Blancett B1500 Specifications

Turbine Flow Meter

B1500

DESCRIPTION

Blancett B1500 turbine flow meters have exceptional mechanical

linearity, resulting in minimizing, or negating, temperature induced

viscosity influence. Meters come with national pipe thread (NPT)

or flange process fittings, sizes up to two inches and can be

ordered with a Blancett B3000 flow monitor for advanced

linearization and to accommodate the requirements of most

applications and flow ranges.

Features Benefits

Expanded

mechanical linearity

Helical rotor design

High-performance

ceramic ball bearings

6-bladed rotor

supports

Facility with NIST

traceable standards

OPERATING PRINCIPLE

As a fluid passes through the meter, the velocity of the fluid

provides rotational energy on the rotor blade assembly. The rotor

blades, passing through a magnetic field (produced by the pickoff),

generate pulses proportional to flow. Each pulse is transmitted to

the flow monitor, where the monitor calculates the flow relative to

received pulses and meter size.

APPLICATIONS

Blancett B1500 flow meters are the ideal solutions for standard

clean, filtered liquid flow applications in precision industrial

processes, found in the chemical/petrochemical, refining and

general industries.

Increased usable flow range with less

sensitivity to fluid temperature/viscosity

effects.

Exceptional speed-of-response, with

reduced pressure drop.

Ceramic bearings provide near-perfect

roundness, higher Rockwell hardness

and are lighter and more tolerant to

temperature than 440C stainless steel

bearings. They eliminate adhesive wear

and perform well in non-lubricating

liquids found in cryogenic fluids

and water.

Improved flow conditioning.

Third party audits to ensure calibration

uncertainty. Laboratory correlation to

verify that all calibrators produce the

same result.

Shown with Blancett B3000

CONSTRUCTION

Blancett B1500 flow meters feature 316 stainless steel housings.

Wetted materials include axial helical rotors, made of 17-4 stainless

steel, that rotate on ceramic ball bearings. The supports and all

other materials are made from 300 series stainless steel.

METER INSTALLATION

Blancett B1500 flow meters mount directly in the piping and

can be installed in any position without affecting performance.

For optimal performance, recalibrate the meter if the mounting

orientation is changed from the original horizontal calibration.

To reduce flow turbulence, install a minimum of 10 diameters in

length of straight piping upstream and a minimum of five pipe

diameters downstream. If this cannot be accommodated due to

space limitations, pay careful attention to the location of valves

and bends. To compensate for piping bends, meters can be

calibrated in the same piping configuration. For best performance

and longevity, upstream filtration (10…75 micron, depending on

meter size), is helpful to prevent bearing contamination and to

avoid rotor blade damage.

CALIBRATION

Meters come with a best-in-class 10-point calibration, traceable to

NIST standards, using calibration solvent.

TRB-DS-01799-EN-02 (June 2016)

Product Data Sheet

Optional System Conguration

Model

Blancett B1500 Turbine Flow Meter B150

Meter Size

1/4 in. (6.3 mm) Bore | 1/2 in. (12.7 mm) End Fitting 501

3/8 in. (9.5 mm) Bore | 1/2 in. (12.7 mm) End Fitting 502

End Fitting

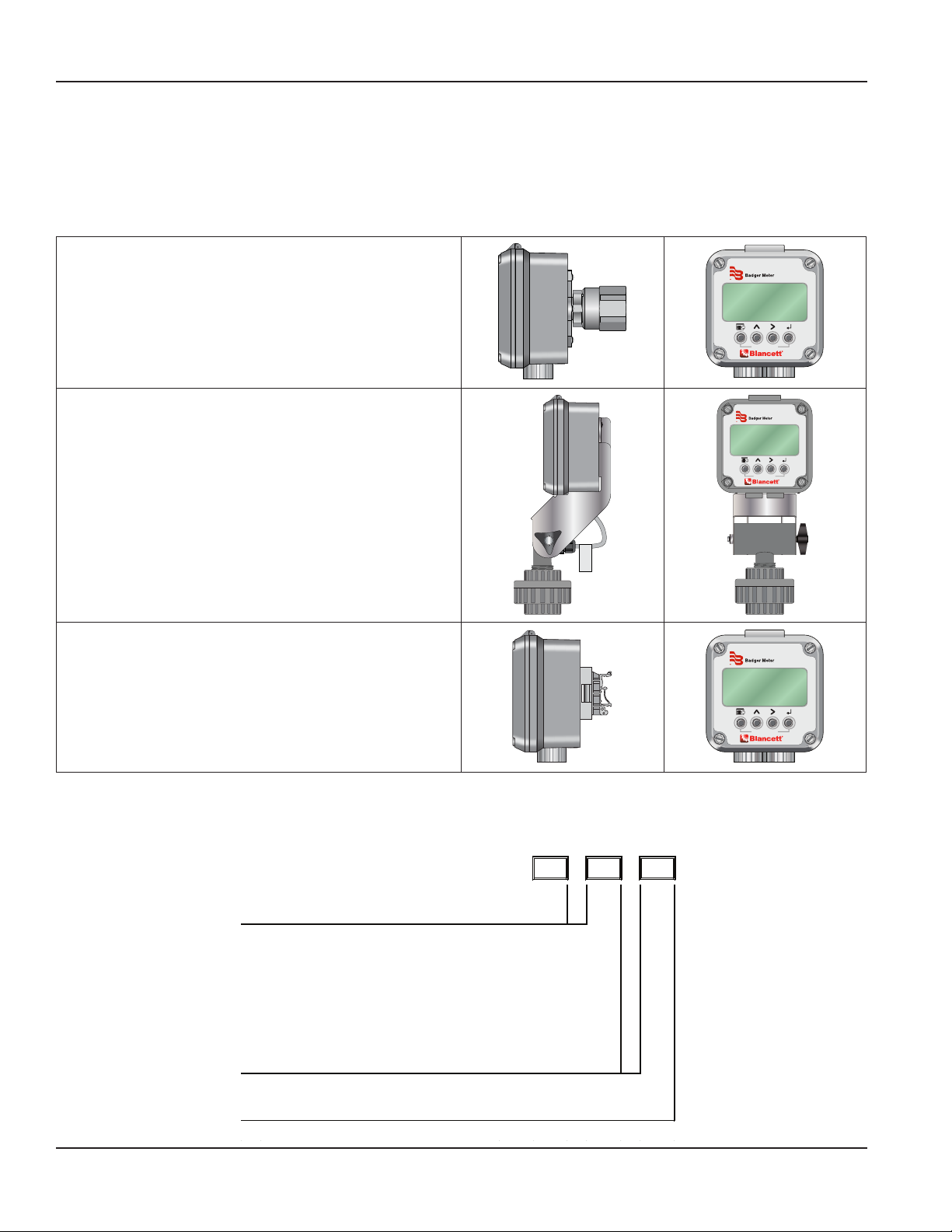

OPTIONAL SYSTEM CONFIGURATION

As an added benefit, B1500 flow meters that are coupled to B3000 flow monitors provide an economical, robust flow metering solution,

with multiple local read and system integration options. Flow rates and totals are presented simultaneously via a crisp dot-matrix LCD

display and/or transmitted to a user interface via Modbus RTU, a 4…20 mA analog output or totalizing pulse output. Basic, advanced and

solar-powered configurations provide users with flexibility to meet the needs of most applications. Product configurations can be mounted

in multiple ways, further expanding product flexibility to create a complete flow metering solution.

Meter Mount

• Monitor is assembled to the flow meter for a complete,

compact flow measurement system

• NEMA 4X (IP 66) rated enclosure

Swivel Mount

• Capable of adjustment pivot of 180 degrees for ease

of viewing

• NEMA 4X (IP 66) rated enclosure

• Remote Swivel mount is available, consult the factory

for details

• Offers additional protection from elements

Remote Mount

• Ideal when then monitor needs to be remotely mounted

• Suitable for high temperature, excessive noise or

inaccessible areas

• NEMA 4X (IP 66) rated enclosure

• Panel, DIN rail and pipe mounting hardware are included

• Cable lengths from 10…100 ft (3…30.5 m) are sold separately

For more information on the Blancett B3000 flow monitor, visit www.badgermeter.com.

B3000

TOTAL FLOW RESET

B3000

TOTAL FLOW RESET

B3000

TOTAL FLOW RESET

METER MODEL NUMBER

1/2 in. (12.7 mm) Bore | 1/2 in. (12.7 mm) End Fitting 503

5/8 in. (15.9 mm) End Fitting 625

3/4 in. (19.0 mm) End Fiting 750

1 in. (25.4 mm) End Fitting 110

1-1/4 in. (31.7 mm) End Fitting 125

1-1/2 in. (38.1 mm) End Fitting 115

2 in. (50.8 mm) End Fitting 120

National Pipe Thread NPT

150# ANSI Rasied Face Flange F15

Page 2 June 2016TRB-DS-01799-EN-02

- -

Loading...

Loading...