model 10E-SB (10 pan convection steamer on a 24” electric boiler base)

CONSTRUCTION

n Stainless steel construction

n Stainless steel doors with strong continuous hinge and are field revers-

ible for left or right swing

n Insulated doors have a one piece, replaceable seal

n Easy open handle and latch provide positive lock and seal when the door

is pushed or slammed shut

n Hidden magnetic door switch cuts power to blower and steam flow to that

cavity, when the door is opened

n Pan support racks shall be polished stainless steel and removable for

easy cleaning

n Wide drip sink with condensate drain is positioned under cavity doors

n Electrically heated, 24” wide cabinet base shall have stainless steel

frame with all stainless steel top deck, hinged front access panel and

removable side and rear panels

n Front and rear legs shall have adjustable bullet feet

6E-SB shown

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

q Flange mounting feet

q Second water connection for condensate spray

OPERATION

n Steamer cavity controls are mounted on the front panel for easy access

n Separate ON-OFF/60 minute timer control with constant steam setting,

for each steamer cavity.

n Electric boiler has a power-ON switch, RESET light, start switch, low

water sensor, pop safety valve, water level sight glass and outside cabinet mounted pressure gauge.

n Unit will shut off if water level is low or unit builds too much pressure

n When power switch is turned “off”, the boiler automatically drains to

reduce sediment build-up, after the water has cooled to 140°F.

n Cabinet mounted boiler shall be CSD-1 compliant, A.S.M.E. Code con-

structed and National Board registered for operation up to 15 PSI.

n Each steamer cavity shall have a powerful side mounted blower, which

increases steam velocity and provides efficient steam distribution

throughout cavity and between loaded pans.

n Electric heated cabinet mounted pressure boiler to provide atmospheric

steam to each chamber at a temperature of approximately 212°F.

CAPACITY

Pan Size 6E-SB 10E-SB

12” x 20” x 1” 12 20

12” x 20” x 2.5” 6 10

12” x 20” x 4” 4 6

STANDARD FEATURES

n 1/2” NPT power take-off valve for powering adjacent equipment (10 gallon

model only)

n One year parts and labor warranty*

* For all international markets, contact your local distributor.

BLODGETT

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

Page 2

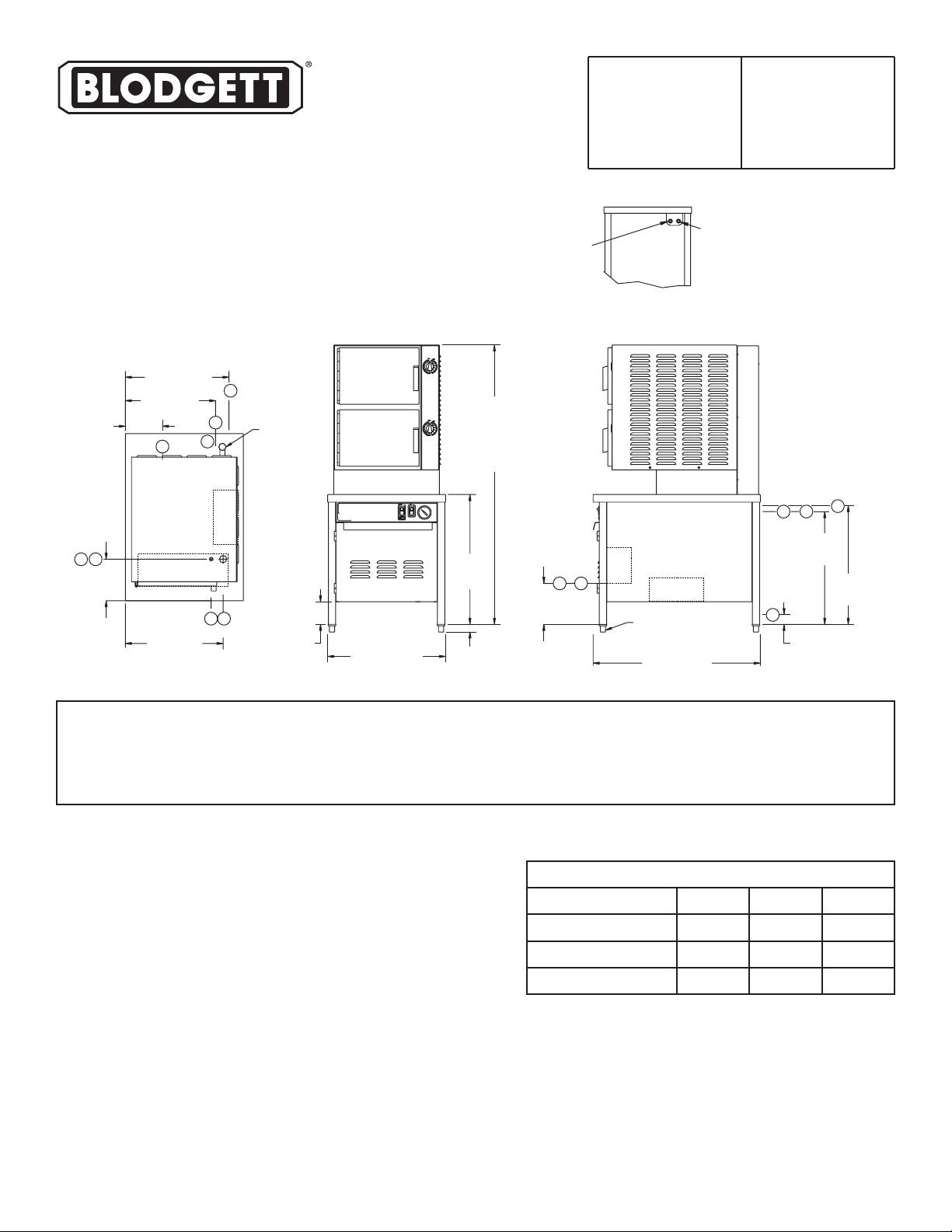

E-SB CONVECTION STEAMER

NOTES:

1. Drain connection: 1-1/4”NPT (includes automatic and manual boiler,

steamers&condensate spray)

2. Cold water supply: ½”NPT (for boiler&condensate spray)

3. Optional separate condensate spray 3/8”NPT (add kit#MS102210)

4. Main electrical connection (all units): 1-31/32”dia hole (ref 1-1/2” conduit

knock out)

5. Aux. electrical connection (208V/240V 48kW only) 1-3/32”dia hole (ref 3/4”

conduit knock out)

6. Steam power take-off½”NPT.(Not available for 24 kW units)

7. Dimensions are in inches (mm).

OFF

ON

5

55

10

50

15

45

20

40

25

35

30

TIMED

OFF

ON

5

55

10

50

15

45

20

40

25

35

30

TIMED

57.19 (1453)

10E-SB

70.19 (1783)

7.56

(192)

21.25 (540)

18.5 (470)

1

2

3

6

Condensate

drain vent

6E-SB

Treated

water supply

connection

DE TA IL VIEW

of water connection

(if second connection ordered)

APPROVAL/STAMP

Un-treated

water supply

connection

(optional)

5

8.5

(216)

4

20 (508)

TO P VIEW

READY ON

RESET

2

26.56

(675)

4

5

8.38

5

4

4.63

(117)

24.13 (613)

1.5 (38) min.

2.63 (67) max.

FRONT VIEW

(213)

Adjustable

bullet feet

34.19 (868)

SIDE VIEW

1

3

2 (51)

6

23.06

(586)

24.31

(618)

SHORT FORM SPECIFICATIONS

Provide Blodgett model 6E-SB (6 pan) or 10E-SB (10 pan) pressureless steamer with electric heated pressure boiler mounted in 24” wide cabinet base. All stainless steel construction,

with two independent steamer chambers each with powerful blower to circulate steam within cavity and individual 60 minute timer with constant steam setting. Doors are insulated, field

reversible with easy open latch and hidden magnetic door switch. Drip sink with condensate drain is provided under cavity doors. Three (2 1/2” deep) pan capacity per chamber. Cabinet

base has stainless steel frame, all stainless steel exterior with hinged front access panel and adjustable bullet feet. Boiler is CDS-1 compliant, ASME code constructed for 15 PSI maximum,

with choice of 24, 36 or 48KW power input. Power takeoff to divert steam to adjacent equipment is standard on 10 gallon models only. UL listed, unit comes standard with automatic boiler

drain. Provide options and accessories as indicated.

WATER SUPPLY:

Water quality is a major factor affecting the performance of your steamer. If you

POWER SUPPLY

Specify 208, 240 or 480 Volt, 3 phase, 60 Hz

are unsure of water quality, consult a local water treatment specialist and have

the water analyzed. Your water supply must be within these general guidelines:

Total dissolved solids: Less than 30 PPM Total alkalinity: Less than 20 PPM

Silica: Less than 13 PPM Chlorine: Less than 1.5 PPM

pH Factor: 7.0 - 9.0

Water which fails to meet these standards should be treated by installation of a

water conditioner. Failure or malfunction of this steamer due to poor water quality is not covered under warranty.

WATER & DRAIN CONNECTIONS:

Drain 1-1/4” NPT free venting drain

Cold Water 1/2” NPT cold water supply line

Appliance is to be installed with backflow protection in accordance with Federal,

State or Local codes.

SHIPPING INFORMATION:

Approx. Weight:

6E-SB 550 lbs. (250 kg)

10E-SB 630 lbs. (286 kg)

NOTE: The company reserves the right to make substitutions of

components without prior notice.

MAXIMUM HEATER ELEMENT CURRENT

208V 240V 480V

24 kW 67 amp 58 amp 29 amp

36 kW 100 amp 87 amp 44 amp

48 kW 134 amp 116 amp 58 amp

BLODGETT

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

P/N S00127 Rev D (11/13)

Loading...

Loading...