Page 1

UNDERCOUNTER DISHWASHER

OWNER'S MANUAL

BLAKESLEE

BL

AKESLEE

MODEL UC-21

I.R.S. INTEGRATED RECIRCULATING SYSTEM DESIGN

1844 South Laramie Avenue

Chicago, IL 60650

Phone: (708) 656-0660

66 Crockford Boulevard

Scarborough Ontario, Canada M1R 3C3

Phone: (416) 751-2625

Page 2

INDEX

gpm

Installation Instructions* 1

Operating Instructions 2

Maintenance Instructions 3

Illustrated Parts List 5

Recommended Spare Parts List 17

* Installation must be made observing applicable

plumbing and electrical codes.

SPECIFICATION

Page

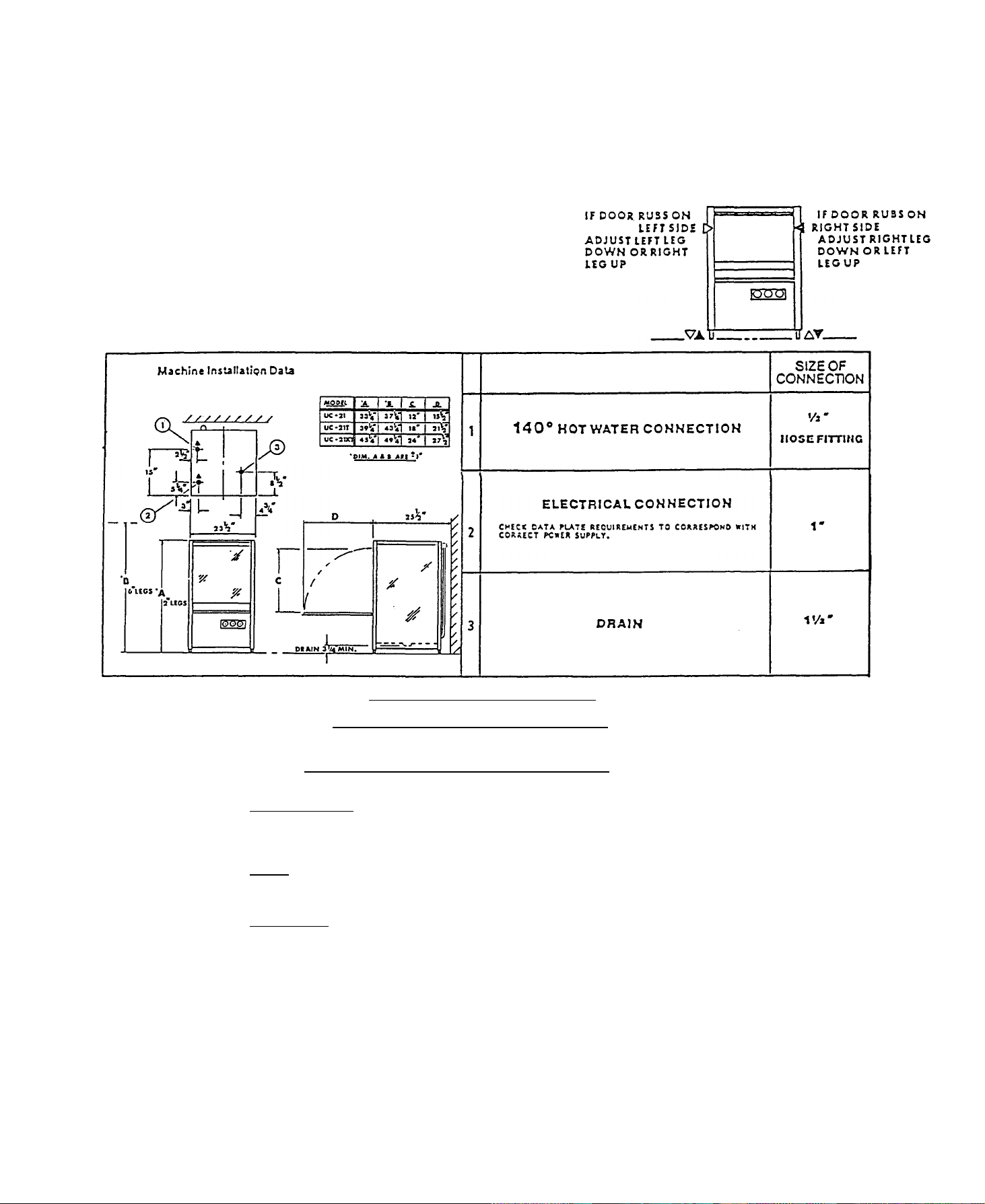

Construction: MACHINE INSTALLATION DATA:

Body of stainless steel con Electrical

struction throughout. Volts Phase Load AMPS

Wash System: 220 1(4 wire) 48.6

Top and bottom counter rotat - 220 3(5 wire) 27.0

ing spray arms.

Rinse System:

Top and bottom counter rotat - Inlet Temperature 140°F

ing spray arms. * Inlet Pressure 20 psi

Recirculating System: Inlet Flow 6

Horsepower 1 Water Consumption 30.5 gph

Hash Tank Capacity: Wash and Rinse Cycle

6.0 gal. Wash time - 105 seconds. Dwell

Water Heating: 12 seconds. Total cycle An electric immersion heater 120 seconds.

rated at 9.0 kw heats both

the wash and rinse water

Control: at the connection point of the

Automatic wash/rinse cycle dishmachine.

control. Thermostatically con

trolled rinse temperture.

Water Supply

Inlet Size 1/2 Hose

time 5 seconds. Rinse time

* Inlet pressure should be measured

Page 3

Installation

The Model is suitable for both under the counter and free standing installations. Access is

required to both the sides and rear of the machine for service and maintenance. Therefore, all

connections should be made with flexible hoses and conduit to ensure that access can be

achieved.

Level machine by adjusting legs as necessary, while

maintaining counter clearance dimensions.

NOTE: If machine is not leveled properly, door

will not close correctly.

INSTALLER WARNING!

TO PROTECT BOOSTER HEATING ELEMENT

DO NOT TURN ON ELECTRICAL POWER SUPPLY TO DISHWASHER

UNTIL WATER SUPPLY HAS FIRST BEEN CONNECTED AND YOU ARE

READY TO PROCEED WITH ACTUAL TEST OPERATION OF MACHINE !

WATER SUPPLY

Connect incoming water supply hose to 1/2" I.D. Hose fitting. Water supply source must be

able to provide 1400 F, water minimum at 20 PSI flow pressure.

DRAIN

Connect 1-1/2" drain tube to waste connection.

ELECTRICAL

Check machine data plate before making any electrical connections. All supply

connections must correspond with data plate information.

-1-

Page 4

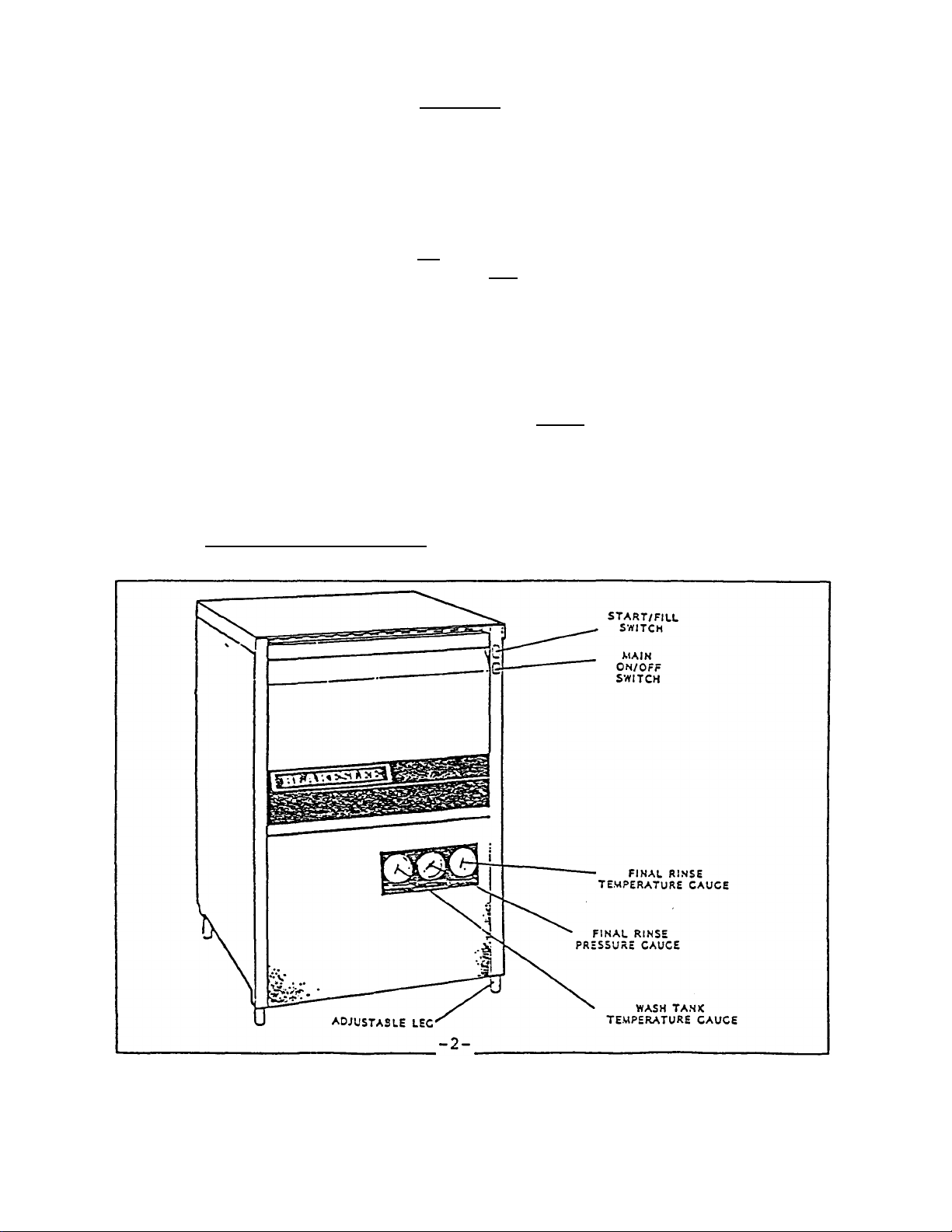

Operation

CAUTION

DO NOT ATTEMPT TO OPERATE WITHOUT WASH TANK BEING

PROPERLY FILLED, AS DRY ROTA TION WILL DAMAGE MOTOR SEALS

AND VOID WARRANTY.

Ensure that all spray arms spin freely and that pump strainer cover and

drain riser pipe are properly installed.

Depress On/Off main switch to ON position. Switch light will indicate power is on.

Close door. Depress and hold Start/Fill switch in FILL position for 50 seconds or until

water can be heard flowing down drain.

If detergent is fed manually, prep full tank of fresh water with 3 oz. of a low suds

detergent, then 1 oz. per each cycle there after. Increase or decrease detergent rate

based on results.

Insert properly pre-scrapped and pre-flushed racked ware.

Close door, depress and hold Start/Fill Switch in START position. Lighted

switch will indicate machine is operating.

Cycle is completed when Start/Fill switch indicator light turns off.

Open door and remove cleaned ware.

Washing operation is completed.

Page 5

Maintenance

After each washing period, pull out the overflow drain tube and wipe down the inside of

the washing tank with a damp cloth. At the end of the day, remove both spray arms and

check that none of the jets are obstructed. Rinse down the inside of the washing tank

with fresh water and leave the door open over night to dry out the tank.

UNSATISFACTORY WASHING RESULTS

1. If grey hard deposits appear on the inside of the tank, you are using an

unsatisfactory detergent or the wrong dilution.

2. If a fi lm of grease appears inside the wash, it could be caused by:

A. Lack of detergent

B. Insufficient water flow on the rinse cycle

C. Tank water may require changing

3. If the dishes are spotted with water, it may be because of:

A. Insufficient water fl ow on the rinse cycle

B. Clogged nozzles on the rinse spray arms

C. The angle of the nozzles on the rinse spray arms may need adjustment to

ensure that the rinse water is sprayed uniformly throughout the wash tank

4. If spray arms do not rotate, look for clogging in the spray arms.

5. If the wash tank foams excessively, it may be because the wrong detergent has

been used. Excessive rinse aid also causes this problem.

6. If the machine stops during a wash cycle and fails to restart, check that the door is

properly closed.

-3-

Page 6

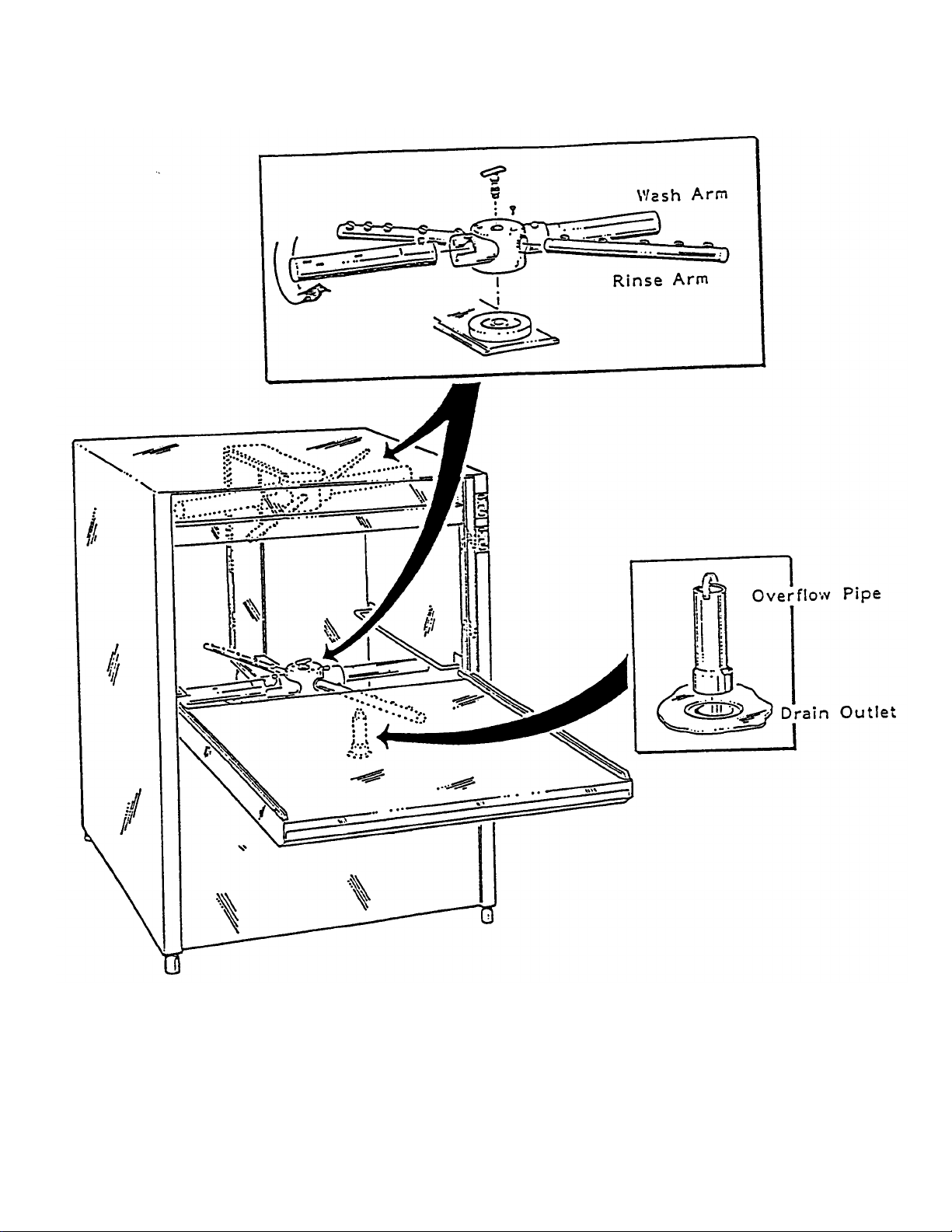

CLEANING BREAKDOWN ILLUSTRATION

-4-

Page 7

Figure 1. Recirculating System

-5-

Page 8

1

1

1

1

FIGURE 1. RECIRCULATING SYSTEM

ITEM

NO.

1 17798 MOTOR 1 H.P., 115/230V, 1 PH 1

1A 8247 MOTOR 1 H.P., 208/240V, 480V, 3 PH 1

2

3 7117 SETSCREW, 5/16 X 3/8 2

4

5 14785 3/8-16 HEX NUT 4

6 17245 3/8" LOCK WASHER 8

7 7522 3/8" FLAT WASHER 8

8 7656 3/8-16 X 1" HEX HD. CAPSCREW 4

9

10 2255 PUMP SEAL ASS'Y. 1

11 95252 IMPELLER SPINDLE 1

12 1658 3/16 SQ. X 3/4" LG. KEY 1

13

14 5587 FLAT WASHER 1

15 7598 5/16" LOCK WASHER 1

16 7621 5/16-18 X 3/4" S.S. H.H.M.S. 1

17 17762 IMPELLER ASSEMBLY

PART

NO.

17794

74505

75004

95673

DESCRIPTION

COLLAR

MOTOR MTG. BRACKET

O-RING

IMPELLER

INCLUDES ITEMS 11, 12, 13, 14. 15 & 16

QTY.

REQ.

-6-

Page 9

FIGURE 2. SPRAY ARMS & MANIFOLDS

-7-

Page 10

4

2

FIGURE 2. SPRAY ARMS & MANIFOLDS

ITEM

NO.

1 75000 WASH MANIFOLD 1

2

3 70087 RINSE ARM NOZZLE 20

4 70083 WASH ARM 4

5 70060 SPRAY ARM KNOB 2

6 09917 RINSE ARM ADJUSTMENT SCREW 4

7 70081 SPRAY ARM ASSEMBLY 2

8

9 70089 BUSHING 4

10 70082 HUB ASSEMBLY 2

11 74691 RINSE BLOCK CONNECTOR 2

12 74693 COMPRESSION RING 2

13 74692 COMPRESSION NUT 2

14 74649 LOWER RINSE MANIFOLD 1

15 13986 COMPRESSION TEE 1

16 70044 UPPER RINSE MANIFOLD 1

17 75001 RISER WELDMENT 1

PART

NO.

70086

70088

DESCRIPTION

RINSE ARM

INCLUDES ITEMS 2, 3, 4, 6 & 10

HUB

INCLUDES ITEMS 8 & 9

QTY.

REQ.

-8-

Page 11

FIGURE 3. ELECTRICAL ASSEMBLY

-9-

Page 12

1

1

2

-10-

FIGURE 3. ELECTRICAL ASSEMBLY

ITEM

NO.

1 70154 SWITCH FILL/START 1

2 70153 SWITCH ON/OFF HEAT 1

3 70431 SWITCH LABEL WASH/START 1

4

5 74217 FLOAT SWITCH 1

6 74602 LIMIT THERMOSTAT 1

7 74599 IMMERSION HEATER 9 KW, 230V 1

7A 71904 IMMERSION HEATER 1.5 KW, 240V 1

7B 71720 IMMERSION HEATER 1.5 KW, 115V 1

8

9* 74964 HEATER COVER 1

10 74114 GROUND LUG 1

11 70191 POWER TERMINAL STRIP 1

12 16779 FUSE 1

13 70190 CONTROL TERMINAL STRIP 1

14 7768 THERMOSTAT 1

15

16 70192 MOTOR CONTACTOR 1

17 71603 OVERLOAD RELAY 7-10 AMP 1

17A 71601 OVERLOAD RELAY 4-6 AMP 1

17B 71605 OVERLOA D RELAY 13-18 AMP 1

18 7210 HEAT CONTACTOR 60 AMP 1

18A 7209 HEAT CONTACTOR 30 AMP 1

19 74980 CYCLE TIMER 1

PART

NO.

71335

75024

14246

DESCRIPTION

DOOR SAFETY SWITCH

GASKET-IMMERSION HEATER

RELAY

QTY.

REQ.

*NOT ILLUSTRATED.

Page 13

FIGURE 4. BODY ASSEMBLY

-11-

Page 14

1

4

1

1

FIGURE 4. BODY ASSEMBLY

ITEM

NO.

1 71594 TOP COVER 1

2 70440 REAR PANEL 1

3

4 70437 DOOR SPRING 2

5

6 74377 FRONT PANEL 1

7 71592 PANEL L.H. 1

8 74655 DOOR 1

9 74227 DOOR HANDLE 1

10 71591 HINGE COVER PANEL 1

11

12 70140* DOOR SWITCH MOUNTING BRACKET 1

13 72724 COILED SPRING PIN 2

14 71553 DOOR HINGE L.H. 1

15 71688* DOOR HI NGE R.H. 1

16

17 74653* DOOR SEAL RETAINER - LOWER 1

18 74654* DOOR SEAL - LOWER 1

PART

NO.

71593

70064

97844*

72625*

DESCRIPTION

PANEL R.H.

ADJUSTABLE FOOT

BLAKESLEE LOGO

UPPER DOOR SEAL

QTY.

REQ.

-12-

Page 15

FIGURE 5. PLUMBING & GAUGES

-13-

Page 16

1

1

1

2

1

1

1

1

FIGURE 5. PLUMBING & GAUGES

ITEM

NO.

1 70201 3/8" VACUUM BREAKER 1

2 72632 3/8" TO 1/2" TUBE ELBOW 2

3

4 72570 VACUUM BREAKER TUBE 1

5

6 70765 OUTLET DRAIN ASSY. 1

7 72630 MALE CONN. 3/8" TO 1/2" TUBE 2

8 72560 FLARED FITTING NUT 1/2" 4

9

10 13884 3/4" X 1/2" X 1/2" BRASS TEE 1

11 18528 1/2" BRASS PIPE PLUG 1

12 12495 1/2" X 90° BRASS STREET ELBOW 1

13 70348 1/2" X 3/8" REDUCING BUSHING 2

14 72641 3/8" X 8" BRASS NIPPLE 2

15 70200 3/8" SOLENOID VALVE 1

16

17 70155 THERMOMETER 2

18 70156 PRESSURE GAUGE 1

19

20 70204 3/8" X 3/8" X 3/8" BRASS TEE 1

21

22 72564 MALE CONN. 1/4" NPT TO 1/4" TUBE 1

23 72561 FLARED FITTING NUT 1/4" 2

24

25 70206 3/8" X 90° STREET ELBOW 2

26 70393 1/2" HOSE NIPPLE 1

27 70099 1/4" X 90° BRASS ELBOW 1

PART

NO.

72569

74960

70395

70441

70392

72631

72568

DESCRIPTION

INLET TUBE

STANDPIPE

* DRAIN CUP

* O-RING 1

* LOCKNUT 1

3/8" CLOSE NIPPLE

INSTRUMENT DATA PLATE

1/2" LINE STRAINER

3/8" TO 1/4" TUBE CONNECTOR

GAUGE TUBE

QTY.

REQ.

-14-

Page 17

Loading...

Loading...