Page 1

SERVICE/PARTS MANUAL

Crockford Boulevard

BLAKESLEE

1844 South Laramie Avenue

Chicago, IL 60804

Phone: (708) 656-0660

BLAKESLEE

66

Scarborough Ontario, Canada M1R 3C3

Phone: (416) 751-2625

Page 2

TABLE OF CONTENTS

2

4

5

7

8

12

14

19

21

21

22

24

26

28

30

32

34

Page

INSTALLATION INSTRUCTIONS

DESIGN AND USE OF BEATERS, WHIPS & OTHER ACCESSORIES

MIXING INSTRUCTIONS

MIXING BOWL CAPACITY CHART

AVAILABLE BEATERS, WHIPS AND ACCESSORIES

OPERATION

TRANSMISSION REMOVAL AND DISASSEMBLY

TROUBLESHOOTING AND REPAIR INSTRUCTIONS

SUGGESTED SPARE PARTS LIST

ILLUSTRATED PARTS LIST

M-5-1505-E MIXER TRANSMISSION, MOTOR AND HOUSING

M-5-3330-D AND M-5-18769 MIXER TRANSMISSION. MOTOR AND HOUSING

MODEL F-30 COLUMN AND BASE ASSEMBLY

MODE LS B-12, W-12, B-20. W-20, F-20. U-20 SERIES COLUMN

AND BASE ASSEMBLY

M-5-1505-E TRANSMISSION ASSEMBLY

M-5-3330 TRANSMISSION ASSEMBLY AND BLAKESLEE HUB

AND M-5-18769 WITH UNIVERSAL HUB (TYPE B)

ELECTRICAL SYSTEM

Your Blakeslee-Built Mixer has been designed and engineered to assist you in

the quick and easy preparation of fine tasting, quality foods. It is a valuable

machine deserving the same maintenance and attention your automobile now

receives. By following the suggestions in this booklet, your mixer will operate

for many trouble-free years.

This booklet has been prepared to give you the necessary knowledge for

correct operation and maintenance of your Blakeslee-Built Mixer.

Every food service operator will be interested in the labor

savings that Blakeslee Mixers make possible. Each beater,

whip and attachment is engineered to perform specific jobs for

you. The planetary action of Blakeslee Mixers (beater travels

around the circumference of the bowl as it rotates) assures you

of a perfectly blended mix every time.

Diagram shows complete coverage of

bowl by planetary action of beaters.

1

Page 3

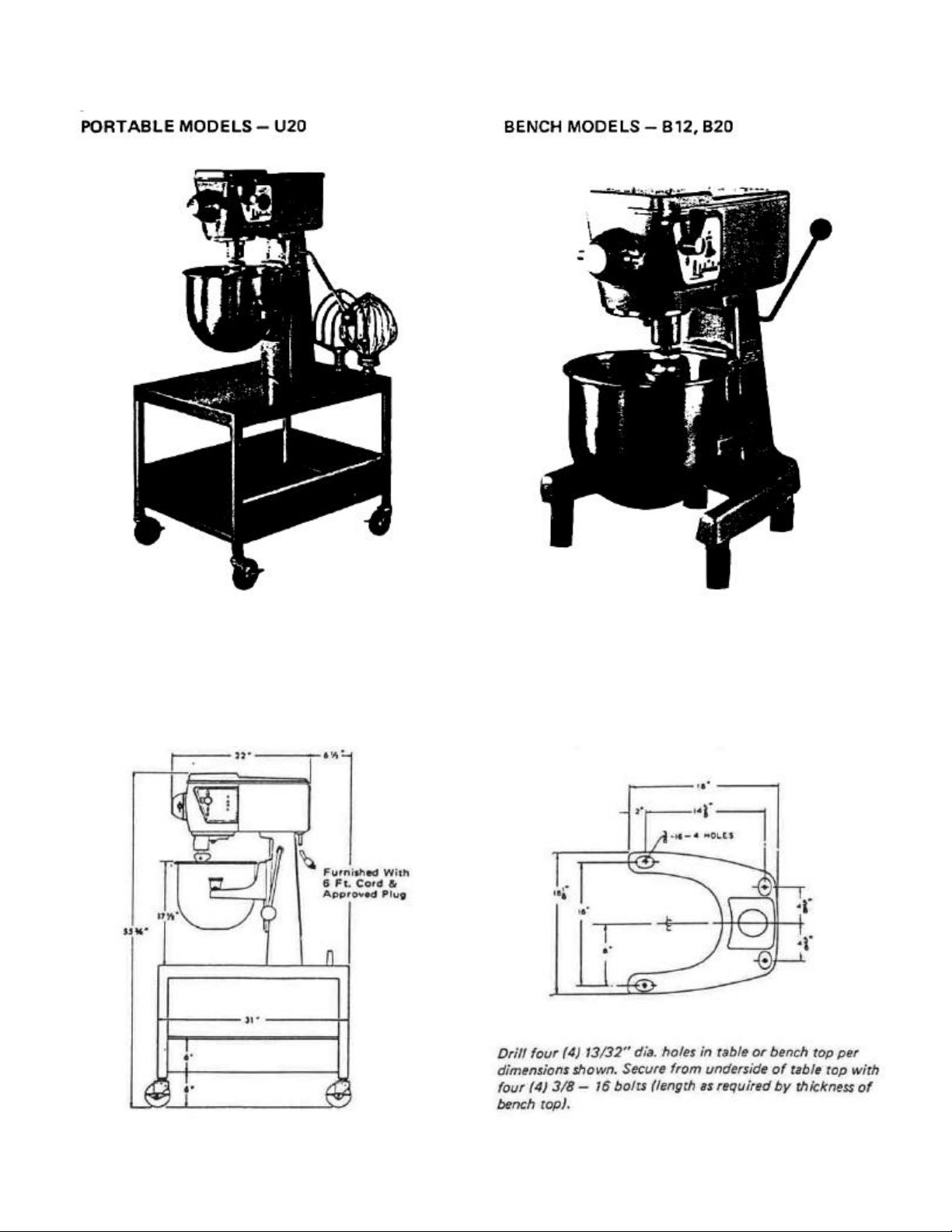

Installation Instructions

Portable model available only in 20 quart size.

1. Store beaters and whips at rear of table top.

2. Lock all four casters before using mixer.

3. Refer to General Installation Instructions for further

information.

Select a location for your mixer that will save

time and steps for the operator. Allow ample

work space in front and to the sides of the mixer.

Mixer should be mounted to a sturdily built table or

bench approximately 25 inches high. Mounting mixer

to bench will insure against mixer slipping on wet

surface or tipping over from pressure exerted as

attachments are used. Refer to mounting hole

dimensional diagram.

2

Page 4

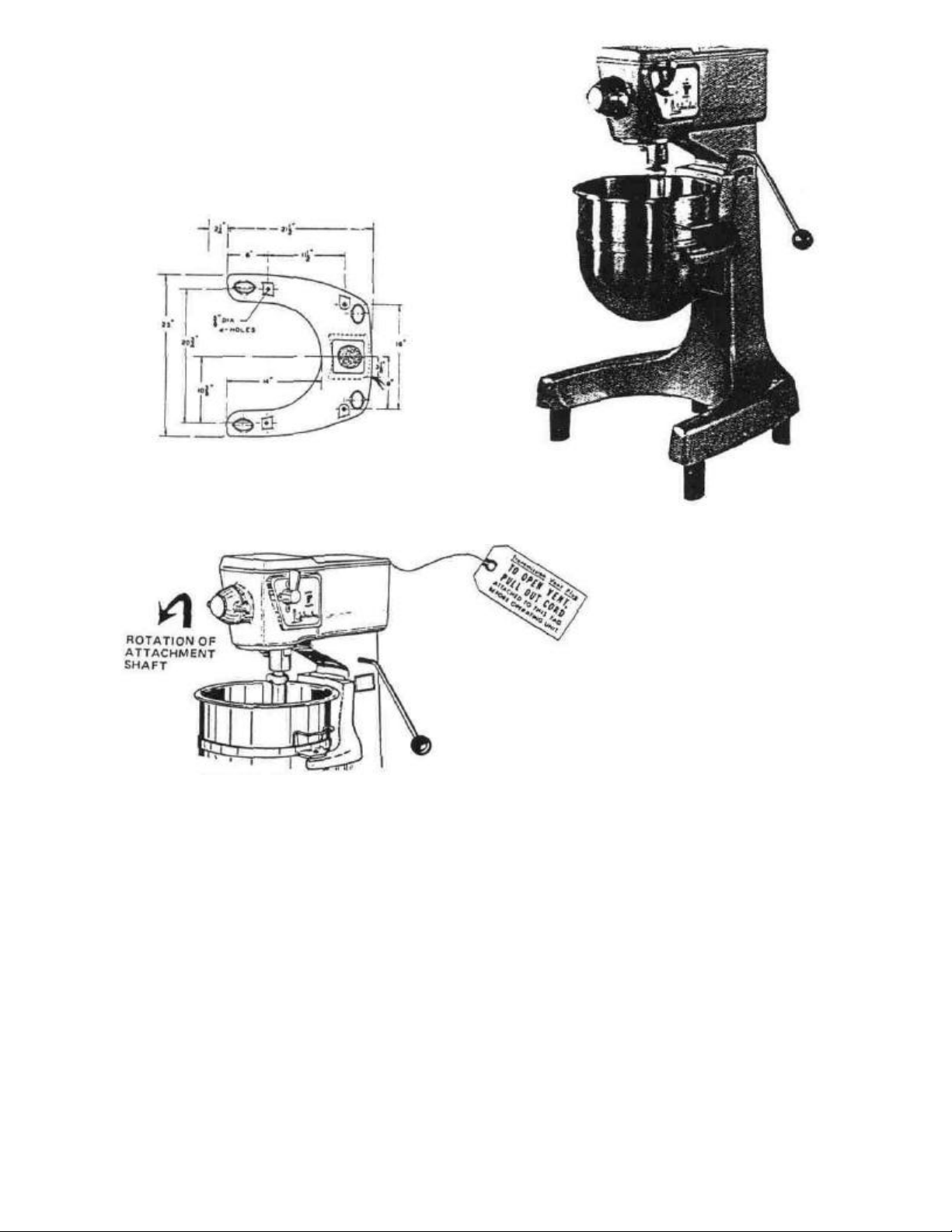

FLOOR MODELS F20, F30

Holes are provided for anchoring the mixer to the

floor, but unless desired, bolting to the floor is not

necessary except on shipboard use.

GENERAL FOR ALL MODELS

1. VENT PLUG SEAL REMOVAL

Remove vent plug seal from

transmission case. Vent plug has been

sealed with wax for shipment. To

remove seal, pull on tagged string. Seal

will completely pull out leaving vent open

and machine ready to run.

2. ELECTRICAL CONNECTIONS

CAUTION: Before making electrical connections be sure that current and voltage of the mixer are identical to those of electrical

inlet lines.

12 and 20 quart, 110 volt mixers are furnished with a six (6) foot flexible cord. Cords for single phase motors are supplied with a 3

prong plug. Cords for 3 phase motors are supplied with a 4 prong plug.

On 30 quart mixers the line cord is to be supplied by the customer. Connections are made inside the mixer column through

cover plate located on back side of column near the bottom. NOTE: A six (6) foot flexible, three (3) prong plug cord is

available as an extra cost option.

IMPORTANT: On 3 phase mixers, after electrical connection has been made, be sure the mixer operates in a counter-clockwise

direction as indicated by the arrow located above the attachment. Remove hub cover to observe shaft rotation. If electrical

connection is reversed the transmission will not shift, nor will the planetary action function.

3. TRANSMISSION OIL

After the first 200 hours of operation and every 6 months or 1000 hours of operation thereafter the transmission oil must be

changed.

When adding or changing transmission oil use #50 heavy duty oil (Hydrol Master 500 or equivalent)

3 pints — M-5-3330 Trans.

4 pints — M-5-1505 Trans.

3

Page 5

beaters or to the mixer proper.

Design and Use of Beaters, Whips & Other Accessories

Each beater and whip has been designed to do a particular type of work. Use only that beater or whip for the work for which it was

designed. For example: Never use a batter beater for mixing heavy doughs. Always use an "H" dough hook for dough work.

Following are illustrations of the different types of beaters and whips with an explanation of the work and the use for which they

were designed.

BOWL EXTENSIONS

Extension Rims are merely vertical sided

Splash Covers. They are not covers in

form, but do provide higher side walls to

prevent throw-out of ingredients. Usually

they are not recommended because they

are often invitations to overloading a

machine beyond its point of maximum efficiency. Extension

rims permit more air to enter the bowl and prevents splash of

light ingredients. The true capacity of a Mixer is not the

amount of material that can be put in the bowl or the amount

of total batch which can be mixed within the power of the

motor. The true capacities and the most efficient (therefore the

best money makers) are the ideal loads which permit a Mixer

to operate at peak efficiency, so far as development, yield or

aeration have their effect on the mixing operation.

SPLASH COVERS

These items provide means for reducing

splash or throw-out on certain mixes

when, for reasons of speed, the operator

prefers to start in a higher speed or

progress quickly to a high speed in order to complete a batch.

These are valuable accessories but should not be used to

increase the mixing capacity of any particular machine, beyond

its recommended maximum. They are convenience items, not

capacity increasers. The best functioning of Blakeslee Mixers

depends on leaving room for proper material aeration or

manipulation. Use Splash Covers or Extenders only for

containing ingredients. They are efficient for their intended

use, but if a Mixer is overloaded and a Splash Cover is used,

aeration is reduced due to restriction in the area where air

enters the mix. The capacity chart located on the column of the

Mixer is a good guide for maximum efficient use for the Mixer.

Experience will have to dictate exact top capacity and Splash

Cover use, under your own needs.

"H" DOUGH HOOK

Used for mixing bread or roll dough of

standard consistency, biscuits, meat loaf,

etc. Dough hooks should always be

operated at low speed only. Do not use

other types of beaters for dough work;

doing so will result in damage to either the

"PK" PASTRY KNIFE

Used for cutting flour and shortening

together in pie dough, pastry shells and

for cutting lard or shortening into flour.

The "PK" pastry knife should always be

used for such work so that pie crusts, etc.

are mixed with as little rubbing as

possible and so that the shortening will

be in small pieces to produce a flaky

product.

"B" BATTER BEATER

Furnished as part of standard equipment.

Used for mixing batters such as cake and

muffin batters, creaming butter, mashing

potatoes and vegetables, light cakes, icings

and the average run of light work. Never

use this beater for heavy dough work.

When mashing potatoes, etc., it is advisable

to start with the bowl at its lowest position

and then as the potatoes or other

ingredients break up, the bowl should be

gradually raised to its working position. This

procedure eliminates severe strain to the

beater and to the mixer proper and

consequently adds to their life and

efficiency.

BRUSH BEATERS

Used with soup strainer and colander

attachment for making creamed soups

such as pea, tomato, corn, potato, etc.,

also for making sauces such as cranberry sauce, applesauce, etc.

"W" WIRE WHIP

Furnished as part of standard equipment.

Used for whipping, creaming, beating eggs,

meringues, small amounts of mayonnaise,

icings and for whipping milk or cream into

mashed potatoes after they have been

broken up with "B" batter beater.

4

Page 6

FOR

BEST

RESULTS

Operators have their own pet ways of operating their mixing

machines, so no attempt will be made to set up iron clad

instructions, but there are certain general principles that

should be followed in the various operations. These general

principles as listed below should be helpful to old and new

operators.

GENERAL POINTS FOR PROPER OPERATION

NOTE

Refer to Mixing Chart before filling bowl.

1. Always start with the bowl in its lowest position.

NOTE

When mashing potatoes, kneading dough, or any

operation of a similar nature, it is advisable to start the

beating with the bowl at its lowest position and as the

potatoes or other ingredients break up, the bowl should

be gradually raised to its working position. This

procedure eliminates severe strain to the mixer and

consequently adds to its life and efficiency.

Mixing Instructions

WHIPPING CREAM

The "W" wire whip (refer to Beaters & Whip chart) should

be used for whipping cream. Cream to be whipped

should be 24 hours old, should contain 30% butter fat

and should be well chilled, in fact near freezing

temperature is desirable, since the cooler the cream, the

better the whipping. Warm cream may turn into butter

instead of whipped cream. Some operators like to use

the "jacket for bowl" attachment to surround the whipping

cream with cold water to maintain a cool temperature. To

prevent splashing out of the bowl, start whipping the

cream at slow speed and increase the speed as the

cream thickens, or use a "bowl splash cover" attachment

on the bowl.

2. In general, start all mixing at slow speed.

3. Gradually raise bowl and its contents to working

position.

4. Always return to slow speed when finishing a mix so

as to leave the mixer at low speed ready for next

operation.

5. In lowering the bowl keep pressure on the hand lever

to prevent too fast lowering of the bowl and undue

strain on the mixer.

6. Bowl should be filled to at least half capacity for best

results.

7. Make sure that bowl-to-beater clearance is about 1/8".

Place a 1/8" layer of paper on bottom of bowl to check

bowl-to-beater clearance. See page 12 for instructions

on how to raise or lower the bowl should adjustment

be necessary for proper bowl-to-beater clearance.

EGG WHITES

Use the "W" wire whip and be sure that the eggs are at

room temperature and that both the mixing bowl and "W"

wire whip are free from all traces of fat or oil, or egg

whites won't whip. In some installations one bowl will be

kept and used exclusively for beating egg whites.

Another bowl will be used exclusively for the oily type

mixes. Start beating the eggs at low speed and gradually

increase the speed.

MERINGUES

Use the "W" wire whip. Meringues can be made perfect

by the gradual addition of sugar to eggs which have not

been too stiffly beaten.

5

Page 7

MAYONNAISE

Use the "M" four wing whip (not available on 12 qt.

models): however, on light batches the "W" wire whip

can be used. The heavier construction of the "M" wing

whips makes it more suitable for better day-in and dayout making of mayonnaise. Depending on the quantity

of mayonnaise to be made, a 1 gallon, 2 gallon or 6

gallon Blakeslee-Built oil dropper attachment should be

used. This oil dropper attachment is attached to the

mixer and automatically adds oil to the batch at a

controlled rate of flow. Most mayonnaise recipes

contain whole eggs, corn or cottonseed oil, vinegar,

sugar, salt, mustard and white pepper. The eggs

should be placed in the mixing bowl first and beaten for

approximately five minutes at high speed. The speed

should then be reduced to slow speed and add dry

ingredients which have been mixed together. Mix at

high speed for approximately five minutes. Then the oil

dropper should be turned on so that the oil is gradually

added to the batch for 10 to 20 minutes, after which

time the vinegar is poured in slowly. The mixing should

be discontinued after the vinegar has been thoroughly

mixed into the batch. The last operation in making

mayonnaise involves stopping the mixer, scraping the

upper part of the bowl with a spatula to make sure that

every portion will be, evenly mixed into the recipe.

Mayonnaise becomes a thicker and more stable

product when the oil is added very slowly.

MASHING POTATOES

Use the "B" batter beater and pre-heat the bowl and

beater. Lower the mixing bowl before putting in the

potatoes to be mashed so that the breaking up starts

with the bowl at its lowest position; then as the

potatoes break up, gradually raise the bowl to its

working position. This procedure eliminates severe

strain to the mixer and the batter beater. Start the

operation on low speed. When the potatoes have been

broken up, stop the mixer and add the milk or cream,

butter and seasoning. Many operators like to change to

the "W" wire whip or to the "M" four wing whip for

whipping in the milk or cream since more of a whipping

action is obtained to produce a fluffier mashed potato.

bowl with a spatula to make sure that every portion will

be efficiently mixed into the recipe. Always operate the

mixer on slow speed while adding dry ingredients.

Many operators use the Blakeslee-Built bowl extension

ring to help confine ingredients to the mixing bowl. Add

dry ingredients alternately with liquid, starting and

ending with dry ingredients. Do most of the beating

before the flour and milk are added. Over beating after

addition of these two ingredients causes a substandard mixture.

MIXING DOUGH

Always use the "H" dough hook for mixing heavy

doughs. Do not overload the mixer with too large

batches. (See the capacity chart on page 7 of this

booklet for capacities of the various size bowls.) When

using the "H" and dough hook, the mixing should be

started at low speed only with the bowl in the lowest

position; then as the mixing continues the bowl should

be gradually raised to its working position. Remember

— an increased mixing time means a decreased

fermentation time. Weighing materials each mixing

time will insure a standard product. Stop the mixer

occasionally to lower the dough mass from the hook

and to scrape the bowl.

Important-In mixing heavy doughs be sure to use the

dough hook, be sure not to overload the mixer (see the

capacity chart on page 5). and be sure to start the

mixer on low speed with the bowl in its lowest position.

BISCUIT MIX

Use "W" wire whip and bowl extension ring (to confine

ingredients to bowl). Mix shortening and dry

ingredients until shortening is blended and mixture is

granular in appearance. Turn off mixer. Scrape bowl

down with bowl knife. Store in covered can until ready

for use. (Use beater or dough hook when adding liquid;

start mixing on slow speed and bowl in lowest position,

then gradually raise to working position. Do not over

mix.)

CAKE BATTERS AND COOKIE DOUGH

Use "B" batter beater. Butter or shortening can be

thoroughly creamed in about 10 minutes. The butter or

shortening should be at room temperature. Always

lower the bowl and start on slow speed and then

gradually raise the bowl to its working position. Sugar

should be added to recipes at a medium speed. When

all of the sugar has been added, stop the mixer and

scrape down the sides of the mixing bowl with a

spatula to insure a smooth mix. Be careful not to add

sugar until the butter or shortening has been

thoroughly creamed. Some recipes call for yolks and

whites to be beaten separately. This is not necessary

with your Blakeslee Mixer as the mechanical mixing is

efficient enough to allow the addition of whole eggs.

When adding dry ingredients, stop the mixer

occasionally and scrape the upper part of the

PASTRIES

Use the "PK" pastry knife, as pastries should be mixed

with as little "rubbing" as possible. The "PK" pastry

knife leaves the shortening in small pieces to produce

a flaky product. Remember, over-worked dough makes

tough pastry, and working in too much flour tends to

toughen pastry.

SWEET DOUGH

For best results use the "SD" sweet dough beater,

(20 & 30 qt. models only).

CREAMED SOUPS AND SAUCES

Use the puree beater or the "BB" brush beater with

the soup strainer and colander attachment for

making creamed soups and sauces.

6

Page 8

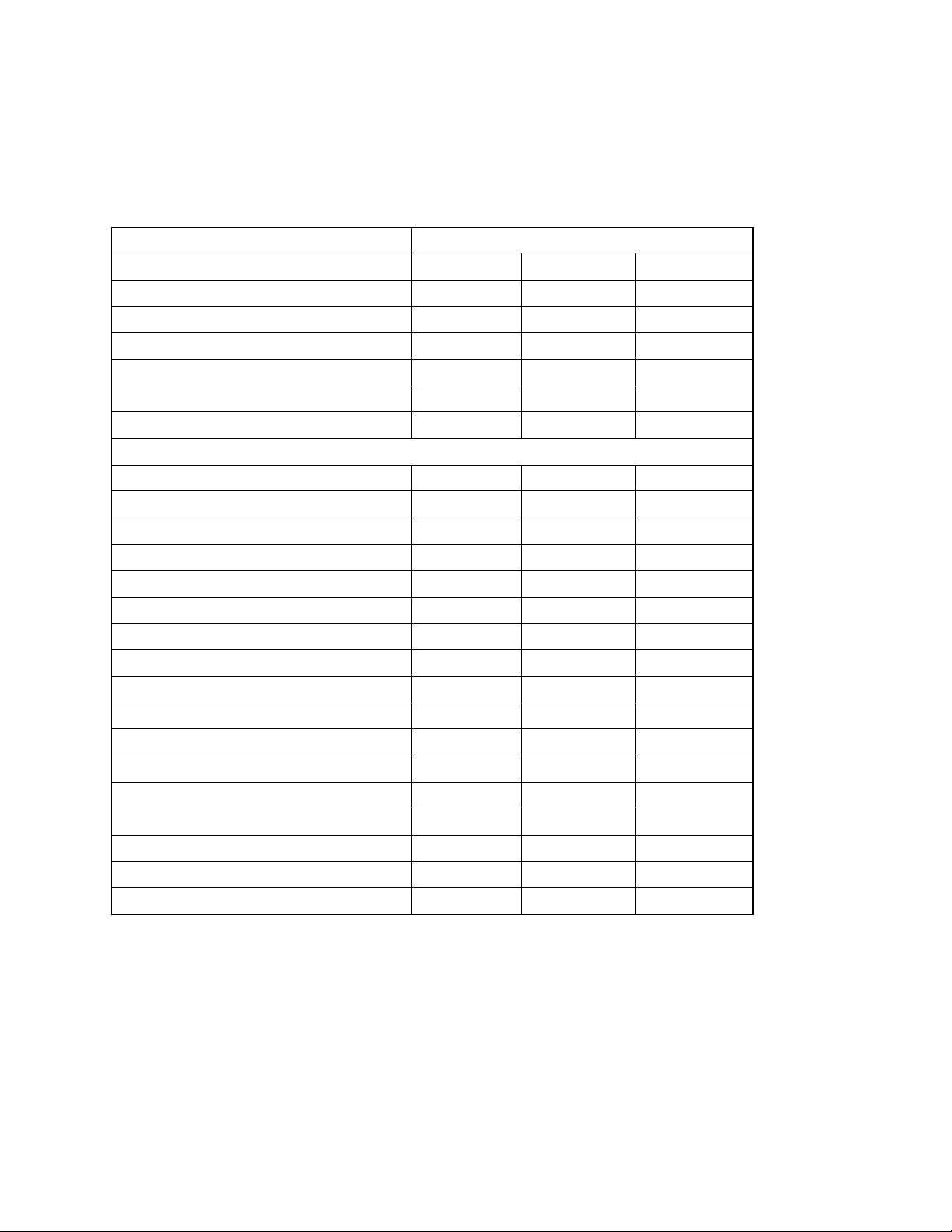

Mixing Bowl Capacity Chart

CAPACITY OF BOWL

KITCHEN MATERIALS 12 Qt. 20 Qt. 30 Qt.

Eggwhites 1-1/4 Pts. 1 Qt. 1-1/2 Qts.

Mashed potatoes 10 lbs. 15 lbs. 23 lbs.

Mayonnaise (qts. of oil) 5 Qts. 10 Qts. 12 Qts.

Meringue (pts. of water) 1 Pts. 1-1/2 Pts. 2 Pts.

Waffle or Hot Cake batter 5 Qts. 8 Qts. 12 Qts.

Whipped cream 2-1/2 Qts. 4 Qts. 6 Qts.

BAKE SHOP MATERIALS

Angel Food (8-10 oz. cake) 8 15 22

Box or Slab Cake 12 lbs. 21 lbs. 30 lbs.

Cup cakes 12 doz. 22 doz. 33 doz.

Layer cakes 12 lbs. 20 lbs. 30 lbs.

Pound cake 12 lbs. 21 lbs. 30 lbs.

Short sponge cake 8 lbs. 15 lbs. 23 lbs.

Sugar cookies 21 doz. 35 doz. 50 doz.

Bread or roll dough 13 lbs. 25 lbs.

Noodle dough 6 lbs. 8 lbs.

Pie dough 10 lbs. 17 lbs. 27 lbs.

Pizza dough 8 lbs. 14 lbs.

Raised doughnut dough 6 lbs. 9 lbs.

Eggs & sugar (for sponge cake) 5 lbs. 8 lbs. 12 lbs.

Fondant icing 7 lbs. 12 lbs. 18 lbs.

(1)

45 lbs.

(1)

10 lbs.

(1)

21lbs.

(2)

15 lbs.

(1)

(1)

(1)

(2)

Marshmallow icing 1-1/4 lbs. 2 lbs. 3 lbs.

Sponge cake batter 7 lbs. 12lbs. 18 lbs.

Shortening & sugar creamed 10 lbs. 16 lbs. 24 lbs.

(1) - First Speed only

(2) - Second Speed only

7

Page 9

QT. WITH

Available Beaters, Whips and Accessories

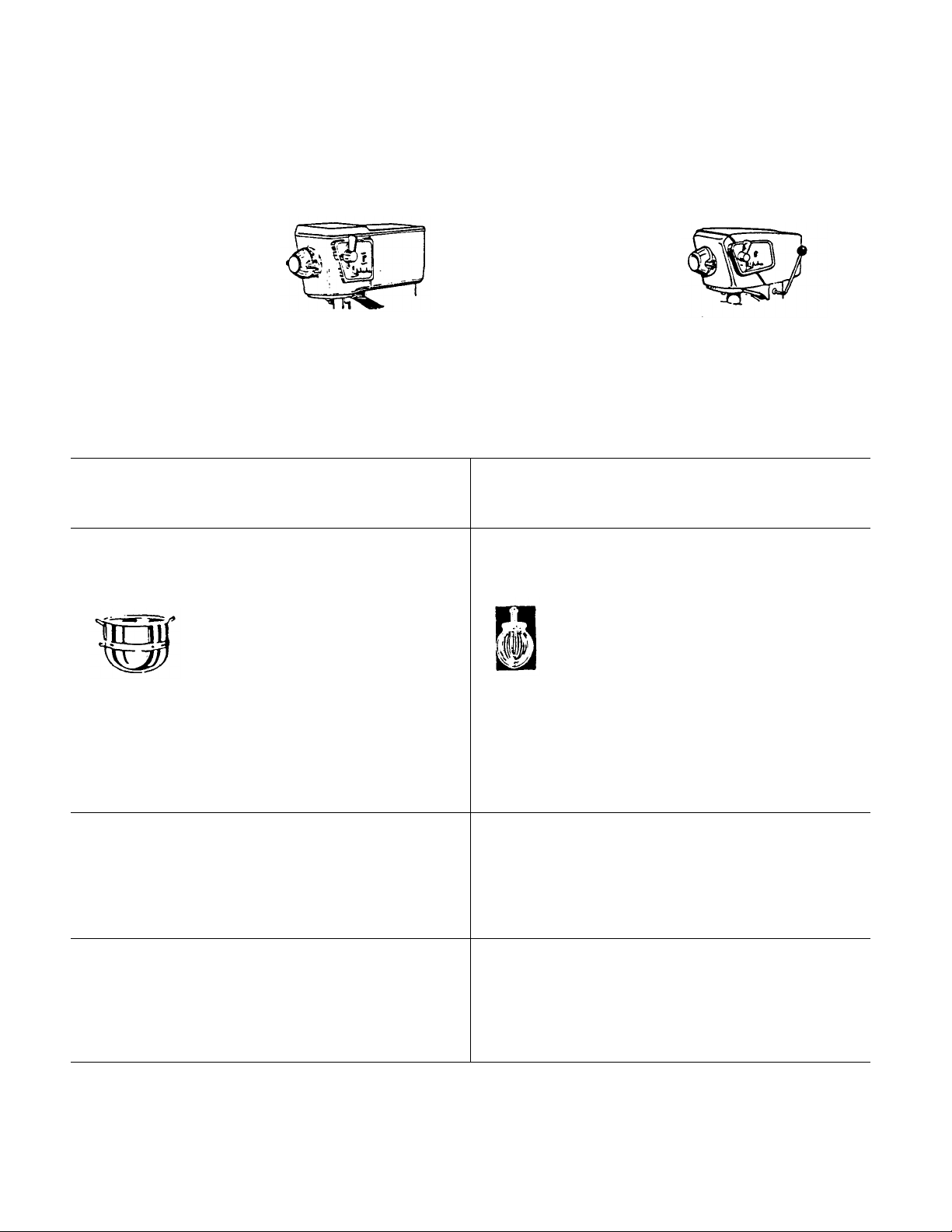

* NOTE — Early model mixers were equipped with M-5-1505 transmission. This can easily be determined by the outside

appearance. The M-5-1505 transmission is more round and has a plastic cover. The later model transmissions M-5-3330 and M-0-

18769 are more square and have an aluminum cover. (See sketch)

M-5-3330 & M-0-18769

TRANSMISSIONS

On 30 quart mixers, the bowls, beaters, whips etc. of the M-5-1505 transmission are not interchangeable with the M-5-3330 and

M-0-18769 transmissions.

The model number of the transmission can also be determined from the identification tag. The tag item 13. pages 28 & 30 is

located under the top cover 4, page 20 or 2, page 22.

The M-0-18769 transmission has a Type B universal attachment hub. Vegetable slicer and meat chopper attachments used on the

M-0-18769 transmission are not interchangeable with the type used on the M-5-1505 and M-5-3330 transmission. See page 10.

TRANSMISSION

M-5-1505

MIXER

MODEL

SIZE PART NO.

DESCRIPTION

MIXER

MODEL

SIZE PART NO. DESCRIPTION

BOWLS — NOTE: Smaller bowls can be used on next

size larger mixer. Bowl adaptors are not

WIRE WHIPS

required.

12 QT. 12 QT. M3-1354 Steel Tinned 12 QT. 12 QT. M3-1764 Steel Tinned

12 QT. 12 QT. M3-1715 Stainless Steel 12 QT. 12 QT. M3-3453 Stainless Steel

20 QT. 12 QT. M3-1447 Steel Tinned 20 QT. 12 QT. M3-1765 Steel Tinned

20 QT. 12 QT. M3-1716 Stainless Steel 20 QT. 12 QT. M3-3455 Stainless Steel

20 QT. 20 QT. M3-1349 Steel Tinned 20 QT. 20 QT. M3-1766 Steel Tinned

20 QT. 20 QT. M3-1717 Stainless Steel 20 QT. 20 QT. M3-3456 Stainless Steel

30 QT. WITH

M5-3330 & M5-18769 TRANSMISSION*

M5-3330 & M5-18769 TRANSMISSION*

30

30 QT. 20 QT. M3-1972 Steel Tinned 30 QT. 20 QT. M3-1767 Steel Tinned

30 QT. 20 QT. M3-3315 Stainless Steel 30 QT. 20 QT. M3-3458 Stainless Steel

30 QT. 30 QT. M4-1971 Steel Tinned 30 QT. 30 QT. M4-1977 Steel Tinned

30 QT. 30 QT. M4-3310 Stainless Steel 30 QT. 30 QT. M4-3459 Stainless Steel

30 QT. WITH M5-1505 TRANSMISSION * 30 QT. WITH M5-1505 TRANSMISSION *

30 QT. 20 QT. M3-1444 Steel Tinned 30 QT. 20 QT. M3-1767 Steel Tinned

30 QT. 20 QT. M3-1718 Stainless Steel 30 QT. 30 QT. M4-1768 Steel Tinned

30 QT. 30 QT. M41368 Steel Tinned

30 QT. 30 QT. M41719 Stainless Steel

8

Page 10

MIXER

30

QT. 30

QT. M4-1978 Aluminum

Allows bowls to

30

QT. 30

QT. M4-1979 Alumin

um

30

QT. 30

QT. M4-3374 Aluminum

MODEL

BATTER BEATERS

12 QT. 12 QT. M3-1376 Aluminum 12 QT. 12 QT. M3-1541 Aluminum

20 QT. 12 QT. M3-1377 Aluminum 20 QT. 12 QT. M3-1543 Aluminum

20 QT. 20 QT. M3-1367 Aluminum 20 QT. 20 QT. M3-1538 Aluminum

30 QT. 20 QT. M3-1378 Aluminum 30 QT. 20 QT. M3-1544 Aluminum

30 QT. 30 QT. M4-1973 Aluminum 30 QT. 30 QT. M4-1976 Aluminum

30 QT. 20 QT. M3-1378 Aluminum 30 QT. 20 QT. M3-1544 Aluminum

30 QT. 30 QT. M3-1371 Aluminum 30 QT. 30 QT. M4-1540 Aluminum

SIZE PART NO. DESCRIPTION

30 QT. WITH M5-3330 TRANSMISSION * 30 QT. WITH M5-3330 TRANSMISSION *

30 QT. WITH M5-1505 TRANSMISSION * 30 QT. WITH M5-1505 TRANSMISSION *

MIXER

MODEL

P.K. PASTRY KNIFE

SIZE PART NO. DESCRIPTION

H. DOUGH HOOKS

12 QT. 12 QT. M3-1387 Aluminum 12 QT. 12 QT.

20 QT. 12 QT. M3-1517 Aluminum 20 QT. 12 QT.

20 QT. 20 QT. M4-1385 Aluminum 20 QT. 20 QT. M4-1542 Aluminum

30 QT. WITH M5-3330 TRANSMISSION * 30 QT. WITH M5-3330 TRANSMISSION *

30 QT. 20 QT. M4-1513 Aluminum 30 QT. 12 QT.

30 QT. 30 QT. M4-1987 Aluminum 30 QT. 20 QT. M4-1573 Aluminum

30 QT. WITH M5-1505 TRANSMISSION *

30 QT. 20 QT. M4-1513 Aluminum

30 QT. 30 QT. M4-1388 Aluminum 30 QT. 20 QT. M4-1573 Aluminum

S.D. SWEET DOUGH BEATERS

12 QT. 12 QT.

20 QT. 12 QT.

20 QT. 20 QT. M3-1394 Aluminum

30 QT. 20 QT. M3-1512 Aluminum

30 QT. WITH M5-3330 TRANSMISSION * 20 QT. 20 QT.

None

None

M-4 WING WHIP

30 QT. WITH M5-1505 TRANSMISSION *

30 QT. 30 QT. M4-1563 Aluminum

BOWL TRUCK be transported without carrying

12 QT. 12 QT.

30 QT. WITH M5-3330 TRANSMISSION *

N.A.

N.A.

N.A.

N.A.

N.A.

30 QT. WITH M5-1505 TRANSMISSION *

30 QT. 20 QT. M3-1512 Aluminum 30 QT. WITH M5-1505 TRANSMISSION *

30 QT. 30 QT. M4-1511 Aluminum 30 QT. 30 QT. M4-1546 Aluminum

9

Page 11

SOUP STRAINER AND COLLANDER

INCLUDES PUREE BEATER AND ONE

20 QT.

20 QT.

M2-

3387

1/8 Perf. Steel

30 QT.

30 QT.

M2-3388

1/8 Perf. Steel

MIXER

MODEL

SIZE PART NO. DESCRIPTION

SIEVE 1/16 PERFORATION

12 QT. 12 QT. M2-1611

20 QT. 20 QT. M2-1612

30 QT. 30 QT. M2-3381

30 QT. 30 QT. M2-1623

30 QT. WITH M5-3330 TRANSMISSION * 30 QT. WITH M5-1505 TRANSMISSION *

30 QT. WITH M5-1505 TRANSMISSION *

MIXER

MODEL

SIZE PART NO. DESCRIPTION

PUREE BEATER

12 QT. 12 QT. M2-1613 Stainless Steel

20 QT. 12 QT. M2-1613 Stainless Steel

20 QT. 20 QT. M2-1614 Stainless Steel

30 QT. WITH M5-3330 TRANSMISSION *

30 QT. 30 QT. M 2-1984 Stainless Steel

30 QT. 30 QT. M2-1622 Stainless Steel

EXTRA SIEVE FOR SOUP

STRAINER AND COLLANDER

Tinned

12 QT. 12 QT. M3-3383 3/32 Perf. Steel 30 QT. 20 QT. M2-1735 Stainless Steel

12 QT. 12 QT. M3-3386 1/8 Perf. Steel

20 QT. 20 QT. M3-1535 1/16 Perf. Steel

Tinned

20 QT. 20 QT. M 2-3384 3/32 Perf. Steel

Tinned

30 QT. 30 QT. M2-1608 1/16 Perf. Steel 20 QT. 12 QT. M2-1737 Stainless Steel

Tinned 20 QT. 20 QT. M2-1738 Stainless Steel

30 QT. 30 QT. M2-3385 3/32 Perf. Steel 30 QT. 20 QT. M2-1738 Stainless Steel

Tinned 30 QT. 30 QT. M2-1736 Stainless Steel

Tinned

Tinned

Tinned

Tinned

BOWL EXTENSION RING

12 QT. 12 QT. M2-1734 Stainless Steel

20 QT. 12 QT. M2-1734 Stainless Steel 12 QT. 12 QT. M3-1520 1/16 Perf. Steel

20 QT. 20 QT. M2-1735 Stainless Steel

SPLASH COVERS

12 QT. 12 QT. M2-1737 Stainless Steel

30 QT. 30 QT. M2-14618 Stainless Steel

10

Page 12

MODEL

12 QT.

M4-

3322 Aluminum

OBSOLETE Meat Chopper Assy

Above Includes Knife

Complete with Slicer

MIXER

SIZE PART NO. DESCRIPTION

RECEIVING PAN BRACKET AND OVER

SHELF, LESS PAN

20 QT. M4-3322 Aluminum

MIXER

MODEL

30 QT. 30 QT. M4-3322 Aluminum

30 QT. 30 QT. M4-1529 Aluminum

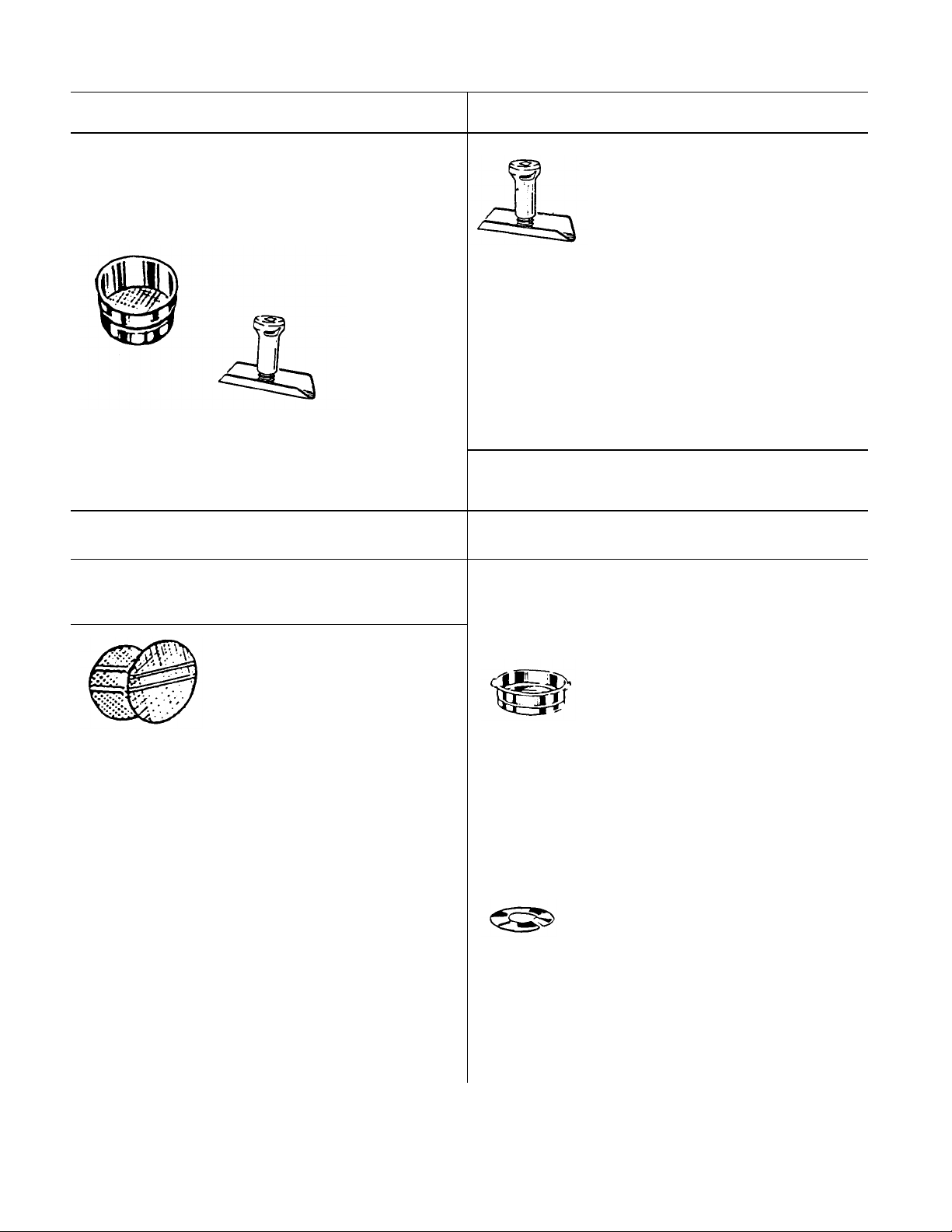

MEAT CHOPPERS - 12-20-30 QT MIXERS

UNIVERSAL TYPE HUB BLAKESLEE HUB

Used on Mixers Beginning with Used on Mixers with Serial # Up to

Serial #1 & Up and Including 1

M-0-20447 Meat Chopper Assy

(Doubled Tinned)

Above Includes Knife

& 1/8" Plate and Pusher

ACCESSORIES FOR MEAT CHOPPER (FOR BOTH BLAKESLEE & UNIVERSAL HUBS)

M-1-1901 Knife M-1-1903 End Plate, 3/16"

M-1-1902 End Plate, 1/8"

Perforations M-1-1904 End Plate, 1/4"

Perforations

Perforations

9" VEGETABLE SLICERS

UNIVERSAL TYPE HUB

Used on Mixers Beginning with

Serial #1 & Up Up to and Including 1

9" Vegetable Slicer OBSOLETE 9" Vegetable Slicer

Plate & Hopper Front

9" Cheese Shredder 9" Cheese Shredder

Complete with Hub & Shaft. M-0-70416 Complete with Hub & Shaft.

5/15" Shredder Plate 5/16* Shredder Plate

and Hopper Front. and Hopper Front.

BLAKESLEE HUB Used on All Mixers with Serial #

SIZE PART NO. DESCRIPTION

30 QT. WITH M5-3330 TRANSMISSION *

30 QT. WITH M5-1505 TRANSMISSION *

(Doubled Tinned)

& 1/5 Plate and Pusher

M-1-1905 End Plate, 3/8"

Perforations

M-1-1906 End Plate, 1/2"

Perforations

Complete with Slicer

Plate & Hopper Front

Adjustable Slicer Plate 9"

OPTIONAL EQUIPMENT FOR M-0-20581 SLICER OPTIONAL EQUIPMENT FOR M-0-70416

furnished w/vegetable slicer

Hub & Shaft Assy CHEESE SHREDDER

Julienne Plate 9" M-0-95042 Julienne Plate 9"

French Fry Plate 9" M-0-95044 French Fry Plate 9"

OPTIONAL EQUIPMENT FOR USE WITH EITHER SLICER

M-3-15071 Grater Disc M-2-15021 3/16" Shredder Disc. M-2-15019 5/16" Shredder Disc.

M-2-15088 3/32" Shredder Disc.

M-2-15072 1/2" Shredder Disc.

11

Page 13

Operation

1. Auxiliary Drive Socket

2. Speed Change Lever

3. "ON-OFF" Power Switch

4. Bowl Lift Hand Lever

5. Nameplate & Serial No.

6. Bowl Support

7. Attachment Spindle

8. Beater Shaft

CAUTION:

DO NOT ATTEMPT TO CHANGE ATTACHMENTS WHILE MIXER IS IN

OPERATION. ALWAYS SHUT OFF MIXER BEFORE PLACING HANDS OR

KITCHEN UTENSILS NEAR ATTACHMENT OR IN THE MIXING BOWL.

OPERATING BOWL LIFT

The bowl is raised to working position by means of a lever located

on the right-hand side of the mixer. Once raised, the bowl will be

automatically located in its proper operating position. The bowl lift

is pro-adjusted to stop at the proper working position before the

mixer is shipped from the factory.

ATTACHING BEATERS AND WHIPS

The beaters and whips used with your mixer have been

designed to make fastening of the attachments positive and

rapid.

To engage the attachment, line up the slots in the attachment

with the drive pin on the beater shaft. Raise the attachment

and twist to the right. When released, the attachment will

drop slightly into full locked position.

To remove the attachment, grasp near the top, raise slightly

while twisting to the left and slide downward.

12

Page 14

In order for your mixer to perform at top efficiency at all times, it is necessary that you follow the recommendations as laid

down by the designing engineers. Give your mixer the same attention you would give your automobile and your

BLAKESLEE-BUILT Mixer will give you many years of satisfactory service.

BOWL LIFT MECHANISM ADJUSTMENT

Bowl lift is factory set. However, should adjustment be necessary

do so as follows:

1. The mixers have adjustable stops to limit upward travel of the

bowl lift.

2. To adjust upward travel of lift (all models) loosen lock nut "B"

and turn bolt "A" clockwise to bring bottom of bowl closer to

attachment end or counter-clockwise to increase the distance

between the bottom of bowl and attachment end. Retighten

lock nut "B". CAUTION: Attachment must not rub on bottom of

bowl.

Operation

CHANGING SPEEDS

It is important to the life of the mixer, and to perfect mixing, to keep

the mix in constant motion. In Blakeslee-Built Mixers, which are

equipped with constant mesh gears and automatic clutch, the speed

may be varied by simply turning the mixer off, selecting the new

desired speed with the speed change lever, and then turn the mixer

back on.

NOTE: When mixing heavy loads, the Transmission should be

fully stopped before shifting speeds.

1 LOW 102 rpm 57 rpm

2 MEDIUM 180 rpm 101 rpm

3 HIGH 354 rpm 197 rpm

Beater Speed Auxiliary Drive

MOUNTING OF ACCESSORIES

Vegetable Slicer, Meat chopper. Knife Sharpener and Oil Dropper

all mount in a similar fashion to the "Auxiliary Drive Socket".

Illustration shows typical mounting using vegetable slicer.

1. Remove cover plate from auxiliary drive socket.

2. Turn thumb screws out so that it does not extend into drive

socket.

3. Insert hub of attachment into drive socket, rotating slightly until

it slides into place against mixer housing. Lubricate with a few

drops of mineral or salad oil.

4. Turn thumb screws to lock attachment in place.

5. Clean drain slot (A) after use.

13

Page 15

NOTE: TRANSMISSION ASSEMBLY DOES NOT HAVE

Transmission Removal and Disassembly

NOTE: REMOVAL AND DISASSEMBLY OF THE M-5-1505-E AND M-5-3330-A TRANSMISSIONS IS

ESSENTIALLY THE SAME. ONLY THE TOP COVER AND MOTOR ENCLOSURE ARE DIFFERENT.

REFER TO PARTS LIST EXPLODED VIEWS TO SEE THESE DIFFERENCES.

TO BE REMOVED FROM MIXER TO REPLACE

AUXILIARY HUB SEALS OR BEATER SHAFT

OIL SEAL. REFER TO DISASSEMBLY STEPS

1 &2.

REMOVAL:

(1) REMOVE DRAIN PLUG (1, FIGURE

1) AND DRAIN OIL FROM

TRANSMISSION.

(2) REMOVE THREE SCREWS (2) AND

LIFT COVER (3) OFF

TRANSMISSION. REMOVE

SCREWS (4) AND SCREEN (5).

(3) WITH SCREWDRIVER PRY OFF

SNAP PLUG (6) FROM SHIFT

LEVER. REMOVE SNAP RING (7)

AND PULL LEVER (8) OFF CAM

SHAFT. REMOVE SCREWS (9) AND

DROP NAMEPLATE (10) AWAY

FROM TRANSMISSION. TAG

ELECTRICAL WIRES FOR

REASSEMBLY IDENTIFICATION

AND DISCONNECT WIRE LEADS

FROM BACK OF TIMER OR TOGGLE SWITCH ON BACKSIDE OF

NAMEPLATE.

(4) USING SOCKET WRENCH AND 12

INCH EXTENSION REMOVE FOUR

LOCK NUTS (11) AND SLIDE

TRANSMISSION AND MOTOR

ASSEMBLY OUT FRONT OF

MOTOR HOUSING. REMOVE FOUR

SOCKET HEAD CAP-SCREWS (12)

AND SEPARATE MOTOR

ASSEMBLY FROM

TRANSMISSION. USE CARE TO

AVOID DAMAGING MOTOR

GASKET.

14

Page 16

15

DISASSEMBLY

1. REPLACEMENT OF AUXILIARY HUB AND SEALS.

NOTE: TRANSMISSION NEED NOT BE REMOVED

FROM MIXER IF ONLY AUX. HUB OR HUB SEALS

NEED REPLACEMENT.

A. REMOVE OIL FILLER PLUG (1, FIGURE 2),

INSERT 3/8 INCH LONG STEMMED ALLEN

WRENCH DOWN THROUGH FILLER PLUG HOLE

AND LOOSEN SETSCREW (APPROX. 3 TURNS).

WITH SCREWDRIVER BETWEEN HUB (8) AND

TRANSMISSION HOUSING, PRY HUB ASSEMBLY

(2) OUT OF TRANS. LIGHT HAMMER TAPS

AGAINST BACK OF HUB MAY BE REQUIRED.

B. PULL BEVEL PINION SHAFT (3) FROM HUB.

REMOVE CAP (5) AND BUSHING (7) FROM HUB

(8) WITH A PIECE OF PIPE INSERTED INTO BACK

OF HUB (SEE FIGURE 2A) TAP SEAL (6) OUT OF

HUB; REPLACE "0" RING SEAL (9). COAT NEW

SEAL (6) WITH LIQUID GASKET MATERIAL

BEFORE REASSEMBLING.

FIGURE 2A

Page 17

2. REPLACEMENT OF BEATER SHAFT AND SHAFT SEAL. NOTE: TRANSMISSION NEED NOT BE REMOVED FROM MIXER IF ONLY BEATER

SHAFT OR SEAL NEED REPLACEMENT.

A. INSERT SCREWDRIVER UNDER DRIP RING (1, FIGURE 3) AND PRY

OFF RING. UNSCREW SELF-LOCKING NUT (2) AND REMOVE WITH

WASHER (3): INSERT SCREWDRIVER BETWEEN TRANSMISSION

HOUSING AND BEATER SHAFT SUPPORT (4). REMOVE SUPPORT

AND SHAFT AS AN ASSEMBLY.

B. BEND TINES OF LOCKWASHER (5) OUT OF SLOTS IN LOCKNUT (6).

REMOVE LOCKNUT AND WASHER. SECURE SUPPORT (4) IN ARBOR

PRESS AND PRESS SHAFT (7) THROUGH THE BOTTOM OF SUPPORT.

GEAR (8) KEY (6) WILL COME OFF SHAFT AS IT IS PRESSED OUT.

PRESS BEARING (10) AND SEAL (11) OFF SHAFT.

C. INSTALL BEARING (10) ON SHAFT (7) AND PRESS INTO SUPPORT

(4). INSTALL GEAR (8) WITH KEY (9) AND SECURE WITH LOCKNUT

(6) AND LOCKWASHER (5). BEND TINES OF LOCKWASHER INTO

LOCKNUT SLOTS.

D. COAT NEW SEAL (11) WITH LIQUID GASKET MATERIAL ON OUTER

EDGE AND SLIDE OVER SHAFT (CUP SIDE UP AGAINST BEARING

(10) AND SEAT IN SUPPORT (4).

E. SLIDE SUPPORT AND SHAFT SUBASSEMBLY ON END OF SUN

SHAFT AND SECURE WITH SELF-LOCKING NUT (2) AND WASHER

(3). REINSTALL DRIP RING (1) BY PRESSING RING FIRMLY INTO

SLOT AROUND RING GEAR.

16

Page 18

3. REMOVAL OF SUN SHAFT. INTERMEDIATE & PINION

SHAFT AS SUBASSEMBLY.

A. REMOVE COVER SCREWS (1, FIGURE 4) AND

WASHERS (2).

B. LAY TRANSMISSION ON ITS SIDE AND WITH A LEAD OR

RUBBER MALLET LIGHTLY TAP THE END OF SUN SHAFT

(SEE FIGURE 4A). COVER WILL SEPARATE FROM

TRANSMISSION HOUSING. STAND TRANSMISSION UP

AND LIFT COVER AND SHAFTS OUT OF HOUSING.

NOTE: ROTATE GEARS AS NECESSARY TO CLEAR

TRANSMISSION HOUSING.

C. USING A PIPE AND MALLET, DRIVE OIL SEAL (3,

FIGURE 4) OUT OF BOTTOM OF TRANSMISSION

HOUSING. WHEN INSTALLING NEW SEAL, COAT OUTER

EDGE OF SEAL AND PRESS INTO HOUSING WITH METAL

SIDE OF SEAL TOWARD MIXING BOWL (DOWN).

D. REMOVE SCREWS (4), WASHERS (5) AND COVER (6).

REMOVE SNAP RINGS (7) AND PULL INTERMEDIATE (8)

AND PINION SHAFT (9) ASSEMBLIES TOGETHER, FROM

COVER.

E. PULL ROD (10) OUT OF COVER TO REMOVE SHIFTER

YOKE (11).

F. REMOVE SNAP RING (12). WITH A CENTER PUNCH. TAP

SUN SHAFT ASSEMBLY (13) OUT OF COVER (14).

17

Page 19

4. DISASSEMBLY OF SUN SHAFT ASSEMBLY. REFER

EXP. VIEW FIGURE 5.

A. REMOVE SPUR GEAR & SLEEVE (23), CLUTCH

(22), BEARING (21) AND SPACER (20) FROM

SHAFT AS AN ASSEMBLY.

B. IN AN ARBOR PRESS, PRESS CLUTCH (22) AND

BEARING (21) FROM GEAR (23). PRESS BEVEL

GEAR (25) OFF SHAFT. ITEMS 26, 27, 28 & 29

WILL SLIDE OFF SHAFT.

NOTE: WHEN REASSEMBLING NEW CLUTCH (22)

INTO GEAR (23) ARROW MARKED ON CLUTCH

MUST BE VISIBLE AS SHOWN IN FIGURE 6.

C. PRESS BEARING (53) OFF SHAFT. REMOVE

SNAP RING (52). ITEMS 47 THRU 51 WILL SLIDE

OFF SHAFT.

5. DISASSEMBLY OF INTERMEDIATE SHAFT. REFER

TO FIGURE 5.

A. PRESS BEARING (6) OFF SHAFT (14). REMOVE

SNAP RING (19) AND PRESS OFF GEAR (18). SLIDE

OFF SLEEVE (17) AND PRESS OFF GEAR (16).

NOTE: IN EARLY MODEL TRANSMISSIONS SHAFT

(14) HAD A MACHINED SHOULDER. BEGINNING IN

1971 HEAVY DUTY SHAFTS WERE USED WITH A

SPACER (14A) INSTEAD OF THE MACHINED

SHOULDER. WHEN REASSEMBLING SPACER (14A)

THE CHAMFERED END MUST FACE FIXED GEAR ON

SHAFT (SEE FIGURE 7).

6. DISASSEMBLY OF PIN ION SHAFT. REFER TO

FIGURE 5.

A. PRESS BEARING (6) OFF SHAFT (35). REMOVE

SNAP RING (38) AND PRESS OFF WORM GEAR (37).

REASSEMBLY & INSTALLATION

(1) REASSEMBLY SUBASSEMBLIES IN REVERSE

ORDER OF DISASSEMBLY AND INSTALL IN

REVERSE ORDER OF REMOVAL.

(2) REFILL TRANSMISSION WITH #50 HEAVY DUTY

OIL. (HYDROL MASTER 500 OR EQUIVALENT)

3 PINTS - M-5-3330 TRANS.

4 PINTS - M-5-1505 TRANS.

18

Page 20

Mixer will not start

Main fuse or circuit breaker out

Reset breaker and change all fuses.

Troubleshooting and Repair Instructions

TYPE OF TROUBLE POSSIBLE CAUSE

Motor runs but will not Speed change lever loose Remove handle, install key, replace

change speed

Unit runs hot or smokes Improper voltage on motor To be checked by electrician.

Attachments strike Bowl support out of adjustment Remove back inspection cover and

bottom of bowl

Attachments striking side Attachments bent or bowl dented Replace damaged part.

of bowl.

Bowl will not raise The drag link spring off of drag link Remove inspection cover from back of

Transmission operates Unit overloaded Shift to lower speed or reduce quantity

with a skipping motion

Bowl support hard to raise Bowl support binding on bowl slides Clean off bowl slides and lubricate with

and lower

Transmission operates in one Broken intermediate shaft Replace intermediate shaft (M-1-15074)

speed only and has a clicking

noise.

Overload switch tripped Push reset button.

Wire loose or broken Visually check all connections, controls

(On timed models)

The timer inoperative Replace timer

Mixer under too great a load Stop mixer, shift to another speed and

Shifting dog stripped or broken Gear box to be repaired after removal

or motor defective

Motor overloaded thus Have amperage draw checked by

overheating an electrician.

Gear box low on lubricant Drain out old oil, remove cover plate

arm machine, replace 2" long heavy spring on

Crank casting loose on drag link Remove inspection cover in back of

shaft machine, reposition crank casting, tighten

Chipped gear in gear box Remove gear box for bench repairs.

RECOMMENDED

CORRECTIVE PROCEDURE

and motor.

handle and snap lock ring.

restart unit.

to workbench.

(which covers the entire gear box and

motor assembly) insert three pints of

S.A.E. 50 oil in vent plug hole. (4 pints

in M5-1505 Transmission)

adjust stop bolt for bowl raising

mechanism located at base of unit.

rocker guide, install nut and washer on

drag link and lock in place by tightening

nuts.

set screws after being sure crank casting

key is in place on shaft.

of material being mixed.

light grade of oil.

in transmission.

19

Page 21

TYPE OF TROUBLE

POSSIBLE CAUSE RECOMMENDED CORRECTIVE

PROCEDURE

Motor runs but transmission does

not operate

Bronze worm gear failure Transmission operated when it was

Transmission runs attachment

shaft but beater shaft does

not turn

Bronze worm gear worn Replace bronze worm gear (M-1-1253-C) in

low on oil

Broken beater shaft or stripped

ring gear

20

transmission.

Check transmission for seal leaks.

Replace broken beater shaft (M-2-1250) or

stripped ring gear (M-2-1264).

Page 22

Suggested Spare Parts List

M-1-15143

Oil Seat. Motor

All Models

B,W,& F SERIES MIXERS

12, 20 and 30 Qt. LATE MODEL (M-5.3330 & M-5-18769) TRANSMISSIONS

Part No. Description Model

M-1-15315 Oil Seal, Sun Shaft All Models

M-1-15314 Oil Seal, Auxiliary Hub All Models

*W-1-12561 Oil Seal, Beater Shaft All Models

**M-0-18752 Oil Seal, Beater Shaft All Models

M-1-15141 "O" Ring, Motor All Models

M-0-17381 "O" Ring, Cam Shaft 902-14 All Models

M-0-17384 "O" Ring, Auxiliary Hub 902-36 All Models

M-2-3427 Gasket. Motor All Models

M-2-1252 Worm, Motor All Models

M-1-1253 Worm Gear All Models

M-2-1250-B Beater Shaft All Models

M-2-1396 Pin, Beater Shaft All Models

M-1-1344 Crank B-12,B-20,W-12,W-20 Only

M-1-1419 Crank F-20,U-20 Only

M-1-1528 Crank Stop F-20,U-20 Only

M-1-1967 Crank F-30 Only

M-2-1969 Drag Link F-30 Only

Electrical Switch Assy See "Motor Control"

Illustrated Parts List

IMPORTANT

When ordering parts please specify machine Model No. and Serial No.

Credit will not be issued for returned piece parts of an assembly.

21

Page 23

M-5-1505-E MIXER TRANSMISSION, MOTOR AND HOUSING

22

Page 24

Item

Part

No.

M-5-1505-E MIXER TRANSMISSION, MOTOR AND HOUSING

Description

M5-1505 TRANSMISSION

1 M5-1505-E TRANSMISSION, Complete, Reconditioned, Exchange 1

2 SEE CHART CONTROLLER 1

2a W0-95645 KNOB, Used With Timer Only 1

3a M3-1460 BAND, Motor Case Securing (for Plastic Cover) 1

3b M3-1568 BAND, Motor Case Securing (for Aluminum Cover) 1

4a M4-1631 MOTOR CASE (Plastic) 1

4b M4-1510 MOTOR CASE (Aluminum) Obsolete Not Available

5 W0-16367 SCREW, 10-24 x 1-1/4" R.H. Machine 1

6 M3-1558-A NAMEPLATE, Timer, 1PH & 3PH 1

7 M3-1480-A NAMEPLATE, Toggle 1PH & 3PH 1

8 Ml-15310 SCREWS, 8/32 x 3/8" Pan Head 2

9 M2-1458 LEVER, Gearshift 1

10 W0-17380 SNAP RING 1

11 M0-17379 PLUG, Snaphole, for M2-1458 1

12a M1-15112 MOTOR 1/4 H.P., 1 Phase (12 Qt. Models) 1

12b M1-15113 MOTOR 1/4 H.P., 3 Phase (12 Qt. Models) 1

12c M1-15117 MOTOR 1/2 H.P., 1 Phase (20 Qt. Models) 1

12d M1-15118 MOTOR 1/2 H.P., 3 Phase (20 Qt. Models) 1

12e M1-15119 MOTOR 3/4 H.P., 1 Phase (30 Qt. Models) 1

12f M1-15120 MOTOR 3/4 H.P., 3 Phase (30 Qt. Models) 1

13 M1-3573 SCREW, 3/8 x 1" Socket Head Machine Screw 4

14 M1-3424 GASKET 1

15 M1-15385 KEY, 1/8 x 1/8 x 1" Lg. 1

16 M1-15141 "O" RING 1

17 M1-15144 WASHER, 1/2 x 3/4" Copper Asbestos 1

18a M1-1491 SPACER (A. 0. Smith Motor) 1

18b M1-1539 SPACER (Howell Motor & Marathon) 1

19 M1-15143 OIL SEAL 1

20 M-1252 WORM 1

21 M1-15142 WASHER 1

22 M1-15145 NUT 1

23a M4-1430 MOTOR MOUNT BRACKET (12 Qt. Models) 1

23b M4-1430 MOTOR MOUNT BRACKET (20 Qt. Models) 1

23c M4-1430 MOTOR MOUNT BRACKET (30 Qt. Models) 1

24 M1-15366 CABLE ASSY, — Motor to Switch (3 ph. only - 208/230V) 1

24a M1-18594 CABLE ASSY, — Motor to Switch (3 ph. only - 440/480V) 1

25 M1-93650 CAUTION LABEL

NOTE: This transmission now discontinued; however, approximately the first 1,000 mixers were

equipped with this transmission. See pages 8-9 for current transmission which is M5-3330

transmission.

SPECIFY MACHINE SERIAL NO. WHEN ORDERING PARTS

23

Page 25

M-5-3330-D & M-5-18769 MIXER TRANSMISSION, MOTOR AND HOUSING

24

Page 26

No.

No.

Reqd.

M-5-3330-D & M-5-18769 MIXER TRANSMISSION, MOTOR AND HOUSING

Item

Φ la M5-3330-D TRANSMISSION, Reconditioned, Exchange 1

Φ1b

2 M3-1961 TOP COVER, Gearbox and Motor Housing 1

3 W1-12549 SCREWS, 1/4 x 1-1/4" Flat Head Machine 3

4a M4-1958 HOUSING, Motor, Cast Aluminum (12 Qt. Models) 1

4b M-3-72974 HOUSING, Motor, Cast Aluminum (20 Qt. Models) 1

4c M-3-72975 HOUSING, Motor, Cast Aluminum (30 Qt. Models) 1

5 M1-3451 COVER PLATE, for Rear of Motor Housing 1

6 W0-20279 SCREWS, 10-24 x 3/8" R. H. Cad. Plated 4

7a M2-3329 NAMEPLATE, M 5-3330 Transmission Tog. Switch-

7b M2-3327 NAMEPLATE & TIMER, 1 PH & 3 PH 1

7c M2-3325 NAMEPLATE, Tog. Switchtype w/Overload 1 PH Only 1

8 M0-17379 PLUG, Snaphole, for M2-1458 1

9 M0-17380 SNAP RING 1

10 M 2-14 58 LEVER, Gearshift 1

11 M-1-15310 SCREWS, 8/32 x 3/8" Pan Head 4

12 SEE CHART CONTROLLER 1

12a W0-95645 TIMER KNOB 1

13a M1-15112 MOTOR 1/4 H. P., 1 Phase (12 Qt. Models) 110V only 1

13b W0-189 03 210 M.F.D. CAPACITOR (for M1-15112 Motor only) 1

13c M1-15113 MOTOR 1/4 H. P., 3 Phase (12 Qt. Models) 1

13d M1-15117 MOTOR 1/2 H. P., 1 Phase (20 Qt. Models) 1

13e M0-20274 270-325 M.F.D. CAPACITOR (for M1-15117 Motor only) 1

13f M1-15118 MOTOR 1/2 H. P., 3 Phase (20 Qt. Models) 1

13g M1-15119 MOTOR 3/4 H. P., 1 Phase (30 Qt. Models) 1

13h W0-18904 540 M.F.D. CAPACITOR (for M1-15119 Motor only) 1

13i M1-15120 MOTOR 3/4 H. P., 3 Phase (30 Qt. Models) 1

13j W0-18512 MOTOR 3/4 H. P., 1 Phase, 1200 RPM Spl. Low-

13k W0-18504 MOTOR 3/4 H. P., 3 Phase, 1200 RPM Spl. Low-

14 M1-3573 SCREWS, 3/8 x 1" Socket Head Machine 4

15 M1-3427 GASKET 1

16 M1-15358 KEY, 1/8 x 1/8" 1

17 M1-15141 "O" RING 1

18 M1-15144 WASHER, 1/2 x 3/4" Copper Asbestos 1

19a M1-1491 SPACER (A. 0. Smith Motor) 1

19b M1-1539 SPACER (Howell Motor & Marathon) 1

20 M1-15143 OIL SEAL 1

21 M-1252 WORM 1

22 M1-15142 WASHER 1

23 M1-15145 NUT 1

24 M1-15366 CABLE ASSY. - Motor to Switch (3 ph. - 208/230V only) 1

24a M1-18594 CABLE ASSY. - Motor to Switch (3 ph. - 440/480V only) 1

25 M2-3427 GASKET Motor to Transmission 1

25a M0-18785 GASKET MATERIAL (Permatex Type 3D), 16 Oz. Can 1

26 M1-95654 SWITCH GUARD 1

27 M1-95650 CAUTION LABEL 1

Part

M5-18769 TRANSMISSION, Reconditioned 1

type, 1 PH only 1

Speed Feature (30 Qt. Models) 1

Speed Feature (30 Qt. Models) 1

Description

No.

*M5-3330-D TRANSMISSION is used with all machines with an M3-1961 Top Cover, up to

Serial #1 .

M5-18769 TRANSMISSION is used from Serial #1 & up.

SPECIFY MACHINE SERIAL NO. WHEN ORDERING PARTS

25

Page 27

MODEL F-30 COLUMN AND BASE ASSEMBLY

26

Page 28

F30 with

3330 or

with

1505

1 M-3-72877

BASE, Floor Type

1 x x

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

MODEL F-30 COLUMN AND BASE ASSEMBLY

Item

No.

Part

No.

Description

No.

Reqd.

M5-

M5-18769

Transmission

2 M1-15320 CAPSCREW, 1/2 x 1-3/4" 4 x x

3 M1-15317 LOCKWASHER, 1/2" Split 4

4 M1-15323 LOCKNUT, 3/8" Hex 4

5 W0-16364 KEY, 3/16 x 3/16 sq. x 1-1/6" lg. 1

6 M1-3442 BOTTOM COVER 1

X

7 M4-1997 COLUMN 1

7 M4-1412 COLUMN 1

8 M4-1998 BOWL SUPPORT 1

8 M4-1414-G BOWL SUPPORT 1

9 M1-1991 BOWL PIN 2

10 M1-1603 BUSHING, Nylon 1

11 M3-3305 BAR, Bowl Support Guide 1

11 M2-1424-F BAR, Bowl Support Guide 1

12 M2-3312 STRAP, Bowl Support Guide 2

12 M2-1425 STRAP, Bowl Support 2

13 M1-15056 SCREW, 3/8 x 7/8" F. H. Machine 4

14 M2-1995 SANITARY SHIELD 1

X

X

14 M2-1461 SANITARY SHIELD 1

15 M1-15339 SCREW, 3/8 x 2" F. H. Machine 6

17 W1-12821 COLLAR, 5/8" Set 1

18 M3-3308 LEVER, Bowl Left 1

X

X

18 M3-1937 LEVER, Bowl Left 1

19 M-0-99066 KNOB, Bowl Lift Handle 1

20 M2-1969 DRAG LINK 1

X

20 M2-1319 DRAG LINK 1

21 M1-1967 CRANK 1

X

21 M1-1419 CRANK 1

21 M1-1528 STOP, Crank 1

22 M2-1968 ROD, Spring 1

22 M2-1514 ROD, Spring 1

23 M1-1322 GUIDE, Rocker 1

X

24 M1-1346 WASHER, Spring 1

25 M1-1320 SPRING 1

X

26 M1-1994 SPRING, Balance 1

27 M1-1515 HEMISPHERICAL SPRING PERCH 1

X

28 M2-3314 ENCLOSURE PANEL, Rear 1

28 M4-1457 ENCLOSURE PANEL, Rear 1

29 M1-3307 PANEL ENCLOSURE, Base 1

30 M1-1516 WASHER, 3/8" Flat 3

31 W0-16365 LOCKNUT, 3/8-16 Flex 1

32 W1-16361 PIN, 1/8 x 3/4" Cotter 1

33 M1-7117 SETSCREW, 5/16 x 3/8" Soc. Hd. 1

X

35 SCREW, Sheet Metal 1

36 P1-5052 PLATE, Data 1

X

37 W2-20878 MOTOR REQUIREMENT NAME PLATE 1

38 W1-8096 SCREW, #4 x 1/4 Self-Tapping 4

39 M-1-73481 PLASTIC LEG CUP 4

X

F30

M5-

Transmission

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

SPECIFY MACHINE SERIAL NO. WHEN ORDERING PARTS

27

Page 29

28

Page 30

1 M-4-72871

BASE, Bench Type

1 x x x x

44 M-1-73480

PLASTIC LEG CUP

4 x

MODELS B-12, W-12, B-20, W-20, F-20, U-20 SERIES COLUMN AND BASE ASSEMBLY

USED ON Item

x x

x x

x x

x x

x

x x

x

x

x x

x x

x x x x

x x

x x

x x

x x

x x

x x

x x

x x x x

x

x x

No.

Part

No.

Description

No.

Reqd

1 M-4-72871 BASE, Floor Type 1

2 Wl-9548 CAPSCREW, 3/8 x 1-3/4" 4

2 Ml-15320 CAPSCREW, 1/2 x 1-3/4" 4

3 M4-1504 BASE, Wall Type 1

4 M4-1506 BRACKET, Wall Mount 1

5 Ml-1361 SUPPORT STUD, Attachment Mount 2

6 Ml-1462 SCREEN, Vinyl 1

7 M4-1413-B COLUMN 1

7 M4-1416 COLUMN 1

7 M4-1557 COLUMN 1

8 M4-1418 BOWL SUPPORT 1

8 M4-1417 BOWL SUPPORT 1

9 M1-1348-B BOWL PIN 2

10 Ml-1603 BUSHING, Nylon 1

11 M2-1428-B BAR, Bowl Support Guide 1

11 M2-1437-B BAR, Bowl Support Guide 1

12 Ml-1427 STRAP, Lock Bowl Support 2

13 Ml-15339 SCREW, 3/8 x 2" F. H. Mach. 4

14 Ml-15056 SCREW, 3/8 x 7/8" F. H. Mach. 4

15 M2-1436 LEVER, Bowl Lift Handle 1

15 M3-1315 LEVER, Bowl Lift Handle 1

16 M-0-99066 KNOB, Bowl Lift Handle 1

16 M-0-99066 KNOB, Bowl Lift Handle 1

17 M2-1426 DRAG LINK 1

17 M2-1422 DRAG LINK 1

17 M2-1420 DRAG LINK 1

18 Ml-1344 CRANK w/SETSCREW 1

18 Ml-1419 CRANK w/SETSCREW 1

19 Ml-1528 CRANK STOP w/SETSCREW 1

20 Ml-1322 GUIDE, Rocker 1

21 Ml-1320 SPRING 1

22 Ml-1346 WASHER, Spring 1

23 M2-1431 PANEL, Column Enclosure 1

23 M2-3359 PANEL, Column Enclosure 1

23 M4-1457 PANEL, Column Enclosure 1

24 Ml-18926 CABINET STAND w/Castors & Att. Holders

25 Ml-15102 CASTORS w/BRAKE 4

26 Ml-3538 WASHER, 3/8" Flat 3

27 Wl-7657 CAPSCREW, 1/4 x 1-1/4" 1

28 W0-7012 NUT, 1/4" Hex 1

29 Ml-15346 COLLAR, 1/2" Set 1

30 Wl-16361 PIN, 1/8 x 3/4" Cotter 2

31 Ml-15323 LOCKNUT, 3/8" Hex 5

32 Ml-15385 KEY, 1/8 x 1/8 sq. x 1" lg. 2

32 Ml-15387 KEY, 3/16 x 3/16 sq. x 1-5/8" lg. 2

33 Ml-15095 CAPSCREW, 3/8 x 2-1/4" Full Thread 1

34 W1-5994 LOCKWASHER, 3/8" Split 4

34 Ml-15317 LOCKWASHER, 1/2" Split 4

35 Ml-3476 SPLASH GUARD 1

36 M1-15345 PIN, 1/8 x 9/16" Drive 1

37 Ml-3514 SCREW, 10-24 x 3/8" Rd.Hd.Self Tapping 2

B12 W12 B20 W20 F20 U20

x x x

X

x

x x

x

x x x x

X

x

X

x

X

x x x x x

X

x x x x x

X

x x x

X

x x x x x

X

x x x x x

X

x x x x x

X

x x x

X

x x x

X

x

X

x x x

X

x x x x x

X

x x x x x

X

x x x x x

X

x

X

x x x x x

X

x x x

X

x x x

X

x x x

X

x x x x x

X

x x x x x

X

x x x

X

x x x x x

X

x x x

X

x x x x x

X

38 Ml-18562 3 WIRE CORD, Rubber Covered 1 Single phase models only

38A MI-15369 4 WIRE CORD, Rubber Covered 1 3 phase models only 208/240 only

38B Ml-18563 CORD SET ASSY. 1 3 phase only 440/480 only

39 Pl-17212 3 PRONG PLUG 1 Single phase models only

39A Pl-17213 4 PRONG PLUG 1 3 phase models only

40 Pl-17227 CABLE CONNECTOR 1

41 Pl-5052 PLATE, Data 1 x x x x x x

42 W2-20878 POWER REQUIREMENT NAMEPLATE 1 x x x x x x

43 Wl-8096 SCREW, #4 x 1/4 Self-Tapping 4 x x x x x x

x

x

SPECIFY MACHINE SERIAL NO. WHEN ORDERING PARTS

29

Page 31

M-5-1505-E TRANSMISSION ASSEMBLY

30

Page 32

.

M-5-1505-E TRANSMISSION ASSEMBLY

Item

No.

14A M-1-15074 INTERMEDIATE SHAFT 1 Tan. 004 thk, Transmatte .0075 thk A/R

14B M-l-15078 SPACER (on hvy. duty shafts only) 1 58 M-0-17386 PLUG, Expansion 1

39A M-1-1539 SLEEVE (for Howell & Marathon Motors) 1 81 M-2-1250-D SHAFT, Beater 1

45A M-2-1271-D SUN SHAFT, 15/16" dia. Shaft (use 46A key) 1

Part

No.

1 M-4-1251-D COVER 1 46 M-1-1657 KEY, 3/16" sq. x 1-7/8" lg. 1

2 M-0-17364 DRIV-LOK PIN, Type B, 3/16 dia. x 1/2 lg. 1 46A M-1-15079 KEY, 1/4 x 1-7/8"lg. (for use w/45A) 1

3 M-1-1681 PLUG ASSY, Trans, Case Vent 1 47 M-2-1259-E GEAR & CLUTCH, Intermediate 1

4 M-0-17365 WASHER, 1/4 I.D. x 1/2 O.D. xp/64"thk. 9 48 M-1-1884-B SPACER & BEARING RACE 1

5 W-0-16074 SCREW, Ph. Truss Hd. 1/4-20 x 3/4" lg 4 49 M-0-17374 BEARING, Needle, Torr. B-2010- 1

6 M-0-17366 BEARING, N.D. #3201 or equiv. 4 50 M-0-17375 BEARING RACE, Thrust, Torr. TRA-2031 2

7 M-0-17367 SNAP RING, Truarc 5100-46 2 51 M-0-17376 THRUST BRG., Needle, Torr. NTA-2031 1

8 W-1-13059 SNAP RING, Truarc 5100-66 1 52 M-0-17377 SNAP RING, Truarc Ext. 5100-125 1

9 M-0-17368 BEARING, N. D. #3203 or equiv. 2 53 M-0-17378 BEARING, N. D. #3205 or equiv. 1

10 M-2-1407-B COVER, Shaft 1 54 M-1-1279 SPACER (used with M-2-1271 shaft) 1

11 W-0-16075 SCREW, Ph. Truss Hd. 1/4-20 x 5/8" lg. 5 54A M-1-1279-B SPACER (used with M-2-1271-D shaft) 1

12 M-0-16076 PIN, Escutcheon #13 x 1/4" lg. brass 4 55 M-1-15316 SEAL (for use with M-1-1271 only) 1

13 M-1-1492-B DATA PLATE 1 55A P-1-5274 SEAL (for use with M-1-1271-D only) 1

14 W-0-14862 SHAFT ASSY, Intermediate (includes 1 56 W-0-16087 SCREW, Fl. hd. 5/16-18 x 7/8" lg. 4

15 M-1-1559 KEY, 3/16" sq. x 5/8" lg. 2 59 M-2-1262-G SHAFT, Bevel Pinion & Attachment Dr. 1

16 M-1-15076 GEAR, Countershaft 1 60 W-0-16086 SETSCREW, Soc. Hd. 3/8-16 x 7/8" lg. 1

17 M-1-15077 SPACER 1 61 W-0-16078 SCREW, Fl. Hd. 10-24 x 5/8" lg. 4

18 M-1-15075 SPUR PINION 1 62 M-1-1408-A BEARING COVER 1

19 M-1-15083 SNAP RING, Truarc 5100-75 1 63 M-0-17381 "0" RING, Garlock 24849-15,

20 M-1-1280-A SPACER 1

21 M-0-17369 BEARING, N. D. #3304 or equiv. 1 64 M-3-3332-D CAM & GEAR SHAFT 1

22 M-1-1934 CLUTCH, Overrun 1 65 M-1-1659 KEY, 3/16" sq. x 1/2" lg. 1

23 M-2-1258-D SPUR GEAR & SLEEVE, Low speed 1 66 M-0-17382 DRIV-LOK, 1/8 dia. x 1/2"lg, Type "D" 1

24 M-0-17370 BUSHING, Flange 1 67 M-4-1397-F HOUSING, Trans. 1

25 M-2-1261-E BEVEL GEAR 1 68 W-0-16079 PLUG, Drain 1/8-27 N. P. T. 1

26 M-0-17371 BEARING, Needle, Torrington B-168 1 69 M-0-16080 LOCKWASHER, Brg, Torr. #W-02 1

27 M-2-1260-F GEAR & CLUTCH, Hi speed 1 70 M-0-16081 LOCKNUT, Brg, Torr. #N-02 1

28 M-0-17372 THRUST BUSHING, Bunting TW-100 1 71 M-2-1264-C RING GEAR, Internal 1

29 M-2-1265-C CLUTCH (Jaw) 1 72 M-l-1292 SPRING 3

30 M-0-17373 SNAP RING, Truarc 5000-50 2 73 W-0-16082 BALL, Steel 1/4" dia. 3

31 M-1-1404-B GUIDE, Actuator rod 1 74 W-0-16083 SCREW, Soc. Hd. 1/4-20 x 1" lg. 6

32 M-1-1288 SPRING, Shifter fork 2 75 M-1-1263-A PINION, Planet 1

33 M-1-3331-B ROD, Actuator 2 76 M-3-1248-C SUPPORT, Beater Shaft (for use with

34 M-2-3345-B SHIFTER YOKE ASSY. (Includes Items 1

35 M-1-1254-C PINION SHAFT 1

36 M-1-1658 KEY, 3/16" sq. x 3/4" lg. 2 77 M-2-1284-A DRIP RING 1

37 M-1-1253-C WORM GEAR 1 78 W-0-16084 WASHER, Fl. 1/2" x 1-1/4" O.D. 1

38 M1-3488 SNAP RING, Truarc 5100-75 1 79 W-0-16085 STOP NUT, Elastic 1/2-20 1

39 M-1-1491-A SPACER (for A. 0. Smith Motor-only) 1 80 M-1-1396-A PIN, S/Stl. 1

40 M-1-1252-A WORM, 5 thread 1 82 W-1-12561-A OIL SEAL, Victor K-3-64254 1

41 M-1-15142 LOCKWASHER, Bearing, Torr. W-01 1 83 M-0-17383 BEARING, N.D. #3204 or equiv. 1

42 M-0-16077 LOCKNUT, Bearing, Torr. N-01 1 84 M-1-1438-A SCREW ASSY, Wing head 1

43 M-1-1293 GUIDE ROD, Shifter Yoke 1 85 M-1-1933 CAP, Aux. Drive Hub 1

44 M-1-1560 KEY, 3/16" sq. x 1" lg. 1 86 M-1-15314 OIL SEAL, Victor K-4-63544 1

45 M-2-1271 SUN SHAFT, 3/4" dia. Shaft 1 87 M-3-1932-A HUB, Aux. attachment 1

Description

items 14A thru 19)

30-31-32-33-34)

No.

Reqd.

Item

No.

76A M-3-1248-E SUPPORT, Beater Shaft (for use with

Part No. Description

57 M-1-1637 GASKET, Plastic - Red . 002 thk,

3/4 x 1" x 1/8" 1

M-2-1271 only) 1

M-2-1271-D only) 1

Reqd

NOTE 1.

In 1967 the thickness of the lower end of the sun shaft was changed

from 3/4" to 15/16". To determine the diameter of the shaft in any

transmission, remove the support (Index 76, Part #M-3-1248) and

NOTE 2.

Certain models of 1505 transmissions used a M-3-1282 attachment

shaft, M-1-1475 cap and M-3-1411 hub. All of these items are now

replaced by index 87, M-3-1932-A Attachment Hub.

measure the shaft end.

No.

SPECIFY MACHINE SERIAL NO. WHEN ORDERING PARTS

31

Page 33

TRANSMISSION

M-5-3330WITH BLAKESLEE HUB

M-5-18769 WITH UNIVERSAL HUB (TYPE B)

32

Page 34

M-5-3330 WITH BLAKESLEE HUB

No.

1

M-5-18769 WITH UNIVERSAL HUB (TYPE B)

Item

No.

1 M-4-1959-A COVER 1

2 M-0-17364 DRIV-LOK PIN, Type B 3/16 dia. x 1/2" lg. 1

3 M-1-1681 PLUG ASSY, Trans. Case Vent 1

4 M-0-17365 WASHER, 1/4 I. D. x 1/2 O.D. x 1/64"thk 9

5 W-0-16074 SCREW, Ph. Truss Hd. 1/4-20 x 3/4" lg. 4

6 M-0-17366 BEARING, N.D. #3201 or equiv. 4

7 M-0-17367 SNAP RING, Truarc 5100-46 2

8 W-1-13059 SNAP RING, Truarc 5100-66 1

9 M-0-17368 BEARING, N.D. #3203 or equiv. 2

10 M-2-1407-B COVER, Shaft 1

11 W-0-16075 SCREW, Ph. Truss Hd. 1/4-20 x 5/8" lg. 5

12 M-0-16076 PIN, Escutcheon #13 x 1/4" lg. brass 4

13 M-1-1492-B DATA PLATE 1

14 W-0-14862 SHAFT ASSY, Intermediate (includes 1

14A M-1-15074 INTERMEDIATE SHAFT 1

14B M-1-15078 SPACER (on hvy. duty shafts only) 1

15 M-1-1559 KEY, 3/16" sq.x 5/8" lg. 2

16 M-1-15076 GEAR, Countershaft 1

17 M-1-15077 SPACER 1

18 M-1-15075 SPUR PINION 1

19 M-1-15083 SNAP RING, Truarc 5100-75 1

20 M-1-1280-A Spacer 1

21 M-0-17369 BEARING, N. D. #3304 or equiv. 1

22 M-1-1934 CLUTCH, Overrun 1

23 M-2-1258-D SPUR GEAR & SLEEVE, Low speed 1

24 M-0-17370 BUSHING, Flange 1

25 M-2-1261-E BEVEL GEAR 1

26 M-0-17371 BEARING, Needle, Torrington B-168 1

27 M-2-1260-F GEAR & CLUTCH. Hi speed 1

28 M-0-17372 THRUST BUSHING, Bunting TW -100 1

29 M-2-1265-C CLUTCH (Jaw) 1

30 M-0-17373 SNAP RING, Truarc 5000-50 2

31 M-1-1404-B GUIDE, Actuator rod 1

32 M-1-1288 SPRING, Shifter fork 2

33 M-1-3331-B ROD, Actuator 2

34 M-2-3345-B SHIFTER YOKE ASSY. (Includes Items 1

35 M-1-1254-C PINION SHAFT 1

36 M-l-1658 KEY, 3/16" sq. x 3/4" lg. 2

37 M-1-1253-C WORM GEAR 1

**37a M0-95492 WORM GEAR 1

38 Ml-3488 SNAP RING, Truarc 5100-75 1

39 M-1-1491-A SPACER (for A. 0. Smith Motor-only) 1

39A M-1-1539 SLEEVE (for Howell & Marathon Mtrs.) 1

40 M-1-1252-A WORM, 5 thread 1

**40a M0-95491 WORM 1

41 M-1-15142 LOCKWASHER, Bearing, Torr. W-01 1

42 M-0-16077 LOCKNUT, Bearing, Torr. N-01 1

43 M-1-1293 GUIDE ROD, Shifter Yoke 1

44 M-1-1560 KEY, 3/16" sq. x 1" lg. 1

45 M-2-1271 SUN SHAFT, 3/4" shaft dia. 1

45A M-2-1271-D SUN AHFT. 15/16" shaft dia. (use 46A key) 1

46 M-1-1657 KEY, 3/16" sq. x 1-7/8" lg.

46A M-1-15079 KEY, 1/4x1-7/8"lg.(for use w/45A) 1

Part

Description

items 14A thru 19)

30-31-32-33-34)

* These parts used only on Universal Hub (Type B) transmissions, beginning with

serial * 1 & up.

** USED WITH M-5-95493 SPECIAL TRANSMISSION (50 cycle)

NOTE 1.

In 1967 the thickness of the lower end of the sun shaft was changed from

3/4" to 15/16". To determine the diameter of the shaft in any

transmission, remove the support (Index 76, Part #M-3-1248) and

measure the shaft end.

SPECIFY MACHINE SERIAL NO. WHEN ORDERING PARTS

TRANSMISSION

No.

Reqd.

Item

No.

47 M-2-1259-E GEAR & CLUTCH, Intermediate 1

48 M-1-1884-B SPACER & BEARING RACE 1

49 M-0-17374 BEARING, Needle, Torr. B-2010 1

50 M-0-17375 BEARING RACE, Thrust, Torr. TRA-2031 2

51 M-0-17376 THRUST BRG., Needle, Torr. NTA-2031 1

52 M-0-17377 SNAP RING, Truarc Ext. 5100-125 1

53 M-0-17378 BEARING, N. D. #3205 or equiv. 1

54 M-1-1279 SPACER (used with M-2-1271 shaft) 1

54A M-1-1279-B SPACER (used with M-2-1271-D shaft) 1

55 M-1-15315 SEAL (for use with M-2-1271-D only) 1

55A M-1-15318 SEAL (for use with M-2-1271 only) 1

56 M-0-17385 PIN, Driv-lok, 5/16 dia. x 3/4" lg. 1

57 M-1-3334 BUSHING, Aux. attachment shaft 1

58 M-0-17386 PLUG, Expansion 1

59 M-2-1262-G SHAFT, Bevel Pinion and Attachment Dr. 1

* 59A M-2-18750 SHAFT, Bevle Pinion and Attachment Dr. 1

60 W-0-16086 SETSCREW, Soc. Hd. 3/8-16 x 7/8" lg. 1

61 W-0-16078 SCREW, Fl. Hd, 10-24 x 5/8" lg. 4

62 M-1-1408-A BEARING COVER 1

63 M-0-17381 "O" RING, Garlock 24849-15,

64 M-2-3332-D CAM & GEAR SHAFT 1

65 M-1-1659 KEY, 3/16" sq. x 1/2" lg.

66 M-0-17382 DRIV-LOK, 1/8 dia.x 1/2" lg. Type "D"

67 M-5-1960-C HOUSING, Trans.

68 W-0-16079 PLUG, Drain 1/8-27 N. P.T.

69 M-0-16081 LOCKNUT, Brg, Torr. #N-02

70 M-0-16080 LOCKWASHER, Brg, Torr. #W-02

71 M-2-1264-C RING GEAR, Internal

72 M-l-l292 SPRING 3

73 W-0-16082 BALL, Steel 1/4" dia. 3

74 S-0-16083 SCREW, Soc. Hd. 1/4-20 x 1" lg. 6

75 M-1-1263-A PINION, Planet 1

76 M-3-1248-C SUPPORT, Beater Shaft (for use with

76A M-3-1248-E SUPPORT, Beater Shaft (for use with

77 M-2-1284-A DRIP RING 1

78 W-0-16084 WASHER, Fl. 1/2" x 1-1/4" O.D. 1

79 W-0-16085 STOP NUT, Elastic 1/2-20 1

80 M-1-1396-A PIN, S/Stl. 1

81 M-2-1250-D SHAFT, Beater 1

82 W-1-12561 OIL SEAL, Victor K-3-64254 1

83 M-0-17383 BEARING, N.D. #3204 or equiv. 1

84 M-1-1438-A SCREW ASSY, Wing head 1

85 M-1-1933 CAP, Aux. Drive Hub 1

*85A M-1-18751 CAP, Aux. Drive Hub 1

86 M-1-15314 OIL SEAL, Victor K4-63544 1

*86A M-0-18752 OIL SEAL 1

87 M-3-3333-A HUB, Aux, attachment 1

*87A M-3-18749 HUB, Aux, attachment 1

88 M-0-17384 "O" RING SEAL 1

M-0-18805 OIL, Transmission (3 pts. reqd)

89 M-1-95032 SLEEVE 1

Part No. Description No.

Reqd.

3/4 x 1" x 1/8" 1

M-2-1271 only) 1

M-2-1271-D only) 1

33

Page 35

Electrical System

Diagram

TIME DELAY FUSE

1 B12,B12D

1/4 115 1 60 4.6 M-1-15112

TOGGLE SW

M-0-

16386

- -

4.6 5.8 15

4 “ “ 220 3 “ 1.3 M-1-15113

TOGGLE SW

P-1-

17203

- -

1.3 1.6 “

4211

3 “ “ 230 “ “

2.5 M-1-15112

“ “ - -

2.3 2.9 “

4211

4211

6 “ “ “ “ “ “ ‘ TOGGLE SW

M-1-

15260

- - “ “ “

A.C.MAN

A.C.MAN

A.C.MAN

A.C.MAN

A.C.MAN

A.C.MAN

A.C.MAN

A.C.MAN

7 F30T,F30DT

“

115 1 “ 9.6 M-1-15119

TIMER 15min

M-1-

1957 - - 9.6 12.0 25

A.C.MAN

7 “ “ 230 “ “ 4.8 “ TIMER 15min

M-1-

1957 - - 4.8 5.0 15

A.C.MAN

Owners

Manual

~

MODELS

Circuit

No.

2 “ “ “ “ “ “ “ MAN STARTER W-1-12413 P-28 M-0-16396 “ “ “

5 “ “ “ “ “ “ “ MAN STARTER W-1-12412

3 B12T, B12DT “ 115 1 “ 4.6 M-1-15112 TIMER 15min M-1-1957 - - 4.6 5.8 “

B20,B20D,F20,

1

F20D,U20,U20D

2 “ “ “ “ “ “ “ MAN STARTER W-1-12413 P-32 M-0-16397 “ “ “

1 “ “ 230 “ “ 3.5 “ TOGGLE SW M-0116386 - - 3.5 4.4 “

2 “ “ “ “ “ “ “ MAN STARTER W-1-12413 P-25 M-0-16398 “ “ “

4 “ “ 220 3 “ 2.0 M-1-15118 TOGGLE SW P-1-17203 - - 2.0 2.5 “

5 “ “ “ “ “ “ “ MAN STARTER W-1-12412

5 “ “ 440 “ “ 1.0 “ “ “

B20T,B20BT,F20T,F

3

20DT,U20T,U20DT

3 “ “ 230 “ “ 3.5 “ “ “ - - 3.5 4.4 15

2 F30,F30D 3/4 115 “ “ 9.6 M-1-15119 MAN STARTER W-1-12413 P-35 M-0-16399 9.6 12.0 25

8 “ “ “ “ “ “ “

11 “ “ “ “ “ “ “

2 “ “ 230 “ “ 4.8 “ MAN STARTER W-1-12413 P-28 M-0-16396 4.8 6.0 15

6 “ “ “ “ “ “ “ TOGGLE SW M-1-15260 - - “ “ “

8 “ “ “ “ “ “ “

11 “ “ “ “ “ “ “

9 “ “ 220 3 “ 2.4 M-1-15120

12 “ “ “ “ “ “ “

10 “ “ 440 “ “ 1.2 “

12 “ “ “ “

8 “ “ “ “ “ “ “

8 “ “ “ “ “ “ “

9 “ “ 220 3

FOOD MIXERS – TOTAL AMPERAGE AND BRANCH CIRCUIT PROTECTION CHART – COMMERCIAL 60 CYCLES

MOTOR CONTROLLER

HP VOLTAGE PH CY F.L.

1/2 115 “ “ 7.0 M-1-15117 TOGGLE SW M-0-16386 - - 7.0 3.8 “

“ 115 / “ 7.0 M-1-15117 TIMER 15min M-1-1957 - - 7.0 8.8 20

“

“

G.S.B. PART

AMPS

2.4 M-1-15120

NO

“ “

TYPE G.S.B.

PART NO.

M-0-16236 N-31 M-0-16403 “ “ “

M-0-16235 “ “ “ “ “

M-0-16236 N-24 M-0-16402 “ “ “

M-0-16235 “ “ “ “ “

M-0-14798 N-17 M-0-16401 2.4 3.0 “

M-0-16240 “ “ “ “ “

M-0-16234 “N-10 M-0-16400 1.2 1.5 “

“ “ “ “ “ “

M-0-16236 N-31 M-0-16403 “ “ “

M-0-16236 N-24 M-0-16402 “ “ “

“ M-0-14798 N-17 M-0-16401 2.4 3.0 “

OVER LOAD

HEATER ELEMENT

MFR

G.S.B.

TYPE

PART NO.

NO.

M-0-16407 “ “ “

M-0-16408 “ “ “

M-0-16406 1.0 1.3 “

MIXER

TOTAL

(AMPS)

BRANCH CIRCUIT

PROTECTION

CONDUCTORS

(MIN)

CAPACITY

SEE PAGE 25 FOR SINGLE PHASE MOTOR CAPACITOR PART NUMBERS

(MAX) AMPICITY

OR CIRCUIT

BREAKER

Page 36

35

Page 37

ITEMS #5, 6 & 7 NOT SHOWN

7 M-3-74955 1 SAFTEY SWITCH ASSY.

6 W-1-7282 2 1/4 - 20 LOCKNUT

5 W-1-8434 2 1/4 - 20 X 1.00 K.H SER

4 W-0-14895 1 PIN

3 M-1-74941 1 HANDLE

2 M-2-74848 1 SIDE PLATE WLDM'T

1 M-3-74845 1 COVER WLDM'T

ITEM PART NO. QTY

---MATERIAL LIST---

DESCRIPTION

BOWL GAURD ASSEMBLY

TYPE "A"

36

Page 38

15 M-2-79291

1

RETAINER

–

30QT

13 W-1-8875 2 #6-32 HEX NUT

12 W-1-

9887 2 #6-32 x .50 K.H.M.S.

11 M-0-

74978

2 #6-

32 x 1.50 K.H.M.S.

10 W-1-

7847 1 ¼-20 x .31 SET SCR.

9 M-1-

74954

1

ACTUATOR WELDM’T

8 M-0-

74951

1

SPACER

7 W-1-

8434 2 ¼-20 x 1.00 K.H.M.S.

6 M-2-

75502

1

RETAINER

–

30 QUART

5 M-1-

74948

1

SPACER

-

SWITCH

4 M-1-

75949

1

PLATE

-

SWITCH

3 M-0-

74073

1

POWER RELAY

–

115V

2 W-0-

70152

1

MICRO

-

SWITCH

ITEM

PART NO

QTY.

DESCRIPTION

16 M-0-75292 1 POWER RELAY –230V

14 W-1-12608 2 ¼-20 x .75 Fip. SCR

1 W-0-16732 2 ¼-20 LOCKNUT

--MATERIAL LIST--

BOWL GUARD ASSEMLY

TYPE “A”

37

Page 39

Loading...

Loading...