Page 1

KPS/KLS-DS Series

DIRECT STEAM STATIONARY FLOOR KETTLE

INSTALLATION - OPERATION - MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Manufacture Service Questions: 866-518-3977

PART NUMBER 170098 REV B (04/11)

Page 2

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND

AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

NOTIFY CARRIER OF DAMAGE AT ONCE

IT IS THE RESPONSIBILITY OF THE CONSIGNEE TO INSPECT THE CONTAINER UPON

RECEIPT OF SAME AND TO DETERMINE THE POSSIBILITY OF ANY DAMAGE, INCLUDING

CONCEALED DAMAGE. WE SUGGEST THAT IF YOU ARE SUSPICIOUS OF DAMAGE TO

MAKE A NOTATION ON THE DELIVERY RECEIPT. IT WILL BE THE RESPONSIBILITY OF THE

CONSIGNEE TO FILE A CLAIM WITH THE CARRIER. WE RECOMMEND THAT YOU DO SO

AT ONCE.

Page 3

IMPORTANT - READ FIRST - IMPORTANT

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING INSTRUCTIONS,

CAUTIONS, AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

WARNING: THIS UNIT IS INTENDED FOR USE IN THE COMMERCIAL HEATING, COOKING AND HOLDING OF

WATER AND FOOD PRODUCTS, PER THE INSTRUCTIONS CONTAINED IN THIS MANUAL. ANY

OTHER USE COULD RESULT IN SERIOUS PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT

AND WILL VOID WARRANTY.

WARNING: KETTLES MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH PLUMBING.

IMPROPER INSTALLATION CAN RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

WARNING: AVOID ANY EXPOSURE TO ESCAPING STEAM. STEAM CAN CAUSE SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT EQUIPMENT SURFACES. DIRECT SKIN CONTACT COULD

RESULT IN SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN KETTLES. DIRECT CONTACT

COULD RESULT IN SEVERE BURNS.

CAUTION: DO NOT OVER FILL THE KETTLE WHEN COOKING, HOLDING OR CLEANING. KEEP LIQUIDS

A MINIMUM OF 2-3” (5-8 cm) BELOW THE KETTLE BODY RIM TO ALLOW CLEARANCE FOR

STIRRING, BOILING AND SAFE PRODUCT TRANSFER.

WARNING: TAKE SPECIAL CARE TO AVOID CONTACT WITH HOT KETTLE BODY OR HOT PRODUCT WHEN

ADDING INGREDIENTS, STIRRING OR TRANSFERRING PRODUCT TO ANOTHER CONTAINER.

CAUTION: KEEP FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS OCCUR, CLEAN

IMMEDIATELY, TO AVOID SLIPS OR FALLS.

WARNING: FAILURE TO CHECK SAFETY VALVE OPERATION PERIODICALLY COULD RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO EQUIPMENT.

WARNING: WHEN TESTING, AVOID ANY EXPOSURE TO THE STEAM BLOWING OUT OF THE SAFETY VALVE.

DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND CLOTHING.

PRECAUTIONS SHOULD BE TAKEN. WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON

THE LABEL OF THE CLEANER TO BE USED.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY THE MANUFACTURER

OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE OPERATOR INJURY AND DAMAGE TO THE

EQUIPMENT, AND WILL VOID ALL WARRANTIES.

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL VOID

WARRANTIES.

OM-KPS/KLS-DS 1

Page 4

Table of Contents

Important Operator Warnings ....................................................... page 1

References.................................................................................... page 2

Equipment Description............................................................... page 3-4

Installation ..................................................................................... page 5

Initial Start-Up................................................................................ page 6

Operation ...................................................................................... page 7

Sequence of Operation ................................................................ page 8

Maintenance................................................................................. page 9

Cleaning................................................................................ page 10-11

Troubleshooting............................................................................ page 12

Parts List..................................................................................... page 13

Piping Diagram........................................................................ page 14-15

Service Log ............................................................................. page 16-17

References

KLENZADE SALES CENTER ECOLAB. Inc.

370 Wabasha St. Pau , Minnesota 55102

800/352-5326 or 612/293-2233

NSF INTERNATIONAL

789 N. Dixboro Road

P.O. Box 130140

Ann Arbor, Michigan 48113-0140

ZEP MANUFACTURING CO.

1310-T Seaboard Industrial Blvd.

Atlanta, Georgia 30318

2 OM-KPS/KLS-DS

Page 5

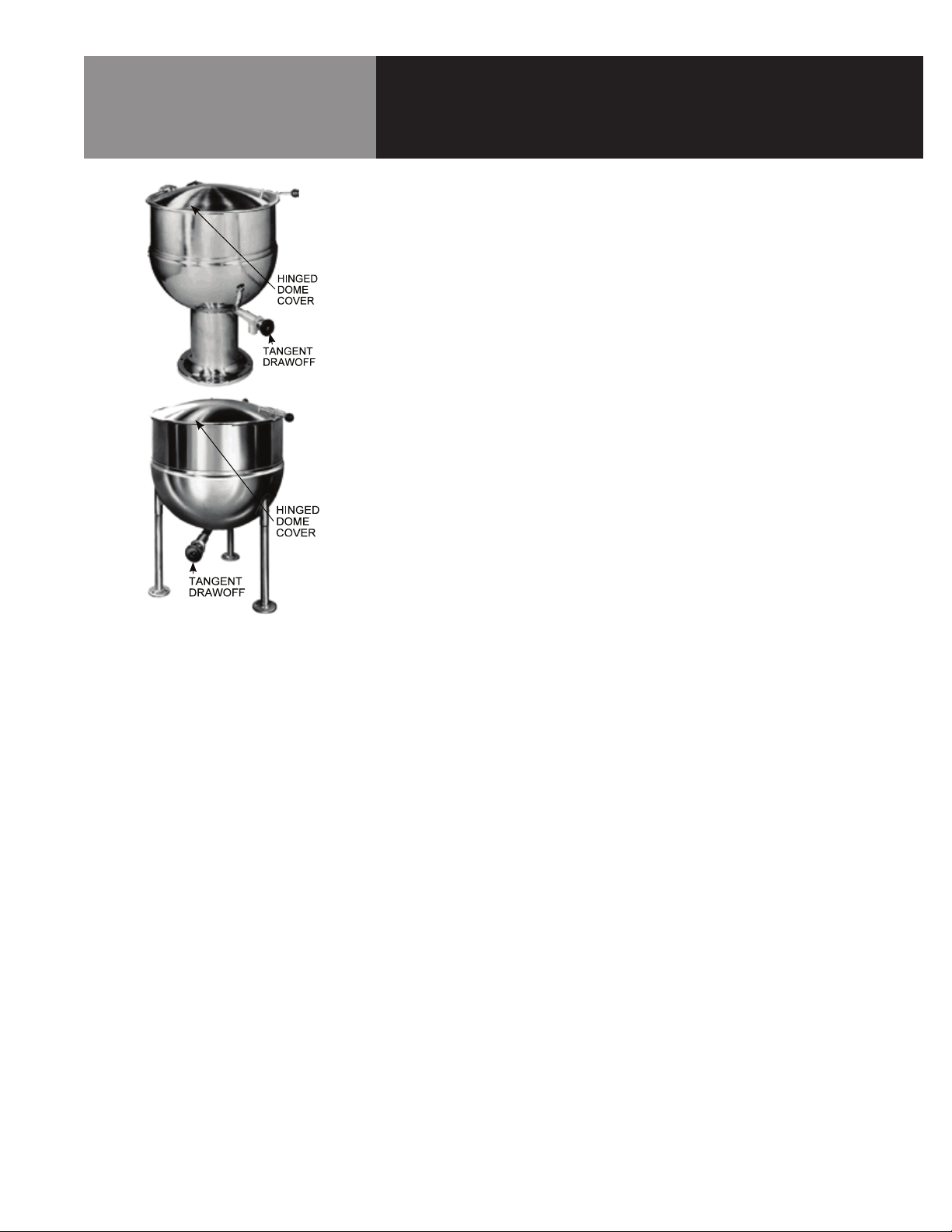

Equipment Description

The direct steam heated kettles covered in this manual are one-piece, welded

constructions of 18.8 type 304 stainless steel, which are listed by the National Sanitation

Foundation. They have bar rims with a continuous seal weld on the underside. The

kettles are ASME shop inspected, and registered with the national board for operation at

pressures up to 25 PSI. They are finished to 180 emery grit interior, and a bright semideluxe exterior. The table on page 4 shows standard kettle sizes.

Steam from a remote source passes directly into the jacket. Steam pressure forces

condensate out through the condensate outlet. The units operate safely and efficiently

at steam pressures from five to 25 PSI. A safety valve works to release any pressure

above the 25 PSI limit. If required, higher jacket pressure (PSI) kettles can be provided. A

globe valve is required on the steam inlet, and a strainer, steam trap and check valve are

needed on the condensate outlet. Each of these may be ordered as an option.

The kettles are emptied by tangent draw-offs. The standard draw-off on current

models is a compression disk type, fabricated from 316 stainless steel with a 2 inch

outer diameter (O.D.). The draw-off has a removable stainless steel strainer which has

¼ inch perforations. Options for the draw-off include a three-inch O.D., a strainer with

1/8 inch perforations, and a solid disk strainer.

Models KPS and KLS are deep kettles with 2/3 jackets. On units with capacities of 40

gallons or less, a one-piece hinged stainless steel dome cover is furnished. On larger

units the cover is counter-balanced with a spring-assisted actuator.

Model KLS stands on stainless steel, tubular legs, that are continuously welded to the

kettle. The legs are fitted with adjustable stainless steel floor flanges.

Model KPS stands on a stainless steel pedestal base. The outer surface of the base is

flanged down vertically to permit proper sealing to the floor or deck. These units are

provided with a standard faucet bracket.

OM-KPS/KLS-DS 3

Page 6

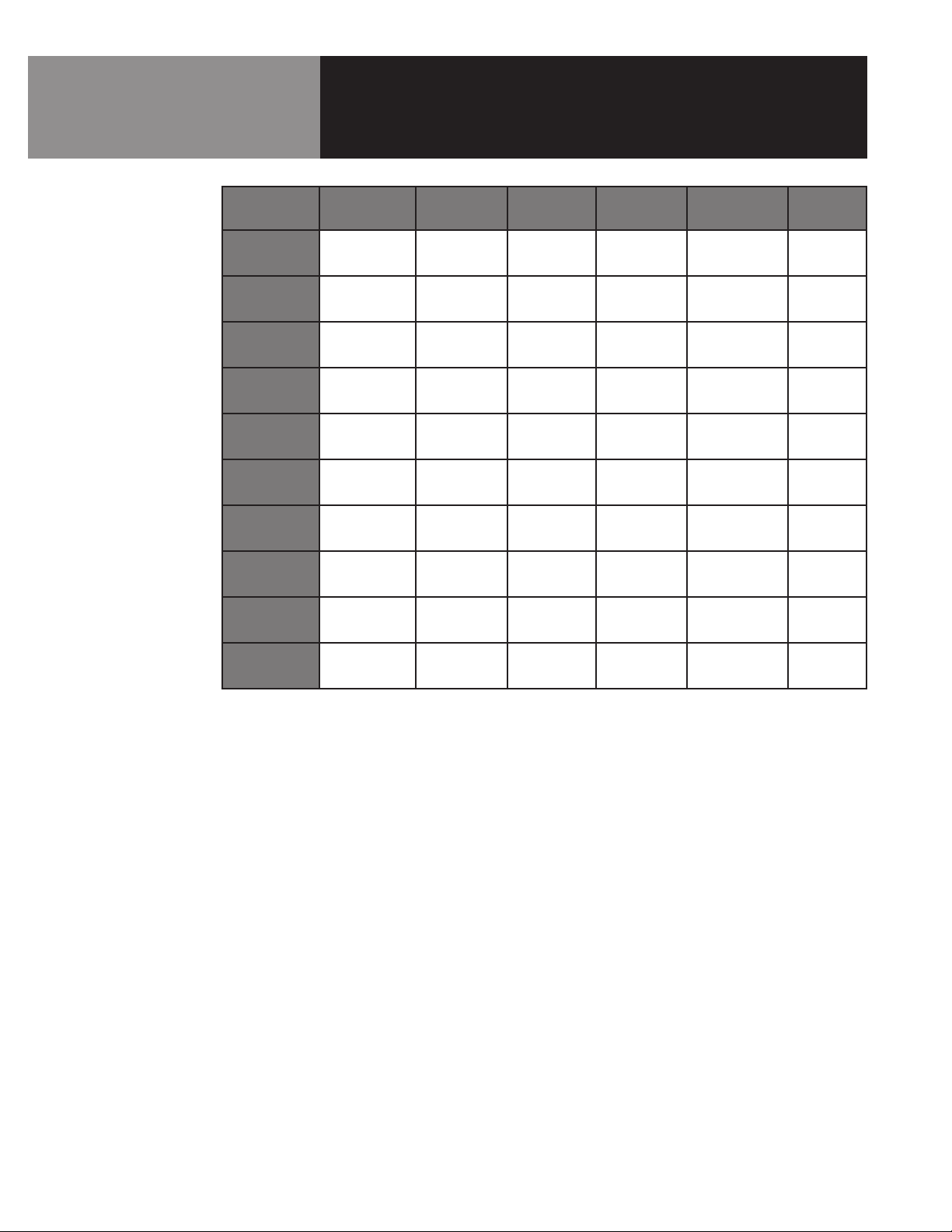

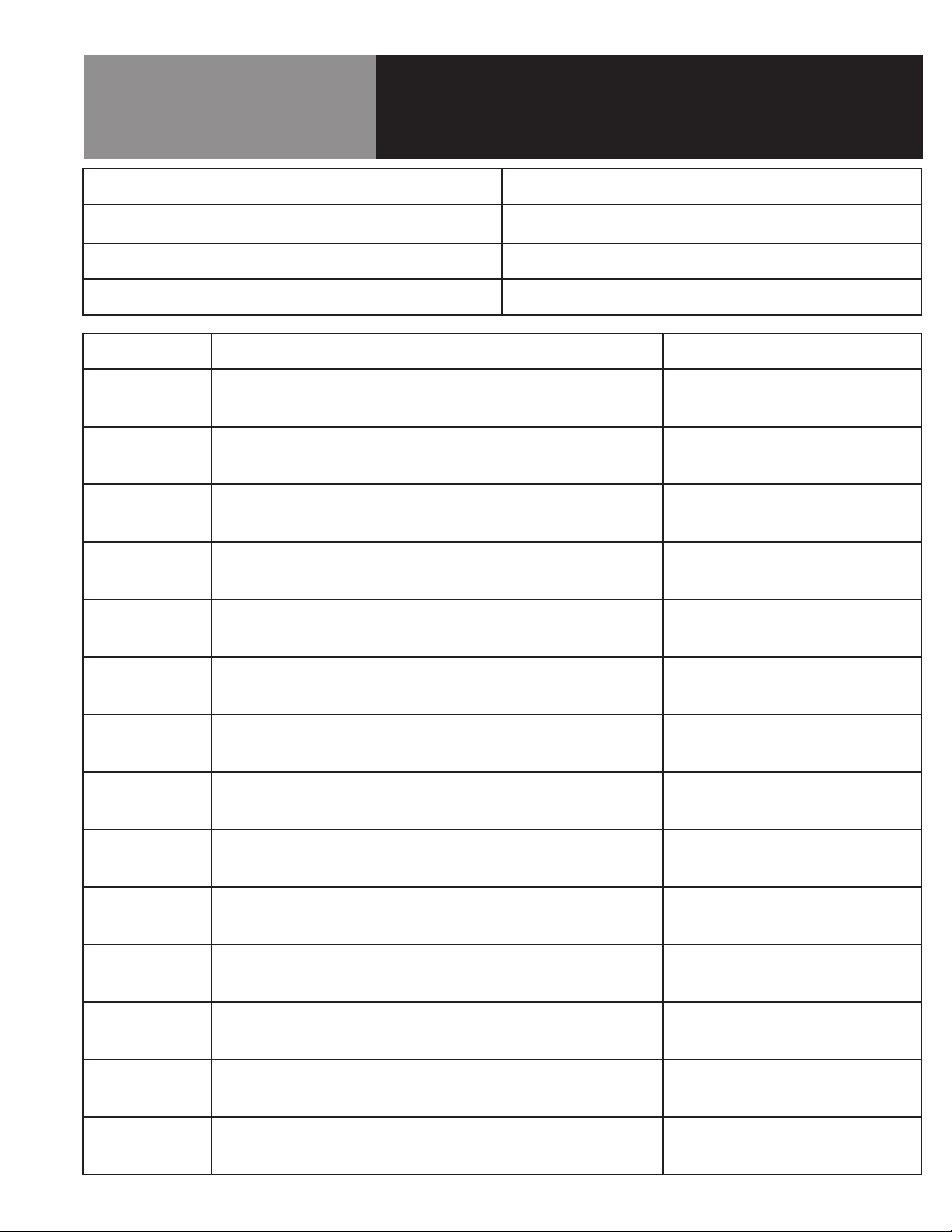

Equipment Description

MODEL

20DS-KPS

40DS-KPS

60DS-KPS

80DS-KPS

100DS-KPS

20DS-KLS

40DS-KLS

60DS-KLS

80DS-KLS

Kettle

Capacity

20 Gallons

75 liters

40 Gallons

150 liters

60 Gallons

225 liters

80 Gallons

300 liters

100 Gallons

375 liters

20 Gallons

75 liters

40 Gallons

150 liters

60 Gallons

225 liters

80 Gallons

300 liters

Inside

Diameter

20 inches

508 mm

26 inches

660 mm

30 inches

762 mm

32 inches

813 mm

36 inches

914 mm

20 inches

508 mm

26 inches

660 mm

30 inches

762 mm

32 inches

813 mm

Rim Height

36 inches

914 mm

36 inches

914 mm

39 inches

991 mm

43 inches

1092 mm

44 inches

1118 mm

36 inches

914 mm

36 inches

914 mm

39 inches

991 mm

43 inches

1092 mm

Overall

Width

22 inches

559 mm

28 inches

711 mm

32 inches

813 mm

34 inches

864 mm

38 inches

965 mm

24 inches

610 mm

30 inches

762 mm

34 inches

864 mm

36 inches

914 mm

Front-to-Back Base Style

26-1/4 inches

667 mm

31-3/4 inches

807 mm

36 inches

914 mm

39 inches

991 mm

40 inches

1016 mm

27-1/2 inches

699 mm

33 inches

838 mm

37 inches

940 mm

38 inches

965 mm

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

Tubular

Leg

Tubular

Leg

Tubular

Leg

Tubular

Leg

100DS-KLS

100 Gallons

375 liters

36 inches

914 mm

44 inches

1118 mm

Optional Equipment may include:

1. Cooking basket system

2. Fill faucet with swing spout

3. Kettle brush kit

4. Cover with actuator (40-gallon kettle)

5. Steam trap assembly

40 inches

1016 mm

40 inches

1016 mm

Tubular

Leg

4 OM-KPS/KLS-DS

Page 7

Installation

WARNING

THIS UNIT MUST BE INSTALLED BY

PERSONNEL QUALIFIED TO WORK WITH

PLUMBING. IMPROPER INSTALLATION CAN

CAUSE INJURY TO PERSONNEL AND/OR

DAMAGE TO EQUIPMENT.

All Models

1. Installation under a ventilation hood is recommended.

2. If the steam supply pressure is greater than the maximum working pressure

stamped on the nameplate, you must install a pressure reducing valve in the

steam supply line near the kettle.

3. Connect the steam supply line to the steam inlet fitting. To obtain the full heating

capability of the kettle, the steam supply line must be as large as the steam inlet

fitting.

4. The safety valve is preset to relieve jacket pressure that exceeds its rated limit.

Do not try to adjust the valve setting, and do not allow the valve outlet or lever to

be blocked.

5. Connect the kettle condensate return line to the boiler return line, or to a drain.

A suitable steam trap, strainer, and check valve must be installed. (See piping

diagram, Page 14-15).

6. Any mechanical change must be approved by the Food Service Engineering

Department.

Floor-Mounted Models

1. Install the unit on a level surface. Ensure that there is adequate clearance at the

sides and rear, as required by the specification drawings. Anchor the pedestal or

legs securely to the floor.

For proper sanitation, a continuous seal

is required between pedestals or flanges

and the mounting surface.

2. Apply a continuous bead of clear silicone sealant (No. 732 or equivalent) to the

junction between the pedestal or leg flange and the surface, as shown. Fill all

cracks and crevices, and wipe excess away.

OM-KPS/KLS-DS 5

Page 8

Initial Start-Up

IMPORTANT

BE SURE ALL OPERATORS READ,

UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS, AND SAFETY

INSTRUCTIONS CONTAINED IN THIS MANUAL.

WARNING

AVOID EXPOSURE TO ESCAPING STEAM,

WHICH CAN CAUSE SEVERE BURNS.

Now that the kettle has been installed, you should test it to ensure that it is operating

correctly.

1. Remove all literature and packing materials from inside and outside of the unit.

2. Pour a small amount of water into the kettle.

3. Open the steam inlet valve.

4. When the water begins to boil, inspect all of the fittings to ensure that there are

no leaks.

5. Check the safety valve by pulling out on its chain, (or lifting its lever on older

models) far enough to let steam escape. Then let it snap back into place to

reseat the valve so that it will not leak.

6. Shut down the unit by closing the steam inlet valve.

7. Operate the drawoff valve to ensure that it functions across the normal range of

operation.

If the unit functions as described above, it is ready for use. If the unit does not function

as intended, contact your local Certified Service Agency.

Test the safety valve each day.

6 OM-KPS/KLS-DS

Page 9

Operation

WARNING

AVOID EXPOSURE TO ESCAPING STEAM,

WHICH CAN CAUSE SEVERE BURNS.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE. DIRECT

CONTACT COULD RESULT IN SEVERE BURNS.

TAKE SPECIAL CARE TO AVOID CONTACT

WITH HOT KETTLE BODY OR HOT PRODUCT,

WHEN ADDING INGREDIENTS, STIRRING OR

TRANSFERRING PRODUCT TO

ANOTHER CONTAINER.

CAUTION

DO NOT OVERFILL THE KETTLE WHEN

COOKING, HOLDING OR CLEANING. KEEP

LIQUIDS AT LEAST 2-3” (5-8 cm) BELOW

THE KETTLE BODY RIM TO ALLOW

CLEARANCE FOR STIRRING, BOILING

PRODUCT AND SAFE TRANSFER.

To heat the kettle, open the condensate return valve and the steam inlet valve.

Adjusting the inlet valve allows the operator to control the heating rate. Opening the

valve more allows steam to flow into the jacket faster, and thereby heats the product

faster.

The kettle operates efficiently with steam pressures from five PSI to the maximum

working pressure for which the kettle was designed. The maximum allowable

pressure (normally 25 PSI for standard units) is stamped on the kettle.

Once a day, while there is still steam pressure in the jacket, bleed off any entrapped

air and double check the operation of the safety valve. Pull out on its chain, (or lift the

lever on older models) far enough to let steam escape. Then let it snap back into place

to reseat the valve so that it will not leak.

OM-KPS/KLS-DS 7

Page 10

Sequence of Operation

The following “action-reaction” outline is provided to help you understand how the

equipment functions.

When the steam inlet valve is opened, steam flows into the jacket at a pressure determined

by the boiler system, or by the pressure reducing valve which serves the kettle. In the jacket

steam releases its heat to the kettle as it condenses into water. The steam trap allows

condensate (water) to leave the kettle while holding the steam in.

When the steam supply is shut off, condensation of the remaining steam produces a

vacuum in the jacket, but the check valve in the condensate return line keeps water from

flowing back into the jacket.

8 OM-KPS/KLS-DS

Page 11

Maintenance

WARNING

WHEN TESTING, AVOID ANY EXPOSURE

TO THE STEAM BLOWING OUT OF THE

SAFETY VALVE. DIRECT CONTACT

COULD RESULT IN SEVERE BURNS.

Test the safety valve each day.

NOTICE: Contact an authorized representative when repairs are required.

Periodic Maintenance

A Service Log is provided at the back of this manual with the warranty information.

Each time maintenance is performed on your kettle, enter the date on which the work

was done, what was done, and who did it. Keep this manual on file and available for

operators to use.

Periodic inspection will minimize equipment down time and increase the efficiency of

operation. The following points should be checked:

1. Once a day, with pressure in the jacket, check the operation of the pressure

relief safety valve. Lift the lever of the safety valve until steam is released.

Then release the lever and let the valve snap shut. If the lever does not activate,

or there is no evidence of discharge, or the valve leaks, immediately discontinue

use of the kettle and contact a qualified service representative.

2. At least once every 90 days, inspect fittings and valves for signs of damage or

wear.

NOTE: Service performed by other than factory authorized personnel will void all

warranties.

OM-KPS/KLS-DS 9

Page 12

Cleaning

WARNING

AVOID ANY DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

CAUTION

MOST CLEANERS ARE HARMFUL TO THE

SKIN, EYES, MUCOUS MEMBRANES, AND

CLOTHING. PRECAUTIONS SHOULD BE

TAKEN. WEAR RUBBER GLOVES, GOGGLES

OR FACE SHIELD, AND PROTECTIVE

CLOTHING. READ THE WARNINGS AND

FOLLOW THE DIRECTIONS ON THE LABEL OF

THE CLEANER CAREFULLY.

CAUTION

DO NOT MIX DIFFERENT KETTLE DRAWOFF

ASSEMBLY PARTS WHEN WASHING.

THEY ARE NOT INTERCHANGEABLE

NOTICE

NEVER LEAVE A CHLORINE SANITIZER IN

CONTACT WITH STAINLESS STEEL

SURFACES LONGER THAN 30 MINUTES.

LONGER CONTACT CAN CAUSE STAINING

AND CORROSION.

A. Suggested Tools

1. Cleaner, such as Klenzade HC-10 or HC-32 from ECOLAB, Inc

2. Long- and short-handled kettle brushes in good condition

3. Brush suitable for cleaning the draw-off port

4. Sanitizer such as Klenzade XY-12

5. Film remover such as Klenzade LC-30

B. Procedure

1. Clean food-contact surfaces as soon as possible after use, preferably

while the kettle is still hot. If the unit is in continuous use, thoroughly clean

and sanitize the interior and exterior at least once every 12 hours.

2. Scrape and flush out food residues with lukewarm water. After flushing the

kettle, close the draw-off valve.

3. Prepare a hot solution of the detergent/ cleaning compound as instructed

by the supplier. Set some of this solution aside to use in cleaning the

draw-off valve and pipe.

4. Clean the unit thoroughly, inside and outside.

5. Drain the kettle.

6. Disassemble the tangent draw-off valve. Clean the draw-off pipe and each

valve part with a brush.

Scrapers or steel wool can harm

the kettle surface.

Use only a sponge, cloth or

plastic brush to clean the kettle.

7. Rinse the kettle and draw-off parts thoroughly with warm water, then

drain completely.

8. As part of the daily cleaning, clean all external and internal surfaces that

may have been soiled. Remember to check such areas as the underside of

the cover.

9. To remove burned-on materials, use a brush, sponge, cloth, plastic or

rubber scraper, or plastic wool with the cleaning solution. To reduce effort

required in washing, let the detergent solution sit in the kettle and soak

into the residue. Do not use abrasive materials or metal tools that might

scratch the surface. Scratches make the surface harder to clean and

provide places for bacteria to grow.

10. Do not use steel wool, which may leave particles in the surface and cause

eventual corrosion and pitting.

11. The outside of the unit may be polished with a stainless steel cleaner such

as “Zepper” from Zep Manufacturing Co.

10 OM-KPS/KLS-DS

Page 13

Cleaning

12. When equipment needs to be sanitized, use a solution equivalent to one

that supplies 200 parts per million available chlorine. Obtain advice on

sanitizing agents from your supplier of sanitizing products. Following the

supplier’s instructions, apply the agent after the unit has been cleaned and

drained. Drain and thoroughly rinse off the sanitizer.

13. It is recommended that each piece of equipment be sanitized just before

use.

14. If there is difficulty removing mineral deposits or a film left by hard water

or food residues, clean the kettle thoroughly and use a deliming agent, in

accordance with the manufacturer’s directions. Rinse and drain the unit

thoroughly before further use.

15. If cleaning problems persist, contact your cleaning product representative

for assistance. The supplier has a trained technical staff with laboratory

facilities to serve you.

OM-KPS/KLS-DS 11

Page 14

Troubleshooting

Your kettle will operate smoothly and efficiently if properly maintained. However, the following is a list of checks to make in the event

of a problem. If the actions suggested do not solve the problem, call your qualified Service Representative. If an item on the list is

followed by * , the work should be done by a qualified service representative.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY THE MANUFACTURER AND/OR AUTHORIZED

DISTRIBUTOR CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

SYMPTOM WHO WHAT TO CHECK

(* indicates work that should only be performed by a qualified service representative)

Kettle will not heat. User a. That the steam inlet valve is open.

b. That the steam supply line is turned on.

c. That the condensate return valve is open.

d. That the boiler is operating properly. Steam should be

supplied at a pressure greater than ve PSI.

Authorized

Service Rep Only

Safety valve leaks a

small amount of steam.

Safety valve leaks a

large amount of steam.

Pipe tting leaks. User a. Is the tting tight?

User a. For contamination that prevents seating the valve. With

Authorized

Service Rep Only

Authorized

Service Rep Only

Authorized

Service Rep Only

e. Steam supply line for blockage.*

f. Condensate return line for blockage.*

g. Steam trap operation.*

substantial pressure in the jacket, lift the valve lever briey

all the way up, to blow the valve clean then let it snap back

down to seat the valve.

b. Safety valve for defects. Defective valve MUST be replaced

with a valve rated at the same pressures.*

a. Steam supply pressure.*

b. Safety valve for defects. Defective valve MUST be replaced

with a valve rated at the same pressures.*

b. If tightening the packing gland does not stop the leak,

replace the packing.*

12 OM-KPS/KLS-DS

Page 15

Parts List

Key Description Part #

1 ¼”-20 N.C. CAP NUT 005471

2 SPACER 012733

3

HANDLE (COVERS W/ACTUATOR)

3 COVER ACTUATOR 120521

3 COVER HANDLE 120915

3 U-HANDLE 010245

4 KNOB (FRICTION) 010245

5 SPRING (28” & 30” COVERS) 012303

6 SPRING (32” & 36” COVERS) 012413

7 SPRING (38” & 42” COVERS) 012533

8 SPRING (44” & 48” COVERS) 012565

9 SPRING (50” COVERS) 012566

½”-20 N.F. X 1” LG HEX HD

10

CAPSCR.

11 ½” BRASS WASHER 002213

12 ½”-20 N.F. JAM NUT 010668

13 ¾” I.P.S. STREET ELBOW 011004

14 #25-¾” SAFETY VALVE 011004

15

2” DRAW-OFF VALVE COMPLETE

15 2” DRAW-OFF TUBE 038418

15

3” DRAW-OFF VALVE COMPLETE

16 STEM FOR 2” VALVE 009048

16 STEM FOR 3” VALVE 001908

17 BONNET FOR 2” VALVE 009047

17 BONNET FOR 3” VALVE 003925

18 O-RING FOR 2” VALVES 009034

19 HEX NUT 2” VALVE 009354

19 HEX NUT 3” VALVE 003927

20 HANDLE FOR 2” VALVE 170061

20 HANDLE FOR 3” VALVE 012209

21

WING NUT FOR 1½” & 2” VALVES

REMOVABLE STRAINER 9” DIA

22

¼” HOLES

REMOVABLE STRAINER 9” DIA

23

1/8” HOLES

REMOVABLE STRAINER 9” DIA

24

NO HOLES

24 STRAINER, ¼” PER. 009986

24 STRAINER, VERTICAL 009987

25 R.H. COVER HINGE 002292

26 L.H. COVER HINGE 002293

27 R.H. HINGE HALF 012877

28 L.H. HINGE HALF 012878

047712

002212

009046

012262

009028

009007

009040

009057

To order parts, contact your authorized Service Agency. Supply the model designation, part

description, part number, quantity, and where applicable, voltage and phase.

Models KPS & KLS, 10-40 Gallon Inclusive

Models KPS & KLS, 60+ Gallon Inclusive

OM-KPS/KLS-DS 13

Page 16

*All of the fittings illustrated are required for

proper and safer installation and operation,

and are NOT PROVIDED as standard with

the unit. Steam trap assemblies can be

purchased in two versions.

1. COMPLETELY PIPED — Complete,

preassembled, with nipples and fittings,

as shown in the diagram.

2. LOOSE — Unassembled, without nipples

and fittings, but includes steam trap,

check valve, globe valve and gate valve.

NOTE - All steam trap assemblies are shipped

in a separate container and are not mounted

on the kettle to prevent damage during

shipment. A steam pressure reducing valve

(PRV) is available at extra cost for installation

when steam pressure exceeds the kettle’s

maximum working pressure. It is to be

mounted on the steam inlet side, just before

the steam valve (globe valve), as close to the

kettle as possible.

Piping Diagram*

Bucket Type Steam Trap Assembly

Item No.

1 Bushing

2 Close Nipple

3 Female Union

4 Street Elbow

5 Bucket Steam Trap

6 Swing Check Valve

7 Gate Valve

8 Globe Valve

9 Close Nipple

10 Female Union

Description

INLET

SIZE

1/2" I.P.S. 1/2" I.P.S.

3/4" I.P.S. 1/2" I.P.S.

1" I.P.S. 3/4" I.P.S.

OUTLET

SIZE

USED ON

20DS-KLS

20DS-KPS

40/60DS-KLS

40/60DS-KPS

80/100DS-KLS

80/100DS-KPS

PART NUMBER

STANDARD

FINISH

025373 044884 062999

025374 040618 040624

025923 065788 024149

ROUGH

CHROME

PLATE

POLISHED

CHROME

PLATE

14 OM-KPS/KLS-DS

Page 17

*All of the fittings illustrated are required for

proper and safer installation and operation,

and are NOT PROVIDED as standard with

the unit. Steam trap assemblies can be

purchased in two versions.

1. COMPLETELY PIPED — Complete,

preassembled, with nipples and fittings,

as shown in the diagram.

2. LOOSE — Unassembled, without nipples

and fittings, but includes steam trap,

check valve, globe valve and gate valve.

NOTE - All steam trap assemblies are shipped

in a separate container and are not mounted

on the kettle to prevent damage during

shipment. A steam pressure reducing valve

(PRV) is available at extra cost for installation

when steam pressure exceeds the kettle’s

maximum working pressure. It is to be

mounted on the steam inlet side, just before

the steam valve (globe valve), as close to the

kettle as possible.

Piping Diagram*

Thermostatic Type Steam Trap Assembly

Item No.

1 Bushing

2 Close Nipple

3 Female Union

4 Street Elbow

5 Thermostatic Steam Trap

6 Swing Check Valve

7 Gate Valve

8 Close Nipple

9 Female Union

10 Globe Valve

Description

INLET

SIZE

1/2" I.P.S. 1/2" I.P.S.

3/4" I.P.S. 1/2" I.P.S.

1" I.P.S. 3/4" I.P.S.

OUTLET

SIZE

USED ON

20DS-KLS

20DS-KPS

40/60DS-KLS

40/60DS-KPS

80/100DS-KLS

80/100DS-KPS

PART NUMBER

STANDARD

FINISH

045171 059473 090530

041065 050948 040685

045171 048763 040686

ROUGH

CHROME

PLATE

POLISHED

CHROME

PLATE

OM-KPS/KLS-DS 15

Page 18

Service Log

Model No: Purchased From:

Serial No: Location:

Date Purchased: Date Installed:

Purchase Order No: For Service Call:

Date Service Performed Performed By

16 OM-KPS/KLS-DS

Page 19

Service Log

Model No: Purchased From:

Serial No: Location:

Date Purchased: Date Installed:

Purchase Order No: For Service Call:

Date Service Performed Performed By

OM-KPS/KLS-DS 17

Page 20

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: 866-518-3977

PART NUMBER 170098 REV B (04/11)

Loading...

Loading...