Page 1

Turbine Flow Meter

B16D Series FloClean Sanitary

DESCRIPTION

The FloClean Sanitary turbine flow meter was developed for use

in the food, beverage and pharmaceutical industries. The 316L

stainless steel construction provides a durable and cost efficient

flow measurement system that offers excellent accuracy

and repeatability.

The FloClean uses the most up-to-date polishing technology

on all internal components and all materials comply with FDA

requirements. FloClean B16D Series meters have removable

thrust bearings for ease of cleaning and inspection, and meet

the requirements of 3-A Sanitary Standard number 28-04 for

use in clean-out-of-place (COP) and sanitize-out-of-place (SOP)

applications and carry the 3-A Sanitary symbol.

The FloClean output signal is a sine-wave that is proportional

to volumetric flow. With optional Blancett electronics, FloClean

provides local flow rate and volume totalization and interfaces with

most displays, PLCs and computers.

INSTALLATION

Install the flow meter with the flow arrow, which is etched on the

exterior of the meter body, pointing in the direction of fluid flow.

Install the meter horizontally with the magnetic pickup facing

upward. For optimum performance, the flow meter should be

installed with a minimum of 10 diameters upstream straight pipe

length and 5 diameters downstream straight pipe length.

REPAIR KITS

Factory calibrated replacement kits are available for field or factory

service. Both of the FloClean models are designed to allow for quick,

easy disassembly and replacement of internal components. The

repair kit contains two retaining rings, two rotor supports, one rotor

assembly and a K-factor tag.

TRB-DS-02185-EN-03 (September 2018)

Product Data Sheet

Page 2

Operating Principle

+1%

+%

AVG. K-FACTOR (K)

-%

STANDARD TURNDOWN APPROX. 10:1

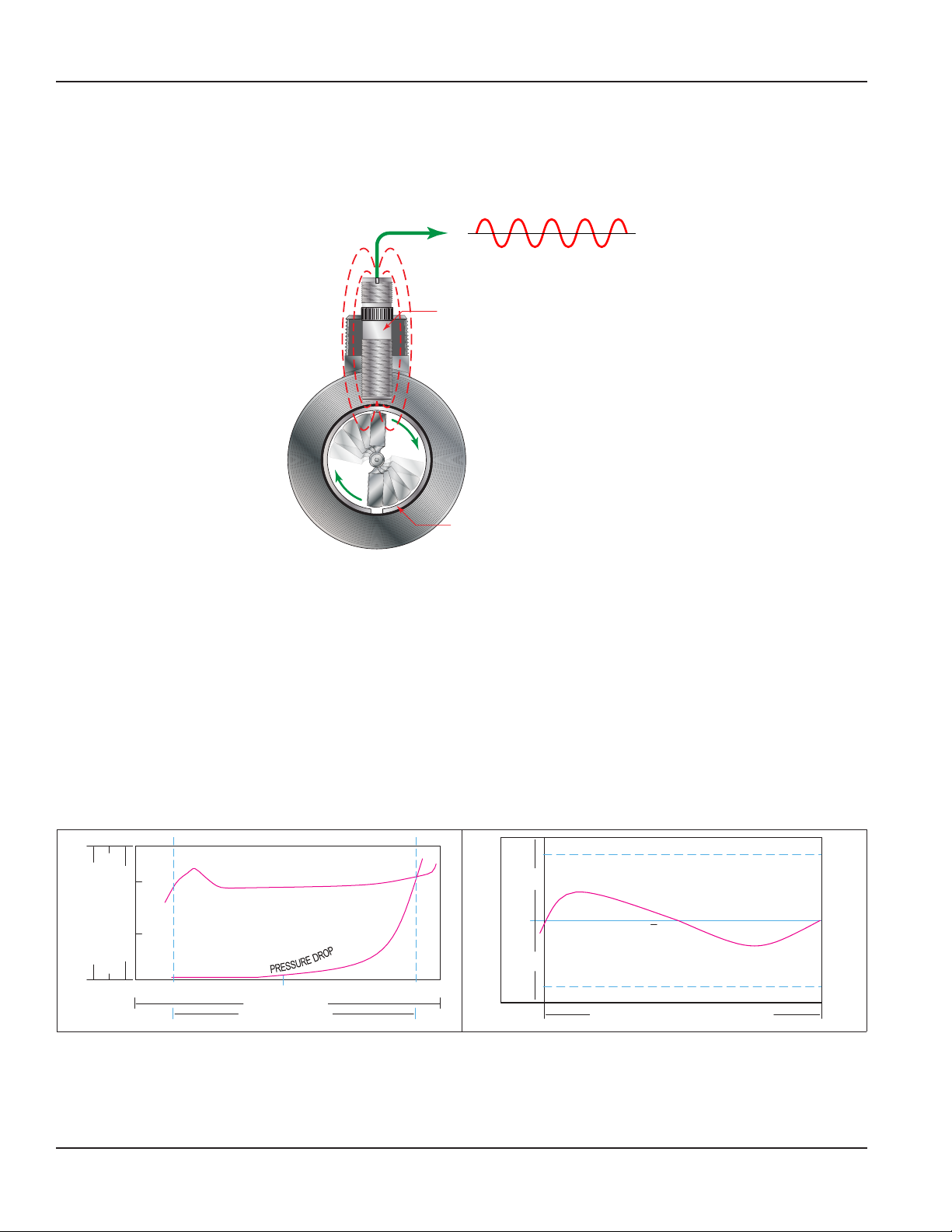

OPERATING PRINCIPLE

Fluid entering the meter first passes through an inlet flow straightener that reduces its turbulent flow pattern. Fluid then passes through

the turbine, causing the turbine to rotate at a speed proportional to fluid velocity. As each turbine blade passes through the magnetic field

generated by the meter’s magnetic pickup, an AC voltage pulse is generated. These pulses provide an output frequency that is proportional

to volumetric flow.

Output Signal

Magnetic

Pickup

Rotor

Figure 1: B142 turbine flow meter

KFACTOR

The K-factor represents the number of output pulses transmitted per gallon of fluid passing through the turbine meter. Each turbine has a

unique K-factor. However, turbine meters are not functionally consistent throughout the full flow range of the meter.

There are several forms of friction inherent in turbine meters that slow down the rotational movement of the turbine rotor. These frictional

forces include: magnetic drag, created by electromagnetic force of pickup transducers; mechanical drag, due to bearing friction; and viscous

drag, produced by flowing fluid.

See charts below.

As flow increases, the frictional forces are minimized and the free-wheeling motion of the turbine rotor becomes more linear (proportional

to flow). The K-factor becomes relatively constant and linear throughout the balance of the linear flow range. This is approximately a 10:1

turndown ratio from the maximum flow rate down to the minimum flow rate.

Typical K-factor Curve (Pulse per US Gallon)

100%

RATE

(CYCLES/SEC)

FLOW

AT

(CYCLES/GALLON)

LUE

A

50%

V

FREQUENCY

CTOR

A

OF

%

K-F

OUTPUT

0% 10%

K-FACTOR (PULSES/GALLON)

50%

FULL FLOW RANGE

LINEAR FLOW RANGE

100%

LINEARITY (DESIGN DEVIATION)

-1%

K

-

F

A

C

T

O

R

(

P

S

U

L

)

N

O

L

L

A

G

/

E

TRB-DS-02185-EN-03Page 2 September 2018

Page 3

SPECIFICATIONS

C

A

B

Body 316L stainless steel

Rotor Nickel plated CD4MCU stainless steel

Materials of Construction

Operating Temperature –150…300° F (–100…149° C)

Pressure Rating 1,000 psi (Rating based on tri-clamp sanitary connection)

End Connections Sanitary clamp end

Turndown Ratio —

Accuracy ±1.0% of reading

Repeatability ±0.1%

Calibration Water (NIST traceable calibration)

Mag Pickup NEMA 6; –150…300° F (–100…149° C)

Certifications

Bearings Standard-nickle bindery tungsten carbide

Rotor Shaft Nickel bindery tungsten carbide

Rotor Support —

Specications

DIMENSIONS

Part No. Part Number Code

A

End to End

003

B16D-0XXA-XXX

005

3.00 in. (76.2 mm) 1.46 in. (37.1 mm) 0.984 in. (25.0 mm)

007

105

B16D-1XXA-XXX

107

108

4.00 in. (101.6 mm) 2.00 in. (50.8 mm) 1.984 in. (50.4 mm)

110

B16D-1XXA-XXX ¹

B16D-2XXA-XXX

115

220

6.25 in. (158.8 mm) 2.33 in. (59.2 mm) 1.984 in. (50.4 mm)

6.50 in. (165.1 mm) 3.20 in. (81.3 mm) 3.047 in. (77.4 mm)

B

Diameter

C

Ferrule Size

TRB-DS-02185-EN-03 Page 3 September 2018

Page 4

Part Number Information

PART NUMBER INFORMATION

Part

Number

Code

003

005

007

105

107

108

110

115

220

Bore Size

3/8 in.

(9.53 mm)

1/2 in.

(12.7 mm)

3/4 in.

(19.05 mm)

1/2 in.

(12.7 mm)

3/4 in.

(19.05 mm)

7/8 in .

(22.23 mm)

1 in.

(25.4 mm)

1-1/2 in.

(38.1 mm)

2 in.

(50.8 mm)

End

Connections

0.984 in.

(25.0 mm)

0.984 in.

(25.0 mm)

0.984 in.

(25.0 mm)

1.984 in.

(50.4 mm)

1.984 in.

(50.4 mm)

1.984 in.

(50.4 mm)

1.984 in.

(50.4 mm)

1.984 in.

(50.4 mm)

3.047 in.

(77.4 mm)

Max

PSI

1000

1000

1000

1000

1000

1000

1000

1000

1000

gpm (lpm) bpd m/d

0.60…3.00

(2.27…11.36)

0.75…7.50

(2.84…28.39)

2.00…15.00

(7.57…56.78)

0.75…7.50

(2.84…28.39)

2.00…15.00

(7.57…56.78)

3.00…30.00

(11.36…113.56)

5.00…50.00

(18.93…189.27)

15.00…180.00

(56.78…681.37)

40.00…400.00

(151.42…1514.16)

Flow Rate

Strainer

Mesh

20.57…102.86 3.27…16.35 — 20,000 —

21.71…257.14 4.09…40.88 — 13,000 —

68.57…514.29 10.90…81.76 — 2750 —

21.71…257.14 4.09…40.88 — 13,000 —

68.57…514.29 10.90…81.76 — 2750 —

102.86…1028.57 16.35…163.53 — 2686 —

171.43…1714.29 27.25…272.55 — 870 —

514.29…6171.43 81.76…981.18 — 330 —

1371.43…13714.29 218.04…2180.40 — 52 —

Approx.

K-Factor

Pulse/US

Gal

Weight

Meter

(lb)

Ferrule

(mm)

0.984

(24.99)

0.984

(24.99)

0.984

(24.99)

1.984

(50.39)

1.984

(50.39)

1.984

(50.39)

1.984

(50.39)

1.984

(50.39)

3.047

(77.39)

Repair Kits

Bore Size Ferrule Size Repair Kit Fits Meter Part Number Part Number Code Repair Kit Part Number

3/8 in. (9.53 mm) 0.984 in. (24.99 mm) B16D-003A-XXX 003 B16D-K03A

1/2 in. (12.7 mm) 0.984 in. (24.99 mm) B16D-005A-XXX 005 B16D-K05A

3/4 in. (19.05 mm) 0.984 in. (24.99 mm) B16D-007A-XXX 007 B16D-K07A

1/2 in. (12.7 mm) 1.984 in. (50.39 mm) B16D-105A-XXX 105 B16D-K05A

3/4 in. (19.05 mm) 1.984 in. (50.39 mm) B16D-107A-XXX 107 B16D-K07A

7/8 in. (22.23 mm) 1.984 in. (50.39 mm) B16D-108A-XXX 108 B16D-K08A

1 in. (25.4 mm) 1.984 in. (50.39 mm) B16D-110A-XXX 110 B16D-K10A

1-1/2 in. (38.1 mm) 1.984 in. (50.39 mm) B16D-115A-XXX 115 B16D-K15A

2 in. (50.8 mm) 3.047 in. (77.39 mm) B16D-220A-XXX 220 B16D-K20A

Size

in.

End to

End

Length

in. (mm)

3.00

(76.2)

3.00

(76.2)

3.00

(76.2)

4.00

(101.60)

4.00

(101.60)

4.00

(101.60)

4.00

(101.60)

6.25

(158.8)

6.50

(165.1)

TRB-DS-02185-EN-03Page 4 September 2018

Page 5

PART NUMBERING CONSTRUCTION

1

M a gn etic | Standard

1

M agnetic w ith Pre-Am plifier | Standard

1

M agnetic w ith F/I Converter (Active 4…20 m A O utput)

1

M a gn etic | High Temperature (-450…450° F/-268…232° C)

1

M agnetic w ith F/V C onverter (Ac tive 0…5V D C O utput)

1

For Indoor Use Only

Part Numbering Construction

Blancett Turbine Flow Meters

B16D

-

A

FloClean: COP/SOP 3-A Compliant

FERRULE & METER SIZE

Ferrule: 0.984 in. | 3/4 in. Clamp x 3/8 in. Bore 003

Ferrule: 0.984 in. | 3/4 in. Clamp x 1/2 in. Bore 005

Ferrule: 0.984 in. | 3/4 in. Clamp x 3/4 in. Bore 007

Ferrule: 1.984 in. | 1-1/2 in. Clamp x 1/2 in. Bore 105

Ferrule: 1.984 in. | 1-1/2 in. Clamp x 3/4 in. Bore 107

Ferrule: 1.984 in. | 1-1/2 in. Clamp x 7/8 in. Bore 108

Ferrule: 1.984 in. | 1-1/2 in. Clamp x 1 in. Bore 110

Ferrule: 1.984 in. | 1-1/2 in. Clamp x 1-1/2 in. Bore 115

Ferrule: 3.047 in. | 2-1/2 in. Clamp x 2 in. Bore 220

BEARING

Nickel Bindery; Tungsten Carbide A

PICKUP

M a gn etic | NEMA 6 0

M agnetic w ith Pre-Am plifier | NEMA 6 1

-

2

3

4

6

M agnetic w ith Pre-Am plifier | NEMA 6 (Less Zenor) 7

8

No Pickup 9

METER BODY HUB

W ith H u b | 1/2 in. Hub for Ferrule Size 0.984; 1 in. Hub for 1.984 in. and 3.047 in A

No Hub B

CALIBRATION

5-Point | Standard A

10-Point B

20-Point C

Example Part Num ber: B16D -110A-2AA

TRB-DS-02185-EN-03 Page 5 September 2018

Page 6

Turbine Flow Meter, B16D Series FloClean Sanitary

INTENTIONAL BLANK PAGE

Page 6 September 2018TRB-DS-02185-EN-03

Page 7

INTENTIONAL BLANK PAGE

Product Data Sheet

Page 7 September 2018 TRB-DS-02185-EN-03

Page 8

Turbine Flow Meter, B16D Series FloClean Sanitary

Control. Manage. Optimize.

Blancett is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: Form No. 1300

Loading...

Loading...