Page 1

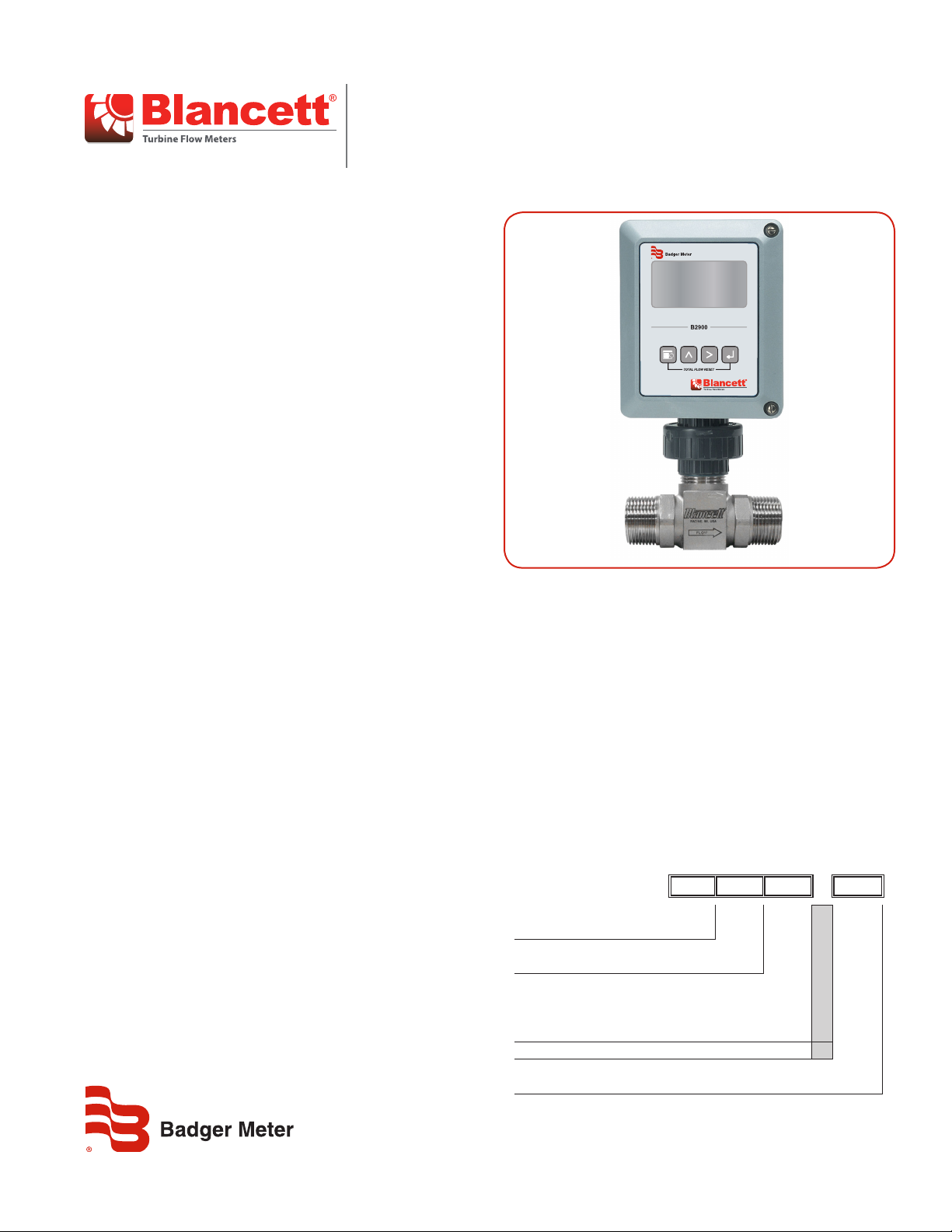

Flow Monitor

B2900 Series

DESCRIPTION

The B2900 flow monitor incorporates state-of-the-art, digital

signal processing technology, designed to provide exceptional

flexibility at a very affordable price. Though it is designed for use

with Blancett flow sensors, this monitor can be used with almost

any flow sensor producing a low amplitude AC output or contact

closure signal.

OPERATION

This monitor can accept low-level frequency input signals typically

found in turbine flow sensors. The output signal for these types of

sensors is a frequency proportional to the rate of flow. The B2900

monitor uses the frequency information to calculate flow rate and

total flow. Through the use of the programming buttons, you can

select rate units, total units and unit time intervals among other

functions. If required, the monitor can easily be re-configured in

the field. Finally, you can choose between simultaneously showing

rate and total, or alternating between rate and grand total.

The monitor provides advanced communication capabilities over

an RS485 bus using Modbus RTU and control outputs.

The package is a polycarbonate NEMA 4X enclosure.

APPLICATIONS

The B2900 monitor is suitable for application in a wide variety of

metering needs. A few of the more common industries are:

• Secondary oil recovery applications

• Remediation and reclamation

• Fracture/refracture

• Coal bed methane

• Regulatory compliance and environmental accountability

• Industrial chemicals

• Aggressive chemical processing applications

• Semiconductor manufacturing

• Fertilizer production and dispensing

• Pesticide manufacture

• Liquid batching and water cooling

FEATURES

• Robust alarm parameters provide faster warning when

something changes in the process or pipeline.

• Greater control and greater visibility of batch operations.

• Advanced connectivity options allow you to connect

meters to your network for remote monitoring and process

automation capabilities.

• Updated display and totalization options provide more flow

information, including simultaneous display of rate and total

as well as standard, batch and grand totals.

• Various mounting options provide a B2900 model for

your operation.

PART NUMBER CONSTRUCTION

Blancett B2900 Display -

Model

Blancett B2900 Display B29

Model

Advanced A

Mounting

Meter M

Remote R

Swivel S

Handheld H

Units of Measure

Customer Selectable CS

DSY-DS-01565-EN-04 (March 2018)

Product Data Sheet

Page 2

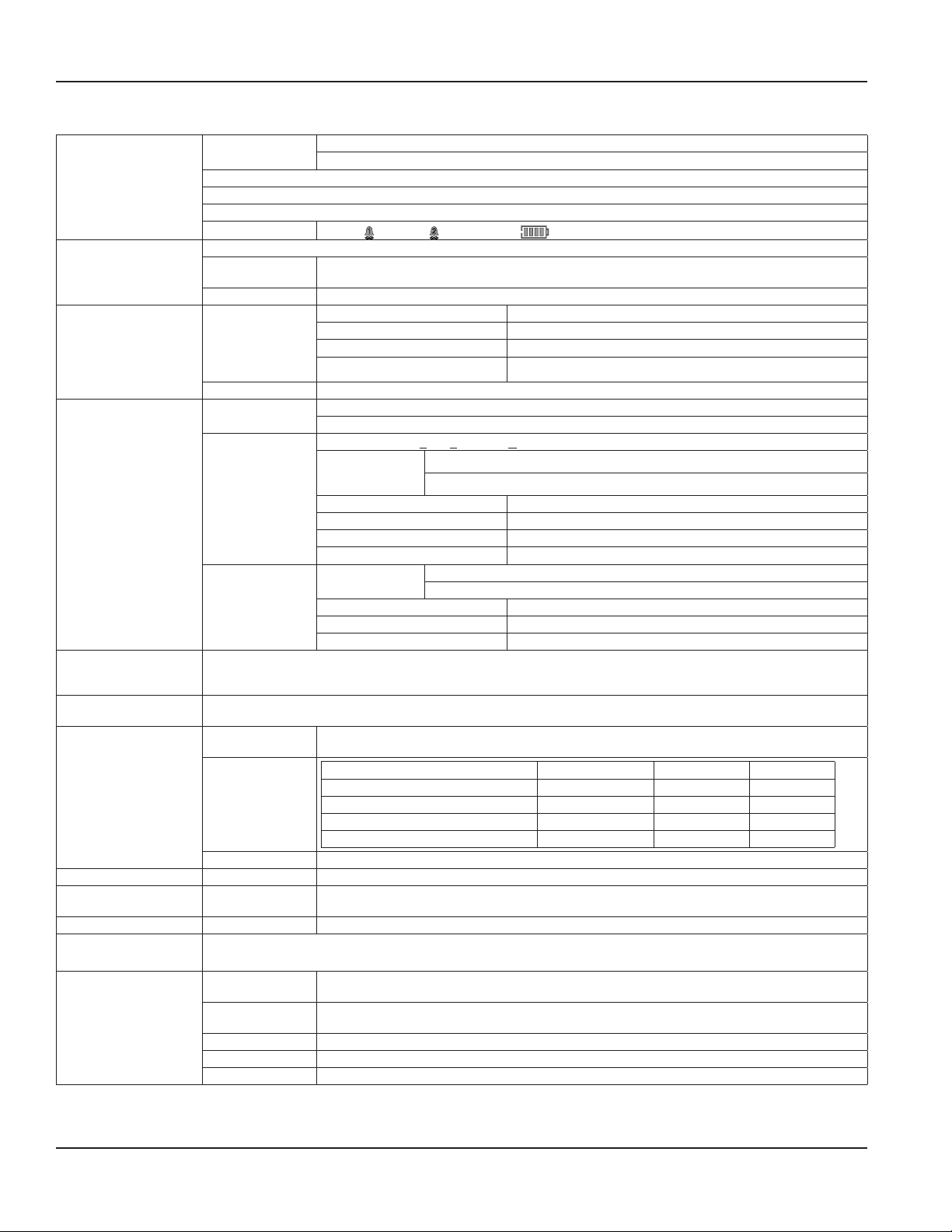

Specications

COM

SPECIFICATIONS

Simultaneously shows Rate and Total

5 x 7 Dot Matrix LCD, STN Fluid

Display

Common

6 Digit Rate, 0.5 inch (12.7 mm) numeric

7 Digit Total, 0.5 inch (12.7 mm) numeric

Engineering Unit Labels 0.34 in. (8.6 mm)

Annunciators

Alarm 1(1), Alarm 2 (2), Battery Level ( ), RS485 Communications (

Auto switching between internal battery and external loop power; includes isolation between loop power and other I/O

Power

Battery

3.6V DC lithium D Cell gives up to 6 years of service life

Note: Modbus enabled at baud rate of 19,200 or higher without loop power reduces battery life to 1 year

Loop 4…20 mA, two wire, 25 mA limit, reverse polarity protected, 7V DC loop loss

Frequency Range 1…3500 Hz

Frequency Measurement Accuracy ±0.1%

Inputs

Magnetic Pickup

Over Voltage Protection 28V DC

Trigger Sensitivity 30 mV

(High) or 60 mV

p-p

Amplified Pulse Direct connection to amplified signal (pre-amp output from sensor)

Analog 4…20 mA

4…20 mA, two-wire current loop

25 mA current limit

One pulse for each Least Significant Digit (LSD) increment of the totalizer

Outputs

Totalizing Pulse

Pulse Type

(selected by circuit

board jumper)

Maximum Voltage 28V DC

Maximum Current Capacity 100 mA

Opto-isolated (Iso) open collector transistor

Non-isolated open drain FET

Maximum Output Frequency 16 Hz

Pulse Width 30 mSec fixed

Open collector transistor

Adjustable flow rate with programmable dead band and phase.

Status Alarms

Type

Maximum Voltage 28V DC

Maximum Current 100 mA

Pullup Resistor External required: 2.2 k ohm minimum, 10 k ohm maximum

Modbus Digital

Communications

Data Configuration and

Protection

Modbus RTU over RS485, 127 addressable units / 2-wire plus ground network, selectable baud rate: 9600, 19200, 38400, 57600

or 115200, long integer and single precision IEEE754 formats; retrieve: flow rate, job totalizer, grand totalizer, alarm status and

battery level; write: reset job totalizer, reset grand totalizer

Two four-digit user selectable passwords; level one password enables job total reset only, level two password enables all

configuration and totalizer reset functions

Safety

Intrinsically Safe

Class I Division 1, Groups C, D; Class II, Division 1 Groups E, F, G

4…20 mA Loop: Vmax = 28V DC Imax = 26 mA Ci = 0.5 μF Li = 0 mH

Certifications

Entity Parameters

Pulse Output: Vmax = 28V DC Imax = 100 mA Ci = 0 μF Li = 0 mH

Reset Input: Vmax = 5V DC Imax = 5 mA Ci = 0 μF Li = 0 mH

RS485: Vmax = 10V DC Imax = 60 mA Ci = 0 μF Li = 0 mH

Turbine Input: Voc = 2.5V Isc = 1.8 mA Ca = 1.5 μF La = 1.65 H

EMC IEC61326-1; 2004/108/EC

Measurement Accuracy Common Accuracy 0.05%

Response Time

(Damping)

Common Response

Time

1…100 seconds response to a step change input, user adjustable

Environmental Limits Common Limits –22…158° F (–30…70° C); 0…90% humidity, non-condensing;

Materials and Enclosure

Ratings

Engineering Units

Polycarbonate, stainless steel, polyurethane, thermoplastic elastomer, acrylic; NEMA 4X/IP 66 meter, remote and swivel mount;

NEMA/UL/CSA Type 4X (IP-66)

Liquid

Gas

US Gallons, Liters, Oil Barrels (42 gallon), Liquid Barrels (31.5 gallon), Cubic Meters, Million Gallons, Cubic

Feet, Million Liters, Acre Feet

Cubic Feet, Thousand Cubic Feet, Million Cubic Feet, Standard Cubic Feet, Actual Cubic Feet, Normal

Cubic Meters, Actual Cubic Meters, Liters

Rate Time Seconds, minutes, hours, days

Totalizer Exponents 0.00, 0.0, X1, x10, x100, x1000

K-factor Units Pulses/US Gallon, Pulse/cubic meter, pulses/liter, pulses/cubic foot

)

(Low) - (selected by circuit board jumper)

p-p

DSY-DS-01565-EN-04Page 2 March 2018

Page 3

MOUNTING OPTIONS AND DIMENSIONS

Meter Mount

B

Mounting Options and Dimensions

C

D

dia

G

A

F

A in. (mm) B in. (mm) C in. (mm) D in. (mm) E in. (mm) F in. (mm) G dia in. (mm)

9.25 (235.0) 7.00 (177.8) 5.75 (146.0) 4.00 (101.6) 3.45 (87.6) 1.50 (38.1) 0.875 (22.2)

E

Remote Mount

D

E

B

C

A

.25 in. dia

(6.4 mm)

(4 HOLES)

A in. (mm) B in. (mm) C in. (mm) D in. (mm) E in. (mm) F in. (mm) G in. (mm) H in. (mm) I dia in. (mm)

7.00 (177.8) 2.40 (61.0) 2.25 (57.2) 7.00 (177.8) 5.75 (146.0) 4.38 (111.2) 3.45 (87.6) 1.50 (38.1) 0.875 (22.2)

F

I

dia

G

H

Handheld

B

C

A

A in. (mm) B in. (mm) C in. (mm)

7.00 (177.8) 5.75 (146.0) 4.38 (111.2)

DSY-DS-01565-EN-04 Page 3 March 2018

Page 4

Flow Monitor, B2900 Series

Swivel Mount

C

D

B

A

E

G

dia

F

A in. (mm) B in. (mm) C in. (mm) D in. (mm) E in. (mm) F in. (mm) G dia in. (mm)

12.25 (311.2) 7.00 (177.8) 5.75 (146.0) 4.00 (101.6) 3.45 (87.6) 1.50 (38.1) 0.875 (22.2)

Control. Manage. Optimize.

Blancett is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Loading...

Loading...