THE CALDERA

USERS’

INSTALLATION

OPERATION &

MAINTENANCE

Page 1

THE CALDERA

DIRECT VENTED TOP OR Rear

VENT GAS Room Heater

For use with natural gas or propane

WARNING: If the information in this manual

is not followed exactly, fire or explosion may

result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other

flammable

vapors and liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch; do

not use any phone in your building.

· Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

· If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

This appliance may be installed in an

aftermarket permanently located,

manufactured (mobile) home, where not

prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

INSTALLER: PLEASE LEAVE THIS MANUAL WITH

THE CUSTOMER

CUSTOMER: PLEASE KEEP MANUAL FOR FU-

TURE REFERENCE

Pour la version française de nos manuels S.V.P. vous référez à notre site web : www.blazeking.com

Version 1.09 SIT

Nov 2010

Page 2

THE CALDERA

CONTENTS

Introduction 4

General Information 5

Appliance Dimensions 6

Installation Clearances 7 - 9

Installation Instructions - Appliance 10 - 12

Assembly Instructions - Log Set 13-14

Installation Instructions - Venting 15-23

Rigid Venting Parts List 24-26

Intermittent Pilot & Valve Information 27-28

Page

Wiring Diagram 29

Lighting Instructions 30-31

Handheld Thermostat Remote Control - Operation instructions 32-36

Maintenance 37-39

Servicing 40-41

Fuel Conversion 42-43

Allowed Termination Location 44

Troubleshooting 45-46

Top / Rear Vent Conversion 47

Fan Kit Installation 48-49

Replacement Parts 50-51

Warranty 52

Notes & Service History 53

MANUFACTURED IN CANADA BY:

Valley Comfort Systems Inc.

1290 Commercial Way

Penticton, BC

V2A 3H5

Ph# 1-250-493-7444

Email vcsales@vip.net

Patents Pending

MANUFACTURED IN USA BY:

Blaze King Industries

146 A Street

Walla Walla, WA.

99362

Ph# 1-509-522-2730

Email bki@bmi.net

Page 3

THE CALDERA

Note: A copy of the certification label is provided here for your review. Due to constant up-grades it

is possible that the information shown here may not coincide with the label as attached to the unit.

In the event of a discrepancy between the labels, the label on the unit is considered as the correct

Page 4

THE CALDERA

INTRODUCTION

Thank you for purchasing the Caldera Zero Clearance Fireplace Gas Heater.

The Caldera is one of the most advanced direct vented zero clearance gas heaters on

the market. It is designed using the latest technology and manufactured to the highest

quality.

Some of the many features are:

Electronic Valve Intermittent pilot & remote capability.

Heater Classification It is classified as a heating appliance. Therefore, it can be

operated continuously for zone heating.

High Efficiency It has high efficiency; therefore, it is less expensive to operate.

Adjustable Flame The flame aesthetics and heat output can be adjusted to suit the

owner’s moods and heating needs.

Solid Construction It is constructed mainly heavy gauge steel for long life and

durability.

Please read the manual carefully prior to installation and operation of the

appliance. Proper installation, operation and maintenance of the appliance will

provide you with many years of enjoyment.

CAUTION

Due to high temperatures, the appliance should be located out of traffic and

away from furniture and draperies.

Children and adults should be alerted to the hazards of high surface

temperature and stay away to avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same room

as the appliance.

Clothing or other flammable material should not be placed on or near the

appliance.

Any parts removed or opened for servicing of the appliance must be properly

replaced prior to operating the appliance.

The appliance must be inspected before use and at least annually by a qualified

service person. More frequent cleaning maybe required due to excessive lint

from carpeting, bedding material, etc. It is imperative that the control

compartments, burners and circulating air passageways for the appliance be

kept clean.

Venting terminals shall not be recessed into a wall or siding.

This gas appliance must not be connected to a chimney flue serving a separate

solid fuel burning appliance.

Page 5

THE CALDERA

GENERAL INFORMATION

APPLIANCE CERTIFICATION

This appliance is tested and certified to the following US and Canadian gas appliance standards.

- ANSI Z21.88-2007 / CSA 2.33-2007 Vented Gas Fireplace Heaters,

- CAN/CGA-2.17-M91 Gas-Fired Appliance fo Use at High Altitudes

- CSA P.4.1-02 Testing Method for Measuring Annual Fireplace Efficiency

Please contact Valley Comfort or Blaze King, if you have any questions regarding the certification of this

appliance.

INSTALLATION CODES

This appliance must be installed by a qualified gas appliance installer. The installation must conform with

the local codes or, in the absence of local codes, with the current National Fuel Gas Code, ANSI Z223.1/

NFPA 54, in the US or Installation Code, CSA-B149.1, in Canada. Electrical connections and grounding

must be in accordance with local codes, if any, if not, follow the current CAN/CSA C22.1 in Canada and

ANSI/NFPA 70 in the US. This appliance is certified for installation in a bedroom or a bedsitting room.

This appliance is only for use with the type of gas indicated on the rating plate and may be installed in an

aftermarket, permanently located, manufactured (mobile) home where not prohibited by local codes. See

owner’s manual for details. This appliance is not convertible for use with other gases, unless a certified kit

is used. This appliance must be installed in accordance with the current Standard CAN/CSA Z240 1411,

Mobile Housing, or with the Manufactured Home Construction and Safety Standard Title 24 CFR, Part

3280, or when such a standard is not applicable, ANSI/NCSBCS A225.1/NFPA 501A, Manufactured

Home Installations Standard.

Only for direct discharge without duct connection. This appliance must be direct vented using listed and

approved Simpson Dura-Vent, Selkirk, Security or American Metal Products vent components.

SPECIFICATIONS

Natural Gas (NG) Propane (LP)

Manifold Pressure

Min. Supply Pressure for

Purpose of Input Adjustment

Orifice Size

Nominal Input Rating

Altitude

Primary Air Opening

3.5 in. W.C. (0.9 kpa) 10.0 in. W.C. (2.5kpa)

5.0 in. W.C. (1.24 kPa) 12.0 in. W.C. (3.0 kPa)

#35 DMS #51 DMS

35,000 - 24,000 BTU/hr

(10.26 – 7.04 kW)

0 - 4,500 ft. (0 - 1372 m) 0 - 4,500 ft. (0 - 1372 m)

closed 100% open

35000 - 26,000 BTU/hr

(10.26 – 7.26 kW)

HIGH ALTITUDE INSTALLATION

When installing this appliance beyond 4500 ft. (1372 m) above sea level, the appliance must be properly

de-rated and installed according to local codes, in the absence of local codes, with the current National

Fuel Gas Code, ANSI Z223.1/ NFPA 54, in the US or Installation Code, CSA-B149.1, in Canada.

THE CALDERA

Page 6

APPLIANCE DIMENSIONS

Figure 1

THE CALDERA

Page 7

INSTALLATION CLEARANCES

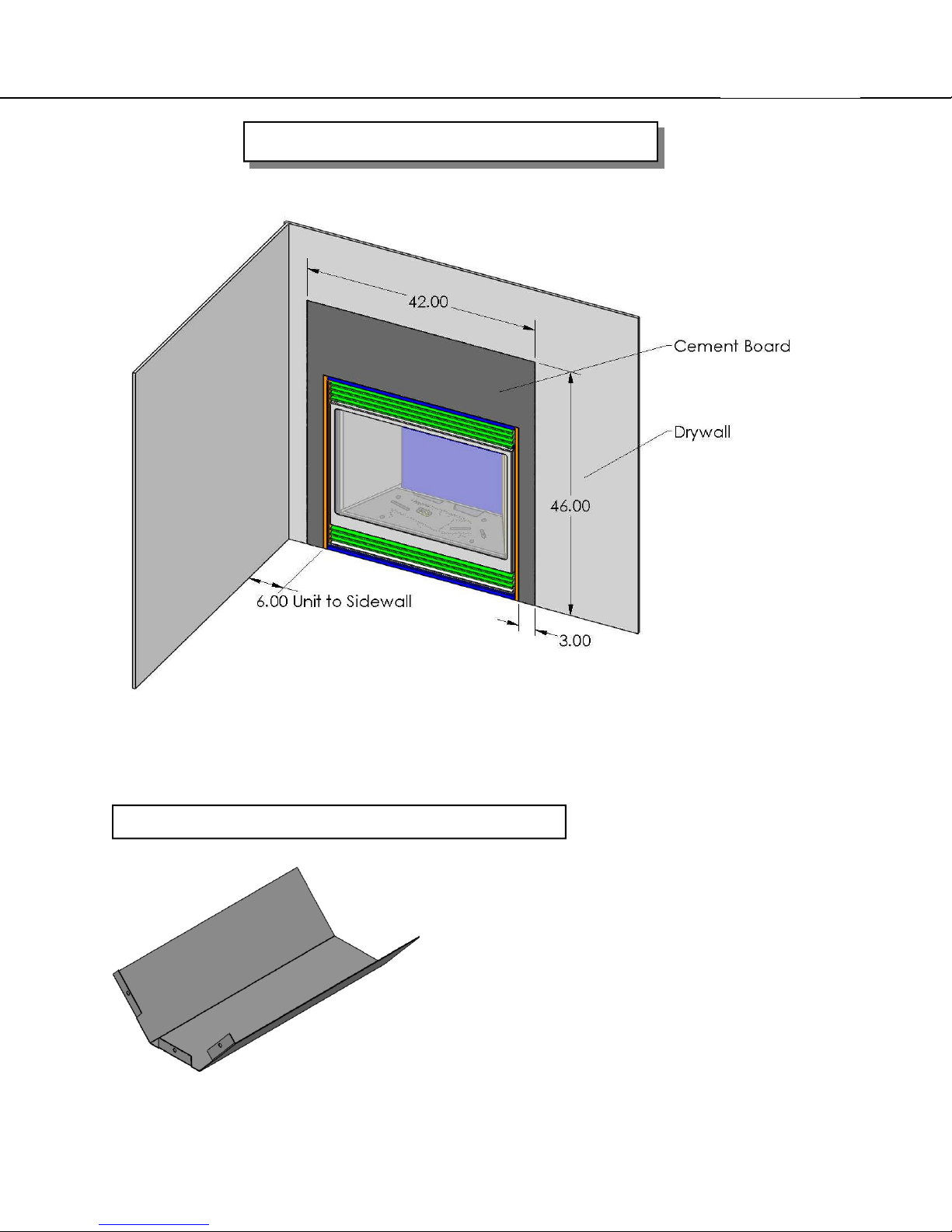

Figure 2

C

A - Internal Ceiling Height min. 60" (1524 mm)

B - Internal Framing min. 45" (1143 mm)

C - Sidewall Clearance min. 6" (152 mm)

D - Unexposed Back & Sides min. 2" (51 mm)

Mantle - See Chart

Vertical Vent - 1" (25 mm) to outside surface

Horizontal Vent - 1" (25 mm) to outside bottom & side surface, 2" (51 mm) to outside top surface

Can be installed on a combustible surface.

D

THE CALDERA

Figure 3A

Minimum framing

dimensions

Page 8

INSTALLATION CLEARANCES

Figure 3B

Mantle Clearances to

Combustibles

Mantle Height

from Floor (B)

50" (1270 mm) 12" (300 mm)

49" (1245 mm) 11-5/16" (287 mm)

48" (1219 mm) 10-9/16" (268 mm)

47" (1194 mm) 9-7/8" (251 mm)

46" (1168 mm) 9-3/16" (233 mm)

45" (1143 mm) 8-7/16" (214 mm)

44" (1118 mm) 7-3/4" (197 mm)

43" (1092 mm) 7-1/16" (179 mm)

42" (1067 mm) 6-5/16" (160 mm)

41" (1041 mm) 5-5/8" (143 mm)

40" 1016 mm) 4-15/16" (125 mm)

39" (991 mm) 4-3/16" 106 mm)

38" (965 mm) 3-1/2" (89 mm)

37" (940 mm) 2-13/16" (71 mm)

36" (914 mm) 2-1/16" (52 mm)

Mantle Depth (A)

Max.

35" (889 mm) 1-3/8" (35 mm)

34" (864 mm) 11/16" (17 mm)

THE CALDERA

Page 9

INSTALLATION CLEARANCES

Figure 3C Minimum Framing Dimensions

Figure 3D Minimum Framing Dimensions

THE CALDERA

INSTALLATION INSTRUCTIONS

Page 10

Figure 3C Cement Board Dimensions

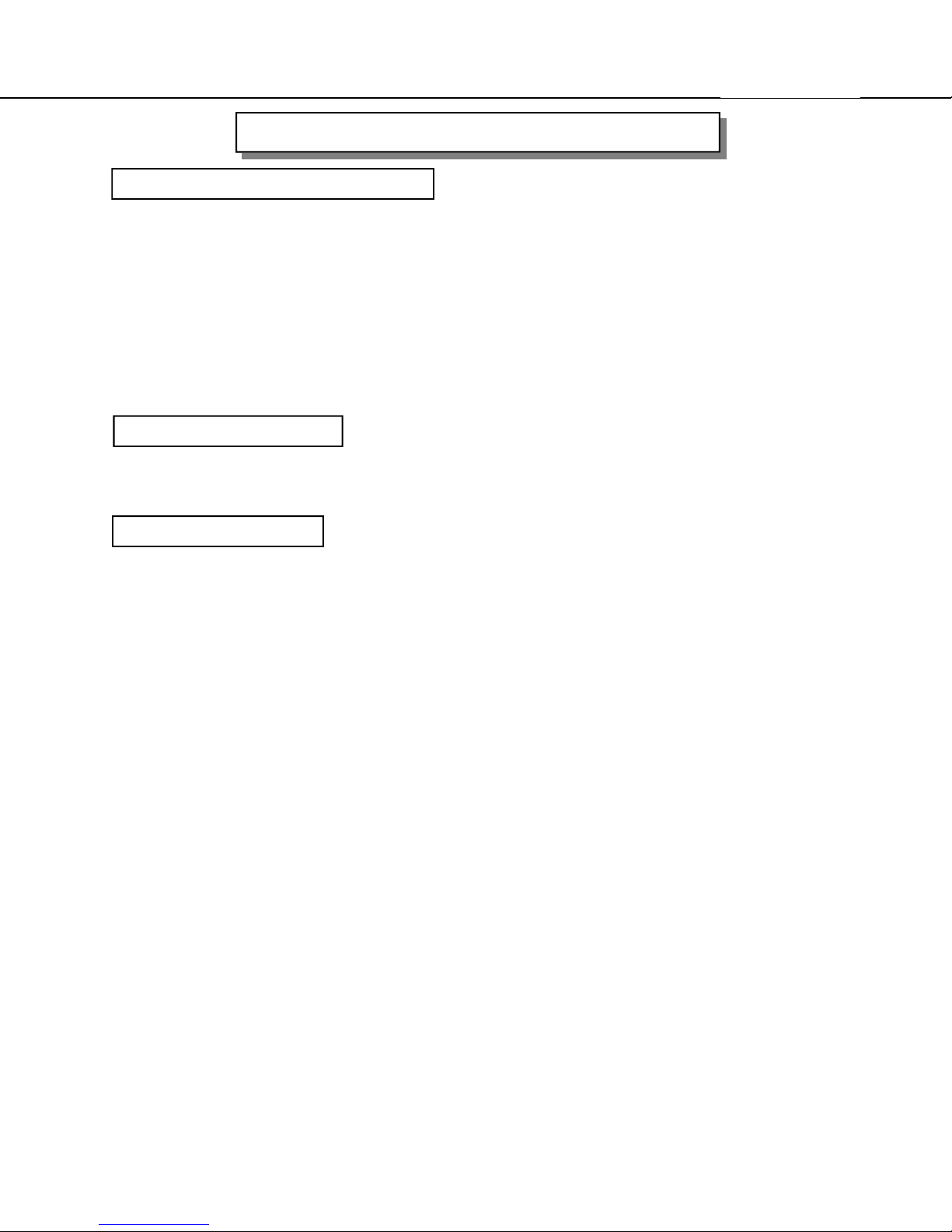

INSTALL VERTICAL HEAT SHIELD (Top Vent Only)

The heat shield which comes with the appliance,

needs to be mounted vertically on top of the appliance. The three holes line up with the ones on top

of the appliance, in front of the flue collar.

Use three screws to mount the heat shield.

IMPORTANT:When the heat shield is not

installed, fire may result, causing property

damage, personal injury or loss of life.

(For top vent only)

Page 11

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

PRECAUTIONS

This appliance must be installed by a qualified gas installer and the installation

conform to applicable installation codes.

This appliance needs fresh air for safe operation and must be installed so there are

provisions for adequate ventilation air. Provide adequate clearance around air openings of

the appliance. Never obstruct front openings.

Provide adequate clearances for proper operation and servicing of the appliance.

This appliance must be properly connected to a venting system.

This appliance must NOT be connected to a chimneyflue serving a solid-fuel appliance.

LOCATING GAS FIREPLACE

The venting system of this appliance must be installed in a location that is free of plumbing,

electrical wiring and heating or air conditioning ducts. Select a location that is accessible for

venting. See the ALLOWABLE TERMINATION LOCATIONS - page 45, in this manual.

ANCHORING UNIT

After determining the location, the appliance needs to be anchored to framing and floor.

Attach to the floor with two screws through the holes in the bottom of the appliance (see Figure

3D) The holes are located behind the bottom louver, one on the left, one on the right.

Attach to the frame by the

standoffs on top of the

unit (See Figure 3D)

The standoffs can be

adjusted by loosening the

screws on top of the

appliance

Figure 3D

Page 12

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

VENT TERMINATION LOCATION

1.Establish a suitable vent termination location. (See ALLOWABLE TERMINATION

LOCATIONS - page 45)

2.In heavy snowfall areas make sure vent termination is located where it can not be blocked by

snowfall or snow from snow removal equipment.

3.Locate vent termination away from plants, bushes or any other object on or near the vent

termination that will interfere or obstruct the air flow around it.

4.DO NOT recess vent termination into walls, sidings or planters.

5.Vent terminations located below 7 ft (2130 mm) from grade level or anywhere that it is a burn

hazard to the public, such as patios and balconies, must be protected with an approved

termination cage.

POWER CONNECTION

You will need to have an electrician supply 120 volts to the area of the fireplace and

terminate in the junction box inside the unit.

GAS CONNECTIONS

Have your gas supplier or a qualified gas fitter run a gas supply line to the gas fireplace. For

your convenience the appliance has a shut-off valve and flex line installed, check with your local

installation codes if this is to code.

There is an access hole situated under the burner for easier access to the gas valve connection.

(Left side under burner, triangular shaped)

CAUTION: The appliance and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure-testing of that system at test pressures

in excess of 1/2 psig (3.5 kPa). The appliance must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any

pressure-testing of the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.5 kPa). Failure to do so will damage the appliance’s gas valve.

Such damage is not covered by the manufacturer’s warranty.

Check for proper gas supply pressure by loosening the set screw on supply pressure tap on the

gas valve with a small flat tip screw driver and placing a test gauge on the tap.

The minimum permissible gas supply pressure is 5 in. w.c. (1.24 kPa) for natural gas and 12.0

in. w.c. (3.00 kPa) for propane. Maximum gas supply pressure should never exceed 14.0 in.

w.c. (3.48 kPa) or 1/2 psi. for both natural gas and propane.

BE SURE TO TIGHTEN THE PRESSURE TAP SET SCREW AFTER CHECKING THE

PRESSURE.

Before connecting the appliance to the gas supply line, double check that the appliance you

have purchased is designed for the gas type you are using. The gas type markings are located

on the certification label and also on the appliance’s gas valve.

Adequate clearance for proper installation and checking of the gas connections must be

provided. All gas connections must be checked for gas leaks.

Page 13

THE CALDERA

ASSEMBLY INSTRUCTIONS

GLASS DOOR REMOVAL

Removing the Glass Door

- Remove the top & bottom louvers.

- Unhook the door latches found on the bottom of the firebox.

- Carefully lift and remove the door.

- Place the door at a safe location where it cannot be scratched or damaged.

- If the glass door is damaged, it must be replaced with another glass door certified with this

appliance only.

- Replacement glass doors are available through your Blaze King dealer (See Replacement Parts

page 51)

Replacing the Glass Door

- Check the condition of the glass and the gasket before installing door.

- Carefully hook the door onto the tabs on the top of the firebox.

- Connect the door latches, at the bottom of the door, and close latches.

Install the top & bottom louvers.

If the glass has been damaged contact your dealer and replace the glass and gasket with a new

glass and gasket provided by your dealer.

WARNING:

- Do not attempt to remove the glass door when the appliance is hot.

- Do not abuse the glass door.

- Do not strike or slam the glass.

- Do not operate this appliance with cracked or broken glass.

- Do not use any substitute materials.

THE CALDERA

ASSEMBLY INSTRUCTIONS Cont...

PLACEMENT OF LOGS AND TWIGS

Page 14

Step 1: Place rear log in notch on left

side and on log pin on right side.

Step 3: Place left log on left front

burner and rear log as shown.

Step 2: Place left and right twigs on log pins

as shown.

Step 4: Place center twig on rear log

and front of burner as shown.

WARNING : Do not place the logs in any other configuration than the one shown. Fire,

explosion or excessive carbon monoxide (CO) may result, causing property

damage, personal injury or loss of life.

Step 5: Place right log on rear log

and front of burner as shown.

Page 15

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

VENTING - Rear Vent

This appliance will not function without being connected to a proper venting system.

This appliance uses 4" x 6-5/8" rigid vent, when used with Simpson Duravent adapter

0923AR (included with appliance). This unit can be used with Selkirk (Direct-Temp),

Security Chimneys or Simpson Duravent 4" x 6-5/8" venting, but for the snorkel only the

American Metal can be used Read the manufacturer’s installation instructions before

installing the venting system.

Typical Installation (for rear vented appliance)

- 7” to 24”(max) horizontal vent pipe exiting wall behind the appliance and a 36"

American Metal snorkel.

- One 45oelbow is allowed for corner installations (24” total length max).

36" Snorkel

(Adj.) Pipe length

24" Max.

Wall Thimble

923AR adaptor

Page 16

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

VENTING - Top Vent

This appliance will not function without being connected to a proper venting system.

This appliance uses 4" x 6-5/8" rigid vent, when used with Simpson Duravent adapter

0923AR (included with appliance). This unit can be used with Selkirk (Direct-Temp),

Security Chimneys or Simpson Duravent 4" x 6-5/8" venting. Read the manufacturer’s

installation instructions before installing the venting system.

Typical Installation

- 9”(min) vertical vent pipe on top of the appliance,

- One 90oelbow, and up to 24” (max) horizontal run to the outside.

Other installations

- Up to 4 - 90oelbows, or equivalent, maximum.

- Minimum 2’ (610mm) straight length between bends.

- The total vertical height up to 30’ (9.1 m) maximum.

- Use vent restrictor over 20’ vertical height (See page 18)

- The total horizontal run up to 16’ (4.9 m) maximum (Note: 4’ (1.2m) minimum of

vertical height required if 16’ horizontal).

Note: Maximum vent lengths may be subject to local codes.

Vent Termination

Typical installation

X

Wall thimble

Z

Pipe Length A

Y

90 Elbow

9" Pipe Length

923AR Adaptor

X = Wall Thickness

Y = Front Fireplace to Wall

Z = Back Fireplace to Wall

Pipe Length A = X+Y-15 ½”

= X+Z- ½”

Examples:

X= Wall

thickness

4” 17 ½” 2 ½” 6”

5” 19 ½” 4 ½”

6” 18 ½” 3 ½” 9”

7” 17 ½” 2 ½”

8” Min.

9” Min.

10” Min.

Y Z

18 ½”

17 ½”

17”

Min.

3 ½”

Min.

2 ½”

Min.

2”

Length Pipe A

9”

9”

11” - 14 5/8”

ADJUSTABLE

11” - 14 5/8”

ADJUSTABLE

11” - 14 5/8”

ADJUSTABLE

Page 17

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

For best venting performance, here are some general venting rules:

1. Use only vent systems and components certified for use with this appliance

2. Maintain a minimum of 1” (26 mm) clearance to combustibles from the outside

surfaces of vertical vents and minimum of 1” (26 mm) sides and bottom, and 2” (51

mm) from top surfaces of horizontal vents. Always use a wall thimble when passing

through combustible construction.

3. Observe all local code restrictions, if any, regarding the installation of this type of gas

appliance.

4. Observe the vent height and length restrictions given in this manual.

5. Never slope horizontal vents downwards.

6. Maintain at least an upward slope of 1/4” (7 mm) for every 1 ft (305 mm) of

horizontal vent.

7. Terminate the vent with a termination certified for use with this appliance.

8. Support horizontal vent every 3 ft (915 mm) to prevent it from sagging.

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

VENTING CHART

Page 18

Example 1

V Value = 3A (12') + 1C (3') = 15'

H Value = 2B (4') =4'

V Value = Total length of all vertical sections in feet.

H Value = Total length of all horizontal sections in

feet.

Note:

for H & V values for 45º venting see Chart IV

elbows are not counted in H or V values

vent chart starts from the top of the unit

Page 19

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

VENT RESTRICTORS FOR TOP VENT INSTALLATIONS

All top vent installations above 20' (6.1 m) require the use of

60% restrictor.

The restrictor is installed in the exhaust of the appliance.

Vent Restrictors

Due to the extra flow produced by certain venting configurations vent restrictors must

be placed in the vent to maintain performance. When your installation requires a vent

restrictor you must remove the flue baffle and install the restrictor in the exhaust box as

shown below. The restrictor is fastened in with 2 screws represented by the dotted

line in the figure below. Once the vent restrictor has been installed the flue baffle must

then be re-installed.

Note: The unit must be cooled to room temperature before installing the restrictor.

Figure 4

Page 20

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

WARNING: A minimum clearance of 1” to combustibles must be maintained

on vertical pipe runs and 2” for horizontal pipe runs (sides and bottom 1”)

The rigid vent systems use twist lock connections. The adaptor attached to the unit

connects to the approved venting system. While you are assembling the pipe bear in mind the

best visual appearance. Seams should be aligned and hidden as much as possible. Make sure

you twist the mating section all the way to make a solid connection.

Note: As this system is a sealed system, a high temperature sealing compound must be

used to seal the metal to metal joint.

Apply a bead of high temperature sealant to both the 4”

exhaust and 6-5/8” intake section of the male pipe. The

female section of the pipe/fitting has four indentations

evenly spaced around the pipe. These indentations are

designed to slide over the male section of the pipe and

locate into the four entry slots of the male section of pipe.

Twist the female section clockwise a quarter turn to fully

lock the sections together.

High

Temperature

Sealant

(Mil-Pac / RTV)

Horizontal Wall Vent Terminations

The position of the horizontal vent termination must be positioned to meet all local building

codes (see termination chart on page 45).

Attach the correct length of vertical section pipe and an elbow fitting to the stove.

Mark the center line of the pipe facing the wall (allowing for a 1/4” rise per foot of horizontal

run). Example 10 ft of horizontal would require a rise of 2.5”.

NOTE: ALLOWING THE VENT PIPE TO SLOPE DOWN TOWARDS THE VENT

TERMINATION COULD CAUSE POOR COMBUSTION AND/OR HIGH TEMPERTURES

THAT MAY PRESENT A FIRE HAZARD. Mark a 10” x 10” square around the center mark

(inside dimensions).

Cut and frame the exterior wall to accept the wall penetration heat shield. Install the

penetration shield using wood screws. If the wall being penetrated is constructed of noncombustible material a 7” hole sufficient for the vent pipe, is acceptable.

Caution: When installing the termination on to vinyl siding, a vinyl siding kit must be

used. This prevents the termination from being recessed into the siding.

When the termination is to be attached to vinyl siding apply a bead of non-hardening mastic

around the outside edge to form a seal between the standoff and the termination cap. Attach

the termination cap to the exterior wall inserting four wood screws through the holes in the

corner of the vent termination. Complete the installation by applying a bead of mastic around

the outer edge of the vinyl standoff.

With the termination cap installed you can now connect the completed vent assembly by

sliding the unit back towards the wall and carefully inserting the pipe into the terminal. Before

the final connection is made slide on the decorative wall thimble. Secure the termination cap by

securing the termination straps to the pipe as close to the exterior wall as possible using sheet

metal screws. Ensure that the straps are hidden by the wall thimble cover. Apply decorative

trim if required.

Page 21

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

Vertical Installations

Always maintain the 1” clearance around the vent pipe (vertical), when passing through

ceilings, walls, roofs, enclosures, attic rafters or any combustible surfaces.

DO NOT PACK AIR SPACES WITH INSULATION.

Refer to the vent chart for maximum allowable vertical and horizontal installations.

When planning your installation determine if ceiling joists, roof rafters or other framing will

obstruct the vent system. You may have to use 45° elbows to navigate around any obstacles.

When passing through a flat ceiling install a Box/Wall thimble. Cut a 10” square hole and frame

as shown in the diagram opposite.

Ensure all pipe sections are fully twist locked.

NOTE: ALWAYS CHECK YOUR LOCAL CODES BEFORE INSTALLING VENTING.

NECESSARY CLEARANCES AND REQUIRMENTS MAY VARY FROM STATE TO STATE

(PROVINCE TO PROVINCE).

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

Page 22

Through Roof Framing

Maintain 10” opening relative to the pitch of

the roof.

10” square

Termination Above Roof

Consult local codes for minimum vent cap

height above the roof, vent must be a

minimum 2’ from any wall.

Use a suitable round or square support

through the roof. Ensure adequate heat

shield protection is provided.

To prevent water seepage install the

flashing with upper portion slid under the

roofing material and the lower portion over

the roofing material.

Note: Do not fasten down until the final

adjustments to the vent have been

made.

THE CALDERA

INSTALLATION INSTRUCTIONS Cont...

Typical vent Installation

Alternate 45° pipe

requiring strap

support

Page 23

High Wind Vertical

Termination Cap

Flashing

Figure 5

Wall Thimble or

Fire-Stop

Twist Lock

Joints

THE CALDERA

Page 24

SIMPSON DURAVENT DIRECTVENT PRO / GS SYSTEM PARTS LIST

Description Part # Old Part #

Description Part #

Horizontal Termination Kit - In Canada—Mandatory to add a wall thimble

Horizontal Termination Kit - In Canada—Mandatory to add a wall thimble. 971

(46DVA-KHC.)

Vertical Termination Kit 978

Vertical Termination Kit - 978

6” Pipe Length -Black 908B

6” Pipe Length -Black 46DVA-06B 908B

9” Pipe Length-Black 907B

6” Pipe Length –Galvanized 46DVA-06 908

12” Pipe Length-Black 906B

8,5” Black Extension (3”-7”) 46DVA-08AB -

12” Pipe Length-Galvanized 906

8,5” Galvanized Extension (3”-7”) 46DVA-08A -

24” Pipe Length-Black 904B

9” Pipe Length-Black 46DVA-09B 907B

24” Pipe Length-Galvanized 904

9” Pipe Length-Galvanized 46DVA-09 907

36” Pipe Length-Black 903B

12” Pipe Length-Black 46DVA-12B 906B

36” Pipe Length-Galvanized 903

12” Pipe Length-Galvanized 46DVA-12 906

48” Pipe Length-Black 902B

16” Black Extension (3”-14.5”) 46DVA-16AB -

48” Pipe Length-Galvanized 902

16” Galvanized Extension (3”-14.5”) 46DVA-16A -

11”- 14 5/8” Adjustable Pipe Length-Black 911B

24” Pipe Length-Black 46DVA-24B 904B

17”- 24” Adjustable Pipe Length-Black 917B

24” Pipe Length-Galvanized 46DVA-24 904

45° Elbow-Black 945B

36” Pipe Length-Black 46DVA-36B 903B

45° Elbow-Galvanized 945

36” Pipe Length-Galvanized 46DVA-36 903

45° Elbow-Swivel-Black 945BG

48” Pipe Length-Black 46DVA-48B 902B

45° Elbow-Swivel-Galvanized 945G

48” Pipe Length-Galvanized 46DVA-48 902

90° Elbow-Galvanized 990

11”- 14 5/8” Adjustable Pipe Length-Black - 911B

90° Elbow-Black 990B

17”- 24” Adjustable Pipe Length-Black - 917B

90° Elbow-Swivel-Galvanized 990G

45° Elbow-Black 46DVA-E45B 945B, 945BG

90° Elbow-Swivel-Black 990GB

45° Elbow-Galvanized 46DVA-E45 945, 945G

Vertical High Wind Termination Cap (must be used for all vertical terminations) 991

90° Elbow-Galvanized 46DVA-E90 990, 990G

Horizontal. DV Termination with 1” return 984GL

90° Elbow-Black 46DVA-E90B 990B, 990BG

Horizontal. Square Termination Cap 984

Vertical High Wind Termination Cap (must be used for all vertical termina-

Horizontal. Square High Wind Termination Cap 985

tions)

Horizontal. DV Termination with 1” return - 984GL

Snorkel-14” Rise Termination Cap 982

Horizontal. Square Termination Cap - 984

Wall Thimble Cover—Support Box 940

Horizontal. Square High Wind Termination Cap 46DVA-HC 985

Cathedral Ceiling Support Box 941

Horizontal Round Termination Cap 46DVA-HRCS -

Brass Trim fro Ceiling Support Box 3951

Sconce Termination Cap 46DVA-HSC -

Fire stop Spacer 963

Wall Thimble Cover—Support Box 46DVA-DC 940

Flashing 0/12-6/12 943

Cathedral Ceiling Support Box 46DVA-CS 941

Flashing 7/12-12/12 943S

Brass Trim fro Ceiling Support Box 3951

Storm Collar 953

Firestop Spacer 46DVA-FS 963

Vinyl Siding Standoff 950

Flashing 0/12-6/12 46DVA-F6 943

Wall Strap 988

Flashing 7/12-12/12 46DVA-F12 943S

Wall Pen Heat Shield (Wall Thimble) 942

Storm Collar 46DVA-SC 953

Vinyl Siding Standoff 46DVA-VSS 950

Wall Strap 46DVA-WS 988

Wall Pen Heat Shield (Wall Thimble) 46DVA-WT 942

SIMPSON DURAVENT GS SYSTEM PARTS LIST

46DVA-KHA 971

46 DVA-VCH 991

THE CALDERA

Page 25

SELKIRK PARTS LIST

PART NUMBER DESCRIPTION

4" x 65/8" LENGTHS

1604006 4DT- 6 DIRECT-TEMP 6" PIPE LENGTH

1604006B 4DT- 6B DIRECT-TEMP 6" PIPE LENGTH BLACK

1604009 4DT- 9 DIRECT-TEMP 9" PIPE LENGTH

1604009B 4DT- 9B DIRECT-TEMP 9" PIPE LENGTH BLACK

1604012 4DT-12 DIRECT-TEMP 12" PIPE LENGTH

1604012B 4DT-12B DIRECT-TEMP 12" PIPE LENGTH BLACK

1604018 4DT-18 DIRECT-TEMP 18" PIPE LENGTH

1604018B 4DT-18B DIRECT-TEMP 18" PIPE LENGTH BLACK

1604024 4DT-24 DIRECT-TEMP 24" PIPE LENGTH

1604024B 4DT-24B DIRECT-TEMP 24" PIPE LENGTH BLACK

1604036 4DT-36 DIRECT-TEMP 36" PIPE LENGTH

1604036B 4DT-36B DIRECT-TEMP 36" PIPE LENGTH BLACK

1604048 4DT-48 DIRECT-TEMP 48" PIPE LENGTH

1604048B 4DT-48B DIRECT-TEMP 48" PIPE LENGTH BLACK

1604082 4DT-AJ12 DIRECT-TEMP 12" ADJ PIPE LENGTH

1604082B 4DT-AJ12B DIRECT-TEMP 12" ADJ PIPE LENGTH BLACK

1604084 4DT-AJ14 DIRECT-TEMP TELESCOPE ADJ LENGTH

1604084B 4DT-AJ14B DIRECT-TEMP TELESCOPE ADJ LEN BLACK

4" x 65/8" FITTINGS

1604215 4DT-EL45 45 DEGREE ELBOW

1604215B 4DT-EL45B 45 DEGREE ELBOW BLACK

1604230 4DT-EL90S 90S DEGREE ELBOW

1604230B 4DT-EL90SB 90S DEGREE ELBOW BLACK

4" x 65/8" ACCESSORIES

1604460B 4DT-WTB WALL THIMBLE BLACK

1604500 4DT-FS FIRESTOP SPACER

1604502 4DT-TP TRIM PLATE BLACK

1604806 4DT-VS VINYL SIDING STANDOFF

4" x 65/8" SUPPORTS

1604400 4DT-CS CEILING SUPPORT

1604424 4DT-CCS CATHEDRAL SUPPORT BOX

1604430 4DT-WS/B WALL SUPPORT/BAND

1604435 4DT-OS OFFSET SUPPORT

4" x 65/8" TERMINATIONS

AND FLASHINGS

1604620 4DT-VKC VERTICAL TERMINATION KIT

1604621 4DT-HKA HORIZONTAL TERMINATION KIT "A"

1604622 4DT-HKB HORIZONTAL TERMINATION KIT "B"

1604802 4DT-VC HIGH WIND VERTICAL CAP

1604804 4DT-HC HIGH WIND HORIZONTAL CAP

1604810 4DT-SC STORM COLLAR

1604825 4DT-AF6 ADJ FLASH 0/12-06/12

1604830 4DT-AF12 ADJ FLASH 6/12-12/12

Page 26

THE CALDERA

AMERICAN METAL PRODUCTS COMPONENTS LIST

Description Part #

7” Pipe Length 4D7

12” Pipe Length 4D12

2’ Pipe Length 4D2

3’ Pipe Length 4D3

4’ Pipe Length 4D4

4” - 10” AdjustableLength 4D12A

45° Elbow 4D45L

90° Elbow 4D90L

Vertical Termination 4DVC

Horizontal Termination 4DHC

36” Snorkel 4D36S

Wall Thimble 4DWT

Wall Strap 4DWS

Fire stop Support Plate 4DFSP

Faceplate, Ceiling Support / Wall Thimble 4DFPB

Roof Support 4DRSB

Storm Collar 4DSC

Standard Flashing 4DF

Steep Pitch Flashing 4DF12

Attic Insulation Shield 4DAIS12

SECURITY VENTING COMPONENTS LIST

6” Pipe Length SV4L6

12” Pipe Length SV4L12

24” Pipe Length SV4L24

36” Pipe Length SV4L36

48” Pipe Length SV4L48

6” Adjustable Length SV4LA

12” Adjustable Length SV4LA12

45° Elbow SV4E45

90° Elbow SV4E90

Wall Band SV4BM

Insulated Attic Shield SV4RSA

Wall Shield SV4RSM

Fire stop SV4BF

Adjustable Roof Flashing 1/12 — 7/12 SV4FA

Horizontal Termination SV4CHC

Vertical Termination SV4CGV

THE CALDERA

INTERMITTENT PILOT & VALVEINTERMITTENT PILOT & VALVE

Page 27

SIT 885 Proflame Valve

Outlet pressure tap

Main valve

Connection

(red)

Inlet pressure tap

Stepper motor

Pilot Connection

(green)

Pilot Flame adjustment

Ground connection

THE CALDERA

INTERMITTENT PILOT & VALVE (cont’d)

Page 28

Optional Wall thermostat

(interrupt green wire)

Page 29

THE CALDERA

WIRING DIAGRAM

Caution: Label all wires prior to disconnection when servicing controls. Wiring errors

can cause improper and dangerous operation. Verify proper operation after servicing.

Figure 16

Page 30

#0361Se

THE CALDERA

LIGHTING INSTRUCTIONS - Intermittent Pilot

FORYOUR SAFETY, READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

A. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the pilot by hand.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the f loor because some gas

is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electric switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

C. Do not use this appliance if any part has been under water. Immediately call a qualified se rvice technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

LIGHTINGINSTRUCTIONS

1. Read the safety information above on this label.

STOP!

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the appliance.

4. Do not attempt to light the pilot by hand.

5. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor. If you smell gas, STOP!

Follow “B” in the safety information above on this label. If you don’t smell gas, go to t he next step.

6. Turn on all electric power to the appliance.

7. You must now synchronize the remote with the Receiver/Battery Pack (for 1st time use)

Battery Pack (fig. 1 (Battery Pack is situated behind the Pedestal front or Louvers)) fol lowed by pressing the “ON” button

on the Remote.

8. Press the "ON" button on the Remote (fig. 2) or if not using the Remote turn the switch on the Battery Pack to the

"ON" position (see figure1 ).

9. If the appliance will not operate, follow the instructions "To Turn Off Gas ToAp pliance" and call your service technician

or gas supplier.

by pressing the PRG button on the

TO TURN GAS OFF TO APPLIANCE

1. Press the "OFF" button on the remote or if not using the remote turn the switch on the batt ery pack to the “OFF” position.

(See fig. 1)

2. Turn off all electric power to the appliance.

ON /OFF

FIG 1: RECEIVER / BATTERY PACK

FIG 2: REMOTE CONTROL

Page 31

THE CALDERA

OPERATION INSTRUCTIONS

LIGHTING INSTRUCTIONS

FOR YOUR SAFETY, READ BEFORE LIGHTING

INITIAL OPERATION

- Check that the appliance is properly vented and connected to the gas supply.

- Check the logs and twigs are properly placed.

- Check all external parts, such as grills, door and control cover are properly attached and fastened.

NOTE : When operated for the first few times, the appliance will emit some odor and fumes. This is

due to the evaporation of oils and solvents used in fabricating the appliance. Close off the

room to the rest of the house and open all windows. Keep the room well ventilated.

Page 32

THE CALDERA

HANDHELD THERMOSTAT REMOTE CONTROL-operation instructions

Fig. 3: Receiver body

Page 33

THE CALDERA

HANDHELD THERMOSTAT REMOTE CONTROL-operation instructions

Page 34

THE CALDERA

HANDHELD THERMOSTAT REMOTE CONTROL-operation instructions

Page 35

THE CALDERA

HANDHELD THERMOSTAT REMOTE CONTROL-operation instructions

Page 36

THE CALDERA

HANDHELD THERMOSTAT REMOTE CONTROL-operation instructions

Continuous Pilot

ON/OFF

Continuous pilot

The pilot on this unit will light automatically when

turning the unit on.

If a standing pilot is preferred (especially in cold

weather) , the pilot can be run continuously by

switching the continuous pilot switch to the ON

position. The switch is located behind the bottom

louver, above the Receiver / Battery pack.

Batteries under

this cover

Page 37

THE CALDERA

MAINTENANCE

CAUTION :Do not conduct maintenance on the appliance while it is operating or while it is still hot.

Make sure Remote switch on the Module is in OFF position (See figure 9 page 29) and turn

burner switch OFF. Turning the electric supply off will not prevent unexpected ignition !!

CLEANING THE APPLIANCE

The exterior surfaces and glass may be cleaned with a soft, non-abrasive cloth and water or a suitable,

mild, non-abrasive cleaner.

Regularly,

- Clean and remove any lint accumulations or debris from the grills and in any combustion and convection

air passage ways.

- Keep the appliance area free from combustible materials, such as paper, wood, clothing, gasoline and

flammable solids, liquids and vapors.

- Check for unusual noise, odor and operation of the appliance.

- Check the vent terminal for any damage, or obstruction by plants or debris accumulation.

- Visually check the height and color of the burner and pilot flames.

MAIN FLAME

INTERMITTENT PILOT FLAME:

Figure 12

Figure 14

Once a Year,

- Remove the glass door and clean the inside of the glass with a soft,

non-abrasive cloth and water or a suitable, mild, non-abrasive cleaner.

- Carefully remove the logs and gently brush off any loose carbon

deposits. This job is best done outside the house, wearing a dust

mask.The logs are very fragile, take care not to break them. After

cleaning, the logs must be replaced as per the instructions in this

manual.

Once a Year have a qualified service technician,

- Completely inspect the appliance and the venting system.

- Clean and remove any lint accumulations or debris in the firebox, on the burners, on the pilot,

at the primary air opening, on the convection air blower and in any combustion and convection

air passage ways.

- Check the safety shut-off system of the gas valve.

WARNING : All parts removed or disturbed must be properly replaced after maintenance.

Service and repair must be conducted by a qualified service person. If these

instructions are not followed, a fire or explosion may result, causing property

damage, personal injury or loss of life.

VERIFY PROPER OPERATION AFTER SERVICING.

Page 38

THE CALDERA

MAINTENANCE

PLATING:

1. The plating requires little maintenance and needs only to be cleaned with a soft damp cloth. Do not

use any abrasive cleaning materials.

2. Avoid fingerprints on gold. Wipe off fingerprints before firing.

DOOR :

Check the gasket to see that it is still forming a seal. Replace gasket if there is any sign of wear.

VIEWING GLASS REPLACEMENT:

This appliance is supplied with high temperature 5mm high temperature ceramic glass that will easily

withstand the heat your unit was designed to produce. In the event the glass breaks, contact your dealer

or BLAZE KING to arrange for your glass to be replaced / repaired (see page 12).

IMPORTANT - GLASS CLEANING - WHITE MINERAL DEPOSITS

One of the byproducts of the combustion process in a gas appliance, is a mineral which can show up as

a white film on the ceramic glass of the viewing door. The composition of the deposit varies widely from

various locations and also from time to time in the same location. You may have the problem for a time

and then not see it for many months when it will reappear in your area. It seems this is associated with

the varying sulfur content of the gas. We have discussed this problem with ceramic glass manufacturers

and they cannot give us a definitive answer to this problem. Dealers have tried various cleaning products

with varying results. The following recommendations will not guarantee results in your particular case.

Ensure the stove is completely cooled before you change the bulb. Make sure switch on the

Battery pack / Receiver is in OFF position.

Turning the electric supply off will not prevent unexpected ignition !!

1. Clean the glass regularly as soon as you notice the buildup (white film). If the film is left for a long

period of time build up will bake on. It is then much harder, if not impossible, to remove.

2. NEVER use an abrasive cleaner on the ceramic glass. Any abrasion of the surface has the

immediate effect of lessening the strength of the glass. An emulsion type cleaner is recommended.

3. Use a soft damp cloth to apply the cleaner. Dry the glass with a soft, dry, preferably cotton cloth.

Most paper towels and synthetic materials are abrasive to ceramic glass and should be avoided.

4. Our dealers have had good results from the products listed below. We can not however guarantee

the results of these products.

a) BRASSO b) POLISH PLUS by KEL KEM

c) COOK TOP CLEAN CREME by ELCO d) WHITE OFF by RUTLAND

NOTE: This is a problem beyond Blaze King’s control and is

not covered under warranty.

NOTICE: COLD WEATHER OPERATION

When using any gas appliance (LPG or NAT Gas) water is a byproduct of the combustion process.

Under normal conditions this moisture is expelled through the vent into the atmosphere and does not

cause any harm. In extreme cold weather the vapor may condense and freeze on any exposed surface

it comes into contact with. This can cause a problem by restricting or blocking the vent, particularly with

direct vent wall terminations as the exhaust is only a few inches away from the outside wall surface.

What happens to the moisture after it leaves the vent cannot be controlled by the manufacturer. To

extend the vent further out from the wall can sometimes but not always be an advantage. Extending the

vent out from the wall may present other design problems such as ice falling from the eaves above. It is

the homeowners responsibility to ensure that there is not an excessive build-up of ice on the termination.

CAUTION: WHEN OPERATING YOUR APPLIANCE DURING COLD WEATHER YOU MUST

FREQUENTLY CHECK THE EXHAUST CAP FOR EXCESSIVE ICE BUILD UP.

If the appliance begins to operate abnormally—Poor flame pattern, shutting down, etc…, this could be

an indication of ice build up.

Page 39

THE CALDERA

MAINTENANCE

REPLACING HALOGEN LIGHT BULB (OPTIONAL SHROUDS ONLY)

The light is situated at the inside of the shroud. Replace with the light bulb specified in the replacement

parts list on page 49. To replace the light bulb follow these instructions:

Ensure the stove is completely cooled before you change the bulb. Make sure switch on the

Battery pack / Receiver is in OFF position.

Turning the electric supply off will not prevent unexpected ignition !!

1. Turn off electric supply

2. Open the right door (arched shroud) or take off shroud (rectangular shroud)

3. Using a screw driver, remove the cover plate (rectangular shroud only)

4. Remove old bulb by pulling straight out, to insert new bulb, push straight in.

(Avoid touching glass with bare hands, hold bulb with clean cloth or tissue)

5. Re-install and turn power back on.

Page 40

THE CALDERA

SERVICING

SERVICING UNDER WARRANTY

Before servicing, read the terms and conditions of the Blaze King warranty at the back of this manual.

Contact the Blaze King authorized dealer which you purchased the appliance from and provide him with

details of the problem and the installation information which the installer filled out at the back of the

manual.

WARNING: Servicing of this appliance must be conducted by a qualified service technician.

Improper servicing, adjustment or alteration of this appliance may cause property

damage, personal injury or loss of life. All servicing should be conducted with the

appliance cold.

ADJUSTING PRIMARY AIR

- Remove the lower louver (open doors/remove optional front first if used) to gain access to the shutter.

- Loosen the primary air shutter screw (above burner rocker switch)

(caution, make sure unit is not hot as burns may result).

- Sliding the shutter lever right increases aeration while sliding the lever to the left decreases

aeration.

- Tighten screw.

CHANGING MAIN BURNER ORIFICE

- Remove the glass door, logs and firebox liner panels.

- Remove the burner. Remove the screws holding the aeration box to the firebox floor and lift it out.

- Use a 1/2” wrench to unscrew the orifice

- Change the orifice. Do not over tighten.

- Replace all parts in reverse order and properly set the primary air shutter according to the specifications.

- Check for leaks.

CHECKING INLET AND OUTLET GAS PRESSURE

- The pressure test taps are located on the valve.

- The taps are located in the front.

- Loosen the set screw inside the tap with a 1/8” wide flat screw driver.

- Connect a 1/4” rubber tube to the tap and a pressure gauge.

- Be sure to tighten the set screw inside the tap after you are finish taking pressure readings.

Page 41

THE CALDERA

SERVICING Cont...

GAS COMPONENTS ASSEMBLY

The gas component assembly can be taken out of the appliance for easier servicing.

Replacing Gas Component Assembly

- Disconnect electricity to the appliance.

- Shut off the gas supply to the appliance and disconnect the gas line at the valve

- Remove the glass door, logs and burner.

- Disconnect the wires from the module-box

- Remove the screws holding the gas component assembly to the appliance firebox bottom.

- Gently lift the assembly out and remove through the front.

- Replacing the assembly is the reverse of the above instructions.

* Check the tray sealing gasket. Replace if damaged.

THE CALDERA

FUEL CONVERSION

“WARNING”

This conversion kit shall be installed by a qualified service

agency in accordance with the manufacturer’s instructions

and all applicable codes and requirements of the authority

having jurisdiction. If the information in these instructions is

not followed exactly, a fire, explosion or production of

carbon monoxide may result causing property damage,

personal injury or loss of life. The qualified service agency is

responsible for the proper installation of this kit. The

installation is not proper and complete until the operation

of the converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

Conversion Kit Contents

This conversion kit contains the following parts:

1) For LPG # 51 orifice and LPG Stepper motor

2) For NG # 35 orifice and NG stepper motor

Page 42

To convert from NG to LPG or reverse, follow the next steps.

- Replace burner orifices,

- Replace stepper motor (see next page).

- Convert pilot fuel (see instructions below)

How to convert Pilot fuel:

Use a 7/16” wrench to loosen the pilot hood

Push the little tab in and the little tab with hole should pop out.

The hole stamp tab (LP) out is used for Propane

The stamped tab (NA) out is for Natural Gas

Re-tighten the pilot hood.

Fill out the fuel conversion label on the appliance (inside side doors)

All valves have been pre-set and certified for installation at elevations from 0 – 4500 feet (1 – 1372m)

above sea level.

High Elevations

When installing this unit at higher elevations, it is necessary to decrease the input rating by replacing

the existing burner orifice with a smaller size for installations over 2000 feet (608 m). The appliances

input should be reduced 4% for each additional 1000 feet (305 m) above sea level. For the USA, derate the unit from sea level according to the gas installation code.

Altitude Natural Gas

0 – 4,500 ft (0 – 1372 m) 35 51

4,500 – 6,500 ft (1372 – 1981 m) 36 52

6,500 – 8,000 ft (1981 – 2438 m) 37 53

Orifice Size

Propane

Orifice Size

THE CALDERA

Page 43

FUEL CONVERSION

THE CALDERA

ALLOWABLE TERMINATION LOCATIONS

Figure 19

Page 44

____________________________________________________________________________________________________

Canadian Installations

A= Clearance above grade, veranda *min. 12”(30mm) *min. 12”(30 mm)

porch, deck or balcony

____________________________________________________________________________________________________

B= Clearance to window or door *min. 12”(30 mm) *min. 12”(30 mm)

that may be opened

_______________________________________________________________________________________________

C= Clearance to permanently closed *min. 12”(30 mm) *min. 12”(30 mm)

window

____________________________________________________________________________________________________

D= Vertical clearance to ventilated *min. 20-1/2” (521 mm) *min. 20-1/2” (521 mm)

soffit located above the terminal within from center of termination from center of termination

a horizontal distance of 2’ (61 cm) from

the centerline of the terminal

1

US Installations

2

____________________________________________________________________________

E= Clearance to unventilated soffit *min. 20-1/2” (521 mm) *min. 20-1/2” (521 mm)

_________________________________________________________________________________________________

F=Clearance to outsidecorner *min. 10”(250 cm) *min. 10” (250 cm)

____________________________________________________________________________________________________

G=Clearance to insidecorner *min. 12-1/2" (318 mm) *min. 12-1/2" (318mm)

____________________________________________________________________________________________________

H= Clearance to each side of centerline 3’ (91cm) within a height15’ (4.5m) *

extended above meter/regulatorassembly above the meter/regulatorassembly

____________________________________________________________________________________________________

I= Clearance to service regulator vent outlet 3’ (91cm) *

____________________________________________________________________________________________________

J= Clearance to no mechanical air supply inlet 12” (30cm) 9” (23cm)

to building or the combustion air inlet to any

other appliance

____________________________________________________________________________________________________

K= Clearance to a mechanical air supply inlet 6’ (1.83 m) 3’ (91 cm) above if within 10’ (3m)

____________________________________________________________________________________________________

L= Clearance above paved sidewalk or paved 7’ (2.13 m)† *

driveway located on public property

____________________________________________________________________________________________________

M = Clearance under veranda, porch, deck or 12” (30 cm)‡ *

balcony

____________________________________________________________________________________________________

1

In accordance with the current CSA B149.1, NaturalGas and Propane Installation Code

2

In accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code

† A vent shall notterminate directly above a sidewalk or paved driveway that is located between two single family dwellings and

serves both dwellings.

‡ Permitted only if veranda, porch, deck or balcony is fully open on aminimum of two sides beneath the floor.

* For clearances not specified in ANSI Z223.1/NFPA54 or CSA B149.1, one of the following shall be indicated:

a) A minimum clearance value determined by testing in accordance with section 2.23.7, or ;

b) A reference to the following footnote: “Clearance in accordance with local installation codes andthe requirements of the gas

supplier”

from center of termination from center of termination

from center of termination from center of termination

from center of termination from center of termination

horizontally

Page 45

THE CALDERA

TROUBLESHOOTING

Please check to make sure the instructions are followed exactly before attempting

trouble shooting of the appliance.

WARNING: Troubleshooting and servicing of gas and electrical devices of the

appliance should only be conducted by a qualified service technician.

The pilot will not stay lit. 1) Confirm that the Spark electrode and sense electrode wires are

properly connected to the DFC board (See page 27 for terminal locations)

2) Confirm that the Pilot burner is properly grounded to the DFC board

and stove chassis.

3) Check the power source or the battery pack connections and

condition of batteries.

If the main burner does not

come ON when the manual

switch or remote control is

turned ON.

Pilot will not light. 1. When lighting the appliance for the first time after installation or after

1) Confirm that the pilot sparks and lights.

2) Confirm that the Spark electrode and sense electrode wires are

properly connected to the DFC board (See page 27 for terminal locations)

3) If using the remote control check the condition of the batteries.

4) Check if there is gas supply to the appliance

servicing, there is air in the gas line. It takes a while for all the air to

purge out of the pilot before gas can reach the pilot and ignite.

Remove the glass door and try lighting the pilot many times to purge

the air.

2. Check to make sure the gas supply to the appliance is turned on and

there is adequate gas supply pressure to the appliance.

3. Check for sparks between the spark electrode and the pilot head

when the unit is turned on. If there are no sparks,

a. Check for broken or poor connection from the sparker to the

electrode.

b. Check for the spark shorting or arcing at other locations.

c. Check for defective sparker.

d. Check for defective spark electrode.

e. Check the power source or the battery pack connections and condi-

tion of batteries.

THE CALDERA

SYMPTOM ACTION

Page 46

TROUBLESHOOTING Cont...

The main burner shuts off

when the appliance is warm.

Sooty deposits on the glass

door.

Sharp blue flames with flames

lifting off the burner at the

ends.

Convection blower does not

turn on.

1. This may be the normal operation of a wall thermostat installed to

appliances.

2. Check for good pilot flames on the flame sensor (see fig.3 page 9).

3. Check for proper functioning of venting system (including termination

for blockage).

4. Check wire connections. Expansion from heat affects a loose connection

5. Check for adequate grounding from the Module ( page 27)

1. If the flame is yellow and lazy, check for lint etc. around primary air

shutter. Increase primary air by opening the primary air shutter if necessary (See page 39for adjusting primary air)).

2. Check for proper placement of the logs and branches. Ensure logs

and burner are clean. See that section in the instruction manual.

3. Check for proper venting and blockage of the vent termination.

4. Check manifold pressure and clock input rating for over-firing.

1. Too much primary air. Reduce primary air by closing the primary air

shutter. During cold temperatures, some flame lifting may occur

during start-up (See page 34 for adjusting primary air).

1. The convection fan is thermostatically controlled. It will only turn on

when the appliance is warmed-up. This may take up to 15 minutes

with the appliance on high.

2. Check for 120VAC electrical supply to the appliance. (Is the cord

plugged in?)

3. Check if speed controller is not in OFF position

4. Check for proper mounting of the thermal snap disc (under firebox).

5. Check electrical connections.

6. Check for defective thermal snap disc.

7. Check for defective convection blower speed controller.

8. Check for defective convection blower.

THE CALDERA

5

TOP/REAR VENT CONVERSION

1

Figure 20

2

Note : When converting from rear to

top vent , make sure heat shield (#5)

3

is installed (see page 9)

Page 47

4

The appliance is easily converted from top vent to rear

vent.

The steps for converting are as follows:

1. Remove the outer shell cover plate (# 1).

2. Remove the heat shield cover plate (# 2).

3. Remove the air intake assembly (# 3).

4. Remove the exhaust assembly (# 4).

5. Rotate the exhaust (# 4) and air intake (# 3) assemblies into the rear vent position and re-install.

6. Rotate the heat shield cover plate (# 2) and re-install.

7. Insert the round blanket cutout into hole on top.

8. Rotate the flue collar plate (# 1) and re-install.

234

Figure 21

1

Page 48

THE CALDERA

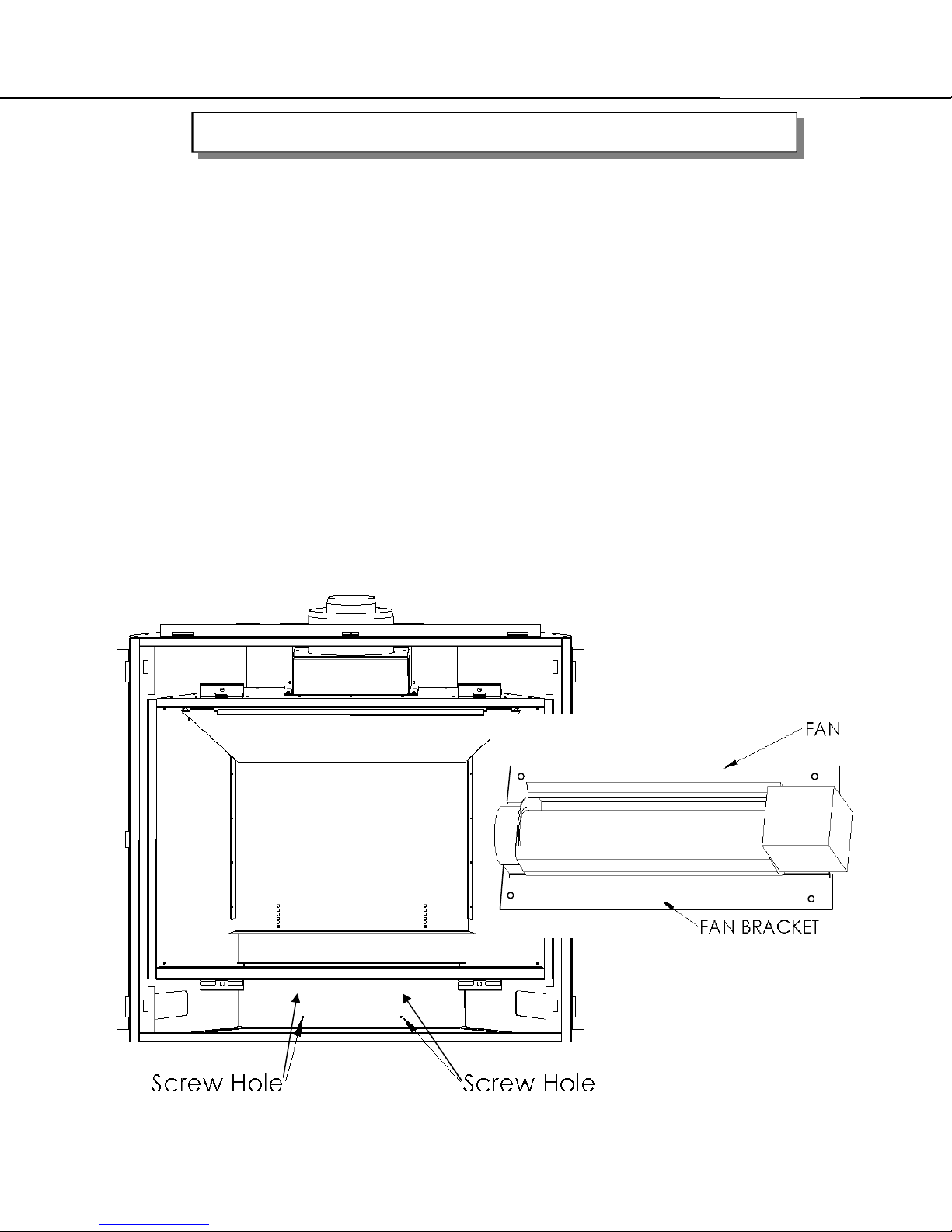

FAN KIT REMOVAL & INSTALLATION

Before removing the fan be sure to let unit cool to room temperature, disconnect electrical power

to the unit, shut off gas to the unit and disconnect the gas line to the appliance.

To remove fan, for maintenance or replacement:

1) Remove the louvers and door.

2) Remove the logs, brick panels and burner. Note: Be careful when handling these items as they

may break if dropped or handled roughly.

3) Remove fan guard (figure 24) and valve tray.

4) Disconnect wires, be sure to label wires prior to disconnecting to ensure they are replaced in the

correct location.

5) Remove the four screws (Figure 22) and take fan out.

6) Installation is the reverse order of the previous steps

See next page for continued installation instructions.

Figure 22

Figure 23

THE CALDERA

Page 49

FAN KIT INSTALLATION - continued

Figure 24

THE CALDERA

Page 50

Replacement Parts list for Caldera

No

Part # Description QTY Unit

expl.

view

OM7405 OWNERS MANUAL, CALDERA DVT/DVR 1 EA

Z0758A CONVERSION KIT-NATURAL GAS TO PROPANE 0-4,500ft 1 EA

Z0758B CONVERSION KIT-NATURAL GAS TO PROPANE 4,500-6,500ft 1 EA

Z0758C CONVERSION KIT-NATURAL GAS TO PROPANE 6,500-8,500ft 1 EA

Z0759A CONVERSION KIT-PROPANE TO NATURAL GAS 0-4,500ft 1 EA

Z0759B CONVERSION KIT-PROPANE TO NATURAL GAS 4,500-6,500ft 1 EA

Z0759C CONVERSION KIT-PROPANE TO NATURAL GAS 6,500-8,500ft 1 EA

01 0254C DOOR GASKET (part # FTI 1071, 114" long) 1 EA

02 0244 GLASS CERAMIC (33-1/8" x 22-15/16") 1 EA

03 M \Z7405B BURNER TRAY 1 EA

04 Z7454 BRICK PANEL SET 1 EA

05 0712A PSE PILOT (PSE-C7-520) 1 EA

06 M \SIT0584302 CONTROL MODULE 1 EA

07 M \SIT0885001 SIT VALVE - MODEL PROFLAME 885 1 EA

08 M \SIT0584521 RECEIVER / BATTERY PACK 1 EA

09 0719D FAN 1 EA

10 0136 RHEOSTAT FAN SPEED CONTROL 1 EA

M \SIT0584121 FAN MODULE 1 EA

13 1144AA SNAPDISK 1 EA

14 7412 FLUE BAFFLE 1 EA

15 7480 60 % VENT RESTRICTOR 1 EA

16 M \SIT0584023 REMOTE TRANSMITTER SIT 1 EA

M \SIT0584912 MODULE/VALVE WIRE HARNESS 1 EA

M \SIT0584905 WIRE HARNESS RECEIVER 1 EA

0822 LOG SET (6 PIECES) 1 EA

0779A LIGHT BULB HALOGEN BI-PIN 12V 20W G6.35 1 EA

Parts can be ordered through your local dealer or distributor by giving PART #

and DESCRIPTION.

THE CALDERA

Replacement Parts list for Caldera

1

Page 51

Page 52

THE CALDERA

Blaze King Warranty

Gas stoves manufactured by Blaze King Industries and/or Valley Comfort Systems Inc. are covered by a limited lifetime warranty against

manufacturers defects in material and workmanship. Details of this comprehensive warranty program are outlined below. In addition to the

terms outlined for the limited lifetime warranty, our products carry a 5 year warranty which covers mechanical and electrical components

includinglabor costs outlined below. The combination of these warranty policies provide a very strong coverage package that we are proud

to offer you, our customers. Our Blaze King tradition of building high quality products for over 25 years is really your most important

assurance of quality but it's nice to know that should something fail (and it occasionally does) you are covered by a warranty policy that

leads the industry. To ensure the coverage is in place you must have your unit properly installed by an authorized Blaze King dealer and

you must register your ownership. Blaze King's warranty policy applies only to units sold, installed and/or for use in the USA or

Canada. No person is authorized to modify this warranty or make any additional warranties on behalf of the manufacturer, Blaze

King.

Components andparts5 year warranty:

Blaze King warrants the following parts; blower motors, door gasket, blower speed control, logs, pilot assembly, gas valve, gas lines,

thermocouple and/or thermopile against defects in material or workmanship to the original purchaser, for five years following the date of

purchase.Consumable items, such as batteriesand light bulbs are not covered by warranty.

Labor costs during the 5 year warranty period:

Blaze King manufacturers warranty covers labor costs to the original purchaser based on our schedule of approved charges, provided to

our authorizeddealers.BlazeKing will only beresponsiblefor labor costs provided by ourauthorized dealers andbasedupon the schedule.

LimitedLifetimeCoverage

This warranty contains different terms that cover specific parts of the gas appliance. Blaze King warrants the following parts of the gas

appliance against defects in material or workmanship to the original retail purchaser. For the first five years of ownership, the combustion

chamber, heat exchanger and burners will be replaced by Blaze King, conditional upon production availability. From year 6 through to the

end of ownership by the original purchaser, Blaze King will provide replacement or repair of the aforementioned parts, conditional upon

current production availability, at 50% of current retail price but does not cover any charges relating to labor. This portion of the warranty

coverage isnot transferableand applies only to the original purchaser.

How to GetService

If this product requires repair or replacement due to defectsin material or craftsmanship duringthe first five years ofownership,contactyour

Blaze King dealer and explain the nature of the problem. If the dealer is unable to repair or replace the product to your satisfaction then

contact Blaze King at 509-522-2730 in the USA or 250-493-7444 in Canada. If a replacement part is sent directly to you, please contact

Blaze King to obtain a Return Authorization Number (RA#) for all defective parts. Blaze King will refuse delivery of any returned packages

not clearly showing an (RA#). All expenses relating to the shippingof defective parts or entirestoveswill be atpurchaser's expense.

BlazeKings Responsibilities:

If the purchaser has complied with all the terms and conditions of this warranty and if the purchaser has notified Blaze King of the defect

prior to the expiration of any warranted items, the following procedure will occur. Blaze King will inspect the product to determine that there

is indeed a defect and that the defect is covered by warranty. Blaze King will either repairor replace the product at its' discretion. Under no

condition whatsoever does Blaze King provide or imply warranty coverage for venting components used in the installation of our products.

This warranty details the obligations and liabilities of Blaze King and no other warranties are expressed or implied. Blaze King reserves the

right to investigate and settle all claims against warranted parts at their discretion. In no event shall Blaze King be held responsible for

indirect or consequential damages of any nature which are in excess of the original purchase price of the product. Blaze King may at its'

discretion discharge any or all obligationsby refundingthe wholesale price of anydefective part or parts.

Misuseof Stove NullifiesWarranty:

The above warranty is conditioned upon the proper installation and use of the product according to the manufacturers instructions as

specified in the "Owners Installation & Operations Instructions" and in compliance with applicable local building and fire codes. Blaze King

recommends thelocal building inspector or firedepartment inspect the unit prior to initialuse. Consult the "Owners Installation & Operations

Instructions" supplied with each unit prior to installation or operation. Alteration, abuse, lack of maintenance, faulty repairs or misuse will

void the warranty. Abuse includes but is not limited to the use of fuels other than as specified in the "Owners Installation & Operations

Instructions."

Legal Rights of Purchaser:

This warrantygives you specific legal rights and you may have other rights that varyfromstate to state (orprovince toprovince).

BlazeKing Assurance Plan:

Includedwitheach gas stove manufactured by Blaze King isa Warranty Card, which must be completed in its entirety and returned to Blaze

king within ten days from thedate of purchase. Blaze King will beunable to properly administerthe warrantyif the cardis not completed and

registered on file. The Protection Plan willpay torepair and or replace parts which fail under normal usage at labor rates established by this

Agreement. Extra charges such as mileage, overtime or shipping are not covered. Nuisance calls are not covered by the Plan. This Plan is

for residential stoves and does not apply to commercial applications. Only repairs attributed to normal failure of the electronic and

mechanical functions of thestove are covered. Failure due butnot limited to, abuse,negligence, impact, fire, lightning, power failures and or

surges, rust and corrosion are not covered. Damage and or repairs to cabinets and all exterior components, remote controls, and normal

maintenance, related duct work, power surges, electrical spikes or electrical circuit overloads, filters, knobs, glass, gaskets, block and tile

etc., are not covered. Additional or unusual utility bills incurred due toany malfunctionor defect in equipment listed on the Plan, labor cost of

gaining access to or removal of a unit that requires special equipment or tools such as cranes, ladder trucks, etc., are not covered. These

include but are not limited to, cleaning, adjustments of the customer controls and customer product education. Labor, materials, expenses

or equipment required to comply with thelaw and orregulations setforthby any governmentalagencies are not covered by thisPlan.

THE CALDERA

Page 53

NOTES

SERVICE HISTORY

DATE CORRECTIVE ACTION (INCLUDE REPLACEMENT PARTS)

Loading...

Loading...