Black Hawk Blue Ray Assembly Manual

Black Hawk R/C Pilots Blue Ray April 2013

Electric Pylon Racer - original design by Tim Batt

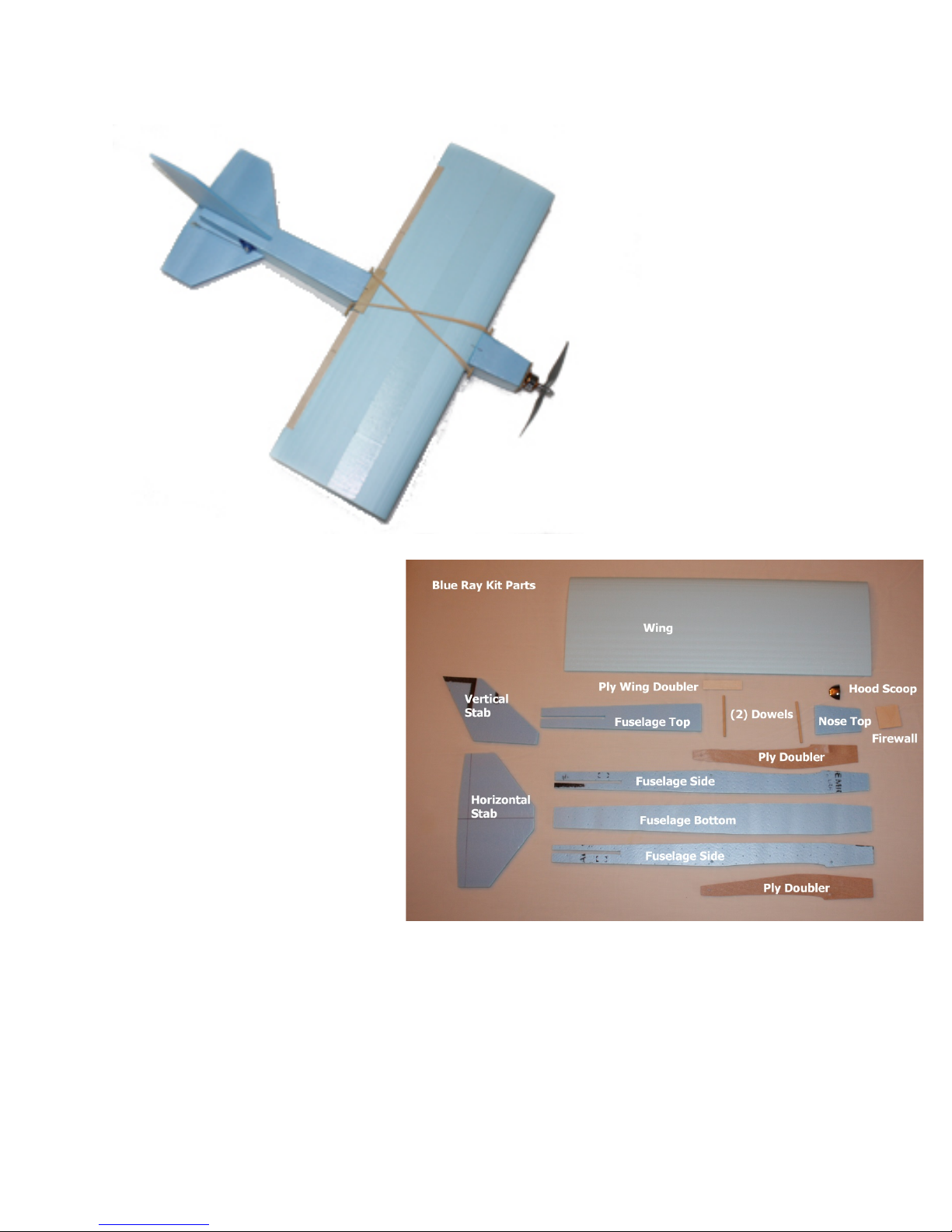

Kit Parts List:

Qty (1) Wing

Qty (1) Ply Wing Doubler

Qty (1) Vertical Stabilizer

Qty (1) Horizontal Stabilizer

Qty (2) Fuselage Sides

Qty (1) Fuselage Bottom

Qty (1) Fuselage Top

Qty (1) Nose Top

Qty (2) Ply Fuse Doublers

Qty (1) Ply Firewall

Qty (2) Dowels

Qty (1) Plastic Hood Scoop

Qty (1) Aileron Drawing

Qty (2) Nose Doublers*

Qty (2) Rear Dowel Doublers*

* not shown in photo

Additional supplies needed to complete this kit:

Aircraft Radio

4 gram (0.14 oz.) Receiver

22 mm stator - 1800 KV Brushless Outrunner Mot or & mounting

20 Amp Electronic Speed Control (ESC)

Deans Ultra Plug or JST connector to connect ESC to battery

Page 1

Li-Po Battery

o 1000 to 1350 mAh

o 2S (7.4 volt) or 3S (11.1 volt)

o 20C or higher recommended

o 130 grams (4.5 oz.) maximum weight

APC 7x5 Thin Electric Propeller (APC p/n LP07050E)

Qty (3) 6 to 8 gram (0.2 to 0.3 oz) ultra-light servos

Qty (3) micro control horns

o Du-Bro #919 or #848 Micro Control Horns or equivalent

Qty (3) micro control horn keepers

o Du-Bro #849 Micro EZ Link for .032 wire

o Du-Bro #920 Micro EZ Link for .047 wire

.032” or .047” diameter wire

Qty (1) 6” servo extension for the eleva tor servo - 32 gauge mi cro wire preferred

Qty (1) “Y” harness for aileron servos or (2) 3” servo extensions if your receiver

allows one aileron servo to be plugged into an alternate channel - 32 gauge micro

wire preferred

(4) #64 rubber bands (#64 Rubber bands are available at any office supply store.)

Hinge Tape

Velcro or double-sided tape

2” or 3" wide strapping tape

5-minute epoxy

Foam safe thick CA and/or low-temp hot glue

o Caution: Foam safe thin CA will generate too much heat when it c ures

and will melt the foam

Introduction:

The BLUE RAY is intended to be a simple-to-build club project. Micro servos, receivers

and electric motors are available at very affordable pri c es. Now is the time to start club

pylon racing!

The completed weight of the BLUE RAY is 8 to 8.5 ounces (228 to 240 grams) without a

battery! The battery adds from 2.2 to 4.0 ounces (62 to 115 grams) for a total readyto-fly weight of 10.2 to 12.5 ounces ( 310 to 355 grams). Typical foamy planes in this

weight class do not do fly well in the wind; however the BLUE RAY handles well in a 10

mph breeze. It has good wind penetration, especially with a 3-cell battery and the

throttle up.

A 1000 to 1300 mAh battery is recommend ed for racing. A smaller battery can be

used, but the flight durat ion is shorter. With the recommended battery, you can get 3

two-minute heat races with a single charge. The BLUE RAY has been flown with a 1700

mAh 3-cell Li-Po battery and it still flies well, but pylon turns get to be sluggish.

If this is to be a club project, the simple fixtures shown in these instructions will make

the assembly quicker and easier. If you are only building one or t wo airplanes,

assemble the fuselage on a flat surfa ce and use a carpenters square or right triangle to

make sure the fuselage sides are perpendicular with the fuselage bottom.

Page 2

Read all of the instructions before starting to assemble your BLUE RAY.

The foam parts can be assembled using either low-temp hot glue , foam safe thick CA or

5-minute epoxy. All three work well with foam. Wood parts can be assembled with

either foam safe CA or 5-minute epoxy. T he fir ew all should only be assembled with

epoxy.

Tip: To keep the aircraft weight light, mix micro-balloons with the epoxy. This will

decrease the pot life of the epoxy, so w ork quickly or use 15-minute or longer epo xy.

Kit Parts:

The Black Hawk R/C Pilots BLUE RAY kit includes a l l of the foam and wood parts

including a precut foam wing. The kit has been cut from blue or pink extruded

polystyrene foam insulation board that is ¼” (6 mm) thick with a plastic film on one or

both sides. The plastic film does not add any appreciable strength to the aircraft

structure. We recommend removing all of the plastic film. If you choose to leave the

plastic film on the parts, cut away the film in the areas that will be glued toget her.

Note: Some parts have lines marked on the film to assist in assembling the aircraft. Do

not remove the plastic film from these parts until you have made the appropriate cuts.

Tip: Rounding the leading edges of the horizontal and vertical stabilizer and the

fuselage corners will require removing the plastic film from the a r eas to be rounded.

It’s easier to remove the film from the entire surface than to just trim it fro m the areas

that are rounded.

Tip: When sanding the foam part, use #220 or finer sandpaper. Coarse sandpaper will

“tear” the foam.

Radio:

Test the radio, servos, ESC and motor. If not already attached, solder male bullet

connectors to the motor wires and female bullet connectors and a male power plug to

the ESC wires. If using a 2.4 GHz radio system, bind the receiver to the transmitter and

setup the radio for the aircraft. Connect all the servos to the radio receiver and make

sure they work before installing them in the aircraft.

Fuselage:

The elevator servo location is mar ked on both fuselage

sides. Decide which side you want to install the

elevator servo in and make the cutout to fit your servo.

Start the fuselage construction by gluing the plywood fuselage doublers to the inside of

the fuselage side pi eces. Make a RIGHT and a LEFT side! Be sure the holes for the

hold-down dowels are lined up.

Page 3

Loading...

Loading...