BLACKHAWK! RIFLE COMPSTOCK User Manual

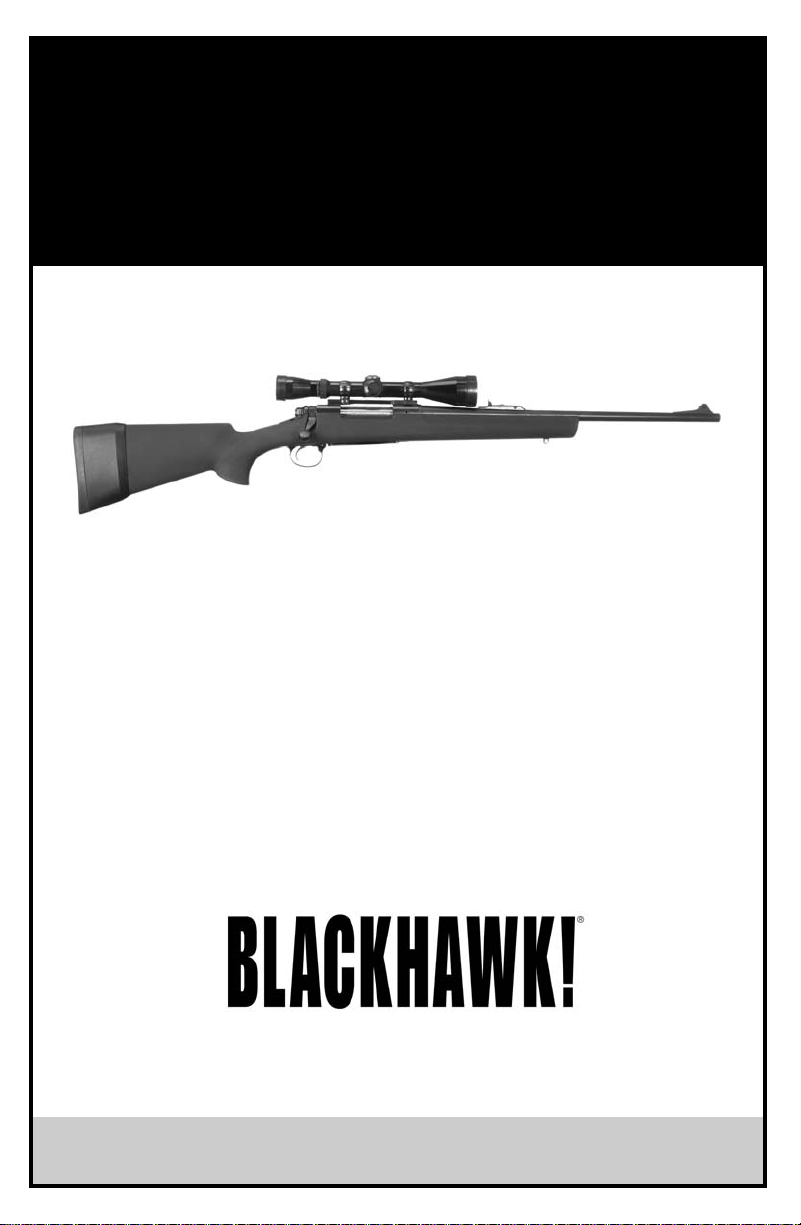

Rifle CompStock

Owner’s Manual

™

www.BLACKHAWK.com

©BLACKHAWK! Products Group™NORFOLK, VA U.S.A. 1.800.694.5263

50107109 REV. 04.08

Page 1 Page 6

www.BLACKHAWK.com

©BLACKHAWK! Products Group™NORFOLK, VA U.S.A. 1.800.694.5263

Installation Instructions Product Maintenance & Information

ATTENTION: Read and follow all instructions and warnings prior to installation and/or

firing a Rifle CompStock equipped firearm.

Take extra time to review the shooting tips

& techniques section of this manual (Page 5).

If you are at all unsure of your ability to

install your Rifle CompStock safely, please seek the services of a competent gunsmith.

WARNING: Before beginning stock installation, make sure that the rifle is

UNLOADED. Carefully check the chamber and magazine making both visual and touch

verification.

NOTICE: Remington 700 and Winchester Model 70 owners please read special installation directions found on page 4.

TOOLS REQUIRED:

• Large Flat Blade Screw Driver

• Hex Key / Allen Wrench Set

INSTALLATION STEPS:

1. Remove action bolt from receiver. Remove original stock. Refer to manufacturer’s

instructions for the best method to remove stock. Normally the barreled action is held in

position by two screws located on the bottom of the stock. Using caution not to damage

screws, use the appropriate size and type of tool to remove the two screws (Fig. 1A).

Note: At this point the trigger guard is disconnected from the stock. For BDL models

remove bottom magazine floor plate along with magazine housing. (Fig. 1B) Remove barreled action from stock. To avoid damage, take caution when removing barreled action

from original stock.

Fig. 1A

Fig. 1B

www.BLACKHAWK.com

©BLACKHAWK! Products Group™NORFOLK, VA U.S.A. 1.800.694.5263

2. Carefully insert receiver or barreled action into the Rifle CompStock. Carefully align

recoil lug and trigger with corresponding pockets or openings. Slowly lower barreled

action into forend until it is fully seated. (Fig. 2) Note: The barreled action should slide

into position with limited hand pressure and when in final position there should very

minimal movement.

NOTE: Utilizing sandpaper and Dremmel tool, barrel channel may be relieved to

increase float.

3. While holding the assembly from Step 2, reinstall the magazine housing into the corresponding pocket on the bottom of the receiver. (Fig. 3) Note: To avoid damage to the

hinged floor plate and trigger guard in the following steps, the magazine housing must

be correctly installed in the receiver. Verify that the magazine housing is properly

installed.

Fig. 2

Fig. 3

Loading...

Loading...