Page 1

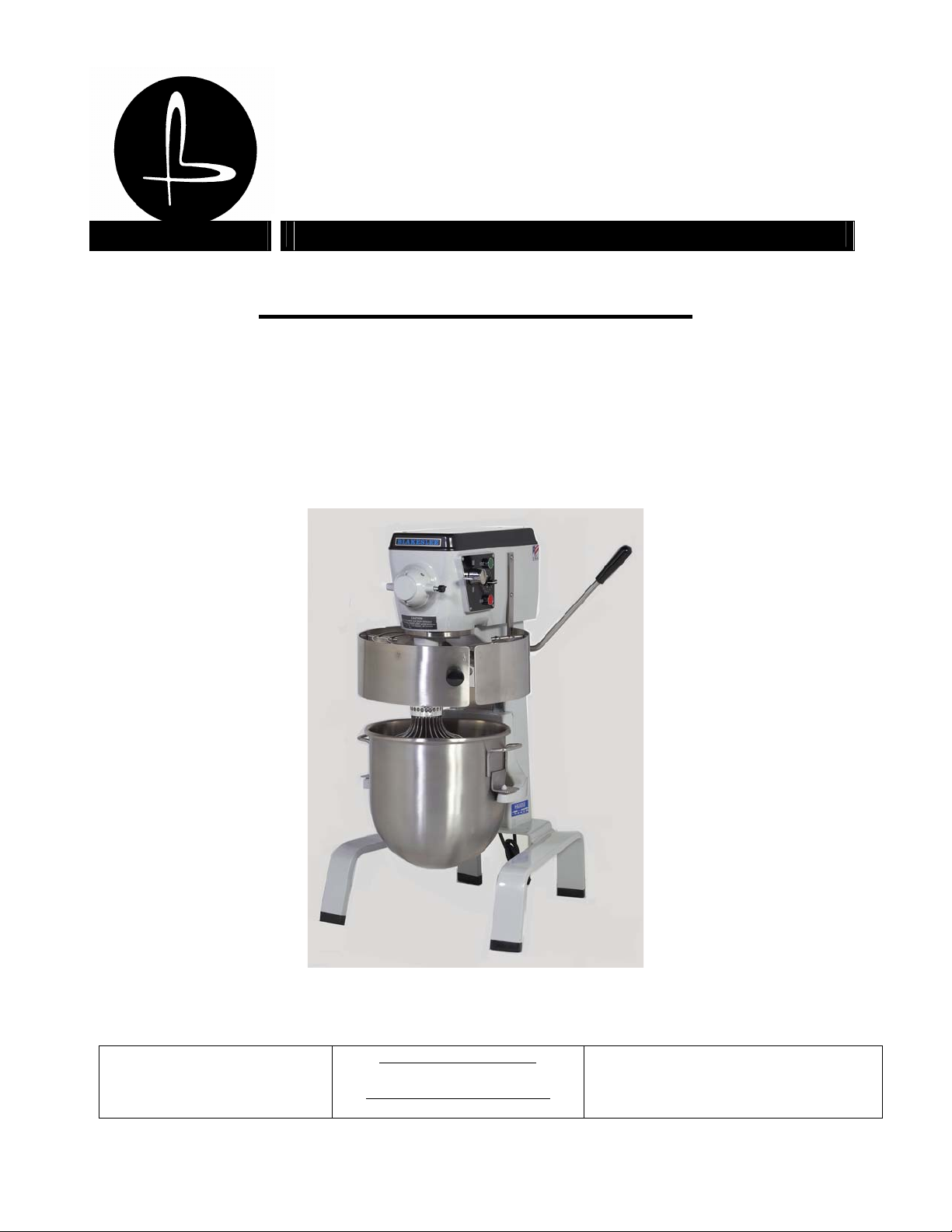

BLAKESLEE

20 QUART: Models B-20, F-20, U-20

OWNERS

MANUAL

Division of Blako Inc.

ELECTRIC FOOD MIXER

30 QUART: Model F-30

1844 South Laramie Avenue

Chicago, IL 60804

Phone (708) 656-0660

Fax (708) 656-0017

www.blakesleeinc.com

service@blakesleeinc.com

1149 Bellamy Road North Unit 19

Scarborough, Ontario Canada M1H1H7

Phone (416) 751-2625

Fax (416) 751-8539

Revision 8/2005

Page 2

INDEX

General Information

Installation Instructions

Design and Use Of Beaters, Whips and Other Accessories

Mixing Instructions

Mixing Bowl Capacity Chart

Available Beaters, Whips and Accessories

Operation

Parts Section:

Figure 1. Column Weldment 14

Figure 2. Bowl Support 16

Figure 3. Power Bowl Lift 18

Figure 4. Motor Mounting Bracket Assembly 20

Figure 5. Motor & Power Train 21

Figure 6. Auxiliary Hub Assembly 22

Figure 7. Lower Planetary 23

Figure 8. Planetary & Beater Shaft 24

Figure 9. Transmission Housing Assembly 25

Wiring Diagrams

Electrical Components

Service & Parts Distributors

Warranty

Page

1

2

5

7

9

11

12

13

30

34

35

37

Page 3

GENERAL INFORMATION

Your Blakeslee Mixer is just one piece of equipment that provides extra profit in your operation.

Consistency of performance will reduce waste and maintain better control over yield.

Your Blakeslee-built mixer has been designed and engineered to assist you in the quick and easy

preparation of fine tasting, quality foods. It is a valuable machine deserving the same maintenance

and attention your other kitchen equipment now receives. By following the suggestions in this

booklet, your mixer will operate for many trouble-free years.

This booklet has been prepared to give you the necessary knowledge for correct operation, load, and

lubrication of your mixer.

The food service operator will also be able to save you labor during the cleaning process due to the

smooth surfaces and design of the Blakeslee mixer. Each beater, whip and attachment is engineered

to perform specific jobs for you. The planetary action of Blakeslee Mixers (beater travels around the

circumference of the bowl as it rotates) assures you of a perfectly blended mix every time.

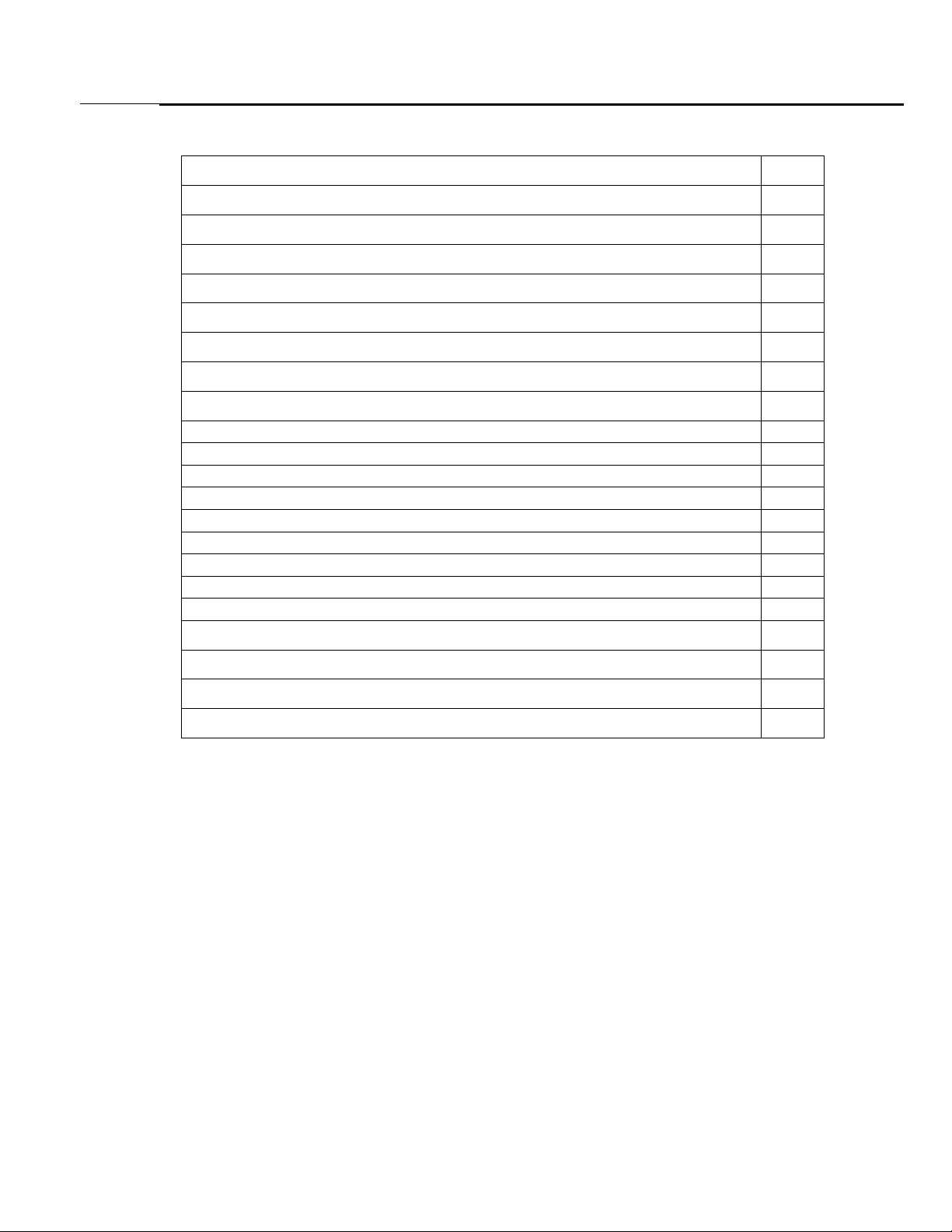

Diagram shows complete coverage of

Bowl by planetary action of beaters

-1-

Page 4

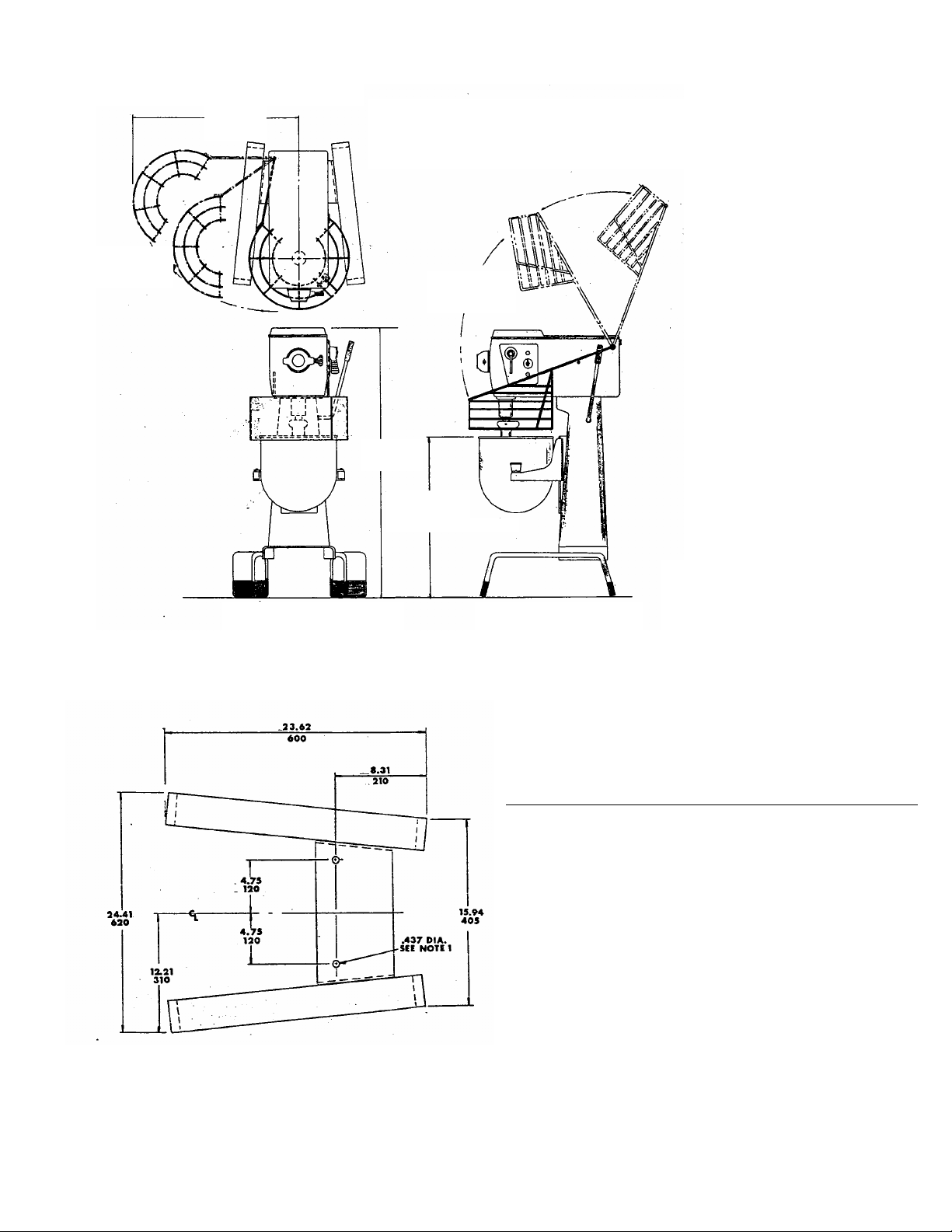

Installation Instructions

y

26.25

670

Travel

Bowl Guard

Travel

Bowl Guard

40.75

10.35

26.50 675

Raised Position

Shown With Type “A” Bowl Guard Shown With Type “B” Bowl Guard

NOTE: Holes used for shipping and mounting unit to floor

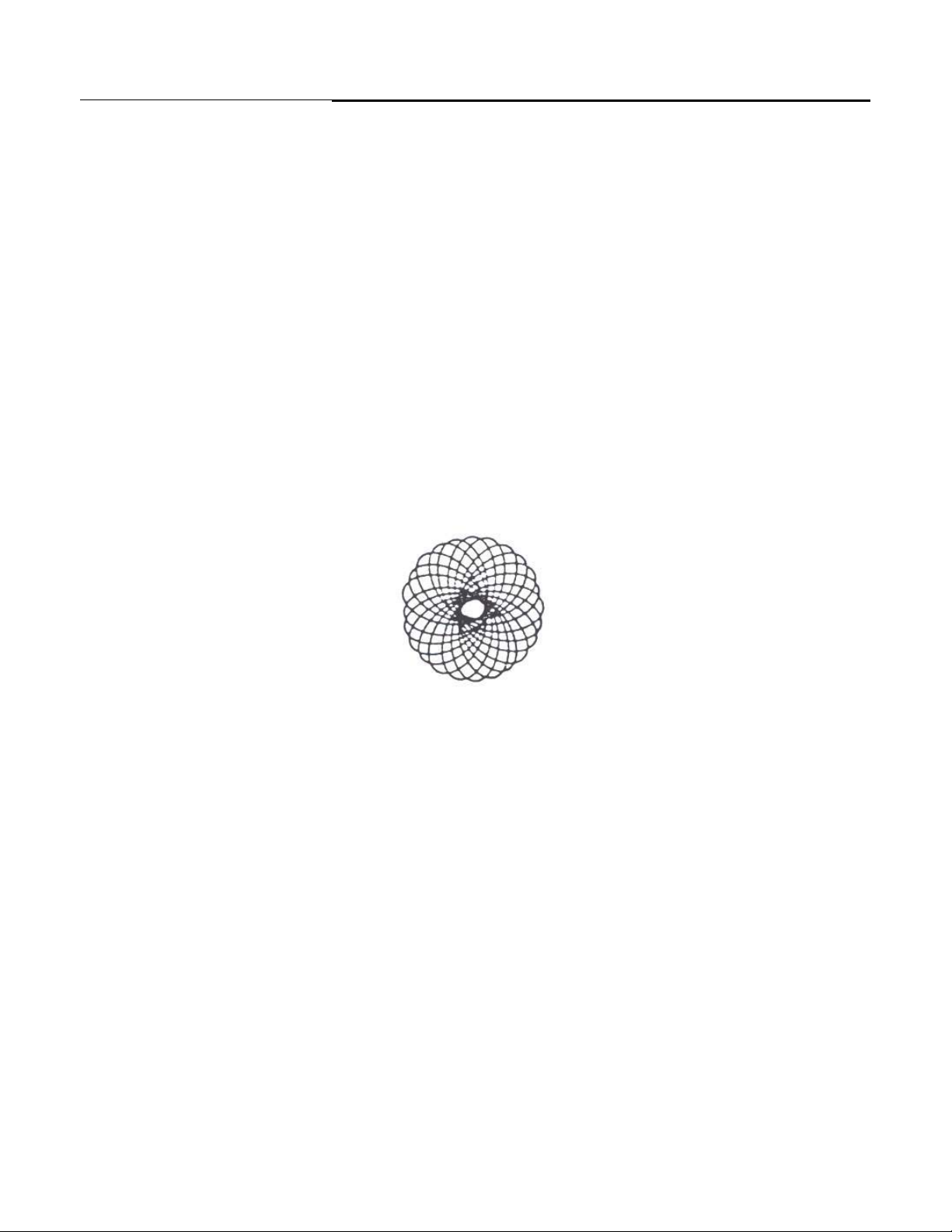

BENCH MODEL – B20

Select a location for your mixer that will save time

and steps for the operator. Allow ample work

space in front and to the sides of the mixer.

Mixer should be mounted to a sturdily built table

or bench approximately 25 inches high. Mounting

mixer to bench will insure against mixer slipping

on wet surface or tipping over from pressure

exerted as attachments are used. Refer to

mounting hole dimensional diagram.

Drill (4) 13/32” dia. Holes in table or bench top per

dimensions shown. Secure from underside of

table with (4) 13/32” – 16 bolts (length as required

b

thickness of bench top).

-2-

Page 5

26.25

670

Travel

Bowl Guard

45.75

1160

Shown With Type “A” Bowl Guard Shown With Type “B” Bowl Guard

NOTE: Holes used for shipping and mounting unit to floor

30.00 760

Raised Position

Travel

Bowl Guard

-3-

FLOOR MODELS – F20, F30

Select a location for your mixer that will save time

and steps for the operator. Allow ample work space in

front and to the sides of the mixer.

Holes are provided for anchoring the mixer to the

floor, but unless desired bolting to the floor is not

necessary except on shipboard use.

Page 6

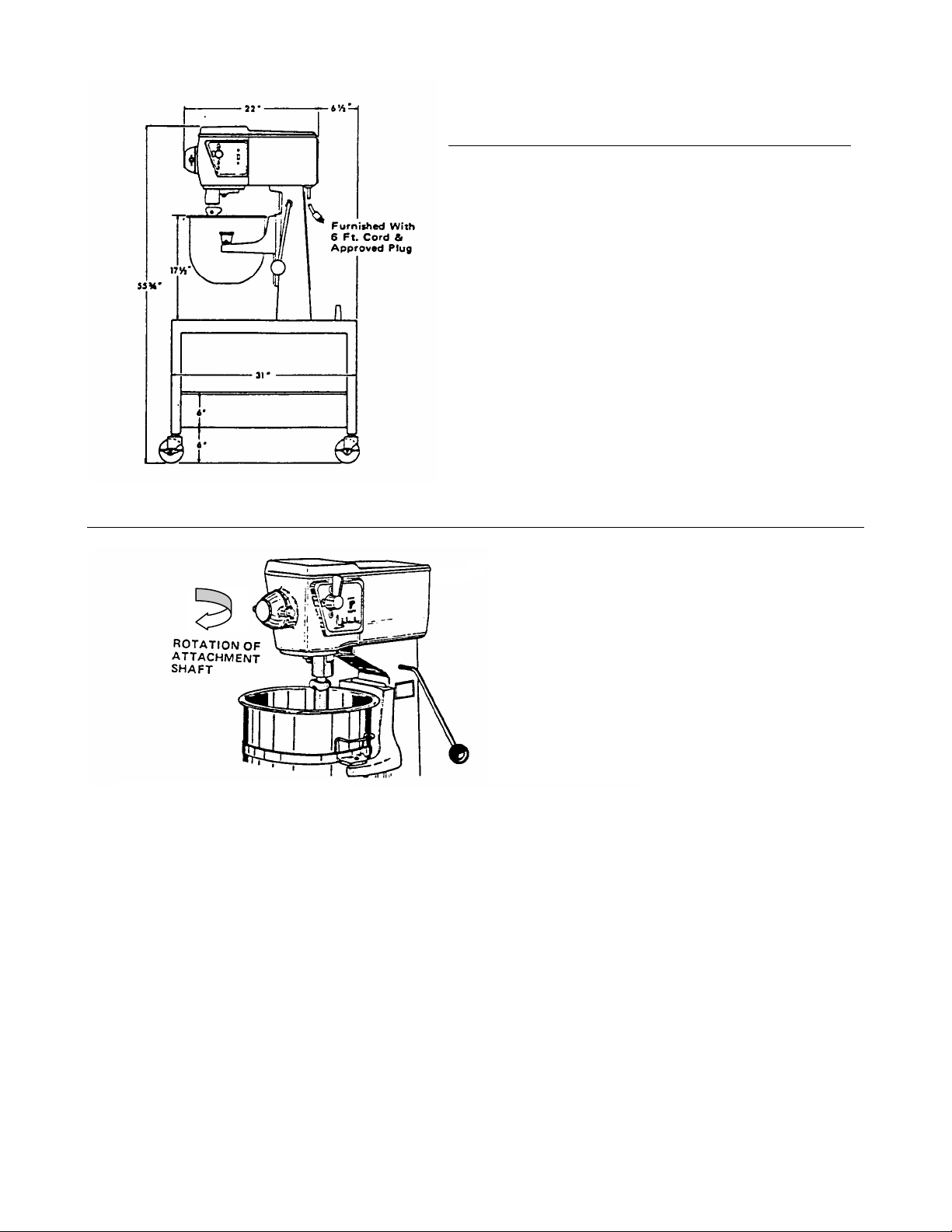

GENERAL FOR ALL MODELS

PORTABLE MODEL – U20

Available only in 20 quart size.

1. Store beaters and whips at rear of table top.

2. Lock all 4 casters before using mixer.

3. Refer to General Installation instruction for further

information.

1.

2

Electrical Connections

CAUTION: Before making electrical connections be sure that current and voltage of the

mixer are identical to those of electrical inlet lines.

20 quart, 110 volt mixers are furnished with a six (6) foot flexible power cord.

On 30 quart mixers the line cord is to be supplied by the customer. Connections are made

inside the mixer column through the cover plate located on the back side of the column

near the bottom. NOTE: A six (6) foot flexible three (3) prong cord is available as an extra

cost option.

IMPORTANT: On 3 phase mixers, after electrical connection has been made, be sure the

mixer operates in a counter-clockwise direction as indicated by the arrow located above

the attachment. If electrical connection is reversed the transmission will not shift, nor will

the planetary action function.

Transmission Oil

After the first 200 hours of operation and every 6 months thereafter the transmission oil

must be changed.

When adding or changing transmission oil use 50 S.A.E. heavy duty oil. 3 pints required.

-4-

Page 7

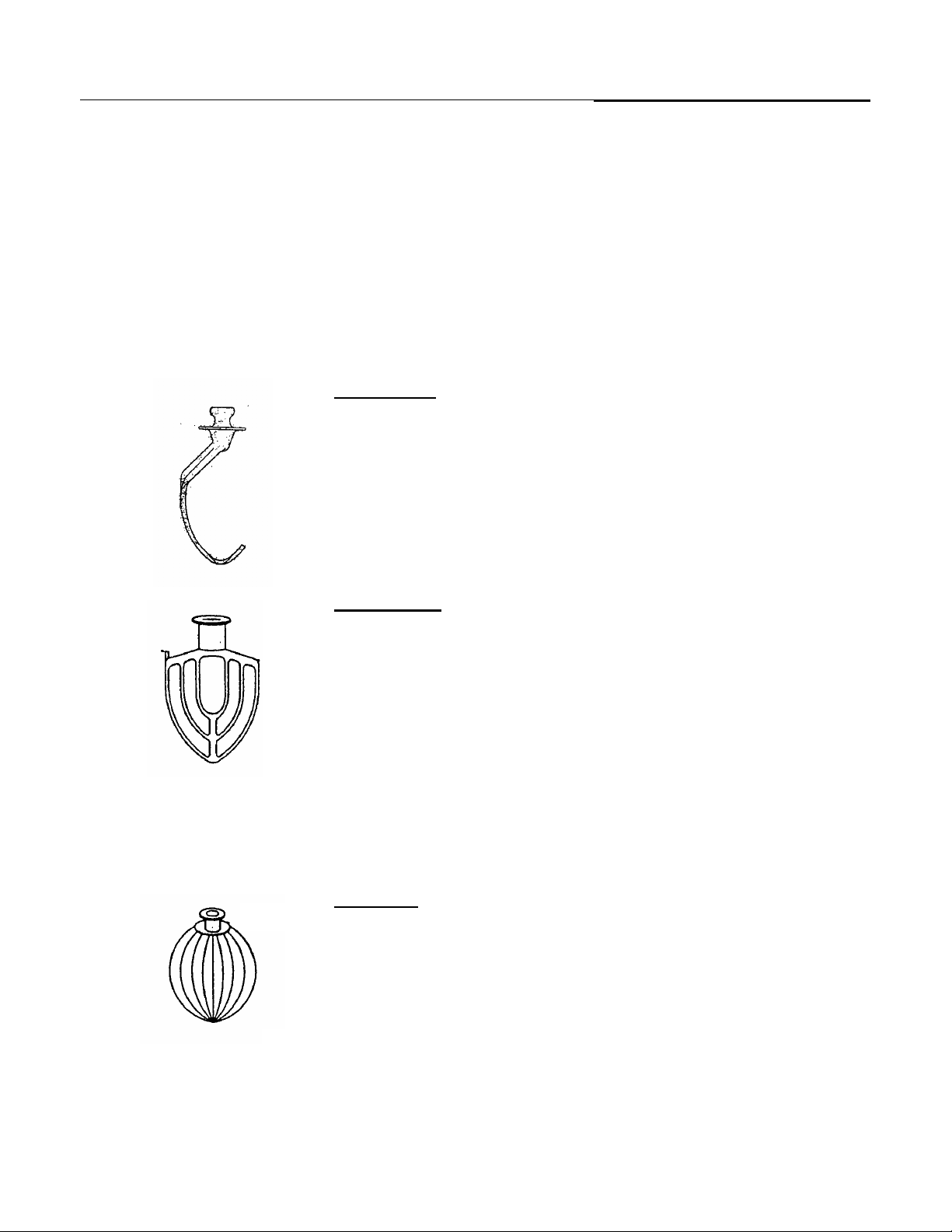

Design and use of Beaters Whips & Other Accessories

Each beater and whip has been designed to do a particular type of work. Use only that beater or whip

for the work for which it was designed. For example: never use a batter beater for mixing heavy

dough’s. Always use a dough hook for dough work.

Following are illustrations of the different types of beaters and whips with an explanation of the work

and use for which they were designed.

Dough Hook

Used for mixing bread or roll dough of standard consistency, biscuits,

meat loaf, etc. Dough hooks should always be operated at low

speeds only. Do not use other types of beaters for dough work;

doing so will result in damage to either the beaters or the mixer

proper.

Batter Beater

Used for mixing batters such as cake and muffin batters, creaming

butter, mashing potatoes and vegetables, light cakes, icings and the

average run of light work. Never use this beater for heavy dough

work. When mashing potatoes, etc. it is advisable to start with the

bowl at its lowest position and as the potatoes or other ingredients

break up, the bowl should be raised to its working position. This

procedure eliminates severe strain to the beater and to the mixer

proper and consequently adds to their life and efficiency.

Wire Whip

Used for whipping, creaming, beating eggs, meringues, small

amounts of mayonnaise, icings and for whipping milk or cream into

mashed potatoes after they have been broken up with a batter beater

-5-

Page 8

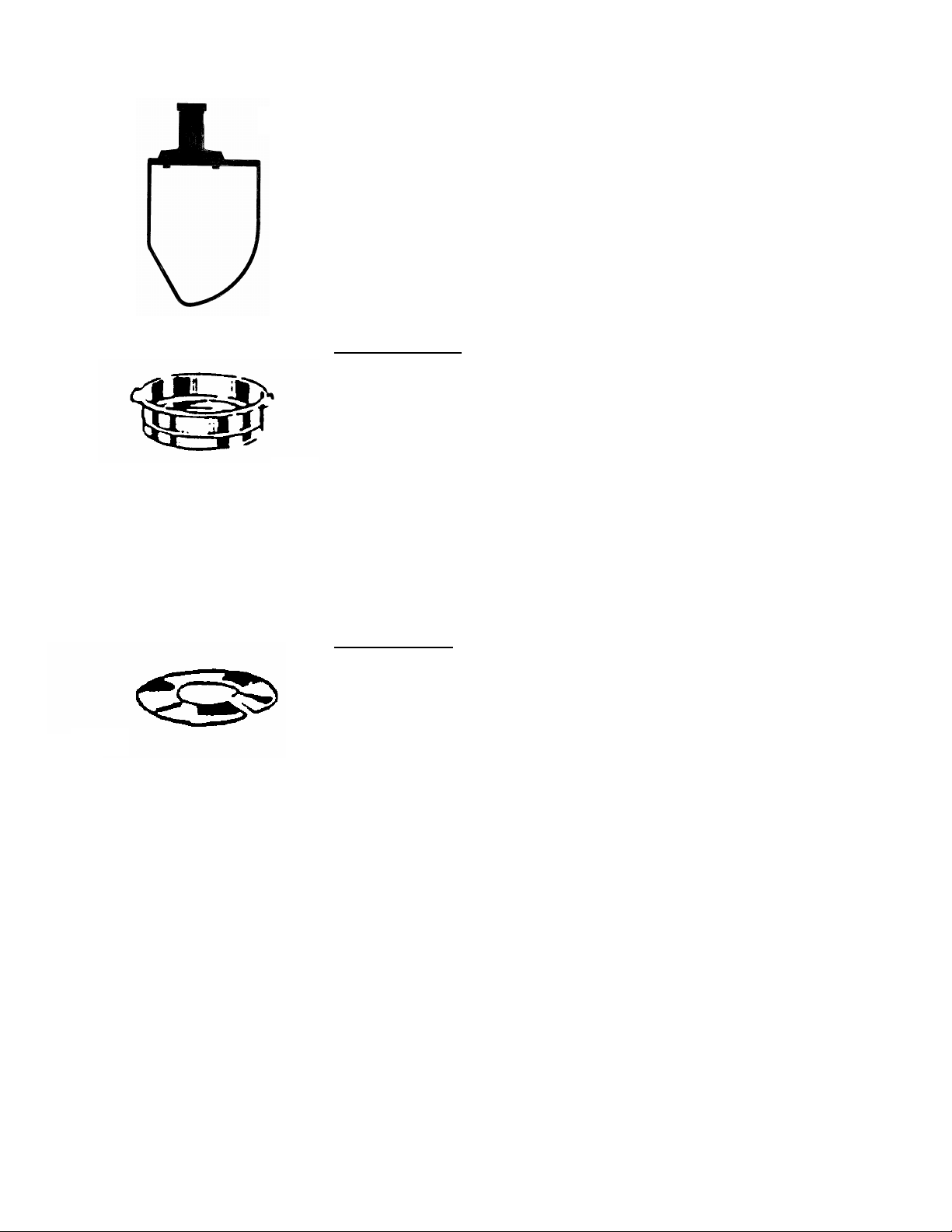

“PK” Pastry Knife

Used for cutting flour and shortening together in a pie dough, pastry

shells and for cutting lard or shortening into flour. The “PK” pastry

knife should always be used for such work so that pie crusts, etc, are

mixed with as little rubbing as possible and so that the shortening will

be in small pieces to produce a flaky product.

The true capacity of a mixer is not the amount of material that can be put in the bowl or the amount of

the total batch which can be mixed with in the power of the motor. The true capacities and the most

efficient (therefore the best money makers) are the ideal loads which permit a Mixer to operate at

peak efficiency, so far as development, yield or aeration have their effect on the mixing operation.

They are convenience items, not capacity increasers. The best functioning of Blakeslee mixers

depends on leaving room for proper material aeration or manipulation. Use splash covers or

extenders only for containing ingredients. They are efficient for their intended use, but if a mixer is

overloaded and a Splash Cover is used, aeration is reduced due to restriction in the area where air

enters the mix. The capacity chart located on the column of the mixer is a good guide for maximum

efficient use for the Mixer. Experience will have to dictate exact top capacity and Splash Cover use

under your own needs.

Bowl Extension

Extension Rims are merely vertical sided splash covers. They are

not covers in form but do provide higher side walls to prevent throwout of ingredients. Usually they are not recommended because they

are invitations to overloading a machine beyond its point of maximum

efficiency. Extension rims permit more air to enter the bowl and

prevents splash of light ingredients.

Splash Covers

These items provide means for providing splash of throw-out on

certain mixers when, for reasons of speed, the operator prefers to

start in a higher speed or progress quickly to a high speed in order to

complete a batch. These are valuable accessories but would not be

used to increase the mixing capacity of any particular machine,

beyond its recommended maximum.

-6-

Page 9

Mixing Instructions

FOR BEST

RESULTS

Operators have their own particular ways of operating their

mixing machines, so no attempt will be made to set up iron

clad instructions, but there are certain general principles that

should be followed in the various operations. These general

principles as listed below should be helpful to old and new

operators.

General Points for Proper Operation

NOTE

Refer to Mixing Chart before filling bowl.

1. In general, start all mixing at slow speed.

2. Always return to neutral position when

finished with a mix.

3. Gradually raise bowl and its contents to

the working position.

4. Bowl should be filled to at least half

capacity to achieve best results.

5. Make sure that bowl-to-beater clearance

is about 1/8”. Place a 1/8” layer of paper

on bottom of bowl to check bowl-to-beater

clearance.

Electrical

“Start-Stop” Push buttons are used to operate the

mixer. There is a thermal overload device with

automatic resetting for protection, internally

mounted. On all machines over 250 volts primary,

a transformer is supplied to reduce voltage to the

pilot circuit.

A timer shuts off the machine in any speed after

the pre-set time has expired. Normal operation is

obtained by setting the timer to “Hold” position.

When the timer is set at “O”, the start button

becomes a jog button, permitting intermittent

operation at the push of a button.

-7-

Whipping Cream

The wire whip (refer to Beaters and Whip chart)

should be used for whipping cream. Cream to be

whipped should be 24 hours old, should contain

30% butter fat and should be well chilled, in fact

near freezing temperature is desirable, since the

cooler the cream the better the whipping. Warm

cream may turn into butter instead of whipped

cream. To prevent splashing out of the bowl,

start whipping the cream at low speed and

increase the speed as the cream thickens.

Egg Whites

Use the wire whip and be sure the eggs are at

room temperature and that both the mixing bowl

and wire whip are free from all traces of fat or oil,

or egg whites won’t whip. In some installations

one bowl will be kept and used exclusively for

beating egg whites. Another bowl will be kept

and used exclusively for the oily type mixes.

Start beating the eggs at low speeds and

gradually increase the speed.

Meringues

Use the wire whip. Meringues can be made

perfect by the gradual addition of sugar to egg

whites which have not been too stiffly beaten.

Page 10

Mashing Potatoes

Use the batter beater and pre-heat the bowl and

beater. Lower the mixing bowl before putting in

the potatoes to be mashed then gradually raise

the bowl to its working position.

Start the operation on low speed. When the

potatoes have been broken up, stop the mixer

and add milk or cream, butter and seasoning.

Many operators like to change to the wire whip for

whipping in the milk or cream since more of a

whipping action is obtained to produce a fluffier

mashed potato.

Cake Batters and Cookie Dough

Use the batter beater. Butter or shortening can

be thoroughly creamed in about 10 minutes. The

butter or shortening should be at room

temperature. Always lower the mixing bowl

before putting in the ingredients then gradually

raise the bowl to its working position.

Sugar should be added to recipes at a medium

speed. When all of the sugar has been added,

stop the mixer and scrape down the sides of the

mixing bowl with a spatula to insure a smooth

mix. Be careful not to add sugar until the butter

or shortening has been thoroughly creamed.

When adding dry ingredients, stop the mixer

occasionally and scrape the upper part of the

bowl with a spatula to make sure that every

portion will be efficiently mixed into the recipe.

Always operate the mixer on slow speed while

adding dry ingredients. Add dry ingredients

alternately with liquid, starting and ending with dry

ingredients. Do most of the beating before the

flour and milk are added. Over beating after

these two ingredients causes a sub-standard

mixture.

Mixing Dough

Always use the dough hook for mixing heavy

doughs. Do not overload the mixer with too large

batches. (See the capacity chart on page 7.)

When using the dough hook, the mixing should

be started at low speed only. The bowl should be

in its lowest position gradually raised to working

position. Remember – an increased mixing time

means a decreased fermentation time. Weighing

materials each mix time will insure a standard

product. Stop the mixer occasionally to lower the

dough mass from the hook and to scrape the

bowl.

Important – In mixing heavy doughs be sure to

use the dough hook, be sure not to overload the

mixer (see capacity chart on page 7,) and be sure

to start the mixer on low speed with the bowl in

operating position.

Biscuit Mix

Use “W” wire whip and bowl extension ring (to

confine ingredients to bowl). Mix shortening and

dry ingredients until shortening is blended and

mixture is granular in appearance. Turn off

mixer. Scrape bowl down with bowl knife. Store

in covered can until ready for use. Use beater or

dough hook when adding liquid; start mixing on

slow speed and bowl in lowest position, then

gradually rise to the working position. Do not

over mix.

Pastries

Use the “PK” pastry knife, as pastries should be

mixed with as little “rubbing” as possible. The

“PK” pastry knife leaves the shortening in small

pieces to produce a flaky product. Remember,

over-worked dough makes tough pastry, and

working in too much flour tends to toughen

pastry.

Sweet Dough

For best results use the “SD” sweet dough

beater.

-8-

Page 11

Mixing Bowl Capacity Chart

CAPACITY OF BOWL

(Finished Material)

KITCHEN MATERIALS 20 Qt. 30 QT.

Egg whites 1 qt. 1 ½ qt.

Mashed potatoes 15 lbs. 23 lbs

Mayonnaise (qts. Of oil) 10 qts 12 qts

Meringue (pts. Of water) 1 ½ Pts. 2 pts.

Waffle or Hot cake batter 8 qts. 12 qts

Whipped cream 4 qts. 6 qts

BAKE SHOP MATERIALS

Angle Food (8 to 10 oz. cake) 15 22

Box or Slab Cake 21 lbs. 30 lbs.

Cup cakes 22 doz. 33 doz.

Layer cakes 20 lbs. 30 lbs.

Pound cake 21 lbs. 30 lbs.

Short sponge cake 15 lbs. 23 lbs.

Sponge cake batter 21 lbs. 18 lbs.

Sugar cookies 35 doz. 50 doz.

Bread or roll dough (60%AR) 25 lbs. (1) 45 lbs. (1)

Noodle dough 8 lbs. 10 lbs.

Pie dough (50%AR) 17 lbs. 27 lbs.

Pizza dough (65%AR) 14 lbs. (1) 21 lbs. (1)

Raised donut dough 9 lbs. (2) 15 lbs. (2)

Eggs & sugar (for sponge cake) 8 lbs. 12 lbs.

Fondant icing 12 lbs 18 lbs.

Marshmallow icing 2 lbs, 3 lbs.

shortening & sugar creamed 16 lbs. 24 lbs.

(1) – First speed

(2) – Second speed

-9-

Page 12

Mixer Capacity

The mixer capacity chart is provided as a guide

for controlling the batch sizes. The capacities

listed take into account the amount of product

which can be contained in a particular size bowl

and the type of dough or product to be mixed and

it’s own unique properties which affect mixer

performance.

Also considered and noted on the chart is the

batch absorption rate, the ratio of the weight of

water to the weight of flour expressed as a

percentage. The absorption rate (AR) measures

how heavy a batch is or the density of the batch.

In fact, the capacities listed on the capacity chart

for the products listed below are based on the

following absorption rates:

Product

Bread dough

Pizza dough

Raised donut dough

Absorption Rate

60%

50%

65%

When mixing any of the above products with an

absorption rate lower than listed, the batch size

should be decreased proportionately to insure

efficient mixing of the product and eliminate the

possibility of over-loading your mixer. For

example: A DD-60 mixer has a pizza dough

capacity of 40 pounds at first speed based on AR

of 50% according to the capacity chart. If the

batch to be mixed has an AR of 45%, the batch

size must be reduced to compensate for the

difference. The size of the reduction is computed

as follows:

1. Divide the AR of the batch to be mixed by

the AR listed on the capacity chart.

45% Actual AR

50% Rated AR

= 90%

2. Multiply the rated batch size by the

percentage obtained in step 1. The result

is the maximum batch size of the DD-60

mixer for pizza dough with a 40% AR.

40 Lbs Rated Batch size

X 90%

36 lbs. Max Capacity @ 45% AR

-10-

Another factor often overlooked is the ability of

your mixer to operate at a higher speed. For

example, the F 30 has a 45 pound capacity of

bread or roll dough with an AR of 60% in first

speed. The batch could be mixed in second

speed but the batch must be reduced by 60% to

27 pounds.

Your Blakeslee mixer is designed and intended to

mix your products in the most efficient way

possible. There is no need for you to sacrifice

individual characteristics when using your

Blakeslee mixer. Care should be taken during

your batch mixing. When results are exactly to

your liking, note carefully the time of operation

and speed setting. Under the same conditions

your Blakeslee mixer will perform exactly the

same, day after day, providing uniformity of your

product. A word of caution: Do not over-mix.

Over mixing can adversely affect the texture of

the product you are mixing. You will also

discover there is often a savings in the time

required for each mixing operation, and that even

delicate products usually mixed by hand can be

adapted to your mixer.

Page 13

Beaters, Whips and Accessories

WHIPS & BEATERS

Batter Beaters

20 QT. 01367

30 QT. 01367

Wire Whips

20 QT. 03456

30 QT. 03459

“H” Dough Hooks

20 QT. 01385

30 QT. 01987

Bowls

20 QT. 01717

30 QT. 03310

MEAT CHOPPER

20447

1901 Knife 1903 End Plate, 3/16” 1905 End Plate, 3/8”

1902 End Plate, 1/8” Perforations Perforations

Perforations 1904 End Plate, 1/4” 1906 End Plate, 1/2”

ACCESSORIES FOR MEAT CHOPPER

Perforations Perforations

Meat Chopper Assembly

Includes Knife and 1/8” Plate and Pusher

-11-

Page 14

20581

1

VEGETABLE SLICER

9” Vegetable Slicer

Complete with Slicer Plate & Hopper Front

3 4

2

CHEESE SHREDDER

99731

9” Cheese Shredder

Complete with Hub & Shaft, 5/16” Shredder Plate and

Hopper Front.

OPTIONAL EQUIPMENT FOR USE WITH SLICERS

20595

5

6

9” Adjustable Slicer Plate

Furnished with Vegetable Slicer

1 15071 Grater Disc

2 15021 3/16” Shredder Disc.

3 15088 3/32” Shredder Disc.

4 15019 5/16” Shredder Disc.

5 15072 1/2” Shredder Disc.

6 20599 Hub & Shaft Assembly - Optional for 20581

(only one required for all sizes of shredder plates and

grater plates)

-12-

Page 15

Part No. Includes

Spindle

Part No. Includes

Spindle

Part No. Includes

Spindle

“SD” Sweet Dough

Beaters

20 QT

40QT

01394

01979

CAP PART

20 Qt

30 Qt

CAP PART

20 QT 01735 Stainless Steel

30 QT 01736 Stainless Steel

“PK” Pastry Knife

20 QT

30QT

01538

01976

“M” Four Wing Whip Bowl Truck

Allows bowl to be transported without carrying

20 QT

30QT

01542

01978

Splash Covers

DESCRIPTION

NO.

01738

14618

Stainless Steel

Stainless Steel

Bowl Extensions

DESCRIPTION

NO.

CAP PART NO. DESCRIPTION

30 QT 03374 Painted Steel

-13-

Page 16

Operation

In Order for your mixer to perform at top efficiency at all times, it is necessary that you follow the

recommendations as laid down by the designing engineers. Give your mixer the same attention you

would give your automobile and your Blakeslee-Built Mixer will give you many years of satisfactory

service.

1

8

7

2

3

4

1. Auxiliary Drive Socket

2. Speed Change Lever

5

3. “ON-OFF” Power Switch

4. Bowl Lift Hand Lever

6

5. Bowl Support

6. Nameplate & serial Number

7. Attachment Spindle

8. Beater Shaft

CAUTION:

Do not attempt to change attachments while mixer in in

operation. Always shut off mixer before placing hands

or kitchen utencils near or in the mixing bowl

Operating the Bowl Lift

The bowl is raised to working position by means of a lever lcated on the right-hand side of the mixer.

Once raised, the bowl will be automatically located in its proper operating position. The bowl lift is

preadjusted to stop at the proper working position before the mixer is shipped.

Attaching Beaters & Whips

The beaters and whips used with your mixer have been

designed to make fastening of the attachment positive and

rapid.

To engage the attachment, line up the slots in the attachment

with the drive pin on the beater shaft. Raise the attachment

and twist to the right. When released the attachment will drop

slightly into full locked position.

To remove the attachment, grasp near the top, raise slightly

while twisting to the left and slide downward.

-14-

Page 17

Bowl Lift Mechanism Adjustment

Bowl lift is factory set. However should

adjustment be necessary ds so as follows.

1. The mixers have adjustable stops to limit

upward travel of the bowl lift

2. To adjust upward travel of lift (all models)

loosen lock nut “B” and turn bolt “A” clockwise to

bring bottom of bowl closer to attachment end or

counter-clockwise to increase the distance

between the bottom of bowl and attachment end.

Retighten lock nut “B”. CAUTION: Attachment

muts not rub on bottom of bowl.

Changing Speeds

It is important to the life of the mixer, and to

perfect mixing, to keep the mix in constant

motion. In Blakeslee Built Mixers, which are

equipped with constant mesh gears and

automatic clutch, the speed may be varied by

simply turning the mixer off, selecting the new

desired speed with the speed change lever, and

then turn the mixer back on.

NOTE: When mixing heavy loads, the

Transmission should be fully stopped before

shifting speeds.

BEATER

SPEEDS

SPEED

(RPM) (RPM)

AUX. DRIVE

SPEED

1 Low 102 57

2 Medium 180 101

3 High 354 197

Mounting of Accessories

Vegtable Slicer, Meat Chopper, and Cheese

Shredder all mount in a similar fashion to the

“Auxillary Drive Socket”. Illustration shows a typical

mounting using vegtable slicer.

1. Remove cover plate from auxillary drive socket.

2. Turn thumb screws out so that it does not extend

into the drive socket.

3. Insert hub of attachment into socket, rotating

slightly untill it slides into place against mixer

housing. Lubricate with a few drops of mineral oil

or salad oil.

4. Turn thumb screws to lock attachment into place.

5. Clean drain slot (A) after use.

-15-

Page 18

Transmission Removal and Disassembly

-16-

Page 19

-17-

Page 20

-18-

Page 21

-19-

Page 22

Troubleshooting

Type of Trouble Possible Cause Recommended Corrective

Procedure

Mixer will not start

Motor runs but will not change

speeds

Unit runs hot or smokes

Attachments strike bottom of

bowl

Attachments striking side of

bowl

Bowl will not raise

Transmission operates with a

skipping motion

Bowl support hard to raise

and lower

Transmission operates in one

speed only and has a clicking

noise.

Main fuse or breaker out Reset breaker and change fuse.

Overload switch tripped

Wire loose or broken

The timer inoperative

Speed change lever loose Remove handle, install key,

replace handle and snap ring.

Mixer under to great a load Stop mixer, shift to another speed

and restart.

Shifter yoke bent or broken Gearbox to be repaired after

removal.

Improper voltage on motor or

motor defective

Motor overloaded Have amp draw checked by

Gear box low on lubricant Drain out old oil (square drain

Bowl support out of adjustment See adjustment procedure on

Attachments bent or bowl

dented

The drag link spring is off drag

link arm

Crank casting loose on drag link Remove inspection cover from

Unit overloaded Shift to lower speed or reduce

Bowl support binding on bowl

slides

Clutch jaw worn Replace clutch and gear

Have electrician check

electrician

plug on bottom of gear box) and

insert 3 pints of S.A.E. 50 oil in

vent plug hole.

page 15

Replace damaged parts

Remove inspection cover from

back of machine, replace 2” long

heavy spring on rocker guide,

install nut and washer on drag link

and lock in place by tightening

nuts.

back of machine, reposition crank

casting, tighten set screws after

being sure crank casting key is in

place on shaft.

quantity of material being mixed

Clean off bowl slides and

lubricate with light grade of oil.

-20-

Page 23

Type of Trouble Possible Cause Recommended Corrective

Procedure

Transmission slips in 1st gear Overrun clutch worn Replace overrun clutch

Motor runs but transmission

does dot operate

Bronze worm gear failure Transmission operated when it

Transmission runs attachment

shaft but beater shaft does

not

Bronze worm gear worn Replace bronze worm gear

Check transmission for seal leaks

was low on oil.

Broken beater shaft or stripped

ring gear

-21-

Replace broken beater shaft or

stripped ring gear

Page 24

Parts Section

PROTECT YOUR EQUIPMENT

USE GENUINE BLAKESLEE PARTS

Page 25

7

28

29

30

31

M-5-3330-D & M-5-18769 TRANSMISSION, MOTOR AND HOUSING

-24-

Page 26

ITEM PART NO. DESCRIPTION QTY

1b 3330-D No Longer Available

2 01961 Top Cover, Gearbox and Motor Housing 1

3 12549 Screws, ¼ x 1-1/4” Flat Head Machine 3

4 72974 Housing, Motor, Steel (20 Quart) 1

4a 72972 Housing, Motor, S/S (20 Quart) 1

4b 72975 Housing, Motor, Steel (30 Quart) 1

4c 72973 Housing, Motor, S/S (30 Quart) 1

5 72667 Cover Plate, for Rear of Motor Housing 1 Steel

5a 03451 Cover Plate, for Rear of Motor Housing 1 Aluminum

5b 72976 Cover Plate, for Rear of Motor Housing 1 S/S

6 20279 Screws, 10-24 x 3/8” R.H. 4

7 73689 Nameplate for Electric Timer 1

7a 03327 Name Plate for Manual Timer 1

8 17379 Plug 1

9 17380 Snap Rin

10 01458 Lever Gear Shift 1

11 15310 Screws, 8-32 x 3/8” Pan Head 1

12 Timer, Elect

12a 1957 Timer, Me

13 15117 Motor, ½ H.P., 1 Phase (20 Quart) 1

13a

13b 15118 Motor, ½ H.P., 3 Phase (20 Quart) 1

13c 15119 Motor, ¾ H.P., 1 Phase (30 Quart) 1

13d 18904 540 M.F.D. Capacitor (for 15119 Motor only) 1

13e 15120 Motor, ¾ H.P., 3 Phase (30 Quart) 1

18512 1

14 03573 Screws, 3/8 x 1” Socket Head 4

15 03427 Gasket 1

16 15358 Key 1

17 15141 ‘O’ Ring 1

18 15144 Washer, ½ x ¾” Copper Asbestos 1

19 1

1

20 15143 Oil Seal 1

21 01252 Worm 1

22 15142 Washer 1

23 15145 Nut 1

24 15366 Cable Assembly, Motor to Switch (3 Ph. 208/230 V) 1

24a 18594 Cable Assembly, Motor to Switch (3 Ph. 440/480V)1 1

25 03427 Gasket , Motor to switch` 1

26 95654 Switch G

27 95650 Caution Lab

28 97275 Start Button

29 97276 Contact Block N.O. 1

30 97274 Stop Button 1

31 97277 Contact Block N.C. 1

* 1 18769 Transmission 1

* 1a 86185 Transmission Reconditioned 1

g 1

ric 1

chanical 1

20274 270-325 M.F.D. Capacitor (for 15117 motor only) 1

uard 1

el 1

1

• 18769 Transmission is used from serial number suffix #1-B A A and up.

Specify machine serial number when ordering parts

-25-

Page 27

MODEL F-30 COLUMN & BASE ASSEMBLY

-26-

Page 28

-27-

Page 29

-28-

Page 30

MODELS B-20, F-20, U-20 SERIES COLUMN & BASE ASSEMBLY

-29-

Page 31

-30-

Page 32

-31-

Page 33

WIRING DIAGRAM

SUPPLY

LINE

INPUT

-32-

3 PHASE

1 PHASE

Page 34

ITEMS # 5,6, & 7 NOT SHOWN

TYPE “A” BOWL GUARD ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 74845 Cover Weldment 1

2 74048 Side Plate Weldment 1

3 74941 Handle 1

4 14849 Pin 1

5 08434 ¼-20 x 1” Screw 2

6 07282 ¼-20 Lock Nut 2

7 74955 Safety Switch Assembly 1

-33-

Page 35

TYPE “A” BOWL GUARD ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 16732 ¼-20 Lock Nut 2

2 70152 Micro-Switch 1

3 74073 Power Relay 115V 1

4 74949 Plat, Switch 1

5 74948 Spacer, Switch 1

6 75502 Retainer 1

7 08434 ¼ -20 x 1” Machine Screw 2

8 74951 Spacer 1

9 74954 Actuator Weldment 1

10 07847 ¼-20 x .31 Set Screw 1

11 74978 6-32 x 1.5 Machine Screw 2

12 09887 6.32 x .50 Machine Screw 2

13 08875 6.32 Hex Nut 2

14 12608 ¼-20 x .75 2

15 75291 Retainer 1

16 75292 Power Relay 1

-34-

Page 36

Page 37

Loading...

Loading...