Page 1

BLAKESLEE

Division of The Legacy Companies

UNDERCOUNTER DISHWASHER

UC20

Blakeslee – Division of The Legacy Companies

1228 Capitol Drive

Addison, IL 60101

Phone (630) 532-5021

Fax (630) 532-5020

www.blakesleeinc.com

service@blakesleeinc.com

OWNER’S

MANUAL

Page 2

Page 3

2

ELECTRICAL WARNINGS

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED

TO INSTALL ELECTRICAL EQUIPMENT.

PERSONNEL SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS

OF THE EQUIPMENT COVERED IN THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

WARNING: Failure to follow all the instructions in this manual can cause property damage, injury

or death.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death.

WARNING: Electrical connections should be performed only by a certified professional.

WARNING: Electrical and grounding connections must comply with the applicable portions of the

National Electric Code and/or all local electric codes. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING: Before connecting the unit to the electrical supply, verify that the electrical and

grounding connections comply with the applicable portions of the National Electric

Code and/or all local electrical codes. Failure to comply with this procedure can cause

property damage, injury or death.

WARNING: Before connecting the unit to the electrical supply, verify that the electrical connection

agrees with the specifications on the data plate. Failure to comply with this procedure

can cause property damage, injury or death.

WARNING: UL73 Grounding Instructions: This appliance must be connected to a grounded,

metal, permanent wiring system; or an equipment-grounding conductor must be run

with the circuit conductors and be connected to the equipment-grounding terminal or

lead on the appliance. Failure to comply with this procedure can cause property

damage, injury or death.

WARNING: Appliances equipped with a flexible electric supply cord are provided with a three-

prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. Failure to comply with this procedure can cause

property damage, injury or death.

WARNING: If the receptacle is not the proper grounding type, contact an electrician. Do not

remove the grounding prong from the plug. Failure to comply with this procedure can

cause property damage, injury or death.

Page 4

3

WARNING: Before performing any service that involves electrical connection or disconnection

and/or exposure to electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING: Before removing any sheet metal panels, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Be sure all circuits are disconnected. Failure to

comply with this procedure can cause property damage, injury or death.

WARNING: Do not operate this equipment without properly placing and securing all covers and

access panels. Failure to comply with this procedure can cause property damage,

injury or death.

WARNING: Do not use or store gasoline or other flammable vapors or liquids in the vicinity of this

or any other appliance. Failure to comply can cause property damage, injury or death.

WARNING: In the event of a power failure, do not attempt to operate this appliance. Failure to

comply can cause property damage, injury or death.

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE

WARNING:

Before performing any service that involves electrical connection or disconnection and/or

exposure to electrical components, always follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply with this procedure can cause property damage, injury

or death.

The Electrical LOCKOUT/TAGOUT Procedure is used to protect personnel working on an electrical

appliance. Before performing any maintenance or service that requires exposure to electrical

components, follow these steps:

1. In electrical box, place appliance circuit breaker into OFF position.

2. Place a lock or other device on electrical box cover to prevent someone from placing circuit

breaker ON.

3. Place a tag on electrical box cover to indicate that appliance has been disconnected for service

and power should not be restored until tag is removed by maintenance personnel.

4. Disconnect appliance power cord from electrical outlet.

5. Place a tag on the cord to indicate that unit has been disconnected for service and power should

not be restored until tag is removed by maintenance personnel.

Page 5

4

TABLE OF CONTENTS

GENERAL DESCRIPTION……………………… …………………… …………………………………….. 5

Model UC20…………………………………………………………………………………………… 5

Door Safety Switch…………………………………………………………………………………… 5

Digital Display………………………………………………………………………………………… 5

Detergent Pumps…………………………………………………………………………………….. 5

Heater…………………………………………………………………………………………………. 5

Scrap Screen Filters…………………………………………………………………………………. 5

Wash Cycles………………………………………………………………………………………….. 5

Pump…………………………………………………………………………………………………… 5

Motor…………………………………………………………………………………………………… 5

Control Circuit…………………………………………………………………………………………. 5

Automatic Tank Fill……………………………………………………………………………………. 5

Final Rinse Booster…………………………………………………………………………………… 5

Racks per Hour………………………………………………………………………………………... 5

Power Saving Mode…………………………………………………………………………………... 5

Wash & Rinse Arms…………………………………………………………………………………... 5

Insulation………………………………… …………………… ………………………………………. 5

INSTALLATION………………………… …………………… ……………………………………………….. 6

Visual Inspection……………………………………………………………………………………… 6

Unpacking the Dishwasher………………………………………………………………………….. 6

Leveling the Dishwasher……………………………………………… …………………………….. 6

Plumbing the Dishwasher………………………………………………........................................ 6

Fill/Rinse…………………………………………………… …… …… ………………………………. 6

Drains…………………………………………………………………….……………………………. 6

Electrical Connections……………………………………………………...................................... 7

OPERATION………………………………………………………………………………………………….. 8

Preparing the Dishwasher for Use…………………………………………………………………. 8

Soiled Ware Operation………………………………………………………………………………. 9

Loading the Dishwasher…………………………………………………………………………….. 9

Detergent………………………………………………................................................................ 10

Operating the Dishwasher………………………………………………………………………….. 10

Programmable Mode………………………………………………….…………………………….. 11

Shutdown, Cleaning & Maintenance……………………………………...................................... 11

TROUBLESHOOTING………………………………………………………………………………………. 12

Error Codes…………………………………………………………………………………………… 13

WIRING DIAGRAM………………………………………………………………………………………….. 14-18

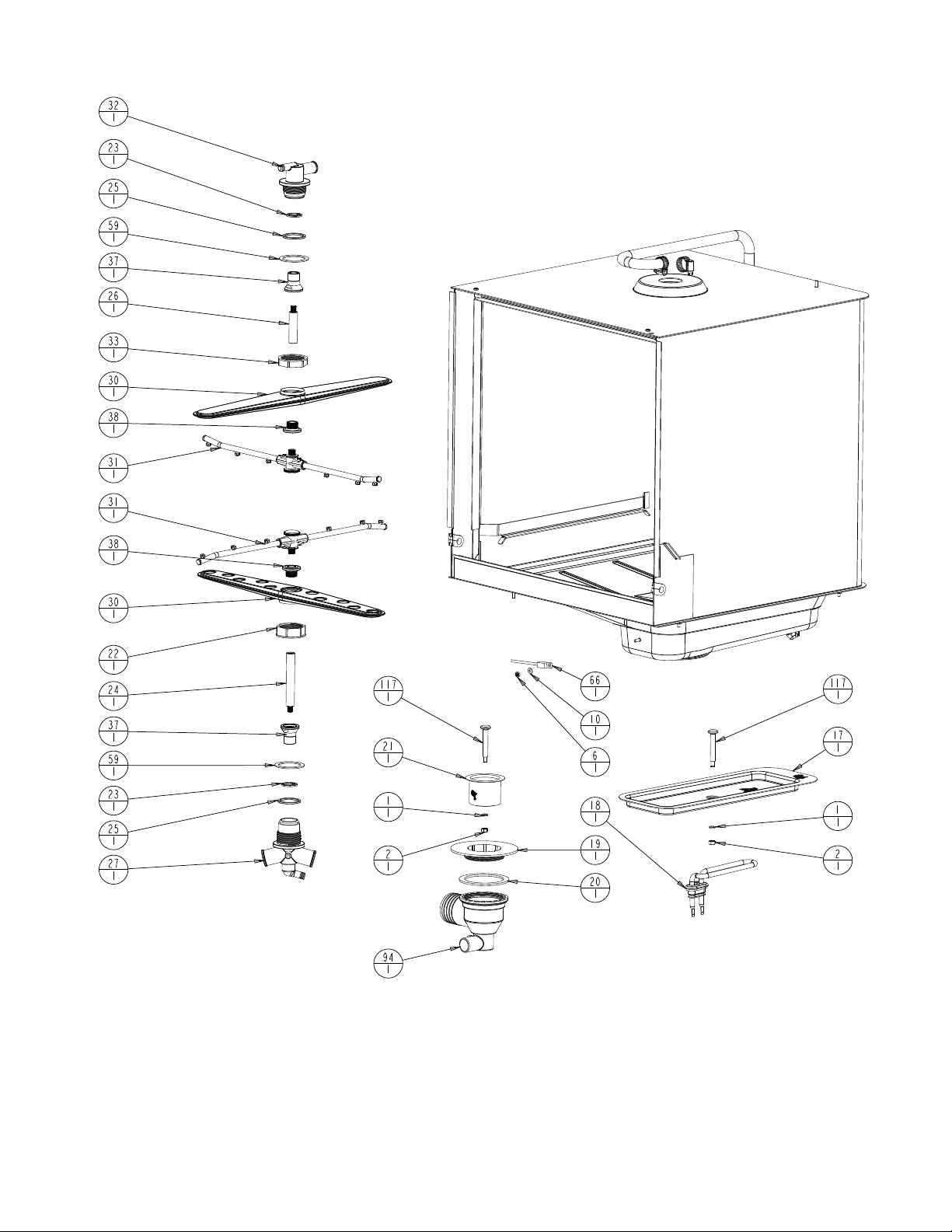

EXPLODED VIEWS…………………………………………………………………………………………. 19-27

WARRANTY………………………………………………………………………………………………….. 28

Page 6

5

GENERAL DESCRIPTION

Model UC20

The UC20 undercounter dishwasher is constructed of 18 gauge stainless steel. An 18-5/16” door

opening allows for oversized ware such as 18’ x 26” sheet pans to be washed.

Door Safety Switch

The UC20 is equipped with a door safety

switch. The machine will not operate when the

door is open. If the door is accidently opened

during a cycle, the machine will stop operating.

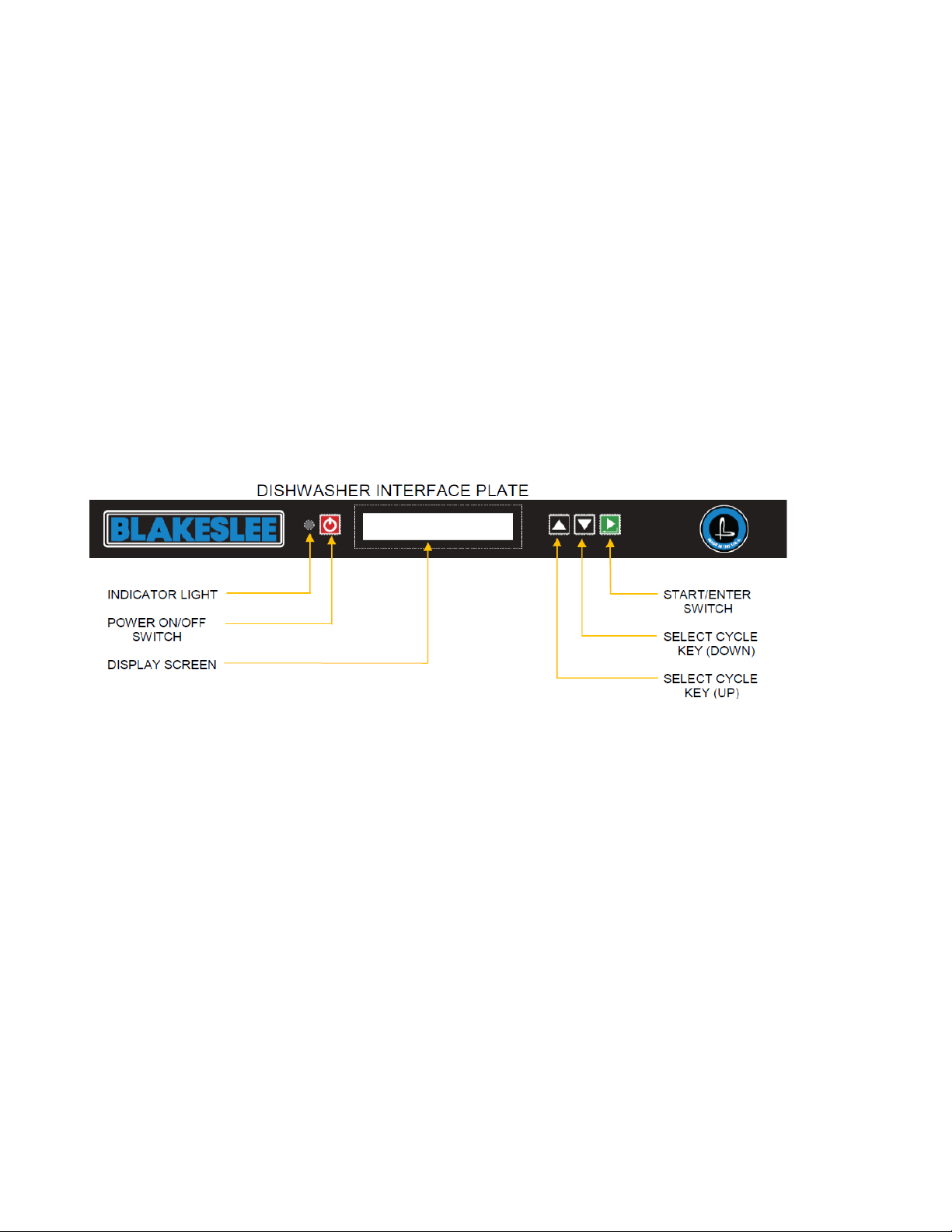

Digital Display

The unit is equipped with a digital display

allowing simplified operational instructions.

Detergent Pumps

All units are equipped with built in detergent

dispensers and rinse dispensers.

Heater

Wash tank water is heated by electricity and

are available in 208, 240, 440, or 480 VAC.

Scrap Screen Filters

Stainless steel scrap filters are used to protect

wash pump. These filters should be cleaned

periodically throughout the washing period.

Wash Cycles

All units contain seven independent cycles:

economy, economy plus, glassware, flatware,

dishware, pot & pan, and programmable.

Control Circuit

All units are supplied with a 24 VAC control

circuit.

Automatic Tank Fill

All machines are supplied with automatic wash

tank fill.

Final Rinse Booster

Machines are equipped with a built-in electric

booster. These boosters are designed to raise

the rinse water temperature from 140°F to

180F°-185°F.

Racks per Hour

Unit is capable of washing up to 50 racks per

hour in the economy modes.

Wash & Rinse Arms

Upper and lower wash and rinse arms are

constructed of stainless steel and are

interchangeable. Periodic cleaning is required.

Insulation

The unit is fully insulated to protect the user

from excessive heat and allow the unit to

operate quietly.

Power Saving Mode

All machines have an automatic power saving

mode that regulates and reduces energy

consumption if the unit is left unattended for

over 30 minutes.

Pump Motor

The unit is equipped with a 0.9 HP motor.

Page 7

6

INSTALLATION

Visual Inspection

Before installing the unit, inspect the shipping container and machine for damage. A damaged container

may indicate there is damage to the machine. If there is damage to both the container and machine, do

not throw away the container. The dishwasher has been inspected and packed at the factory and is

expected to arrive in an undamaged condition. However, rough handling by carriers or others may

result in damage to the unit while in transit. If such a situation occurs, do not return the unit to

Blakeslee; instead, contact the carrier and ask them to send a representative to the site to inspect the

damage to the unit and to complete an inspection report. You must contact the carrier within 48 hours

of receiving the machine. Also, contact the dealer where you purchased the unit.

Unpacking the Dishwasher

Once the machine has been removed from the container, make sure that there are no parts missing

from the machine. This may not be obvious at first. If an item is missing, contact Blakeslee immediately

to have the missing item shipped to you.

Leveling the Dishwasher

The dishwasher must be level to operate correctly. This allows the door to open and close properly and

ensures the best results while washing. The unit comes with adjustable feet. Ensure that the unit is

level from side to side and from front to back before making any service connections.

Plumbing the Dishwasher

All plumbing connections must comply with all applicable local, state, and national plumbing codes. The

installing plumber must flush the incoming water line thoroughly prior to connecting it to the dishwasher.

Any valves that are fouled as a result of foreign matter left in the water line, and any expenses resulting

from this fouling, are not covered under the manufacturer’s warranty.

Fill/Rinse

Final Rinse water is used to fill the dishwasher’s booster and wash tank. The water supply must have

an incoming water temperature of 140°F with a dynamic flow pressure of 15 to 25 PSI at the

dishwasher.

If the incoming water supply pressure is below the required 15 PSI, an optional pressure booster pump

will be required. If the incoming water supply pressure is greater than 25 PSI, a pressure reducing valve

will be needed.

Drains

Drain connections must comply with all local and national code requirements.

Connect the tank drain to the building drain connection using 1/2 inch hose with 3/4 NPT fitting.

Page 8

7

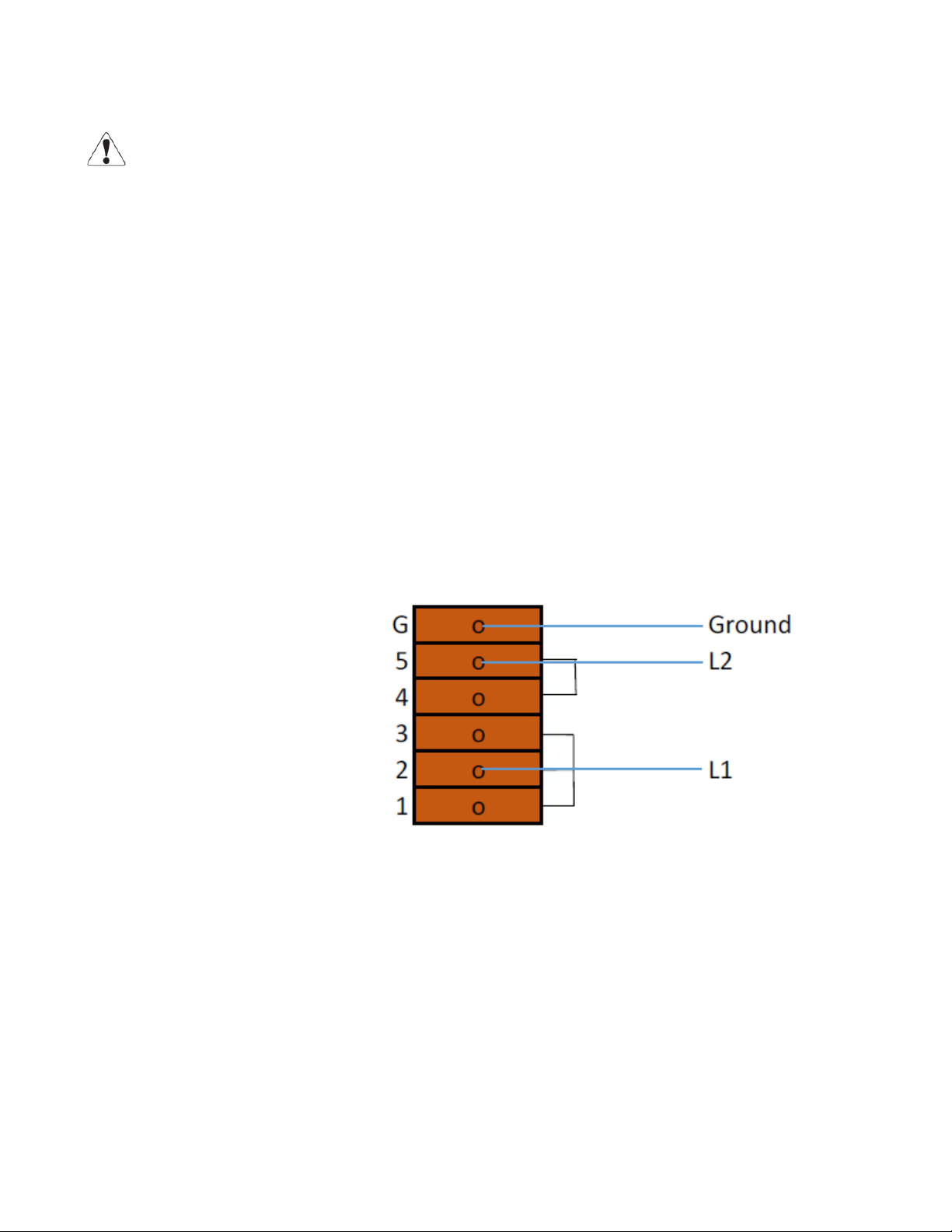

ELECTRICAL CONNECTIONS

WARNING

Before performing any service that involves electrical connection or disconnection and/or

exposure to electrical components, always perform the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to comply with this procedure can cause property

damage, injury or death.

Refer to the unit’s data plate before making any electrical connections.

Any connections must correspond to the information specified on the data plate. A fused disconnect

switch or circuit breaker (not supplied) MUST be installed in the electrical supply line for the

dishwasher.

This service connection must meet all local and national electrical code requirements. All connections

are made at one common location in the control box. The control box cover is lipped and can be

opened by removing two (2) #10-32 screws.

Use ¾ ” knockout hole in back of dishwasher to connect to terminal block located on front of unit.

Incoming connection shown below.

240 Volt 1 Phase

Page 9

8

OPERATION

Preparing the Dishwasher for Use

1. Ensure that all spray arms spin freely and that scrap filter is properly installed.

2. Close dishwasher door.

3. Turn on main water supply to dishwasher.

4. Turn on main power supply to dishwasher.

5. Press dishwasher Power On/Off switch to fill dishwasher. Blue indicator light will appear.

6. The default language that appears on the display screen is set to English. The default

temperature that appears on the display screen is set to Fahrenheit. To change either one of

these settings, press and hold the Select Cycle Up and Down Keys simultaneously for fifteen

seconds. This will prompt the dishwasher into a setup screen.To change language, press the

Select Cycle Down Key until the desired language appears on the display screen. Press the

Select Cycle Up Key to save language setting. Repeat for temperature setting. When all

selections have been made, depress the Start/Enter switch to exit the setup screen.

7. Load Washer (see proper procedures for scraping and loading ware)

8. Close dishwasher door.

Page 10

9

SOILED WARE OPERATION

To increase speed and efficiency and reduce breakage, a few simple rules need to be observed:

• All food must be removed from dishware before placing them in stacks. This will maintain cleaner

wash water and reduce detergent usage.

• Stackable ware, such as dishes and trays, should have food debris removed and be placed in

manageable stacks. A “buildup” area should be designated for these stacks until dish racks are filled.

• Items such as coffee cups, glasses and bowls, do not stack well and should be placed directly into

racks for transport.

• When racks are filled, they should be kept in the buildup area until they can be washed.

• Good organization is key to speed and efficiency in dish room operation, as well as reduced

breakage.

• Silverware should be presoaked in a sink or other container to keep food particles from drying out.

Silverware should then be placed in an appropriate rack and sent through the dishwasher.

Note: When placing silverware in flat racks, do not overload. The silverware should be spread out

evenly in the rack so the surfaces are exposed and can be cleaned by the dishwasher’s spray.

Note: As much as possible, keep soil from entering the dishwasher. This will help maintain cleaner

wash water and reduce detergent usage.

LOADING THE DISHWASHER

Wash similar dishes at the same time, as often as possible, to reduce sorting once the dishes have

been cleaned. When several racks in the buildup area have been filled, run them through the

dishwasher one after the other. This will allow the loading operator to return to scrapping and stacking

.

Page 11

10

DETERGENT

Use a low-suds, good commercial grade detergent. Never use a foaming soap or soap flakes. Your

local detergent representative knows the capabilities of their detergents and can determine the proper

treatment of your water for proper use with the manufacture’s product. The wash water must be kept at

an effective strength to obtain good washing results. Ask your local detergent supplier for their advice.

OPERATING THE DISHWASHER

Once the wash tank is filled and the dishwasher is properly loaded, choose a cycle mode per the following

instructions:

1. Use the up/down arrows on the Select Cycle Key to choose the desired ware-washing cycle. The

choices are: Economy (default), Economy Plus, Glassware, Flatware, Dishware, Pots and Pans,

and Programmable.

2. “HEATING UP WATER”. The indicator light is red and the wash cycle cannot start until the

dishwasher reaches the required temperature. An exception to waiting period is the Economy cycle;

in which, the wash cycle can be started regardless of water temperatures.

3. When proper temperatures are reached, a green indicator light appears and the dishwasher is

ready for a washing cycle. To start the washing cycle, press the Start/Enter switch.

4. At the beginning of the wash cycle, a detergent pump will systematically add detergent into the

wash tank.

5. At the end of the wash cycle, a blue indicator light appears. The final rinse is now in process. The

dishwasher will perform a slight draining operation prior to the final rinse cycle. Towards the end of

the rinse cycle, a rinse aid will automatically inject the additive into the final rinse water line.

6. Operation is complete when the blue indicator light turns off.

7. The dishwasher is ready for the next loading session.

NOTE: It is important to check and clean the strainer when prompted to do so.

A “CLEAN STRAINER” prompt will appear after:

a. Several loads have been washed in the same washing mode.

b. Washing mode has been changed (e.g. changing from a dishware mode to a flatware mode).

Page 12

11

PROGRAMMABLE MODE

The programmable mode allows an operator to manually select and program a custom wash and rinse

cycle. Selections include:

Wash and rinse mode

• Low

• Medium

• Heavy

Temperature Modes

• Wash - 150°F to 170°F

• Rinse - 180°F to 190°F

The default in the wash mode is “low”. The default in the temperature mode is 150°F wash and 180°F

rinse. To change either one of these settings, press and hold the Select Cycle Up and Down Keys

simultaneously for fifteen seconds. This will prompt the dishwasher into a setup screen. To change

Wash and rinse mode, press the Select Cycle Down Key until the desired cycle appears on the display

screen. Press the Select Cycle Up Key to save the cycle. Repeat for wash and rinse temperature

settings. When all selections have been made, press the Start/Enter switch to exit the setup screen.

Shutdown and Cleaning

An important part of maintaining the dishwasher is keeping it clean. A thorough cleaning before shutting

the unit down will help keep it working at peak performance.

Shutdown

1. Press dishwasher once to allow dishwasher to fully drain.

2. Press Power On/Off switch a second time to power down the unit.

Cleaning

1. Open door and allow interior to cool down before cleaning.

2. Remove the scrap filter screens and empty them. Take them to a sink and clean them using a

suitable brush. Make sure all debris is removed. Rinse thoroughly.

3. Inspect the rotating wash arms for blockage of any opening and free rotation. Remove and

clean as needed.

4. Thoroughly wash and rinse the interior of the dishwasher.

5. Leave door open to dry interior.

Page 13

12

TROUBLESHOOTING

Problem(

Possible(Cause(

Corrective(Action(

Dishwasher does not run

Main power off

Check breaker panel

Dishwasher does not fill

Main water off

Open supply valve

Rinse nozzles clogged

Clean rinse nozzles

Solenoid filter clogged

Clean filter

Lime build-up

De-Lime rinse line

Defective pressure switch

Replace pressure switch

Indicator light flashing and/or error code

is displayed on screen

See error codes

Poor wash results

No detergent supplied

Add detergent supply

Ware loaded incorrectly

Load ware correctly

Clogged spray arms

Clean spray arms

Detergent dispenser defective

Contact factory

Wash water dirty

Drain and refill tank

Insufficient wash time

Select a longer wash mode or repeat

cycle

Low water temperature

Contact factory

Foam developing

Use a low suds detergent or reduce the

amount of rinse aid by adjusting the

dispenser screw

Clogged sump filter

Clean sump filter

Streaks and spotting on

dishes and glasses

Too much rinse aid being dispensed

Reduce the amount of rinse aid by

adjusting the dispenser screw

Water too hard

Contact detergent representative

Clogged rinse nozzles

Clean rinse nozzles

Insufficient flow pressure

Increase incoming flow pressure to

20-25 psi

Page 14

13

ERROR CODES

Resetting an error code

An error code can be reset by pressing the Power On/Off switch three consecutive times. If the error

code fails to reset, refer to the below chart before contacting factory.

ERROR CODES

B1

heat alarm

Check power connection to booster element

B2

rinse failed

Check incoming water supply and flow pressure

B3

overheating

Contact factory

E1

water load

Open the main water supply valve. Contact factory

T1

heating

Check power connection to tank heating element

T2

overheating

Contact factory

T3

drain

Check drain pump operation and sump filter

T4

sensor

Check for proper polarity connection and/or loose connection

T5

high level

Drain and load tank

T6

low level

Drain and load tank

Check incoming water and flow pressure

Page 15

14

Page 16

15

Page 17

16

Page 18

17

Page 19

18

Page 20

19

Page 21

20

Page 22

21

Page 23

22

Page 24

23

Page 25

24

Page 26

252627

Page 27

Page 28

Page 29

Date of Installation

Serial No.

Model No.

Limited Warranty

Your new Blakeslee dishwashing machine is warranted for one year from date of installation shown above

against defective materials and workmanship. If any defects are found within the warranty period; parts, and

labor involved with their replacement will be covered free of charge. Service must be performed by a Blakeslee

authorized service agency. All labor to be performed during regular working hours. Overtime premium will be

charged to the customer. All warranty parts are shipped by surface transportation. If other means of

transportation is requested the customer is required to pay the premium. This warranty does not apply to

damages resulting from errors in installation on the part of other contractors, nor does it apply to machines

which have been subject to accident, misuse, or abuse. It is understood that Blakeslee’s warranty obligation

with respect to machines located outside of the United States or located in the state of Alaska is limited to the

furnishing of replacement parts only. In the state of Hawaii, repair labor is provided free of charge; travel time

and expenses paid by the customer. On the island of Oahu, repair labor, travel time and expenses are provided

free of charge. This is the entire and only warranty of Blakeslee. We neither assume nor authorize anyone else

to assume for us any other obligation or liability in connection with Blakeslee Machines.

•

In no case can this warranty exceed eighteen (18) months from the

date of shipment from our plant at Addison, Illinois

Items NOT Covered Under Warranty

1. Replacing Fuses or resetting Overloads.

Replacing a blown fuse or resetting an open overload breaker is a very simple procedure and is the

owner’s responsibility. If the machine continues to blow fuses or open the overload breaker, contact

your nearest authorized Blakeslee Service Center.

2. Adjusting Tank Heats.

Heat adjustments are covered in The Owners Manual and must be adjusted depending upon desired

results.

3. Proper Loading of Dishes.

It is important that the machine owner’s personnel observe the instructions outlined in The Owners

Manual.

4. Cleaning Drain Valves.

Foreign articles lodged in the drain valve seat should be removed as a part of the normal daily cleaning.

5. Cleaning Rinse or Wash Nozzles and Line Strainers.

Keeping a dishwasher clean and removing obstructions from the nozzles and line strainers will be a

periodic function of the machine owner’s personnel. The cleaning periods will vary depending upon

impurities in the water supply and cleanliness of the washing operation.

6. Final Rinse Water.

Most frequent of all complaints in any dishwashing machine is that of poor final rinse. It is the

responsibility of the owner to provide 180 to 195 degree (plus) water at 20-25 lb. flow pressure through

clean unobstructed water lines. If the machine has a factory equipped final rinse water booster, the

owner must supply the booster with a minimum of 140 degree temperature water.

28

Page 30

Notes:

29

Page 31

Page 32

MADE IN USA

PROTECT YOUR EQUIPMENT

USE GENUINE BLAKESLEE PARTS

Loading...

Loading...